Page 1

SMR130G SMR315G

USER AND MAINTENANCE MANUAL

Page 2

Rev. 01

User and maintenance manual

2

Smeg S.p.A. – Instruments Division

Via Leonardo da Vinci, 4

42016 Guastalla (RE)

www.smeg-instruments.com

READ CAREFULLY

This manual constitutes an integral part of the refrigerating unit.

It must be kept intact and at hand for the entire life cycle of the machine. It is necessary to read the

following manual carefully prior to using the device. Failure to read or thoroughly comprehend the

instructions in this manual may cause the device to malfunction and present hazards to the user.

Machine installation, maintenance, and repair operations must be performed

by authorized technical staff.

Repair operations performed by unauthorized staff, besides leading

invalidating the product warranty, can be source of danger for the user.

In case of replacement, an original spare part must be used.

If the device was not used in accordance to the instructions presented in this

manual, the product may no longer be covered by warranty and the safety of

this device could be compromised.

The producer declines all liability for any use that differs from what indicated in

the present manual.

The refrigerating unit has not to be used in presence of explosive gases or near

sources with high electronic or magnetic fields.

The content of this manual is for information purposes only. The content and the equipment

described here may be subject to change without notification. The colours used in photographs of

the product (finishing panels), in diagrams and in screenshots are all purely guideline.

Page 3

Rev. 01

User and maintenance manual

3

SUMMARY

Products applicable to this manual ....................................................................................................................... 4

Table of capacity and dimensions ........................................................................................................................ 4

Table of technical specifications ........................................................................................................................... 5

Standard and optional fitting ................................................................................................................................. 5

1 STANDARDS AND GENERAL WARNINGS .............................................................................................. 6

1.1 Certification ............................................................................................................................................. 6

1.2 Initial recommendations .......................................................................................................................... 6

1.3 Precautions for use ................................................................................................................................. 9

1.4 Aim, content and intended user of this manual ...................................................................................... 9

1.5 General safety regulations .................................................................................................................. 100

1.6 Customer responsibilities...................................................................................................................... 10

1.7 Customer service requests ................................................................................................................... 11

1.8 Ordering of spare parts ......................................................................................................................... 11

1.9 Aim and intended use of device ........................................................................................................... 11

1.10 Unsuitable conditions for use ............................................................................................................... 11

2 INSTALLATION ........................................................................................................................................ 12

2.1 Transport and handling ......................................................................................................................... 12

2.2 Positioning ............................................................................................................................................ 12

2.3 Wiring and electrical hook-up ............................................................................................................... 13

2.4 Set-up operations ................................................................................................................................. 13

2.5 Re-installation ....................................................................................................................................... 14

2.6 Scrapping and disposal ........................................................................................................................ 14

3 OPERATION ............................................................................................................................................. 15

3.1 Safety and accident prevention ............................................................................................................ 15

3.2 Safety dataplates and guards ............................................................................................................... 15

3.3 Operating limits ..................................................................................................................................... 15

3.4 Environmental storage conditions ........................................................................................................ 15

4 USER INSTRUCTIONS ............................................................................................................................ 16

4.1 Appliance start-up ................................................................................................................................. 18

4.2 Functions .............................................................................................................................................. 18

4.3 Control panel ...................................................................................................................................... 200

4.4 Alarm codes .......................................................................................................................................... 26

4.5 Troubleshooting .................................................................................................................................... 27

5 ROUTINE MAINTENANCE ...................................................................................................................... 28

5.1 Cleaning of the refrigerator ................................................................................................................... 28

5.2 Cleaning of the interior and exterior ..................................................................................................... 29

5.3 Cleaning of the condenser .................................................................................................................... 29

5.4 Precautions for prolonged disuse ......................................................................................................... 30

6 ELECTRICAL DIAGRAM .......................................................................................................................... 31

7 AFTER-SALES SERVICE .............................................................. Errore. Il segnalibro non è definito.3

Page 4

Rev. 01

User and maintenance manual

4

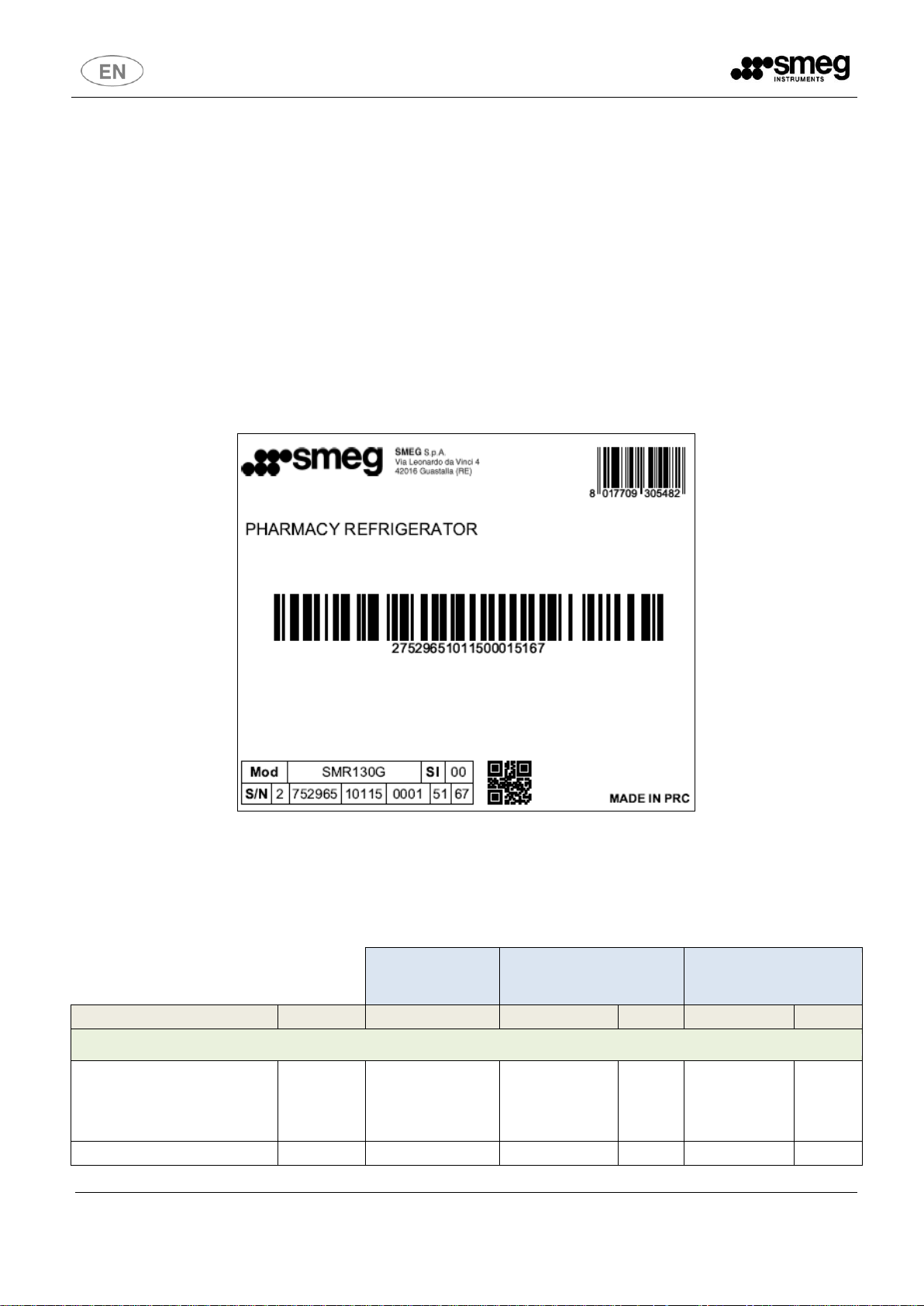

Products applicable to this manual

The present manual is exclusively valid and applicable to the following SMEG product series.

Laboratory refrigerators SMR series

Adjustable temperature control range: highest T = +10°C, lowest T = +2°C

Models:

SMR130G

SMR315G

All relevant data referring to SMEG products can be found on the data label visible on the side part of the

cabinet. Here is an example of the label:

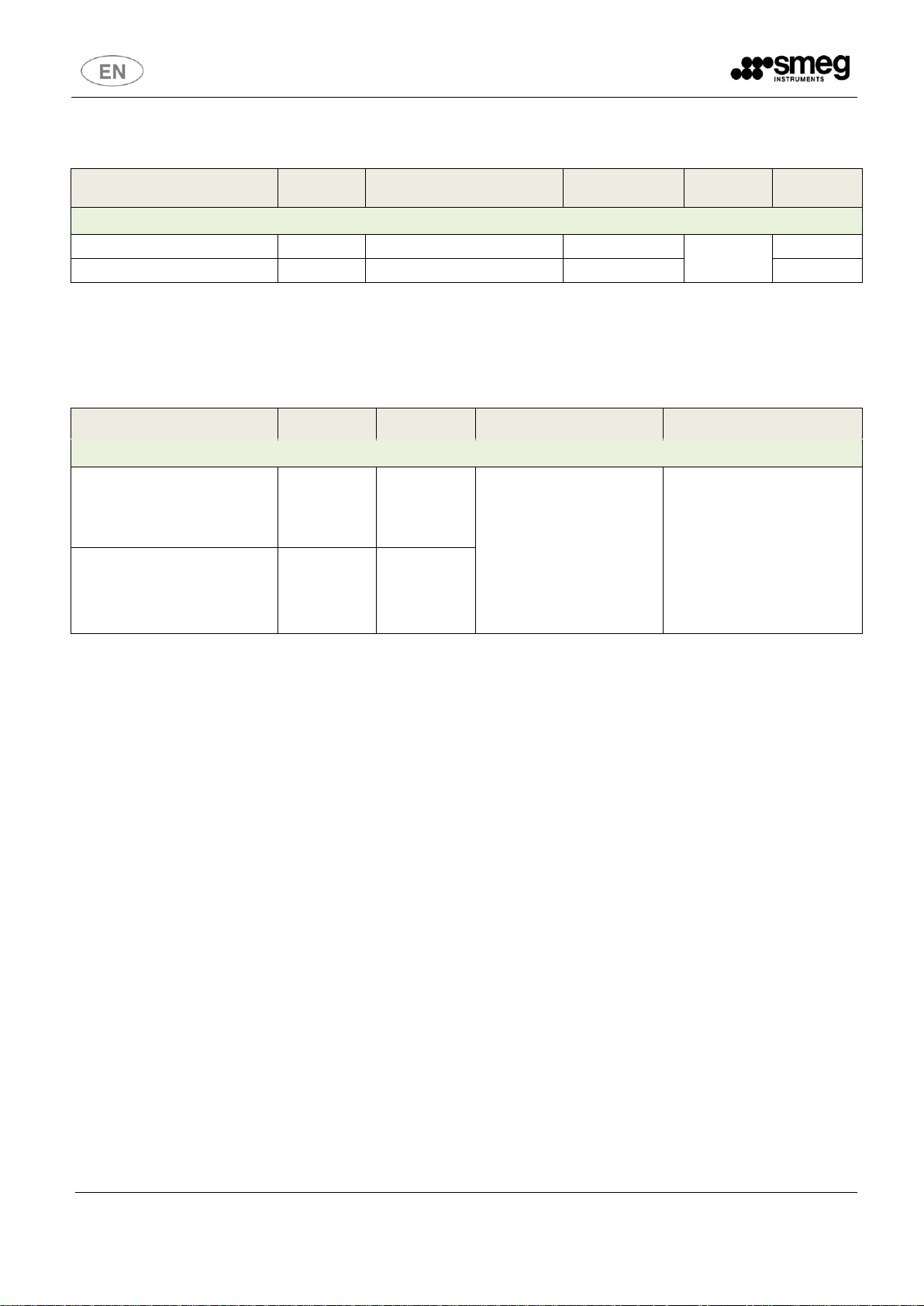

Table of capacity and dimensions

Internal

dimensions

External dimension and

unit net weigth

Dimensions of

packaging and shipping

weight

MODEL

Volume (L)

LxDxH (mm)

LxDxH (mm)

Kg

LxDxH (mm)

Kg

Laboratory refrigerators – SMR series

SMR130G

130

554 x 450 (318*) x

383 (205*)

*smaller dimensions

on the lowest part of

the chamber

650 x 625 x 810

51

707 x 687 x 870

61

SMR315G

315

580 x 533 x 1122

650 x 673 x 1762

87

727 x 737 x1785

99

Page 5

Rev. 01

User and maintenance manual

5

Table of technical specifications

MODEL

Volume (L)

Voltage (V) / Frequency (Hz)

Rated Power

Absorption (W)

Gas

Q.ty (Kg)

Laboratory refrigerators – SMR series

SMR130G

130

230 / 50

150 (164 input)

R600a

0,055

SMR315G

315

230 / 50

250 (277 input)

0,022

Standard and optional fitting

MODEL

Shelves

Drawers

Standard fitting

Optional accessories

Laboratory refrigerators – SMR series

SMR130G

2 + 1 lower

basket

-

Shelves

Wheels + adjustable feet

Schuko plug

Panel control board with

alarm system

Dry contact remote alarm

USB port

Datalogger

Backup battery

Pass-through hole

Safety thermostat +2°C

Additional shelves

SMR315G

4 + 1 lower

basket

-

Page 6

Rev. 01

User and maintenance manual

6

1 STANDARDS AND GENERAL WARNINGS

1.1 Certification

All appliances are produced in accordance with European Community Regulations applicable at the

time of its appearance on the market. All appliances are manufactured in accordance with European

Directive 2014/35/UE, 2014/30/UE and following integrations and according to safety requirements

for electrical equipment for laboratory use (IEC 61010-1).

1.2 Initial recommendations

READ THE PRESENT INSTRUCTION MANUAL CAREFULLY

This manual constitutes an integral part of the machine.

It must be kept intact and at hand for the entire life cycle of the machine.

It is necessary to read the following manual carefully prior to using the device.

Failure to read or thoroughly comprehend the instructions in this manual may cause the device to

malfunction and present hazards to the user.

Machine installation, maintenance, and repair operations must be performed by

authorized technical staff.

Repair operations performed by unauthorized staff, besides leading invalidating the

product warranty, can be source of danger for the user.

In case of replacement, an original spare part must be used.

If the device was not used in accordance to the instructions presented in this

manual, the product may no longer be covered by warranty and the safety of this

device could be compromised.

The producer declines all liability for any use that differs from what indicated in the

present manual.

The product warranty does not cover faulty parts due to negligence, inappropriate

use, or failure to comply with the instructions of the device operations; incorrect

installation or maintenance; repair and maintenance operations performed by

unauthorized staff or with non-original spare parts; transportation damages; and any

circumstance that cannot be ascribed to the device manufacturing defects.

Moreover, the warranty does not cover operations related to installation and

connection of alimentation and drain systems as well as maintenance operations

provided in the instruction booklet.

The installation of any accessory on the machine must be performed by authorized

technical staff.

To request further information about accessories: contact your trusted seller and/or

the authorized technical assistance, using the contact details provided in this

manual.

The content of this manual is for information purposes only. The content and the equipment

described here may be subject to change without notification.

Page 7

Rev. 01

User and maintenance manual

7

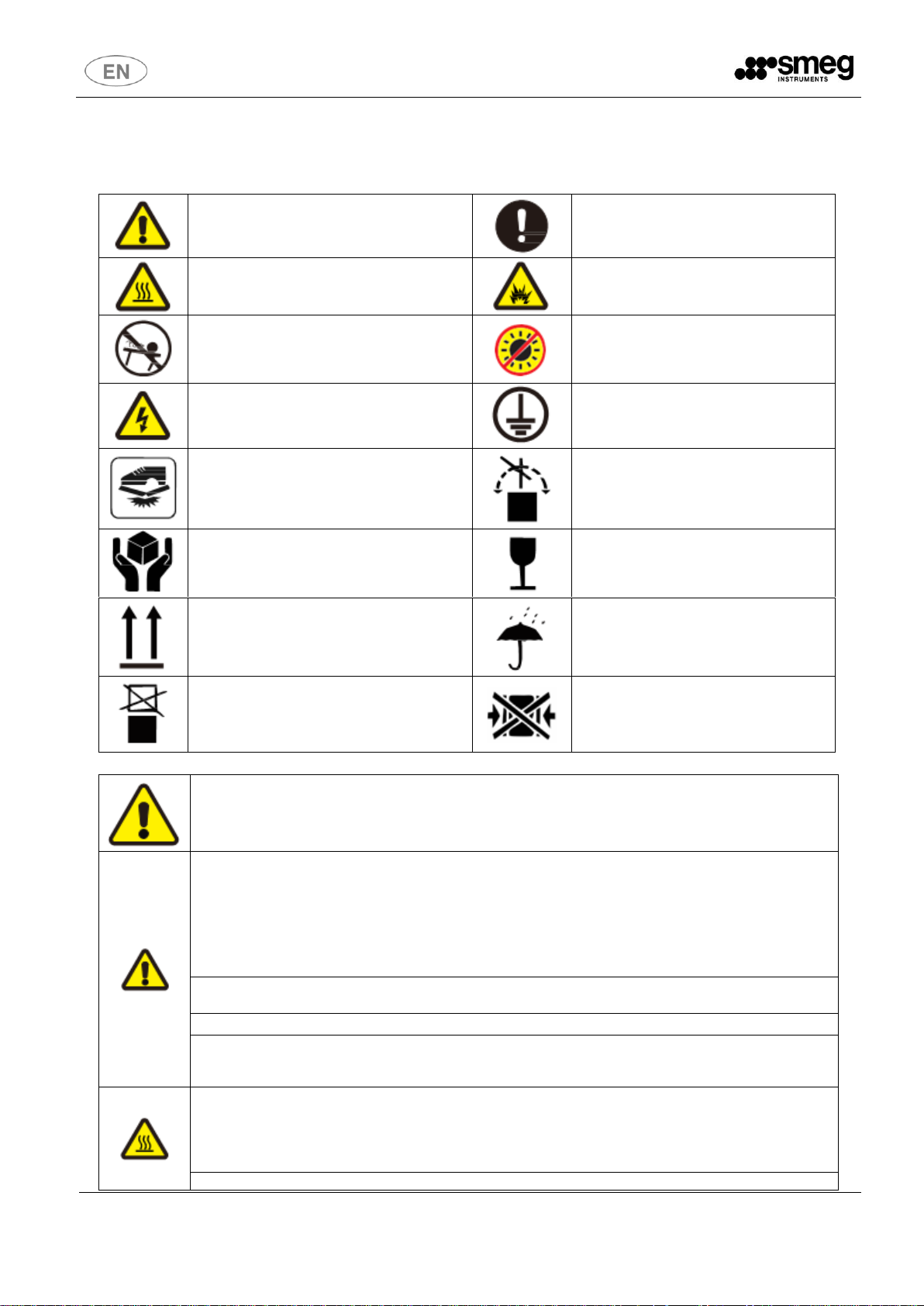

WARNING

Failure to observe WARNING signs could result in

a hazard to personnel possibly resulting in serious

injury or death.

CAUTION

Failure to observe WARNING signs could

result in injury to personnel and damage to

the unit and associated property.

CAUTION HOT

The sign inform the users about the danger of

burns for high temperature.

DANGER OF EXPLOSION

The sign inform the danger of the application of

volatile, explosive chemical substances.

NO TILTING

STAY OUT OF SUN

BEWARE OF ELECTRIC SHOCK!

Dangerous voltage may cause personal injury!

Please disconnect the power supply before repair.

GROUNDING MARK

NO TRAMPLING EQUIPMENT

NO TUMBLING TRANSPORT

PACKAGES

PRECISION INSTRUMENTS

HANDLE WITH CARE

THE CONTENTS MUST BE

PLACED AT THE ARROW

FEAR OF THE RAIN

NO STACKING

NO CLAMPING

WARNING

Failure to observe WARNING signs could result in a hazard to personnel possibly

resulting in serious injury or death.

As with any equipment that uses CO2 gas, there is a likelihood of oxygen depletion in

the vicinity of the equipment.

It is important that you assess the work site to ensure there is suitable and sufficient

ventilation.

If restricted ventilation is suspected, then other methods of ensuring a safe

environment must be considered. These may include atmosphere monitoring and

warning devices.

Do not touch any electrical parts such as the power supply plug or any switches with

a wet hand. This may cause electric shock.

Only qualified and authorised engineers shall install the unit.

Be sure to install the unit on a sturdy floor. If the floor is not strong enough or the

installation site is not adequate, this may result in injury from the unit falling or tipping

over.

Carefully with the power cord to avoid short circuit or open circuit. When removing the

plug from the power supply outlet, grip the power supply plug, not the cord. Pulling the

cord may result in electric shock or fire by short circuit. Don't make the power line pack

and pressed by furnish or heavy goods. Also please don't close to the compressor and

heat source.

Please insert the power plug firmly to avoid leakage.

Page 8

Rev. 01

User and maintenance manual

8

Use a power supply outlet with ground (earth) to prevent electric shock. If the power

supply outlet is not grounded, it will be necessary to install a ground by qualified

engineers.

Make sure a dedicated power source is used as indicated on the rating label attached to

the unit. Out of the rate, should install a property transformer and a proper voltage

stabilizer for safe operation.

Be sure to install the unit on a sturdy floor, no shaking and tilting.

Never install the unit in a flammable or volatile location. This may cause explosion or fire.

Never install the unit in a humid place or outdoor or a place where it is likely to be basked

straightly. Deterioration of the insulation may result which could cause current leakage

or electric shock.

Do not place the device lateral tilt, do not impact the device; the device is equipped with

refrigeration systems, roll or shock will easily damage the device.

Be sure to install the device in a dry dust-free environment to avoid overheating, short

circuit and other dangers.

If there is an unexpected sound, smell, smoke when the power is turned on, unplug the

power and contact the manufacturer or supplier. Continued abnormal operation may

cause electric shock or fire.

Make sure to put the device in a dry and ventilated location, to ensure that equipment

vents and wall surface of the instrument or other items have not been blocked; Do not

use the device in a poorly ventilated environment, or the equipment may be damaged by

the release of heat.

Never disassemble, repair, or modify the unit by yourself.

Any such work carried out by an unauthorized person may result in fire or injury due to a

malfunction. Smeg will be no responsible for such work.

Use this unit in safe area when treating the poison, harmful or radiate articles. Improper

use may cause bad effect on your health or environment.

Never place the unit through on a gas pipe, water main, telephone line or lightning rod.

Such grounding may cause electric shock in the case of an incomplete circuit.

Use a power supply outlet with ground (earth) to prevent electric shock. If the power

supply outlet is not grounded, it will be necessary to install a ground by qualified

engineers.

CAUTION

Failure to observe WARNING signs could result in injury to personnel and damage

to the unit and associated property.

Ultra-low temperature device is not available to store liv ing things or other critical

articles which is not suitable for low temperature storage.

The temperature inside the device is very low during the normal working. Do not

touch the interior surface of the chamber or the object inside without wearing

protective gear.

Always disconnect the power plug when the unit is not used for long periods.

Make sure to prepare a safety check sheet when you request any repair or

maintenance for the safety of service personnel. Be sure to check set point of the

controller before restarting the device.

Always hold the handle when closing the door. This will reduce the likelihood of a

trapped finger.

Keep the key properly avoiding the children take it to open the door which may

result in unexpected injury.

Select a level and sturdy floor for installation. This precaution will prevent the unit

from tipping. Improper installation may result in water spillage or injury from the

unit tipping over.

Check the filter mentioned in this manual and clean it properly and periodically.

Page 9

Rev. 01

User and maintenance manual

9

A dusty filter may cause temperature rise or failure.

Do not tilt the unit more than 45 degrees when moving the unit.

All transportation shall be done carefully.

1.3 Precautions for use

• When the device is running, the front part of the device may get hot. This is not a

malfunction: In order to prevent dew condensation around the case body, a heated anticondensation tube is installed in the cryogenic storage case.

• Before putting the items in the device, please make sure the temperature inside the

chamber has reached the set temperature, and then put the items in batches. Add no more

than 1/3 of the container volume each time, in case the temperature rises too much.

• The temperature display value shows the temperature of temperature sensors inside the

device. Although the displayed temperature may sometimes differ from the actual

temperature in the center of the device, it will get close to the real temperature gradually.

• A through-hole is installed on the side or back of the device to allow test lines to exit the test

box. After drawing out the test lines, be sure to re-plug the test hole with insulating material,

otherwise the temperature inside the box will not be completely lowered, resulting in

condensation around the outside of the hole.

• Clean the device with diluted neutral detergent. Do not use brushes, acid, gasoline, soap,

polish or hot water to clean the frozen storage container, as these materials may damage

the surfaces and plastic and rubber components.

• After a period of operation, mostly if the frequency of door openings is high, a layer of frost

may form on the inner wall and the inner door. If the frost layer is too thick, it will affect the

insulation effect of the device and increase the power consumption. Therefore, after a

period of time, when the frost layer reaches about 5mm, it should be defrosted with the

defrost shovel included.

• Please remove the frozen items in the device and put them in a suitable storage place

before defrost, so as to avoid the damage of goods for temperature rise.

• There are many cooling coils on the back and side of the inner wall. Don't use sharp objects

such as knives, ice chisel, or screwdrivers to remove the frost on the inner wall. Be careful

not to scratch the inner wall when defrosting, otherwise it will cause a failure of the device.

• Cut off the power when the refrigerated storage box will not be used for a long time.

1.4 Aim, content and intended user of this manual

This manual has been prepared with the objective to supply all instructions required for the correct

use of the appliance and to keep it in optimal condition. It also contains important user safety

information.

The following professional roles are explained in order to define the responsibilities of each

involved parties.

Installer: a qualified technician, authorised by the manufacturer, who installs the appliance in

accordance with the instructions herein contained.

Page 10

Rev. 01

User and maintenance manual

10

User: the person who, after having read this manual carefully, uses the appliance in accordance

with the intended specification of use described in this manual.

User’s responsibilities:

▪ ensure that the product is kept at suitable temperatures without exceeding +38° of ambient

temperature;

▪ be aware of the regulations governing the conservation of products to refrigerate and to

observe any whatsoever hygiene indications that may be applicable.

The user is obliged to read carefully the manual and refer to its information at all times. Particular

attention must be paid to the contents of heading 1.4 General safety warnings.

Routine maintenance technician: qualified operator able to perform routine maintenance of the

appliance by following the instructions in this manual (can be the customer too e).

Service engineer: qualified technician, authorised by the manufacturer to perform extraordinary

maintenance of the appliance.

Installer and service engineer must always be authorized by the manufacturer.

The manufacturer declines any whatsoever responsibility in case of improper use of the appliance

deviating from the reasonably construed intended use, and for all operations carried out that are

not in compliance with the instructions reported in the manual.

This manual must be stored in an accessible and known place for all operators (installer, user,

routine maintenance technician, service engineer).

1.5 General safety regulations

Read this manual carefully and follow the prescriptions contained herein.

The user assumes full responsibility in case of operations carried out without observing the

instructions in the manual. None of SMEG products are designed to work in presence of flammable

gases or solvent that may easily burn, hence keep off the unit of any of these situations.

Primary general safety regulations:

▪ do not touch the unit with wet hands and/or feet

▪ do not use the appliance with bare feet

▪ do not insert screwdrivers or other pointed objects between guards or moving parts of the

appliance

▪ do not pull the power cord to disconnect the appliance from the electrical mains

▪ make sure that the appliance is not used by unsuitably qualified persons

▪ before performing any cleaning or maintenance on the appliance disconnect it from the

electrical mains by switching off the main switch and extracting the plug

▪ in case of faults or malfunctions, switch off the appliance and do not attempt to repair it by

yourself. All service and repair operations must be performed exclusively by a suitable

authorized engineer.

This symbol on the equipment indicates a situation of danger. Pay attention

and read carefully what it refers to.

1.6 Customer responsibilities

The customer is required to:

▪ execute the electrical connection of the appliance

Page 11

Rev. 01

User and maintenance manual

11

▪ prepare the place of installation

▪ provide consumable materials for cleaning

▪ perform routine maintenance

In the case of power failures or malfunctions do not open the doors in order to maintain as much

as possible the internal temperature. If the problem persists for more than few hours, move the

contents to a more suitable place.

1.7 Customer service requests

For all technical problems and any requests for technical service, refer exclusively to your local

dealer, pointing out model and serial number.

1.8 Ordering of spare parts

Orders of spare parts should be made by consulting the part reference code and the serial number

of your appliance. Consult your dealer.

The user must consult the dealer or the manufacturer, as the case of SMEG

appliances require original spare parts, failing of which product certification

decades.

1.9 Aim and intended use of device

The appliance is conceived for the use in hospitals, laboratories, pharmacies and industries and it

is intended solely for the preservation of laboratories and medical products, which request various

controls and warning in case of sudden alteration of temperature.

In particular: medicinal products; laboratory samples; thermo-sensitive chemical reactants

It is absolutely not intended for storage of flammable materials, gas or explosive materials

Products must be stored in order to ensure efficient air circulation inside the

appliance and shall not come out of the shelf perimeter.

All uses except authorized used of the appliance shall be construed as “improper

use” for which the manufacturer declines all responsibility.

1.10 Unsuitable conditions for use

The appliance must not be used exposed to bad weather, with adapters, multiple sockets or

extension leads, in an explosive atmosphere or in an atmosphere with a fire risk or closed to

heating sources.

In case of built-in refrigerator a proper ventilation of compressor must be provided.

Page 12

Rev. 01

User and maintenance manual

12

2 INSTALLATION

2.1 Transport and handling

The appliance must be transported and handled exclusively in upright position, in

observance of the instructions printed on the packing.

This precaution is necessary to avoid contamination of the refrigerant circuit with compressor lube

oil with resulting valve and heat exchanger coil failure and problems starting the electric motor.

The manufacturer cannot be considered responsible for any problems due to transport executed in

conditions other than those specified herewith.

The appliance is secured to a wooden base by means of a screw and wrapped in a cartoon box.

The appliance must be handled using a folk lift truck or a pallet truck with suitable forks (fork length

at least equal to 2/3 length of unit). The dimensions and weight of the packed appliance are shown

in technical tables (see tables at the beginning of manual).

2.2 Positioning

Incorrect positioning can cause damage to the appliance and generate hazardous conditions for

personnel. The installer must therefore observe the following general regulations:

▪ make sure you maintain a minimum of 30 cm from the walls and the ceiling

▪ the room must be well ventilated

▪ Ambient temperature:10°C-32°C, optimal ambient temperature 18°C-25°C, air conditioning

system is required if necessary

▪ Relative humidity: ≤80% RH

▪ Altitude where the device is located below 2000 m on sea level

▪ keep well away from sources of heat

▪ avoid direct sunlight

▪ remove packing material

▪ remove accessories from inside the unit

▪ wood basement removal: by means of a hammer until the feet-block hinder ledge, tilt the

cabinet to one side and loosen the two thread-forming screws, drag the cabinet from the

back side holding the basement still until the four feet have gone out from the containing

holes, slightly tilt the cabinet backward and take the basement away pulling it from the front

side

Use gloves when handling wooden packing materials and the wooden base to

protect the hands from splinters.

▪ position the appliance with the help of a spirit level. Adjust the levelling feed on the metal

base of the unit if necessary.

▪ remove the protective PVC film from the external surfaces of the unit

▪ position the shelf runners in the holes in the uprights

▪ insert the shelves in the runners

▪ insert the condensate collection tray, if needed, in the relevant runners located beneath the

unit

Page 13

Rev. 01

User and maintenance manual

13

2.3 Wiring and electrical hook-up

The electrical plant and electrical hook-up operations must be performed by a qualified electrician.

For safety reasons adhere to the following indications:

▪ check that the electrical plant is suitably sized for the absorbed power of the unit

▪ if the electrical socket and the plug on the appliance power cord are incompatible, charge the

plug with a suitable component, ensuring the replacement part is of the approved type

▪ insert the cable into the jack

▪ do not use reductions or multi-way adapters

It is important to connect the appliance correctly to an efficient earth system

executed in compliance with the relevant legislation.

▪ the appliance must be positioned so that plug can be easily reached

▪ socket inputs shall be connected to circuit protection facilities, such as: an air switch which

the rated current is bigger than the required for the device.

▪ check the working voltage of the place before starting the device. A voltage stabilizer is

suggested to be used at the place where the voltage is not stable. Power of voltage stabilizer

shall be more than the required for the device.

2.4 Set-up operations

To avoid errors and accidents, perform a series of checks for possible damage sustained during

transport, installation and hook-up operations before starting up the unit.

PRELIMINARY CHECKS

▪ check the condition of the power cord (no cut or chaffing)

▪ check that the feed, door hinges and shelf support are stable

▪ check the door seals and drawers are not damaged (broken or scratched) and that the door

closes and is sealed properly

▪ make sure pipelines, unions are in perfect condition

INDICATIONS FOR OPTIMAL DUTY

▪ do not block the motor compartment air vents

▪ do not lay objects on the top of the appliance

▪ before storing products wait until they are cold

▪ arrange the products on suitable shelves or in containers. Do not place products directly on the

base or against the walls, doors or fixed guards of the unit

▪ make sure doors are kept closed

▪ keep the defrost water drain outlet clear

▪ limit the frequency and duration of opening; each time the door is opened the internal

temperature will alter

▪ load products at ambient temperature gradually to allow correct refrigeration

▪ perform routine maintenance regularly (see Chapter 5)

Page 14

Rev. 01

User and maintenance manual

14

2.5 Re-installation

Observe the following procedure:

▪ switch off the appliance from the main switch

▪ disconnect the power cord from the electrical outlet

▪ handle the appliance in accordance with the instruction heading 2.1

▪ follow the instructions in heading 2.2 for positioning and hook-ups in the new location

2.6 Scrapping and disposal

SMEG appliances may contain materials, which at the end of the working life of the apparatus,

must be disposed at one of the recycling centres nominated by your Local National Health

Department or as specified by the law in force. Scrapping and disposal of the appliance must be

carried out in full observance of established legislation in your country.

In particular, the apparatus may contain the following materials:

- Iron

- Copper

- Aluminium

- Non-biodegradable plastics

- Fibre glass for printed circuits

- Ferrite

- Batteries

- CFC-free refrigeration gas

- Electrical and electronic equipment (WEEE)

SMEG shall not be chargeable for any disposal of the apparatus at the end of its working life.

In line with European Directive 2012/19/UE for waste electrical and electronic

equipment (WEEE), this electrical product must not be disposed of as unsorted

municipal waste. Please dispose of this product by returning it to your local

municipal collection point for recycling.

The term of the useful life of refrigerator/device is 10 years. After this period, the device must be

checked and possibly re-conditioned only by the manufacturer

Before you dispose, verify that the appliance has been sanitized in accordance

with internal procedures.

Page 15

Rev. 01

User and maintenance manual

15

3 OPERATION

3.1 Safety and accident prevention

SMEG devices are designed to include several features to ensure the safety and the

protection for the Operators and for the material stored in the cabinets.

The following list describes the protections adopted against mechanical risks:

▪ stability: the appliance is designed and built so that even with the shelves fully extracted in

the intended conditions of operation may remain stable, so that it can be used without risk of

tipping, falling or sudden movement.

▪ surfaces, edges, corners: accessible parts of the appliance have no sharp corners, sharp

edges or rough surface that could cause injuries.

▪ moving parts: moving parts of the unit are designed, built and configured to avoid risks.

Moving parts are protected by fixed guards to prevent accidental contact that could result in

injury.

Measures adopted for protection against additional risks:

▪ electrical power: the appliance is designed, built and fitted out with the aim of preventing

the risk of electric shock in compliance with established safety legislation

▪ noise: the appliance is designed and built to reduce risks related to the emission of airborne

noise to the minimum level (below 54 dB)

3.2 Safety dataplates and guards

It is strictly forbidden:

▪ to tamper or remove the evaporator cover that protects the user from the risk of cutting on

the heat exchanger fins;

▪ to remove the data plate fixed to the inside edge of the motor housing showing technical

specification and earth connection warning;

▪ to remove the data plates on the evaporator unit cover near the electrical wiring inside the

motor housing which warn the user to disconnect electrical power before working on

appliance;

▪ to remove the data tag fixed to the power cord showing the type of power supply.

The manufacturer declines all responsibility for safety of the appliance if the above

recommendations are not observed.

3.3 Operating limits

The appliance is designed and built to work with ambient temperatures between +10 °C and +32

°C. It is also destined and tested for tropical countries. If the ambient conditions are different it will

not be possible to achieve the top performance levels specified by the manufacturer.

Power supply can be one of the following: 230 V - 50Hz

3.4 Environmental storage conditions

The appliance when not in use must be stored indoors at a temperature not exceeding +40 °C and

below 0 °C.

Page 16

Rev. 01

User and maintenance manual

16

4 USER INSTRUCTIONS

SMR130G

A

Display

B

Door lock

C

Glass door with gasket and anti-condense system

D

Ergonomic handle

E

Pass-through test hole 25 mm

F

Internal ventilation system

G

Internal led light

H

Shelf

I

Rack support system

J

Lower basket

K

Adjustable feet

Page 17

Rev. 01

User and maintenance manual

17

SMR315G

A

Display

B

Door lock

C

Glass door with gasket and anti-condense system

D

Ergonomic handle

E

Pass-through test hole 25 mm

F

Internal ventilation system

G

Internal led light

H

Shelf

I

Rack support system

J

Lower basket

K

Adjustable feet

Page 18

Rev. 01

User and maintenance manual

18

4.1 Appliance start-up

Before switching on the unit, check that the electrical connections have been made correctly and

above all, that the ground connection is available and working properly (Sect. 2.2.). Perform

preliminary cleaning of the unit as described in Section 5.1.

SWITCH ON THE UNIT

To start the appliance, it is necessary to turn on the power-lock at the rear side of the machine. It is

suggested to switch on both general power supply and backup battery, to enable the backup battery

charge.

TEMPERATURE SET POINT

Set the desired temperature setpoint between +2°C to +10°C.

Standard factory setting at +5°C.

To edit the temperature set point, please see below display navigation instructions.

The high temperature alarm will be activated when the power is on.

That's a normal phenomenon.

Once the temperature comes down to the set point, the alarm will be closed.

The alarm buzzer voice can be muted by touching the MUTE button.

DEVICE LOADING

Articles can be stored inside the device after set point temperature reached.

To store the load, each time do not load over 1/3 of available volume; after temperature

stabilization, store another 1/3 and so on.

Avoid opening the door during the cooling process, if not strictly necessary, this will cause a

physiological temperature rise.

4.2 Functions

DATALOGGER

When the appliance is on, alarms and data of probes are recorded. Each single record is related to

date and time. The freezer records up to every minute. Then you have to download records on a

USB pen drive.

SMR130G and SMR315G: standard record pace every 10’ (2 years of records can be stored),

modifiable up to 1’

BACKUP BATTERY

In case of power failure, the device will not be able to proceed to be supplied, so compressor and

device will stop the operation. Display and microprocessor will be supplied by a backup battery

(standard for those models), so that data, temperature and alarms can be stored for at least 48h.

Page 19

Rev. 01

User and maintenance manual

19

EXTERNAL COMMUNICATION SYSTEM

Page 20

Rev. 01

User and maintenance manual

20

4.3 Control panel

SMR130G

N°

Description

1

4 digit display

2

Opened door feedback

3

Alarm warning

4

USB port

5

Confirmation button - Mute

6

Up 7 Down

8

Print (optional not available on this model)

9

LED light

SMR315G

N°

Description

1

Function or alarm warning symbols

2

3 digit display

3

Confirmation button - Mute

4

Up 5 Down

6

Print (optional not available on this model)

7

LED light

8

USB port

Page 21

Rev. 01

User and maintenance manual

21

Door switch

WIFI

Defrosting

Key lock

Power failure

Print

Door heating

Refrigeration

Mute

Backup battery

Serial port

Fan

a. Door switch indicator light

When the door is open, the door switch indicator light will be on; when the door is closed, the door

switch indicator light will be off.

b. WIFI

Wifi not available on this device.

c. Defrosting

Automatic activation. Not settable on this model.

d. Key lock/unlock

When the display is in locked status, the buttons will not respond, and the key lock light will be on.

At this time, press and hold the UP + DOWN buttons for 3 seconds, it will ask to insert the password,

the default password is “005” (SMR315G), “0005” (SMR130G).

After inputting the password correctly, press the setting/mute key, the key lock will be disabled and

the key lock indicator light will be off.

If no key is pressed for 60s in the unlocked status, the key lock will be enabled, and the key lock

indicator light is on.

Press and hold the UP + DOWN buttons for 3s, the display will be locked.

e. Power failure indicator light

The device is normally powered at a voltage of 220V. When the input power is disconnected, the

buzzer will sound, the display will blink the power failure code “Pf” alternately at a 3s interval and the

power failure indicator light be on.

When the input power is connected, it will resume normal and the power failure indicator light

becomes off.

f. Print

Print not available on this device.

g. Door heating

Door heating system active.

Page 22

Rev. 01

User and maintenance manual

22

h. Refrigeration

If the compressor is in the operation status, the refrigeration indicator light will always be on; if the

compressor is in the shutdown status, the refrigeration indicator light will be off.

i. Mute indicator light

When the alarm tone key is muted, the indicator light will be on; when the alarm tone mute function is

disabled, the indicator light will be off.

j. Low backup battery

When the backup battery voltage is lower than 10.8V, the buzzer will sound, the low battery indicator

light will be on, and the display will blink to show the related low battery code “PL” alternately at a 3s

interval; when the battery voltage is greater than 12V, the buzzer will become mute, the low battery

indicator light be off and the display tube resume normal display.

k. Serial port

When the device is not connected to the reserved RS-485 serial port, the serial port indicator light is

off; when the device is successfully connected to the reserved RS-485 serial port, the serial port

indicator light is on.

l. Fan

Refrigerating ventilated system active.

Normal display view

is the temperature display window, used to display the average internal temperature

inside the device under normal operating conditions, in the unit of °C;

To display the external ambient temperature

When the keys are locked, press the key, the display will show the ambient temperature.

It will resume normal display if no key is pressed for 5 seconds or by pressing and .

To display the chamber % HR value

Press and hold and .

It will resume normal display if no key is pressed for 5 seconds or by pressing and .

Buttons description

UP

In the parameter setting mode, press it to move to the next parameter or increase the parameter

value.

For example, when setting the temperature, it may be used to increase the set temperature value.

When setting the parameter value, press and hold the up key to increase the parameter value

quickly.

Under normal conditions, press and hold the UP key for 3s to import the data of 12 months into

the USB flash disk.

DOWN

In the parameter setting mode, it may be used to move to the previous parameter or decrease the

parameter value.

For example, when setting the temperature, it may be used to decrease the set temperature value.

When setting the parameter value, press and hold the down key to decrease the parameter value

Page 23

Rev. 01

User and maintenance manual

23

quickly.

OK - MUTE

When there is no alarm and the keys are not unlocked, press it and will display the ambient

temperature, and will resume normal display after 5s; in the unlocked status, press for more than

3s to enter the user menu.

When the buzzer sounds and the keys are not unlocked, press it for the first time, the buzzer will

stop sound, and it will display the ambient temperature and resume normal display after 5s (only

the buzzer for this abnormal status alarm is turned off by pressing the mute key, although the fault

is eliminated, the buzzer will also sound if it becomes abnormal again).

Press it again, the buzzer will sound, it will display the ambient temperature and resume display

of cabinet temperature and alarm status after 5s.

When the keys are unlocked, can be used as the setting key.

When the keys are unlocked, in the parameter setting mode, press this key to display the

parameter value and parameter name. Press and hold it for more than 3s, it will save the setting

and return to the normal interface.

USB

Automatic export

When the USB flash disk is connected to the USB interface, the recorder buzzer will sound once,

the display will show “on”, and the PDF file of the current month and the previous month will be

generated in the USB flash disk.

After the data transmission is completed, the buzzer will sound once, and the display will show

“End”, and resume normal display after 6s.

Note: When there is little data, the display tube will not display "on" or "End".

Manual export

When the keys are not locked, the USB flash disk is properly connected, and the file has not been

generated yet, press and hold for 3s, the display will show “d01”, press or to

adjust it to “d00~d12”, press , the file generated this time (d00) or the file for the previous

month (1-12) will be saved in the USB flash disk in PDF format.

Note: When the display blinking shows “LoF”, the recorder has not been started yet; press

and for 3s, “LoF” will disappear, the buzzer sound once, and the recorder will be started.

Page 24

Rev. 01

User and maintenance manual

24

USER PARAMETER SETTINGS

Unlock: In normal operation, press and hold and simultaneously for 3s, the display will

show the parameter code “000”, enter the password “005” (when entering the user menu password,

enter “099” to restore the key lock password to the default “005”.) to unlock.

After unlocking, press and hold for 3s, the display will show the parameter code “PS1” and enter

the settings to adjust the parameters.

Use the or to roll the parameters.

The display order is:

• Ps1

• b1

• b2

• Set

• H

• L

• N

• Y

• R

• S

• F

• Pt

• tH1

• P1

• P2

Press Use the or to roll the parameters to confirm the parameter category, the first

parameter name of each category will be displayed.

1. Use or to roll the parameters;

2. Press to display the corresponding parameter value;

3. Use or to increase or decrease the value;

4. Press to temporarily store the modified value and return to the display parameters;

5. If you want to modify other parameters, repeat steps 1. 2. 3. and 4.;

6. Press and hold for more than 3s to store the modified parameters and return to the

display parameter category.

7. Exit the parameter setting program by pressing and holding for more than 3s, or after no

button is pressed within 60s.

Page 25

Rev. 01

User and maintenance manual

25

PARAMETERS

Menu

item

Parameter range

Default value

Remarks

Ps1

0000-9999

0005

User menu password setting

b1

Not editable

Hardware version

b2

Not editable

Software version

Set

+2/+10 [°C]

+5

Temperature set point

H

0,0-10,0 [°C]

5,0

High temperature alarm set value "set+H"; (if H=0,

alarm is automatically cancelled);

When the temperature is too high, the high

temperature alarm shows H1

L

0,0-10,0 [°C]

4,0

Low temperature alarm set value "set-L"; (if L=0,

alarm is automatically cancelled);

When the temperature is too low, the low

temperature alarm shows L1

n

Technical password needed

Year

y

Technical password needed

Month

r

Technical password needed

Day

S

Technical password needed

Hour

F

Technical password needed

Minute

Pt

0-240min

20

Print interval

tH1

20,0-50,0 [°C]

50

Ambient temperature alarm upper limit

P1

Technical password needed

Door heating modality

P2

1. Average temperature

2. Upper temperature

3. Lower temperature

Displayed temperature (default 1. Average

temperature)

Page 26

Rev. 01

User and maintenance manual

26

4.4 Alarm codes

Temperature alarms are activated with a delay.

Alarm Code

Error Description

H1

High temperature alarm

L1

Low temperature alarm

H2

Alarm for high ambient temperature

H3

Condenser overheat alarm

do

Door opening alarm

PF

Power failure alarm

bL

Battery low alarm

Er

The recorder is not connected

LoF

The data recorder is not started (press and 3 seconds, until

“LoF” disappears

EE

Communication failure

Page 27

Rev. 01

User and maintenance manual

27

4.5 Troubleshooting

PROBLEMS

CAUSES AND SOLUTIONS

Equipment does not work

Is the power outlet charged?

Is the power plug plugged in or lose?

Is the power fuse disconnected?

Is the supply voltage too low or too high?

Compressor is not running

Is the temperature set correctly?

Is the temperature inside the cabinet too low?

The temperature does not reach the set

value

Are the doors not tightly closed or open too many times?

Are there too many items put in at one time?

Is the ambient temperature too high?

High noise

Is the cabinet placed on a flat ground? Does the cabinet contact the

wall?

Condensation on cabinet surface

In rainy and humid seasons, door condensation is normal, and it shall

be wiped off with a dry cloth.

The door is not closed properly, and the

cool air leaks

Is the temperature set correctly?

Is the temperature inside the cabinet too low?

Follows are not failure

• There will be a slight crash sound of the compressor switch when the compressor is starting and

stopping. The cooling time is longer than normal for the first use of the device. These are normal

phenomenon.

• In humid ambient, there can be a little frost forming on the surface of the device, use the dry cloth to

wipe it off will be OK.

• The twice opening of the door should after 5 minutes, otherwise the outside warm air will come in, the

negative pressure inside the device caused by a decline will make the door difficult to open.

• A sound of liquid flow inside the device is a normal sound of refrigerant circulating.

Page 28

Rev. 01

User and maintenance manual

28

5 ROUTINE MAINTENANCE

Basic safety regulations

We summarise the elementary safety regulations to ensure that the user or maintenance technician

can perform the work in conditions of total safety:

▪ do not touch the unit with wet hands and/or feet;

▪ do not use the appliance with bare feet;

▪ do not insert screwdrivers or other pointed objects between guards or moving parts of the

appliance;

▪ do not pull the power cord to disconnect the appliance from the electrical mains;

▪ before performing any cleaning or maintenance on the appliance disconnect it from the electrical

mains by switching off the main switch and extracting the plug

Prohibited: removal of guards and safety devices

It is strictly forbidden to remove guards or safety devices when performing routine maintenance work.

The manufacturer disclaims all liability that may arise if this regulation is not observed.

Emergency measures in case of fire

- Disconnect the unit from the electrical power socket.

- Do not use water to extinguish the fire.

- Use powder or foam extinguishers.

5.1 Cleaning of the refrigerator

The unit is designed to preserve medical/laboratory products so it is important to keep it clean for

reasons of hygiene and health. The appliance is thoroughly cleaned in our factory before delivery.

We recommend, however, that you clean the interior of the appliance before use. Before cleaning the

appliance make sure the power cord is disconnected.

5.2 Cleaning of the interior and exterior

To this end, we indicate cleaning products to be used for exterior and interior of the appliance:

▪ Water and neutral detergent only and not abrasive. Do not use solvent or thinners.

▪ Cleaning methods: use soft clean cloth with suitable products for both external and internal

surfaces.

▪ Disinfection: Avoid substances that can alter the organoleptic characteristics of products.

▪ Rinsing: use a cloth or sponge soaked with fresh clean water. Do not use water jets.

▪ Frequency: once a week or at different intervals in accordance with the type of product stored.

Page 29

Rev. 01

User and maintenance manual

29

5.3 Cleaning of the condenser

The condenser is a heat exchanger hence if it is dirty or clogged the air cannot pass freely into the

same, it cannot do its job properly and the efficiency of the refrigeration system falls down

proportionally. FOR THOSE REASONS IT IS IMPORTANT TO KEEP CLEAN THE CONDENSER

WHERE TYPICALLY IT MEANS TO CLEAN IT MONTHLY.

WARNING!!!

Always switch off the unit and disconnect power cord before cleaning, it is dangerous to do it

with power: fan may start suddenly at any time!

Use an air jet or an aspirator with a soft dry brush if necessary and remove any dust or fluff from the

heat exchanger fins.

After cleaning, start the appliance.

During this operation use the following personal safety measures:

- safety glasses

- respiratory protection mask

- gloves

After removal, use an air jet or an aspirator with a soft dry brush if necessary and remove any dust or

fluff from the heat exchanger fins.

Page 30

Rev. 01

User and maintenance manual

30

5.4 Precautions for prolonged disuse

If the refrigerator should remain unused for more than 15 days please proceed as follows:

▪ switch off the appliance and disconnect the power cord

▪ clean the interior of the cabinet, shelves, trays, runners and supports, paying special attention to

critical areas such as articulations and magnetic sealing strips

▪ leave doors slightly open to prevent accumulation of residual humidity

Page 31

Rev. 01

User and maintenance manual

31

6 ELECTRICAL DIAGRAM

SMR130G

Page 32

Rev. 01

User and maintenance manual

32

SMR315G

Page 33

Rev. 01

User and maintenance manual

33

7 AFTER-SALES SERVICE

Our After-Sales Department will be able to provide you with guidance about keeping your device

functioning correctly and put you in touch with your nearest authorised Service Centre.

Italy only

▪ After Sales Service (Assistance and Technical Information) contact:

o National number 0522.184.85.95

o Fax 02.38073401

o Email: assistenza.instruments@smeg.it

▪ For further information

o Email: instruments@smeg.it

International Customers

Please contact your Local Smeg Distributor or write an email to:

▪ After Sales Service (Assistance and Technical Information) contact:

o Email: service.instruments@smeg.it

▪ For further information

o Email: instruments@smeg.it

Page 34

Rev. 01

User and maintenance manual

34

SMEG S.p.A.

Instruments Division

Via Leonardo da Vinci, 4 – 42016 Guastalla (RE) Italy

www.smeg-instruments.com

Loading...

Loading...