Page 1

Instructions Manual

SHW935X - SHW1235X

Page 2

INDEX

RECOMMENDATIONS AND SUGGESTIONS.....................................................................................................................3

CHARACTERISTICS.............................................................................................................................................................4

INSTALLATION...................................................................................................................................................................... 6

USE......................................................................................................................................................................................10

MAINTENANCE...................................................................................................................................................................11

EN

2

2

Page 3

2°

RECOMMENDATIONS AND SUGGESTIONS

The Instructions for Use apply to several versions of this appliance. Accordingly, you may fi nd

descriptions of individual features that do not apply to your specific appliance.

INSTALLATION

• The manufacturer will not be held liable for any damages resulti ng from incorrect or improper

installation.

• The minimum safety distance between the cooker top and the extractor hood is 650 mm (some

models can be installed at a lower height, please refer to the paragraphs on working dimensions

and installation).

• Check that the mains voltage corresponds to that indicated on the rating plate fixed to the inside of

the hood.

• For Class I appliances, check that the domestic power supply guarantees adequate earthing.

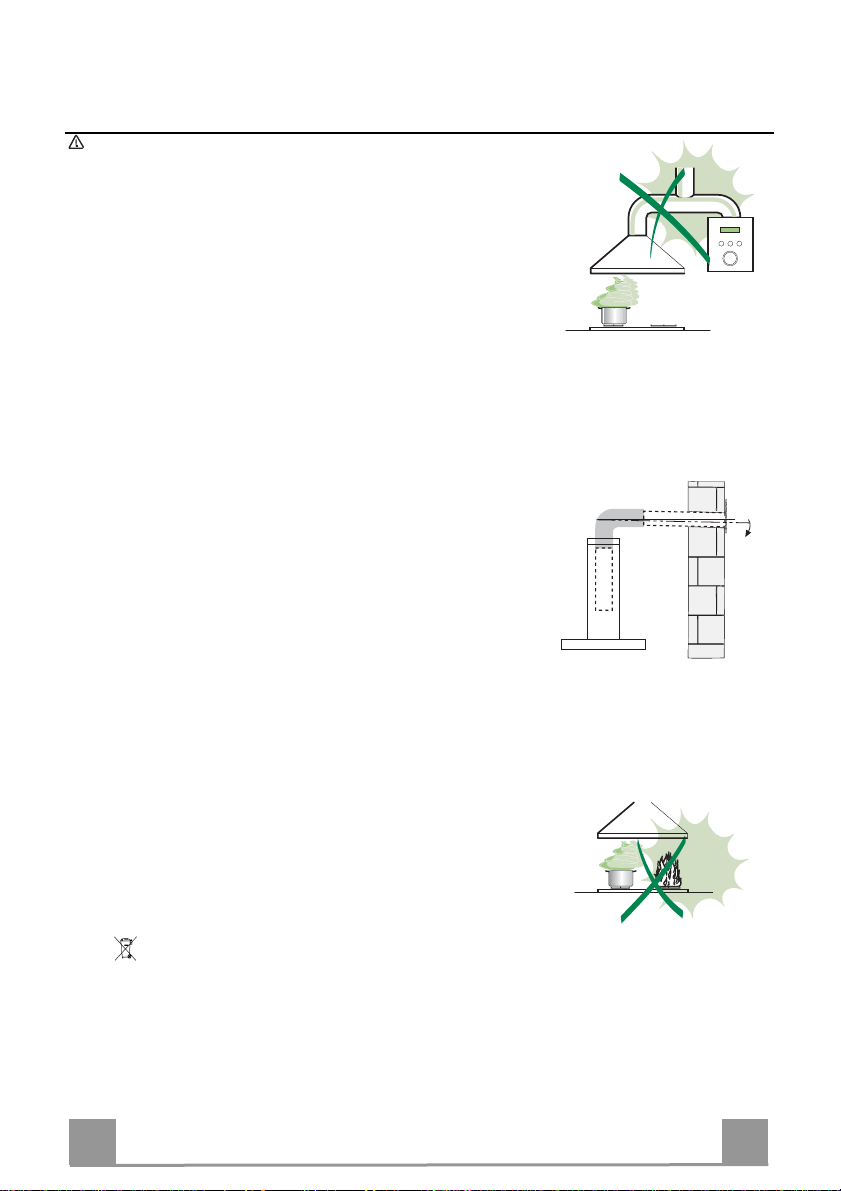

Connect the extractor to the exhaust flue through a pipe of minimum diameter 120 mm. The route

of the flue must be as short as possible.

• Do not connect the extractor hood to exhaust ducts carrying combustion fumes (boilers, fireplaces,

etc.).

• If the extractor is used in conjunction with non-electrical appliances (e.g. gas burning appliances), a

sufficient degree of aeration must be guarant eed i n the r oom in o rde r to p reve nt the b ackflow of

exhaust gas. The kitchen must have an opening communicating directly with the open air in order

to guarantee the entry of clean air. When the cooker hood is used in conjunction with appliances

supplied with energy other than electric, the negative pressure in the room must not exceed 0,04

mbar to prevent fumes being drawn back into the room by the cooker hood.

• In the event of damage t o the power cable, it must be replaced by the manufacturer or by the

technical service department, in order to prevent any risks.

“WARNING: Failure to install the screws or fixing device in accordance with these instructions may

result in electrical hazards.”

USE

• The extractor hood has been designed exclusively for domestic use to eliminate kitchen smells.

• Never use the hood for purposes other than for which it has been designed.

• Never leave high naked flames under the hood when it is in operation.

• Adjust the flame intensity to direct it onto the bottom of the pan only, making sure that it does not

engulf the sides.

• Deep fat fryers must be continuously monitored during use: overheated oil can burst into flames.

• Do not flambè under the range hood; risk of fire

• This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance by a person responsible for their safety.

• Children should be supervised to ensure that they do not play with the appliance.

• “WARNING: Accessible parts may become hot when used with cooking appliances.”.

MAINTENANCE

• Switch off or unplug the applian ce from the mains supply b efore carrying out any mai ntenance

work.

• Clean and/or replace the Filters after the specified time period (Fire hazard).

• Clean the hood using a damp cloth and a neutral liquid detergent.

The symbol on the product or on its packaging indicates that this product may not be treated as household waste. Instead it

shall be handed over to the applicable collection point for the recycling of electrical and electronic equipment. By ensuring this product

is disposed of correctly, you will help prevent potential negative consequences for the environment and human health, which could

otherwise be caused by inappropriate waste handling of this product. For more detailed information about recycling of this product,

please contact your local city office, your household waste disposal service or the shop where you purchased the product.

EN

3

3

Page 4

2.1

2.2

2

12c

12a

7.2.1 11

11

12a

9

12e

8

1

3

12f

19

10

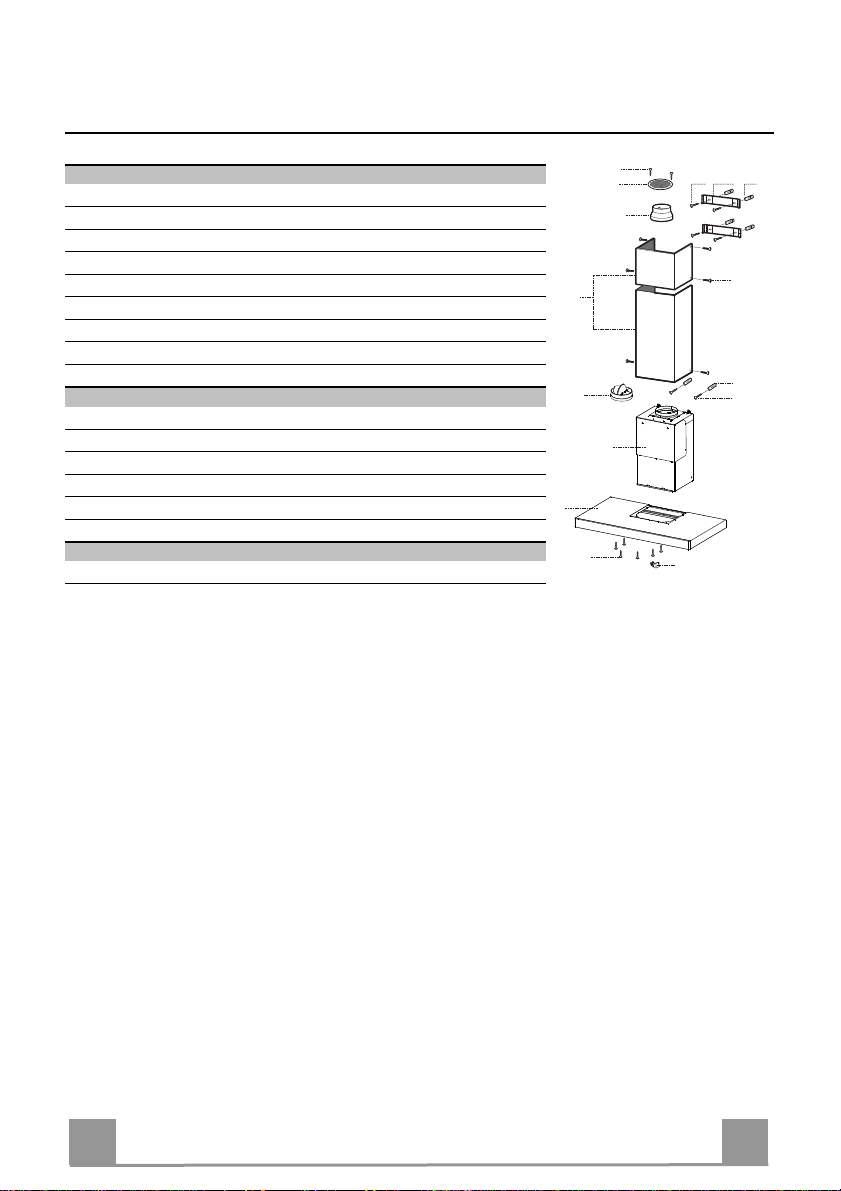

CHARACTERISTICS

Components

Ref. Q.ty Product Components

1 1 Hood Canopy complete with: Controls, Light, Filters

2 1 Telescopic chimney, made up of:

2.1 1 Upper chimney

2.2 1 Lower chimney

3 1 Motor unit

8 1 Directional Grille ø 125 mm

9 1 Reduction Flange ø 150-120 mm

10 1 Dumper ø150 mm

19 1 Cable raceway

Ref. Q.ty Installation Components

7.2.1 2 Upper chimney fixing brackets

11 6 Plugs

12a 6 Screws 4.2 x 44.4

12c 6 Screws 2.9 x 9.5

12e 2 Screws 2.9 x 9.5

12f 6 Screws 3.5 x 9.5

Q.ty Documentation

1 Instruction Manual

EN

4

4

Page 5

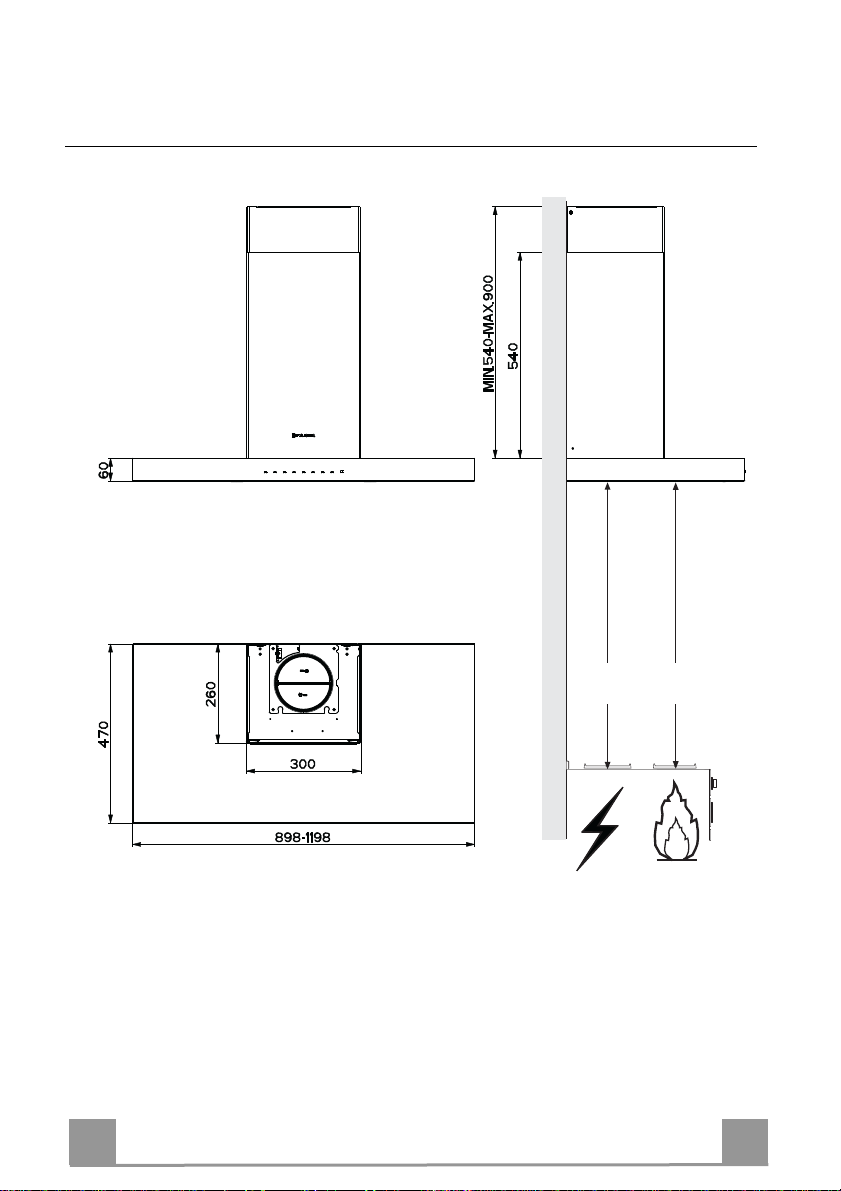

Dimensions

EN

Min.

650mm

Min.

650mm

5

5

Page 6

INSTALLATION

CONNECTION OF MOTOR UNIT/HOOD

• Remove the Grease filters from the Hood Canopy 1.

• Unfasten the 4 screws on the corners of the Suction

Panel.

• Remove any Activated charcoal filters from the

Motor unit 3.

• From inside the Hood canopy, screw the Motor unit 3

to the Hood canopy 1 using 6 Screws 12f provided.

Warning: Cable raceway 19 must be screwed into

place using one of the Screws 12f to fix it in the

position shown in the figure, locking the Hood wiring

in place.

• Make the electrical connections between the Motor

Unit 3 and the Hood Canopy 1, connecting the

Controls connector and the Lighting connector.

Warning: Make sure that the Connectors are

properly inserted into the housing.

Warning: There will be a specific Connector

according to the type of controls.

• For the Recirculation Version, fit the Activated

Charcoal Odour Filter, if there is one.

• Replace the Suction Panel, using the 4 screws

removed as above.

• Replace the metal grease filters.

1

3

12f

Connector

Lux

1

19

2

I

L

O

P

0

1

3

EN

6

6

Page 7

Drilling the Wall and Fixing the Brackets

1÷2

7.2.1

11

12a

650 min.

116

116

X

545

7.2.1

Min. 50mm

Draw the following on the Wall:

• a Vertical line up to the ceiling or top surface, at the centre of the area in which the Hood is to be fitted;

•

a Horizontal line: 650 mm min. above the Cooker Top.

• Rest the Bracket 7.2.1 as indicated, 1-2 mm from the ceiling or surface above the hood, aligning its

centre (grooves) with the vertical reference line.

• Mark the centres of the holes in the bracket.

• Rest the Bracket 7.2.1 as indicated, X mm under the first bracket (X = height of the Upper chimney

provided), aligning its centre (grooves) with the vertical reference line.

Warning: The Bracket must be in a position that allows a minimum distance of 50mm from the upper

part of the Motor unit, so if when measured the position of the Bracket is found to be below the Motor

unit, the bracket must be fitted 50 mm above this.

• Mark the centres of the holes in the bracket.

• As shown in the drawing, mark a reference point 116 mm from the vertical reference line, and 545 mm

above the horizontal reference line.

• Repeat this operation on the other side.

• Drill the points marked using a ø 8 mm drill bit.

• Insert the plugs 11 into the holes.

• Fix the brackets, using the screws 12a (4.2 x 44.4 ) provided.

•

Tighten the 2 screws 12a (4.2 x 44.4) provided in the hood canopy fixing bores, leaving a

gap of 5-6 mm between the wall and the heads of the screws.

EN

7

7

Page 8

9

ø 120ø 150

10

10

9

ø 125

8

12e

Mounting the hood body

• Before attaching the hood body, tighten the two screws Vr located on the hood body mounting points.

• Hook the hood body onto the screws 12a.

• Fully tighten the support screws 12a.

• Adjust the screws Vr to level the hood body.

Connections

DUCTED VERSION AIR EXHAUST SYSTEM

When installing the ducted version, connect the hood to the

chimney using either a flexible or rigid pipe ø 150 or 120mm, the

choice of which is left to the installer.

To install a ø 150 pipe

• To install the dumper 10

• Fix the pipe in position using sufficient pipe clamps (not supplied).

To install a ø 120 pipe

• To install a ø 120 mm air exhaust connection, insert the reducer flange 9 on the dumper 10.

• Fix the pipe in position using sufficient pipe clamps (not supplied).

• Remove any activated charcoal filters.

Vr

12a

RECIRCULATION VERSION AIR OUTLET

• Cut a hole ø 125 mm in any shelf that may be positioned over

the hood.

• Insert the reducer flange 9 on the hood body outlet.

• Connect the flange to the outlet on the shelf over the hood by

using a flexible or rigid pipe ø120 mm.

• Fix the pipe in position using sufficient pipe clamps (not supplied).

• Fix the air outlet grid 8 on the recirculation air outlet by using

the 2 screws 12e (2,9 x 9,5) provided.

• Ensure that the activated charcoal filters have been inserted.

EN

8

8

Page 9

12c

2.1

2.2

2

7.2.1

12c

ELECTRICAL CONNECTION

• Connect the hood to the mains through a two-pole switch having a contact gap of at least 3 mm.

• Remove the grease filters (see paragraph Maintenance) being

sure that the connector of the feeding cable is correctly inserted

in the socket placed on the side of the fan.

Fitting the Chimney

Upper chimney

• Open the two side pieces out slightly, hook them up behind the

brackets 7.2.1 and bring them back together again until they

are in contact.

• Fix the upper part of the Chimney to the upper Bracket at the

side, using the Screws 12c (2.9 x 9.5) provided.

Warning: If it has been extended so far that the lower slots in

the upper chimney are level with the holes in the bracket, use

the screws 12c provided to fix it; otherwise only use the

bottom bracket as a stop for the upper chimney.

Lower chimney

• Open out the two Chimney side flaps, hook them up between

the upper chimney and the wall and then close them up again

until they touch.

• Fix the lower part to the Hood canopy at the sides, using 2

screws 12c (2.9 x 9.5) provided.

EN

9

9

Page 10

USE

Button Function Led

A Turns the lighting system on and off at maximum in-

tensity.

Press and hold for 2 seconds to turn the lighting system

on and off at reduced inte nsity .

B Turns the Motor off.

Press and hold for approximately 5 seconds to Lock /

Unlock the Keyboard, for example in order to clean the

surface.

C Turns the Motor on at Speed one. On/Off

D Turns the Motor on at Speed two. On/Off

E Turns the Motor on at Speed three. On/Off

F Activates/Deactivates intensive speed from any o ther

speed, including motor off. This speed is set to operate

for 10 minutes, after which the system returns to the

speed that was set before. Suitable to deal with

maximum levels of cooking fumes. Can also be

deactivated by pressing button B.

Press and hold the button for approximately 5 seconds,

with all the loads turned off (Motor and Lights), to turn

the Activated Charcoal Filter alarm on/off.

G 24H function

Starts the Motor at a speed that allows suction of 100

m3/h for 10 minutes per hour for 24h, after which the

Motor will stop. It cannot be activated if the Intensive

or Delay functions are in use.

When the filters alarm is triggered, the alarm can be

reset by pressing and holding this button for

approximately 5 seconds.

These indications are only visible when the motor is

turned off.

H Delay function

Activates/Deactivates automatic switch-off with a 30’

delay. Suitable to complete elimination of residual

odours. Can be activated from any position. It cannot

be activated if the Intensive or 24H functions are in

use.

Press and hold the button for approximately 5 seconds,

with all the loads turned off (Motor and Lights), to turn

the Remote control on/off.

R Remote control receiv er.

Control panel

On/Off

On/Off

The buttons turn light up one at a time in cycle.

Flashes once a second.

Button G (Flashes twice)-Alarm Activated.

Button G (Flashes once)-Alarm Deactivated.

On/Off

B flashes two t imes.

When the procedure terminates, the indication shown

previously turns off:

Button G flashes, indicating the need to wash the metal

grease filters. The alarm is triggered after the Hood has

been in operation for 100 working hours.

Button G flashes, indicating the need to change the

activated charcoal filters, and also to wash the metal grease

filters. The alarm is triggered after the Hood has been in

operation for 200 working hours.

On/Off

Button B (Flashes twice)-Remote control Activated.

Button B (Flashes once)-Remote control Deactivated.

EN

1

10

Page 11

MAINTENANCE

REMOTE CONTROL (OPTIONAL)

The appliance can be controlled using a remote control powered

by a 1.5 V carbon-zinc alkaline batteries of the standard LR03AAA type (not included).

• Do not place the remote control near to heat sources.

• Used batteries must be disposed of in the proper manner.

Metal grease filters

They can be washed in the dishwasher, and need to be cleaned

whenever Button G flashes or at least once every 2 months use,

or more frequently if use is particularly intensive.

Resetting the alarm signal

• Turn the Lights and the Suction motor off, then disable the 24h

function, if enabled.

• Press button G and hold for approximately 5 seconds (See

paragraph on Use).

Cleaning the Filters

• Remove the filters one at a time holding them up with one

hand and pulling the handle downwards with the other hand at

the same time.

• Wash the filters, taking care not to bend them. Allow them to

dry before refitting.

• When refitting the filters, make sure that the handle is visible

on the outside.

EN

1

11

Page 12

Activated Charcoal Filter (Recirculation Version)

This cannot be washed or regenerated, and must be changed when G starts to flash, or at least

once every 4 months. The Alarm signal, if it has been activated, only appears when the Suction

motor is turned on.

Activating the alarm signal

• In Recirculation Version Hoods, the Filter Saturation Alarm must be activated on installation or at a later date.

• Turn the Lights and the Suction Motor off.

• Press F and hold for approximately 5 seconds:

• Button G flashes twice -- A.C. Filter saturation alarm ACTIVATED

• Button G flashes once -- A.C. Filter saturation alarm DEACTIVATED

CHANGING THE ACTIVATED CHARCOAL FILTER

Resetting the alarm signal

• Turn the Lights and the Suction Motor off.

• Press button G and hold for approximately 5 seconds (See

paragraph on Use).

Changing the Filter

• Remove the Metal grease filters.

• Remove the Suction Panel by unfastening the 4 screws at the

corners.

• Remove the saturated Activated charcoal filter, using the hooks

provided.

• Fit the new Filter, hooking it into place.

• Replace the Panel and the Metal grease filters.

EN

1

12

Page 13

DISMANTLING/CLEANING SOUNDPROOFING ELEMENTS

• Remove the Metal grease filters.

• Remove the Suction Panel by unfastening the 4 screws at the

corners.

• Remove the Activated charcoal filter, using the hooks

provided.

• Extract the Soundproofing Elements by pressing on them.

• Clean them with a damp cloth and replace them, first making

sure that they are completely dry.

• Replace the Activated charcoal filters.

• Replace the Metal grease filters and the Suction Panel.

Warning: Take care not to damage/break the element when it is

being removed/replaced.

Lighting unit

Warning: This appliance is fitted with a white LED lamp classed as 1M

according to EN 60825-1: 1994 + A1:2002 + A2:2001 standards; maximum optical power emitted @439nm: 7µW. Do not look directly at the

light through optical devices (binoculars, magnifying glasses…).

• For replacement contact technical support. ("To purchase contact technical support")

EN

1

13

Page 14

Page 15

Page 16

436006024_ver2

Loading...

Loading...