SGR

2

0S

Betriebsanleitung

Operating Instructions

Istruzioni per l’uso

9.696.037

1

SGR20S

Table of Contents

& ENGLISH

Contents Page

1 Table of contents 1

2 Introduction 2

3 Before Starting

Guide to these Operating Instructions 3

Intended Use 3

Set -Up and Function 4

Safety instructions 5

Installation 5

Start –Up 6

4 Basic Functions

Programming Aids 7

Configuration of the device 8

Configuration of the printer 8

Data Input 9

Activation of the printing data 10

Special functions 11

Operation 12

5 Troubleshooting and Maintenance

Troubleshooting Chart 13

Maintenance Chart 15

Parts Service 15

Parts Required for Maintenance and Wear 16

Replacement parts 17

Part numbers 18

Maintenance Information

Replacing ink ribbon 19

Replacing PTFE strip on guide rail 20

Replacing PTFE strip for heating die 21

Replacing pressure roller 22

Calibration 23

Stand by 24

6 Technical Data

Circuit and Wiring Diagram 230 / 115 V 25

Specifications 26

Declaration of Conformity 27

9.696.037

GB

1

ENGLISH

2

SGR20S

Operating Instructions

Introduction

First we would like to thank you for purchasing the SGR20S sealing machine.

These instructions include information on the machine, its function and operation.

! Please read these operating instructions thoroughly before using the machine so that you will

be familiar with the capabilities of the machine and can utilise its features to the optimum.

FAlways keep these instructions in the vicinity of the machine.

Important note:

This device is a packaging machine for the processing of thermoplastic films and composite films

according to the thermal – bonding or sealing process.

In this respect , please pay attention to the “Intended use” chapter in the operating instructions.

According to the intended use , the CE symbol was affixed on the basis

of the EU Directives named below:

89/336/EEC, 98/37/EEC

and 73/23EEC amended by 93/68EEC.

The 93/42EEC Directive is not applicable to bonding and sealing devices.

The limit values stipulated in IEC 60601 – 1 cannot be applied in case of the electrical repetition tests.

The manufacturer will not assume any liability for damage caused by tests according to standards which

are not listed in the declaration of conformity .

Note

Since we continuously improve our products we reserve all

rights to modify these operating instructions and the

functions described therein.

We make all possible efforts to keep these instructions free of

errors and complete. If you note any errors or unclear points

please advise us.

GB

2

9.696.037

ENGLISH

3

SGR20S

Before Starting

Guide to these Operating Instructions

Before Starting

Basic Functions

Troubleshooting

and

Maintenance

Technical Data

This chapter contains information on the functions of the machine and

instructions for handling and installation.

BE SURE TO READ!

Adjustment and operation of the machine are explained here.

Instructions for finding causes of malfunctions and eliminating them.

This chapter includes information on the required maintenance, parts

subject to wear and replacement parts.

Shows the interrelationship between various item numbers, the circuit

and diagram plans and machine specifications.

Intended Use

The SGR20S machine is intended for commercial and industrial applications and should

be used only for the intended purpose.

The SGR20S machine is a sealing machine for sealing sterilization packages

consisting of paper, paper laminate foil or Tyvek foil.

! It is not suitable for sealing pure polyethylene foils, soft PVC foils, hard PVC foils,

polyamide foils or polypropylene foils.

The machine capacity depends on the characteristics of the sealing material used.

9.696.037

GB

3

ENGLISH

3

SGR20S

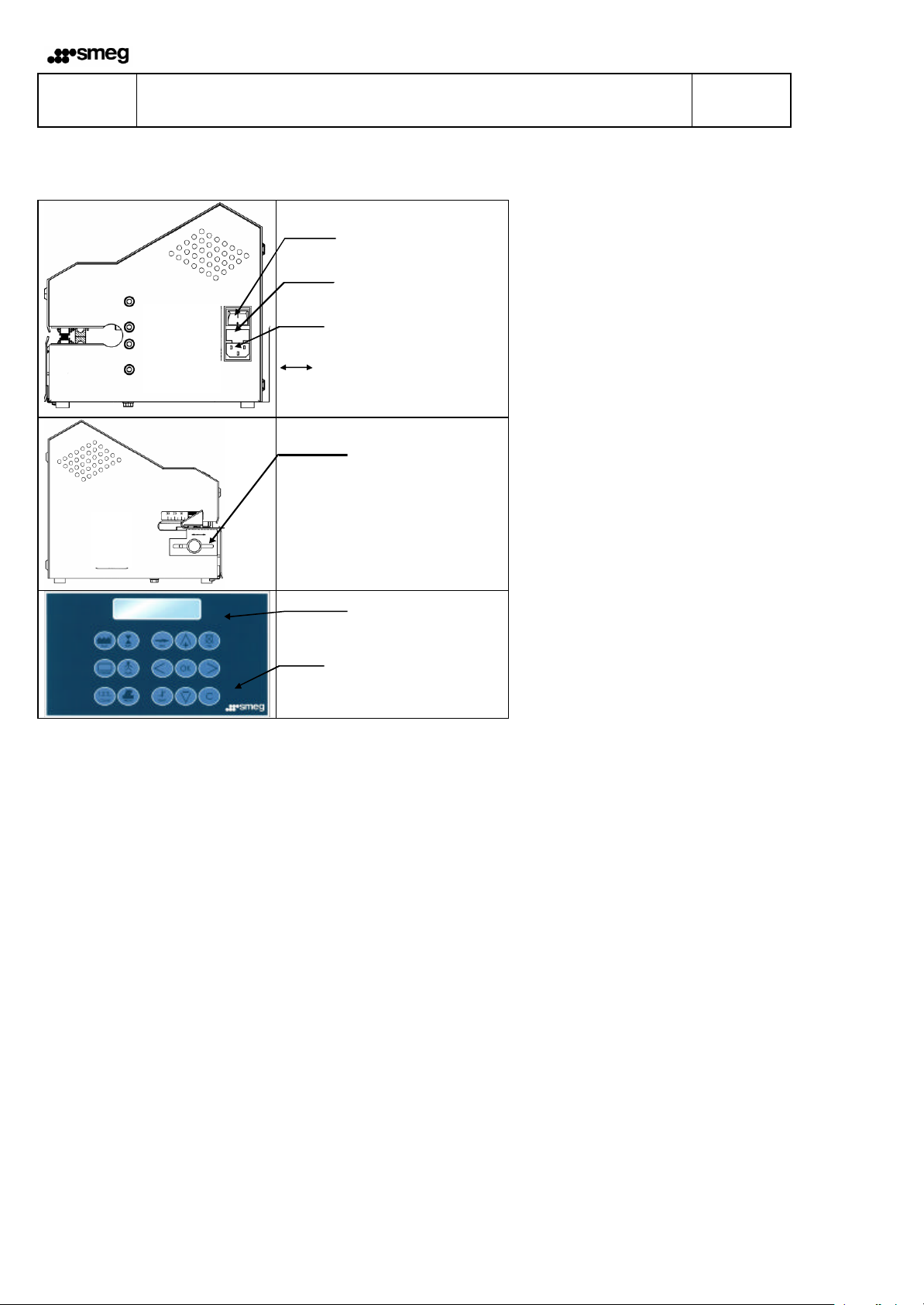

Set-Up and Function

Before Starting

Power switch

Power fuse

Power connection

Adjustable for the user manual

Peel edge adjustment

5 - 30 mm

Display

Input and

function keys

Sealing and Printing Operation Sequence

1. After inserting the sterilization package switch on transport.

2. The sterilization package is then transported and the area of the sealing seam is heated to the sealing

temperature set on the upper and lower heating dies.

3. The hot seam is pressed together by the sealing roller sealing it.

4. The printing operation is activated and the activated print data is printed onto the sealed package.

5. The finished sterilization package is transported to the discharge side.

6. If more packages to be sealed are not fed in the transport mechanism shuts off after approx. 30 s.

GB

4

9.696.037

ENGLISH

3

•

Œ

SGR20S

Before Starting

General safety instructions

The device must not be installed or operated by persons under

14 years of age.

The device must not be operated unattendedly.

I

Turn of the device or disconnect the power cord when it is not in use.

The device should only be cleaned with a dry or slightly damp cloth.

Warning! Never clean the device wet!

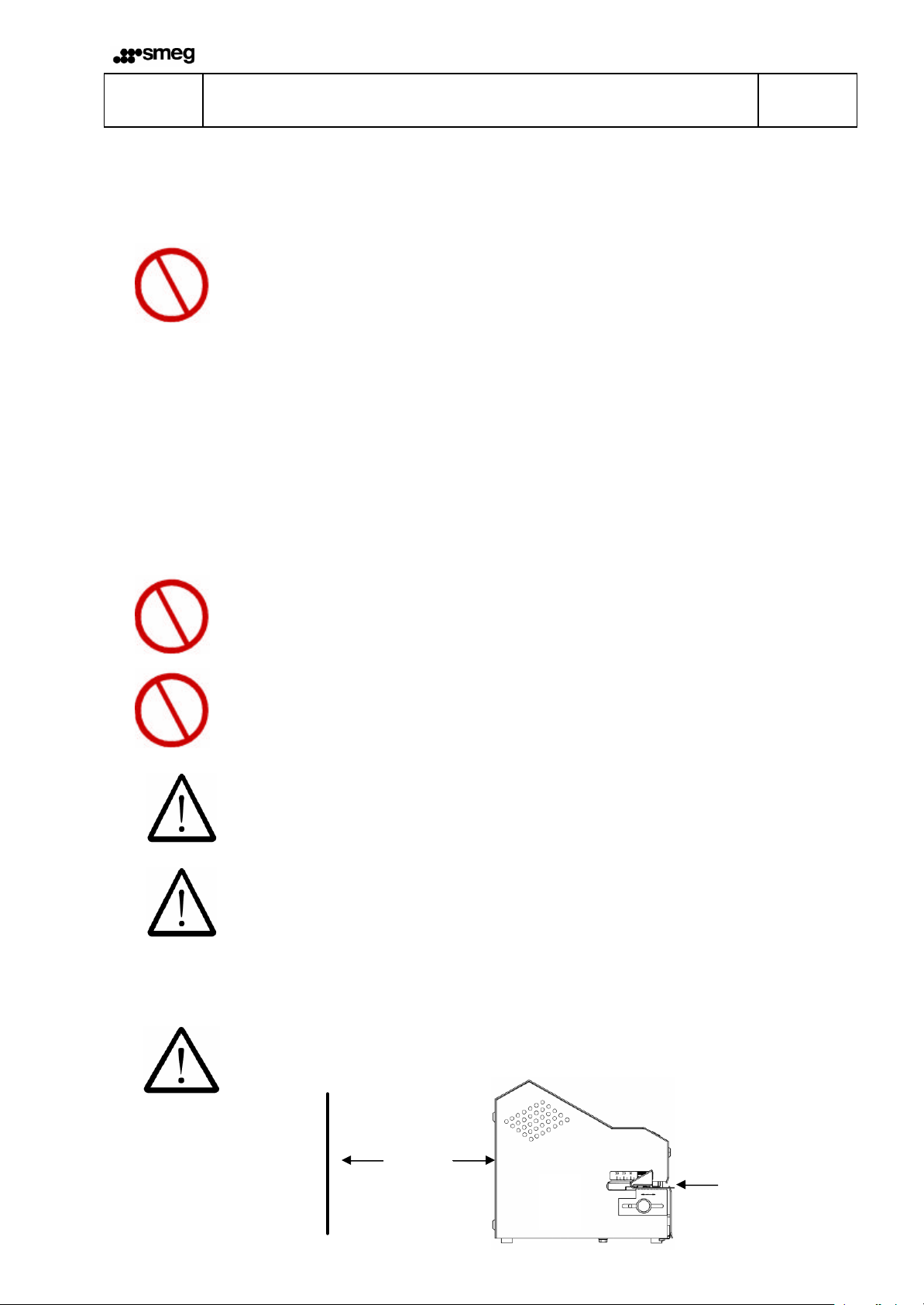

Installation

Do not install or operate the machine in explosion hazard areas.

I

I

Use only power sockets with protective ground.

Set up the machine only in dry areas.

Heavy dust, vapour, dripping or spraying water have a negative effect

on the machine functions.

Always ensure that the operating power corresponds to the specifications on the

machine rating plate.

F Please choose a socket where the line power is stable.

Please do not transport device on the peel edge setting! Œ

Leave a gap of 200 mm between the device and the wall. •

9.696.037

200 mm

5

GB

3

956579

Nominal temp 140°C

SGR20S

Start-Up

ENGLISH

Before Starting

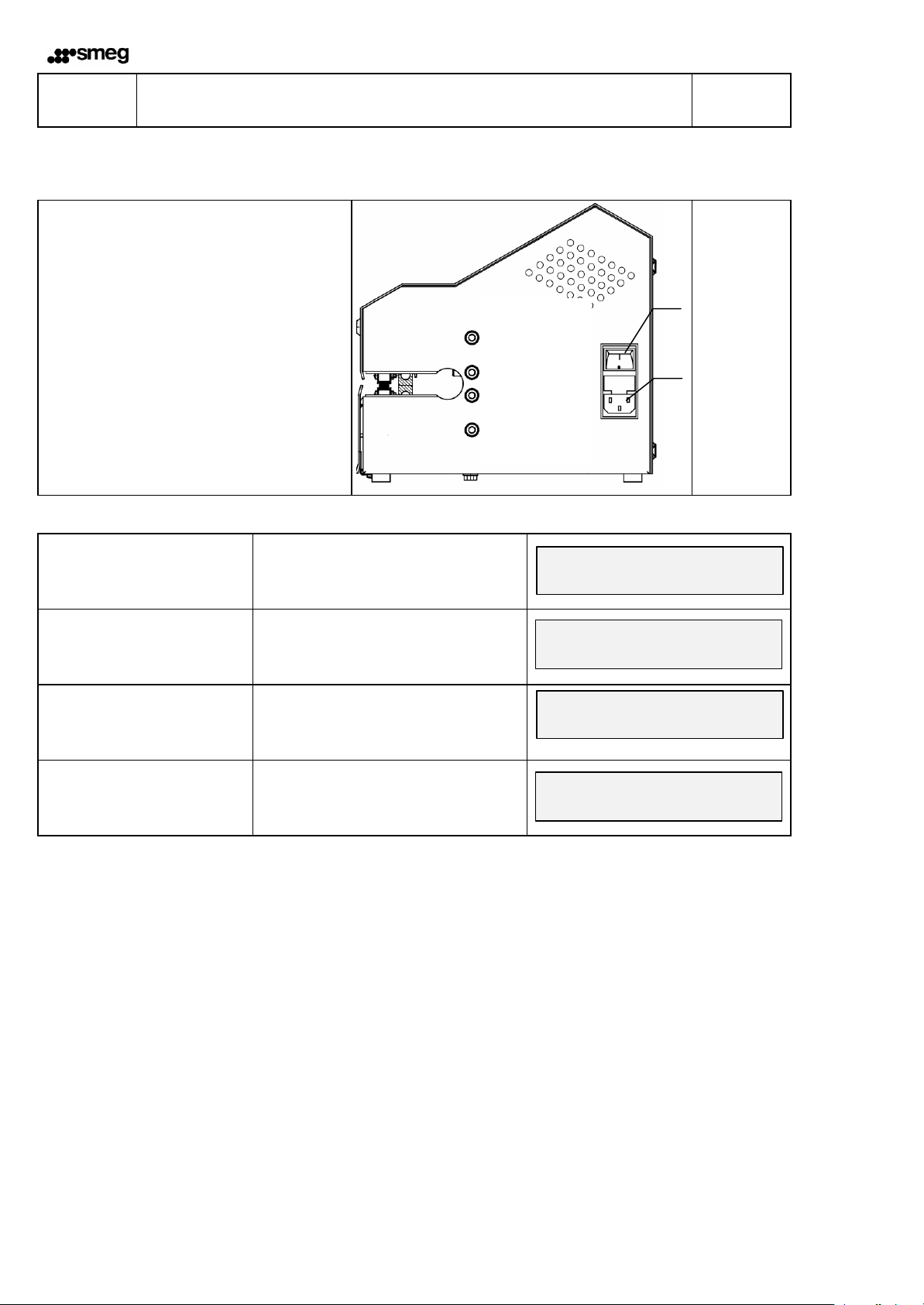

l Plug power cable into power socket

on machine

l Insert plug into wall socket

l Switch on machine

with power switch

FUNCTION DISPLAY

Machine switched on

Self-test runs for approx. 30 s

Display for approx. 5 seconds:

V2.8 = Program version

956579 = Machine number

Display of

date, time

Actual temperature.

Setemperature

After 5 minutes is the

set temperature reached

Machine is ready for operation

Please wait

Control 800 V2.8

17-02-00 14:30 025°C

17-02-00 14:35 140°C

Power switch

Switch

conection

6

GB

9.696.037

ENGLISH

4

SGR20S

Basic Functions

Programming Aids

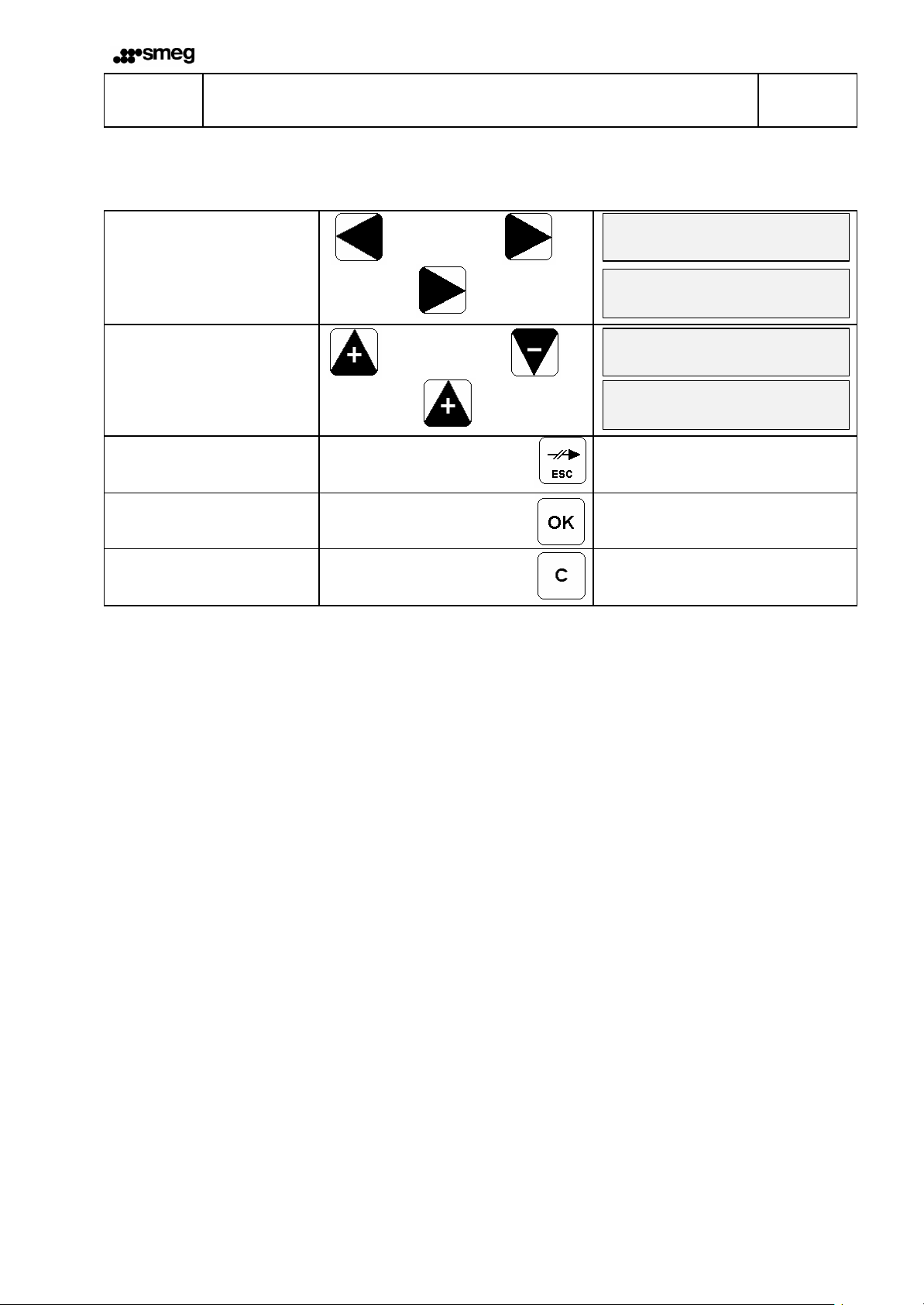

FUNCTION KEYS DISPLAY

INPUT AIDS

Cursor control

Press - cursor right - key once

INPUT AIDS

Changing numbers and

letters

Press key - position +1 - once

INPUT AIDS

Return to previous menu

point without activating entry

INPUT AIDS

Activate input

Cursor Cursor

1x

left right

Position +1Position -1

1x

100°C

5Cursor flashes at 1st digit

100°C

5Cursor flashes at 2nd digit

100°C

st

51

digit is number 1

200°C

51st digit is number 2

INPUT AIDS

Space at selected point

Set piece counter to 0

9.696.037

GB

7

ENGLISH

YES

00 0

-

99mm

0 0

-

5

4

GB

C

SGR20S

Basic Functions

Configuration

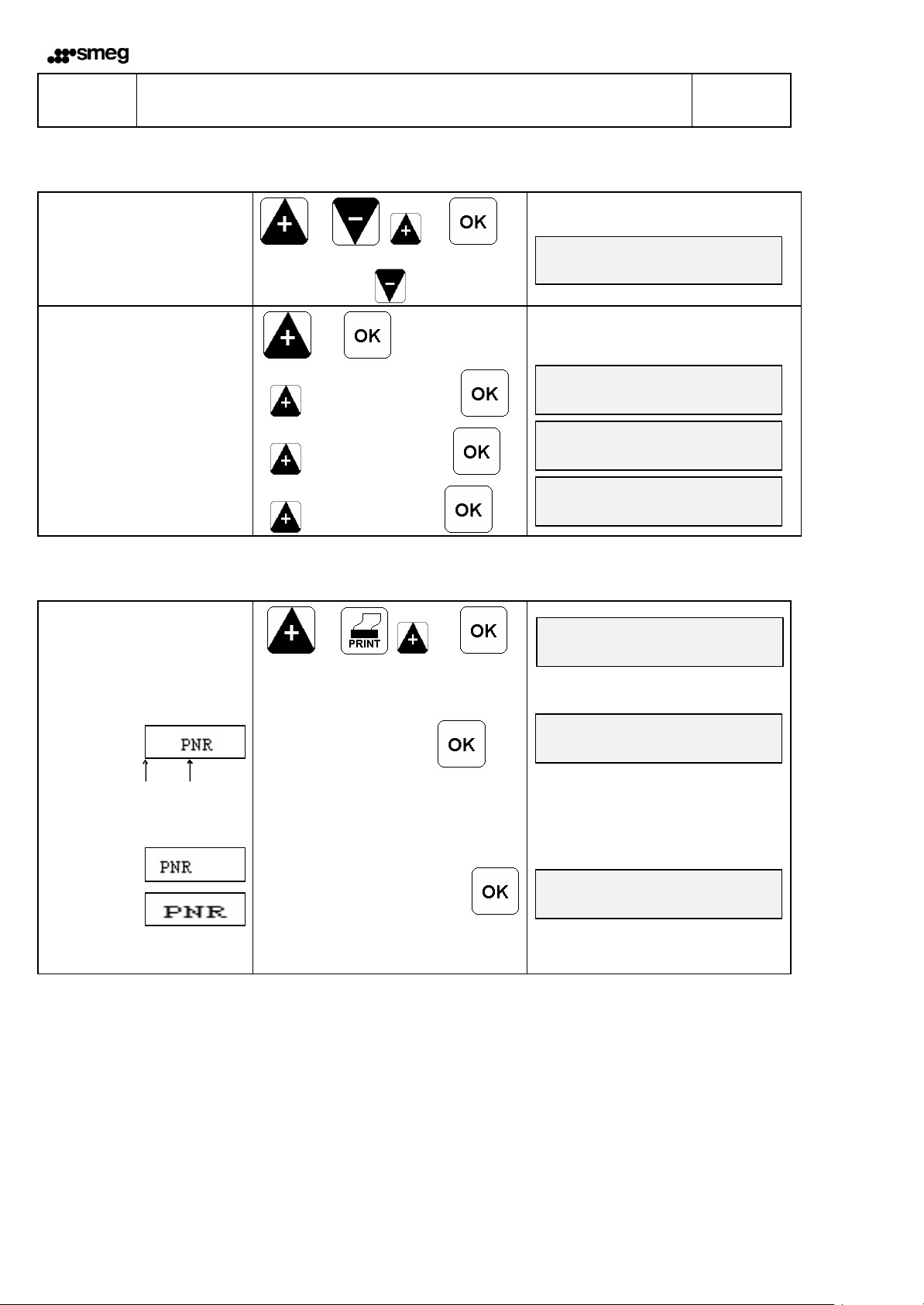

FUNCTION KEYS DISPLAY

CONTRAST SETTING

DATA INPUT

Selection: Language, symbols,

temperature unit

Language:

DE, GB, FR, ES, IT, FI, SE, PL

Symbols: yes/no

Temperature unit : C / F

è

è

Language selection

yes / no

Celsius / Fahrenheit

Contrast é

Contrast ê

display - contrast

set language

pictogramm NO

temperature unit

Printer Set-Up

FUNCTION KEYS DISPLAY

PRINTER SET UP

Start printing

0 - 99 mm

Character width

0 - 5

è

Yes / No

Input

Start printing

Input

Character width

Input

printer set up

distance

character width

8

GB

9.696.037

ENGLISH

4

DD-MM

-

YYYY

17-03-2000 1

1234567890

0987654321

123

4567

SMEG

17-02-2000 08:57

175°C

SGR20S

Basic Functions

Data Input

FUNCTION KEYS DISPLAY

TEMPERATURE

Nominal temperature input

80 - 220 °C / 176 - 428 ° F

DATA INPUT

Date and time

Input of 6 different date

formats

1 dd-mm-yyyy 2 mm-dd-yyyy

3 yyyy-mm 4 mm-yyyy

5 yyyy 6 yyyy-mm-dd

DATA INPUT

Expiration date

Enter 3 differnt expiration

dates,

ex works: 1= Date + 1 Month

2= Date + 3 Month

3= Date + 6 Month

DATA INPUT

Charge number

10-digit, alphanumerical

DATA INPUT

Personnel number

20-digit, alphanumerical

DATA INPUT

Piece counter

7-digit, numerical

DATA INPUT

Text

20-digit, alphanumerical

Input

Temperature

è ê

1,2,3,4,5,6

Input

ê

1,2,3

date, time

Input

Expiration date

Input

Charge number

Input

Personnel number

Input

Piece Counter

Input

Text

nominal temp.

for mat date & time

DD-MM-YY hh:mm

DD-MM-YYYY

piece counter

text input

9.696.037

GB

9

ENGLISH

ays print in the same

4

17-02-2000

17-03-200

0 1

1234567890

0987654321

12345

SMEG

17-03-2000

17-02-2000

17-02-2000

SGR20S

Basic Functions

Data Activa tion / Deactivation

FUNCTION

The print sequence is

predefined, this means the

individual information like

Sterlization date

Expiry date

Charge number

Personnel number

Piece counter

Text

get alw

sequence

FUNCTION KEYS DISPLAY

PRINT

Sterilization date

PRINT

Expiration date

Selection of 3 different

expiration dates

PRINT

Charge number

PRINT

Personnel number

PRINT

Piece counter

PRINT

Text

Print: Sterlization date, Expiry date, Personnel number

Print: Sterlization date, Personnel number

Print Do not print

Miller

Print Do not print

ê

1,2,3

Print Do not print

Print Do not print

Print Do not print

Print Do not print

piece counter

text input

Miller

10

GB

9.696.037

ENGLISH

1234567

000053 h 25 min

printer off

4

SGR20S

Basic Functions

Special functions

FUNCTION KEYS DISPLAY

PRINT

Printer OFF/ON

DISPLAYS

Absolute part counter

è

DISPLAYS

Operating time counter

è

17-02-2000 14:30 180°C

absolute p. counter

operating time

9.696.037

GB

11

ENGLISH

4

SGR20S

Basic Functions

Operation

Sealing Operation

l Adjust peeling edge width

After loosening the arrest the peeling edge can be adjusted infinitely between 5 mm and 30 mm

by moving the plate.

l Insert sterilization package

The drive is switched on automatically.

l Removed sealed sterilization package and allow to cool briefly.

F Check strength by tearing open seal.

If unsealed points are present increase the sealing temperature. If the paper discolors or the

foil peels off the temperature is too high.

Deter mine suitable sealing temperature with sealing tests.

GB

12

9.696.037

ENGLISH

5

SGR20S

Troubleshooting and Maintenance

Troubleshooting Chart

Malfunction Possible cause Remedy

Machine cannot be switched

on

No data on display

Machine does not heat up

No transport Motor sensor

Power connection

Power cable not plugged in

Power cable defective

Power fuse

Control board

Display board

Nominal temperature too low

Temperature limitation active

Temperature sensor

Heating cartridge

Control board

Front flap not closed

Front flap - sensor

Transport belt

Damaged

No transport

Motor

Control board

Check power connection, if

necessary connect to different

socket.

Replace power cable.

Replace power fuse

! If fuse blow s again always have

machine checked.

Replace control board

Replace display board

Increase nominal temperature

Reset temperature limiter

by pressing in pin

! If temperature limiter trips again

always have machine checked

Replace temperature sensor

Check heating cartridges, replace if

necessary

Replace control board

Replace light barrier

Close front flap

Replace front flap sensor

Replace transport belt

Check belt tension

Replace motor

Replace control board

9.696.037

GB

13

ENGLISH

5

SGR20S

Troubleshooting and Maintenance

Troubleshooting Chart

Malfunction Possible cause Remedy

Material feed not uniform or

loud running noise

Seal does not hold

Sealing seam distorted Pressure

Paper side of

package discolored

or side fold shrunk

No imprint or

imprint incomplete

Imprint too weak

Keyboard does not work Keyboard

Transport belt guide

Transport belt

Damaged

No transport

Motor

Temperature

too low

Pressure

too low

too high

Temperature

too high

Programming

Start of print not correctly adjusted

Ink ribbon

Printer head

Control board

Ink ribbon

Print head

Paper hold-down

Display board

Control board

Replace PTFE belt on guide die

Replace transport belt

Check belt tension

Replace motor

Increase temperature

Readjust pressure of sealing roller or

replace sealing roller

Loosen upper guide die and readjust

downward

Reduce temperature

Reprogram start of print

Ink ribbon not correctly installed

Replace ink ribbon

Replace print head

Replace control board

Replace ink ribbon.

Readjust print head.

Replace pressure spring for paper

hold-down

Check keyboard connector for good

contact.

Replace keyboard

Replace display board.

Replace control board

GB

14

9.696.037

ENGLISH

5

Check

Replace

Adjust

Measure

SGR20S

Troubleshooting and Maintenance

Maintenance Chart

As all technical equipment your equipment is also subject to technical wear.

In order to ensure that your machine is always ready for use it should be serviced at least

once annually by a trained technician.

Maintenance

chart

At least every

3 months

Depending on

use, at least

once annualy

Ink ribbon

PTFE strip

for guide

die

PTFE strip

for sealing

die

Pressure

roller

Parts Service

F Simply order parts by fax:

l Please copy the following pages according to the parts required.

Page 17: Parts required for maintenance and wear

Page 18: Replacement parts

l Enter machine number.

l Enter machine model

l Enter name, address, fax number and order number.

l Mark items required

l Enter quantity required.

l Sign order.

l Fax order.

Toothed

belt

No.: 123456

Type: SGR20S

Sealing die

interval

Sealing

temperature

between

sealing die

9.696.037

GB

15

To:

Fax

Order Nr ______________ Date: ________________

Machine Model ______________ Machine number _______________

þ

¨

¨

¨

¨

¨

¨

¨

¨

¨

¨

Ink ribbon

PTFE strip for sealing die

PTFE strib for upper guide rail

PTFE strib for lower guide rail

Pressure roller plastic

Toothhead belt drive 225 mm

Toothhead belt drive 355 mm

Toothhead belt, material transport

Heating cartridge

From:

Designation

Part No

6.813.104

6.105.125

6.105.139

6.105.138

2.230.008

6.271.004

6.271.002

6.271.008

6.536.032

qty

¨

¨

¨

¨

Signature __________

GB

16

9.696.037

To:

Fax

Order No ______________ Date: ______________

Machine model ______________ machine number _______________

þ

From:

Designation

Part No

qty

¨

¨

¨

¨

¨

¨

¨

¨

¨

¨

Print head

Control board 230V

Control board 115V

Display board

Gear motor 230V

Gear motor 115V

Light barrier

Temperature limit switch

Thermocouple

1.653.002

1.410.063

1.410.064

1.410.017

1.212.005

1.212.014

1.561.003

6.564.018

6.564.023

¨

¨

¨

¨

Signature ____________________

9.696.037

GB

17

5

6.105.139

2.301.027

SGR20S

ENGLISH

Troubleshooting and Maintenance

Part numbers

Heating die

upper guide rail

lower guide rail

6.105.285

6.564.023

6.536.032

6.564.018

2.301.027

2.651.186

6.181.011

2.301.027

6.105.139

2.301.027

GB

18

9.696.037

ENGLISH

5

H

SGR20S

Troubleshooting and Maintenance

Maintenance Information

Replacing ink ribbon

l Switch off machine

l Open front flap

l Press lever for ink ribbon holder Πdown with left hand.

l Press holder for rink ribbon cassette • to side and remove cassette.

l Insert new ink ribbon cassette.

Always ensure that the transport opening Ž in the cassette is attached to the transport shaft •.

l Press ink ribbon cassette toward rear until holder • catches .

l Close front flap

l Switch on machine and check printing function after reaching nominal temperature.

E•

Œ

•

Ž

9.696.037

GB

19

ENGLISH

5

Ž

SGR20S

Troubleshooting and Maintenance

Maintenance Information ! Please use only genuine replacement parts.

Replacing PTFE strip on guide rail

l Switch off machine and DISCONNET POWER PLUG !

l Open housing

l Remove mounting screws Πfor upper guide rail and remove guide rail or

l Remove mounting screws• for lower guide rail and remove guide rail

l Remove mounting screws Ž and detach PTFE strip

l Pull backing foil off of new PTFE strip and glue new PTFE strip on straight and without wrinkles

l Fasten PTFE strip with screws Ž

l Install guide rail

FWhen installing the upper guide rail before fastening, push the die down so that the interval between the screw head

and rail is 1 mm on both sides. This ensures the correct contact pressure for the guide rail.

l Close housing

Œ Œ Œ

• •

Ž

Distance between screw head and rail = 1 mm

PTFE strip

GB

20

9.696.037

ENGLISH

5

Œ • • ‘ ‘

SGR20S

Troubleshooting and Maintenance

Maintenance Information ! Please use only genuine replacement parts.

Replacing PTFE strip for upper and lower heating die

l Switch off machine and DISCONNET POWER PLUG !

l Open housing

l Remove mounting screws Πfor upper guide rail and remove guide rail.

l Remove pressure spring •

Œ

l Remove backing foil on new PTFE strip and glue newe PTFE strip on straight and without wrinkels

l Fasten PTFE strip with screw ‘

l Install heating die

l Insert spacer and fasten with mounting screws •

l Reconnect electrical connections to heating die

l Install pressure spring •

l Install guide rails.

Œ

l Disconnect electrical connections for heating die

l Unscrew mounting srew • and remove spacer

l Remove top or bottom heating die

l Unscrew mounting screw ‘ and detach PTFE

strip

FWhen installing the upper guide rail before fastening , push the die down so that the interval

between the srew head and rail is 1mm on both sides.

This ensures the correct contact pressure for the guide rail

l Close housing

9.696.037

Distance between screw head and rail = 1mm

GB

21

ENGLISH

5

SGR20S

Troubleshooting and Maintenance

Maintenance Information ! Please use only genuine replacement parts.

Replacing pressure roller

l Switch off machine and DISCONNET POWER PLUG !

l Open housing

l Remove mounting screws Πfor upper guide rail and remove guide rail.

l Loosen mounting screw Ž and pull pressure roller completely out of holder

l Detach snap ring • and remove pressure roller

l Install new pressure roller and fasten with snap ring •

l Position complete pressure roller in holder, center in relation to bottom roller and tighten mounting screw Ž

l Install guide rail

Œ Œ Œ

Ž

•

FWhen installing the upper guide rail before fastening, push the die down so that the interval between

the screw head and rail is 1 mm on both sides. This ensures the correct contact pressure for the guide rail.

l Close housing

Distance between screw head and rail = 1 mm

GB

22

9.696.037

ENGLISH

5

next key

GB

test print

distance 1 mm

distance 2

SGR20S

Troubleshooting and Maintenance

Calibration

After replacing the temperature sensor or heating elements it is necessary to calibrate the temperature. After replacing the

print head or "print start" light barrier it is necessary to calibrate the printer.After replacing the electronic unit it is necessary

to perform both adjustment operations.

FUNCTION KEYS DISPLAY

Switch off machine

All 3 keys together

Switch on machine

Self-test runs for approx. 30 s

Select language

Language:

German, English, French,

Spanish, Italian

SYSTEM CALIBRATION

TEMPERATURE

Measure temperature between

printing dies

PRINTER

1. Print test with

specimen > 150 mm

2. Measure distance 1 and 2

Bottom of specimen

Distance 1 Distance 2

+

+ +

Language selection

Temperature Printer

After reaching T=120 °C / 248 °F:

Enter measured temperature 1 after

waiting 120 sec.

Input

temperature 1

After reaching T=200 °C / 392 °F:

Enter measured temperature 2 after

waiting 120 sec.

Input

temperature 2

Confirm test printout

Input distance 1

Input distance 2

Please wait

Set language

system calibration

Time 1 Temperature 1

120 120°C

reading : °C

Time 2 Temperature 2

120 200°C

reading : °C

printer calibration

printer calibration

printer calibration

mm

Switch off machine

9.696.037

GB

23

ENGLISH

6

120 min

20 min

Yes

GB

SGR20S

Stand by function

Switch off machine

All 3 keys together

Switch on machine

Self-test runs for approx. 30 s

Select language

Language:

German, English, French,

Spanish, Italian

Press buttons in sequence

Enter time for switch over the

standby operation,

min 10 min

max 120 min

Stand by function

activate / deactivate

+ + +

Technical Data

+

Input

yes / no

Please wait

Set language

Stand by after

Stand by after

Activate Stand by

GB

24

9.696.037

ENGLISH

6

230V ~

− +

− +

SGR20S

Technical Data

Circuit and Wiring Diagram 230 V

Display board

Thermocouple

24V

Motor

Transport

M

1 2

4 3

Relais

Fan

Temperature limit switch

230V ~

Heating

Cardridge

115V 200W

1 2 3 4 5 6 7 8 9

2 1 1 3 5 4 4 6 8 7 7 9

OPB 704

OPB 704

OPB 704

Motor Printer Front flap

Circuit and Wiring Diagram 115 V

Display board

Thermocouple

Print head

115V ~

Motor

Transport

M

1 2

4 3

Main fuse 2 x 2 AT

Fan

115V ~

Relais

Temperature limit switch

24V

1 2 3 4 5 6 7 8 9

2 1 1 3 5 4 4 6 8 7 7 9

OPB 704

OPB 704

OPB 704

Motor Printer Front flap

9.696.037

Print head

Main fuse 2 x 5 AM

Heating

Cardridge

115V 200W

GB

25

6

ENGLISH

SGR20S

Technical Data

Specifications

Power connection [ V ] 230 / 115

Main fuse 230 V (115V) [ A ] 2 T ( 5 M )

Power consumption max [ W ] 500

Heat dissipation [ kJ/s] 0,1

Noise intensity [ dB/ A ] <70

Ambient temperature [ °C ] 5-25

Dimensions, length [ mm ]

width

height

Weight approx. [ kg ] 23

Processing speed [ m / min ] 10

Sealing temperature [ °C ] 80-220

Sealing temperature tolerance [+ - % ] 2

Sealing seam [ mm ] 12

Infinitely adjustable sealing edge [ mm ] 5-30

Sealing seam length [ mm ] unlimited

620

260

250

GB

26

9.696.037

Loading...

Loading...