Page 1

WASHING MACHINE

INSTRUCTION MANUAL

EN

Page 2

Contents

1. Precautions for safety and use 2

2. Installation instructions 5

3. Description of controls 8

4. Using the appliance for washing 9

5. Cleaning and maintenance 15

6. Troubleshooting 17

This appliance is tagged in accordance with European Directive 2002/96/EC on Waste Electrical and Electronic Equipment - WEEE.

This directive contains the regulations governing the collection and recycling of decommissioned appliances

throughout the European Union.

The symbol of the rubbish bin with a line through it on the appliance or its packaging indicates that the product must be disposed of separately from other waste at the end of its life cycle. The user is thus obliged to

consign scrapped appliances to the special electronic and electrotechnical waste disposal centres, or return

them to the dealer on purchase of a similar new appliance, on a one-to-one basis.

Consignment to the appropriate facility for environmentally responsible recycling, treatment and disposal

helps to prevent any negative effects on the environment and health, and encourages the reuse and/or recycling of the appliance’s component materials.

Illegal dumping of the appliance by the user will be subject to prosecution under the relevant law.

1

Page 3

EN

READ THE INSTRUCTIONS

Attention!

You are advised to read all the instructions in this manual carefully; it will inform

you about the right conditions for the proper, safe use of your washing machine.

It is very important to keep this instruction manual with the appliance for future reference.

In the event of sale or transfer, ensure that the manual always accompanies the

appliance, to provide the necessary information about its use.

1. PRECAUTIONS FOR SAFETY AND USE

Attention!

These precautions are detailed for reasons of safety.

This section must be read carefully before installation and use.

Disposing of packaging

• Never leave packaging residues unattended in the home. Separate waste packaging materials by

type and consign them to the nearest recycling centre.

• Packaging materials (plastic bags, polystyrene, etc.) must not be left within reach of children.

Disposing of old appliances

• Once no longer in use, the appliance must be rendered unusable: permanently disarm the

lock on the door (this will prevent children risking their lives by locking themselves inside

during play) and cut the power supply lead after removing the plug from the socket.

The appliance must be delivered to a recycling facility.

Environmental protection

• Use the whole of the maximum recommended capacity. Never exceed the maximum permitted lo-

ad.

• Do not use the prewash function for lightly or normally soiled items.

• Follow the manufacturer's recommendations on detergent usage.

• Use the highest spin speed permitted for the fabric type. Fast spins reduce the drying time and

thus energy consumption.

Safety instructions

• This appliance is intended for domestic use and is compliant with Directives 72/23/EEC and

89/336/EEC (including Directives 92/31/EEC and 93/68/EEC) currently in force.

• Read all the instructions in this manual carefully before installation and use.

• Check that the drum assembly has been released before use (see instructions). Failure to release

the drum assembly may cause damage to the washing machine and the surrounding furniture or

appliances during the spin cycle.

• This Instruction Manual is an integral part of the appliance: it must always be kept intact with the

appliance. Installation must be carried out by qualified staff in compliance with the relevant regulations. The appliance is built to provide the following functions: washing and drying of clothes or fabrics stated to be suitable for machine washing by the producer on the relevant label. All other uses are to be considered improper. The manufacturer declines all liability for uses other than

those stated above.

• The nameplate with the technical data, serial number and mark is in a visible position in the part in

view after the door has been opened. The nameplate must never be removed.

• The electrical and plumbing works required to install the appliance must only be carried out

by skilled staff.

• The appliance must be connected to earth in compliance with electrical system safety regulations.

The manufacturer declines all liability for direct or indirect injury or damage deriving from a

non-existent or defective earth connection.

• In the event that the appliance is not connected by means of a plug, an omnipolar circuit-breaker

device with contact gap of at least 3 mm must be provided.

• The plug to be connected to the power supply lead and the relative socket must be of the same

type and comply with the relevant regulations. Check that the mains voltage and frequency are the

2

Page 4

same as the values marked on the nameplate. The use of adapters or junctions is not recommended. Never disconnect the plug by pulling on the power supply lead.

• The appliance is only disconnected from the electricity supply if the plug has been removed

from the socket or the electrical system master switch has been turned off. The power plug

must be accessible after the appliance has been installed.

• The appliance must be installed using new sets of hoses (supplied with the appliance). Old hose

sets should not be reused.

• Take care that the appliance is not standing on the power supply cable.

• The washing machine must never be used on vehicles, on board ships or planes, or in environ-

ments with hazards, such as explosive or corrosive environments (powders, vapours and gases)

or explosive and/or corrosive liquids.

• Do not install the washing machine in places with a risk of frost. Frozen pipes may burst under the

pressure.

• Make sure that the drain hose connected to the sink is securely fastened and cannot move.

• If it is not fixed in place, the repulsive force of the water might thrust it away from the sink, causing

the risk of flooding.

• When connecting the hose to a sink also check that the water drains from it quickly, as otherwise the sink may overflow.

• Do not overload the appliance.

• Never use detergents which contain solvents or chemicals for washing in the washing machine.

They might damage the appliance and form poisonous vapours. These fumes might also

catch fire and explode.

• Garments soaked in petroleum products must not be washed in the washing machine. Before wa-

shing, check that garments do not contain inflammable devices (e.g. cigarette-lighters, matches,

etc.)

• If volatile cleaning fluids are used, ensure that these substances have been removed from the

garments before they are placed in the appliance.

• Before loading garments for washing, check that the pockets are empty, buttons secure and zips

fastened.

• Do not wash frayed or torn garments.

• During washing at high temperatures, the glass in the door will become very hot.

• Check that all water has been drained from the appliance before opening the door.

• If there is water inside, pump it out before opening the door. If in doubt, read the instruction man-

ual.

• The water in the appliance is not suitable for drinking!

• Swallowing washing machine detergents may injure the mouth and throat.

• Before removing the garments from the washing machine check that the drum is at a standstill.

• Switch the appliance off after each use to avoid wasting electricity.

• Leave the door ajar between washes to keep the gasket in good condition.

• In the event of a malfunction never attempt to repair the appliance yourself. Disconnect the ap-

pliance from the electricity supply and turn off the water tap. Then contact a qualified engineer.

Repairs must only be carried out by qualified staff.

• The appliance is intended for use by adults. Do not allow children to tamper with the washing

machine's controls or play with it and do not keep children in the vicinity while the programme

is in progress.

• Young animals or small children might climb into the washing machine.

• Always check the inside of the drum before use and do not allow children to play with the ap-

pliance.

• Keep children away from the appliance when the door or the detergent drawer is open; the appli-

ance might contain detergent resides which may cause permanent injury to the eyes, mouth and

throat, or even cause death by suffocation.

• The appliance is not intended for use by persons (including children) with reduced physical, sen-

sory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance by a person responsible for their safety.

• Do not store flammable fluids near the appliance.

Length periods out of use.

• If the appliance is not to be used for a lengthy period it should be disconnected from the electricity

and water supplies and the door should be left ajar to prevent unpleasant smells from building up

inside.

EN

3

Page 5

For Great Britain only

Warning: this appliance must be earthed.

Fuse replacement

If the mains lead of this appliance is fitted with a

BS 1363A 13amp fused plug, to change a fuse in

this type of plug use an A.S.T.A. approved fuse to

BS 1362 type and proceed as follows:

1. Remove the fuse cover (A) and fuse (B)

2. Fit replacement 13A fuse into fuse cover

3. Refit both into plug

Important:

The fuse cover must be refitted when changing a

fuse and if the fuse cover is lost the plug must not

be used until a correct replacement is fitted.

Correct replacement are identified by the colour

insert or the colour embossed in words on the

base of the plug.

Replacement fuse covers are available from your

local electrical store.

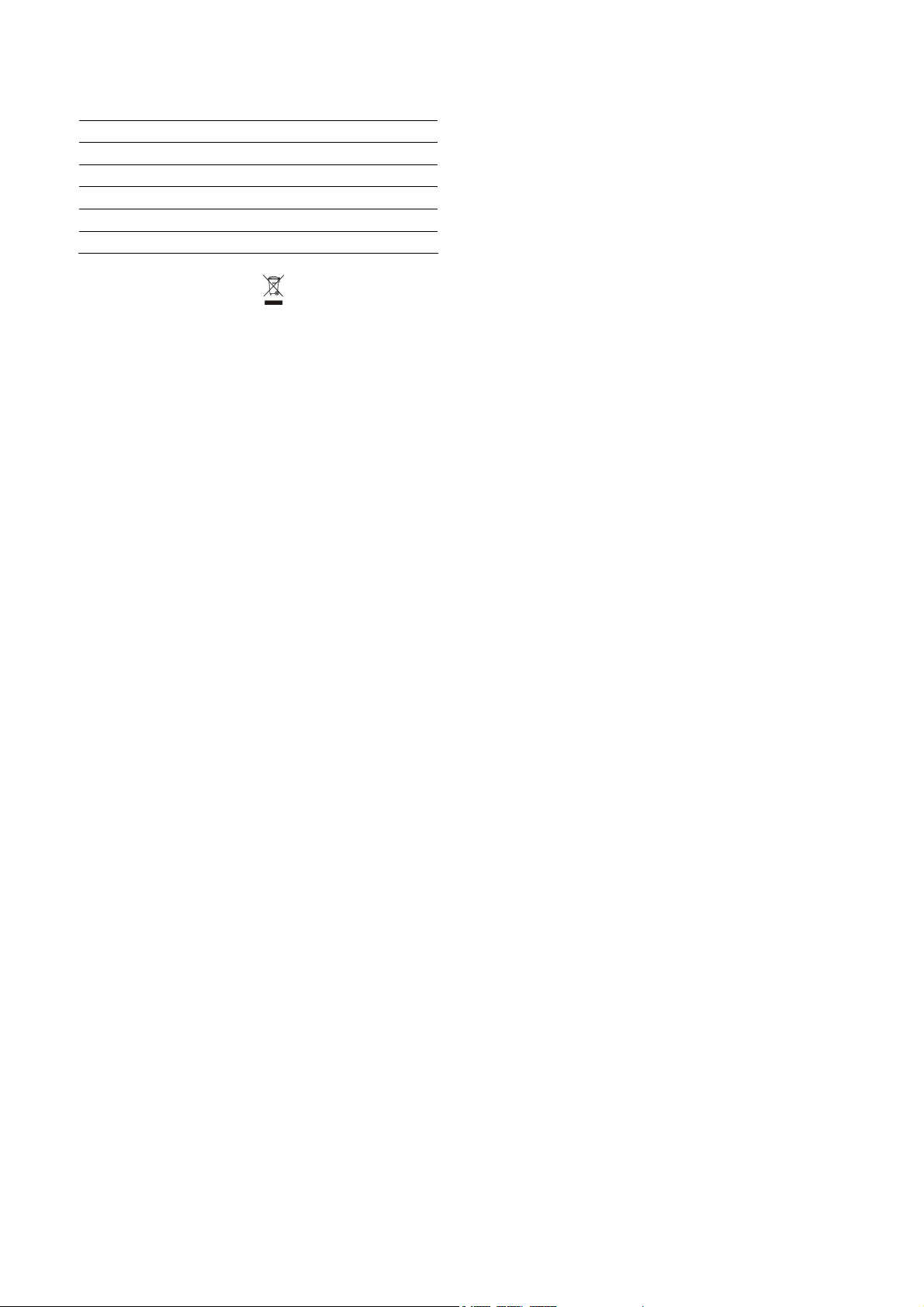

If the appliance is provided with a plugless supply cord:

• It is necessary to install in the fixed wiring an all-pole disconnection device having a gap be-

tween contacts of at least 3,5mm. After installation the disconnection device has to be easy to

reach.

• The connection to the mains must be carried out by a qualified technician in accordance to the

scheme shown below and the regulations in force

EN

L

= brown

N

= bl ue

= yellow-green

• In the event of damage to the supply cord, it has to be replaced by the manufacturer or an au-

thorized technical service center in order to avoid any risk.

Important!

This appliance is easy to use.

However, for the best results it is important to read this manual carefully and follow all the instructions

before putting it into operation.

The manual provides the correct instructions for installation, use and maintenance, as well as giving

useful advice.

The manufacturer declines all responsibility for injury or damage caused by failure to

comply with the above regulations or deriving from tampering with even just one part of the

appliance and the use of non-original spare parts.

4

Page 6

5

EN

2. INSTALLATION INSTRUCTIONS

Important!

The appliance must be installed by a qualified engineer in compliance with the relevant regulations.

The washing machine is heavy. Take care when lifting it.

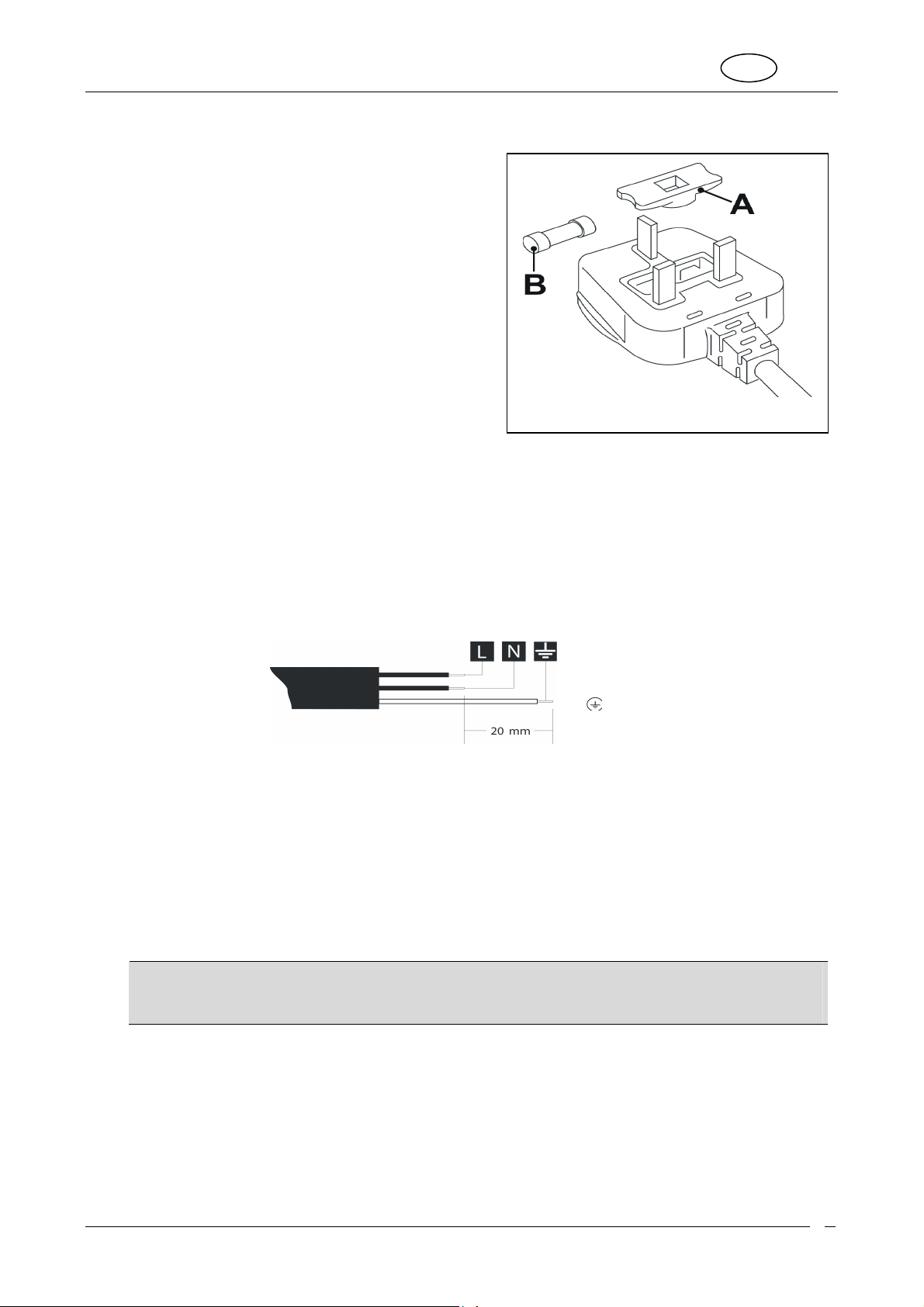

2.1 UNPACKING

The unit on flexible mounts is fixed in place for transport using the screws (A) on the rear of the washing machine

with the relative plastic spacers (B). Once the screws have been removed, the power supply lead can be used.

A+B

1. Undo all the screws with a 10 mm spanner.

2. Remove all the screws (A) from the rear

3. Remove all the plastic spacers (B)

B

A

4. Fit all the plastic plugs (C) provided, to prevent water splashes from

getting into the appliance, and contact with live parts.

Warning!

• Do not turn the appliance upside-down or place it on its sides.

• All the transport retainer fittings should be kept in a safe place; they must be fitted again if the appliance has to

be moved around in the future.

C

Page 7

EN

2.2 POSITIONING AND LEVELLING

1. Place the appliance in the

chosen position.

2. Level the appliance carefully

in all directions with the aid of

a spirit level, adjusting the

height of the feet if necessary.

Once done, fix the feet in place with the locknuts provided.

3. On appliances with adjustable rear feet, note that the rear of the appliance rests on skids and not on the feet.

Before inserting the appliance into its place between the kitchen units, check that the rear feet are screwed

fully in to prevent damage as the appliance is shifted into position.

Once the appliance is in position in the kitchen, the height of the rear feet has to be increased so that the appliance no longer stands on the skids. After adjusting the rear feet, level the appliance and fix the front feet at

the height required.

The water intake and drain hoses can be fitted pointing to the left or right for effective installation.

Warning!

• This operation must be carried out with care to prevent the washing machine from vibrating, moving or

generating excessive noise during use.

• If the appliance is installed on a carpeted floor, take care to ensure that the openings in the bottom of

the washing machine are not obstructed.

• Also check that during operation the washing machine is not resting against walls, kitchen units, etc.

• The appliance must not be installed behind a door with lock, a sliding door, or a door with hinge on the oppo-

site side.

6

Page 8

7

EN

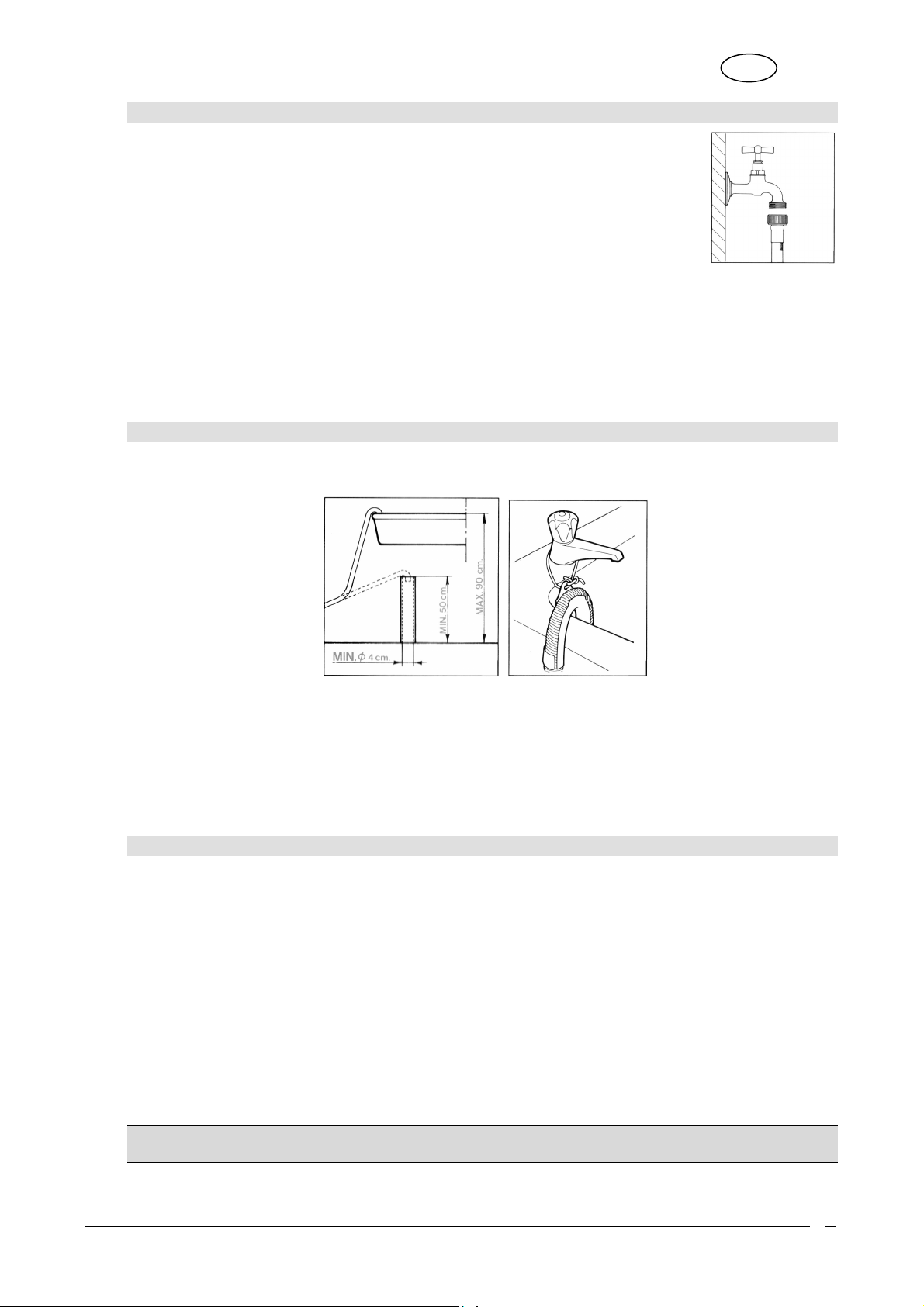

2.3 CONNECTING TO THE WATER SUPPLY

1. Check that the water supply pressure is in the following range: 0,05-0,9MPa. With

higher pressures, use a pressure reducer.

2. Connect the cold water supply hose (blue screw collar) to the cold water tap with ¾

gas threaded connector, taking care to tighten firmly to prevent leaks. The water supply hose must not be kinked or crushed and must not be changed or cut. Threaded

connections must only be tightened by hand.

3. When appliances are supplied with hot water, the intake water temperature must not

exceed 60°C and the hose with red screw collar must be connected to the hot water supply tap.

Warning!

• If the connection is made to new pipelines, or lines which have been out of use for a long time, allow a considerable amount of water to flow out before connecting the intake hose. This prevents any sand or other dirt

from fouling the filters installed in the appliance to protect the water intake valves.

• The new intake hose supplied with the appliance must be used, and the old water supply hose must not be

used.

2.4 CONNECTING TO THE DRAIN

1. Insert the end of the drain hose into a drain pipe having inside diameter of at least 4 cm, at least 50 to 90 cm

above floor level, or connect it securely (using the plastic fitting on the elbow in the hose) to a sink or bathtub.

2. In all cases, check that the end of the drain hose is securely fixed to prevent the repulsive force of the water

from pushing it out of place.

Warning!

• Avoid kinks or restrictions to ensure effective drainage.

• Any drain hose extensions must be no more than 1 metre long, must be of the same diameter and must be

free from restrictions of all kinds.

• The end of the drain hose must never be submerged in water.

2.5 ELECTRICAL CONNECTION

Before connecting the plug to the power socket ensure that:

1. The electrical system voltage is the same as that stated on the nameplate on the front of the appliance,

in the zone visible when the door is open. The rated power supply and the fuses required are specified

on the nameplate.

2. The meter, safety breakers, power supply line and power socket are rated to withstand the maximum lo-

ad required, stated on the nameplate.

3. The power supply socket and the plug fitted to the appliance are compatible without the use of reduc-

tions, multiple sockets, adapters and extension leads which might cause overheating or scorching.

If the power supply socket is not compatible with the plug supplied, replace the socket with one of the

appropriate type.

Warning

• The power plug must be accessible after the appliance has been installed.

• It is absolutely essential to connect the appliance to earth. Connect the plug to a socket with an earth

connection in good working order.

The manufacturer declines all liability for direct or indirect injury or damage deriving from a non-existent

or defective earth connection. Correct electrical connection guarantees conditions of maximum safety.

• This appliance is compliant with the requirements of EEC directive 89/336 of 3.5.89 (including the amendment directive 92/31/EEC) concerning the elimination of radio-frequency disturbance.

Page 9

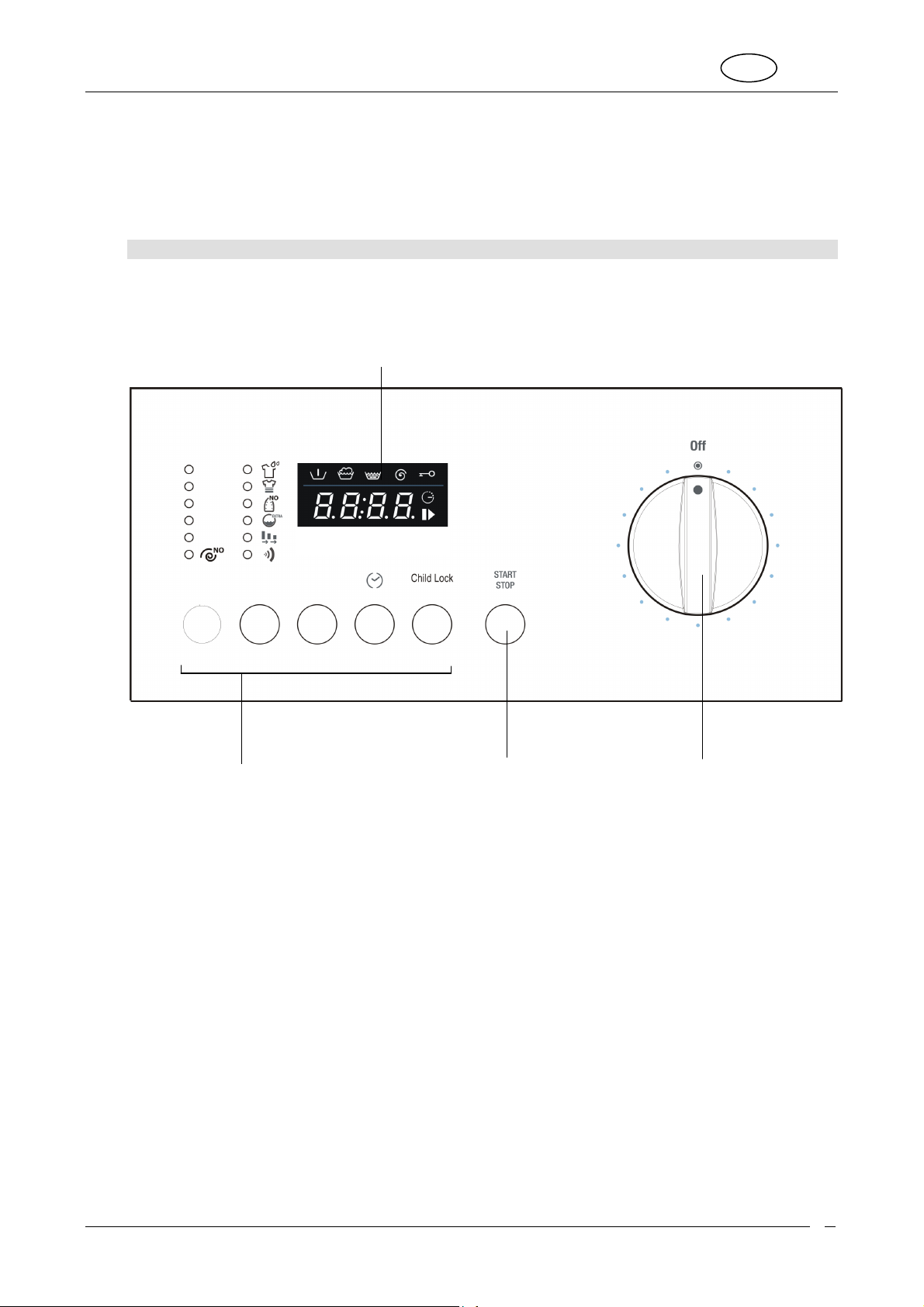

Programme Selector

Start/Pause button

Display

• If the power supply lead is damaged, it must only be replaced with an original spare, available from the AfterSales Service.

• Do not connection/disconnect the power supply plug from the socket with wet hands

• Only disconnect the power supply plug from the socket by taking hold of the plug itself, never by

pulling on the lead.

EN

3. DESCRIPTION OF CONTROLS

3.1 CONTROL PANEL

All the appliance's control and monitoring devices are placed together on the front panel.

fied using the buttons underneath.

: shows the settings (spin speed, cycle status, child lock on/off). The settings can be modi-

Buttons (from left to right):

Spin speed selection

Option selection

Confirm option

Delay Timer

Child Lock

For starting and stopping

working cycles.

:

For switching the washing machine on and off and selecting

programmes. Can be turned in

either direction. Does not turn

while programmes are in progress.

8

Page 10

EN

4. USING THE APPLIANCE FOR WASHING

4.1 PREPARING THE ITEMS FOR WASHING

1. Subdivide the items for washing by fabric type and colour fastness.

2. Wash white and coloured items separately. New coloured items should be washed separately the first time.

Normally, items carry labels with washing instructions. The following is a short description of the symbols used on these labels.

Warning!

• Do not wash unhemmed or torn items as they may fray.

• Unrelated items in the wash may damage the garments or parts of the washing machine. So: empty pockets

and turn them inside-out, and remove wheels from curtains or wrap them in a mesh bag.

• Wash very small items (belts, handkerchiefs, socks, padded bras, etc.) in a white canvas bag. Fasten pressstuds and zips and sew on loose buttons.

• The use of modern detergents and the correct washing temperature is generally sufficient to remove stains

from fabrics. However, some difficult stains such as grass, fruit, egg, blood, rust, ballpoint pen, etc. should be

dealt with before washing. Depending on the type of fabric, there are a large number of commercial

stain removers on the market. In all cases, stains should be cleaned or diluted at once, since the older

they are, the harder they are to remove.

• Failure to comply with washing guidance symbols may result in damage to the items washed.

WASHING BLEACHING

Machine wash at max. 90°C

Machine wash at max. 60°C

Machine wash at max. 40°C

Machine wash at max. 30°C

Machine wash, delicate cycle

at max. 60°C

Machine wash, delicate cycle

at max. 40°C

Machine wash, delicate cycle

at max. 30°C

Hand wash

Do not wash

Bleaching allowed

Hot iron

High tem-

perature

Any solvent

Warm iron

Any solvent e-

xcept trichloroe-

thylene

Less than 60°C

IRONING

DRY CLEANING

Cool iron

Petroleum

solvent and

R113

DRYING

Do not bleach

Do not dry clean

Do not tumble dry

Do not iron

Wool – Only wool marked as pure new wool, with the mark, or labelled "shrink-proof, machine-washable"

can be washed in a washing machine on the specific programme; other types of wool should be hand-washed or

dry-cleaned.

4.2 OPENING THE DOOR

The appliance is fitted with a safety device which prevents the door from being opened while the programme is in

progress.

1. Check that all the water has been drained from the tank and the drum is at a standstill.

Warning!

• If the washing programme is interrupted, it will be from 3 to 15 minutes before the door can be opened, depending on the temperature reached inside the appliance.

Warning!

The water may still be boiling hot if the wash was at high temperature.

Do not open the door if there is still water in the drum!

4.3 LOADS OF WASHING

As far as possible, to save electricity, it is more economical to wash complete loads of the various types of

fabric. Shake out the washing before loading, and alternate large and small items. It is best to weight the load the

first few times, after which you will be able to rely on your experience. As a guide, the following is a list of the average weights of the standard items:

9

Page 11

4.4 LOADING THE ITEMS FOR WASHING

1. Open the door and load the washing, distributing it evenly over the drum, with items opened out and not

bundled together; if possible, large and small items should be well mixed.

2. The washing machine covered by this manual can be loaded with up to 7kg of washing for each wash.

If this weight is exceeded, the washing results will be poor and the appliance may malfunction.

3. To save energy it is more economical to wash full loads of the various types of fabric, following the

guidance on quantities provided in the “Programmes Table” supplied in this manual.

4. Close the door by pressing against the frame until you hear it click shut. Take care not to trap items of

washing between the door and the rubber gasket.

Warning!

• If the door is not properly closed, a safety device prevents the washing machine from starting.

• Do not exceed the maximum load: overloading adversely affects washing results.

4.5 ADDING DETERGENT AND ADDITIVE

The internal tray comprises three compartments, marked with the symbols

prewash detergent

main wash detergent

EN

for fabric conditioner, starch, additives, etc. (e.g. treatment products).

the washing tank automatically during the final rinse.

The additives are added to

The main wash detergent compartment has a tang allowing the use of liquid detergent. To insert it, pull it towards

the front and then lower it.

Following the recommendations in the "Programmes Table" supplied

with this manual, place the detergent and any additives in the drawer

before the start of the programme.

Never fill with liquids above the maximum level marked; otherwise

the trays will empty too quickly.

Before pouring dense additives into the container, dilute with a little

water to ensure they do not clog the outlet.

Use only low-foam detergents suitable for use in a washing machine.

The amount of detergent must be decided in relation of the hardness of the water, the type and quantity of items loaded, and their

degree of dirt.

This will provide the desired effect with optimal detergent consumption.

On detergent packs the recommended dose is indicated for 4 levels of water hardness and for loads of 4-5 kg of

washing with average dirt levels.

Request information about the water's hardness from your water supply company.

Water hardness

Level of hardness French degrees fH German degrees dH

Soft Up to 15° Up to 8°

Medium 15° - 25° 8° - 14°

Hard 25° - 40° 14° - 22°

Very hard More than 40° More than 22°

10

Page 12

Time to end

Spin Speed selection

EN

4.6 POWDER DETERGENT DOSES

Laundry with normal dirt

1. Choose a programme without prewash.

2. Pour the total amount of detergent shown on the pack into the main wash compartment of the detergent dra-

wer.

Very dirty laundry

1. Choose a programme with prewash.

2. Place ¼ of the recommended amount of detergent in the prewash compartment of the detergent drawer and

¾ of the detergent in the wash compartment.

Warning!

• If no recommended doses are provided, for delicate items in synthetic fibre use from ½ to 2/3 of the recom-

mended dose for washing tough cotton fabrics.

• Only neutral detergents recommended for wool should be used on the wool programme.

• Use the doses recommended by the detergent producer.

4.7 LIQUID DETERGENT DOSES

1. Pour the dose required into the measuring cap supplied with the bottle of liquid detergent and place it in the

drum, or use the main wash compartment of the detergent drawer, fitting the insert provided.

2. The scale on the red insert is intended as an aid when deciding the dose of liquid detergent.

Warning!

• Liquid detergents can be used, at the doses recommended by the producer, only for the main wash, i.e. in

all programmes without prewash.

4.8 DESCALERS

Descalers can be added to the prewash and main wash compartments as recommended by their producers.

Place the detergent in the compartments first, followed by the descaler.

4.9 PROGRAMMES AND FUNCTIONS

For advice on selecting programmes in relation to the type of fabric, refer to the "Programmes Table",

supplied with this manual.

4.10 SWITCHING ON THE APPLIANCE AND SELECTING THE WASHING PROGRAMME

To switch on the appliance and select the programme, proceed as follows:

1. Turn the programmes knob in either direction. This switches on the washing machine.

2. Select the washing programme. The time left to the end of the programme appears on the display. The sym-

bols on the display light up to identify the information shown.

3. The default spin speed values are shown. The initial settings can be modified using the button underneath the

sequence of spin speeds.

4. If spin speed is set, there will be

no spin cycle and the appliance will stop with the tank full. If

this value is set the appliance does not perform the final spin and the washing programme ends

with water in the tank.

11

Page 13

Option selection

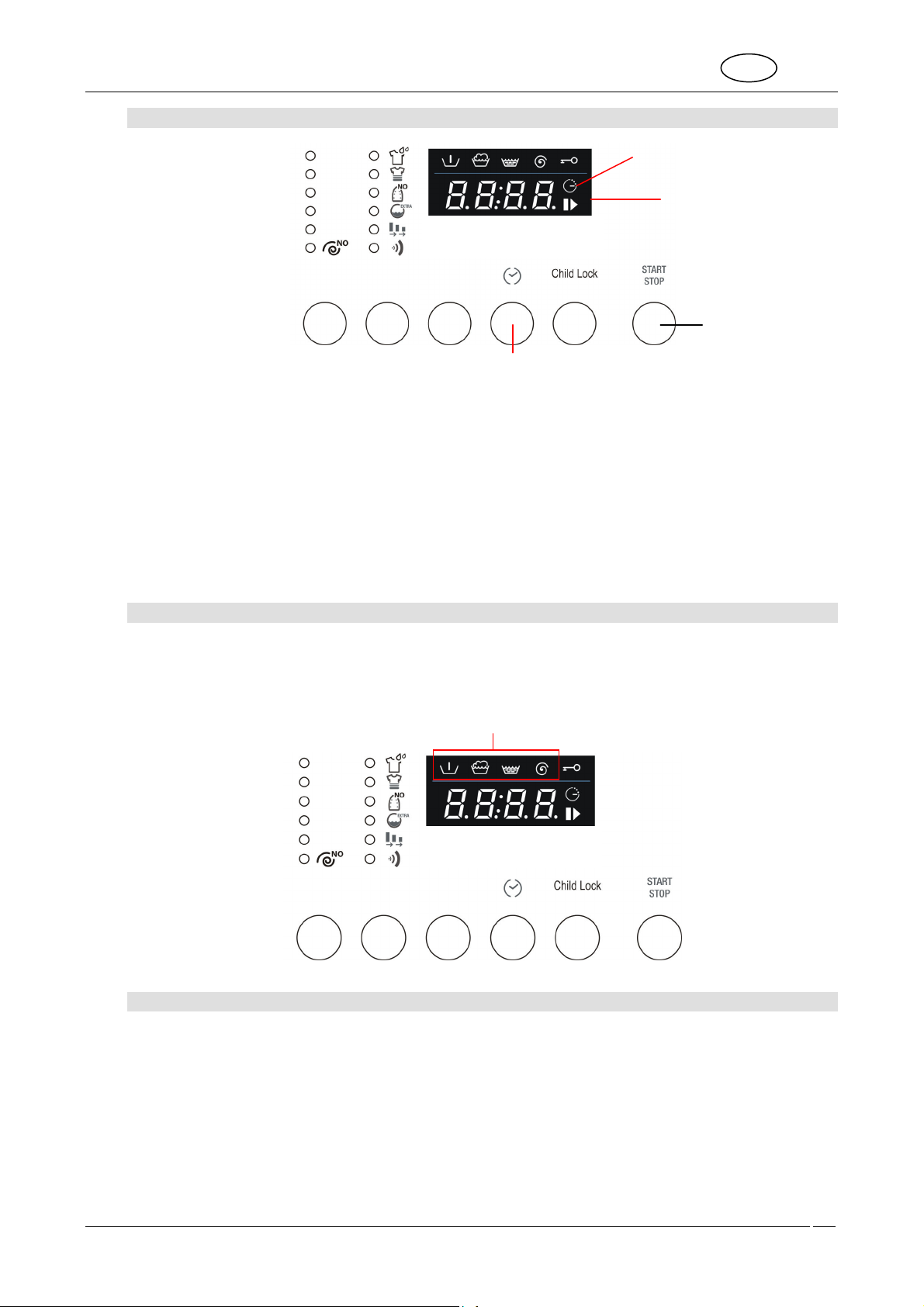

4.11 SELECTING AND CONFIRMING OPTIONS

Options

EN

1. The Option Selection button can be used to select the following options in sequence (from the top down):

Prewash: adds a stage before the main wash, lasting about 20 minutes at a temperature of 35°C. Suitable for loads of particularly dirty items.

Intensive: the max. temperature is changed to 60°C and the washing stage is extended to increase the

effectiveness of the enzymes in the detergents. Suitable for delicate but dirty items.

Easy iron: produces items which are less creased and easy to iron.

Water plus: Increases the amount of water used for washing and rinses.

In alternative Extra rinse: this option adds a rinse to the selected washing programme.

Rapid: reduces the duration of the washing cycle. Suitable for small amounts of laundry with only light

dirt.

Buzzer: sets whether or not the buzzer will sound at the end of the cycle. The appliance comes with the

buzzer function "on".

2. To confirm the selected option, simply press the Confirm options button and the LED of the option re-

mains on.

3. To delete an option selection, simply return to the option with the Selection button and press the Confirm

options button. To annul all the options previously selected in a single operation, simply hold down the

Confirm options button for 4 seconds.

4. The Buzzer option retains its "on" or "off" status for subsequent cycles. It is only automatically switched

to "off" if the Night Wash programme is chosen.

Confirm option

Start Pause

12

Page 14

4.12 TIME TO END

Delay Time to end

Start pause symbol

Start Pause

1.

The Time to End key can be pressed repeatedly to select the time after which the washing programme

will end. The time to end of cycle function calculates the initial duration of the washing cycle, the settings

made (temperature, spin speed and options) which may shorten or lengthen the cycle's initial duration,

and the delay time the user wishes to add before the cycle starts.

2. After the time to end has been set, the symbol on the display remains on.

3. To annul the Time to End function, keep pressing the key repeatedly until the display shows 0.

4. The Start Pause symbol flashes on and off until the cycle starts. After the cycle starts, the symbol re-

mains constantly lit.

Delay Time to end

4.13 STARTING THE WASHING PROGRAMME

1. To start the washing programme after making your personal settings, press the Start Pause button.

2. Once the cycle has started, the display shows the time remaining before the end of the cycle and the

Start Pause symbol on the display is constantly on.

3. During performance of the washing programme, the symbols which identify the various phases light up:

Cycle phase symbols: Prewash, wash, rinse and final spin.

EN

4.14 INTERRUPTING OR CHANGING THE WASHING PROGRAMME

The washing programme in progress can be interrupted at any moment:

1. Press the “Start/Pause” button for about 3 seconds: the display shows the word PAUS (for 1 second) al-

ternating with the time remaining until the end of the cycle (for 1 second). The Start/Pause light flashes

on and off.

Programmes can also be interrupted by turning the programme/temperature setting knob while the cycle

is in progress.

2. To change the washing programme, simply turn the programme knob to select the new programme; the-

re is no need to set the appliance in pause status. The new cycle will be carried out completely, beginning from the start. If the tank had already been filled with water during the previous cycle, the water intake phase will be omitted from the new programme.

3. To restart the cycle, press the Start-Pause button again.

13

Page 15

1 2

EN

4.15 PROGRAMME END

Washing programmes are completed automatically. The word END appears on the display and the "Time remaining" light goes out.

1. Switch the appliance off by turning the programmes knob to OFF

2. Unload the laundry from the drum.

3. Leave the door ajar to allow the interior of the washing machine to dry out.

4. Turn off the water intake tap.

If during the initial spin speed setting stage, the "no spin" mode with stop with tank full (spin speed set as

0) was selected, at the end of the washing programme the word STOP appears on the display, alternating with ---(spin speed of 0) and the spin light is on.

To proceed with the pump-out and spin, press the spin selection button twice. The appliance restarts the cycle

with the pump-out and spin. To select the spin speed required, press the button until the chosen speed is displayed. To pump out the water from the tank without performing the spin, press the spin selection button until the

display indicates speed of 0: the pump-out will be run without spin.

4.16 CHILD LOCK

1. When this function is activated, the modification of options, temperatures, spin speed and the wash-

ing/drying cycle is not possible while the cycle is in progress.

Child Lock Symbol

2. To activate the Child Lock Function, press the Child Lock (1) button and hold it down. Also press the Op-

tions selection (2) button within 3 seconds.

3. The Child Safety Function symbol lights up to show that the function has been activated.

4. Repeat the same procedure to deactivate the function.

4.17 OPENING THE APPLIANCE IN AN EMERGENCY

In the event of a power failure, the door is opened using the

mechanical release device activated by means of the lever in

the bottom of the appliance:

• Turn the knob to Off and disconnect the power

supply plug from the socket.

• Drain off the water (see point 5.4)

• Pull the lever down and open the door.

Warning, scolding hazard: before opening the door, check

that the appliance does not contain boiling hot water and detergent which may pour out and cause injury when the door is

opened.

Warning: do not open the door using the emergency release

lever while the drum is turning.

14

Page 16

driver as a lever to remove the plugs shown here,

Insert a small screwdriver

the front of the plinth, then apply

upward leverage with the screwdriver to release the

EN

5. CLEANING AND MAINTENANCE

Important – Before carrying out any cleaning or maintenance procedure, the plug must be disconnected

from the power supply socket.

5.1 CLEANING THE OUTSIDE OF THE APPLIANCE

• Regular, thorough cleaning will keep your appliance looking good.

• Clean the exterior of the appliance with soap and water only, then dry thoroughly with a soft cloth.

• The plastic parts should just be wiped with a damp cloth.

• Do not scrape with pointed objects, or use solvents or products containing abrasive substances because

they damage the surfaces.

• For reasons of safety, never spray the washing machine with jets of water.

5.2 CLEANING THE DRUM

• Remove any rust marks from the drum using a stainless steel cleaner, or very fine sandpaper for particu-

larly stubborn cases.

• For descaling the washing machine use only brand-name descalers which contain an anti-corrosion a-

gent for washing machines.

• Always follow the producer's instructions with regard to use and dosages.

• After descaling or removing rust from the drum, carry out a few rinse cycles to remove all acid

residues which might damage the appliance. Never use cleaners which contain solvents. There is

the risk of the formation of vapours which might catch fire and explode.

5.3 CLEANING THE DOOR GASKET

Check regularly that there are no paper clips, buttons, nails or pins in the folds of the door gasket.

5.4 CLEANING THE DRAIN PUMP

The drain pump only needs cleaning if it has been blocked by buttons, brooches or similar objects and the water is

not being pumped out.

In this case, proceed as described below.

1. Remove the mains plug to disconnect the appliance from the electricity supply.

2. Depending on the model, proceed as follows:

Built-in/totally concealed model – use a small screw-

turn the plinth downwards and access the pump.

Free-Standing Model –

through the slits in

top of the plinth from the cabinet.

Tilt the plinth forward slightly and pull it upward to remove it completely.

15

Page 17

3. Extract the drain hose ”A”.

Warning: if the hose is hot, the water is hot or boiling hot. Place a

shallow container on the floor and remove the plug “B” to drain off

the water.

Depending on the amount of water in the appliance, the container

may have to be emptied several times.

When no more water is coming out, close the hose again by pushing the plug “B” firmly back into place.

4. Unscrew the cover of the pump “D” by turning it to the left.

Clean the pump and remove any foreign bodies.

Also check the inside “E”, making sure that the impeller turns freely; any foreign

bodies stuck in it must be removed.

5. Screw the cover back on the pump.

Secure the drain house by snapping the plug back into place "C".

Depending on the model, replace the plinth as follows:

Built-in/completely concealed model - Fit the bottom of the plinth first. Push it towards the cabinet and put the

plugs back into place.

Free-standing model – Fit the bottom of the plinth first and then push it towards the cabinet until it snaps into

place.

5.5 CLEANING THE DETERGENT DRAWER

The detergent drawer should be kept clean, removing all solid deposits.

To simplify this operation, completely remove the detergent drawer (pull the

drawer fully out, press in the zone marked PUSH and then remove completely).

Remove the siphon "A" and clean all parts with hot water.

Fully re-insert the siphon and remove any detergent deposits before putting

the drawer back in position.

5.6 CLEANING THE WATER INTAKE FILTERS

The machine is fitted with a filter which protects the water intake valves.

The filter is in the fitting on the intake hose which is connected to the tap

The filter must be cleaned if the washing machine is not taking in water or the amount of

water is insufficient.

To clean, proceed as follows:

• Remove the mains plug to disconnect the appliance from the electricity

supply.

• Turn off the water tap.

• Unscrew the intake hose fitting from the tap.

• Unscrew the intake hose fitting from the tap.

• Clean the filter with water, with the aid of a small brush.

• When screwing the intake hose fitting back into place, check that the filter is positioned correctly.

EN

16

Page 18

17

EN

6. TROUBLESHOOTING

This produce complies with the relevant regulations governing the safety of electrical equipment. For safety reasons, any technical inspections or repairs must be performed by qualified staff, to prevent all hazards for the user.

If the appliance does not work, before calling the After-Sales Service, to avoid unnecessary expense, check yourself that the operations listed in this troubleshooting table have been carried out..

1 Appliance does not start

2 No water filling

3 No water visible in washing

drum

4 Water not pumped out

5 Water not pumped out after

last rinse in delicate fabrics

and wool wash programmes

6 Water takes in and pumps

out water continually

7 Strong vibrations during

spins

8 Too much foam formed in

tank and flowing out of

drawer

9 Water on floor

10 Not all fabric conditioner

used or too much water left

in compartment

Check that:

- plug is properly connected to socket

- door is securely closed

- “Start/Pause” button has been pressed.

Check that:

- plug is properly connected to socket

- door is securely closed

- water tap is turned on

- water intake hose filters not fouled.

- water intake hose not trapped or kinked.

No malfunction.

The water level is below the level of the glass in the door because new

appliances use very little water to achieve the same washing and rinsing

results.

Check that:

- drain hose is not kinked

-

drain pump not fouled.

It is not a malfunction: pause programmed into washing programme to

prevent creasing of fabrics.

To pump out water, proceed as described in "Programme End" point.

Check that end of drain hose is not too low down.

Check that:

- Appliance is properly levelled

- washing machine not too close to walls or kitchen units

- internal unit on flexible mounts locked in position.

Check that:

- detergent used is recommended for automatic washing machines

and not for hand washing

- quantity used is as stated in manual and no more

Check that:

- water intake hose fittings not loose

- end of drain hose still correctly positioned.

Check that detergent drawer siphons are correctly fitted and not fouled.

Page 19

11 Appliance does not spin

12 Emptying water from drum

13 Laundry not properly spun

14 Traces of detergent on

laundry

15 Washing results unsatis-

factory

Anti-imbalance safety device tripped because laundry not evenly distributed in drum. If laundry is still wet at end of cycle, rearrange it in the drum

by hand and repeat spin programme only.

In the event of a power blackout or appliance failure, the water can be

removed from the drum using the emergency procedure.

Large items screwed up and not evenly distributed within drum. Always

wash a mix of large and small items.

Many phosphate-free detergents contain substances with low water solubility.

Select Rinse programme or brush the laundry.

- Probably too little detergent or unsuitable detergent used

- Difficult stains not dealt with before washing

- Correct temperature not set

- Basket overloaded.

ERROR DISPLAY

In case of a malfunction, the appliance will identify the problem by showing an error code on the display.

EN

Error code Key to problem

Door not properly closed. Try reclosing.

Aqua stop device tripped. Cut off power supply, turn off water tap and contact nearest

service centre.

Water not taken in for washing. See point 2 in troubleshooting table.

Water not pumped out. See point 4 in troubleshooting table.

For all the other error codes displayed, cut off the electricity supply, turn off the water tap and contact your nearest

Service Centre.

18

Page 20

PROGRAM GUIDE

Temp.

Max. Spin

Options

Detergent drawer compartments

Programs

Cotton and

coloureds

Wool

Rinse & Spin

Drain & Spin

Synthetics

Delicates

Mix

Super Fast

Delicate coloureds with

light dirt

Delicate coloureds with

normal dirt

Tough coloureds with

normal dirt

Tough coloureds with

heavy dirt

Hand wash

Wool and silk

Items for refreshing

Items with light dirt

Items with normal dirt

Items for refreshing

Items with light dirt

Cotton and synthetics

with light dirt

Light cotton or delicate

fabrics for refreshing

(°C)

Cold Max

40° Max

60° Max

90° Max

Cold 800

30° 800

Cold 800

30° 800

40° 800

Cold 600

30° 600

30° Max

30° 800

(rpm)

-

-

Max

Max

Max.

washing

load (kg)

7

7

7

7

2

2

7

7

3,5

3,5

3,5

2

2

3

2

Prewash Wash Conditioner Prewash Intensive Easy

Extra rinse Rapid Wash program description

Iron

-

-

- -

- - - - -

-

-

- - - - -

- - - - -

- -

-

-

-

-

-

-

-

-

-

-

- - - - -

Cold wash, rinses and final spin at the selected speed

Wash at 40℃, rinses and final spin at the selected speed

Wash at 60℃, rinses and final spin at the selected speed

(Standard cycle with only "intensive" option selected)

Wash at 90℃, rinses and final spin at the selected speed

Cold wash, rinses and final spin at the selected speed

Wash at 30℃, rinses and final spin at the selected speed

Rinse and pump-out only, or pump-out and final spin at the

selected speed

Pump-out only, or pump-out and final spin at the selected

speed

Cold wash, rinses and final spin at the selected speed

Wash at 30℃, rinses and final spin at the selected speed

Wash at 40℃, rinses and final spin at the selected speed

Cold wash, rinses and final spin at the selected speed

-

Wash at 30℃, rinses and final spin at the selected speed

-

Wash at 30℃, rinses and final spin at the selected speed

Wash at 30℃, rinses and final spin at the selected speed

:

Option available

: Options which cannot be selected simultaneously

Code 19392001600

Page 21

ISTRUZIONI DI MONTAGGIO DELLE

IT

LAVATRICI INTEGRABILI

ASSEMBLY INSTRUCTIONS FOR BUILT-IN WASHING

MACHINES

MONTAGEANLEITUNG FÜR EINBAUBARE-

WASCHMASCHINEN

INSTRUCTIONS DE MONTAGE DES LAVE-LINGE

INTÉGRABLES

INSTRUCCIONES DE INSTALACIÓN DE LAS

LAVADORAS INTEGRABLES

INSTRUÇÕES DE MONTAGEM DAS MÁQUINAS DE

LAVAR ROUPA INTEGRÁVEIS

MONTAGEINSTRUCTIES VAN INTEGREERBARE

WASMACHINES

MONTERINGSANVISNING FOR INTEGRERBARE

VASKEMASKINER

MONTERINGSANVISNINGAR FÖR

INBYGGNADSBARA TVÄTTMASKINER

EN

DE

FR

ES

PT

NL

DK

SE

ANKASTRE ÇAMAŞIR MAKĐNELERĐ

ĐÇĐN MONTAJ TALĐMATLARI

ИНСТРУКЦИИ ПО МОНТАЖУ

ВСТРОЕННЫХ СТИРАЛЬНЫХ МАШИН

TR

RU

Page 22

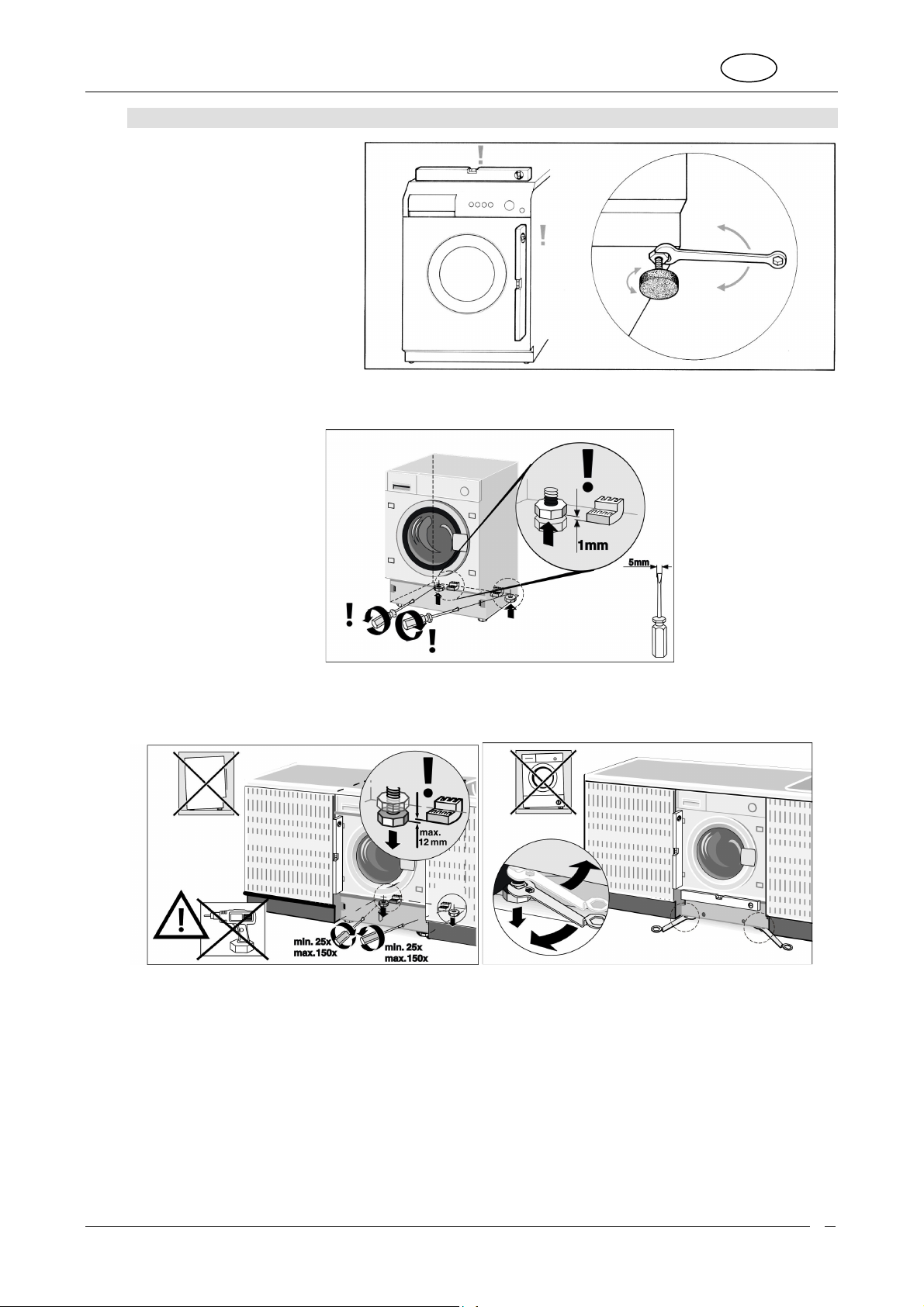

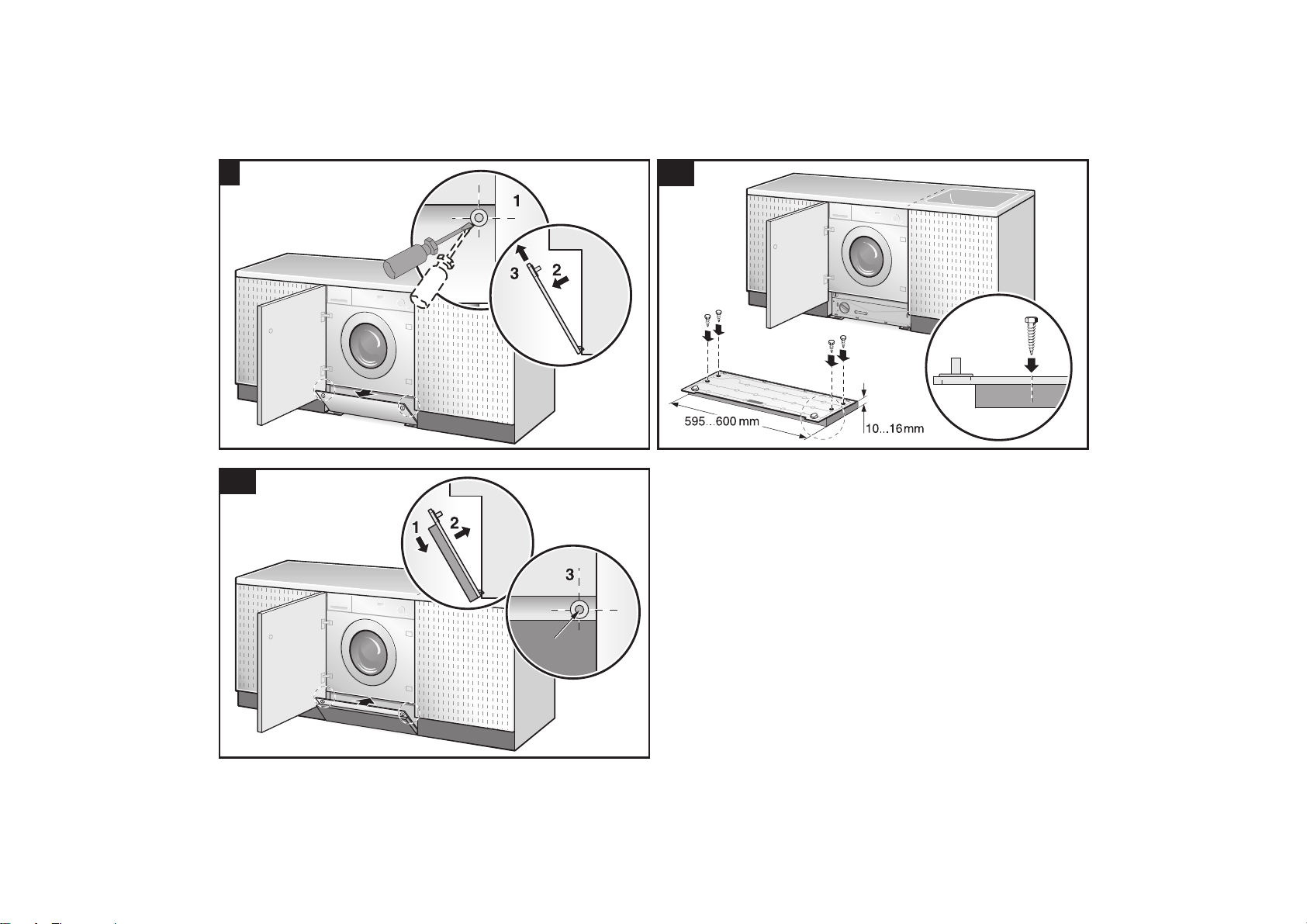

ASSEMBLY INSTRUCTIONS FOR BUILT-IN WASHING MACHINES

IMPORTANT - This machine complies with current safety regulations governing electrical appliances and, to ensure user safety, it must be installed by a

qualified technician as required by current legislation

Size of cabinet The minimum dimensions of the cabinet are: height 820 mm,

width 600 mm, depth 584 mm (fig. 1).

Applying the

panel

Important! Before fitting the panel (removing all the hinge

Warning - To fix the panel on the right-hand side (direction of

Using the template

The panel may be attached to the left- or right-hand side of the

washing machine (fig. 2)

The machine is supplied fitted for a left-hand side panel attachment as the right-hand side is fitted with the push-pull lock

(upper part) and the rubber pad (lower part).

Should you wish to use the magnetic lock instead of the pushpull lock, remove the push-pull lock support and fit the supplied

magnetic lock support.

and locking elements from the front) make sure the washing machine is totally disconnected from the mains power

supply.

opening opposite to that of the door) dismount the push-pull

lock (or the magnet lock) from the front of the machine and the

rubber pad (fig. 3-A) and fit them on the opposite side (fig. 3-

B).

All the elements applied to the front of the washing machine

must be remounted correctly (no holes must remain open) in

order to make it impossible to touch live components inside the

machine.

Our company declines all liability for failure to observe the

above safety requirement.

1) Measure the height of the kitchen baseboard: the height of

E.g.: for a 100 mm high baseboard, the maximum height of

the wooden panel is obtained by first establishing the height

of the kitchen baseboard.

the panel is 720 mm. If the height of the baseboard must be

increased, the height of the wooden panel must be reduced.

4

Page 23

Applying the

panel elements

and fixing the

panel

Adjusting the

hinges

Positioning the

washing machine in the

cabinet

Place the template of the inner side of the panel and match the

height of the baseboard with the lower edge of the panel (fig. 4)

using the graduated scale. Make sure the template is horizontally centred with reference to the vertical lines marked at the

ends.

After placing the template in the correct position, trace the positions of the following holes, pushing in with the tip of your pencil:

• holes for the hinges and hinge screws (fig. 4)

•

holes for fixing the metal plate (if the magnetic lock is

used), or the hook for the push-pull lock (fig. 4, A - B)

1) Drill the holes for the hinges (fig. 5), the hook for the pushpull lock (fig. 5), or the metal plate if you decide to use the

magnetic lock (fig. 6), and the holes for fixing the hinges

(fig. 6).

2) The 13 mm depth of the 2 mm holes, for fixing the hinges

and a metal plate for the magnet lock, only applies to the

solid wood panel. For the chipboard panel, simply drill the

upper coating – fig. 6.

3) Screw the two hinges to the panel (fig. 7)

4) Mount the hook for the push-pull lock or the metal plate for

the magnet lock on the side opposite the hinges (fig. 7).

5) Fix the panel to the washing machine following the instructions shown in fig. 8.

If, after applying the panel to the washing machine, it is slightly

inclined or off-centre with respect to the front of the machine,

correct its position by adjusting the mobile part of the hinges

(fig. 9).

Position the washing machine in the cabinet and, if necessary,

adjust the feet to level it and lock them with the relative locknut.

On appliances with adjustable rear feet, refer to the operator’s

manual.

To prevent the vibrations generated by the washing machine

from being transmitted to the cabinet, make sure the sides and

top do not touch the cabinet. There must be a gap of at least

2 mm. The back of the machine must also remain detached

from the rear panel.

If the cabinet is 870 mm high, the washing machine heightening kit on sale from the Spare Parts Service, must be

used.

To comply with safety legislation, any gaps between the floor

and the bottom of the baseplate and between the floor and the

sides of the machine when it is positioned at the end of a line of

furniture must be completely closed.

The cover must be installed in such a way as to make it

5

Page 24

Applying the

baseboard

impossible to touch live components and a tool must be

required to remove it.

Our company declines all liability for failure to observe the

above safety requirement.

It must be possible to remove the continuous kitchen baseboard

to allow the drain pump to be cleaned if necessary.

In some cases, the baseboard is not continuous but limited to

the width of the washing machine. In this case, the kitchen

baseboard can be fixed to the washing machine baseboard with

4 screws, respecting the 4 reference marks (see fig. 9-10-11).

When applying the kitchen baseboard, the washing machine baseboard may not be removed or adapted as, for

reasons of safety, it must remain as it is, in one piece and

fixed to the washing machine.

6

Page 25

1

!

!

820mm

!

!

2

820mm

150mm

16mm

596mm

A B

560mm

58mm

ca.82kg

9

Page 26

3

3- A

22

11

33

C

22

3

3

8

8

77

99

9

-

A B

5

4

4

6

6

1111

1010

12

12

C

C

66

55

7

7

88

B

11

33

A

D

22

-

A B

4

4

11

3

232

D

C

4

3-B

545

Page 27

4

16...21mm

Unterkante

Loweredge

ôtéinférieur

ee

C

Latoinferiore

Ladoinferior

Onderkant

Нижнийкрай Нижнийкрай

9

16...21mm

ee

Unterkante

Lower edge

ôté inférieur

C

Lato inferiore

Lado inferior

Onderkant

592...595mm

5

592...595mm

ee

ee

6

13mm13mm

Ø 35mmØ35mm

13mm13mm

Ø2mmØ2mm

Page 28

7

2

8

2

9

?

1

33

11

22

11

3

4

5

6

2

2

11

33

Page 29

9

11

10

Loading...

Loading...