Page 1

1 INSTRUCTIONS FOR SAFE AND PROPER USE ____________________ 25

2 POSITIONING OF THE HOB ____________________________________ 27

3 ELECTRICAL CONNECTION ____________________________________ 29

4 GAS CONNECTION ___________________________________________30

5 ADAPTATION TO DIFFERENT TYPES OF GAS _____________________32

6 FINAL OPERATIONS __________________________________________36

7 USING THE HOB______________________________________________ 39

8 CLEANING AND MAINTENANCE_________________________________ 42

THESE INSTRUCTIONS ARE VALID ONLY FOR END USER COUNTRIES

WHOSE IDENTIFICATION SYMBOLS APPEAR ON THE COVER OF THIS

MANUAL.

INSTRUCTIONS FOR THE INSTALLER: these are for the qualified

technician who must carry out a suitable check of the gas system, install

the appliance, set it functioning and carry out an inspection test.

INSTRUCTIONS FOR THE USER: these contain user advice,

description of the commands and the correct procedures for cleaning

and maintenance of the appliance.

Contents

24

Page 2

1 INSTRUCTIONS FOR SAFE AND PROPER USE

THIS MANUAL IS AN INTEGRAL PART OF THE APPLIANCE AND

THEREFORE MUST BE KEPT IN ITS ENTIRETY AND IN AN

ACCESSIBLE PLACE FOR THE WHOLE WORKING LIFE OF THE

COOKING HOB. WE ADVISE READING THIS MANUAL AND ALL THE

INSTRUCTIONS THEREIN BEFORE USING THE COOKING HOB.

ALSO KEEP THE SERIES OF NOZZLES SUPPLIED. INSTALLATION

MUST BE CARRIED OUT BY QUALIFIED PERSONNEL IN

ACCORDANCE WITH THE REGULATIONS IN FORCE. THIS

APPLIANCE IS INTENDED FOR DOMESTIC USES AND CONFORMS

TO CURRENT REGULATIONS IN FORCE. THE APPLIANCE HAS

BEEN BUILT TO CARRY OUT THE FOLLOWING FUNCTIONS:

COOKING AND HEATING-UP OF FOOD. ALL OTHER USES ARE

CONSIDERED IMPROPER. THE MANUFACTURER DECLINES ALL

RESPONSIBILITY FOR IMPROPER USE.

DO NOT LEAVE THE PACKING IN THE HOME ENVIRONMENT.

SEPARATE THE VARIOUS WASTE MATERIALS AND TAKE THEM TO

THE NEAREST SPECIAL GARBAGE COLLECTION CENTRE.

IT IS OBLIGATORY FOR THE ELECTRICAL SYSTEM TO BE

GROUNDED ACCORDING TO THE METHODS REQUIRED BY

SAFETY RULES.

THE PLUG TO BE CONNECTED TO THE POWER CABLE AND THE

SOCKET MUST BE THE SAME TYPE AND MUST CONFORM TO

CURRENT REGULATIONS.

NEVER UNPLUG BY PULLING ON THE CABLE.

IMMEDIATELY AFTER INSTALLATION CARRY OUT A BRIEF

INSPECTION TEST OF THE COOKING HOB, FOLLOWING THE

INSTRUCTIONS BELOW. SHOULD THE APPLIANCE NOT FUNCTION,

DISCONNECT IT FROM THE SUPPLY AND CALL THE NEAREST

TECHNICAL ASSISTANCE CENTRE.

NEVER ATTEMPT TO REPAIR THE APPLIANCE.

ALWAYS CHECK THAT THE CONTROL KNOBS ARE IN THE

POSITION "ZERO" (OFF) WHEN YOU FINISH USING THE HOB.

Introduction

25

Page 3

THE IDENTIFICATION PLATE, WITH TECHNICAL DATA, SERIAL

NUMBER AND MARKING IS CLEARLY VISIBLE UNDER THE CASING.

THE PLATE ON THE CASING MUST NOT BE REMOVED.

BEFORE CONNECTING THE DEVICE, MAKE SURE THAT IT HAS

BEEN REGULATED FOR THE TYPE OF GAS THAT WILL FEED IT,

CHECKING THE LABEL UNDER THE HOB.

DO NOT PUT PANS WITHOUT PERFECTLY SMOOTH AND FLAT

BOTTOMS ON THE COOKING HOB GRIDS.

DO NOT USE PANS OR GRIDDLE PLATES THAT EXTEND BEYOND

THE EXTERNAL PERIMETER OF THE HOB.

THE HOB IS TO BE USED BY ADULTS ONLY. DO NOT LET

UNSUPERVISED CHILDREN PLAY WITH THE HOB.

THIS APPLIANCE IS MARKED ACCORDING TO THE EUROPEAN

DIRECTIVE 2002/96/EC ON WASTE ELECTRICAL AND ELECTRONIC

EQUIPMENT (WEEE).

THIS GUIDELINE IS THE FRAME OF A EUROPEAN-WIDE VALIDITY

OF RETURN AND RECYCLING ON WASTE ELECTRICAL AND

ELECTRONIC EQUIPMENT.

The manufacturer declines all responsibility for damage to persons or

things caused by non-observance of the above prescriptions or by

interference with any part of the appliance or by the use of non-original

spares.

Introduction

26

Page 4

Instructions for the installer

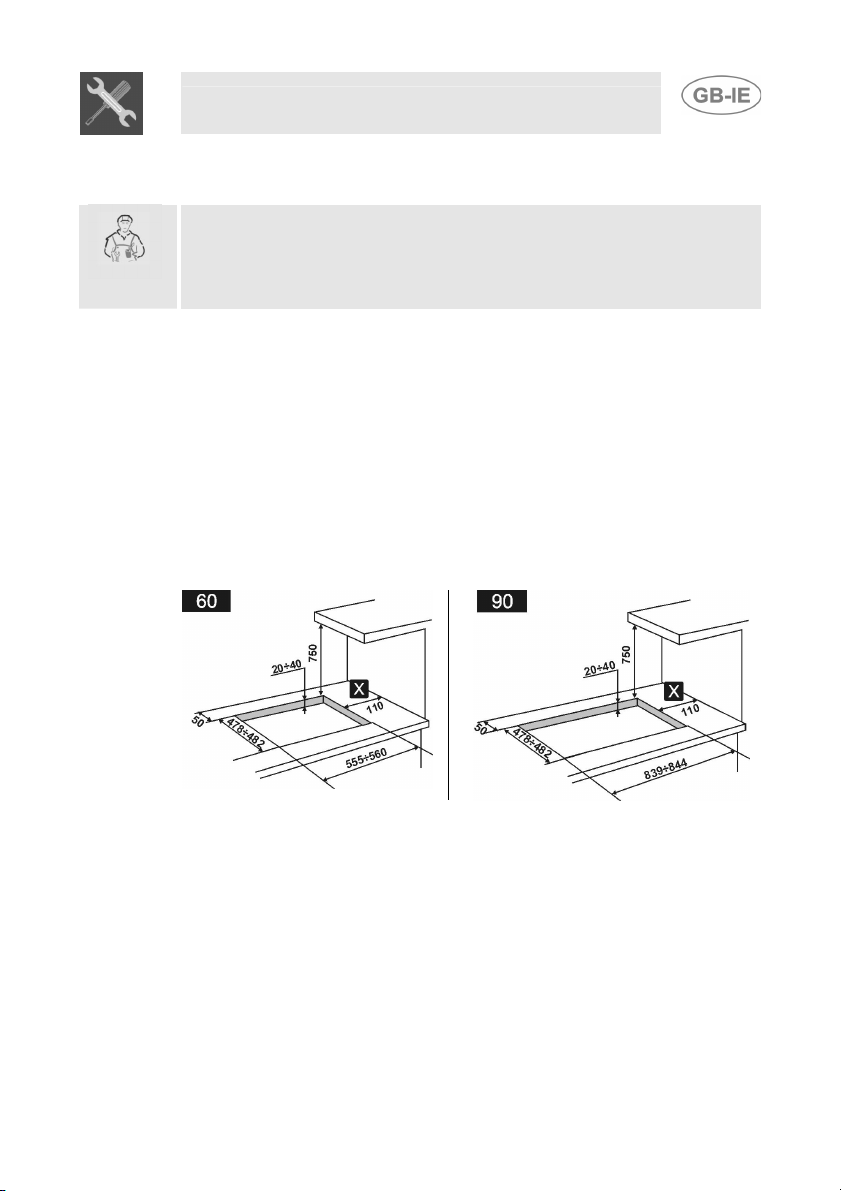

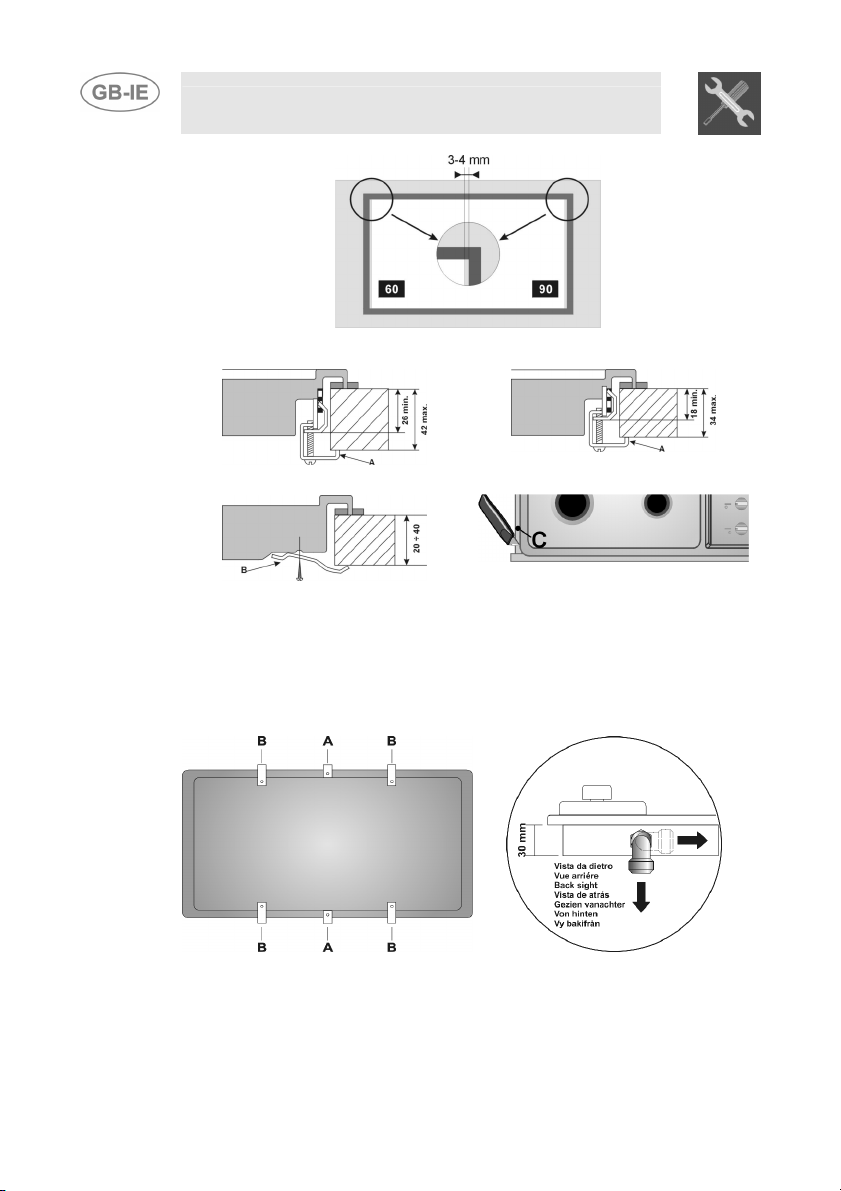

Create an opening with the dimensions shown in the figure in the top

2 POSITIONING OF THE HOB

The following operation requires building and/or carpentry work so must

be carried out by a competent tradesman.

Installation can be carried out on various materials such as masonry,

metal, solid wood or plastic laminated wood as long as they are heat

resistant (T 90°C).

2.1 Attachment to support structure

surface of the counter, keeping a minimum distance of 50 mm from the

rear border.

This appliance is classified as “type Y” in relation to fire hazards and

can therefore be mounted against walls higher than the work surface on

condition that a certain distance “X” be kept between the appliance and

the wall as shown in the figure so as to avoid damage from

overheating.

Make sure there is a minimum of 750 mm between the hot plate flames

and any shelf that may be installed directly above them.

Accurately position the gasket provided all around the outer edge of the

hole in the top surface as shown in the figures below, pressing it down

so as to make it adhere properly. For measurements, refer to the figure

depending on the hob model to be installed, bearing in mind that in both

models the front and rear sides must skim the hole. Secure the hob to

the counter with brackets A or B(supplied). Carefully trim any excess

from border C of the gasket. The distances in the following drawing

refer to the hole on the inner side of the gasket.

27

Page 5

Instructions for the installer

Bracket ‘A’ in the 1st slot

Bracket ‘B’

Bracket ‘A’ in the 2nd slot

2.2 Fixing 90 cm hobs on 60 cm base unit

If a 90 cm hob is to be bracketed to a 60 cm base unit, 2 central

brackets “A” have to be used in addition to the side brackets “B” as

shown in the drawing below. The gas connection also has to be turned

through 90° in relation to the original position(see paragraph 4 GAS

CONNECTION).

28

Page 6

Instructions for the installer

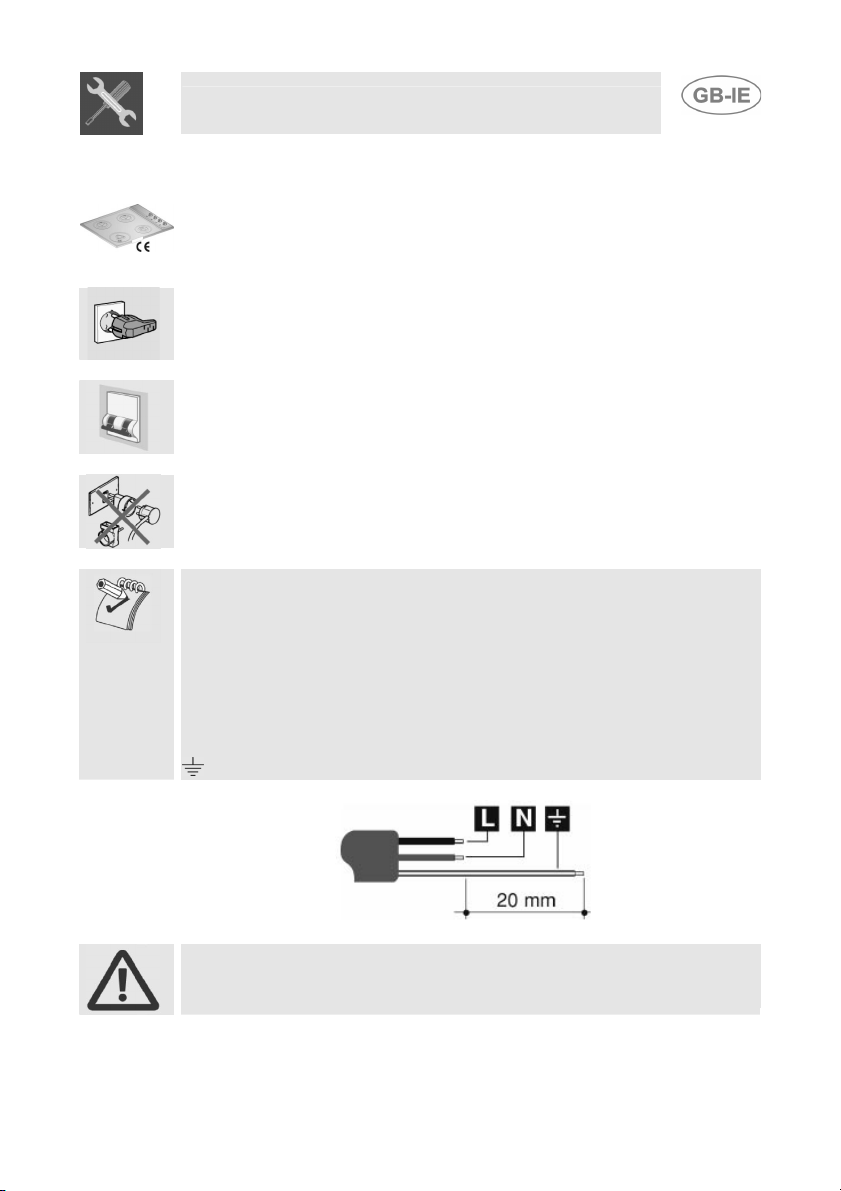

3 ELECTRICAL CONNECTION

Make sure that the voltage and capacity of the power line conform to

the data shown on the plate located under the casing. Do not remove

this plate for any reason.

The plug on the end of the supply cable and the wall socket must be

the same type and conform to the current electrical system regulations.

Check that the power line is adequately grounded.

On the power line, install an omnipolar cut-off device with contact cut-

off distance greater than or equal to 3 mm, located in an easily

accessible position near the unit.

Do not use reducers, adapters or shunts.

If the power cable is replaced, the wire section on the new cable must

not be less than 1 mm

be connected to the hob must have the ground wire (yellow-green)

longer by at least 20 mm. Use only H05V2V2-F cable or similar which

has a maximum temperature of 90°C. Any replacement needed should

be carried out by a specialised technician who should make the mains

connections according to the following diagram.

L = brown

N = blue

= yellow-green

The manufacturer will not be liable for any damage to persons or

property caused by non-observance of the above instructions or

deriving from the tampering of even a single part of the hob.

2

(3 x 1 cable), keeping in mind that the end to

29

Page 7

Instructions for the installer

4 GAS CONNECTION

Connection to the gas mains may be made with a rigid copper pipe or

with a flexible pipe and conforming to the provisions defined by

standard regulations in force.

To facilitate connection, fitting A on the rear of the appliance may be

adjusted laterally. For this purpose, loosen hexagon nut B, turn fitting A

to the desired position, and retighten hexagon nut B (tightness is

ensured by a biconical brass ring). Use a soapy solution to check for

proper tightness. Never use a free flame. The hob has been inspected

for G20 (2H) natural gas at a pressure of 20 mbar. For use with other

types of gases, see Section “ ADAPTATION TO DIFFERENT TYPES

OF GAS”. The gas intake fitting is ½” gas external threaded (ISO 228-

1).

Connection with rigid copper pipe: the

connection to the gas mains must not

provoke stress of any kind on the hob.

Connection may be made by using biconical

adapter D with insertion of gasket C

(supplied).

Connection with flexible pipe: use only

flexible pipes conforming to standard

regulations in force, inserting gasket C

(supplied) between fitting A and flexible pipe

E.

The flexible pipe has to be installed so that pipe length does not exceed

1.5 meters of maximum extension. Make sure that the pipes do not

touch any moving parts or become damaged.

30

Page 8

Instructions for the installer

4.1 Connection to LPG

Use a pressure regulator and make the connection to the tank

according to the provisions of standards regulations in force. Make sure

that feed pressure conforms to the levels shown in the table in

paragraph “5.3 Regulation for LPG”.

4.2 Ventilation of rooms

The hob may be installed only in rooms with permanent ventilation, as

required by standards regulations in force. The room in which the hob

is installed must have sufficient air flow to satisfy the requirements of

normal gas combustion and of necessary air exchange in the room.

The air intakes, protected by screens, must be appropriately sized

(regulations in force) and placed so as not to be blocked in any way.

The room where the oven is installed should be suitably ventilated to

avoid overheating or excess humidity produced by cooking, and in the

case of lengthy use a window should be opened or the speed of any

ventilators should be increased.

4.3 Discharge of combustion products

Discharge of combustion products must be guaranteed by means of

hoods connected to a natural draught flue with certain efficiency, or by

means of forced aspiration.

An efficient aspiration system requires careful planning by a specialist

capable of installing it, respecting the positions and distances

prescribed by standards. After installation, the installer must issue a

certificate of conformity.

31

Page 9

Instructions for the installer

5 ADAPTATION TO DIFFERENT TYPES OF GAS

Before performing any cleaning or maintenance work, disconnect the

appliance from the electrical socket.

The hob has been inspected for G20 (2H) natural gas at a pressure of

20 mbar. For functioning with other types of gas the nozzles must be

replaced and the primary air adjusted.

To replace the nozzles and regulate the burners, you have to remove

the top as described in the following paragraph.

5.1 Removing the separable control panel (models with

separable control panel)

1. Remove the knobs and the knob guard

tube “A” by pulling them up;

2. Use a crosshead screwdriver to remove

the screws and the two cylindrical

supports “B”;

3. Raise the left-hand side of the control

panel slightly and shift it to the right to

remove it completely;

4. In models with electric hotplate, the body

of the pilot light has to be removed to free

the control panel;

5. Raise the ignition crosspiece “C” and rest

it on the other side.

5.2 Removing the hob (models with integrated control

panel)

1. Remove the knobs, the

griddles, the burner caps, the

flame caps and the two rear

plugs;

2. Remove the screws “A” which

fix the burner supports;

3. Raise the hob, sliding it off the

ignition plugs and/or the

thermocouples and the gas

tap rods;

4. Lift the ignition crosspiece and

rest it on the other side.

32

Page 10

Instructions for the installer

Check that the connection has been made as described in the “Gas

5.3 Regulation for LPG

connection” section.

Undo the screw “D” and push the air regulator “C” fully down. Use a

spanner to remove the nozzles “B” and fit those of suitable type

following the instructions given in the tables for bottled gas G30/G31 –

28/37 mbar. The nozzle must not be tightened to a torque of over 3 Nm.

Regulate the air flow by moving the Venturi pipe “C”, until the gap “A” is

as shown in the table in point “5.5 Regulation of primary air” and fix it

with the screw “D”. After making the adjustments, restore the seals

with sealing wax or an equivalent material.

Rated

Burner

Auxiliary 1.05 48 30 360 76 75

Semi-rapid 1.7 62 30 360 124 121

Rapid 2.55 76 40 650 185 182

Rapid large 3.1 85 45 800 225 222

Fish pan 2.9 82 50 950 211 207

heating

capacity

Nozzle

Diameter

1/100

mm

LPG – G30/G31 28/37 mbar

By-pass

1/100

mm

Reduced

flowrate

(W)

Flowrate

g/h G30

Flowrate

g/h G31

Ultra rapid 4.0 95 65 1600 291 286

33

Page 11

Instructions for the installer

5.4 Regulation for natural gas

The hob has been inspected for G20 (2H) natural gas at a pressure of

20 mbar. To allow the unit to work with this type of gas, perform the

same operations described in paragraph “5.3

Regulation for LPG”, but

choose the nozzles and regulate the primary air for natural gas, as

shown in the following table and in paragraph “5.5

Regulation of

primary air”. After the regulations have been carried out, restore the

seals with sealing wax or equivalent material.

Rated

Burner

Auxiliary 1.05 73 360

Semirapid 1.7 93 360

Rapid 2.55 115 650

Rapid large 3.1 128 750

Fish pan 2.9 123 950

heating

capacity

Natural gas – G20 20 mbar

Nozzle diameter

1/100 mm

Reduced flowrate

(W)

Ultra rapid 4.0 142 1400

34

Page 12

Instructions for the installer

90 cm hobs with separable control panel.

To identify the burners on your hob, refer to the drawings in point “6.3/6.4 Arrangement of

burners on hob “

5.5 Regulation of primary air

Referred to distance “A” in mm.

60 cm hobs with separable control panel.

Burner

Auxiliary (1) 3.0 2.5

Semirapid r (2) 1.0 2.0

Semirapid l (3) 1.0 1.5

Rapid large (4) 1.0 2.5

G20

20 mbar

Ultrarapid (5) 1.5 4.0

Burner

Auxiliary (1) 2.5 2.5

Semirapid (2) 1.0 2.0

Rapid (3) 1.5 1.5

Fish burner (4) 0.5 8.0

20 mbar

G20

Ultrarapid (5) 1.5 5.5

60 cm hob with built-in control panel.

Burner

Auxiliary (1) 3.0 2.5

Semirapid r (2) 1.0 2.5

Semirapid l (3) 1.0 2.0

Rapid medio (4) 1.0 2.5

20 mbar

G20

Ultrarapid (5) 1.0 3.0

G30/G31

28/37 mbar

G30/G31

28/37 mbar

G30/G31

28/37 mbar

35

Page 13

Instructions for the installer

6 FINAL OPERATIONS

Having carried out the above adjustments, reassemble the appliance

following, backwards, the instructions in paragraph “5.1 Removing the

separable control panel

6.1 Regulation of minimum for natural gas

Replace the components on the burner and

slide the knobs on the gas tap pins. Light the

burner and set it at minimum position. Remove

the knob and turn the regulation screw inside or

next to the gas tap pin (depending on the

model) until you get a suitable minimum flame.

Replace the knob and check burner flame

stability: (rapidly turning the knob from

maximum to minimum position, the flame should

not go out).

6.2 Regulation of minimum for LPG

To regulate the minimum for LPG, completely tighten (clockwise) the

screw inside or next to the gas tap pin (depending on the model).

The diameters of the by-passes for each burner are given in table “5.3

Regulation for LPG”.

After having regulated the device with gas other than the one tested,

replace the label located on the guard with the one that corresponds to

the new gas. The label is inside the bag that contains the nozzles

provided.

/ 5.2 Removing the hob”.

36

Page 14

Instructions for the installer

6.3 Arrangement of the burners on the hob (Hob with

separable control panel)

60 cm. hob

BURNERS

1. Auxiliary

2. Semirapid r

3. Semirapid l

4. Rapid large

5. Ultrarapid

90 cm. hob

BURNERS

1. Auxiliary

2. Semirapid

3. Rapid

4. Fish burner

5. Ultrarapid

37

Page 15

Instructions for the installer

6.4 Arrangement of the burners on the hob (Hob with

built-in control panel).

60 cm. hob

6.5 Lubrication of gas taps

With time it may happen that the gas taps get blocked and hard to turn.

Clean them inside and re-grease them. This operation must be done

by an authorised person.

BURNERS

1. Auxiliary

2. Semirapid r

3. Semirapid l

4. Rapid

5. Ultrarapid

38

Page 16

7 USING THE HOB

Before turning on the burners, make sure that the burner rings, caps

and grids have been fitted correctly.

In the ultrarapid burner, notch A must be aligned with pin B.

Grid C provided is intended for use with woks (Chinese pans).

Adapter D comes only with open grids models and is intended for use

with small sized vessels.

7.1 Ignition of the burners

The device is fit with electronic ignition. Simply press and

simultaneously turn the knob counter-clockwise on the low point flame

symbol, until the burner is ignited.

as to be turneh

ignition the knob has to be kept pressed for about 2 seconds to keep

the flame lit and to activate the safety device.

The burner might go off when the knob is released. In this case repeat

the aforesaid operation keepin

econds.

s

Should the burners go off accidentally in the models with valves, a

safety device will trip after approximately 20 seconds to block the gas

outlet even if the cock is open.

.2 Practical advice for using the burners

7

For better burner performance and minimum gas

consumption, flat bottomed, even pans must be used,

with covers and proportional in size to the burners (see

aragraph “7.3 Diameter of the pans”). p

o avoid overcooking or damage to the surface top

T

Instructions for the user

In models with safety valve, the knob

d to the ignition symbol

before it is pressed, and after

g the knob pressed for more than 2

39

Page 17

Instructions for the user

c s must be positioned

while ooking, all pans or griddle

within the co

inimum

oking hob perimeter an

distance of 3-4 cm from t kn

d must be a

obs. m he

7.3 Diameter of the pans

Burners Ø min. and max. (en cm.)

Auxiliary 12-14

Sem pid ira 16-20

Rapid medio 22-26

Rapid large 22-26

Ultrarapid 22-26

Fish burner Special oval-shaped vessels

.4 Electric elements

7

7.4.1 Turning on electric elements

obs may be fitted with an electric element of varyin

H

d ameter. The

i e ctric t is ontrolle

nd is turned le

a on b a pria

elemen c

ppro

d by a switch

te knob to the y rotating the

desired position.

ow the ta re merely indicative.

7.4.2 ing th elec ment

Us e tric ele s

The settings sh n in ble a

POSITION HEAT

INTENSITY

0 Off

1 Wreak

2 Soft To heat larger amounts of liquid.

3 Slow

4 Medium

POSSIBLE COOKING

To melt butter, chocolate, etc.

To heat small amounts of liquid.

To defrost frozen food and prepare

stews, cooking at or just below

boiling point.

To cook food which has to reach

boiling point, to roast delicate meat

g

40

Page 18

Instructions for the user

5 Strong

6 Very strong

ARNING

W

When switching on the electric e

or fish.

For roasts, steaks and large boiled

joints.

To boil large amounts of water, to

fry.

lement for the

first time, or if the electric element has not been

used for a long time, to remove any

humidity

from the insulating material it should be dried

out by placing the electric element on position 1

for 30 minutes.

To use correctly remember to:

• Switch the electric element only after having placed the pan on it.

• Use flat and thick bottomed pans.

• Never use pans which are smaller than the electric element.

• Dry the bottom of the pan before placing it on the electric element.

• oking with flammable oils and fats, never leave the

When co

ap

pliance.

• The electric elements will stay hot for a long time after use: do

touch them or place any objects on them.

• If any dents appear in the electric element surface, switch it off

immediately and contact the nearest authorised servicing centre.

• Never place sheets of aluminium foil directly on the surface of the

hotplate.

A ew re necessary if you wish to use a griddle plate:

7.5

Using a griddle plate

f precautions a

• leave a gap of at least 160 mm between the edge of the griddle

plate and the side wall;

if one of the burners close to the wooden rear wall is o

• f triple flame

type, leave a gap of at least 160 mm between this wall and the

edge of the griddle plate

;

• do not allow the burner flames to extend beyond the edge of the

griddle plate;

• operate the burners underneath the griddle plate for 10 minutes at

maximum power, then turn them down to the minimum setting.

Never use the griddle plate for more than 45 minutes.

not

41

Page 19

8 CLEANING AND MAINTENANCE

Never use a steam jet to clean the appliance.

Instructions for the user

Before any intervention, disconnect the power supply of the device.

8.1 Cleaning

Clean the cooking top regularly every time you use it, obviously after it

has cooled.

8.1.1 Regular daily cleaning of the hob

In order to clean and preserve the surface, always use specific

products only, which do not contain abrasive substances or chlorinebased acid substances.

How to use: pour the product on a damp cloth and wipe the surface,

rinse thoroughly and dry with a soft cloth or deerskin.

8.1.2 Food stains or residues

Do not use metallic sponges or sharp scrapers: they will

damage the surface.

Use normal non-abrasive products and remove spots or

residuals with non-scratch sponges or, if need be, with wood

or plastic utensils.

Rinse thoroughly and dry with a soft cloth or deerskin.

42

Page 20

8.2 Cleaning of cooking hob components

CAUTION: do not wash these components in a dishwasher.

In normal use of the hob, the stainless steel burner caps and panstands tend to be burnished by the high temperature. Clean these parts

using very fine abrasive sponges or similar commercial products. Then

use a specific paste polish to restore the steel’s shine. Your local

authorised after-sales technician is able to supply professional products

for appliance cleaning and care.

Grids, caps, flame cap crowns and burners can be

removed for ease of cleaning. Wash them in warm

water using a non-abrasive detergent, taking care to

remove all tough spots. Before remounting, allow the

components to fully dry out. In fact, humidity residues

inside the burner holes might impair burner operation.

8.2.1 Ignition plugs and safety devices

For good functioning of the lighting ignition plugs and the safety

devices, keep them very clean.

Check frequently and clean with a damp cloth when necessary.

8.2.2 The electric element

After use, to make sure that the surfaces are clean and long lasting, the

electric element must be treated with specific cleaning products which

are available on the market. This necessary operation prevents

oxidisation (rust formation).

8.2.3 The cover

Clean the glass or steel cover, where mounted, with warm water. Never

use abrasive sponges or detergents.

Never lower the cover when burners or electric elements are on or

still hot.

Attention: the glass lid may break if overheated. Make sure that all the

burners are switched off and let them cool down before lovering the lid.

Instructions for the user

43

Loading...

Loading...