Smeg SNZ91MFA1, SNZ91MFX1 User Manual

Table of Contents

E

E

_

4

k

s

1 PRECAUTIONS FOR SAF

TY AND US

_____________________________________

2 INSTALLING THE APPLIANCE______________________________________________6

3 ADAPTING TO DIFFERENT TYPES OF GAS __________________________________9

4 FINAL OPERATIONS ____________________________________________________12

5 DESCRIPTION OF FRONT PANEL CONTROLS _______________________________14

6 USING THE HOB________________________________________________________16

7 USING THE OVEN ______________________________________________________17

8 ELECTRONIC PROGRAMMER (ON SOME MODELS ONLY)_____________________21

9 DIGITAL TIMER (ON SOME MODELS ONLY) _________________________________23

10 ANALOGUE CLOCK (ON SOME MODELS ONLY) _____________________________23

11 CLEANING AND MAINTENANCE ___________________________________________24

12 EXTRAORDINARY MAINTENANCE _________________________________________26

INSTRUCTIONS FOR THE INSTALLER: these are intended for the qualified engineer who is to chec

the gas supply system and install, commission and test the appliance.

INSTRUCTIONS FOR THE USER: these provide recommendations for use, a description of the control

and the correct procedures for cleaning and maintaining the appliance.

3

1 PRECAUTIONS FOR SAFETY AND USE

THIS MANUAL IS AN INTEGRAL PART OF THE APPLIANCE. TAKE GOOD CARE OF IT AND

KEEP IT TO HAND THROUGHOUT THE COOKER'S LIFE CYCLE. WE URGE YOU TO READ THIS

MANUAL AND ALL THE INFORMATION IT CONTAINS CAREFULLY BEFORE USING THE

COOKER. ALSO KEEP THE SET OF NOZZLES PROVIDED IN A SAFE PLACE. INSTALLATION

MUST BE CARRIED OUT BY QUALIFIED STAFF IN COMPLIANCE WITH THE RELEVANT

REGULATIONS. THIS APPLIANCE IS INTENDED FOR HOUSEHOLD USE AND COMPLIES WITH

THE EEC DIRECTIVES CURRENTLY IN FORCE. THE APPLIANCE IS BUILT TO PROVIDE THE

FOLLOWING FUNCTION: COOKING AND HEATING FOODS; ALL OTHER USES ARE TO BE

CONSIDERED IMPROPER.

THE MANUFACTURER DECLINES ALL LIABILITY FOR USES OTHER THAN THOSE STATED

ABOVE.

NEVER LEAVE PACKAGING RESIDUES UNATTENDED IN THE HOME.

SEPARATE WASTE PACKAGING MATERIALS BY TYPE AND CONSIGN THEM TO THE NEAREST

SEPARATE DISPOSAL CENTRE.

THE APPLIANCE MUST BE CONNECTED TO EARTH IN COMPLIANCE WITH ELECTRICAL

SYSTEM SAFETY REGULATIONS.

Presentation

THE PLUG TO BE CONNECTED TO THE POWER SUPPLY LEAD AND THE RELATIVE SOCKET

MUST BE OF THE SAME TYPE AND COMPLY WITH THE RELEVANT REGULATIONS.

THE POWER SUPPLY SOCKET MUST BE ACCESSIBLE EVEN AFTER THE APPLIANCE HAS

BEEN BUILT-IN.

NEVER DISCONNECT THE PLUG BY PULLING ON THE POWER SUPPLY LEAD.

IMMEDIATELY AFTER INSTALLATION, CARRY OUT A QUICK TEST ON THE APPLIANCE

FOLLOWING THE INSTRUCTIONS PROVIDED LATER IN THIS MANUAL. IF THE APPLIANCE

FAILS TO OPERATE, DISCONNECT IT FROM THE ELECTRICAL MAINS AND CONTACT YOUR

NEAREST SERVICE CENTRE.

NEVER ATTEMPT TO REPAIR THE APPLIANCE.

AFTER EACH USE, ALWAYS CHECK THAT THE CONTROL KNOBS ARE TURNED TO THE

(OFF).

NEVER PLACE FLAMMABLE OBJECTS IN THE OVEN: IF IT SHOULD ACCIDENTALLY BE

SWITCHED ON, THIS MIGHT CAUSE A FIRE.

THE NAMEPLATE WITH THE TECHNICAL DATA, SERIAL NUMBER AND MARK IS IN A VISIBLE

POSITION INSIDE THE STORAGE COMPARTMENT.

THE NAMEPLATE MUST NEVER BE REMOVED

NEVER PLACE PANS WITH BOTTOMS WHICH ARE NOT PERFECTLY FLAT AND SMOOTH ON

THE HOB PAN STANDS.

NEVER USE PANS OR GRIDDLE PLATES WHICH PROJECT BEYOND THE OUTSIDE EDGE OF

THE HOB.

4

ALWAYS KEEP HOLD OF THE HOB'S GLASS LID WHEN LOWERING IT.

WARNING: THE GLASS LID MAY SHATTER IF OVERHEATED.

TURN OFF ALL THE BURNERS AND WAIT FOR THEM TO COOL BEFORE CLOSING IT.

THE APPLIANCE BECOMES VERY HOT DURING USE. TAKE CARE NOT TO TOUCH THE

HEATING ELEMENTS INSIDE THE OVEN.

Presentation

THE APPLIANCE IS INTENDED FOR USE BY ADULTS. KEEP CHILDREN AT A SAFE DISTANCE

AND NEVER ALLOW THEM TO PLAY WITH IT.

WHEN THE GRILL IS IN OPERATION, ACCESSIBLE PARTS MAY BECOME VERY HOT: KEEP

CHILDREN AT A SAFE DISTANCE.

IF THE APPLIANCE IS MOUNTED ON A STAND, IT MUST BE INSTALLED IN SUCH A WAY THAT

IT CANNOT SLIP OFF.

DO NOT SPRAY AEROSOLS IN THE VICINITY OF THIS APPLIANCE WHILE IT IS IN OPERATION.

THIS APPLIANCE IS DESIGNED FOR COOKING FOOD AND IT SHALL NOT BE USED AS A

SPACE HEATER.

REPLACED APPLIANCES MUST BE TAKEN TO A SPECIAL GARBAGE COLLECTION CENTRE.

BEFORE THE APPLIANCE IS PUT INTO OPERATION, ALL THE LABELS AND PROTECTIVE

FILMS APPLIED INSIDE OR OUTSIDE MUST BE REMOVED.

The manufacturer declines all responsibility for injury or damage caused by failure to comply with

the above regulations or deriving from tampering with even just one part of the appliance and the use

of non-original spare parts.

5

2 INSTALLING THE APPLIANCE

It is the law that all gas appliances are installed by authorised persons. Clearance around

the cooker must comply with the requirements of AS5601.

2.1 Electrical connection

Check that the voltage and size of the power supply line are as specified on the nameplate inside the

storage compartment.

This nameplate must never be removed.

If a permanent connection to the electrical mains is used, the appliance's power supply line must be

fitted with an omnipolar breaking device with contact breaking gap of at least 3 mm located in an

easily accessible position close to the appliance itself.

For operation on 220-240 V∼: use an H05RR-F or H05V2V2-F type

three-core cable (3 x 2.5 mm2).

For operation on 380-415 V 2N∼: use an H05RR-F or H05V2V2-F

type four-core cable (4 x 1.5 mm2).

For operation on 380-415 V 3N∼: use an H05RR-F or H05V2V2-F

type five-core cable (5 x 1.5 mm2).

The cable end to be connected to the appliance must be

provided with an earth wire (yellow-green) at least 20 mm

longer.

Instructions for the Installer

The manufacturer declines all responsibility for damage to persons or things caused by nonobservance of the above prescriptions or by interference with any part of the appliance.

6

Instructions for the Installer

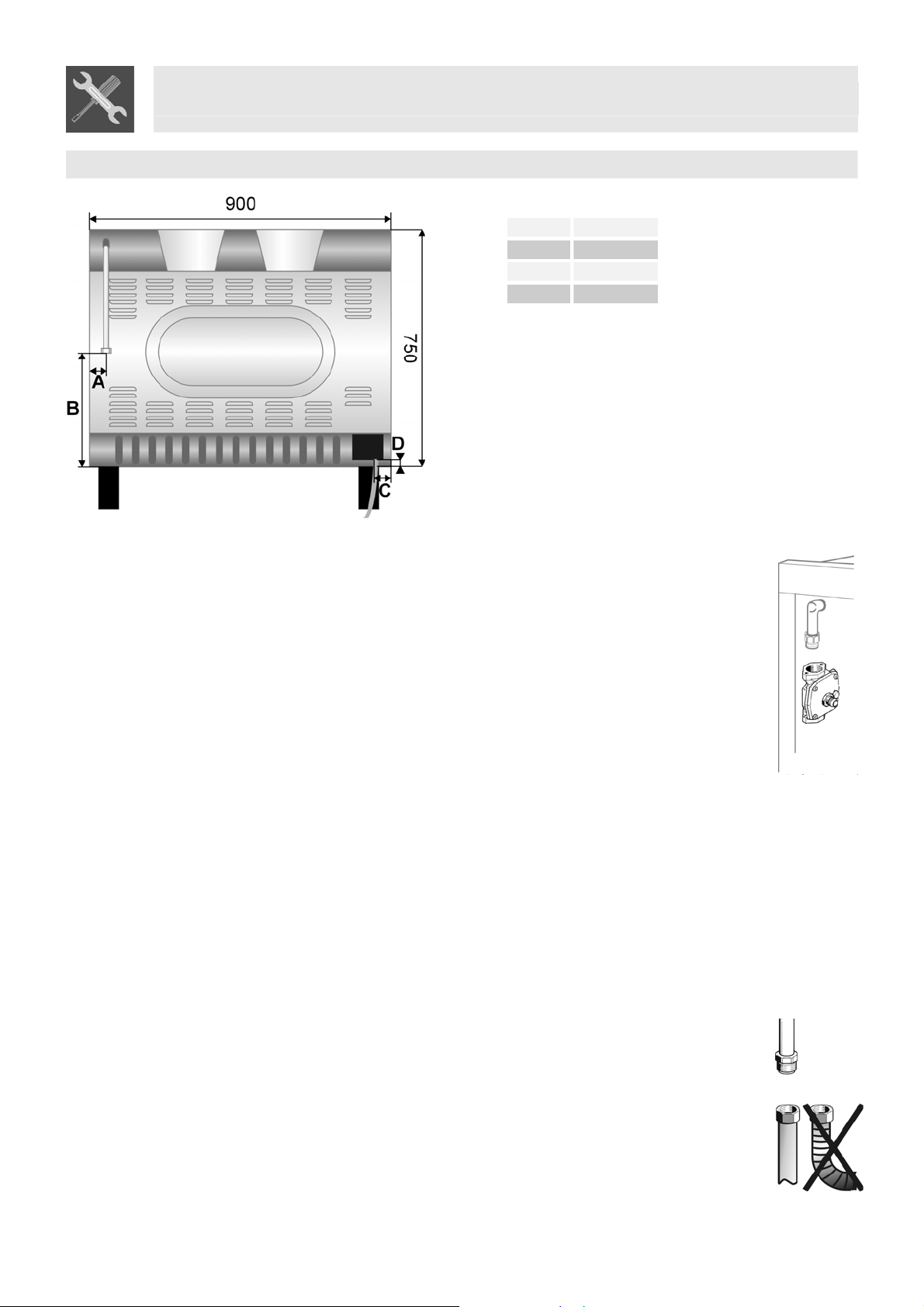

Overall dimensions: location of gas and electrical connection points (all measures in mm).

A 60

B 410

C 60

D 70

2.2 Gas connection

This appliance is suitable for installation with Natural Gas or LPG (propane). Refer to

page 12 for the relevant burner pressure and appropriate injector sizes. When the

appliance is to be connected to Natural Gas then the pressure regulator supplied

must be fitted to the gas inlet. A test point (for checking the gas pressure) is supplied

either with the regulator or as a separate fitting in the case of LPG (propane)

appliances.

Connection of the appliance to the gas supply must be in accordance with the

requirements of AS5601. A ½” BSP connector at the inlet is recommended and the

gas supply line to the appliance must be of adequate length to allow sufficient

withdrawal of appliance for service or disconnection and be annealed copper pipe.

The cooker must be installed with provision to allow the gas to be turned off and

disconnected for servicing and removal of the appliance as required from the gas

supply.

Before the cooker is operated make certain all relevant parts are placed in the

correct position.

When the installation is completed the installation connections of cooker will require

to be leak tested, the burner operating pressure and flame checked and adjusted.

Warranty service calls do not cover these adjustments!

To check the operating pressure of the appliance it is recommended at least 2 large

size burners are used. Ensure appliance is secured to wall when installation is

completed.

N.G. The regulator supplied must be fitted to the ½ BSP thread at the rear of the

appliance. An approved manual shut-off valve must be installed. The N.G. regulator

must be checked and adjusted to 1.0kPa after installation.

L.P.G. Can be connected to the inlet fitting directly. The pressure must be

checked to ensure it is operating at 2.75kPa. A separate test point fitting must

be installed between the piping & the appliance for the pressure to be checked

to ensure it is operating at 2.75kPa.

7

Instructions for the Installer

2.3 Room ventilation

Caution – This cooker may only be installed and operated in rooms permanently ventilated

in accordance with current regulations. For proper operation of a gas appliance it is

essential for the air necessary for combustion of the gas to be able to flow naturally into the

room. Air must flow directly into the room through openings in its outside walls. This (these)

opening (s) must have a free passage cross-section of at least 100 cm2, or 200 cm2 for

appliances not equipped with gas safety device. These openings must be constructed so

that they cannot be obstructed indoors or outdoors, and should preferably be close to the

floor on the side opposite to the combustion gas discharge point. If it is not possible to

make the openings in the room where the cooker is installed, the necessary air may be

taken from an adjoining room, proveded it is not a bedroom or a room with fire risk.

2.4 Clearance above and around domestic cookers

Extract from AS5601

8

REQUIREMENTS

1 Overhead clearances – (Measurement A)

Range hoods and exhaust fans shall be installed in accordance with the manufacturer’s

instructions. However, in no case shall the clearance between the highest part of the hob of the

cooking appliance and a range hood be less than 600 mm or, for an overhead exhaust fan, 750

mm.

Any other downward facing combustible surface less than 600 mm above the highest part of the

hob shall be protected for the full width and depth of the cooking surface area in accordance with

Clause 5.12.1.2. However, in no case shall this clearance to any surface be less than 450 mm.

2 Side clearances – (Measurements B & C)

Where B, measured from the periphery of the nearest burner to any vertical combustible surface, is

less than 200 mm, the surface shall be protected in accordance with Clause 5.12.1.2 to a height C

of not less than 150 mm above the hob for the full dimension (width or depth) of the cooking surface

area. Where the cooking appliance is fitted with a ‘splashback’, protection of the rear wall is not

required.

3 Additional requirements for Freestanding and Elevated Cooking Appliaces – (Measurements D & E)

Where D, the distance from the periphery of the nearest burner to a horizontal combustible surface

is less than 200 mm, then E shall be 10 mm or more, or the horizontal surface shall be above the

trivet. See insets above.

y

NOTES

1 Requirement 3 does not apply to a freestanding or elevated cooking appliance which is

2 The ‘cooking surface area’ is defined as that part of the appliance where cooking normally

3 For definition of hob, see Clause 1.4.64.

4 For definition of trivet, see Clause 1.4.109.

5 Consideration is to be given to window treatments when located near cooking appliances.

3 ADAPTING TO DIFFERENT TYPES OF GAS

Before carrying out the operations described below, disconnect the appliance from the electricit

supply.

Instructions for the Installer

designed to prevent flames or the cooking vessels from extending beyond the periphery of

the appliance.

takes place and does not include those parts of the appliance containing control knobs.

See Clause 5.3.4.

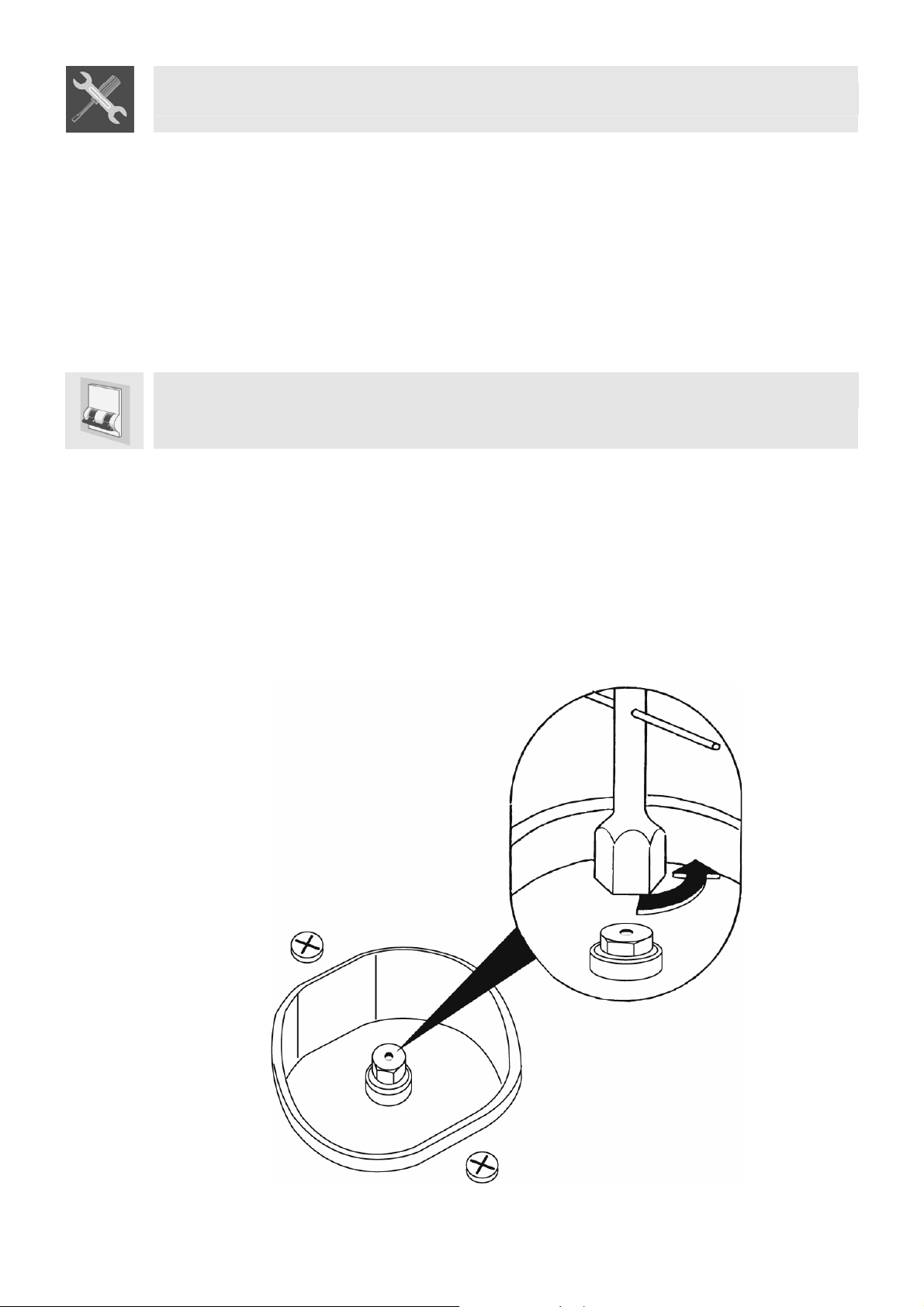

1. Remove the pan stands, all the burner caps and the flame diffuser rings

The hob of the cooker is adjusted for use with either natural gas at a pressure of 1.0kPa. If used with

other types of gas, you have to replace the nozzles, then adjust the minimum flame on the gas taps.

For nozzle replacement and burner adjustment operate as described in the following paragraph.

3.1 Changing the hob nozzles

2. Use a 7 mm socket wrench to unscrew the burner nozzles;

3. Replace the burner nozzles depending on the type of gas to be used (see point “3.2 Burner and

nozzle characteristics table").

4. Put the burners back into place correctly.

9

Instructions for the Installer

Burner

Nozzle

Auxiliary 1 50 30 350 73 71

Semi-rapid 1.75 65 33 450 127 125

Rapid 3 85 45 800 218 214

Triple Flame 4.2 66/66/46 * 60/30 1600 305 300

Triple Flame -

internal auxiliary

Oven 3.2 87 48 850 233 229

Maxi oven 5.2 110 59 1200 378 371

Grill 2.9 87 // // 218 214

Maxi grill 4.0 100 // // 291 286

*= the identical nozzles are the external ones. The smallest diameter nozzle is the central one

Burner

Nozzle diameter

Auxiliary 1 72 350

Semi-rapid 1.75 97 450

Rapid 3 115 800

Triple Flame 4.5 102/102/70 * 1600

Triple Flame -

internal auxiliary

Oven 3.2 130 850

Maxi oven 5.2 164 1200

Grill 2.9 130 //

Maxi grill 4.0 150 //

*= the identical nozzles are the external ones. The smallest diameter nozzle is the central one

3.2 Burner and Nozzle Data Tables

Nominal

heat

capacity

(kW)

By-pass

diameter

1/100 mm

0.9 46 30 350 73 71

Nominal

heat

capacity

(kW)

1/100 mm

1.0 70 350

mm

1/100

LPG (PROPANE) – 2.75 KPa

Reduced

heat capacity

(W)

NG – 2.0 KPa

Reduced heat capacity

Flow rate

g/h G30

(W)

Flow rate

g/h G31

10

Loading...

Loading...