Smeg WIL61BVM User Manual

Contents

F

E

_

4

N

a

e

1 INSTRUCTIONS FOR SA

E AND PROPER US

_______________________________

2 INSTALLATION OF THE APPLIANCE__________________________________________6

3 ADAPTATION TO DIFFERENT TYPES OF GAS _________________________________8

4 FINAL OPERATIONS______________________________________________________11

5 DESCRIPTION OF FRONT PANEL CONTROLS ________________________________13

6 USE OF THE COOKING HOB _______________________________________________15

7 USE OF THE OVEN_______________________________________________________17

8 ELECTRONIC PROGRAMMER (ONLY ON EQUIPPED MODELS) __________________21

9 DIGITAL TIMER (CERTAIN MODELS ONLY) ___________________________________23

10 ANALOGUE CLOCK (ONLY ON EQUIPPED MODELS) _________________________23

11 CLEANING AND MAINTENANCE ___________________________________________24

12 EXTRAORDINARY MAINTENANCE _________________________________________26

THESE INSTRUCTIONS ARE VALID ONLY FOR END USER COUNTRIES WHOSE IDENTIFICATIO

SYMBOLS APPEAR ON THE COVER OF THIS MANUAL.

INSTRUCTIONS FOR THE INSTALLER: these are for the qualified technician who must carry out

suitable check of the gas system, install the appliance, set it functioning and carry out an inspection test.

INSTRUCTIONS FOR THE USER: these contain user advice, description of the commands and th

correct procedures for cleaning and maintenance of the appliance.

3

1 INSTRUCTIONS FOR SAFE AND PROPER USE

THIS MANUAL IS AN INTEGRAL PART OF THE APPLIANCE AND THEREFORE MUST BE KEPT

IN ITS ENTIRETY AND IN AN ACCESSIBLE PLACE FOR THE WHOLE WORKING LIFE OF THE

COOKER. WE ADVISE READING THIS MANUAL AND ALL THE INSTRUCTIONS THEREIN

BEFORE USING THE COOKER. ALSO KEEP THE SERIES OF NOZZLES SUPPLIED.

INSTALLATION MUST BE CARRIED OUT BY QUALIFIED PERSONNEL IN ACCORDANCE WITH

THE REGULATIONS IN FORCE. THIS APPLIANCE IS INTENDED FOR DOMESTIC USES AND

CONFORMS TO CURRENT REGULATIONS IN FORCE. THE APPLIANCE HAS BEEN BUILT TO

CARRY OUT THE FOLLOWING FUNCTIONS: COOKING AND HEATING-UP OF FOOD. ALL

OTHER USES ARE CONSIDERED IMPROPER.

THE MANUFACTURER DECLINES ALL RESPONSIBILITY FOR IMPROPER USE.

DO NOT LEAVE THE PACKING IN THE HOME ENVIRONMENT. SEPARATE THE VARIOUS

WASTE MATERIALS AND TAKE THEM TO THE NEAREST SPECIAL GARBAGE COLLECTION

CENTRE.

IT IS OBLIGATORY FOR THE ELECTRICAL SYSTEM TO BE GROUNDED ACCORDING TO THE

METHODS REQUIRED BY SAFETY RULES.

Introduction

WHEN LINKING UP TO MAINS BY PLUG AND SOCKET, MAKE SURE THAT BOTH ARE

COMPATIBLE AND CONNECT BY MEANS OF A POWER CABLE COMPLYING WITH APPLICABLE

REGULATIONS.

THE SOCKET MUST BE ACCESSIBLE AFTER THE APPLIANCE HAS BEEN BUILT IN.

NEVER UNPLUG BY PULLING ON THE CABLE.

IMMEDIATELY AFTER INSTALLATION CARRY OUT A BRIEF INSPECTION TEST OF THE

APPLIANCE, FOLLOWING THE INSTRUCTIONS BELOW. SHOULD THE APPLIANCE NOT

FUNCTION, DISCONNECT IT FROM THE SUPPLY AND CALL THE NEAREST TECHNICAL

ASSISTANCE CENTRE.

NEVER ATTEMPT TO REPAIR THE APPLIANCE.

WHEN NOT IN USE, MAKE SURE THAT THE CONTROL KNOBS ARE IN THE CORRECT (OFF)

POSITION

NEVER PUT INFLAMMABLE OBJECTS IN THE OVEN: THEY COULD BE ACCIDENTALLY

LIGHTED AND CAUSE FIRES.

THE I.D. PLATE WITH TECHNICAL DATA, REGISTRATION NUMBER AND BRAND NAME IS

POSITIONED VISIBLY IN THE STORAGE COMPARTMENT.

THE PLATE MUST NOT BE REMOVED.

DO NOT PUT PANS WITHOUT PERFECTLY SMOOTH AND FLAT BOTTOMS ON THE COOKING

hob GRIDS.

.

DO NOT USE CONTAINERS OR BROILERS THAT EXTEND BEYOND THE OUTER PERIMETER

OF THE HOB.

4

-

e

LOWER THE GLASS COVER SLOWLY AND BY HAND.

WARNING: THE GLASS COVER MAY SHATTER IF IT OVERHEATS. SWITCH OFF ALL RINGS

AND WAIT FOR THEM TO COOL DOWN BEFORE CLOSING THE COVER.

DURING USE THE APPLIANCE BECOMES VERY HOT. TAKE CARE NOT TO TOUCH THE

HEATING ELEMENTS INSIDE THE OVEN.

Introduction

THE APPLIANCE IS DESIGNED FOR USE BY ADULTS. DO NOT ALLOW CHILDREN TO GO

NEAR OR PLAY WITH IT.

WHEN OPERATING THE GRILL ALL ACCESSIBLE PARTS COULD BECOME VERY HOT: KEEP

OUT OF THE WAY OF CHILDREN.

IF THE APPLIANCE IS TO BE POSITIONED ON A PLATFORM IT MUST BE INSTALLED IN SUCH

A WAY AS TO PREVENT IT FROM SLIPPING OFF THE FORMER.

THIS APPLIANCE IS MARKED ACCORDING TO THE EUROPEAN DIRECTIVE 2002/96/EC ON

WASTE ELECTRICAL AND ELECTRONIC EQUIPMENT (WEEE).

THIS GUIDELINE IS THE FRAME OF A EUROPEAN-WIDE VALIDITY OF RETURN AND

RECYCLING ON WASTE ELECTRICAL AND ELECTRONIC EQUIPMENT.

BEFORE THE APPLIANCE IS PUT INTO OPERATION, ALL THE LABELS AND PROTECTIVE

FILMS APPLIED INSIDE OR OUTSIDE MUST BE REMOVED.

The manufacturer declines all responsibility for damage to persons or things caused by non

observance of the above prescriptions or by interference with any part of the appliance or by the us

of non-original spares.

5

e

k

e

r

2 INSTALLATION OF THE APPLIANCE

It is the law that all gas appliances are installed by competent persons. Corgi gas installers ar

approved to work to safe and satisfactory standards. All gas installation, servicing and repair wor

must be in accordance with the gas safety regulations 1984 (installation and use) as amended 1990.

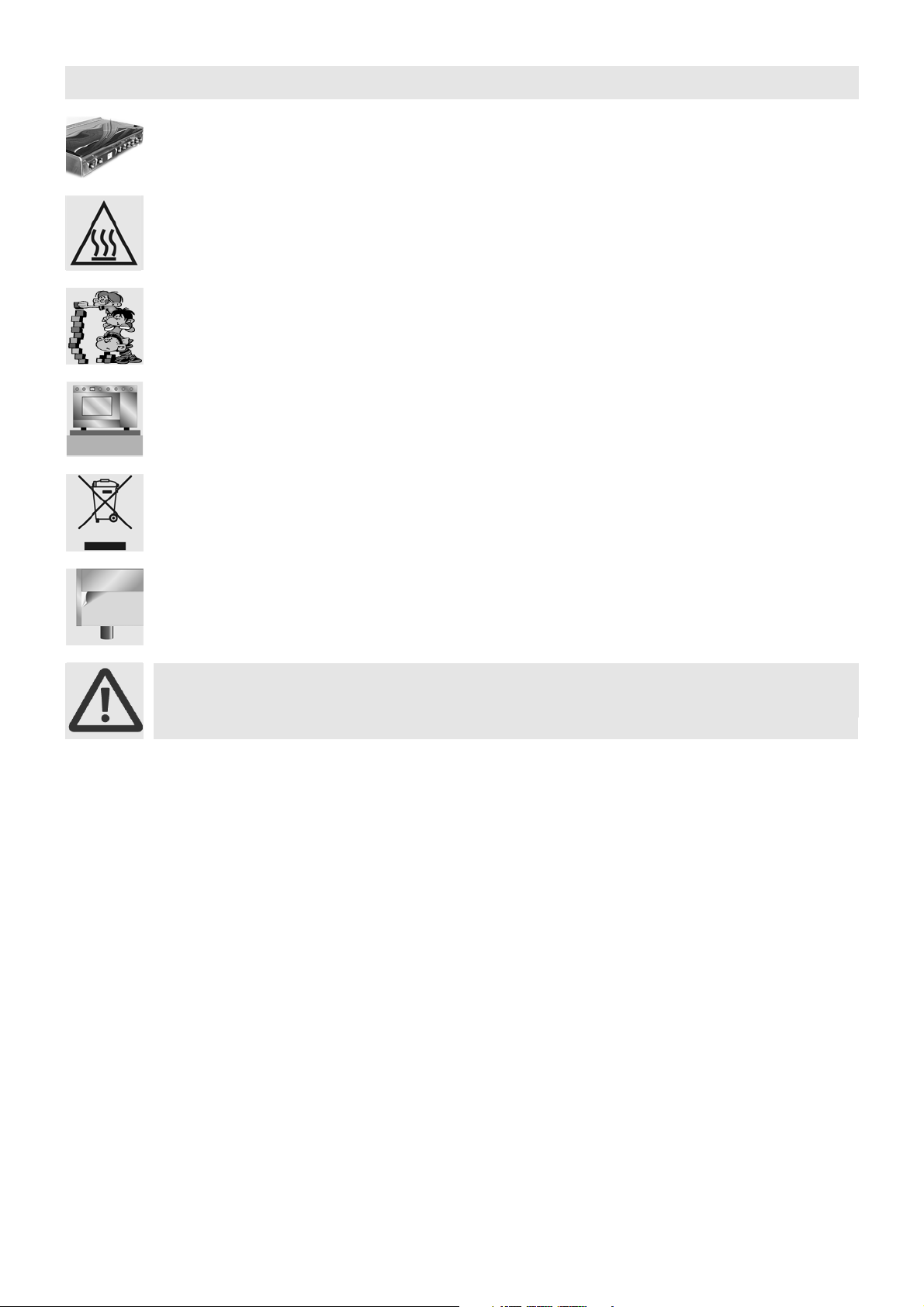

It can be placed against walls higher than the hob, at a distance of at least 50 mm from the side of th

appliance, as shown in the drawings A and B relating to the installation classes. Wall units or extracto

hoods located above the hob must be at least 750 mm away from it.

Instruction for the installer

Built-in appliance Free-standing installation

2.1 Electrical connection

Make sure that the power line voltage matches the specifications indicated on the rating plate located

inside the storage compartment.

This rating plate must never be removed.

If the appliance is hooked-up to the supply by means of a fixed connection, install a multipolar cut-out

device on the line, with contact opening distance equal to or greater than 3 mm, located near the

appliance and in an easily reachable position.

Hook-up to the supply may be fixed or with plug and socket. In the latter case the plug and socket

must be suitable for the cable employed and conform with the regulations in force. Regardless of the

type of connection, earthing of the appliance is absolutely obligatory. Before connection make sure

that the supply line is suitably earthed. Avoid the use of reducers, adapters or shunts.1

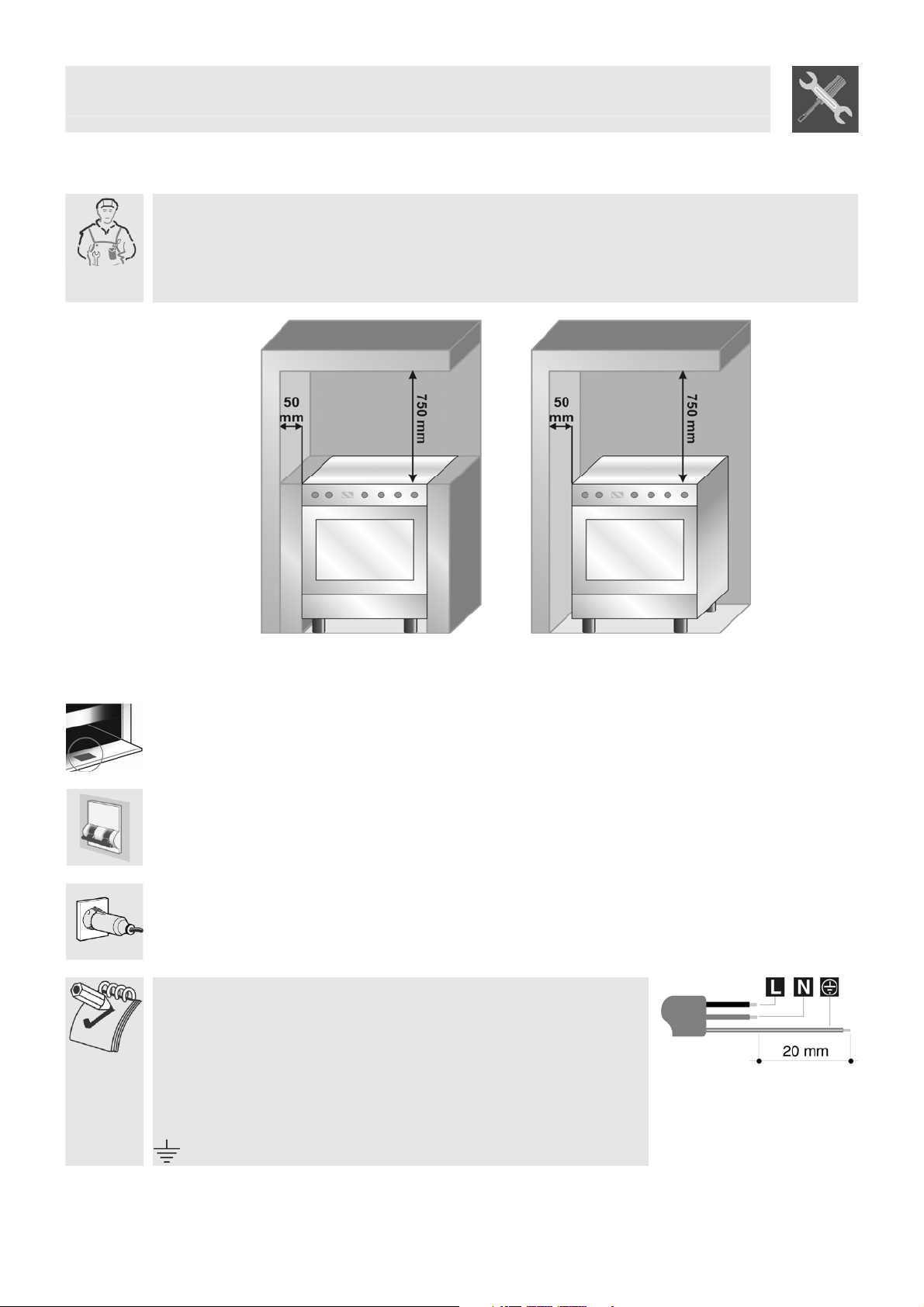

If the power cable is replaced, the wire section on the new cable must

not be less than 1.5 mm2 (3 x 1.5 cable), keeping in mind that the end to

be connected to the hob must have the ground wire (yellow-green)

longer by at least 20 mm. Use only H05V2V2-F cable or similar which has

a maximum temperature of 90°C. This must be done by a specialised

technician, who must connect the cooker to the electricity supply

according to the diagram shown here.

L = brown

N = blue

= yellow-green.

A

B

6

r

Instruction for the installer

Make the connection to the appliance using flexible bayonet style hose in

2.2 Ventilation requirements

The room containing the appliance should have an air supply in accordance with regulation in force.

1. All rooms require an opening window or equivalent, and some rooms will require a permanent vent

as well.

2. For room volumes up to 5 m

3. If the room has a door that opens directly to the outside, and the room exceeds 1 m

required.

4. For room volumes between 5 m

5. If there are other fuel burning appliances in the same room B.S. 5440 part 2 1989 should be

consulted to determine the air vent requirements.

6. This appliance must not be installed in a bed sitting room of less than 20 m

shower room.

Windows and permanent vents should therefore not be blocked or removed without first consulting a

Corgi gas installer.

Failure to install appliances correctly is dangerous and could lead to prosecution.

3

an air vent of 100 cm2 is required.

3

and 10 m3 an air vent of 50 cm2 is required.

3

or in a bathroom o

2.3 Connecting to natural and LPG gas

(Please see connection diagram)

accordance to B.S. 669. The hose connection at the rear of the appliance has a ½”

BSP internal thread. Please use seal C between the flexible connection L and the

appliance supply tube B. When making the connection, make sure that no stress of

any kind is applied to the cooker and that the hose does not touch any sharp

edges.

If connecting to LPG the bayonet hose must have red bands on it.

3

no air vent is

2.4 Bottled gas connection (Only on some models)

Use a pressure regulator complaint with the relevant standards and make the connection to the gas

cylinder in accordance with the relevant regulations.

Make sure that the gas supply pressure is as stated in the table in point "3.2/3.3 Burner and Nozzle

Data Tables".

Screw the small hose connector F onto the large hose connector A and

connect the resulting unit to the gas union B (or use the hose connector

G for connection straight to the gas union B) and fit the seal C. Fit the

ends of the rubber hose H onto the hose connector A+F (or G) and to

the outlet union of the pressure reducer on the gas cylinder. Fix the end

of the hose H to the hose connector A+F (or G) using the regulation

hose clamp I .

The hose connector G shown is not supplied with the appliance. Use only hose connectors

compliant with the relevant regulations.

7

/

3 ADAPTATION TO DIFFERENT TYPES OF GAS

Before performing any cleaning or maintenance work, detach the appliance from the electrical socket.

Instruction for the installer

This operation requires no primary air regulation.

The cooker hob is set for LPG G30/G31 (3+) at a pressure of 28/37 mbar. In the case of functioning

with other types of gas the burner nozzles must be changed and the minimum flame adjusted on the

gas taps. To change the nozzles, proceed as described below.

3.1 Replacement of nozzles on the hob

1. Extract the grids and remove all the caps and flame-spreader crowns;

2. unscrew the burner nozzles with a 7 mm socket wrench;

3. replace the nozzles according to the type of gas to be used and the description in paragraph “3.2

3.3 Burner and nozzle characteristics table”.

4. Replace the burners in the correct position.

8

Instruction for the installer

Burner

Auxiliary

Semi-rapid

Triple crown

Oven

Burner

Auxiliary

Semi-rapid

Triple crown

Oven

3.2 Burner and nozzle characteristics table

Rated

heating

capacity

(kW)

1.0 50 30 350 73 71

1.75 65 33 450 127 125

3.2 91 65 1500 233 229

3.2 87 48 850 233 229

Rated

heating

capacity

(kW)

1.0 72 350

1.75 97 450

3.5 133 1500

3.2 130 850

diameter

1/100 mm

Nozzle

LPG – G30/G31 28/37 mbar

By-pass

mm

1/100

NATURAL GAS – G20 20 mbar

Nozzle diameter

1/100 mm

Reduced

flowrate

(W)

Flowrate

g/h G30

Flowrate

Reduced Flowrate

(W)

g/h G31

9

Instruction for the installer

To adjust the oven burners follow the procedure described below from

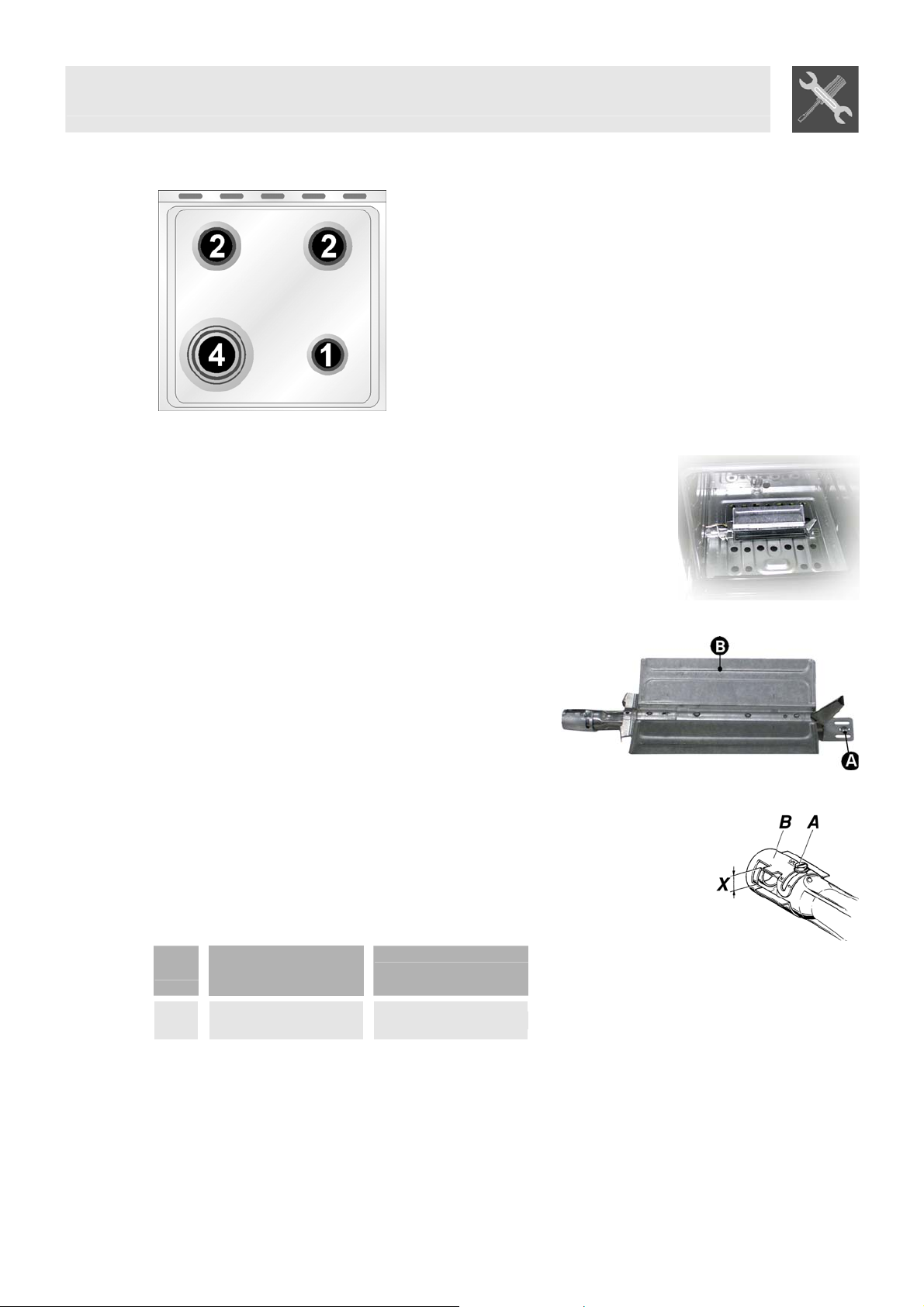

3.3 Arrangement of burners on cooking hob

BURNERS

1. Auxiliary

2. Semi-rapid

4. Triple crown

3.4 Adjustment of the oven burner (only for gas oven models)

inside the oven:

• Open the oven door;

• Remove the oven dish and shelf.

• Lift up the oven floor and remove.

3.4.1 Replacement of the oven burner nozzle

• Loosen the fixing screws A on the oven burner.

• Push the burner B towards the right to get to the

nozzle.

• Use a 13 socket wrench to change the nozzle, fitting

the one for the type of gas to be used (see point

“3.2/3.3 Table of burner and nozzle characteristics”).

3.4.2 Regulation of the primary air on the oven burner

• Loosen the register screws “A” on the air regulation coupling.

• Turn the register coupling “B” to the position corresponding to the type of gas

to be used according to the table below.

• Tighten the register screws and mount the seals.

• Once the operation is completed reassemble the burner correctly.

X =

NATURAL (N)

G30/G31 (LPG)

5 mm 15 mm

10

Loading...

Loading...