Page 1

WO-04

Reverse osmosis equipment for dish/glass washmachines.

MANUAL

use and maintenance

SERIAL N°: __________________

CODE: __________________

Note: _____________________________________________

- 1 -

Page 2

INDEX

1 GENERAL INFORMATIONS .................................................................................................................................... 3

1.1 MANUFACTURER / ASSISTANCE ............................................................................................... 3

1.2 CERTIFICATION .................................................................................................................. 3

1.3 AIM AND CONTENTS ............................................................................................................. 3

1.4 CONSERVATION .................................................................................................................. 3

1.5 SYMBOLS USED................................................................................................................... 3

2 EQUIPMENT FEATURES ......................................................................................................................................... 4

2.1 USE ............................................................................................................................... 4

2.2 PARTS THAT MAKE UP THE MACHINE ......................................................................................... 4

2.3 COMPONENTS .................................................................................................................... 5

2.4 DESCRIPTION ..................................................................................................................... 5

2.5 TECHNICAL SPECIFICATIONS ................................................................................................... 7

3 INSTALLATION ........................................................................................................................................................ 8

4 FUNCTIONING ........................................................................................................................................................ 10

4.1 FIRST START UP ................................................................................................................ 10

4.2 NORMAL USE .................................................................................................................... 10

4.3 INACTIVITY ...................................................................................................................... 10

4.4 ELECTRONIC BOARD OPERATING............................................................................................. 10

5 ROUTINE MAINTENANCE ..................................................................................................................................... 13

5.1 MAINTENANCE PERSONNEL QUALIFICATIONS .............................................................................. 13

5.2 MAINTENANCE PERSONNEL TASKS ........................................................................................... 13

5.3 REPLACING FILTER CARTRIDGE .............................................................................................. 14

5.4 PRELOAD EXPANSION TANK ................................................................................................... 14

5.5 VERIFICATION OF THE SETTING .............................................................................................. 15

5.6 CLEANING CONDUCTIVITY PROBE CONNECTORS .......................................................................... 15

5.7 CLEANING SOLENOID VALVES FILTER ........................................................................................ 16

5.8 MACHINE SANITATION ......................................................................................................... 16

6 EXTRAORDINARY MAINTENANCE ...................................................................................................................... 17

6.1 ELECTRONIC BOARD WHIT DISPLAY REPLACEMENT ....................................................................... 17

6.2 PROTECTION FUSE REPLACEMENT ........................................................................................... 17

6.3 PUMP REPLACEMENT .......................................................................................................... 18

6.4 CHECK/REPLACEMENT OF OSMOTIC MEMBRANES ......................................................................... 19

7 TROUBLE-SHOOTING ........................................................................................................................................... 20

- 2 -

Page 3

1 GENERAL INFORMATIONS

1.1 MANUFACTURER / ASSISTANCE

MANUFACTURER ASSISTANCE

SMEG S.p.A

Via L. da Vinci, 4

42016 Guastalla (RE)

1.2 CERTIFICATION

WO-04 was manufactured in compliance with the following EU Directives:

Machines 2006 / 42 / CE

Low Voltage 2006 / 95 / CE

Electromagnetic Compliance 2004 / 108 / CE

1.3 AIM AND CONTENTS

The purpose of this manual is to provide the user with all the necessary information so that, apart from

correct machine use, he or she is able to run it in the most autonomous and safest way. It also includes

information on operating the machine and routine maintenance.

This manual is for both users and technicians in charge of machine maintenance.

Before carrying out any operation on the machine, both the users and installation

personnel as well as qualified technicians must carefully read the instructions in this

manual.

Users can only carry out the operations indicated in this manual and must not perform

any operations reserved for maintenance personnel or qualified technicians.

ATTENTION

ATTENTION

Personal Data of the Retail Seller

All maintenance operations must be performed by qualified perso nnel.

1.4 CONSERVATION

The instruction manual is an integral part of the machine, therefore it must be kept within reach, inside a

proper container and, above all, safe from liquids and any other substance that could make it illegible.

1.5 SYMBOLS USED

GENERAL DIRECTIONS

Indicates a warning or notes on key functions or useful information. Pay the utmost

attention to texts indicated by this symbol.

Indicates a manual adjustment that can also foresee the use of portable equipment or

utensils.

Requires finding a measurement value, checking a signal, carrying out a visual control,

etc.

DANGER INDICATIONS

Generic danger, with risk to the user

Danger of lectrical kind.

PROHIBITION INDICATIONS

Prohibited.

- 3 -

Page 4

K

2 EQUIPMENT FEATURES

2.1 USE

WO-04 is an equipment designed for dish/glass wash machine water treatment. It is able to modify

organoleptic and chemical characteristics of potable water, reducing saline content.

The machine can preserve water from possible problems that can occur below the aqueducts, such as

infiltrations due to work on the network or breakage, and also from the consequences of keeping water in

decantation basins.

WO-04 is used to supply treated water to dishwasher and glasswesher machines, with frontal load.

The internal pressure tank can supply up to 5lt of treated water with an instant maximum capacity of

15lt/min, at a pressure of 2.5bar.

The treated water capacity is 1.5lt/min; water is stored in the pressure tank to supply high quantity of

water during the rinsing phase of the dish/glass washmachine cycle.

ATTENTION

The water consuption of the dish/glass washmachine installed after the WO-04 must

respect the maximum performance of the system.

All components of the dish/glass washmachine in contact with water must be compatible

with osmosi trated water.

It is forbidden to use brass; all tanks and pipes in stell AISI 304 must be without weldings.

It is racommended to use only plastic parts and stell AISI 316.

The company SMEG. is not responsible of any demage or injury to things or people if

these instructions are not respected.

ATTENTION

WO-04 is not a water purifier.

Using WO-04 to condition water that is not drinkable is ABSOLUTELY PROHIBITED.

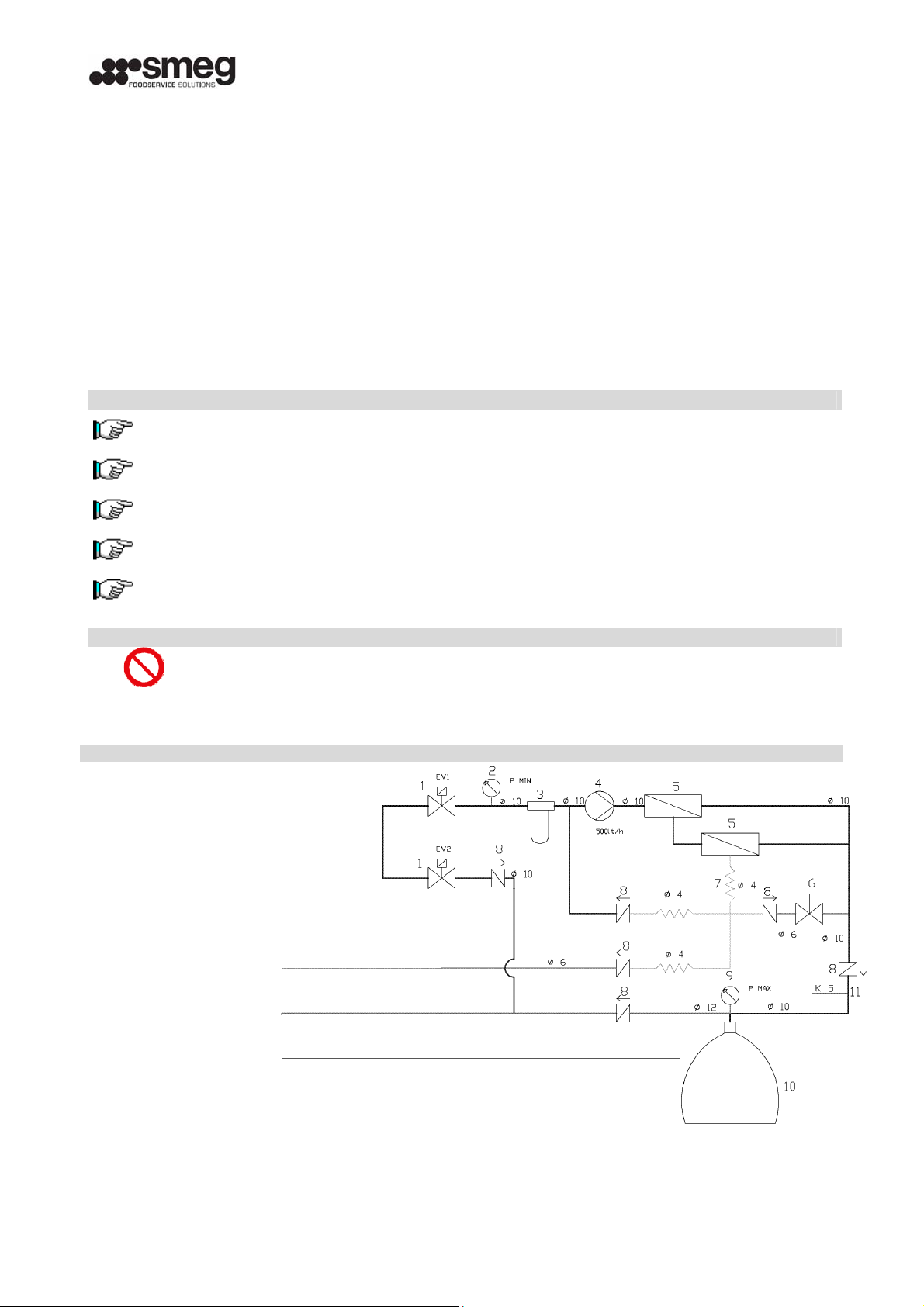

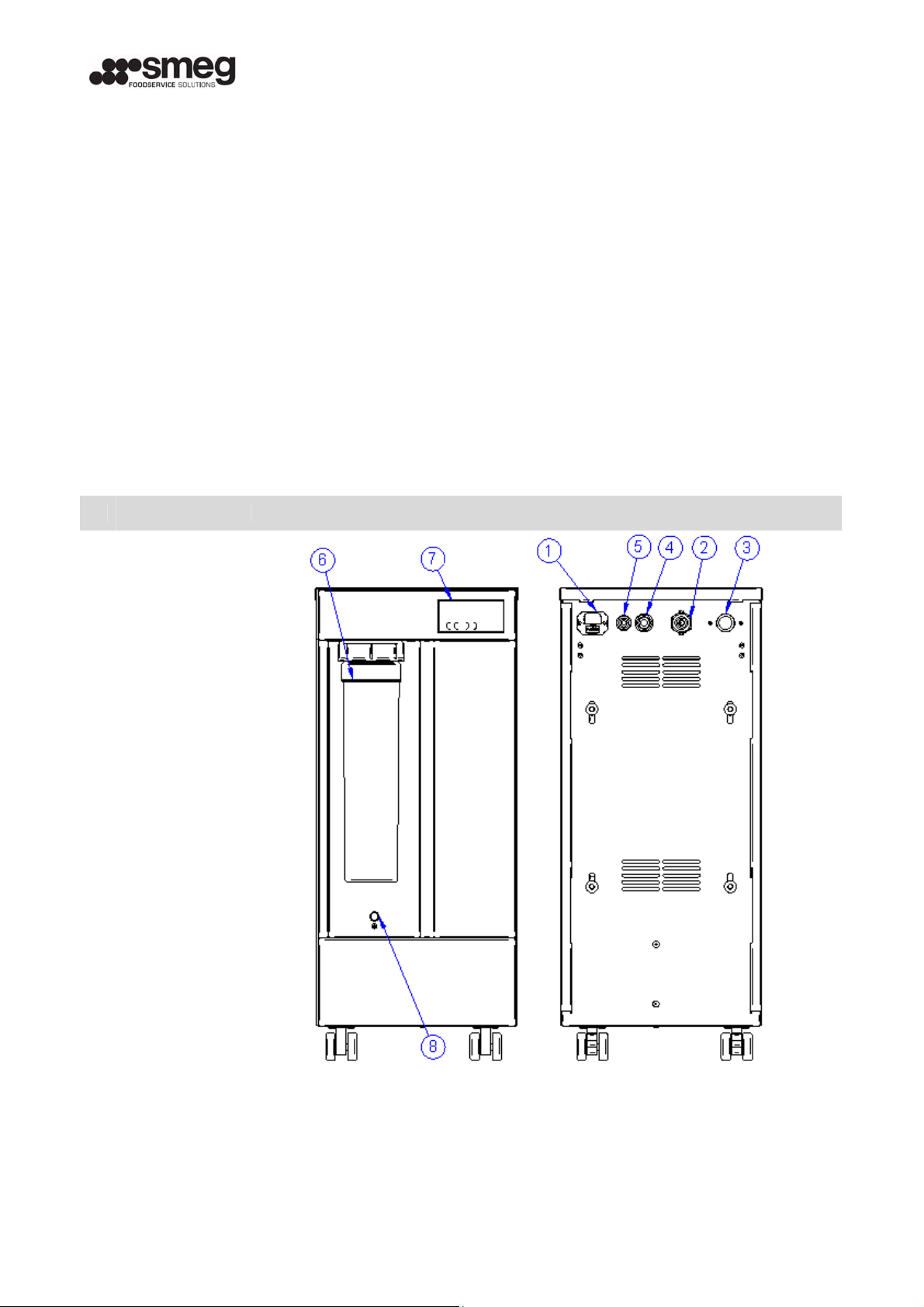

2.2 PARTS THAT MAKE UP THE MACHINE

N° DESCRIPTION SCHEMATIC REPRESENTATION

1 SOLENOID VALVE

MINIMUM PRESSURE

2

SWITCH

3

INTERNAL

PREFILTER

Inlet ¾”

4 PUMP

5 MEMBRANES

6 VALVE MIX

7 CALIBRATED PIPE

8 CHECK VALVE

MAXIMUM PRESSURE

9

SWITCH

10 EXPANSION TAN

CONDUCTIVITY

11

PROBE

Drain

Outlet ¾”G

Auxiliary outlet

- 4 -

Page 5

2.3 COMPONENTS

2.3.

1 Internal prefilters

The device is equipped with a cartridge PROFINE carbon block.

2.3.2 Membrane

The membranes are the core of the machine; two membranes TW3012 300gpd are installed.

2.3.3 Pressure Tank

The machine has inside a 24lt pressure Tank with replacable membrane to store trated water.

2.4 DESCRIPTION

The machine has on the rear side no.4 hydraulic connections, for inlet water, permeated water, drain and

auxiliary permeate outlet.

On the rear side, there is also the electric socket whit fuse.

On the front side of the machine, there is the electronic board with display, the ¼ turn rapid filter and

the mix valve.

N° DESCRIPTION GENERAL SCHEMATIC REPRESENTATION

1 POWER SOCKET

PERMEATED

2

OUTLET

SOLENOID VALVE

3

WATE INLET

AUXILIARY

4

OUTLET

5 DRAIN

6 FILTER

ELECTRONIC

7

BOARD

8 MIX VALVE

- 5 -

Page 6

From the inlet valve, the water flows to the inlet solenoid valve, on the rear side of the machine, and

then through the prefilter.

After prefiltering, the water is pumped at high pressure to the osmosis vessel with membranes.

The sediment filtration removes suspended solids from water that may damage pump and membranes.

The activated carbon filters facilitate the elimination of the unpleasant chlorine taste, without

compromising the desirable mineral properties of the water. These activated carbon filters can also

absorb potential trace organic micro pollutants, various chemicals organic and inorganic (i.e. chlorine

composites), chlorine residue used to disinfect water, haloforms, pesticides, surface-active agents.

The reverse osmosis phase is the last and most important process that occurs inside the membrane itself.

The water permeates the layer flowing into the collection tubes, and then it is directed to the main tube

of the membrane, wrapped in various layers. The permeate yield comes from the main tube of the

membrane and is sent directly to the permeate outlet.

While the membrane allows the water to filter through, it traps the unwanted concentrated impurities.

The drainage flow is also used to clean the membrane and is directly connected to the drainage system by

plastic brackets.

The mix valve allows the user to choose the hardness or the saltiness of the water produced. The mixer

should be calibrated during the installation phase.

WO-04 permits the treated water to retain about 10 to 15% of the original saline properties.

The machine has a conductivity probe to check water quality on the display.

For the start/stop signal, the machine has a high pressure switch on the permeate line.

For pump safety, the machine has an adjustable minimum pressure switch.

The machine has an auxiliar bypass solenoid valve to supply raw water if water consumption is higher than

the maximum performance of the machine.

ATTENTION

The percentage of dissolved salts and other rejected elements is influenced by the water

quality, temperature, pressure, and total dissolved salts and differs according to the type

of salts or elements.

The treatment of particularly turbid water or water with many impurities can clog the

prefilters and/or membranes, causing a loss in water flow rate.

Reflux water, salt water or water in chemical, physical and bacteriological conditions

that cannot be treated by Reverse Osmosis (industrial reflux or chemical processing)

cannot be treated.

- 6 -

Page 7

F5A

2.5 TECHNICAL SPECIFICATIONS

WO-04

STANDARD

TECHNICAL SPECIFICATIONS EASY:WASH

Height x Width x Depth (mm) 300x462x688

Weight (kg) 30

Approved Decibel Level under normal operating conditions

(dB (A))

R/O Membrane (n° 2) 3012 300GPD

Filter with active carbon cartridge PROFINE medium.

WATER SUPPLY SPECIFICATIONS

Water type Drinkable

Minimum temperature (°C)

Maximum temperature (°C) 30

Minimum inlet capacity (l/h) 400

Maximum inlet pressure (bar) 3

Minimum inlet pressure (bar) 1,5

POWER SUPPLY SPECIFICATIONS

Power supply type MONOPHASE + GROUND

Voltage (V) 230

Frequency (Hz) 50

Absorbed current (A) 2.5A

Power (W) 250W

Fuse type electronic board

Fuse type elettrica connector F4A

PERMEATE WATER SPECIFICATIONS

Maximum capacity at 15° C (l/h) c.a 120

Flow with pressure at 3 bar of 15°C (l/h) c.a 80

Recovery (%) c.a 50

OPERATION UNDER NORMAL WORKING CONDITIONS

Filter with active carbon (l) 22.000

R/O Membrane UPON CLOGGING

ATTENTION

Any use of this device, which has not been stipulated in this manual, will constitute

IMPROPER USE, thereby rendering the guarantee null and void. The manufacture WILL

NOT be liable for any damages caused by the IMPROPER USE of this device, due to

negligence, failure to follow the manual, or permitting unauthorized maintenance

personnel to tamper with machine.

<70

5

- 7 -

Page 8

3 INSTALLATION

WO-04 installation must be performed in a cool, dry and well ventilated place.

ATTENTION

WO-04 must be installed by qualified

there must be a tap above (to exclude the equipment from the water system in the case

of maintenance interventions), a check valve, water supply pipes above and below the

equipment and an electrical outlet.

Avoid subjecting the machine to excessive temperature changes that could cause

condensate to form inside, which can damage the electronic part.

Make sure the air vents are never blocked in order to not compromise motor cooling.

Instructions and representation to follow are to be considered for typical installations,

the specific components may vary depending on the accessories that accompany the car

and taps derivation and delivery chosen.

CONTROLS TO BE CARRIED OUT BEFORE INSTALLATION

Mains grounding present and efficient

Main compatible with the electrical specifications indicated on the plate on the back of the

machine

Diameter of feed circuit electrical wires greater than 1 mm

Stability of network tension (rushes lower than 10%)

TYPICAL INSTALLATION DIAGRAM

personnel and in compliance with regulations,

DESCRIPTION.

1 POWER SOCKET

2 PERMEATED OUTLET

3 SOLENOID VALVE WATE INLET

4

5 DRAIN

6 FILTER

7 ELECTRONIC BOARD

AUXILIARY

OUTLET

- 8 -

Page 9

3.1 INSTALLING THE DRAIN CLAMP

Install the drain clamp on the drain siphon diam. 40mm of the sink.

Make sure the washer correctly rests on the pipe and the bolts are tightened.

Remove the screw nut from the drainpipe.

Using a drill with 4-mm tip, make a hole in the drain siphon pipe in correspondence

with the nut that has just been removed.

Insert the drainpipe in the nut for about 2 cm and screw the nut on the clamp.

Fasten the screw nut and install the check valve with the arrow pointing towards the

clasp, as near as possible to the drain.

1. Drain pipe 6mm

2. Check valve 6mm

3. Drain pipe screw nut

4. Drain clasp

5. Washer

6. Bolt

7. Bolt screw nut

8. Sink drain siphon pipe

Drain clamp

Hole diam. 4mm

Bolt screw nut

- 9 -

Page 10

4 FUNCTIONING

4.1 FIRST START UP

ATTENTION

The first start up of the system must be carried out by the installer who will make sure

the machine runs properly.

Insert the feed plug in a 230V 50Hz outlet equipped with efficient grounding. Now the

system is able to work. It advisable to run the run for at least a half an hour before

drinking it, in order to allow the system to eliminate the substances used to conserve the

reverse osmosis membrane.

Make sure there are no leaks in the circuit and fasten the antiflooding probe on the

bottom of the machine.

Close the cover with the screws position the machine in its final destination and push the

brakes of the whells.

Operate sanitation of equipment as described in section 5.8.

The WO-04 membranes are provided saturated in a maintenance solution. Before taking water, let it run

for at least 15-30 minutes.

4.2 NORMAL USE

In order to normally use WO-04 the machine must always be kept on.

The machine starts automatically at every rising cycle of the dish/wash machine. Every six hours the

machine automatically opens the inlet solenoid valve, in this way the membranes are washed for 2

minutes.To adjust the salinity of the water, acting on the valve for mixing later.

If high water consumption occurs, the by-pass solenoid valve opens and raw water flows to the outlet.

ATTENTION

Absolutely avoid letting the membranes dry out; this could irreparably compromise its

functioning.

4.3 INACTIVITY

It is advisable, each time the machine is inactive for a period over one week, to let the

water run for at least 10 minutes before using it.

It is advisable to sanitize the system every six months during routine maintenance

procedures.

Contact assistance in order to carry out this operation, which must be performed by

specialized personnel/installation technicians.

4.4 ELECTRONIC BOARD OPERATING

4.4.1 Normal functioning

SMEG

When the card is in normal functioning mode, the name of the reseller is

displayed.

When the faucet is opened, the machine starts to produce permeate water;

uS/cm

0050

pushing the key ENTER

ATTENTION

, the conductivity is displayed.

- 10 -

Page 11

When the faucet will be closed, the board returns in stand-by mode.

Main water pressure failure

Alarm

When faucet is opened, if low pressure failure occurs, the display shows “Alarm

P. min” and the board makes a beep.

P. min

Leakage

Alarm

Leakage

4.4.2 Display pages

WO-04

Mikrotec

Ver 1.02

Manual

Flush.

Flushing

T remain

0000:00

To restart the machine, turn OFF and ON with the key

If water leakage alarm occurs, the machine stops and makes a continuous beep

displaying “Alarm Leakage”.

To restart the machine, turn OFF and ON with the key

When the card is in stand-by mode, the name of the installer is displayed.

Pressing the

To scroll the next pages press the

carryng out the manual flow of the membrane; in order to carry out the

operation, press the

Pressing the

remaining functioning before the filter change; from this page, pressing the key

key displays the version of software installed in the card.

key ; the first page displayed enables

key; the card displays “Flow in progress”.

key again moves to the display of the hours-minutes of

.

.

L remain

0000000

displays the residual autonomy.

T Total

0000:00

L Total

0000000

4.4.3 Programming pages

- 11 -

Pressing the

running since the last reset; from this page, pressing the

total liters consumed.

key again moves to the display of the hours-minutes of

key displays the

Page 12

Settings

Press E

In order to have access to the programming pages, unplug the machine and press

the

key while connecting the feed plug.

Data

saved

Filter

Reset

Press E

to reset

Faucet

Setting

Subsequently the card will require pressing the

the programming.

Scroll the programming pages with the

Each time a value is modified, press the

save the datum; “Loaded value” appears on the display and it returns to the

programming menu.

The first page enables the hour counter reset by pressing the

The card displays “press E Reset T”; pressing the

zeroing of the counter; the card will therefore display “Data saved”

Move to the next page with the

key; access the selection of the tap type

and keys.

key to confirm the change and

key to confirm access to

key.

key again confirms the

Manual

Faucet

Customer

Setting

Function

WO-04

mode

Time

limit

with the

and

“Data saved”

Move to the next page with the

stand-by with the

keys and confirm with the

Move to the next page with the

functioning mode with the

limit with the

therefore indicates “Data saved”

key. Select the type of tap (manual or electric) with the

keys and confirm with the key. The card therefore indicates

key. Select the saved names with the and

and keys and confirm with the key. The card

key; access the selection of the writing in

key. The card therefore indicates “Data saved”

key; access the selection of the

key. Select functioning by time or without time

In equipment for hosehold use the time limit functioning is recommended.

- 12 -

Page 13

K convers

setting

K Convrs

h 0070

Set

language

Set

English

lt/h 180

Time

setting

Funz

Move to the next page with the

liters/hour conversion parameter with the

and keys and confirm with the key. The card therefore

indicates “Data saved”

Move to the next page with the

with the

confirm with the

Move to the next page with the key

the key

with the key

key. Modify the value with the and keys and

key. The card therefore indicates “Data saved”

. Set the language with the keys and and confirm

. The card therefore indicateds “Data saved”.

key; access the modification of the

key. Modify the value with the

key; modify the “filter hours” parameter

; modify the language parameter with

5 ROUTINE MAINTENANCE

5.1 MAINTENANCE PERSONNEL QUALIFICATIONS

Personnel in charge of Maintenance must have the requisites indicated in the following and be familiar

with this manual and all information concerning safety:

Sufficient level of general and technical knowledge in order to understand the contents of this

manual.

Knowledge of the main hygienic, accident-prevention and technological regulations.

Complete knowledge of the machine as well as electrical and hydraulic problems that can arise

where the machine is installed.

5.2 MAINTENANCE PERSONNEL TASKS

The routine maintenance program described in this paragraph must be carried out according to the

schedule indicated in order to keep the machine running efficiently and to guarantee the quality of the

water treatment.

ATTENTION

The operations indicated in the following must be carried out by qualified personnel

according to the instructions in this manual and only using original spare parts.

Maintenance performed must be documented and signed by the technician in charge

in the proper space on the maintenance register in the ATTACHMENT.

It is advisable to carry out routine maintenance at least once every 6 months, even if

the filters have not run out.

- 13 -

Page 14

Y

ITEM TO CHECK CONTROL

Preload expansion tank

Visual control of the integrity and state of

Machine

Filters with active carbon Replacement

(*)Particular water conditions can require more frequent maintenance.

Use only original parts SMEG.

The internal WO-04 electrical apparatus is fed by 230-VOLT electrical current.

Before opening the machine, remove covers and/or panels and/or protection grids and

make sure the switch is off and the machine is unplugged.

When cleaning the machine do not use corrosive products, acids, abrasive or steel

brushes.

Do not directly wash the machine with high-pressure jets of water.

conservation

General cleaning

Check running

ATTENTION

ATTENTION

ATTENTION

FREQUENC

6 MONTHS

o

10000 liters

(*)

22.000 liters

5.3 REPLACING FILTER CARTRIDGE

The repleace the prefilter follow these steps:

Remove the power plug.

Remove the filter cartridge, turning it left ¼.

Install new cartridge in the machine; take caref about the filter o-rings.

Reset the electronic board (if used with time limit funciont) (see § 4.4.3).

Sterilize the system (see § 5.8).

5.4 PRELOAD EXPANSION TANK

To check the preload of the pressure tank, follow these steps:

Remove the power plug.

Empty the expansion tank delivering water to the permeate auxiliary outlet.

Remove the side panels and identify the connection of the preload in the tank.

With a compressor and a pneumatic gun, bring the preload pressure at 2.5bar

Install the panels and connect the power plug.

- 14 -

Page 15

5.5 VERIFICATION OF THE SETTING

For proper operation of the machine, check periodically the calibrations.

All the calibrations must be performed by qualified personnel.

5.5.1 Setting pressure switch

Install a pressure gauge (0-6 bar or similar) between

the permeate outlet and the faucet.

Screw two turns the calibration nut of the pressure

switch.

Open the knob of the tap, after which it slowly close

the tap until the pressure gauge reaches about 3.5 bar.

Slowly unscrew the calibration nut of pressure

switch

until the operation of the machine becomes

discontinuous.

vite regol az ione

pressost ato

Apply the glue sealant to calibration nut.

5.5.2 Check operating pressure

Install a T fitting and a pressure gauge 0-10 bar (or similar) on the pump outlet line.

The operating pressure must be between 6 and 7 bar.

5.5.3 Calibrating conductivity probe

Open the electronic board box.

Start the machine and deliver water.

After 2 minutes, take a sample and measuring the

conductivity with a reference instrument properly

calibrated.

Turn the conductivity calibration potentiometer until

the displayed value matches the value measured by

the instrument.

5.6 CLEANING CONDUCTIVITY PROBE CONNECTORS

Disconnect the connectors of the conductivity probe.

Clean the male and female connectors from possible

oxidation.

Tighten the connector with pliers and reassembly.

- 15 -

Page 16

5.7 CLEANING SOLENOID VALVES FILTER

Close the inlet water valve.

Open the faucet to remove the pressure in the feed

pipe.

Turn off the machine and remove the ¾” fitting from

the solenoid valve.

Using pliers, gently pull the solenoid valve filter.

Clean the filter with tap water and/or compressed air.

5.8 MACHINE SANITATION

Perform the sanitation of the machine at each filter replacement, and at intervals not

exceeding 6 months.

Perform sanitation also after long not-use periods of the machine.

All sanitation operations must be performed by qualified personnel.

Be careful in the use and dosage of chemicals.

Use protective clothing to the skin, hands and eyes as shown in the safety data sheet

of chemicals used.

Close the mixing valve and fill a tank with 10 liters of permeate water.

Add hydrogen peroxide to achieve a concentration of 0.2% by weight.

Put 650ml of hydrogen peroxide at 10 volumes per 10 liters of permeated water.

Put 250ml of hydrogen peroxide at 24 volumes per 10 liters of permeated water.

Put 180ml of hydrogen peroxide at 36 volumes per 10 liters of permeated water.

Put 50ml of hydrogen peroxide at 130 volumes per 10 liters of permeated water.

Connect the water pipes of entry, drain and permeated by the machine, at the tank;

make a bridge on the low pressure switch connectors.

Open a bit the mix valve and turn on the machine and let the solution recirculated for at

least 10 minutes.

Wait 10 minutes that the solution acts on the machine.

Reconnect the drain and permeated pipes.

Connect the water pipes of entry, drain and permeated by the machine, at the tank.

Turn on the machine until the sanitation solution is empty; then turn off the machine.

Reconnect the inlet water pipe and open the water valve.

Replace the filter and reconnect the cables of the minimum pressure switch.

Turn on the machine and suplly water for at least 10 minutes until the sanification

solution resids are totally drained.

- 16 -

Page 17

6 EXTRAORDINARY MAINTENANCE

ATTENTION

The internal WO-04 electrical apparatus is fed by 230-VOLT electrical current.

Before opening the machine, remove covers and/or panels and/or protection grids and

make sure the switch is off and the machine is unplugged.

6.1 ELECTRONIC BOARD WHIT DISPLAY REPLACEMENT

Remove the cover of the machine, accessing the tray card.

Unscrew the screws fastening the electronic board box.

Remove the electronic board box, disconnect the power connector.

Mount the new electronic board with reverse procedure.

DESCRIPTION.

1 M4 SCREW

2 ELECTRONIC BOARD

6.2 PROTECTION FUSE REPLACEMENT

The machine is equipped with two fuses, one on the electronic board and one on the power socket.

6.2.1 Protection fuse replacement on power socket

Remove the fuse compartment under the attack of the power cord.

Replace the burned fuse with a similar. (Attachment V)

Mount the power cord with reverse procedure.

- 17 -

Page 18

6

.2.2 Protection fuse replacement on electronic board

Remove the top cover of the machine, accessing the tray card.

Remove the support and the cover of the electronic board.

Replace the burned fuse with a similar. (Annex V)

Mount the electronic board with reverse procedure.

6.3 PUMP REPLACEMENT

Remove the top and right panels of the machine.

Disconnect the piping from the pump.

Unscrew the screw of the clamp connecting and disassemble the pump.

Install the new pump with fittings previously removed.

Mount the new pump with reverse procedure.

- 18 -

Page 19

6.4 CHECK/REPLACEMENT OF OSMOTIC MEMBRANES

A decay of performance rating of 10% per year is considered normal wear for osmotic

membranes. Special conditions of entry and/or high consumption may accelerate the

clogging of the membranes.

Close the mixing valve completely.

Supply water and verify scope permeated and conductivity with a reference tool.

If the capacity is reduced more than 50% of the initial conditions and/or the conductivity

is greater than 80 μS/cm, replace the osmotic membrane as follows.

Disconnect the tubes from the fittings of the vessel containing the membrane.

Dismantle the vessel from the machine and unscrew the caps.

Dismantle the membranes clogged and replace with new membranes of the same type.

Clean the vessel on the inside by removing all traces of dirt and scale.

The new membrane must be removed immediately prior to their installation and

handling, using protective gloves sterile.

Before installing the membrane in the vessel, lubricate the o-ring and the upper seal.

Install the vessel with reverse procedure.

Supply water for at least 15 minutes, then check permeated flow and quality.

3

4

5

8

7

2

DESCRIZIONE.

1 INLET

1

6

2 CAP VESSEL

3 VESSEL

4 PERMEATE

5 DRAIN

6 O RING VESSEL

7 MEMBRANE 3012

8 O RING VESSEL

- 19 -

Page 20

7 TROUBLE-SHOOTING

The operations indicated should be performed only by qualified personnel, except

those marked with *.

Problem: The display is off.

Cause Solution

Electric supply failure. Check power plug is connected. *

Burned fuse. Open the board cover and check the fuse; if burned replace it.

Display cable removed. Check display cable is connected on the board socket.

Damaged display. Replace the display.

Damaged board. Replace the board.

Problem: Burned fuse and thermal protection switch.

Cause Solution

Motor in short circuit. Replace the motor and the protection fuse of the electronic board.

Incorrect wiring. Check the wiring and the fastening of the cables to the terminals.

Leakage.

Problem: The ground protection switches.

Cause Solution

Defective motor. Replace motor.

Incorrect wiring. Check the wiring and the fastening of the cables to the terminals.

Problem: The display shows “Alarm Leakage”.

Cause Solution

Leakage

Leakage probe in short

circuit.

Damaged board. Replace the board.

Problem:

With the display turned on and running, after opening the faucet, the engine will

not start.

Cause Solution

Vane pump blocked. Replace the vane pump.

Burned motor. Replace the motor.

Incorrect wiring. Check the wiring and the fastening of the cables to the terminals.

Incorrect faucet setting

manual / electric.

Problem: With the board on, at operating start, the inlet solenoid valve never opens.

Cause Solution

Solenoid valve damaged. Replace the solenoid valve.

Coil burned. Replace solenoid valve coil.

Electric connection failure. Check electric connections and tight if necessary.

Check the insulation of the wiring and clamp, and check the operation

of the electronic board.

Open the machine and check carefully all hydraulic circuit for

leakages.

Check water leakage probe position; if directly at contact with metal

parts of the machine, place in a different position.

Access the programming menu of the electronic board and check the

faucet setting.

- 20 -

Page 21

Problem: Low permeate water production.

Cause Solution

Clogged solenoid valve. Check solenoid valve functioning, if clogged, replace it.

Clogged filter. Replace the filter.

Clogged pump. Replace the pump.

Clogged membranes. Replace the membranes.

It is recommended to install a manometer on the pump outlet to check operating pressure.

Problem: Treated water has a bad taste.

Cause Solution

Exausted filters. Replace the filters.

Biofouling. Make machine disinfection.

Problem: With the faucet closed, the machine restarts for a few seconds.

Cause Solution

Replace the check valve installed on the permeate line before max.

Check valve damaged.

Water leakage.

Problem: With faucet opened, the machine doesn’t start.

Cause Solution

Defective pressure switch. Check pressure switch functioning, if damaged replace it.

Electric connection failure. Check electric connections and tight if necessary.

Problem: Witch faucet closed, the machine never stops.

Cause Solution

Defective pressure switch. Check pressure switch functioning, if damaged replace it.

Damaged board. Replace the board.

Problem: With faucet opened, the machine operates in a discontinuous mode.

Cause Solution

Max pressure switch

calibration is too low.

Problem: Service pressure is too low.

Cause Solution

Preload too low. Run the preloading of the pressure tank.

Max pressure switch

calibration is too low.

pressure switch (install a manometer on permeate line and check

water pressure on permeate line).

Check the permeate hydraulic circuit for leakages (install a manometer

on permeate line and check water pressure on permeate line).

Perform the calibration of pressure switch.

Perform the calibration of pressure switch.

- 21 -

Page 22

The consumer has an important role in reducing the disposal of waste by returning waste electronic/electrical tool for

recycling. Recycling avoids the dispersion of hazardous materials into the municipal waste stream.

The crossed-out bin symbol reminds the user not to dispose of this product as unsorted municipal waste.

(I) Ai sensi dell’art. 13 del Decreto Legislativo 25 luglio 2005, n°151 “Attuazione dell e Direttive 2002/95/CE, 2002/96/CE

e 2003/108/CE, relative alla riduzione dell’uso di sostanze pericolose nelle apparecchiature elettriche ed elettroniche,

nonché allo smaltimento dei rifiuti.

Il simbolo del cassonetto barrato riportato sull’apparecchiatura o sulla confezione indica che il prodotto

alla fine della propria vita utile deve essere raccolto separatamente dagli altri rifiuti.

L’utente dovrà, pertanto, conferire l’apparecchiatura giunta a fine vita agli idonei centri di raccolta d iffere nziata dei rifiuti

elettronici ed elettrotecnici, oppure riconsegnarla al rivenditore al momento dell ’acquisto di una nuova apparecchiatura di

tipo equivalente, in ragione di uno a uno.

L’adeguata raccolta differenziata per l’avvio successivo dell’apparecchiatu ra dismessa al riciclaggio, al trattamento e allo

smaltimento ambientale compatibile contribuisce ad evitare possibili effetti negativi sull’ambiente e sulla salute e

favorisce il reimpiego e/o riciclo dei materiali di cui è composta l’apparecchiatura.

Lo smaltimento abusivo del prodotto da parte dell’utente comporta l’applicazione delle sanzioni amministrative previste

dalla normativa vigente.

(P) A directiva 2002/96/EC classifica este producto como um instrumento eléctrico/electrónico.

Não deitar este instrumento com lixo municipal não classificado.

Deitar este aparelho em um centro de recolha ou de reciclagem segundo a lei local e nacional.

O consumidor tem uma importante responsabilidade na redução do lixo, preparando a rec iclag em dos instrumentos

eléctrico/electrónicos. A reciclagem previne a dispersão de materiais perigosos nos li xos minicipais.

O símbolo da barra no barril lembra ao utilizador de não jogar este producto como um lixo municipal não classificado.

(D) Gemäß Richtlinie 2002/96/EC wird diese Produkt als elektrisches/elektronisches Gerät eingestuft.

Dieses Gerät nicht als nicht klassifizierten Stadtmüll beseitigen.

Diese Gerät an eine dafür vorgesehene Sammelstelle bringen, gemäß den vorortigen und auf nationalem Gebiet

geltenden Gesetzesbestimmungen.

Der Verbraucher kann beträchtlich dazu beitragen den Abfall zu verringern, indem er ein Recycling der

elektrischen/elektronischen Geräte vorsieht.

Ein Recycling verhindert, dass gefährliches Material im allgemeinen Stadtmüll beseiti gt wird.

Das Symbol mit ausgestrichener Tonne soll bedeuten, dass das damit gekennzeichnete Produkt nic ht als nicht

klassifizierter Stadtmüll zu beseitigen ist.

(ES) La directiva 2002/96/EC clasifica este producto como un aparato eléctrico/electrónico.

No tire este aparato como si fuera un residuo municipal no clasificado.

Tire este aparato en un centro de recogida o de reciclaje según la ley local o nacional.

El consumador cumple un papel importante en la reducción de la eliminación de residuos, predisponiendo el reciclaje de

los aparatos eléctricos/electrónicos. El reciclaje previene la dispersión de materiales pe ligrosos en la gran cantidad de

residuos municipales. El símbolo del bidón con una banda transversal recuerd a al usuario que no debe tirar este

producto como si fuera un residuo municipal no clasificado.

(F) La directive 2002/96/EC classifie ce produit comme appareil électrique/électronique.

Ne pas jeter cet appareil avec les déchets municipaux non classifiés.

Jeter cet appareil dans un centre de collecte ou de recyclage conformément à la loi locale et nationale.

Le consommateur joue un rôle important dans la réduction des déchets, en prévoyant le recyclage des app areils

électriques/électroniques. Le recyclage permet d’éviter la dispersion de matériau dangereux dans la masse des déchets

municipaux. Le symbole du bidon barré rappelle à l’utilisateur de ne pas jeter ce produit avec les déchets municipaux

non classifiés.

(NL) De richtlijn 2002 / 96 / EC classificeert dit product als een elektrisch / elektronisch gereedschap.

Gooi dit gereedschap niet weg als een niet geclassificeerd gemeentelijk afval.

Breng dit gereedschap in een verzamel- of verwerkingscentrum volgens de plaatselijke en nationale wet.

De verbruiker speelt een belangrijke rol in het verminderen van het afval door de verwerking van de elektrische / elektronische

gereedschappen voor te bereiden.

De verwerking voorkomt de verspreiding van gevaarlijk materiaal in de massa van het gemeentelijk afval.

Het symbool van de versperde vuilnisbak herinnert aan de verbruiker dit product niet weg te gooien als een niet geclassificeerd

gemeentelijk afval.

WASTE OF ELECTRICAL / ELECTRONIC EQUIPMENT

RACCOLTA RIFIUTI DI MATERIALE ELETTRICO / ELETTRONICO

RECOLHA DE RESÍDUOS DE MATERIAIS ELÉCTRICO / ELECTRÓNICOS

ABFALLENTSORGUNG ELEKTRISCHES / ELEKTRONISCHES MATERIAL

RECOGIDA DE RESIDUOS ELECTRICOS / ELECTRONICOS

COLLECTE DES DÉCHETS DE MATÉRIEL ELECTRIQUE / ELECTRONIQUE

VERZAMELING AFVAL ELEKTRISCH / ELEKTRONISCH MATERIAAL

(UK) EU directive 2002/96/EC classifies this product as an electrical or electronic tool.

Do Not dispose of this tool as unsorted municipal waste.

Dispose of this tool at a collection or recycling centre according to local and national law.

- 22 -

Loading...

Loading...