1

PW4060 Series

- TABLE OF PROGRAMS -

PW4060 series: punch washer, 60cm, with

forced-air drying system.

WARNING

This document is an appendix to the device's user manual and must be consulted together with the manual for proper, safe use of the device.

It contains up-to-date information concerning the characteristics of the washing programs installed in the device. Due to changes made in response to improvements in products, the

programs described here may differ from those described in the manual: in this case, only refer to the information provided in this document.

Programs may vary depending on the firmware version installed in the device. If in doubt, have Smeg authorised staff check on the appliance that the installed version is the same as the

version stated in the table at the back of this document.

ALL PRESET PROGRAMMES CAN BE MODIFIED EXACTLY AS REQUIRED

ABBREVIATIONS USED IN THE TABLE OF PROGRAMS

Demi: demineralised water, the type of water used in a specific phase of the program.

Cold: cold mains water, the type of water used in a specific phase of the program.

INT: intensive - refers to programs which include particularly intensive washing phases.

N.C.: "NOT CONTROLLED" - refers to the relatively short heating phases during which the heating elements are on but no target temperature value is set.

TD, Therm: thermal disinfection - phase during which the target temperature is kept above a target value for a specified time. The efficacy of the thermal disinfection process is indicated by means of

parameter A0. In Smeg programs, the target value for a thermal disinfection process is always at least 80°C.

Target T [°C]: Target temperature of the current phase. The temperature inside the tank is kept constant around the specified value for the time shown in the table. The phase during which the

temperature is held at the target value is called the EXTENSION phase. When no target temperature is indicated or the indication is (“0”), the heating elements are not activated (e.g. during a cold

prewash or for cold rinses).

Un: universal – a type of washing program designed to be particularly intensive.

P1, ... P3: the code refers to the activation of the relative peristaltic pump, with dispensing of the liquid detergent associated to it.

P2a: the code refers to dispensing by pump P2 at a rate different from the default rate, used in special cases, as specified in the table.

Each pump has a default dispensing rate set in the factory.

DD: Activation of powder dispenser. If this dispenser is used, the user must place the correct amount of product inside it by hand at the start of the cycle.

2

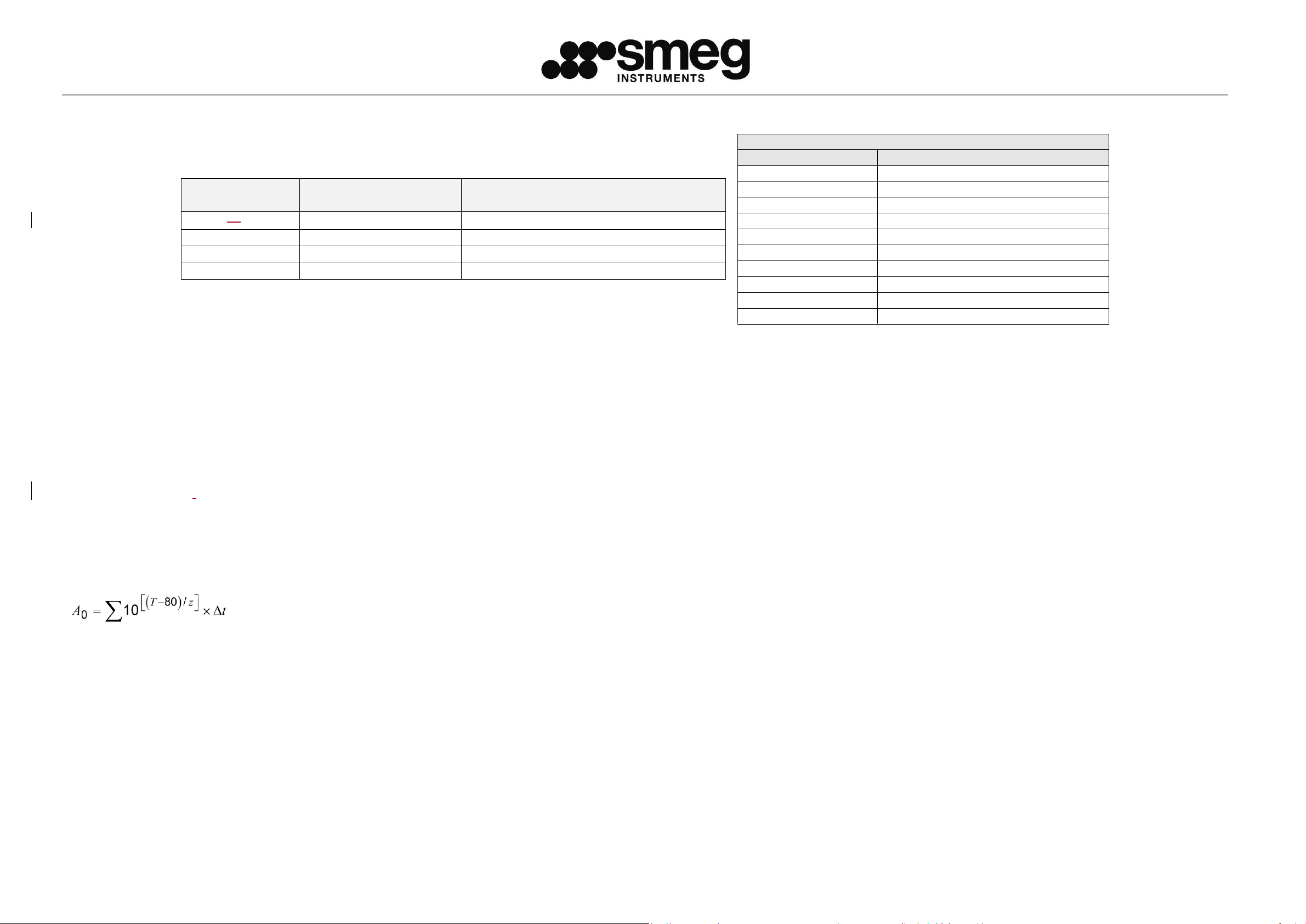

PUMP

PW DEFAULT DOSAGE

[ml/litre]

DOSAGE FOR SERVICE PROGRAM 16 ONLY

[ml/litre]

P1P1

5

12

DD

3-5 [g/litre]

-

P2

3

12

P3

2 (equivalent to 0.3ml/l)

12 (equivalent to 1.8ml/l)

Operating PARAMETERS for P3

Display shows “SEt – 3”

ml dispensed by pump per litre of water

1

0.14

2

0.29

3

0.43

4

0.57

5

0.71

6

0.86

7

1.00

8

1.14

9

1.29

10

1.43

VARIOUS NOTES:

WATER INTAKE: water intake for each phase is 9 litres. For program “16 Service” only, water intake is 6 litres for phases 1 and 2 and 9 litres for the rinse phase 3. Program “16 Service”

only comprises 3 phases and is generally used during installation, to prime the detergent inlet lines correctly and prepare the device for use.

PHASE NUMBERING: a record of the parameters for the various cycle phases is maintained in the device’s memory. The first phase is numbered “PHASE 1”, the second “PHASE 2”, etc.

CYCLE TIME: the stated time for the complete cycle refers to standard test conditions: intake water pressure 3bar, cold water temperature 25°C, three-phase power supply 3/N/PE 7kW,

drying cycle included – the cycle time not including the drying cycle is shown in brackets [E.g.. “89 (50)” means total time with drying cycle: 89min, without drying cycle: 50min]. If the

appliance is operated on single-phase power, only one heating element is operated instead of three, so cycle times are significantly longer.

PARAMETER A0

Parameter A0 is used by product standard UNI EN ISO 15883-1 to assign a numerical value to the thermal disinfection process.

It is calculated mathematically using the formula:

z = 10°C - t = duration of time interval considered in seconds - T = load temperature in °C.

When calculating the parameter, only the time intervals during which the temperature is above 65°C are considered.

For SMEG thermal disinfection programs, the calculation is simplified by only including the “extension” phase, when the temperature is kept constant with reference to the target value set.

PROCESSABLE LOAD: never exceed a total load of 23 kg to ensure good washing results.

The items in the load must be positioned correctly, with no overlapping.

DRYING

Good drying results, with the preset times and temperatures, are obtained using a load for drying weighing no more than 15kg. The items in the load must be positioned correctly, with

absolutely no overlapping.

Loading...

Loading...