FRANÇAIS

NEDERLANDS

DEUTSCH

NORSK

SLOVENSKI

SVENSKA

SUOMI

DANSK

ITALIANO

ENGLISH

ESPAÑOL

INSTALLATION / USAGE / ENTRETIEN - FR

INSTALLATIE / GEBRUIK / ONDERHOUD - NL

INSTALLATION / GEBRAUCH / WARTUNG - DE

ASENNUS / KÄYTTÖ / HUOLTO - FI

INSTALLATION / ANVÄNDNING / UNDERHÅLL - SE

INSTALLASJON / BRUK / VEDLIKEHOLD - NO

INSTALACIJA / UPOR ABA / VZDR ŽEVANJE - SI

INSTALLATION / USE / MAINTENANCE - GB

INSTALLA ZIONE / USO / MANUTENZIONE - IT

INSTALLATION / BRUG / VEDLIGEHOLDELSE - DK

INSTALACIÓN / USO / MANUTENCIÓN - ES

INSTALAÇÃO / UTILIZAÇÃO / MANUTENÇÃO - PT

PORTUGUÊS

7003 - 7023 - 7103 - 7123 - 8103 VD - 8103 VDM - 8123 VD - 8123 VDM

8203 - 8203 M - 8223 - 8223 M - MO8302 - MO8303 - MO8322 - MO8323

MO8342 - MO8362 - MO8801D - MO8801S - MO8821D - MO8821S

MO9122 - MO9202D - MO9202S - MO9222D - MO9222S - PI7203 - PI7223 - PI7703

PI7723 - PI8002 - PI8003 - PI8022 - PI8023 - PI8042 - PI8043 - PI8062 - PI8063

PI8403 - PI8423 - PI8443 - PI8463 - PI8502 - PI8503 - PI8522 - PI8523 - PI8542

PI8543 - PI8562 - PI8563 - PI8621A - PI8621R - PI8621S - PI8802D - PI8802S

PI8822D - PI8822S - PI8842D - PI8842S - PI8862D - PI8862S - PI9003 - PI9023

12

ENGLISH

SYMBOLS

WARNINGS AND SAFETY SYMBOLS

The safety symbols utilised identify possible hazards to users.

Always respect all safety warnings identified with these symbols:

INDEX

INSTALLATION 13

SAFETY WARNINGS 13

CABINET APERTURE 13

CONNECTING TO GAS SUPPLY 14

WIRING- CONNECTING TO ELECTRICITY SUPPLY 15

FIXTURE 15

USE 16

WARNINGS 16

CONTROLS 16

BURNERS: 17

HOB: 18

SELECTING BURNER 18

ELECTRONIC IGNITION HOB (DEPENDING ON MODEL) 18

MANUAL IGNITION HOB 18

HOB FLAME REGULATION 18

VISUAL FLAME CONTROL 19

GAS CYLINDERS / BOTTLES 1

9

MAINTENANCE 20

CLEANING 20

INJECTORS 20

SMEV ACCESSORIES 20

TEST PRESSURE POINT10

FIGURES AND TECHNICAL DRAWINGS 122-135

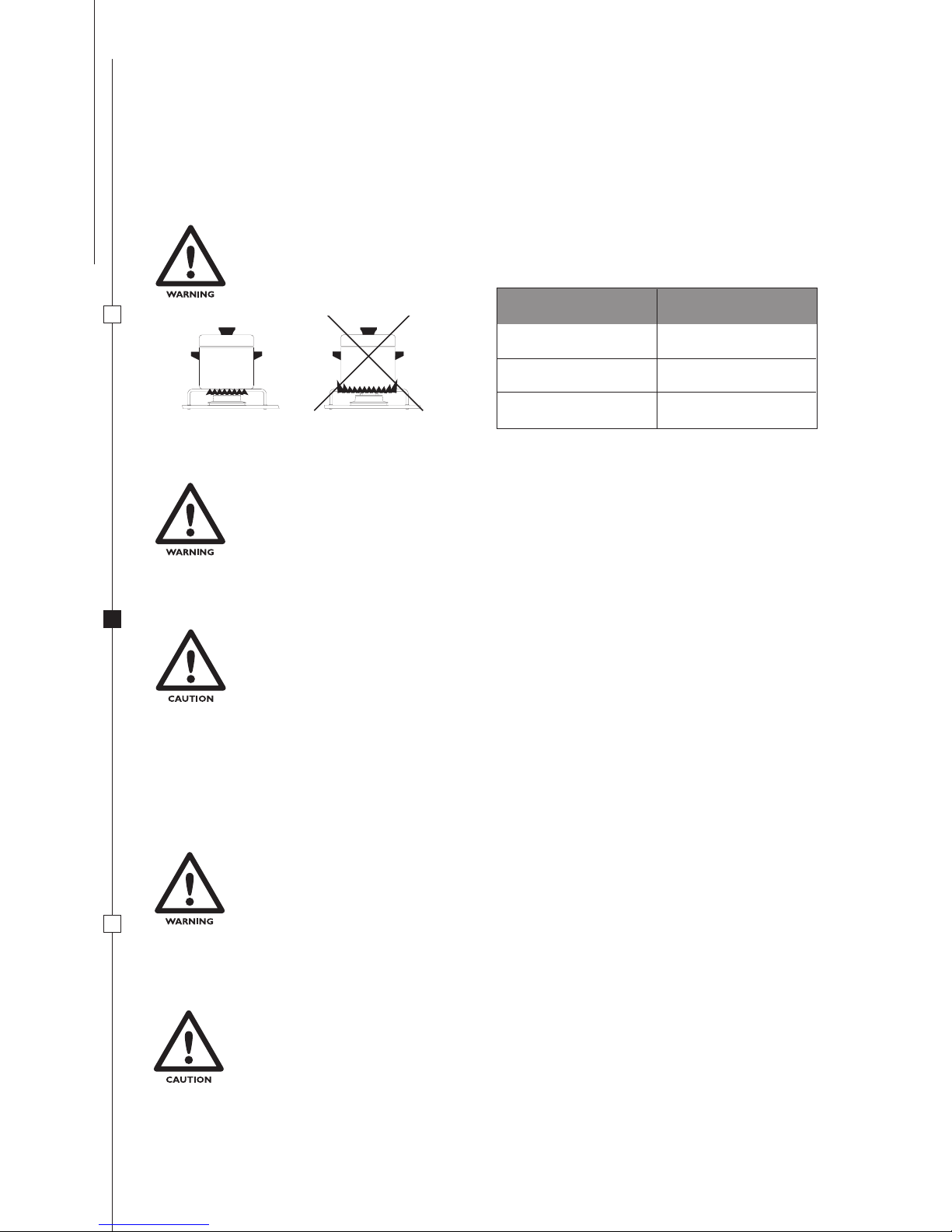

WARNING

Hazard of injury or death.

CAUTION

To prevent possible injury

and / or damage

INSTALL ATIONUS E

MAINTENA NC E

13

ENGLISH

SAFETY WARNINGS

THIS APPLIANCE MUST BE INSTALLED IN ACCORDANCE WITH THE

REGULATIONS IN FORCE AND ONLY USED IN AN ADEQUATELY VENTILATED

AREA. ALWAYS READ THE INSTRUCTIONS PROVIDED THOROUGHLY BEFORE

INSTALLING AND USING THIS APPLIANCE.

THIS APPLIANCE MUST BE INSTALLED BY SPECIALISED GAS SERVICE ENGINEERS.

THIS APPLIANCE IS DESIGNED AND MANUFACTURED FOR COOKING FOOD

ONLY. ANY OTHER USE IS CONSIDERED IMPROPER AND INCORRECT CREATING

HAZARDOUS CONDITIONS. THE MANUFACTURER DECLINES ALL RESPONSIBILITY

FOR DAMAGE TO THINGS OR INJURIES TO PERSONS CAUSED BY INCORRECT

INSTALLATION AND / OR INCORRECT AND IMPROPER USE.

BEFORE INSTALLING CHECK THAT THE LOCAL GAS AVAILABLE (GAS TYPE AND

PRESSURE) AND THE APPLIANCE REGULATORS ARE COMPATIBLE WITH THE

APPLIANCE ITSELF.

GAS REGULATING SPECIFICATIONS FOR THIS APPLIANCE ARE PROVIDED ON THE

LABEL AFFIXED TO THE APPLIANCE (OR ON THE SERIAL PLATE).

THIS APPLIANCE IS NOT CONNECTED TO A FUME EXTRACTION FLUE FOR

EXTRACTING PRODUCTS OF COMBUSTION THEREFORE IT MUST BE INSTALLED

AND CONNECTED (FITTED) CONFORMING TO INSTALLATION REGULATIONS

IN FORCE FOR APPLIANCES OF THIS TYPE. IT IS OF UTMOST IMPORTANCE TO

RESPECT LEGISLATION REGARDING VENTILATION.

THE APPLIANCE MUST FITTED AT AN APPROPRIATE AND SAFE DISTANCE FROM

FLAMMABLE MATERIALS.

CABINET APERTURE

This hob has a class 3 grading: BUILT-IN APPLIANCE FOR KITCHENS OR WORKTOPS

MINIMUM ALLOWABLE DISTANCES FROM WALLS (FIG. 1 - PG. 122):

A / B FROM THE OUTER EDGE OF THE BURNER HEAD NEAREST ONE OF THE SIDE WALLS AND / OR

REAR WALL:

135 mm

C THE DISTANCE BETWEEN THE TOP OF THE BURNER AND THE BOTTOM OF THE UNITS AND /

OR SHELVES FITTED ABOVE THE HOB:

500 mm

D THE DISTANCE BETWEEN THE BOTTOM OF THE BURNER AND THE UNDERSIDE:

30 mm

SIZE OF CABINET APERTURE

Cut-out a hole in the cabinet as illustrated in FIG. 2 - PG. 123 depending on model to install.

The cabinet must be appropriately constructed and aligned horizontally with the worktop and with the unit.

The cabinet aperture must be perfectly squared and aligned.

If there are apertures for cabinet ventilation, prevent flammable materials from entering these.

Models PI8621A, PI8621S and PI8621R are modular.

It is possible to connect from 1 to 5 appliances in series.

ALWAYS RESPECT THE DISTANCE BETWEEN ONE CABINET APERTURE AND ANOTHER (FIG. 2 – PG. 130).

INSTALL ATION

US E

MAINTENA NC E

14

ENGLISH

CATEGORY AND COUNTRY OF DESTINATION

I3B/P(30)

AT BE DK FI DE GB NL NO SE CH SI

I3+ (28-30/37)

BE FR IE IT ES CH GB PT SI

GAS PRESSURE

30 mbar Butane (G30)

30 mbar Propane (G31)

28-30 mbar Butane (G30)

37 mbar Propane (G31)

This appliance is designed for running off the following types of gas at the corresponding operating pressures. The gas

category (or categories) of the appliance is given on the specifications label affixed to the appliance.

CONNECTING TO GAS SUPPLY

CHECK THESE SPECIFICATIONS BEFORE CONNECTING THE APPLIANCE TO THE

GAS CYLINDER /BOTTLE. THE PRESSURE REGULATORS CONNECTED BETWEEN

THE GAS CYLINDER AND APPLIANCE MUST CONFORM WITH THE CATEGORIES

GIVEN IN THE TABLE BELOW.

MODEL TOTAL NOMINAL THERMAL

CAPACITY

AIR VOLUME REQUIRED FOR

COMBUSTION

MO8801D - MO8801S - MO8821D

MO8821S - PI8621A

PI8621S

PI8621R

MO8302 - MO8322 - MO8342

MO8362 - MO9202D - MO9202S

MO9222D - MO9222S

PI8002 - PI8022 - PI8042 - PI8062

PI8502 - PI8522 - PI8542 - PI8562

PI8802D - PI8802S - PI8822D - PI8822S

PI8842D - PI8842S - PI8862D - PI8862S

MO9122

7003 - 7023 - 7103 - 7123

8103 VD - 8103 VDM

8123 VD - 8123 VDM

8203 - 8203 M - 8223 - 8223 M

MO8303 - MO8323 - PI9003 - PI9023

PI7203 - PI7223 - PI7703 - PI7723

PI8003 - PI8023 - PI8043 - PI8063

PI8403 - PI8423 - PI8443 - PI8463

PI8503 - PI8523 - PI8543 - PI8563

kW - gr/h m3/h

1,0 - 73

1,8 - 131

2,2 - 160

2,8 - 204

3,2 - 233

3,6 - 262

3,8 - 277

4,6 - 335

2,0

3,6

4,4

5,6

6,4

7,2

7,6

9,2

INSTALL ATIONUS E

MAINTENA NC E

15

ENGLISH

FIXTURE

THIS APPLIANCE MUST BE FITTED AND SECURED TO THE CABINET UTILISING THE FIXTURE SCREWS AS

ILLUSTRATED IN FIG. 3 - PG.131.

The gas supply pipe connected to the appliance must be a rigid metal pipe with sealed fittings. It is possible to fit

a flexible hose, however, in this case the following conditions must be respected:

a) The hose can be accessed easily for inspection;

b) The hose must be protected against coming into contact with parts which heat up (for example parts

underneath the burners);

c) The hose must be protected against being damaged (twisting, pulling, trapping,….);

d) The hose must be protected against being trapped by moving parts (e.g. drawers);

e) The hose must not have a length over 1.5 m;

f) The hose must be replaced before its expiry date;

For models PI8621A, PI8621S, PI8621R seal the appliance gas pipe utilising the sealed tube with pre-mounted

gas fitting provided. Once the appliance has been connected to the gas supply check for gas leaks utilising a noncorrosive fluid. Do not use a water and soap solution. NEVER USE A FLAME TO TEST FOR GAS LEAKS

Models PI8621A, PI8621S and PI8621R are modular. It is possible to connect from 1 to 5 appliances in series.

Disconnect and remove the sealed tube mounted to the gas pipe on the installed appliance and connect it to the

gas pipe on the appliance to install. Connect the appliances together by connecting the gas pipes in series utilising

the fitting.

CONNECTING TO ELECTRICITY SUPPLY

THIS APPLIANCE MUST BE CONNECTED TO A 12 VDC POWER PACK ONLY. THE

CIRCUIT MUST BE FITTED WITH A SAFETY FUSE NOT HIGHER THAN 3 AMP.

WHEN WIRING RESPECT CORRECT POLARITY!

IT IS OF UTMOST IMPORTANCE NEVER TO CONNECT THIS APPLIANCE TO MAINS

VOLTAGE (230 V) WHICH IRREVERSIBLY DAMAGES APPLIANCE COMPONENTS AND

CREATES A HAZARD TO THE USER.

To connect the appliance use a 1.5 mm2 double red and black wire and wire to the terminal junction box located at the

rear of the appliance. The red terminal is the positive pole and the black terminal is the negative pole.

This chapter refers only to models with the wording 12 VDC on the appliance specifications label affixed to the

appliance.

WHEN INSTALLING AND CONNECTING THE APPLIANCE TO THE GAS SUPPLY,

ENSURE THAT THE GAS SUPPLY HOSE IS NOT TWISTED, STRETCHED OR

SUBJECTED TO ANY FORM OF STRAIN WHICH COULD CREATE A HAZARD.

INSTALL ATION

US E

MAINTENA NC E

16

ENGLISH

WARNINGS

THIS APPLIANCE MUST ONLY BE USED BY RESPONSIBLE ADULTS. DURING USE

AND IMMEDIATELY AFTER USE THE BURNER AND OTHER ACCESSIBLE PARTS MAY

BE HOT; DO NOT TOUCH THESE PARTS AND ALWAYS KEEP CHILDREN AT A SAFE

DISTANCE. AFTER USING THE APPLIANCE ENSURE THE KNOB/KNOBS ARE OFF.

AFTER USE ALWAYS SHUT OFF THE GAS SUPPLY AT THE MAIN GAS TAP.

THE USE OF GAS APPLIANCES GENERATES HEAT AND MOISTURE IN THE

IMMEDIATE AREA. ALWAYS ENSURE A GOOD VENTILATION IN THE COOKING

AREA: KEEP ALL AIR VENTS OPEN FOR NATURAL VENTILATION OR INSTALL AN

EXTRACTOR FAN (COOKERHOOD).

DUE TO INTENSIVE USE OF THE APPLIANCE IT MAY BE NECESSARY TO INCREASE

VENTILATION SUCH AS OPENING A WINDOW OR INCREASING COOKERHOOD

(EXTRACTOR FAN) SPEED.

FOR MODELS MO8800 THE DRAINER MUST BE REMOVED WHEN UTILISING THE

HOB BURNER/S.

CAUTION: THIS WARNING IS AFFIXED IN VISIBLE LOCATION ON THE HOB

GLASS LID. GLASS HOB LIDS MAY SHATTER WHEN HEATED. ALWAYS RAISE

THE LID BEFORE IGNITING A BURNER/S (HOB, OVEN AND GRILL) AND TURN OFF

ALL BURNERS (HOB, OVEN AND GRILL) AND LET THEM COOL DOWN BEFORE

LOWERING THE HOB GLASS LID.

CAUTION: THIS WARNING REFERS TO MODELS WITH INCORPORATED SINK

UNIT AND HOB AND WITH GLASS LID DIVIDED BETWEEN SINK AND HOB.

THIS WARNING IS AFFIXED IN A VISIBLE POSITION ON THE SINK UNIT GLASS

LID. WHEN USING THE HOB WITH THE GLASS LID ON THE SINK UNIT CLOSED,

ALWAYS KEEP PANS ON HOB AT A DISTANCE OF 10 MM MINIMUM FROM SINK

UNIT GLASS LID.

The following symbols indicate the burner corresponding to the control knob.

NOTE: different models may have different knobs and different symbols.

THIS SYMBOL IS PLACED NEXT TO THE HOB BURNER KNOBS.

FULL DOT REFERS TO THE CORRESPONDING HOB BURNER.

GAS OFF

HIGH FLAME

LOW FLAME

The following symbols indicate the burner regulation corresponding to the knob position.

NOTE: different models may have different knobs and different symbols.

OTHER SYMBOLS

PUSHBUTTON ELECTRONIC IGNITION

CONTROLS

INSTALL ATIONUS E

MAINTENA NC E

17

ENGLISH

BURNERS

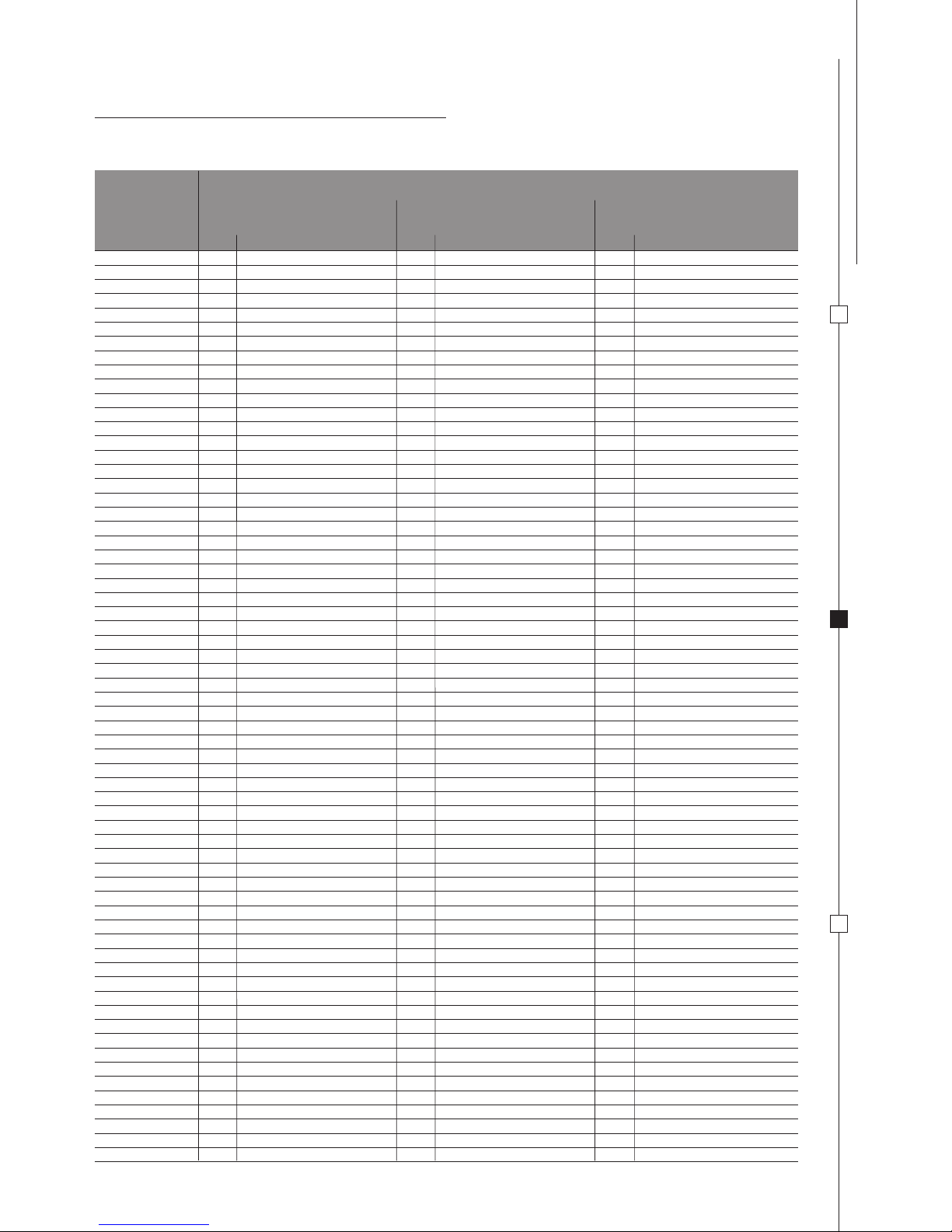

Technical specifications for burners referring to appliance model:

7003 2 1 73 1 1,8 131

7023 2 1 73 1 1,8 131

7103 2 1 73 1 1,8 131

7123 2 1 73 1 1,8 131

8103 VD 2 1 73 1 1,8 131

8103 VDM 2 1 73 1 1,8 131

8123 VD 2 1 73 1 1,8 131

8123 VDM 2 1 73 1 1,8 131

8203 2 1 73 1 1,8 131

8203 M 2 1 73 1 1,8 131

8223 2 1 73 1 1,8 131

8223 M 2 1 73 1 1,8 131

MO8302 1 1 73 1 1,8 131

MO8303 2 1 73 1 1,8 131

MO8322 1 1 73 1 1,8 131

MO8323 2 1 73 1 1,8 131

MO8342 1 1 73 1 1,8 131

MO8362 1 1 73 1 1,8 131

MO8801D 1 1 73

MO8801S 1 1 73

MO8821D 1 1 73

MO8821S 1 1 73

MO9122 2 1,8 131

MO9202D 1 1 73 1 1,8 131

MO9202S 1 1 73 1 1,8 131

MO9222D 1 1 73 1 1,8 131

MO9222S 1 1 73 1 1,8 131

PI7203 1 1 73 2 1,8 131

PI7223 1 1 73 2 1,8 131

PI7703 1 1 73 2 1,8 131

PI7723 1 1 73 2 1,8 131

PI8002 1 1 73 1 1,8 131

PI8003 1 1 73 2 1,8 131

PI8022 1 1 73 1 1,8 131

PI8023 1 1 73 2 1,8 131

PI8042 1 1 73 1 1,8 131

PI8043 1 1 73 2 1,8 131

PI8062 1 1 73 1 1,8 131

PI8063 1 1 73 2 1,8 131

PI8403 1 1 73 2 1,8 131

PI8423 1 1 73 2 1,8 131

PI8443 1 1 73 2 1,8 131

PI8463 1 1 73 2 1,8 131

PI8502 1 1 73 1 1,8 131

PI8503 1 1 73 2 1,8 131

PI8522 1 1 73 1 1,8 131

PI8523 1 1 73 2 1,8 131

PI8542 1 1 73 1 1,8 131

PI8543 1 1 73 2 1,8 131

PI8562 1 1 73 1 1,8 131

PI8563 1 1 73 2 1,8 131

PI8621A 1 1 73

PI8621R 1 2,2 160

PI8621S 1 1,8 131

PI8802D 1 1 73 1 2,2 160

PI8802S 1 1 73 1 2,2 160

PI8822D 1 1 73 1 2,2 160

PI8822S 1 1 73 1 2,2 160

PI8842D 1 1 73 1 2,2 160

PI8842S 1 1 73 1 2,2 160

PI8862D 1 1 73 1 2,2 160

PI8862S 1 1 73 1 2,2 160

PI9003 2 1 73 1 1,8 131

PI9023 2 1 73 1 1,8 131

THERMAL CAPACITY BURNERS MODEL

SEMI-RAPID

Ø 62 mm

AUXILIARY

Ø 47 mm

RAPID

Ø 77 mm

nr. Kw gr/h nr. Kw gr/h nr. Kw gr/h

INSTALL ATION

US E

MAINTENA NC E

AUXILIARY

Ø 47 mm

from 6 to 16 cm

SEMI-RAPID

Ø 62 mm

from 16 to 22 cm

RAPID

Ø 77 mm

from 16 to 22 cm

BURNER PAN DIAMETER

18

ENGLISH

To ignite burner, gently push-in and turn the control knob to position HIGH FLAME and maintaining the knob pushed

at the same time press the electronic ignition pushbutton. Once the burner is alight maintain the knob in this position

for a few seconds to the ensure the flame remains alight.

-MANUAL IGNITION HOB

THE FLAME MUST NEVER EXTEND BEYOND THE EDGE OF THE PAN. CENTRE THE

PAN OVER THE BURNER ENSURING STABILITY ON THE PAN SUPPORT.

- SELECTING BURNER

- ELECTRONIC IGNITION HOB (DEPENDING ON MODEL)

HOB

Manual ignition when the appliance is not fitted with the electronic ignition feature or in the event of failure in the

electronic ignition.

MAKE SURE THERE ARE NO PANS OR OTHER ANY OBJECTS ON THE BURNERS

WHEN IGNITING.

IF THE BRUNER DOES NOT IGNITE IMMEDIATELY REPEAT IGNITION AFTER

HAVING FOLLOWED EACH STEP BELOW:

• TURN THE KNOB TO “SMALL FLAME”

• PROCEED WITH MANUAL IGNITION

• CHECK THERE IS SUFFICIENT GAS IN THE GAS BOTTLE.

IF THE APPLIANCE STILL DOES NOT IGNITE SHUT OFF THE GAS SUPPLY AT THE

MAIN GAS TAP AND CONTACT YOUR LOCAL DEALER.

MAKE SURE THERE ARE NO PANS OR OTHER ANY OBJECTS ON THE BURNERS

WHEN IGNITING.

To ignite burner, gently push-in and turn the control knob to position HIGH FLAME and maintaining the knob pushed at

the same time light the burner with a match or gas lighter. Once the burner is alight maintain the knob in this position

for a few seconds to ensure the flame remains alight.

IF THE BURNER DOES NOT IGNITE IMMEDIATELY CHECK THERE IS SUFFICIENT

GAS IN THE GAS BOTTLE.

IF THE APPLIANCE STILL DOES NOT IGNITE SHUT OFF THE GAS SUPPLY AT THE

MAIN GAS TAP AND CONTACT YOUR LOCAL DEALER.

- HOB FLAME REGULATION

To regulate flame turn the knob to the desired cooking flame.

INSTALL ATIONUS E

MAINTENA NC E

19

ENGLISH

GAS CYLINDERS/BOTTLES

The appliance runs off standard gas bottles which can be found in the country of use. The type of gas to use is clearly

marked on the packaging and on the specifications label affixed to the rear of the appliance. However always respect the

following instructions: gas bottles must always be located and positioned in the compartment provided for this purpose.

They must always be vertical and fitted with a valve and pressure regulator. Do not obstruct or impede access to the

gas bottle to permit quick and easy access when replacing.

WARNING! When replacing the gas bottle always take the following precautions:

a) close all gas knobs (Pos. OFF);

b) make sure there are no flames or fires in proximity of the gas bottle;

c) close the gas valve on the bottle to be replaced;

d) unscrew the pressure regulator on the empty bottle and remove the bottle from the purpose compartment. This

procedure is inverted for fitting a new bottle. Check for gas leaks utilising a non-corrosive fluid. Do not use a water

and soap solution.

NEVER USE A FLAME TO CHECK FOR GAS LEAKS;

e) ignite the burners to check they function correctly. If there are problems call in an authorised gas service engineer.

AFTER APPLIANCE USE ALWAYS TURN OFF THE GAS TAP ON THE BOTTLE

GAS LEAKS

We recommend the use of an electronic and homologated gas detector for checking ambient air.

If there is a smell of gas;

a) immediately open the windows and evacuate the vehicle or caravan.

b) do not turn on or off light switches or other electronic appliances, do not light matches or lighters or anything that

could cause the gas to ignite;

c) put out any flames

d) shut off the valve on the gas bottle or cylinder. Do not re-open this valve unless the gas leak has been identified and

eliminated.

e) contact a specialised gas service engineer.

NEVER OPERATE THE APPLIANCE WITH GAS AND OR AT GAS PRESSURES

DIFFERENT TO THOSE INDICATED BY SMEV AS THIS COULD CAUSE IRREGULAR

AND INCORRECT OPERATION. SMEV DECLINES ALL RESPONSIBILITY FOR

DAMAGE OR INJURY CAUSED BY AN INCORRECT OR IMPROPER USE OF THE

APPLIANCE.

VISUAL FLAME CONTROL

Depending on the type of gas used the flame should be:

Propane (G31): blue flame without yellow tips.

Butane (G30): flame with yellow tips when ignited which becomes more intense in colour as the burner heats.

INSTALL ATION

US E

MAINTENA NC E

BURNER

Ø INJECTOR (mm)

SEMI-RAPID

Ø 62 mm

STAMPED N.

AUXILIARY

Ø 47 mm

0,50 50

RAPID

Ø 77 mm

0,75 75

When removing and mounting the injectors the injector holder must be must be held in place with the aid of a tool

(FIG. 5 - PG. 134).

0,67 67

20

ENGLISH

SMEV ACCESSORIES

GLASS LID (FIG. 6 - PG. 135) only for models PI8621A, PI8621S, PI8621R.

This optional accessory has two functions: when closed it can be used as an additional work surface and when open,

during cooking, it protects the wall behind the appliance from food splashes.

To request a GLASS LID, please contact your local dealer

TEST PRESSURE POINT (IF FITTED)

THE TEST PRESSURE POINT (PRESSURE CHECK VALVE) IS FITTED UNDER THE HOB. (FIG. 4 - PG. 133).

Removing and mounting this test pressure point (pressure check valve) must be performed by a qualified gas service

engineer. Gas pressure is related to the type of gas used to supply the appliance. Refer to chapter GAS in this manual.

BEFORE CLEANING THE APPLIANCE ALWAYS TURN IT OFF AND DISCONNECT

FROM POWER SUPPLY AND WAIT UNTIL IT HAS COOLED DOWN.

SURFACES THAT ARE STILL HOT CAN BE DAMAGED IF THEY COME INTO

CONTACT WITH COLD WATER OR A DAMP CLOTH.

NEVER USE ABRASIVE, CORROSIVE OR CHLORINE BASED CLEANING PRODUCTS.

NEVER USE STEEL OR PLASTIC SCOURING PADS. NEVER LEAVE DEPOSITS OF

ACID OR ALKALINE SUBSTANCES (VINEGAR, SALT, LEMON JUICE ETC.) ON THE

APPLIANCE. STAINLESS STEEL OR ENAMELLED SURFACES MUST BE CLEANED

ONLY WITH WATER AND SOAP OR A NEUTRAL DETERGENT, THOROUGHLY RINSE

AND DRY. USE CLEAN SPONGES OR CLOTHS TO CLEAN.

INJECTORS

CLEANING OR REPLACING GAS INJECTORS MUST ONLY BE PERFORMED BY

AUTHORISED AND QUALIFIED GAS SERVICE ENGINEERS. THE MANUFACTURER

DECLINES ALL RESPONSIBILITY IN REGARD.

CLEANING

121

SLOV E NSKI

OPOMBE

122

1 F I G .

A

C

D

B

B

A

B

C

D

135

135

500

30

mm

123

2 F I G .

X

Y

275 mm

10 mm

421.7 mm

54.9 mm

448 mm

478 mm

X

Y

478 mm

448 mm

253 mm

421.7 mm

R30 mm

R

30

mm

151.7 mm

178 mm

13

5°

135°

R

30

R3

0

129.8 mm

9

0°

29.8 mm

178 mm

225 mm

R2

53

mm

45 mm

285.7 mm

R167

m

m

33.9 mm

R3

0

178 mm

R3

0

R

30

178 mm

151.7 mm

R203

mm

5 mm

10

10

54.9 mm

208 mm

208 mm

A

A

SEZ. A-A

SEZ. B-B

193,01 mm

213,01

mm

205,97 mm

232,89

mm

Y

X

304,65 mm

212,14 mm

mm 393mm 393

57,91 mm

A

A

R2

2

8

0,

4

8

mm

176,73 mm

B

90°

R

20

8,5 mm

SEZ. A-A

170,35 mm57,69 mm

193,01 mm

R1035

,

5

mm

135°

R

20

90°

60°

R20

B

445,89

mm

170 mm

R57 mm

18,

4

mm

12 mm

R57 mm

155 mm

8,5 mm

10 mm

31,6 mm31,6 mm

18,4

mm

MOD. X mm Y mm

7103

7123

786 445,89

MOD. X mm Y mm

8103 VD

8103 VDM

8123 VD

8123 VDM

956 416

124

222,36 mm

R

173

mm

Y

R

10

R

10

R173

R173

45

°

X

R

10

m

m

339,67 mm

22,5°

2

2,

5

°

314 mm

R1

0

mm

R10 mm

R173 mm

90

°

19 mm

R40

m

m

R

10

R

17

3 mm

217 mm

R10

232,5 mm

191 mm

R1

0

300,25 mm

R10

mm

R1

0

m

m

11 mm

11 mm

11 mm

X

Y

R 173

m

m

A

A

SEZ. A-A

X

Y

R88

R1

95

R182

99,0

5

R7

7

R20

8

R8

8

213

125,05

113,95

201,95

125,36

100

62

212,4

5,28

158,3

133,2

241,26

79,08

R69

3

89,07

106,05

X

Y

A

A

8,5

SEZ. A-A

MOD. X mm Y mm

MO8302

MO8322

MO8303

MO8323

MO8342

MO8362

666 426

MOD. X mm Y mm

PI8802D

PI8822D

PI8842D

PI8862D

MO8801D

MO8821D

511,02 408

125

R69

3

133,2

R182

R19

5

113,95

SEZ. A-A

R8

8

213

8,5

A

A

125,05

5,28

79,08

R77

241,26

158,3

99,0

5

125,36

R20

8

62

212,4

Y

X

100

201,95

R8

8

89,07

106,05

X

Y

MOD. Y mmX mm

511,02 408

PI8802S

PI8822S

PI8842S

PI8862S

MO8801S

MO8821S

X

Y

2

Y

1

18 mm

7,5 mm

SEZ. A-A

B

6 mm

5 mm

R 2,

5

A

B

A

135°

135°

14 mm12,2 mm

13,8 mm

40 mm

X

804 mm

316,7 mm

Y2

Y1

R 3045,3

mm

R

3039,3 mm

12,3 mm

X mm

MO9122

816 316,6 322,7

MOD. Y1 mm Y2 mm

126

MOD. X mm Y mm

MO9202D

MO9222D

883 307

MOD. X mm Y mm

MO9202S

MO9222S

883 307

49 mm49 mm

70 mm

79,3 mm 494,5 mm

150,7 mm 439 mm158,9 mm

211,2 mm

141 mm70 mm

X

Y

1

25

°

R4

5

mm

R100 mm

96 mm

100 mm

45 mm

45 mm

12

5

°

166 mm

2 mm

1

45

°

15 mm

36,4 mm

748,6 mm

793 mm

65,8 mm65,8 mm

67,2 mm67,2 mm

R10

0

94 mm

100 mm

96 mm

94 mm

40 mm

1

45

°

36,4 mm

45 mm

45 mm

R45 mm

166 mm

A

A

7 mm

SEZ. A-A

49 mm 49 mm

70 mm

79,3 mm494,5 mm

150,7 mm mm 9,851mm 934

211,2 mm

141 mm70 mm

X

Y

12

5°

R4

5

m

m

R100 mm

96 mm

100 mm

45 mm

45 mm

12

5

°

166 mm

2 mm

1

45

°

15 mm

36,4 mm

748,6 mm

793 mm

65,8 mm 65,8 mm

mm 2,76mm 2,76

R

10

0

m

m

94 mm

100 mm

96 mm

94 mm

40 mm

14

5

°

36,4 mm

45 mm

45 mm

R

45

mm

166 mm

A

A

7 mm

SEZ. A-A

127

278 mm

139,40 mm

60

°

159,27 mm

25,10 mm

225 mm

173 mm

A

9 mm

SEZ. A-A

R15

m

m

R10 mm

R10 mm

R

10 mm

R2

1

5

m

m

R2

2

2,5

mm

R2

2

9

m

m

R2

2

4 mm

R2

29

m

m

A

X

MOD. X mm Y mm

7003

7023

456,2 466,1

228,1 mm

228,1 mm

238 mm

294,57 mm

13,51 mm

170,07 mm

193,1 mm

13

5°

433,17 mm

278,79 mm

27

8

,79 mm

294,57 mm

X

Y

228,1 mm

193,1 mm

193,1 mm

R35 mm

228,1 mm

228,1 mm

238 mm

294,57 mm

13.51 mm

170.07 mm

193.1 mm

135°~

433,7 mm

278,79 mm

278,79 mm

294,57 mm

456,2 mm

466.1 mm

228,1 mm

193,1 mm

193,1 mm

R3

5

mm

A

A

2 mm

SEZ. A-A

MOD. X mm

PI7203

PI7223

PI7703

PI7723

458

128

248 mm

248 mm

233 mm

179 mm179 mm

233 mm

R7

0

mm

R7

0

mm

135°

135°

Y

X

R3

0

mm

R3

0

mm

R3

0

mm

R3

0

mm

248 mm

248 mm

233 mm

179 mm179 mm

233 mm

301 mm

301

mm

273 mm 273 mm

R70 mm

R70 mm

R7

0

mm

R7

0

mm

135

°

1

35

°

135°

135°

214 mm 214 mm

Y

Y

X

X

R30

m

m

R3

0

mm

R3

0

mm

R3

0

mm

R3

0

mm

R3

0

mm

R30

mm

R3

0

mm

PI8002

PI8022

PI8042

PI8062

PI8502

PI8522

PI8542

PI8562

X mm

466

MOD.

358

Y mm

PI8003

PI8023

PI8043

PI8063

PI8503

PI8523

PI8543

PI8563

X mm

546

MOD.

428

Y mm

129

PI8403

PI8423

PI8443

PI8463

X mm

572

MOD.

332

Y mm

8203

8203 M

8223

8223 M

X mm

506

MOD.

416

Y mm

220 mm

205 mm 76 mm

76 mm

54 mm

92 mm

70 mm

70 mm

8,5

mm

202 mm199 mm

R

55

m

m

R71

mm

R3

1

1 mm

R53

1

m

m

25 mm

130 mm

199 mm

55 mm

216 mm

Y

135°

90°

A

X

X

Y

A

SEZ. A-A

R30

m

m

178 mm

178 mm

Y

151,6 mm

151,6 mm

45 mm

13

5

°

135°

R253

m

m

R30 mm

446 mm

X

R30

mm

393,3 mm

R3

0

mm

SEZ. B-B

B

B

130

X

X

Y

Y

224 mm

46 mm

4 mm

4 mm

R5

mm

54 mm

SEZ.A-A

AA

224 mm

3 mm

3 mm

3 mm

R54 mm

259,47 mm

R136,6 mm

143,5 mm

140 mm

77,54 mm

22,86

°

143,24 mm

119,12 mm

R54 mm

160,14 mm

235 mm

X

Y

109,3 mm

104,13 mm

79 mm

235 mm

278,79 mm

R677 mm

278,79 mm

238 mm

R54 mm

235 mm

294,57 mm

25,98 mm

177,48 mm

R10 mm

R140 mm

R

20

mm

101,6 mm

R

101,6 mm

R140 mm

140 mm

R10

m

m

R20 mm

110,09 mm

A

SEZ. A-A

A

135°

135°

228,1 mm

X

Y

5 mm

PI9003

PI9023

MOD. Y mmX mm

470 473

PI8621A

PI8621S

PI8621R

MOD. Y mmX mm

216 296

131

FIG. 3

MOD:

PI8621A

PI8621R

PI8621S

MOD:

7003

7023

7103

7123

MO8302

MO8303

MO8322

MO8323

MO8342

MO8362

MO8801D

MO8801S

MO8821D

MO8821S

MO9202D

MO9202S

MO9222D

MO9222S

PI7203

PI7223

PI7703

PI7723

PI8403

PI8423

PI8443

PI8463

PI8802D

PI8802S

PI8822D

PI8822S

PI8842D

PI8842S

PI8862D

PI8862S

PI9003

PI9023

132

Y

X

≥ 21 mm

≤ 25 mm

≥ 16 mm

≤ 21 mm

X

MOD:

PI8002

PI8003

PI8022

PI8023

PI8042

PI8043

PI8062

PI8063

PI8502

PI8503

PI8522

PI8523

PI8542

PI8543

PI8562

PI8563

Y

X

X

≥21 mm

≤25 mm

≥16 mm

≤21 mm

MOD:

8103 VD

8103 VDM

8123 VD

8123 VDM

8203

8203 M

8223

8223 M

133

MOD:

MO9122

FIG. 4

134

FIG. 5

135

FIG. 6

Loading...

Loading...