Smith Meter UPT Installation Service

Universal Pulse Transmitter (UPT)

Installation/Service

Bulletin MN01045 Issue/Rev. 0.7 (11/17)

General

The Smith Meter® Model UPT (Universal Pulse) Transmitter is a photo-electric, dual channel, high resolution, pulse

generator that is directly connected to the output shaft of a

positive displacement meter.

The UPT Transmitter is installed at the lowest level in the

meter accessory stack. It is designed to be mounted directly

on the meter dome adaptor and replaces the manual calibrator. If other mechanical stack accessories are required,

a calibrator adaptor kit is used for mounting the manual

calibrator above the UPT Transmitter.

MANUAL

Reference Publications

Specication Bulletin SS01105

Parts List PO01056 (P0907.05)

Receipt of Equipment

When the equipment is received, the outside packing case

should be checked immediately for any shipping damage.

If the packing case has been damaged, the local carrier

should be notied at once regarding his liability. Carefully

remove the unit from its packing case and inspect for

damaged or missing parts.

If damage has occurred during shipment or parts are

missing, a written report should be submitted to the Inside

Sales Department, Measurement Solutions, PO Box 10428,

Erie, Pennsylvania 16514.

Prior to installation, the unit should be stored in its original

packing case and protected from adverse weather conditions and abuse.

Mechanical Installation

When ordered with a Smith Meter® positive displacement

(PD) meter, the Model UPT Transmitter will normally be

factory installed directly on the meter. The following steps

are required for eld mounting the UPT Transmitter to a

Smith Meter PD meter:

1. Remove all accessories (counters, mechanical temperature

compensators, transmitters, etc.) from the meter.

2. Remove the existing calibrator, located inside the meter

dome adaptor.

a. Remove the cap protecting the external calibrator

adjusting stem by removing the two mounting screws.

b. Indicate the calibrator setting with a line that intersects the

calibrator dial and its adjacent part.

c. Remove the calibrator adjusting assembly by removing

the two mounting screws and carefully withdraw the stem

assembly from the housing without changing the adjusting

screw.

d. Remove the calibrator from the meter dome adaptor by

removing the two small hold-down screws and carefully

rotating the calibrator body clockwise.

e. Attach the blind plate (provided in the adaptation

kit) over the calibrator stem assembly hole.

3. Mount the UPT Transmitter onto the meter dome

adaptor. A weatherproof gasket and three 3/8" - 16 x

1-1/4" mounting bolts are provided. Care must be taken

to properly engage the transmitter coupling or gear to the

meter drive coupling or gear.

For adaptation to old style (single case) PD meter (old

style PD meters include Models AB, AS, B, or S-12, 13,

24, 28, 30, 35, 42, 45, 50, 60, 65, 75, and 100), also

mount the 5/8" spacer between the UPT Transmitter and

meter dome adaptor. An additional weatherproof gasket

and longer mounting bolts are provided.

4. If a live calibrator is required to be installed below the

UPT Transmitter then a UPT calibrator adapter kit is

required P/N 529288011. If a live calibrator is required on

top of the UPT Transmitter then a remote calibrator kit is

required P/N 529288001.

5. If additional stack accessories are not required, install a

blind cover plate (10078-1) on the top of the UPT Transmitter. The manual calibrator and other parts removed in

previous steps can be discarded (see note below).

6. If additional stack accessories are required, reinstall

the previously removed calibrator and stem assembly

into the new calibrator adaptor housing located on top

of the transmitter by reversing the removal procedure

described in Step 2 above (see note below).

7. Install oiler in calibrator housing (parts provided in the

adaptation kit):

a. Attach tube to oiler.

b. Insert tube through calibrator housing.

c. Drive oiler (force t) into housing.

d. Attach oiler tube to top of calibrator, just below drive

coupling.

8. Reassemble the accessories (counter, mechanical temperature compensator, etc.) onto the calibrator housing.

9. Check the calibrator setting and adjust (if necessary) to

the setting recorded in Step 2b. Recalibration of the me-

ter may be required due to breaking of seals on original

calibrator adjustment and is recommended to maintain

optimum meter accuracy.

For adaptation to old style PD meters, the meter must be

recalibrated because the new factory-installed calibrator

is not adjusted.

10.If desired, a seal wire can be installed (like a belt) around

the middle of the UPT Transmitter cover and housing to

prevent unauthorized tampering with internals.

Note: With the calibrator removed from the meter, the oiler

tting on the PD meter is no longer needed and should be

sealed off.

ATEX/IECEx Installation

Standards Used:

IEC 60079-0 6th Edition, EN 60079-0: 2012 +A11:2013,

UL 60079-0 6th Edition, CAN/CSA C22.2 No. 60079-0:11

IEC 60079-1 7th Edition, EN 60079-1: 2014. UL 60079-1

7th Edition, CAN/CSA C22.2 No. 60079-1:11

Cable entries must be in accordance to EN/IEC 60079-1

section 13.

For wiring systems utilizing cable glands the gland and or

thread adaptor must be Ex certied.

The cable end must be securely installed and depending

on the cable type be properly protected from mechanical

damage.

For wiring systems utilizing conduit, an Ex certied sealing

device must be used immediately at the entrance of the

enclosure. Any unused entry must be suitably blocked

with an Ex db IIB IP65 certied plug for ATEX and IECEx

applications.

Equipment bonding shall be provided at the external

grounding facility terminal, external connection is not

required when using metallic conduit or armored cable.

External grounding facility terminal wire range:

10-12 AWG (5.26 sq mm to 3.31 sq mm) wire.

CAUTION: To prevent ignition of hazardous atmospheres,

disconnect from supply circuit before opening. Keep tightly

closed when circuits are in operation.

WARNING: To prevent ignition of hazardous atmospheres,

do not open enclosure unless area is known to be nonhazardous. To reduce the risk of ignition of hazardous

atmospheres, conduit runs must have a sealing tting

connected within 18 inches of the enclosure.

Special Conditions For Safe Use:

- Special Fasteners: Cover Bolts - DIN 912 grade 12.9 (alloy

steel) M8 x 1.25, thread tolerance 6g, only replace with this

type.

- Select wiring and cable glands suitable for 80°C operation.

- Contact manufacturer at address listed for information on

the dimensions of the ameproof joints.

FMC Technologies Measurement Solutions Inc.

1602 Wagner Avenue

Erie, Pennsylvania 16510

USA

Marking Equipment

Ex db IIB T6

Tamb = -40°C to 70°C IP65

Covered

Model: UPT DEMKO 03 ATEX 0308254X

Certicate

IEC Ex UL 04.0009X

Page 2 • MN01045

Issue/Rev. 0.7 (11/17)

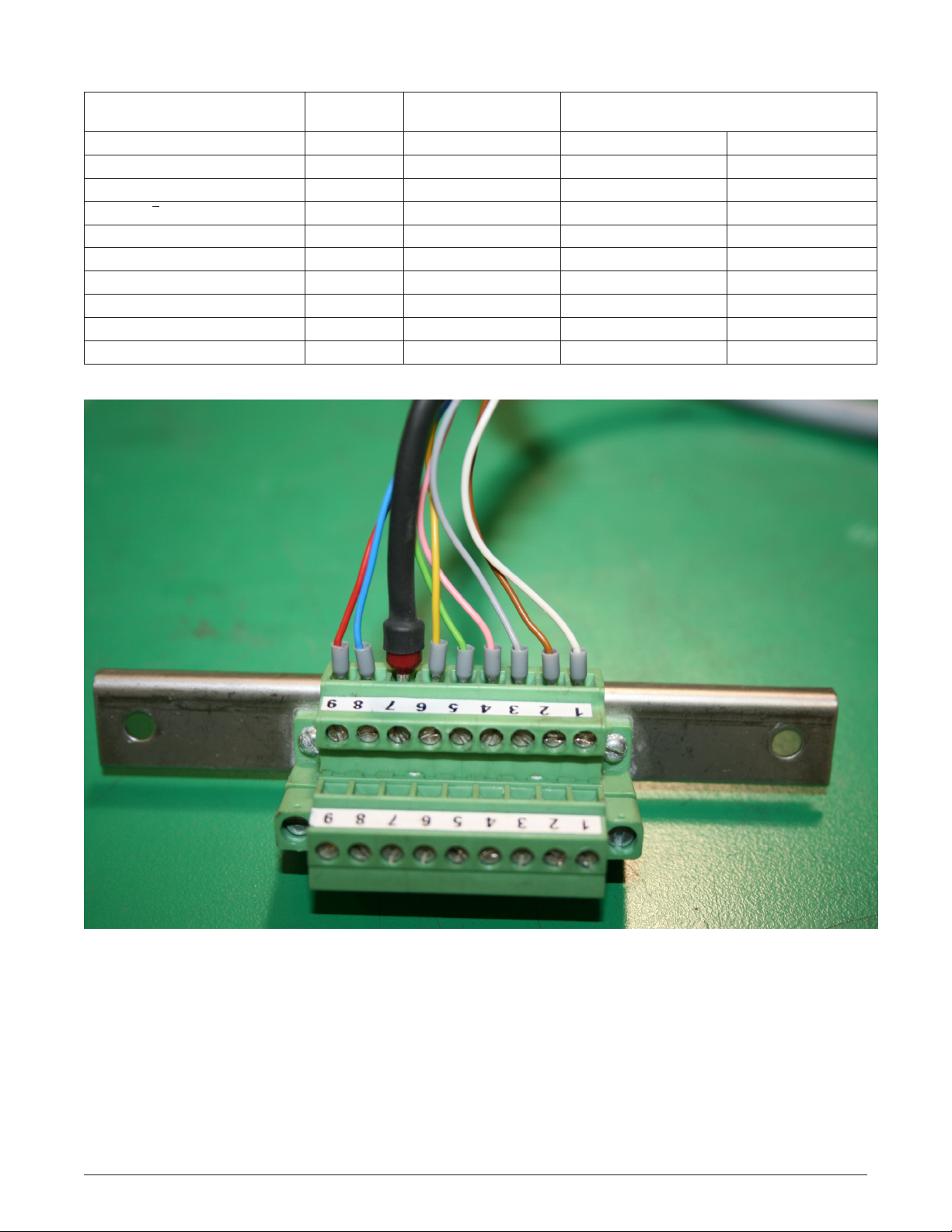

Wiring Diagram

Function Color

Electronics Ground white

Input Power (12-24 Vdc) brown

Channel "B" Output grey

Channel "B" Output pink

Channel "A" Output green

Channel "Ā" Output yellow

Shield black

Verication Pulse Output blue

Inverted Verication Pulse red

(Not used)

Standard Version Pin

Connections

[ 1 ]

[ 2 ]

[ 3 ]

[ 4 ]

[ 5 ]

[ 6 ]

[ 7 ]

[ 8 ]

[ 9 ]

[10]

Rotation of Transmitter Shaft Reference

Dimensions Drawing Below

Counter-Clockwise Clockwise

Leading Lagging

Lagging Leading

Figure 1 – Terminal Block Wires

Note: Picture in color, black and white, follow wire diagram table.

Issue/Rev. 0.7 (11/17) MN01045 • Page 3

Loading...

Loading...