Page 1

Contents

1. INSTRUCTIONS FOR PROPER USE ..................................................................................... 4

2. DISPOSAL INSTRUCTIONS – OUR ENVIRONMENT POLICY ............................................. 5

3. SAFETY PRECAUTION .......................................................................................................... 6

4. INTENDED USE OF THE APPLIANCE ................................................................................... 6

5. KNOW YOUR COOKER .......................................................................................................... 7

6. BEFORE FIRST USE .............................................................................................................. 7

7. USE OF THE HOB .................................................................................................................. 8

8. FRONT CONTROL PANEL ..................................................................................................... 9

9. USE OF THE OVEN .............................................................................................................. 10

10. AVAILABLE ACCESSORIES .............................................................................................. 12

11. CLEANING AND MAINTENANCE ....................................................................................... 13

12. EXTRAORDINARY MAINTENANCE ................................................................................... 15

13. PROBLEMS AND CAUSES ................................................................................................ 16

14. INSTALLATION OF THE APPLIANCE ................................................................................ 17

15. ADAPTATION TO DIFFERENT TYPES OF GAS ............................................................... 20

16. FINAL OPERATIONS .......................................................................................................... 21

Thank you for choosing our product.

We advise you to read this manual carefully. It contains all necessary instructions for maintaining

unaltered the appearance and functional qualities of the cooker.

INSTRUCTIONS FOR THE USER: these provide recommendations for use, a description of the controls

and the correct procedures for cleaning and maintaining the appliance

INSTRUCTIONS FOR THE INSTALLER: these are intended for the qualified engineer who is to install,

commission and test the appliance

3

Page 2

Instructions for proper use

1. INSTRUCTIONS FOR PROPER USE

THIS MANUAL IS AN INTEGRAL PART OF THE APPLIANCE AND THEREFORE MUST BE KEPT IN

ITS ENTIRETY AND IN AN ACCESSIBLE PLACE FOR THE WHOLE WORKING LIFE OF THE

COOKER. WE ADVISE READING THIS MANUAL AND ALL THE INSTRUCTIONS THEREIN BEFORE

USING THE COOKER. ALSO KEEP THE SERIES OF NOZZLES SUPPLIED. INSTALLATION MUST

BE CARRIED OUT BY QUALIFIED PERSONNEL IN ACCORDANCE WITH THE REGULATIONS IN

FORCE. THIS APPLIANCE IS INTENDED FOR DOMESTIC USES AND CONFORMS TO CURRENT

REGULATIONS IN FORCE. THE APPLIANCE HAS BEEN BUILT TO CARRY OUT THE FOLLOWING

FUNCTIONS: COOKING AND HEATING-UP OF FOOD. ALL OTHER USES ARE CONSIDERED

IMPROPER.

THE MANUFACTURER DECLINES ALL RESPONSIBILITY FOR IMPROPER USE.

NEVER USE THIS APPLIANCE FOR HEATING ROOMS.

DO NOT LEAVE THE PACKING IN THE HOME ENVIRONMENT. SEPARATE THE VARIOUS WASTE

MATERIALS AND TAKE THEM TO THE NEAREST SPECIAL GARBAGE COLLECTION CENTRE.

THIS APPLIANCE IS MARKED ACCORDING TO THE EUROPEAN DIRECTIVE 2002/96/EC ON

WASTE ELECTRICAL AND ELECTRONIC EQUIPMENT (WEEE).

THIS GUIDELINE IS THE FRAME OF A EUROPEAN-WIDE VALIDITY OF RETURN AND RECYCLING

ON WASTE ELECTRICAL AND ELECTRONIC EQUIPMENT.

DO NOT OBSTRUCT VENTILATION OPENINGS AND HEAT DISPERSAL SLITS.

THIS APPLIANCE IS DESIGNED FOR COOKING FOOD AND IT SHALL NOT BE USED AS A SPACE

HEATER.

THE I.D. PLATE WITH TECHNICAL DATA, REGISTRATION NUMBER AND BRAND NAME IS VISIBLY

POSITIONED IN THE STORAGE COMPARTMENT.

THE PLATE MUST NOT BE REMOVED.

DO NOT USE METALLIC SPONGES OR SHARP SCRAPERS: THEY WILL DAMAGE

THE SURFACE.

USE NORMAL NON-ABRASIVE PRODUCTS FOR STEEL, AND A WOODEN OR

PLASTIC TOOL IF NECESSARY.

RINSE THOROUGHLY AND DRY WITH A SOFT CLOTH OR DEERSKIN.

DO NOT ALLOW RESIDUES OF SUGARY FOODS (SUCH AS JAM) TO SET INSIDE THE

OVEN. IF LEFT TO SET FOR TOO LONG, THEY MIGHT DAMAGE THE ENAMEL LINING

OF THE OVEN.

The manufacturer declines all responsibility for damage to persons or things caused by nonobservance of the above prescriptions or by interference with any part of the appliance or by the use of

non-original spares.

4

Page 3

Safety instruction

2. DISPOSAL INSTRUCTIONS – OUR ENVIRONMENT POLICY

Our appliances are only packaged using non-pollutant, environment-friendly, recyclable materials. We

urge you to cooperate by disposing of the packaging properly. Contact your local dealer or the

competent local organisations for the addresses of collection, recycling and disposal facilities.

Never leave all or part of the packaging lying around. Packaging parts, and especially plastic bags, may

represent a suffocation hazard for children.

Your old appliance must also be disposed of properly.

Important deliver the appliance to your local organisation authorised to collect scrapped appliances.

Proper disposal allows the intelligent recovery of valuable materials. Refrigeration appliances contain

gases which may damage the environment; it is important to ensure that the refrigeration circuit

pipelines are not damaged until the competent service has taken delivery of the appliance.

Before scrapping your appliances it is important to remove doors and leave shelves in position as for

use, to ensure that children cannot accidentally become trapped inside during play. Also, cut the power

supply lead and remove it and the plug.

5

Page 4

Safety instruction

3. SAFETY PRECAUTION

ELECTRICAL CONNECTION: PLEASE REFER TO INSTALLATION INSTRUCTION FOR THE GAS &

ELECTRICAL SAFETY REGULATIONS AND THE VENTILATION REQUIREMENTS.

IN YOUR OWN INTEREST, AND THAT OF SAFETY, IT IS THE LAW THAT ALL GAS APPLIANCES BE

INSTALLED AND SERVICE BY COMPETENT PERSONS, WHO WILL COMPLY WITH THE

RELEVANT STANDARDS AND REGULATIONS.

CORGI REGISTERED INSTALLERS UNDERTAKE TO WORK TO SATISFCTIORY STANDARDS.

DISCONNECTION OF GAS AND ELECTRIC APPLIANCES SHOULD ALWAYS BE CARRIED OUT BY

COMPETENT PERSON.

THE PLUG TO BE CONNECTED TO THE POWER CABLE AND THE SOCKET MUST BE THE SAME

TYPE AND MUST CONFORM TO CURRENT REGULATIONS.

THE SOCKET MUST BE ACCESSIBLE AFTER THE APPLIANCE HAS BEEN BUILT IN.

NEVER UNPLUG BY PULLING ON THE CABLE.

DO NOT INSTALL THIS APPLIANCE ON A RAISED PLATFORM.

IT IS COMPULSORY THAT THE APPLIANCE BE GROUNDED ACCORDING TO THE METHODS

REQUIRED BY SAFETY RULES.

IMMEDIATELY AFTER INSTALLATION CARRY OUT A BRIEF INSPECTION TEST OF THE

APPLIANCE, FOLLOWING THE INSTRUCTIONS BELOW. SHOULD THE APPLIANCE NOT

FUNCTION, DISCONNECT IT FROM THE SUPPLY AND CALL THE NEAREST TECHNICAL

ASSISTANCE CENTRE. NEVER ATTEMPT TO REPAIR THE APPLIANCE.

DO NOT PUT PANS WITHOUT PERFECTLY SMOOTH AND FLAT BOTTOMS ON THE HOB GRIDS.

DO NOT USE CONTAINERS OR BROILERS THAT EXTEND BEYOND THE OUTER PERIMETER OF

THE HOB.

NEVER PUT INFLAMMABLE OBJECTS IN THE OVEN: THEY COULD BE ACCIDENTALLY LIGHTED

AND CAUSE FIRES.

DURING USE THE APPLIANCE BECOMES VERY HOT. TAKE CARE NOT TO TOUCH THE HEATING

ELEMENTS INSIDE THE OVEN.

THE APPLIANCE IS DESIGNED FOR USE BY ADULTS. DO NOT ALLOW CHILDREN TO GO NEAR

OR PLAY WITH IT.

WHEN OPERATING THE GRILL ALL ACCESSIBLE PARTS COULD BECOME VERY HOT: KEEP OUT

OF THE WAY OF CHILDREN.

WHEN NOT IN USE, MAKE SURE THAT THE CONTROL KNOBS ARE IN THE CORRECT (OFF)

POSITION .

DO NOT SPRAY AEROSOLS IN THE VICINITY OF THIS APPLIANCE WHILE IT IS IN OPERATION.

BEFORE THE APPLIANCE IS PUT INTO OPERATION, ALL THE LABELS AND PROTECTIVE FILMS

APPLIED INSIDE OR OUTSIDE MUST BE REMOVED.

4. INTENDED USE OF THE APPLIANCE

THE APPLIANCE HAS BEEN BUILT TO CARRY OUT THE FOLLOWING FUNCTIONS: COOKING

AND HEATING-UP OF FOOD. ALL OTHER USES ARE CONSIDERED IMPROPER.

The manufacturer declines all responsibility for damage to persons or things caused by nonobservance of the above prescriptions or by interference with any part of the appliance or by the use of

non-original spares.

6

Page 5

Instructions for the user

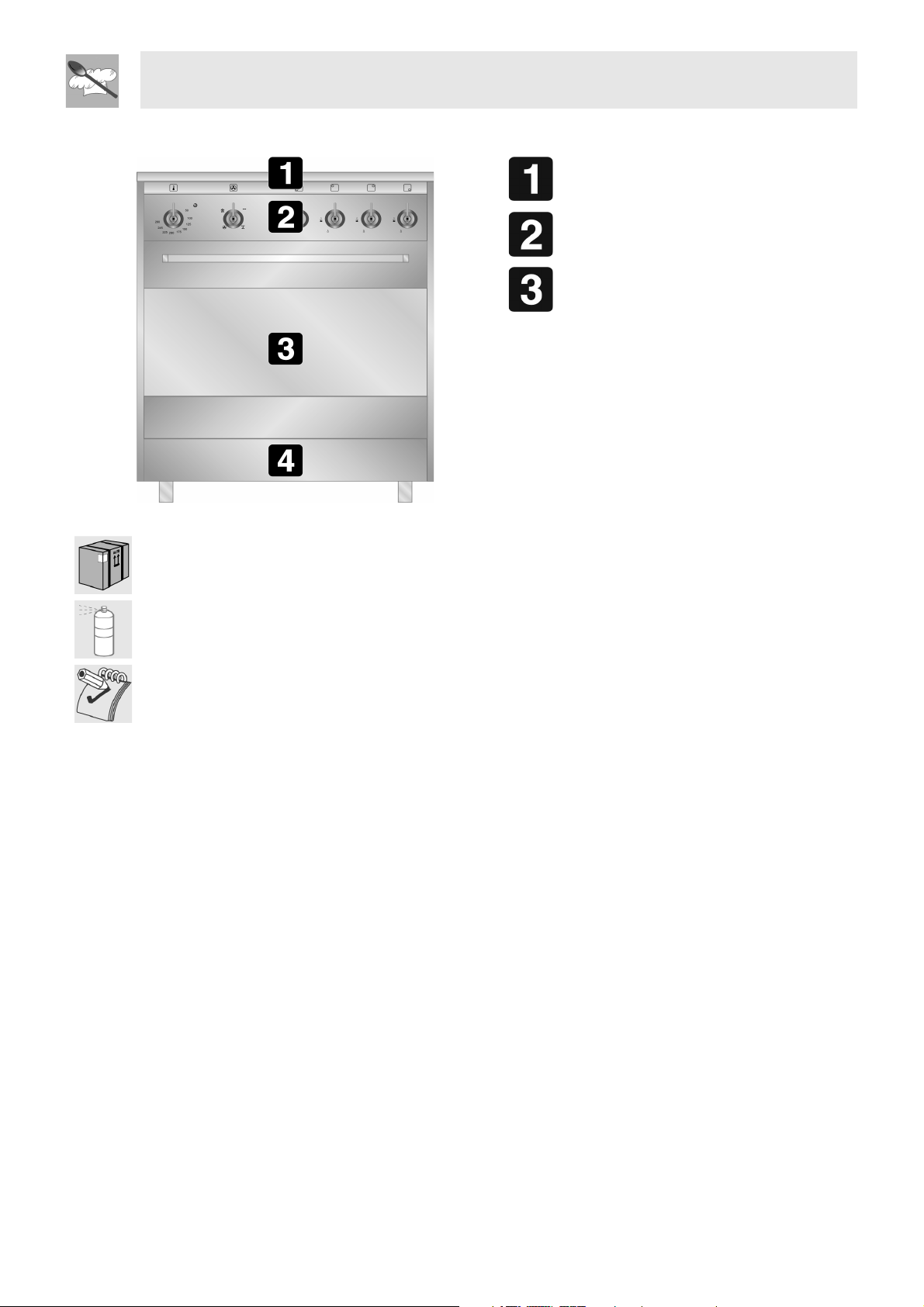

5. KNOW YOUR COOKER

COOKING HOB

CONTROL PANEL

MAIN OVEN

6. BEFORE FIRST USE

Do not leave the packing in the home environment. separate the various waste materials and take them to

the nearest special garbage collection centre.

The inside of the appliance should be cleaned to remove all manufacturing residues. For further

information about cleaning, see section "11. CLEANING AND MAINTENANCE"

Using the oven and the grill for the first time, heat them to the maximum temperature (260°C) for as long

as it takes to burn off any production oil residues which could give a nasty flavour to the food.

7

Page 6

Instructions for the user

7. USE OF THE HOB

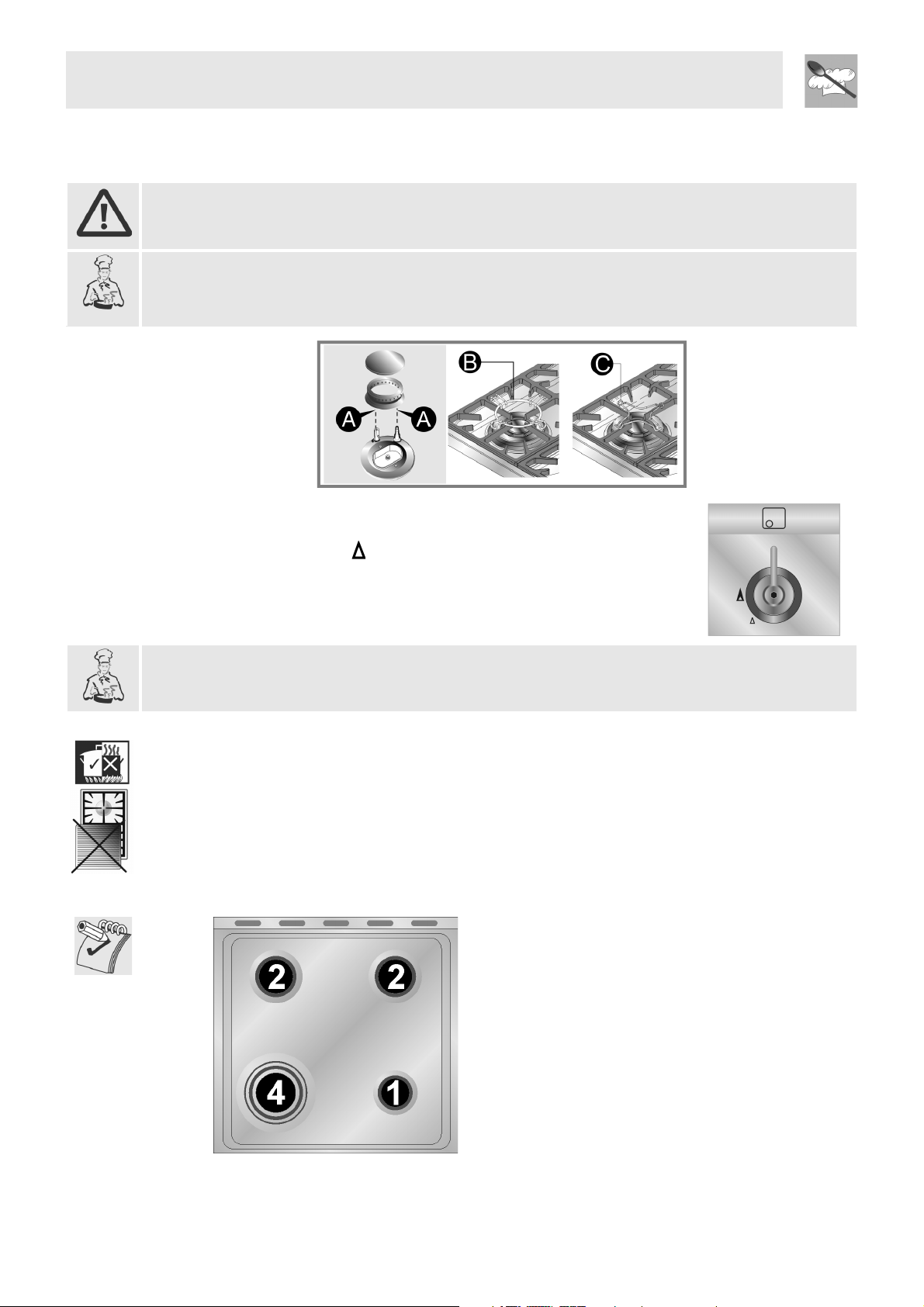

7.1 Lighting of the hob burners

Before lighting the hob burners check that the flame caps are in the correct position and that

their burner caps are in place, making sure that the holes A in the flame caps correspond to the

spark plugs and thermocouples.

The optional grid B is for use with “woks” (Chinese pans).

To prevent deterioration of the hob we have equipped the cooker with a raised pan stand C to be placed

underneath pans more than 26 cm in diameter.

The supplied reduction rest C is used also for small pans.

The drawing next to each knob shows the corresponding burner. The appliance

has an electronic lighting device. Simply press and turn the knob anticlockwise

to the minimum flame symbol , until the flame is lit. Hold the knob down for a

few seconds to allow the thermocouples to heat up. The burner may go out

when the knob is released: this is because the thermocouple has not been

sufficiently heated. Repeat the operation holding down the knob a little longer.

This operation is not necessary for burners without thermocouples.

For models with thermocouples, should the burner accidentally go out, a safety device will be activated

which stops the gas flow even if the tap is open.

7.2 Practical advice for using the hob burners

For better use of the burners and lower gas consumption, use covered vessel that are proportional in

size to the burner to prevent the flame from licking the sides (see paragraph “ 7.3 Diameter of the

vessels to be used on each burner”). When water reaches the boiling point, lower the flame so that it

doesn’t overflow. To avoid burns or damage to the hob, all vessels or griddle plates must be placed within

the perimeter of the hob. All vessels must have a flat and smooth bottom. When using fats or oils, be

extremely careful that they don’t overheat and catch fire.

If the flame accidentally goes out, turn off the control knob and wait at least 1 minute before trying to relight the burner.

7.3 Diameter of the vessels to be used on each burner

BURNERS

1. Auxiliary

2. Semirapid

4. WOK

Ø MIN. AND MAX. (IN CM.)

12 - 14

16 - 24

18 - 26

8

Page 7

Instructions for the user

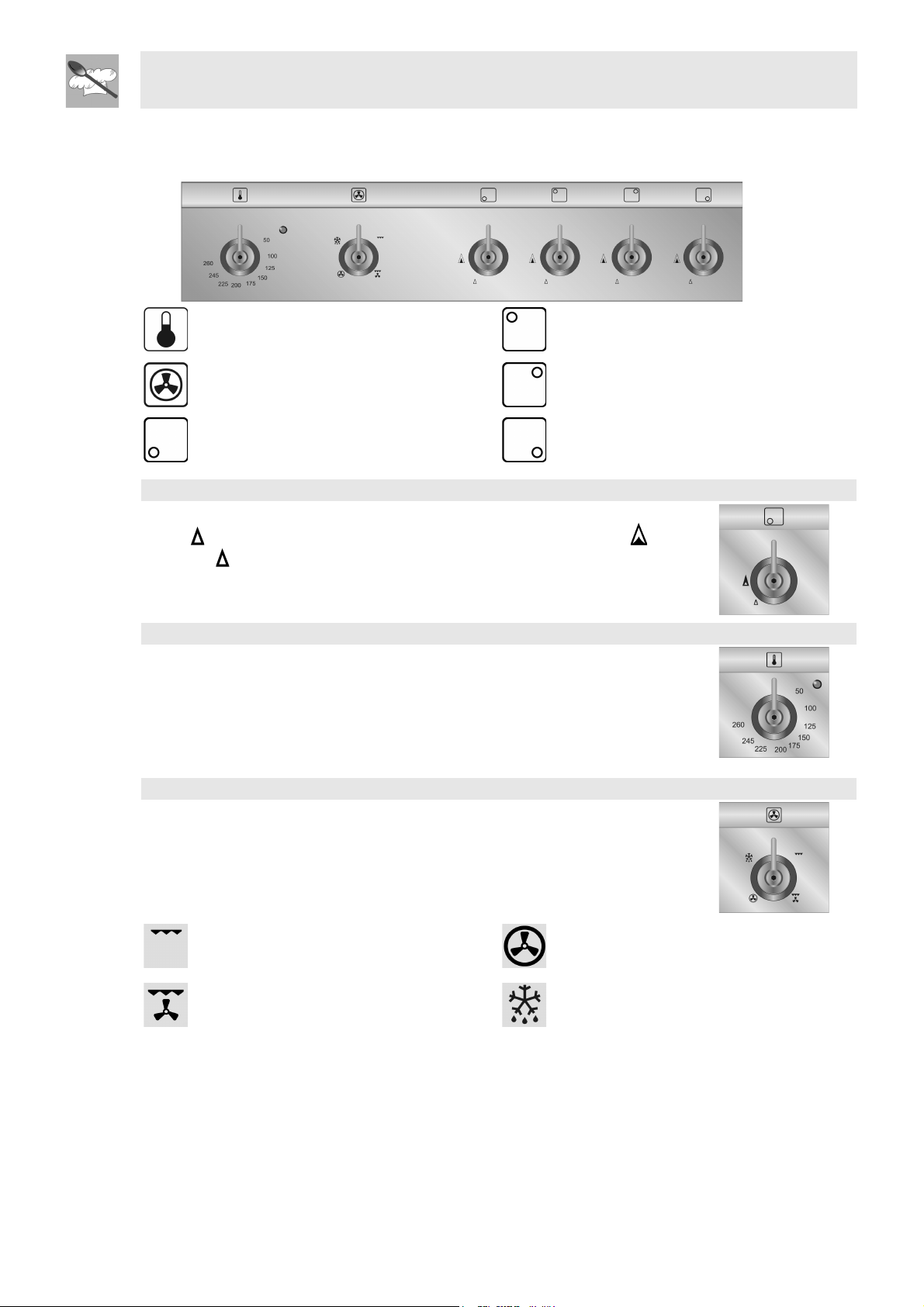

8. FRONT CONTROL PANEL

All the cooker controls and commands are on the front panel.

ELECTRIC OVEN THERMOSTAT REAR LEFT BURNER

ELECTRIC OVEN FUNCTION KNOB REAR RIGHT BURNER

FRONT LEFT BURNER FRONT RIGHT BURNER

HOB BURNER COMMAND KNOB

The flame is lit by pressing the knob and turning it anticlockwise to minimum

flame . To adjust the flame turn the knob between maximum ( ) and

minimum ( ). The burner goes out when the knob is returned to the position.

MAIN OVEN THERMOSTAT KNOB

Selection of cooking temperature is carried out by turning the knob clockwise to

the required temperature, between 50° and 260°C.

If the appliance has an electric oven, the warning light will come on when the

oven is heating up. When it goes out it means that the required temperature has

been reached. Regular flashing means that oven temperature is being

constantly maintained at the programmed level.

MAIN OVEN CONTROL KNOB

Each of the functions listed below can be used (except the oven light and the

small grill) only together with the correct temperature thermostat regulation as

described on page of this manual.

GRILL ELEMENT VENTILATED HEATING ELEMENT +

VENTILATION

GRILL ELEMENT + VENTILATION DEFROSTING

9

Page 8

Instructions for the user

9. USE OF THE OVEN

9.1 Warnings and general advice

Using the oven and the grill for the first time, heat them to the maximum temperature (260°C) for as long

as it takes to burn off any production oil residues which could give a nasty flavour to the food.

During cooking, do not cover the bottom of the oven with aluminium or tin foil and do not place pans or

oven trays on it as this may damage the enamel coating. If you wish to use greaseproof paper, place it

so that it will not interfere with the hot air circulation inside the oven.

Oven accessories which may come into contact with foods are made from materials complying with the

requirements of the current directive.

To prevent problems caused by steam in the oven, open the door in two stages:

half open (5 cm approx.) for 4-5 seconds and then fully open.

To access food, always leave the door open as short a time as possible to

prevent the temperature in the oven from falling and ruining the food.

9.2 Cooling system

The oven is equipped with a cooling system which automatically comes on upon a few minutes after the

oven has been turned on.

Fans cause a steady outflow of air from above the door which may continue for a brief period of time

even after the oven has been turned off.

9.3 Use of the electric grill

For short cooking procedures, such as the final crisping of meat which is already cooked, select the

static grill function and turn the thermostat knob to the maximum temperature. The fan grill function

allows actual cooking procedures to be carried out, thanks to the fan function which ensures that the

heat penetrates into the food. For this cooking mode, select the fan grill function and turn the

thermostat knob to the ideal cooking temperature (never set at more than 220). Cooking procedures in

this mode must never last more than 60 minutes.

All cooking with the grill and grill + spit must be done with the door closed to prevent the knobs

and the front panel of the equipment to overheat.

Failure to do this will void the warranty.

9.3.1 How to use the grill

Food should be flavoured and basted with oil or melted butter before cooking. An oven dish should be

used to contain the sauces. The food should be placed on the oven shelf which is positioned on one of

the guides supplied with the different ovens, following the instructions below:

FOOD GRILLE ON THE SHELF

Flat or thin meat 3

10

Rolled roast joints 2 - 3

Poultr y 2 - 3

Page 9

Instructions for the user

9.4 WARNING

• Cooking procedures in this mode must never last more than 60 minutes.

• In models with electric oven, the door must be close during grilling and grill-rotisserie cooking.

• To avoid dangerous overheating when the oven or the grill is used, the glass cover must always be

up.

• During and after use the accessible parts of the oven may be very hot, and children must always be

kept at a distance.

• During cooking with the rotisserie, one of the oven trays provided with the cooker should be placed in

the bottom of the oven, inserting it on the bottom runners, in order to collect the grease and fats which

may be formed.

• When using the oven, remove all unused baking sheets and shelves from the interior.

11

Page 10

Instructions for the user

10.AVAILABLE ACCESSORIES

The oven has 4 support for positioning plates and racks at various

heights.

Oven grill: for cooking food on plates, small cakes, roasts or food

requiring light grilling.

Plate grill: for placing above plate for cooking foods that might drip.

Oven plate: useful for catching fat from foods on the grill above.

Pastry plate: for baking cakes, pizza and oven desserts.

Some models do not feature all accessories.

12

Page 11

Instructions for the user

11.CLEANING AND MAINTENANCE

NEVER USE A STEAM JET TO CLEAN THE APPLIANCE.

11.1 Cleaning stainless steel

To maintain stainless steel in good condition clean it regularly after each use, once it has cooled down.

11.2 Ordinary daily cleaning

To clean and preserve the stainless steel surfaces, always use only specific products that do not contain

abrasives or chlorine-based acids.

How to use: pour the product on a damp cloth and wipe the surface, rinse thoroughly and dry with a soft

cloth or deerskin.

11.3 Food stains or residues

Do not use metallic sponges or sharp scrapers: they will damage the surface.

Use normal non-abrasive products for steel, and a wooden or plastic tool if necessary.

Rinse thoroughly and dry with a soft cloth or deerskin.

Do not allow residues of sugary foods (such as jam) to set inside the oven. If left to set for too

long, they might damage the enamel lining of the oven.

11.4 Cleaning of the hob components

11.4.1Grids

Remove the grids and clean them in warm water with a non-abrasive detergent, taking care to remove

any encrustations. Replace them on the hob.

Continuous contact of the grids with the flame can cause the enamel near the hot areas to be altered.

This is completely natural and does not compromise the functionality of the component.

11.4.2Burner caps and flame cap crowns

The caps and flame-spreader crowns are extractable to facilitate cleaning. Wash

them in hot water with non-abrasive detergent, taking care to remove any

encrustations, and wait until they are perfectly dry.

WARNING: do not wash these components in the dishwasher.

The burners can be left to soak in hot water and detergent.

Replace the flame-spreader crowns, checking that they are positioned in their

housing with their respective caps, taking care that flame-spreader holes A

correspond to the spark plugs and the thermocouples.

11.4.3The spark plugs and thermocouples

To function properly the spark plugs and thermocouples must always be clean (on the

models which are equipped with them). Check them regularly and clean with a damp

cloth if necessary. Any dry residues can be removed with a toothpick or a needle.

13

Page 12

Instructions for the user

11.5 Cleaning of oven

For best oven upkeep clean regularly after having allowed to cool. Take out all removable parts.

• Clean the oven grill with hot water and non-abrasive detergent. Rinse and dry.

• Do not allow residues of sugary foods (such as jam) to set inside the oven. If left to set for too long,

they might damage the enamel lining of the oven.

11.6 Door glass

The door glass should always be kept clean. Use absorbent kitchen paper to clean. In case of tough

spots, clean with a damp sponge using regular detergent.

When cleaning, the appliance must be dried thoroughly since detergent and water drips might damage

its operation and appearance.

14

Page 13

Instructions for the user

12.EXTRAORDINARY MAINTENANCE

The oven may require extraordinary maintenance or replacement of parts subject to wear such as seals,

bulbs, and so on. The following instructions describe how to carry out these minor maintenance

operations.

Before any intervention, disconnect the power supply of the device.

12.1 Lubrication of the taps

In time the taps may be difficult to turn or may be blocked. Clean them inside and replace the lubrication

grease. This operation should be carried out by a specialised technician.

12.2 Replacement of light bulb

Remove cover A by twisting anticlockwise, replace bulb B with another similar bulb (25 W). Refit the

cover A.

Only use oven bulbs (T 300°C).

12.3 Removing the door

Hold the door on both sides with both hands near hinges A and

raise levers B. Lift up the door forming an angle of about 45° and

remove. To refit, slide the hinges A in the grooves, drop the door

and release levers B.

12.4 Oven door gaskets

To permit thorough cleaning of the oven, the seal may be removed. Before

removing the seal, take off the door as described above. Once the door has

been taken off, lift the tabs at the corners as shown in the figure.

15

Page 14

Instructions for the user

12.5 Preventive maintenance

This appliance does not need any special maintenance. However, a few simple operations have to be

carried out periodically to prevent malfunctioning:

Burners: the burners must be cleaned after every use to ensure correct combustion; make sure that all

the openings and flame ports are clean and free of obstacles, and that the burners rest firmly on their

supports.

Gas connection: the gas connection must be checked periodically (at least every 2 years). Each time

the cooker is moved the connection may be stressed: test it for leakages using special sprays or a

solution of soap and water.

Flexible pipes: if a flexible pipe is used, it must be inspected periodically (once a year) for leakages: if

the surface of the pipe appears rigid and cracked, disconnect immediately the cooker from the gas

supply and replace the pipe with a new one.

Val ves: if the gas valves get stuck or hard to turn, they need to be cleaned and re-greased; this

operation must be carried out by an authorised person

Oven gasket: with time the oven gasket may harden and crack on the surface, resulting in leakage of

heat from the oven and higher temperatures on the control panel and knobs. Check it periodically (once

a year) and replace it if necessary.

13.PROBLEMS AND CAUSES

Each of the following cases is caused by an abnormal operation of the appliance and should be dealt

with by a authorised person: please contact your local dealer or Service Center in case you detect any of

these malfunctioning.

PROBLEM CAUSE WHAT TO DO

The flame is very long with bright

yellow tips.

Black deposits on the bottom of the

pans.

The flame is very short and noisy.

The flame moves away from the

burner ports.

Defect of comburent air or

incorrect injectors.

Excess of comburent air. Call Service Center.

Call Service Center.

The flame extinguishes when the

burner knob is set to the low flame

position.

The valve knob is hard to rotate. Gas valve worn out or needs

The cooker suddenly stops

working during operation of the

oven.

The electronic programmer is not

operating.

Overheating of the appliance.

Incorrect adjustment of the

minimum heat input or excess of

comburent air.

lubrification.

Overheating of the appliance. Let the appliance cool down: the

Call Service Center

Call Service Center.

safety thermal cut-out will selfreset when the temperature has

decreased to a correct value.

Should the problem arise again,

call the Service Center.

16

Page 15

Instructions for the user

14.INSTALLATION OF THE APPLIANCE

It is the law that all gas appliances are installed by authorised persons. Clearance around the cooker

must comply with the requirements of AS5601.

14.1 Electrical connection

Make sure that the power line voltage matches the specifications indicated on the rating plate located

inside the storage compartment.

This rating plate must never be removed.

On the power line, install a two-pole cut-off device with contact cut-off distance greater than or equal to 3

mm, located in an easily accessible position near the unit.

The wire section on the cable must not be less than 2.5 mm 2 (3 x

2.5 cable), keeping in mind that the end to be connected to the

cooker must have the ground wire (yellow-green) longer by at least

20 mm. Use only the special cables available at our Service Centres.

The manufacturer declines all responsibility for damage to persons or things caused by nonobservance of the above prescriptions.

Overall dimensions: location of gas and electrical connection points (all measures in mm).

A 60

B 410

C 100

D 140

17

Page 16

Instructions for the user

14.2 Gas connection

This appliance is suitable for installation with Natural Gas or LPG (propane).

Refer to page 12 for the relevant burner pressure and appropriate injector sizes.

When the appliance is to be connected to Natural Gas then the pressure regulator

supplied must be fitted to the gas inlet. A test point (for checking the gas

pressure) is supplied either with the regulator or as a separate fitting in the case

of LPG (propane) appliances.

Connection of the appliance to the gas supply must be in accordance with the

requirements of AS5601. A ½” BSP connector at the inlet is recommended and

the gas supply line to the appliance must be of adequate length to allow sufficient

withdrawal of appliance for service or disconnection and be annealed copper

pipe.

The cooker must be installed with provision to allow the gas to be turned off and

disconnected for servicing and removal of the appliance as required from the gas

supply.

Before the cooker is operated make certain all relevant parts are placed in the

correct position.

When the installation is completed the installation connections of cooker will require to be leak tested,

the burner operating pressure and flame checked and adjusted.

Warranty service calls do not cover these adjustments!

To check the operating pressure of the appliance it is recommended at least 2 large size burners are

used. Ensure appliance is secured to wall when installation is completed.

N.G. The regulator supplied must be fitted to the ½ BSP thread at the rear of the appliance. An approved

manual shut-off valve must be installed. The N.G. regulator must be checked and adjusted to 1.0 kPa

after installation.

L.P.G. Can be connected to the inlet fitting directly. The pressure must be

checked to ensure it is operating at 2.75 kPa. A separate test point fitting must be

installed between the piping & the appliance for the pressure to be checked to

ensure it is operating at 2.75 kPa.

18

14.3 Room ventilation

Caution – This cooker may only be installed and operated in rooms permanently ventilated in

accordance with current regulations. For proper operation of a gas appliance it is essential for the air

necessary for combustion of the gas to be able to flow naturally into the room. Air must flow directly into

the room through openings in its outside walls.

This (these) opening (s) must have a free passage cross-section of at least 100 cm

appliances not equipped with gas safety device. These openings must be constructed so that they

cannot be obstructed indoors or outdoors, and should preferably be close to the floor on the side

opposite to the combustion gas discharge point. If it is not possible to make the openings in the room

where the cooker is installed, the necessary air may be taken from an adjoining room, proveded it is not

a bedroom or a room with fire risk.

2

, or 200 cm 2 for

14.4 Clearance above and around domestic cookers

Page 17

Instructions for the installer

14.5 Clearance above and around domestic cookers

Extract from AS5601

REQUIREMENTS

1 Overhead clearances – (Measurement A)

Range hoods and exhaust fans shall be installed in accordance with the manufacturer’s instructions.

However, in no case shall the clearance between the highest part of the hob of the cooking appliance

and a range hood be less than 600 mm or, for an overhead exhaust fan, 750 mm.

Any other downward facing combustible surface less than 600 mm above the highest part of the hob

shall be protected for the full width and depth of the cooking surface area in accordance with Clause

5.12.1.2. However, in no case shall this clearance to any surface be less than 450 mm.

2 Side clearances – (Measurements B & C)

Where B, measured from the periphery of the nearest burner to any vertical combustible surface,is

less than 200 mm, the surface shall be protected in accordance with Clause 5.12.1.2 to a height C of

not less than 150 mm above the hob for the full dimension (width or depth) of the cooking surface

area. Where the cooking appliance is fitted with a ‘splashback’, protection of the rear wall is not

required.

3 Additional requirements for Freestanding and Elevated Cooking Appliaces – (Measurements D & E)

Where D, the distance from the periphery of the nearest burner to a horizontal combustible surface is

less than 200 mm,then E shall be 10 mm or more, or the horizontal surface shall be above the trivet.

See insets above.

NOTES

1 Requirement 3 does not apply to a freestanding or elevated cooking appliance which is designed

to prevent flames or the cooking vessels from extending beyond the periphery of the appliance.

2 The ‘cooking surface area’ is defined as that part of the appliance where cooking normally takes

place and does not include those parts of the appliance containing control knobs.

3 For definition of hob, see Clause 1.4.64.

4 For definition of trivet, see Clause 1.4.109.

5 Consideration is to be given to window treatments when located near cooking appliances. See

Clause 5.3.4.

19

Page 18

Instructions for the installer

A

A

170

900

BB

14.6 Instruction for wall fixing

1 Fasten the two wall brackets to the wall taking care to comply with the centre distances and

measurements indicated in the images below. The dimensions are given in mm.

A= 262 / B = 168

2 Attach the chain to the cooker 3 Stretch out the chain attached to the cooker horizontally so that the other end touches the wall. 4 Mark the wall in the position where the hole is to be drilled. 5 Drill the hole, insert a wall plug and attach the chain.

20

6 Once these operations are completed, push the appliance against the wall taking care to insert the

wall brackets correctly in the slots on the back of the cooker.

Page 19

Instructions for the installer

15.ADAPTATION TO DIFFERENT TYPES OF GAS

Before performing any cleaning or maintenance work, disconnect the appliance from the mains.

The hob of the cooker is adjusted for use with either natural gas at a pressure of 1.0kPa. If used with

other types of gas, you have to replace the nozzles, then adjust the minimum flame on the gas taps. For

nozzle replacement and burner adjustment operate as described in the following paragraph.

15.1 Replacement of nozzles on the hob

This operation requires no primary air regulation.

1 Extract the grids and remove all the caps and flame-spreader crowns;

2 Unscrew the burner nozzles with a 7 mm socket wrench;

3 Replace the nozzles according to the type of gas to be used and the description in paragraph "15.2

Burner and nozzle characteristics table ";

4 Replace the burners in the correct position.

21

Page 20

Instructions for the installer

15.2 Burner and nozzle characteristics table

Burner LPG (PROPANE)–2.75 KPA

NOMINAL GAS

CONSUMPTION

(MJ/H)

Auxiliary 3.9 1.5 0.54

Semi rapid 6.3 1.5 0.68

WOK 12.8 5.4 1.00

Burner NG –1.0 KPA

NOMINAL GAS

CONSUMPTION

(MJ/H)

Auxiliary 3.9 1.5 0.90

Semi rapid 6.5 1.5 1.20

WOK 15.0 5.4 1.75

TURN-DOWN GAS

CONSUMPTION

(MJ/H)

TURN-DOWN GAS

CONSUMPTION

(MJ/H)

INJECTOR

(MM)

INJECTOR

(MM)

15.3 Arrangement of the burners on the hob

BURNERS

1 Auxiliary

2Semi rapid

ø min e max (in cm.)

12 - 14

16 - 24

3WOK

18 - 26

22

Page 21

Instructions for the installer

16.FINAL OPERATIONS

After replacing the nozzles, reposition the flame-spreader crowns, the burner caps and the grids.

Following adjustment to a gas other than the preset one, replace the gas adjustment label fixed to the

appliance with the one corresponding to the new gas. This label is in the packet together with the

nozzles.

16.1 Regulation of the hob burner minimum level for natural gas

Light the burner and turn it to the minimum position . Remove the gas tap knob

and adjust the regulator screw inside or beside the tap rod (depending on the

model) until an even minimum flame is obtained. Put the knob back in place and

check the stability of the burner flame (the flame must not go out when the knob

is turned quickly from the maximum to the minimum setting). Repeat the

operation on all the gas taps.

For models with valves, keep the knob at minimum level for about 1 minute to keep the flame lit and to

activate the safety device.

16.2 Mounting the rear top skirtboard (where applicable)

• Loosen screws A located beneath the skirt.

• Loosen nuts B.

• Position the skirt above the top, taking care to align pins C with

holes D.

• Secure the skirt to the top by tightening screws E.

16.3 Wall fixing (where applicable)

• Stretch out the chain attached to the cooker horizontally so that

the other end touches the wall.

• Mark the wall in the position where the hole is to be drilled.

• Drill the hole, insert a wall plug and attach the chain.

• Move the cooker up against the wall.

23

Page 22

914772495/ E

Loading...

Loading...