Page 1

INSTALLATION,

USER AND MAINTENANCE MANUAL

FOR WATER OSMOSIS UNIT

WO-01

Page 2

Page 3

EQUIPMENT FOR POTABLE WATER TREATMENT

CONTENTS:

Paragraph

GENERAL WARNINGS.................................................................................................................

TECHNICAL CHARACTERISTICS ...............................................................................................

POSITIONING AND INSTALLATION............................................................................................

MAINTENANCE............................................................................................................................

PLUMBING DIAGRAM..................................................................................................................

WIRING DIAGRAM .......................................................................................................................

FAULTS ........................................................................................................................................

ELECTRONIC CIRCUIT BOARD AND PROGRAMMING .............................................................

EXPLODED VIEWS ......................................................................................................................

LIST...............................................................................................................................................

TECHNICAL INSTRUCTIONS:

These are intended for the qualified staff who are to install, commission and test the appliance

and carry out any servicing and repairs.

USER INSTRUCTIONS:

These provide recommendations for use, a description of the controls and the correct

procedures for cleaning and maintaining the Osmosis Treatment Unit.

WARNINGS:

Warnings regarding operations which are prohibited inasmuch as they can result in injury or

damage.

THIS MANUAL IS AN INTEGRAL PART OF THE OSMOSIS TREATMENT UNIT; KEEP IT

CAREFULLY IN THE VICINITY OF THE MACHINE AND READ THE INSTALLATION AND USER

INSTRUCTIONS CONTAINED IN IT.

- 29 -

Page 4

1. General warnings

STORAGE:

THE PACKED APPLIANCE MUST BE STORED IN A DRY, CONDENSATION-FREE AREA,

UNDER COVER. THE ADMITTED STORAGE TEMPERATURE IS 4-50°C.

ALWAYS DISCONNECT ELECTRICAL POWER BEFORE WORKING ON THE APPLIANCE OR

DISASSEMBLING IT.

POSITIONING, HOOKUP, COMMISSIONING, TROUBLESHOOTING AND REPLACING POWER

CABLES MUST ALWAYS BE DONE BY QUALIFIED PERSONS.

CHANGES IN THE POWER VOLTAGE OF MORE THAN 10% OF THE RATED VALUE CAN

DAMAGE THE ELECTRICAL CIRCUITS; MONITOR THE MAINS VOLTAGE CONSTANTLY.

THE APPLIANCE MUST BE GROUNDED AS REQUIRED BY ELECTRICAL EQUIPMENT

SAFETY STANDARDS.

THIS UNIT IS INTENDED ONLY FOR THE INTENDED PURPOSE OF TREATING WATER FOR

TECHNICAL PURPOSES.

SHIPPING/DELIVERY:

THERE ARE NO SPECIAL PRECAUTIONS FOR UNPACKING THE APPLIANCE, EXCEPT FOR

THE NORMAL CARE REQUIRED IN HANDLING FRAGILE MATERIALS. BEFORE DISPOSING

OF THE PACKAGING, MAKE SURE IT DOES NOT CONTAIN ANY PARTS, INSTRUCTION

BOOKLET OR OTHER DOCUMENTATION.

THE PACKAGING (CARDBOARD, EXPANDED POLYSTYRENE, PALLET, ETC.) MUST NOT BE

LEFT WITHIN THE REACH OF CHILDREN, SINCE THEY ARE HAZARDOUS MATERIALS.

THE OSMOSIS TREATMENT UNIT MAY BE REMOVED FROM ITS ORIGINAL POSITION ONLY

BY SPECIALISED PERSONS.

WHEN CLEANING THE APPLIANCE DO NOT USE CORROSIVE PRODUCTS, ACIDS, STEEL

PADS OR BRUSHES.

DO NOT WASH THE APPLIANCE WITH DIRECT OR HIGH PRESSURE JETS OF WATER.

THE MANUFACTURER DECLINES ALL LIABILITY FOR INJURY/DAMAGE TO PERSONS OR

PROPERTY CAUSED BY NON-OBSERVANCE OF THE INSTRUCTIONS GIVEN IN THIS

MANUAL, INCORRECT USE, TAMPERING BY UNQUALIFIED PERSONS, TAMPERING WITH

MODIFICATIONS, ACCESSORIES OR DEVICES OF ANY KIND APPLIED TO THE APPLIANCE

EVEN ONE PART OF THE APPLIANCE, OR THE USE OF NON-ORIGINAL SPARE PARTS, OR

UNLESS EXPRESSLY SPECIFIED IN THIS MANUAL.

- 30 -

Page 5

THIS APPLIANCE IS MARKED AS REQUIRED BY EU DIRECTIVE 2002/96/EC, WASTE

ELECTRICAL AND ELECTRONIC EQUIPMENT (WEE).

BY MAKING SURE THAT THIS PRODUCT IS DISPOSED OF CORRECTLY THE USER

HELPS TO PREVENT POTENTIAL DETRIMENTAL EFFECTS ON HEALTH AND THE

ENVIRONMENT.

THE SYMBOL

INDICATES THAT THIS PRODUCT MUST NOT BE TREATED AS ORDINARY DOMESTIC

WASTE BUT MUST BE CONSIGNED TO THE SPECIAL COLLECTION POINT FOR THE

RECYCLING OF ELECTRICAL AND ELECTRONIC EQUIPMENT.

WHEN DECOMMISSIONING THE APPLIANCE COMPLY WITH THE LOCAL WASTE DISPOSAL

REGULATIONS.

FOR FURTHER INFORMATION ON THE TREATMENT, RECOVERY AND RECYCLING OF THIS

PRODUCT, CONTACT THE COMPETENT LOCAL OFFICE, THE DOMESTIC WASTE

COLLECTION SERVICE, OR THE SHOP WHERE THE PRODUCT WAS PURCHASED.

FOR ANY TECHNICAL OR OPERATIONAL INFORMATON, PLEASE CONTACT OUR

TECHNICAL SERVICE DEPARTMENT.

IMPORTANT:

DURING THE WARRANTY PERIOD THE MACHINE MAY NOT BE WORKED ON WITHOUT

ADVANCE AUTHORISATION FROM OUR TECHNBICAL SERVICE DEPARTMENT. FAILURE

TO ABIDE BY THIS RULE VOIDS THE WARRANTY.

ON THE PRODUCT OR IN THE TECHNICAL DOCUMENTATION

2. Technical characteristics

GENERAL DESCRIPTION:

THE APPLIANCE PRODUCES OSMOSIS- TREATED WATER, WITHOUT DISSOLVED SALTS,

WITH A RESIDUAL CONDUCTIVITY IN THE RANGE 20 TO 100 MICROSIEMENS, INTENDED

EXCLUSIVELY FOR TECHNOLOGICAL APPLICATIONS. THE UNIT CONSISTS OF AN ARRAY

OF FILTER CARTRIDGES. THE INVERSE OSMOSIS MEMBRANES ARE LODGED IN

POLYPROPYLENE HOUSINGS. THE OSMOSIS PUMP IS CONSTRUCTED IN BRASS

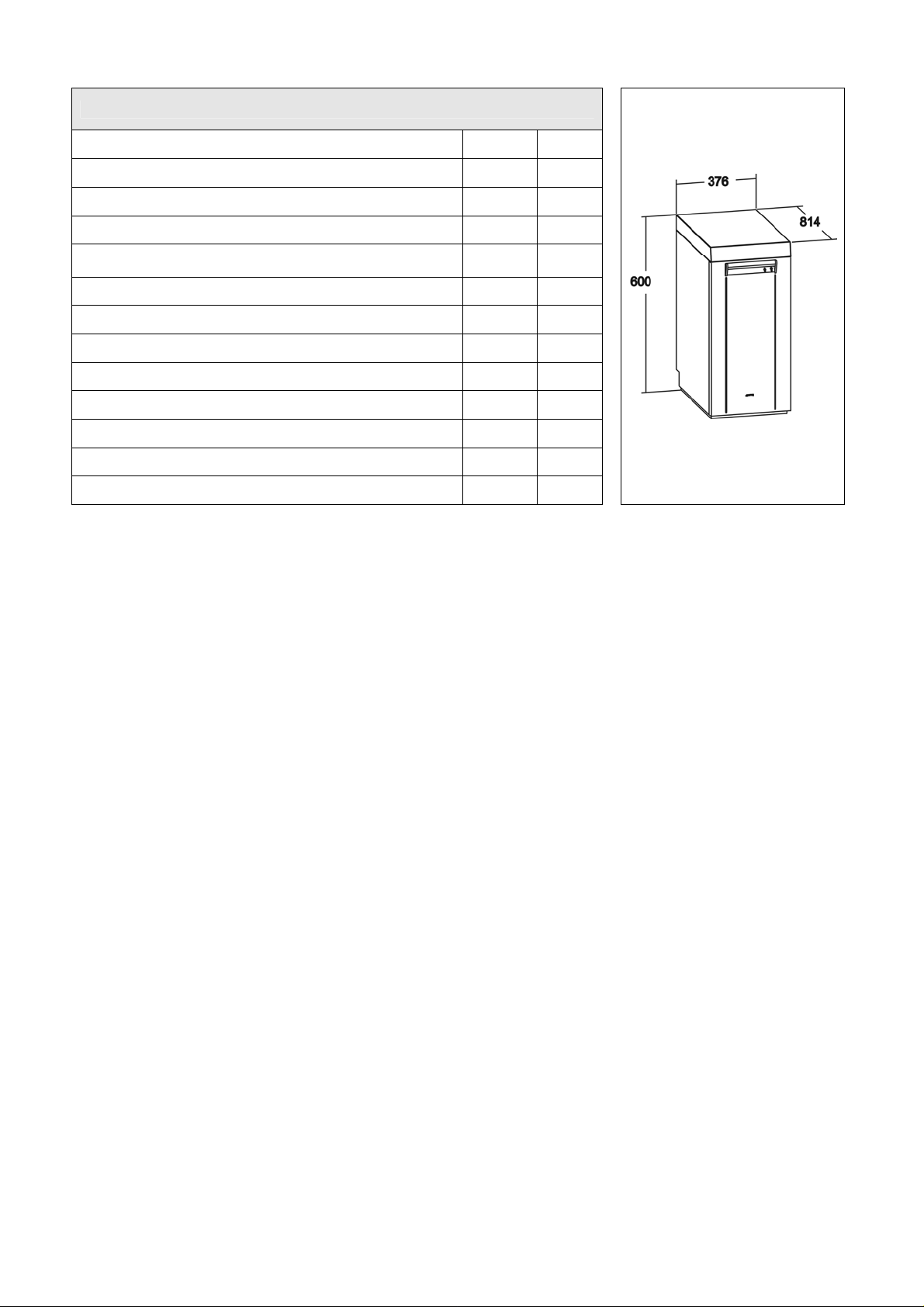

Dimensions

Height 814 mm Empty weight 60 kg

Width 376 mm Empty weight including packaging 67 kg

Depth 600 mm

Power cable 3x1 length 1.5 m Diameter of waste discharge pipe 4 mm

Plug Schuko Length of waste discharge pipe 1.5 m

Length of filler pipe 1.5 m Delivery fitting 3/4 inches

Filler pipe collar

¾

Installation characteristics

inches

- 31 -

Page 6

Technical characteristics

Single phase power voltage 230 v

Frequency 50 Hz

Osmosis pump power rating 450 w

Delivery pump power rating 300 w

Min/max water supply pressure

150-600

(1.5-6)

kPa

(bar)

Max osmosis-treated water output 150 l/h

Max water supply temperature 30 °C

Max water supply hardness 40 °F

Max water supply conductivity 2.000 µS/cm

Max water supply chlorine content <0.1 mg/l

Max water supply iron content <0.02 mg/l

Min/max delivery pump pressure 0.5-1.8 Bar

Max delivery pump output 20 l / h

- 32 -

Page 7

3. Positioning and installation

THE APPLIANCE MUST BE CONSIDERED AND HANDLED AS FRAGILE MATERIAL.

THE CIRCUIT DOWNSTREAM OF THE UNIT MUST BE CONSTRUCTED IN PLASTIC AND

STAINLESS STEEL TO PREVENT CORROSION.

Positioning:

Before installing the appliance, check that there is sufficient clearance for easy extraction of consumables and

for servicing the unit. Check that there is a power socket in the vicinity of the unit. The appliance is designed for

installation in clean area, protected from freezing temperatures.

Before installation, check:

- that there is sufficient space for the plumbing

- that there is good access for equipment, inspections and maintenance

Electrical hookup:

Make sure the power supply is adequate to the unit’s draw.

Caution: the power voltage rating is given on the unit’s dataplate.

WARNING: Do not open the unit’s electrical panel ; only qualified persons may do this.

Plumbing hookup:

Hook the machine up as indicated on the unit itself, “IN” indicates the water supply inlet, “OUT” indicates the

osmosi-treated water outlet, RJ indicates the discharge outlet. Remove the red cap “T” from the RJ fitting and

insert the water drain pipe supplied with the unit.

Apply the supplied pipe to the OUT fitting and equip its free end with a corrosion-proof cock if it is not hooked up

directly to the service.

The water supply pressure may not exceed 6 bar nor be less than 1.5 bar.

IF THE WATER SUPPLY CONTAINS PARTICLES IN SUSPENSION, AN EXTERNAL FILTER

MUST BE INSTALLED TO PROVIDE SUFFICIENT DOWNSTREAM FLOW AND PRESSURE ;

THIS FILTER MUST BE KEPT IN PERFECT CONDITION AT ALL TIMES .

WHEN FIRST RUNNING THE UNIT AND AFTER ANY SERVICE, RUN THE WATER DELIVERY

TO A DRAIN FOR AT LEAST 20 MINUTES SO AS TO ELIMINATE ANY IMPURITIES

RESULTING FROM THE WORK JUST DONE

All quick fittings are of the type

- 33 -

Page 8

Water circuit and electrical hookup diagram

Installing the membranes

Open the front door to access the membrane housings, which must be kept in their original

packaging until the machine is started up

Disconnect Undo Fit Screw on Reconnect

the quick coupling the base the membrane the base the hoses

hoses

Membrane mount

- 34 -

Page 9

Pressurizing and starting up the unit:

After all pipes have been connected, pressurise

the system gradually and check for leaks.

Turn the “Osmosis pump” switch to “I”. Check

that the following message displays:

In normal operation the value Rj varies during

osmosis-treated water production.

Wait 5-10 minutes, then continue by starting up

the delivery pump.

I M P O R T A N T !!!

Delivery pump startup (first startup)

Remove the red bleeder cap P (“Sfiato innesco”)

on the front (close to the pressure gauge,

labelled as such) .

To remove the cap, press the John Guest clip

and allow a bit of water to run into a container;

refit the cap P, and actuate the “Delivery pump”

switch.

FAILURE TO FOLLOW THIS PROCEDURE TO

THE LETTER CAN CAUSE SERIOUS

DAMAGE TO THE DELIVERY PUMP.

Osmosis pump switch

Delivery pump switch Cap “P”

- 35 -

Page 10

4. Maintenance

The osmosis treatment unit runs completely

automatically and maintenance is minimal. The

only essential operation is periodic replacement

of the filter cartridges.

IMPORTANT

Replace the pre-filter every 3000 hours of

operation and AT LEAST 1 time a year.

Replacing the pre-filter:

Filter cartridge replacement procedure

- Shut off power;

- Close the side cocks (RL);

- Vent the circuit from the top cap (S);

- Unscrew the filter housing (use the special wrench supplied in the

accessories bag). Place a container to drain the water in the filter

into;

- Fit the new cartridge and check it is correctly seated;

- Close vent S and open the side cocks RL;

- Check for leaks and water in the bottom of the appliance;

- Dry it off thoroughly.

Pre-filter Membrane

Replacing the membranes:

Cartridge replacement procedure.

- Shut off power;

- Disconnect all hoses from the membrane

housings, unscrew the base, and place a

container to catch the water contained in the

cartridges;

- Refit the membrane, check the seating of the

o-ring and screw the housing fully in;

reconnect the hoses and make sure they are

correctly seated;

- Do not apply excessive force;

- Fit the new cartridge and check it is correctly

seated;

- Start the unit up and check for leaks.

- 36 -

Page 11

Special adjustments:

RECIRCULATION

Recirculation retreats the waste water to reduce the amount of

water rejected. Turn the needle valve “Recirculation” to retreat

the waste water, thus reducing overall water consumption.

Important!

Make sure, when making adjustments, that the pressure

gauge reading never exceeds 10-11 bar.

BYPASS

Turn the “Bypass” needle valve to adjust the conductivity of the

osmosis-treated water, at the expense of the hourly water

production and the amount of water rejected.

NOTE:

In both cases, before setting the needle valves you must slacken

off their collars and tighten them down after the adjustment has

been made.

Recirculation Bypass

Collar

Inactivity:

There are no special warnings regarding maintaining the appliance’s operability

periods of time.

For long periods of inactivity contact your local Authorised Reseller so that he can remove and store the

inverse osmosis membranes and also restart the unit after recommissioning as for the first installation.

when kept inactive for short

- 37 -

Page 12

5. Plumbing diagram

- 38 -

Page 13

LEGEND HYDRAULIC DIAGRAM

IN Water inlet F1 Product flow meter

E1 Filler solenoid valve P2 Delivery minimum pressure switch

P1 Filler pressure switch R Vat cock

FIL Filter - CARBONLOK 5 micron M2 Delivery pump

M1 Osmosis pump F2 Waste flow meter

SR “Re-treatment” needle valve E2 Discharge solenoid valve

VR Non-return valve SS Discharge choke

MP Pump pressure gauge VE Espansion tank

SM Mixer needle valve P3 Delivery pressure switch

MO Osmosis membrane SC Water discarded

CO Conductivity meter PR Produced water

LEGEND ELECTRIC DIAGRAM

SA Anti flooding sensor IO Osmosis switch

CO Conductivity meter E1 Filler solenoid valve

LR Red led E2 Discharge solenoid valve

LV Green led M1 Osmosis pump

SE Electronic board LB Low level switch

M2 Delivery pump LA High level switch

P3 Delivery pressure switch PB Low pressure switch

P2 Delivery minimum pressure switch F2 Waste flow meter

SS Shuko plug SE Selector

IR Delivery switch F1 Product flow meter

- 39 -

Page 14

6. Wiring diagram

- 40 -

Page 15

Electrical specifications:

Power supply: 230v AC 50/60Hz

Max motor outlet load: 16A_ at 230V AC

Max load on solenoid valve 1 outlet: 1A_ at 230v AC

Max load on solenoid valve 2 outlet: 1A_ at 230V AC

Instrumentation:

Conductivity meter (normalised at 20°C ) scale: 0-200uS/cm with probe

K=5. Class (overall): 1

Calibrated by samples. Switchable display of uS/cm and mg/l; simply press the down button during operation.

Flow meter: pulses/l given by sensor: programmable (to account for laminar and lamellar water flow). Just one flow

meter is provided, which can be switched to read a second flow (simultaneous reading: not possible).

CONDUCTI

VITY

METER

CELL

HOOK UP J2

GREEN

POWER LED

(RES 390)

+

-

HOOK UP J4

RED ALARM

LED

(RES 390)

+

-

MAX

PRESS.

ALARM

TRIPS

WHEN IT

CLOSES

INPUT, FLOODING

AND MAX

PRESSURE

Minimum pressure switch

High level

Low level

Flow meter switch

Flow meter

Inputs: high level, low level, flow meter switch, minimum pressure switch: inputs receive only voltage-free

contacts. Caution: do not route these cable together with power or other loads (duct them se parately).

- 41 -

Page 16

6- Faults

Front door leds

List of faults

The door has two leds to indicate:

- Green: power on, normal operation;

- Red: fault, production of osmosis-treated water stopped

Important:

THE DOOR GIVES NO INDICATION OF DELIVERY

CIRCUIT FAULTS

See below for details.

Green

Red

A) No osmosis-treated water delivery

Possible causes Subcause Solution

No water in vat See point "B" see point "B"

Check power supply and power switch ON

(see “Positioning and installation”)

Power plug not inserted in electrical panel

(insert)

Check connections and whether board

is sending a signal

Pump condenser faulty (replace)

Empty vat (manually with jumper on delivery

pump or cock –fig.4) and replace pressure

switch (fig.1)

Replace, or adjust the pressure with the

adjuster screw (fig.2)

Check valve, if jammed replace/clean (fig.3)

Remove obstacle/open cock (fig.4)

Delivery pump not

running

No electrical power

No power to pump

Vat pressure switch faulty (jammed on

empty)

Delivery pressure switch faulty (jammed

on full)

Non-return valve jammed (does not

open)

Vat not full enough for use (min level) Wait for a few minutes while it fills

No water arriving at pump: vat suction

pipe blocked/crimped/cock closed

Display alarm

message

none

Delivery pump runs

but does not deliver

or only insufficiently

- 42 -

Air in delivery pipe Shake pipe and see if air rises into the vat

Impeller damaged/broken Replace

The user requires minimum intake

pressure of >1.8 BAR

The user requires flow > 20 l/min Reduce user load

System limit

Page 17

B) Osmosis-treated water not produced

Possible

causes

Osmosis pump

not running

No electrical power

No power to pump

Intake pressure switch faulty (jammed on full)

Vat level switch (low) faulty (jammed on full)

No water supply or supply pressure/flow

inadequate

Subcause Solution

Check power supply and power switch ON

(see “Positioning and installation”)

Power plug not inserted in electrical panel

(insert)

Check connections and whether board is

sending a signal

Pump condenser faulty (replace)

Replace, or adjust the pressure with the

adjuster screw (fig.5)

Max level switch faulty, does not send

production enable signal (replace/clean)

(see wiring diagram)

- Supply cock closed OPEN;

- Supply filter blocked CLEAN

- Supply pressure should be > 1.5 bar

- Pre-filter up/downstream cocks closed

OPEN (see maintenance section)

- Filter blocked – REPLACE (fig.5)

- Filler solenoid valve faulty or no power –

REPLACE IF FAULTY (fig.5)

- Intake pressure switch faulty (jammed on

empty) – REPLACE (fig.5)

Display

alarm

message

none

Low pressure

Osmosis pump

running but

production low

Water in vat

Water supply too cold (<10°)

Pre-filter blocked

Membranes blocked

Impeller damaged/broken

Bypass valves need adjustment

Discharge pipe crimped

Pressure drop in vat supply hoses

Vat level switch (high) faulty, does not

switch to full: continues producing with

overflow. REPLACE (see wiring diagram)

Increase supply temperature

Replace pre-filter (see maintenance

section)

Replace membranes (see maintenance

section)

Check pressure gauge reading

if > 8, replace pump or impeller as

required

See special adjustments section

Route pipe properly

Shut off power, dry thoroughly and repair

leak

Flooding

alarm

- 43 -

Page 18

C) Water production not conforming

Display alarm

message

Cause of alarm Solution

HHHH

LLLL

Figures

The treated water does not conform

with settings

The water production is below the set

value

Adjust "bypass" needle valve

Replace membranes

Replace pre-filter (see maintenance section)

Replace membranes (see maintenance

section)

Adjust "bypass" needle valve

Fig.1

Fig.2

Pressure switch

Delivery pressure

switch with adjust

screw

- 44 -

Page 19

Non-return valve

Fig.3

Fig.4

Vat cock

Pressure switch

Solenoid valve

Filter

Fig.5

- 45 -

Page 20

7. Electronic circuit board and programming

Hold down F1 and press ENTER to enter conductivity programming.

We can now read the calibrated value. Press UP/DOWN to set the value.

Press ENTER to save and quit. Press F1 to abort without saving.

- 46 -

Page 21

In standby (system not running) :

Display:

Pressing F1 runs a water flushing cycle.

X.X indicates the software version (e.g. 2.1)

After a few minutes, switch off and on again with the osmosis pump switch.

In stand by: hold down UP/DOWN together to enter programming mode:

(in all the following procedures: UP/DOWN changes the value, ENTER saves and continues, F1 continues

without saving).

Programming procedures: >>>>>>>>>>>>>>>>>>>>>>>>

Display: Program filtration hours

X.X indicates the software version (e.g. 2.1)

Press ENTER or F1:

Flussaggio auto (auto flush):

This is an auto flush cycle run by the system to prevent

stagnation in the circuit. After the set number of hours, the

solenoid valves open to flush/refresh the water in the

circuit.

- 47 -

Page 22

Press ENTER or F1:

Stop motore se in moto per … (Stop motor after …)

The following two messages concern the osmosis pump

motor condition. Set = 0 to exclude this mode; if the value

is not 0, the motor stops running after having run

continuously for the set period, then starts again.

After two seconds, the system displays:>>>>>>>>>>>>>>

Press ENTER or F1:

If the conductivity value remains below set value, no alarm

trips, otherwise an alarm displays.>>>>>>>>>>>>>>>>>>>

Press ENTER or F1:

Set number of pulses per litre for the product flow

meter.>>>>>>>>>>>>>>>>>>>>>>>>>>

Press ENTER or F1:

Set number of pulses per litre for the waste flow

meter.>>>>>>>>>>>>>>>>>>>>>>>>>>>>

Press ENTER or F1:

Set minimum production below which a fault is

reported.>>>>>>>>>>>>>>>>>>>>>>>>>>>>

- 48 -

Page 23

Press ENTER or F1; the system returns to standby.

The switch at the top of the display, if pressed to the right,

switches from the waste water flow display

to the osmosis-treated water flow display. When it

is released, the display returns to waste water

flow mode.

- 49 -

Loading...

Loading...