PW4060

PUNCH WASHER

USER MANUAL

User Manual

PW4060 Series

Page 2 - 78

READ THE USER MANUAL WITH CARE

This manual is an integral part of the appliance.

Take good care of it and keep it to hand throughout the appliance’s life cycle.

This manual and all the information it contains must be read carefully before using the appliance.

Failure to read, any misunderstanding or incorrect interpretation of the instructions provided in this manual may lead

to misuse of the device, put the operator at risk and impair the device’s performance.

Installation, maintenance and any repairs must be carried out by authorised technical staff.

Apart from leading to forfeiture of warranty cover, repairs performed by unauthorised staff may

put the user’s safety at risk.

Any components must always be replaced with genuine Smeg spare parts.

Use of the device in breach of the instructions provided by the manufacturer may jeopardise the

specified protection level (safety of the appliance) and the warranty cover for it (see point 5.4.4

of IEC 61010-1:2001).

The manufacturer declines all liability for uses other than those described in this manual.

Consumables (detergents, air filters, thermal printer paper, etc.) are not covered by the

warranty, except for any manufacturing defects.

The Warranty does not cover any parts found to be faulty due to negligent or careless use,

improper use, failure to comply with the appliance’s operating instructions, incorrect installation

or maintenance, maintenance or repairs performed using by unauthorised staff or repairs made

with non-genuine parts, damage during transport, or any circumstances in which the appliance’s

defects cannot be traced back to manufacturing faults. Any work relating to installation and

connection to the intake and drain systems, and the maintenance work described in the

operator’s manuals, are also excluded from the Warranty.

Any accessories may not be installed on the appliance by the user; this must be done by Smeg

authorised technical staff.

To request technical documentation relating to accessories from Smeg: instruments@smeg.it

(ref. 5.4.4.c IEC61010-2-040:2005)

The information in this manual is provided for guidance only. The contents and the equipment described may be

subject to change without notice.

19 390 6446 00

24/10/2016

Manual Ed.

Date

User Manual

PW4060 Series

Page 3 - 78

INFORMATION AND AFTER-SALES SERVICE FOR SMEG PRODUCTS

Our Sales Department staff will be able to provide you with information about prices and special offers.

Our After-Sales Department will be able to provide you with guidance about keeping your appliance functioning

correctly and put you in touch with your nearest authorised Service Centre.

Customer Service - Instrument Division Service +39 0522 184 85 95

instruments@smeg.it

assistenza.instruments@smeg.it

service.instruments@smeg.it

Our entire product offering can be viewed at:

www.smeg-instruments.com

User Manual

PW4060 Series

Page 4 - 78

CONTENTS

1 INTRODUCTION ................................................................................................................................................... 6

1.1 PW FAMILY - INTENDED USE ............................................................................................................................... 7

1.2 DEFINTITION: “RESPONSIBLE AUTHORITY” IN RELATION TO THE DEVICE .......................................................... 7

1.3 WASHING TROLLEYS AND ACCESSORIES ............................................................................................................. 8

1.3.1 Smeg WD-PRINTE printer – ......................................................................................................................... 8

1.4 PERISTALTIC PUMP P3 ........................................................................................................................................ 8

1.5 LIST OF MODELS .................................................................................................................................................. 9

2 KEY TO THE SYMBOLS USED IN THE MANUAL AND ON THE APPLIANCE .............................................................10

3 GENERAL WARNINGS .........................................................................................................................................11

3.1 ACCESSING AND REUSING THE DEVICE AFTER AN INCOMPLETE CYCLE ........................................................... 12

3.2 DOOR OPENING ................................................................................................................................................ 13

3.3 MANUAL DOOR RELEASE PROCEDURE ............................................................................................................. 14

4 DESCRIPTION OF CONTROLS AND PROGRAMS ...................................................................................................14

4.1 CONTROLS ......................................................................................................................................................... 14

4.2 CONTROLS - DETAILED DESCRIPTION ............................................................................................................... 16

4.2.1 DISPLAY OF PARAMETER A0 ..................................................................................................................... 17

4.3 INDICATOR LEDS - INTRODUCTION ................................................................................................................... 18

4.4 INDICATOR LEDS - DETAILED EXPLANATION ..................................................................................................... 19

4.5 SELECTING THE WASHING PROGRAMME ......................................................................................................... 21

4.6 BRIEF TABLE OF THE PROGRAMS INSTALLED.................................................................................................... 23

4.6.1 RESINS - SOFTENER, REGENERATION AND WASHING PHASE ................................................................... 24

4.6.2 DRYING PHASE .......................................................................................................................................... 24

4.6.3 CUSTOM PROGRAMS ................................................................................................................................ 26

4.7 A0 THERMAL DISINFECTION PARAMETER ........................................................................................................ 27

4.8 PREPARING THE LOAD FOR WASHING AND DISINFECTION .............................................................................. 28

4.9 END OF CYCLE ................................................................................................................................................... 29

4.10 HALTING A PROGRAM IN EXECUTION .............................................................................................................. 30

4.11 PROGRAM SPECIAL OPTIONS ............................................................................................................................ 31

4.11.1 DELAYED START - Setting the hours .......................................................................................................... 31

4.11.2 DELAYED START - Starting the program and display ................................................................................. 31

4.11.3 TEMPORARY DISABLING OF DEMI WATER ................................................................................................ 32

4.11.4 Deleting “Delayed start” - “No Demi” settings ......................................................................................... 33

4.12 RESET PROCEDURE............................................................................................................................................ 34

4.13 PRINTING THE CYCLE AND APPLIANCE PARAMETERS ....................................................................................... 35

5 SETUP MODE - “FUNCTIONS” .............................................................................................................................35

5.1 ACCESSING THE SETUP MODE / ENTERING THE PASSWORD ........................................................................... 35

5.2 ACCESS AND PARAMETER MODIFICATION ....................................................................................................... 37

5.3 “SET“ PARAMETERS .......................................................................................................................................... 39

5.3.1 APPLIANCE DATA STORAGE, OVERWRITING, PARAMETER Set -b ............................................................ 42

5.4 “CLOC” – DATE AND TIME PARAMETERS .......................................................................................................... 44

5.5 SETTING THE “PrEn” “PROGRAM ENABLING” FUNCTION................................................................................. 45

6 COMMISSIONING INSTRUCTIONS ......................................................................................................................47

6.1 USING THE WATER SOFTENER .......................................................................................................................... 47

6.2 USING DETERGENT AND NEUTRALISING AGENT .............................................................................................. 48

6.2.1 LIQUID DETERGENT INTAKE SYSTEM ........................................................................................................ 48

6.3 RECOMMENDED DETERGENTS ......................................................................................................................... 50

7 ALARMS AND WARNING MESSAGES ..................................................................................................................52

User Manual

PW4060 Series

Page 5 - 78

8 CLEANING AND MAINTENANCE .........................................................................................................................60

8.1 CLEANING THE APPLIANCE AND ITS PARTS ...................................................................................................... 60

8.1.1 Filter elements .......................................................................................................................................... 62

8.2 IF THE APPLIANCE IS TO BE OUT OF USE........................................................................................................... 62

8.3 REUSING THE APPLIANCE AFTER A PERIOD OUT OF USE .................................................................................. 62

8.4 TROUBLESHOOTING .......................................................................................................................................... 63

9 ROUTINE INSPECTIONS AND MAINTENANCE .....................................................................................................64

9.1 DAILY ................................................................................................................................................................. 64

9.2 WEEKLY ............................................................................................................................................................. 64

9.3 EVERY SIX MONTHS .......................................................................................................................................... 64

9.4 EVERY YEAR ....................................................................................................................................................... 64

10 TECHNICAL DATA ...........................................................................................................................................65

11 PRODUCT DIMENSIONS - MEASUREMENTS IN MM ........................................................................................67

11.1 PW4060 SERIES ................................................................................................................................................. 67

12 POSITIONING THE APPLIANCE ........................................................................................................................67

13 ELECTRICAL SYSTEM REQUIREMENTS .............................................................................................................70

13.1 - POWER SUPPLY CABLE AND DISCONNECTION DEVICE ................................................................................... 70

14 WATER CONNECTION FITTINGS ......................................................................................................................71

14.1 WATER INTAKE .................................................................................................................................................. 71

14.1.1 WATER INTAKE CONNECTION ................................................................................................................... 71

14.1.2 POSITION OF FILL COCKS ........................................................................................................................... 71

14.1.3 WATER SUPPLY SYSTEM REQUIREMENTS ................................................................................................. 72

14.1.4 PAD ACCESSORY FOR UNPRESSURISED DEMI WATER .............................................................................. 73

14.2 WATER DRAIN ................................................................................................................................................... 74

15 DATA CONNECTION ........................................................................................................................................76

User Manual

PW4060 Series

Page 6 - 78

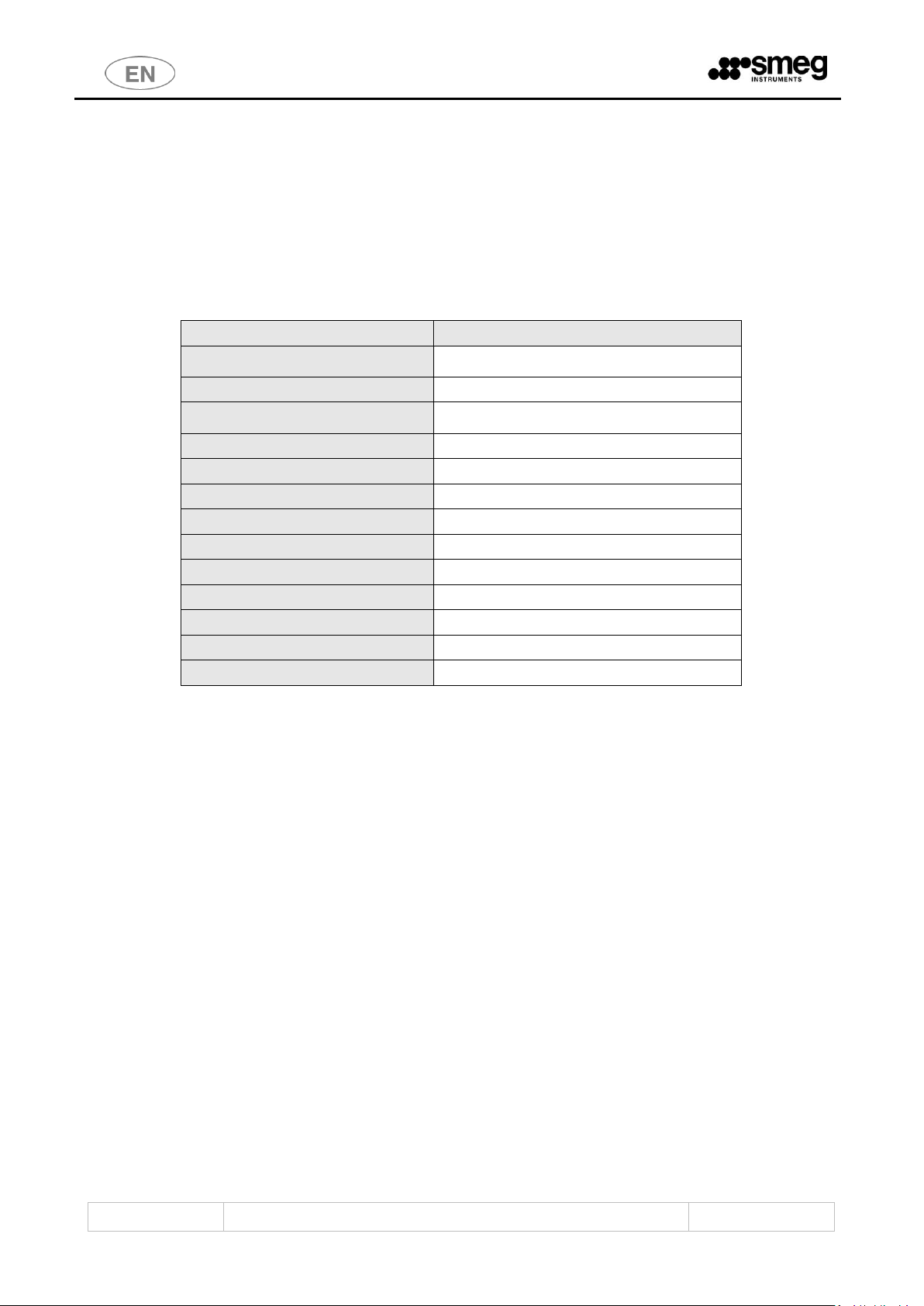

1 INTRODUCTION

PW4060 – are professional glassware washing machines.

Smeg PW4060 series products comply with all the prerequisites of the relevant safety regulations and the standards in

force for electrical equipment.

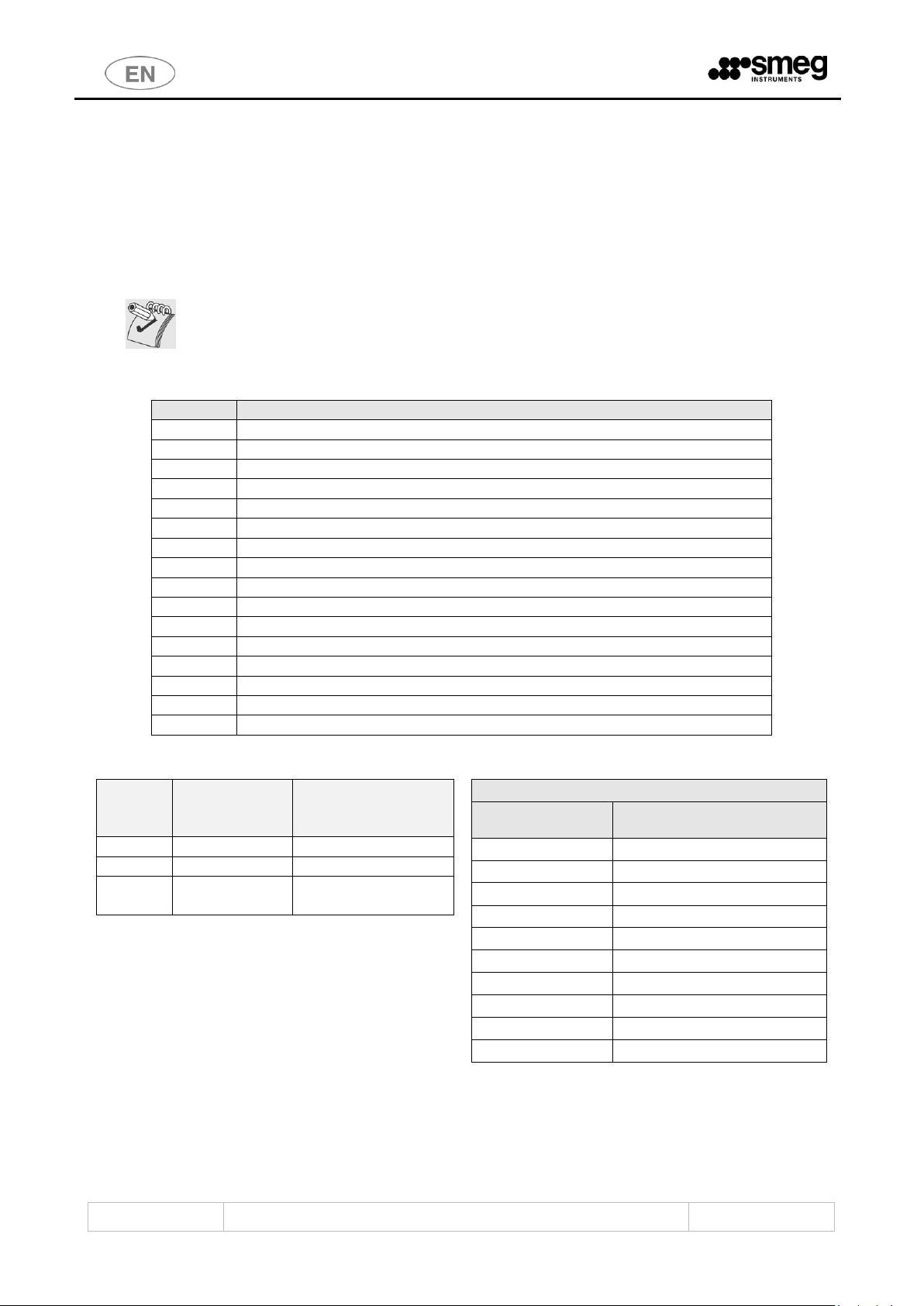

The table below summarises the product’s main characteristics. (For a full list of models and their configurations refer

to the “LIST OF MODELS” point below).

PW – basic model

CONTROL

ELECTRONIC with MICROPROCESSOR

(with Time and Date functions)

OPENING THE DOOR

Automatic

DETERGENT DISPENSING

Peristaltic pumps P1, P2 and P3

CONTROL OF DETERGENT DISPENSING

Optional (only on P1 and P2)

DETERGENT JERRY CAN LEVEL CONTROL

SI

TEMPERATURE CONTROL

Single Platinum PT probe (TL1)

STEAM CONDENSER

SI

DRYING SYSTEM

Forced air

ABSOLUTE DRYING FILTER

Optional

RUNNERS IN TANK FOR TOP BASKET

NO

WATER INTAKE CONNECTIONS

Mains and Demineralised

PRESET PROGRAMS

Free presets

COMMUNICATION

RS232 serial (For PC or Printer)

User Manual

PW4060 Series

Page 7 - 78

1.1 PW FAMILY - INTENDED USE

Pharmaceutical punch washer.

The appliance is built to provide the following function:

Punch washing;

The appliance cannot be used to sterilize instruments or any other device.

Any use other than that described in this manual constitutes misuse.

SMEG declines all liability for uses other than those stated above.

SMEG declines all liability for any damage caused by the use of the appliance to wash objects not

approved by their manufacturers for automatic decontamination by means of thermal disinfection.

The appliance may only be used by specifically trained staff. Smeg will train the staff assigned

to use the appliance at the time of installation.

Smeg declines all liability in the event of malfunctions or accidents caused by use of the appliance

by untrained staff.

The training of the staff responsible includes specific information on the possible risks involved

in the use of the appliance, and training in the safest possible way of carrying out the operating

procedures.

The Smeg installation engineer is also responsible for notifying the responsible authority of the

USER and SUPERUSER passwords for access to the setup parameters. The responsible authority

must keep these passwords in a safe place.

It is the duty of the appliance’s RESPONSIBLE AUTHORITY to ensure that those using the

equipment have been suitably trained in its operation, its safe use and routine checks, and that

this training is suitably maintained.

Staff training should be checked regularly.

The installation engineer is responsible for ensuring that it operates correctly after

commissioning.

Safety information supplied in compliance with 5.4.101.1 IEC61010-2-040:2005

Instrument manufacturers’ instructions should always be followed when choosing the most

appropriate disinfection treatment.

In particular, it is important to check the compatibility of the load for treatment with the specific

washing cycle chosen, in terms of the maximum temperatures reached and the chemicals used.

Information supplied in compliance with point 5.4.4.r IEC61010-2-040:2005.

1.2 DEFINTITION: “RESPONSIBLE AUTHORITY” IN RELATION TO THE DEVICE

Responsible authority: “Person or group responsible for the use and ordinary maintenance of the unit and for

operator training.

Definition taken from point 3.5.13 of the IEC61010-1:2001 standard.

The responsible authority should be clearly identified within the facility where the appliance is used, (for example by

recording the relative names and responsibilities on corporate forms).

User Manual

PW4060 Series

Page 8 - 78

1.3 WASHING TROLLEYS AND ACCESSORIES

N.B: the device is supplied without the washing trolleys and instrument holder baskets.

Contact Smeg for details of the range of racks and baskets best suited to your washing

requirements.

Visit www.smeg-instruments.com for information about the standard range of products

available.

The appliance may only be installed, serviced or repaired by a technician authorised to do so by

the Manufacturer.

Any components must always be replaced with genuine spare parts.

1.3.1 Smeg WD-PRINTE printer –

The appliance’s RS232 port can be used to connect the external Smeg WD-PRINTE printer, supplied with its own

power transformer.

This accessory should be used only with thermal paper, 57.5mm ± 1mm, recommended weight 55 g/m2.

To operate this accessory, simply connect the transformer to the power socket and connect the R-S232 port to the RS232 socket on the rear of the device.

Refer to the accessory’s manual for detailed instructions.

fig. 1 – Smeg desktop printer.

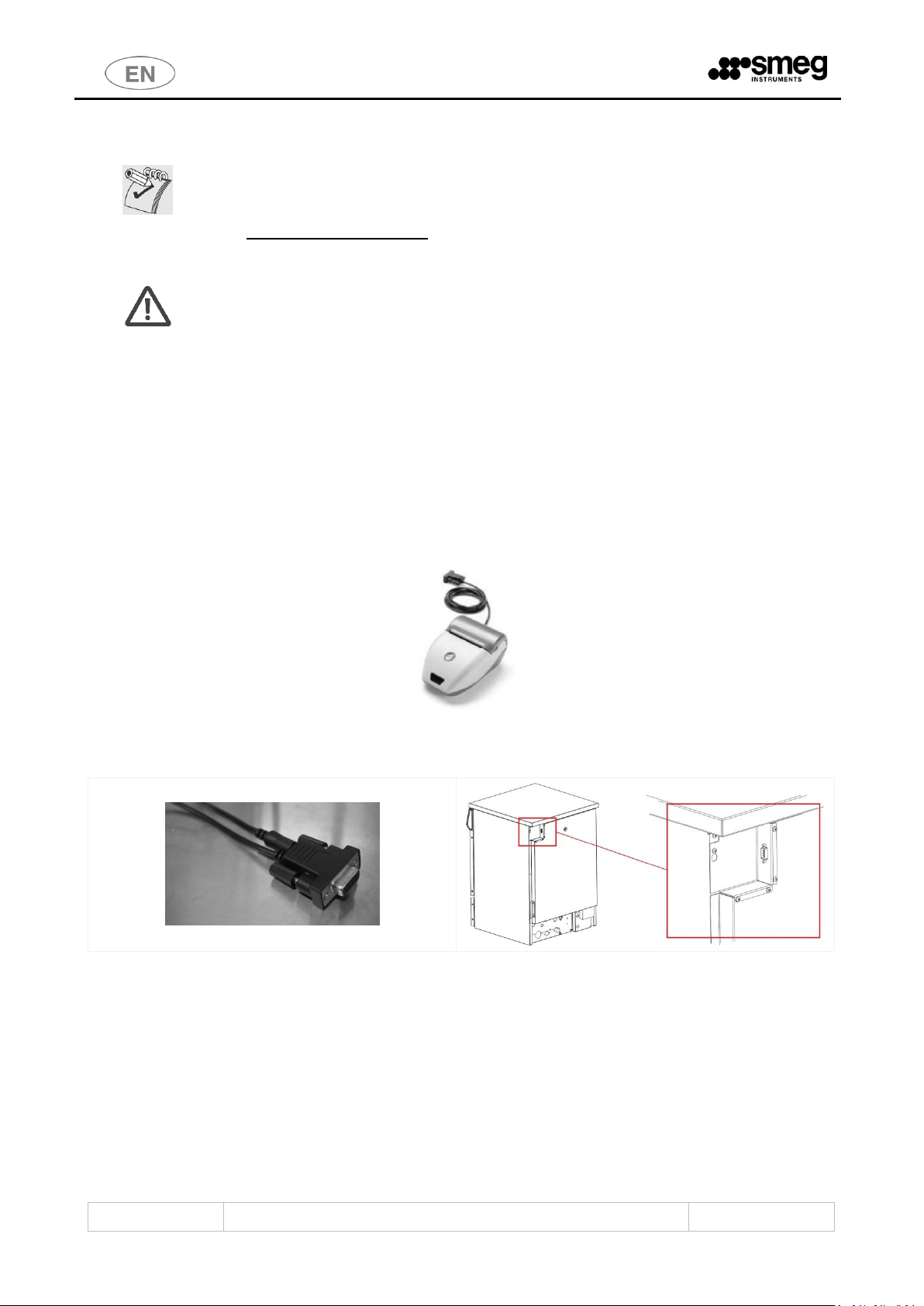

fig. 2 – R-S232 cable supplied with the printer and position of the RS-232 socket on the device.

1.4 PERISTALTIC PUMP P3

Peristaltic pump P3 is installed to dispense a protective additive: contact Smeg for advice about the model best suited

to your needs.

User Manual

PW4060 Series

Page 9 - 78

1.5 LIST OF MODELS

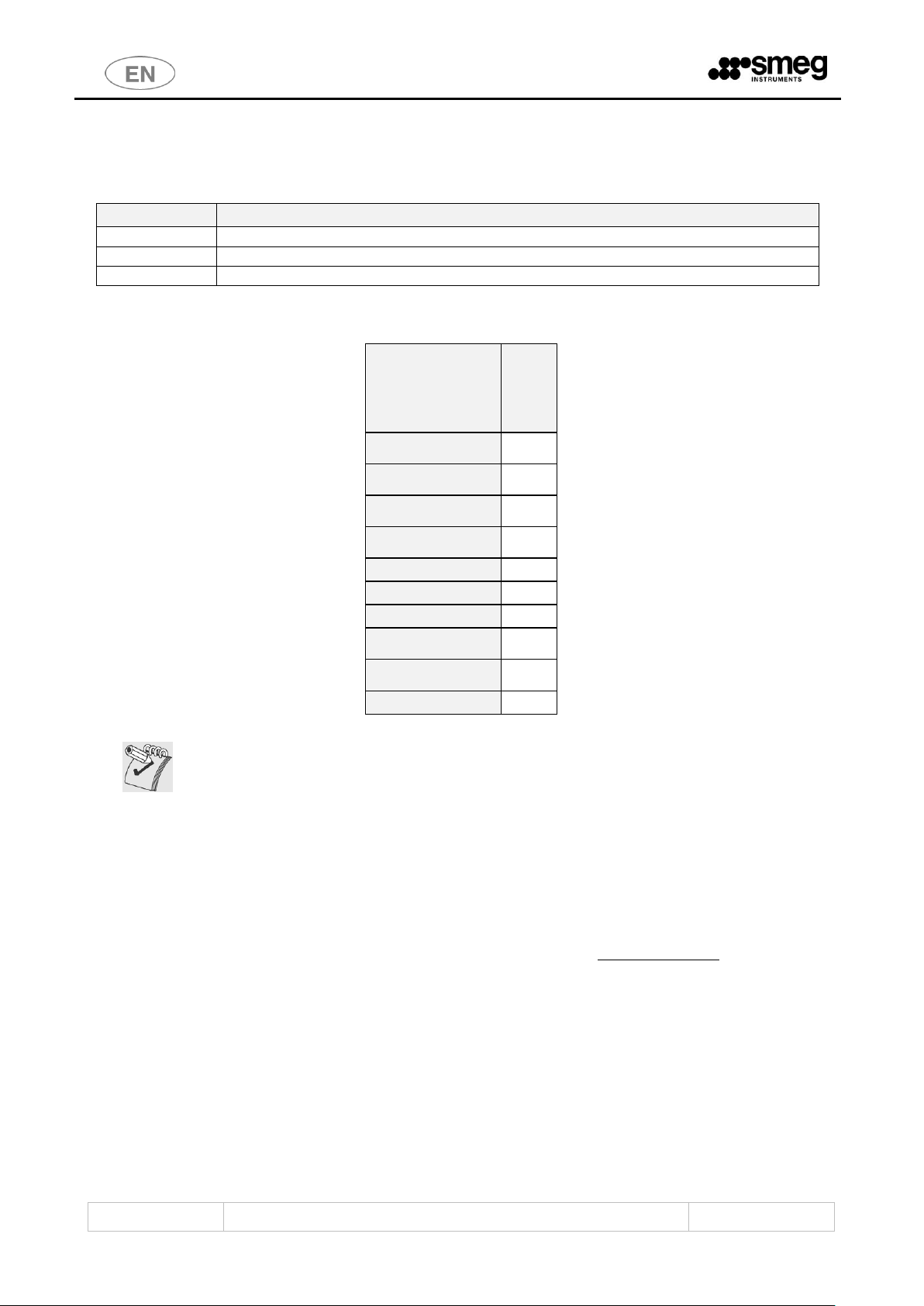

Model configuration chart.

Symbols used:

SYMBOL

MEANING

feature present on the model in question.

optional accessory, installable on the model in question.

-

feature not present and not installable on the model in question.

Configuration chart

MOD. PW

Features

PW4060

DD - Powder detergent

dispenser in inner door

-

P1 - Peristaltic

detergent pump

P2 - Neutralising agent

peristaltic pump

P3 - Optional peristaltic

pump

Dryer

Absolute drying filter

Steam condenser

Control of detergent

dispensing

Detergent jerry can

level control

Aquastop

ELECTRICAL CONFIGURATION

A number of different electrical setups are available for every model.

The names of the models have different suffixes to identify the power supply rating. Example:

- “PW4060-1” refer to 230V single-phase models: “ 1N~ ”

- “PW4060-3”, refer to three-phase models, 230V between phases, without neutral: 3~ ”

- “PW4060”,. If the model does not have a suffix it will be three-phase, with neutral, 400V between phases:

“ 3N~ ”.

- “PW4060U”,. The “U” suffix refers to “North American models”, convertible 208V models: 208V 3~ 60Hz *

/ 208 V ~ 60Hz (* default connection).

Contact Smeg for advice about the model best suited to your needs instruments@smeg.it

User Manual

PW4060 Series

Page 10 - 78

2 KEY TO THE SYMBOLS USED IN THE MANUAL AND ON THE APPLIANCE

The following is the key to the symbols used on the appliance and in this manual, as required by point 5.4.4.e of

IEC61010-2-040:2005.

Read with particular attention.

(Symbol which appears beside particularly important instructions or warnings).

Warning, danger: refer to the manual.

(The symbol appears on the appliance’s technical dataplate to emphasise that staff must read

the manual before using it.

The symbol appears in the manual next to safety instructions)

Warning, hot surface.

(the symbol is affixed to the appliance close to parts which may heat to high temperatures and

constitute a burn hazard - do not touch parts near this symbol. The symbol appears in the

manual to emphasise safety instructions relating to the burn hazard).

Warning, electric shock hazard.

(The symbol is affixed close to live parts - the appliance’s power supply must be disconnected

before doing any work on these parts. Never touch live parts unless the electricity supply is

disconnected).

Transport and unpacking precautions.

Flammability hazard.

Biological hazard.

At the end of its working life, the product must be consigned to a disposal plant for recovery and

recycling in accordance with the relevant legislation in the country of installation. Contact the

specialist disposal consortia. This appliance is tagged under European Directive 2002/96/EC ON

WASTE ELECTRICAL AND ELECTRONIC EQUIPMENT (WEEE).

By making sure that this product is disposed of correctly, the user helps to prevent potential

detrimental effects on health and the environment.

CE marking; the manufacturer guarantees compliance with the EU directives applicable to the

product.

This symbol appears on the machine’s technical data label and in this manual.

User Manual

PW4060 Series

Page 11 - 78

3 GENERAL WARNINGS

Leaning or sitting on the open door of the device might cause it to tip over, putting people in

danger. The door is not designed primarily to support loads.

The maximum weight which can be loaded on the door, including the weight of the instrument

rack, must never exceed 30kg.

If the weight of the instrument trolley and baskets is excluded, the maximum processable load

must never exceed 23kg.

For optimal DRYING, the load for processing must never exceed 15 kg.

With use of the appliance, localised or general discolouring of the heating element may occur.

This is normal since it is due to the operating mode and does not reduce the appliance’s

effectiveness.

In the event of malfunction, disconnect the appliance from the electricity supply and turn off the

water tap. Then contact your nearest authorised Service Centre.

Open the door carefully, first waiting for the wash cycle to end.

The appliance has an automatic door opening system; do not force the door open while a

program is in progress.

The appliance must only be used by staff suitably trained in its operation.

The tank of the appliance is not designed for users to climb into it. The user must never climb into

the tank; this might put his safety at risk (ref. 7.102 IEC61010-2-040:2005).

Do not place flammable substances inside the appliance. Do not use flammable detergents.

Never place alcohol or solvents such as turpentine, which might cause an explosion, inside the

appliance. Do not place materials dirty with ash, wax or paint inside the appliance.

N.B. - ABSENCE OF DEMINERALISED WATER SUPPLY

If demineralised water is not available, the user is responsible for ensuring that the quality of the

water supplied to the appliance does not cause mineral salts or other substances to be deposited

on the instruments processed, rendering their subsequent use unsafe.

Never touch the heating element immediately after the end of a wash programme.

Do not touch any residual liquids left inside the washing chamber; scalding hazard (ref. 7.102.c

IEC61010-2-040:2005).

When moving the appliance around, a forklift truck or pallet truck must be used.

Before leaving the factory, the base of the appliance is secured to a pallet, which is used for lifting

and transporting it.

Do not use appliances which have been damaged in transit!

If in doubt, contact your dealer.

Once decommissioned, the appliance must be rendered unusable. Cut the power supply cable

after removing the plug / disconnecting the cable from the power socket.

User Manual

PW4060 Series

Page 12 - 78

3.1 ACCESSING AND REUSING THE DEVICE AFTER AN INCOMPLETE CYCLE

The instructions relating to the device’s safety in the event of an incomplete operating cycle are provided in

compliance with points 5.4.4.g and 13.1.102 of IEC61010-2-040:2005.

WARNING

Warning applicable if the appliance is used for processing biologically contaminated material.

If a disinfection cycle is interrupted (by the user or due to an alarm generated by the appliance

itself): take care when handling the instruments and the load in general in the washing chamber.

The load and the internal parts of the appliance might be biologically contaminated/infected.

Before handling the items in the load or performing any maintenance procedures: perform a full

thermal disinfection cycle or, if a complete cycle is not possible, handle the load with due care

(e.g. using the protective equipment specified when handling the infected load, e.g. gloves, lab

coat).

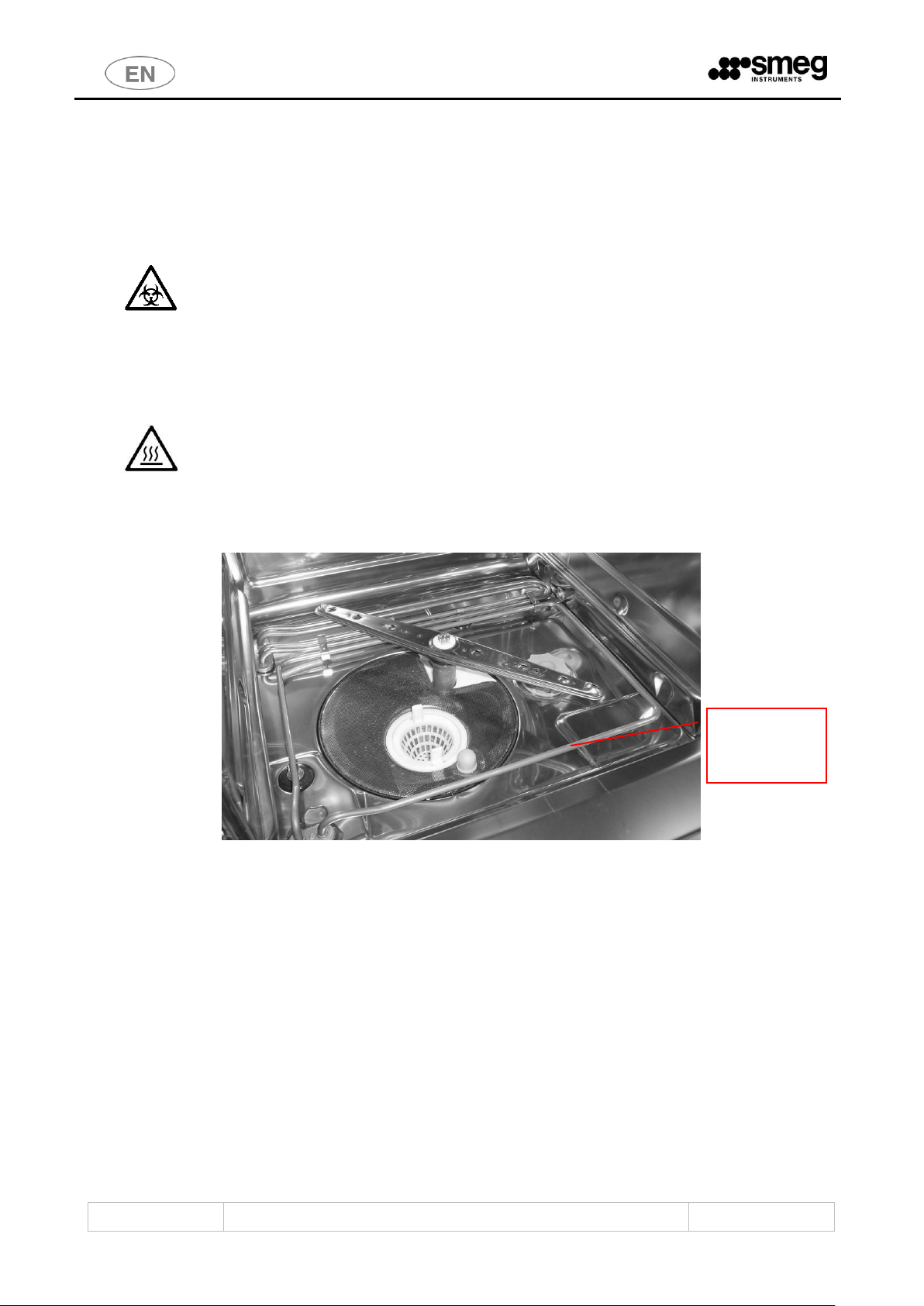

DANGER, HOT SURFACES

The appliance performs a thermal disinfection cycle using water at high temperatures (up to

93°C) and detergents. If, in the event of a failure, there is water in the tank when the door is

open: avoid contact with the skin, burning hazard and risk of irritation due to the toxicity of the

chemicals used.

Never touch the heating elements inside the tank.

Contact Smeg authorised technical staff in the event of a failure.

fig. 3 – View of inside of tank, detail of heating elements.

Do not touch

the heating

elements

User Manual

PW4060 Series

Page 13 - 78

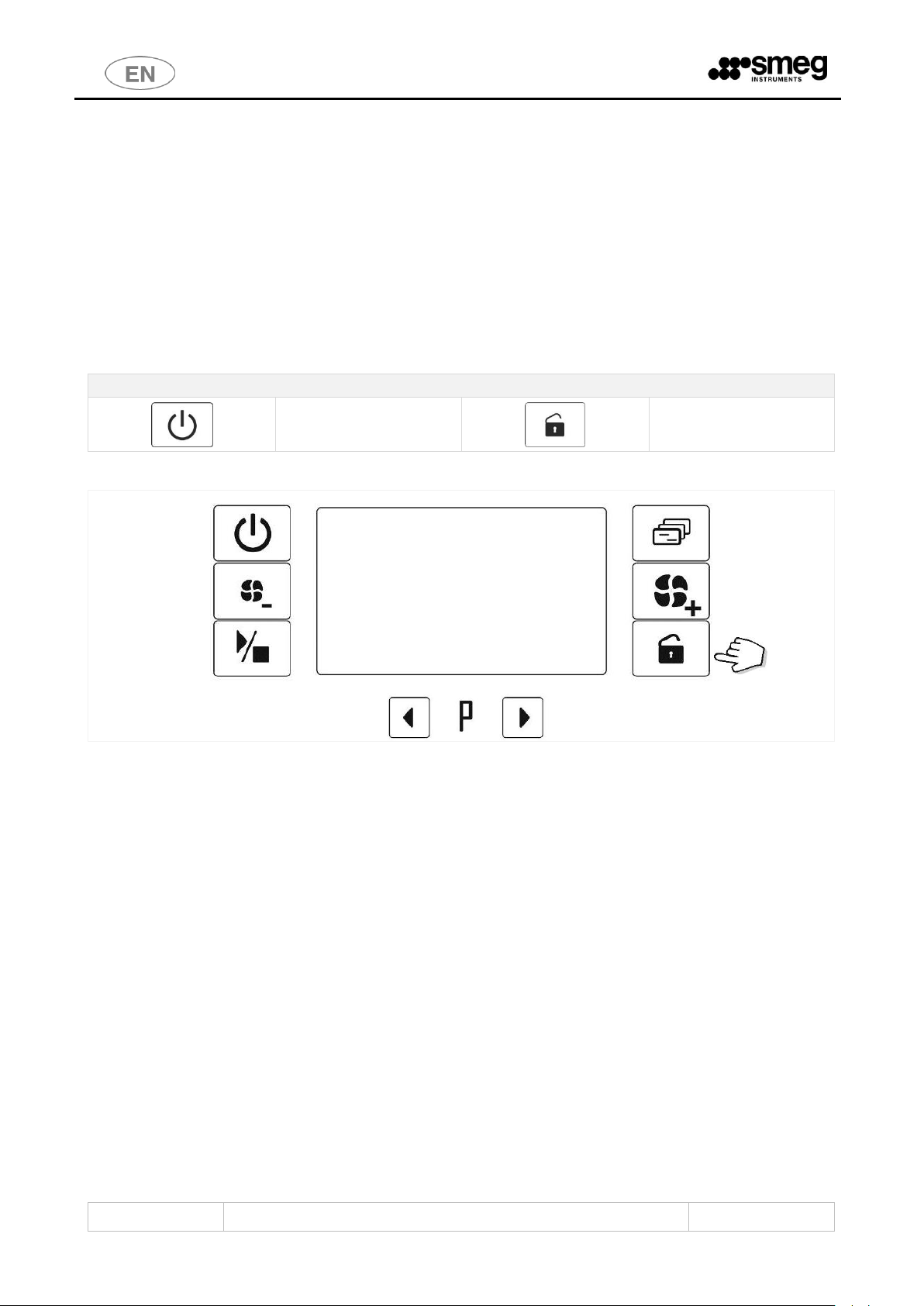

3.2 DOOR OPENING

We consider the door opening procedure here to facilitate access to the interior of the machine.

The remaining controls are covered in the following paragraphs.

The appliance is equipped with an automatic door locking system.

Do not force the door open, rather proceed as follows:

Connect the machine to its power supply.

Hold down the button with the On/Off symbol for 2 seconds to switch the appliance on.

Press the Open door button: the machine beep when the signal is received; release the button and the door

will open of its own accord after a few seconds.

DOOR OPEN BUTTONS

On/Off

Open door

fig. 4 – Selecting automatic door opening.

To open the door without connecting the appliance to the electricity supply (useful for emergencies or in case of

power blackouts), the manual release system has to be used (see next point).

User Manual

PW4060 Series

Page 14 - 78

3.3 MANUAL DOOR RELEASE PROCEDURE

If necessary, due to a malfunction or power blackout, the appliance can be opened manually by releasing the lock

using a screwdriver with stem Ø4mm; be gentle, taking care not to damage the device.

1. This procedure is only possible with the appliance in standby status, with no cycle running.

2. Warning: before opening the appliance manually, disconnect it from the electricity supply.

3. Insert a screwdriver or a rod 4 mm in diameter into the hole in the bottom of the centre of the front panel.

4. Push the pin upward until the lock is released.

fig. 5 – Diagram, manually releasing the lock in case of emergency.

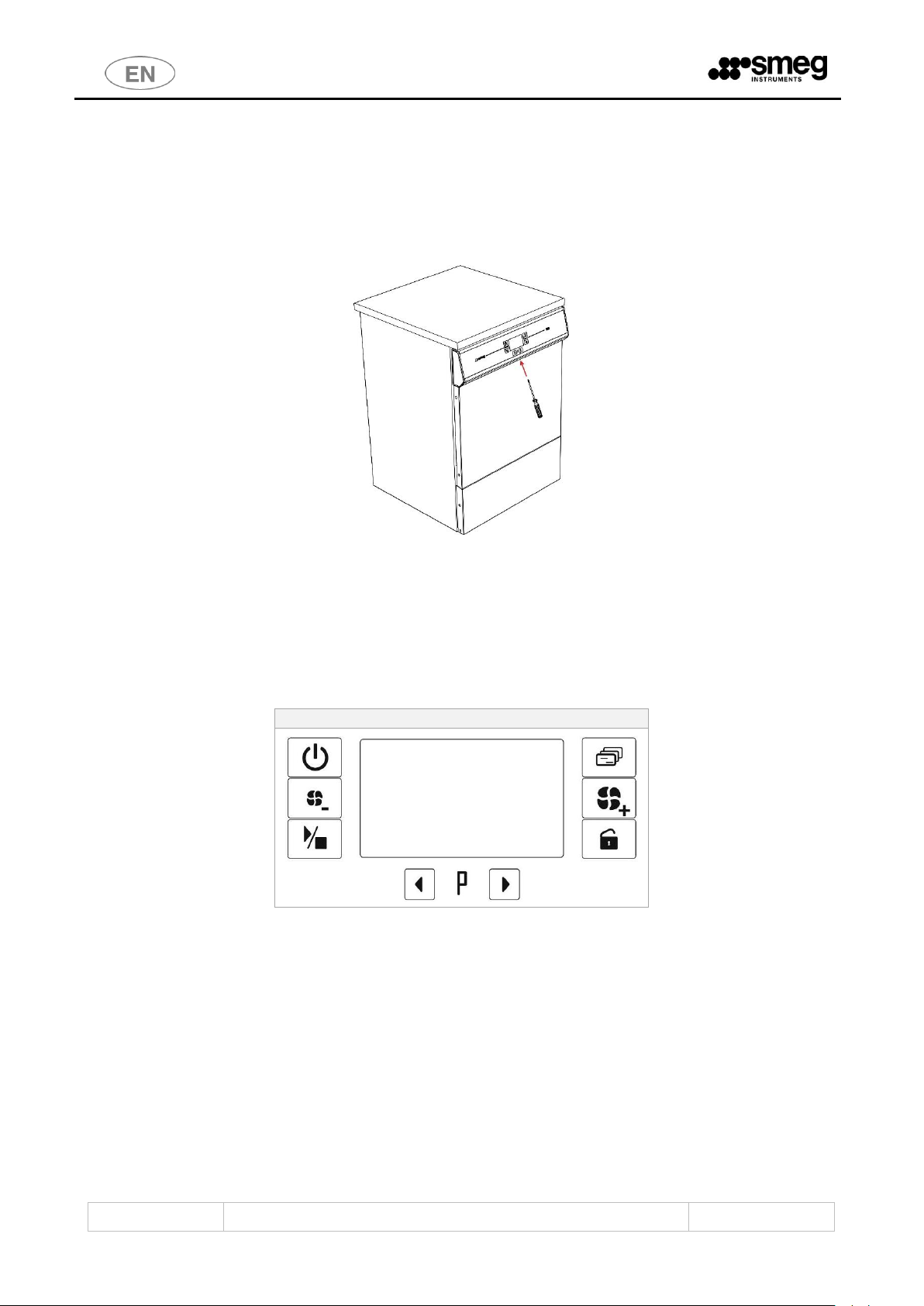

4 DESCRIPTION OF CONTROLS AND PROGRAMS

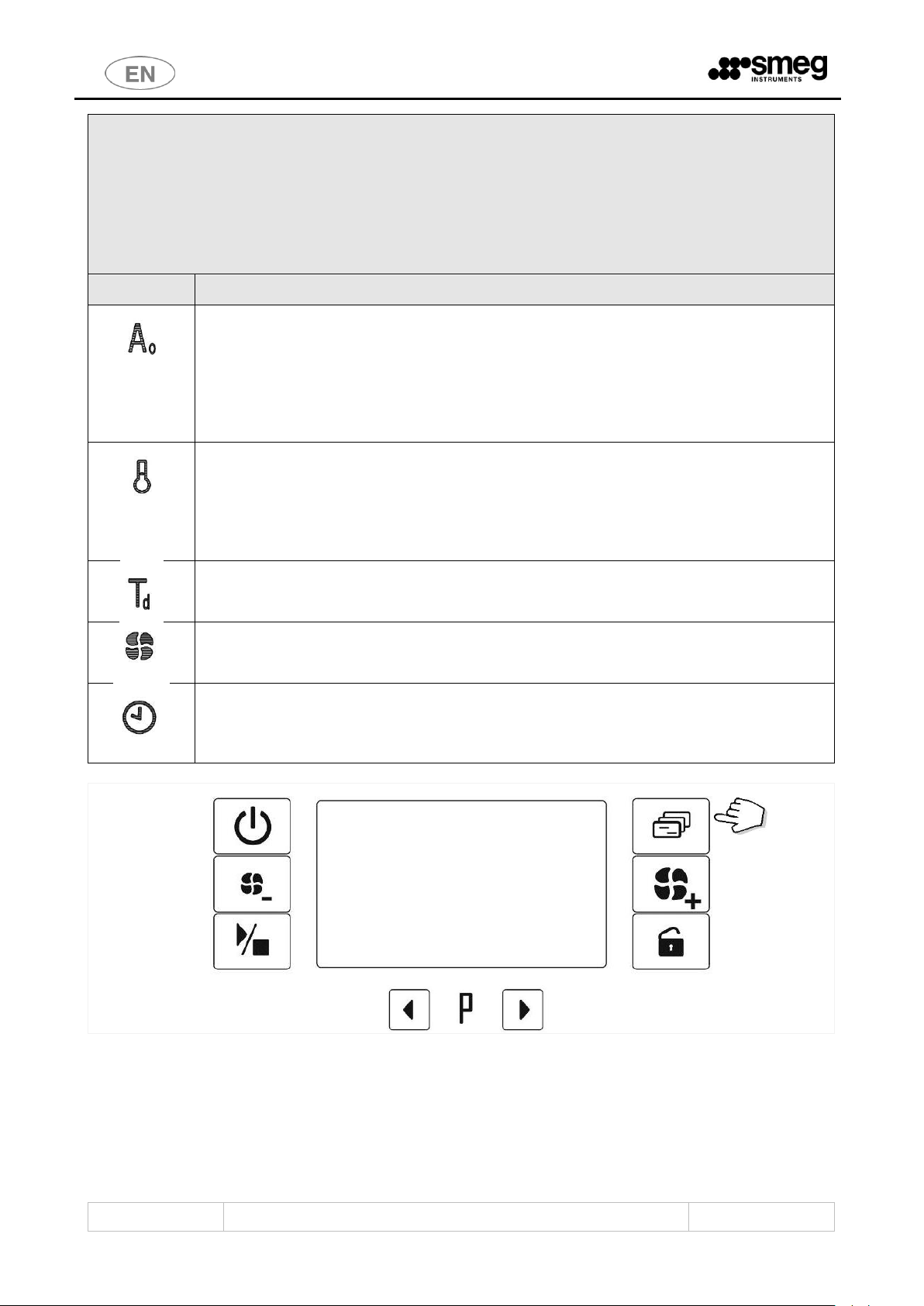

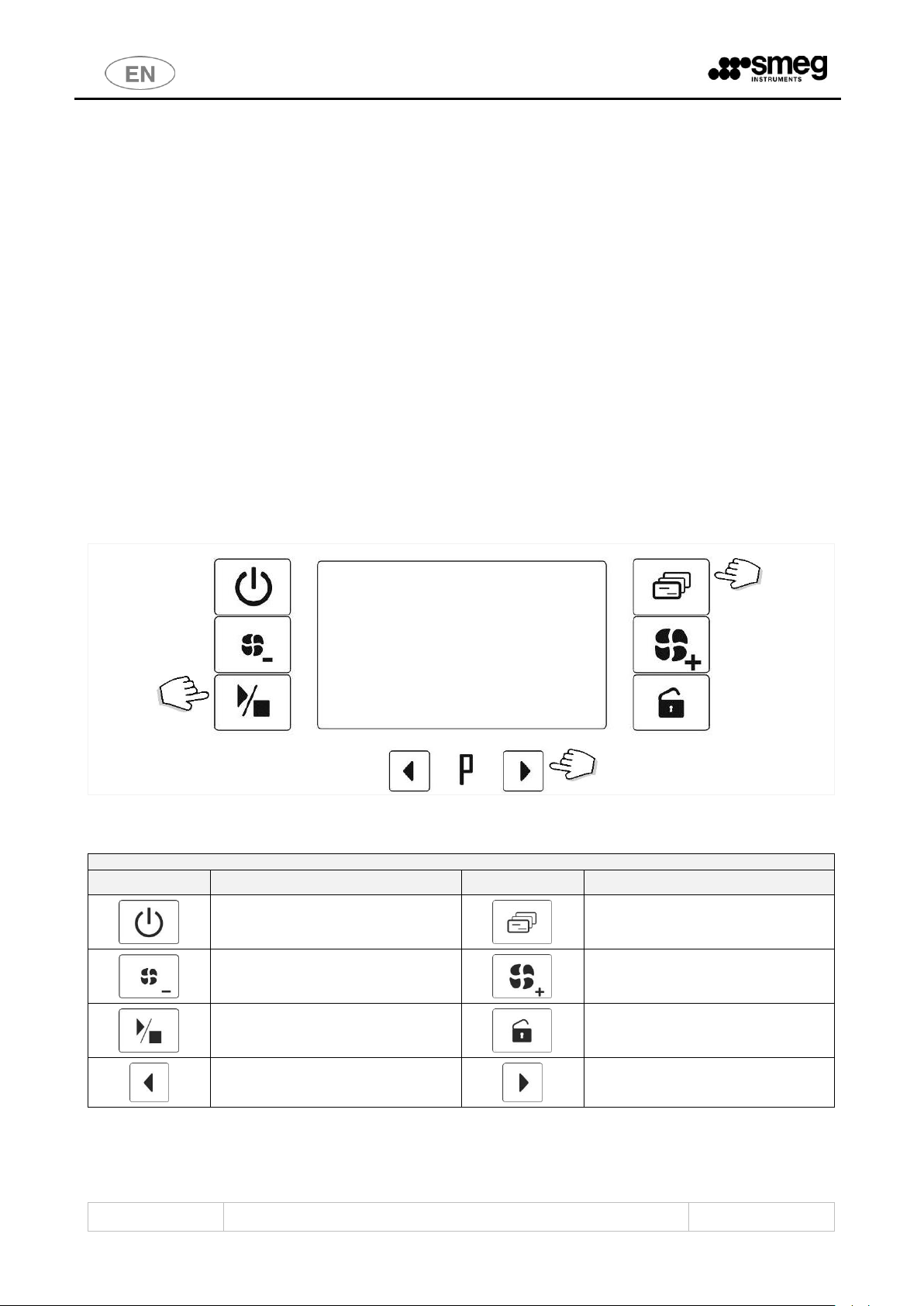

4.1 CONTROLS

All the device’s control and monitoring devices are placed together on the front panel.

CONTROL PANEL PW4060

fig. 6 – Control panel. The display and indicator LEDs are in the middle and the control buttons at the sides and bottom.

User Manual

PW4060 Series

Page 15 - 78

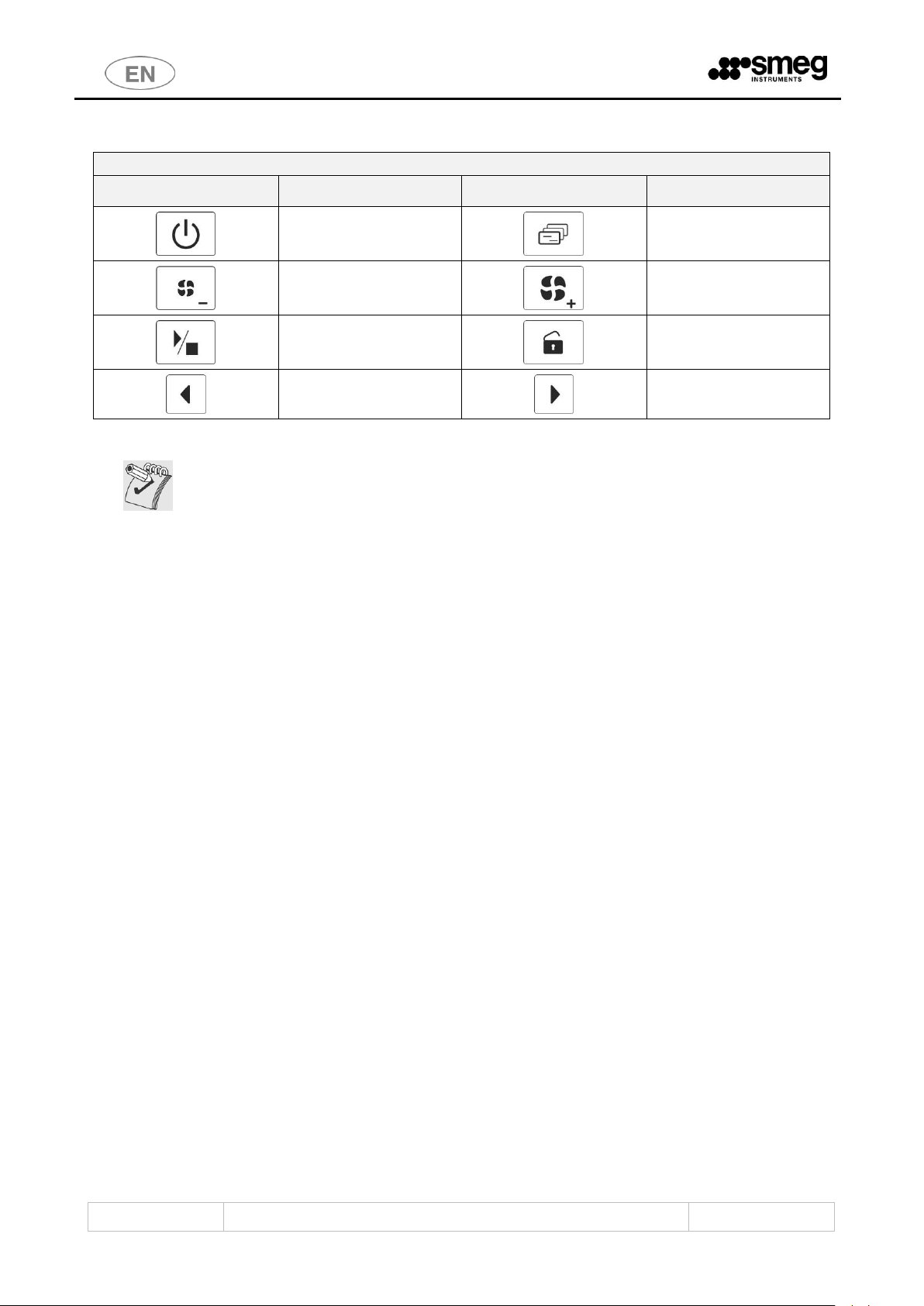

CONTROL PANEL SYMBOLS

SYMBOL

MEANING

SYMBOL

MEANING

On/Off

Functions

Drying Decrease

Increase

Drying

Start / Stop

Open door

Select

Select

The diagrams below only us the layout relating to PW4060 models.

User Manual

PW4060 Series

Page 16 - 78

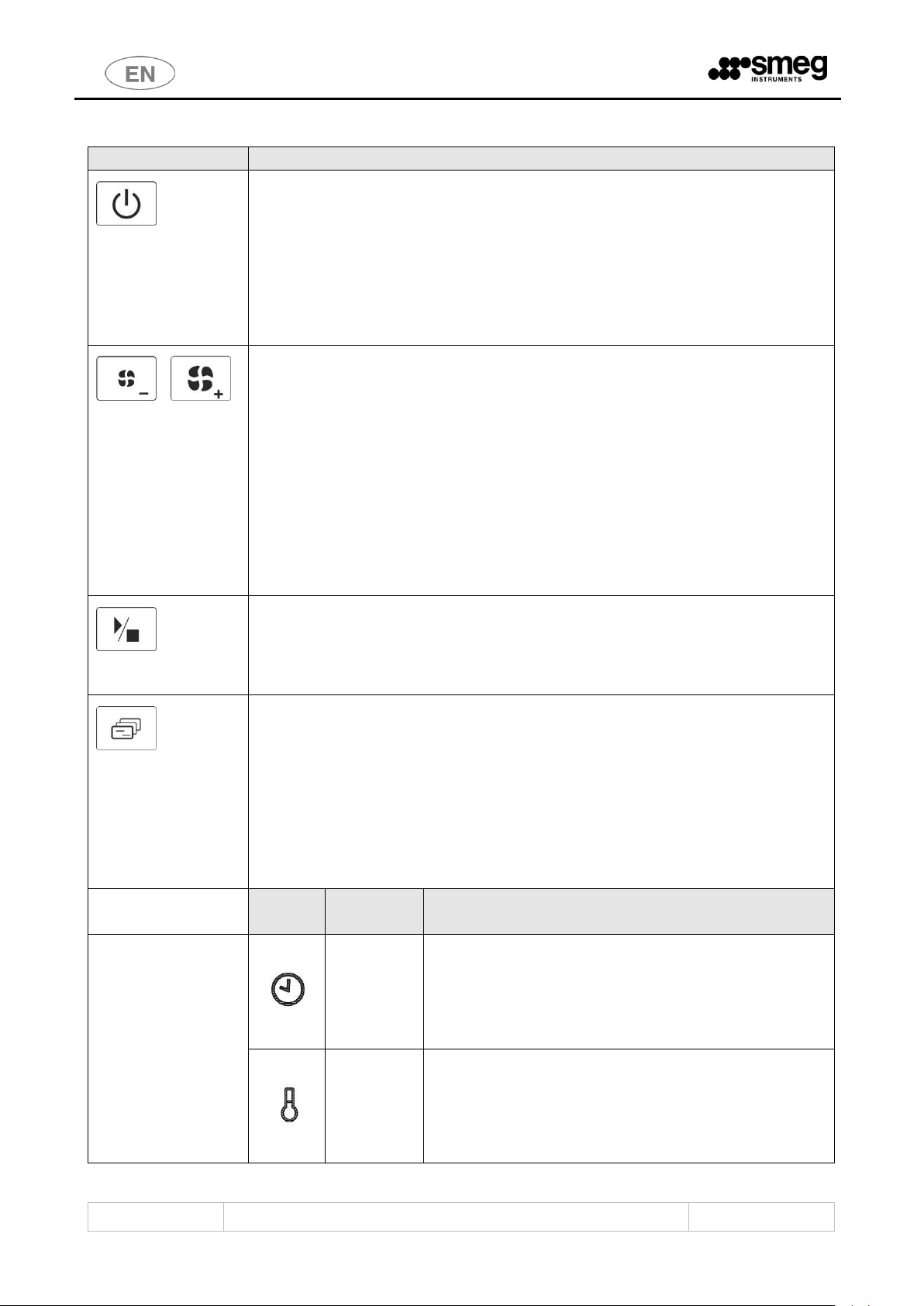

4.2 CONTROLS - DETAILED DESCRIPTION

BUTTONS

DESCRIPTION

On/Off

The button is enabled with the door open or closed.

The button turns the device’s interface on and off, allowing its use. Hold the button down

for 2 seconds to turn it on or off.

Once the appliance has been switched on, the code of the selected program appears on

the display (e.g. “Pr 03”).

When the interface is switched off, the display reads “OFF”.

When the door is open the display shows four dashes and the other buttons are disabled.

The device is still powered up even when the interface is off.

-

Drying +/-

The buttons increase/decrease the intensity (and duration) of the drying phase.

Holding down the “Drying–” button selects a separate drying program; the display shows

the message “Pdry”.

If the cycle set has a drying phase, these buttons are enabled and the drying LED

illuminates.

If the cycle set does not include a drying phase, the buttons are not enabled and the

drying LED remains off.

These are “first touch” buttons; there is no need to hold them down.

The drying duration set is displayed as follows:

- 3 horizontal bars on the display; maximum time setting, default time

- 2 horizontal bars, medium duration

- 1 horizontal bar, short duration

Start/Stop

Starts a new cycle or pauses the current one. Must be held down for 2 seconds.

When the cycle starts or pauses, a double beep will sound.

The button is also used (again holding it down) to confirm the value of an appliance

parameter during modification.

Functions

Hold down: access to the appliance setup parameters, password required. Refer to the

SETUP MODE - “FUNCTIONS” section for a detailed explanation.

Short press: whenever the Functions button is pressed,

the display screen changes; the various screens show the parameters of the cycle

selected in combination with the LED which explains their meaning.

For a full understanding of the values shown on the display, note that they depend on the

appliance’s status:

1. Appliance in standby

2. Washing cycle running

LED

ON THE

DISPLAY

Meaning of LED on

<

With device at a standstill

The value gives the nominal cycle duration. The time led also

turns on. The duration is guideline; it applies in test conditions

and with correct electrical connection.

If a cycle is running

Remaining cycle time.

-- : 90

With device at a standstill

Maximum temperature reached in the cycle set

If a cycle is running

- During washing: Tank temperature

- During drying: Inlet air temperature (function introduced

from firmware version 4.6.xx.yy).

User Manual

PW4060 Series

Page 17 - 78

BUTTONS

DESCRIPTION

600

With device at a standstill

A0 value associated to the selected cycle, if the cycle includes

a thermal disinfection phase.

If a cycle is running

Display function which starts from the thermal disinfection

phase: displays the A0 value reached.

The value reached during the thermal disinfection phase is

displayed during the phases which follow.

[Displayed on two screens from firmware version 1.11.0.33.

This parameter displays on two consecutive screens. The

thousands value is followed by “t”, the units value by “u”]

-

F5

With device at a standstill

Number of phases in the program

If a cycle is running

Current phase

Note: Wash cycles always start with a short pump-out phase

to bring the device to the standard starting condition: this

phase is called “phase 0”.

-

PR 03

After 5 seconds of user inactivity, the display returns to the

program number.

Open door

The door is opened automatically by means of an electric lock; opening is only permitted

in conditions of safety for the user.

The user simply presses the button; there is no need to hold it down.

The button also provides an “Escape” function; it is pressed to quit the procedure for

displaying or modifying an appliance parameter. In this case, it has to be held down (2

seconds).

-

Select

Program selection buttons. The letter “P” and the name of the selected program appear

on the display.

These buttons can be used to increase or decrease the current value during modification

of an appliance parameter.

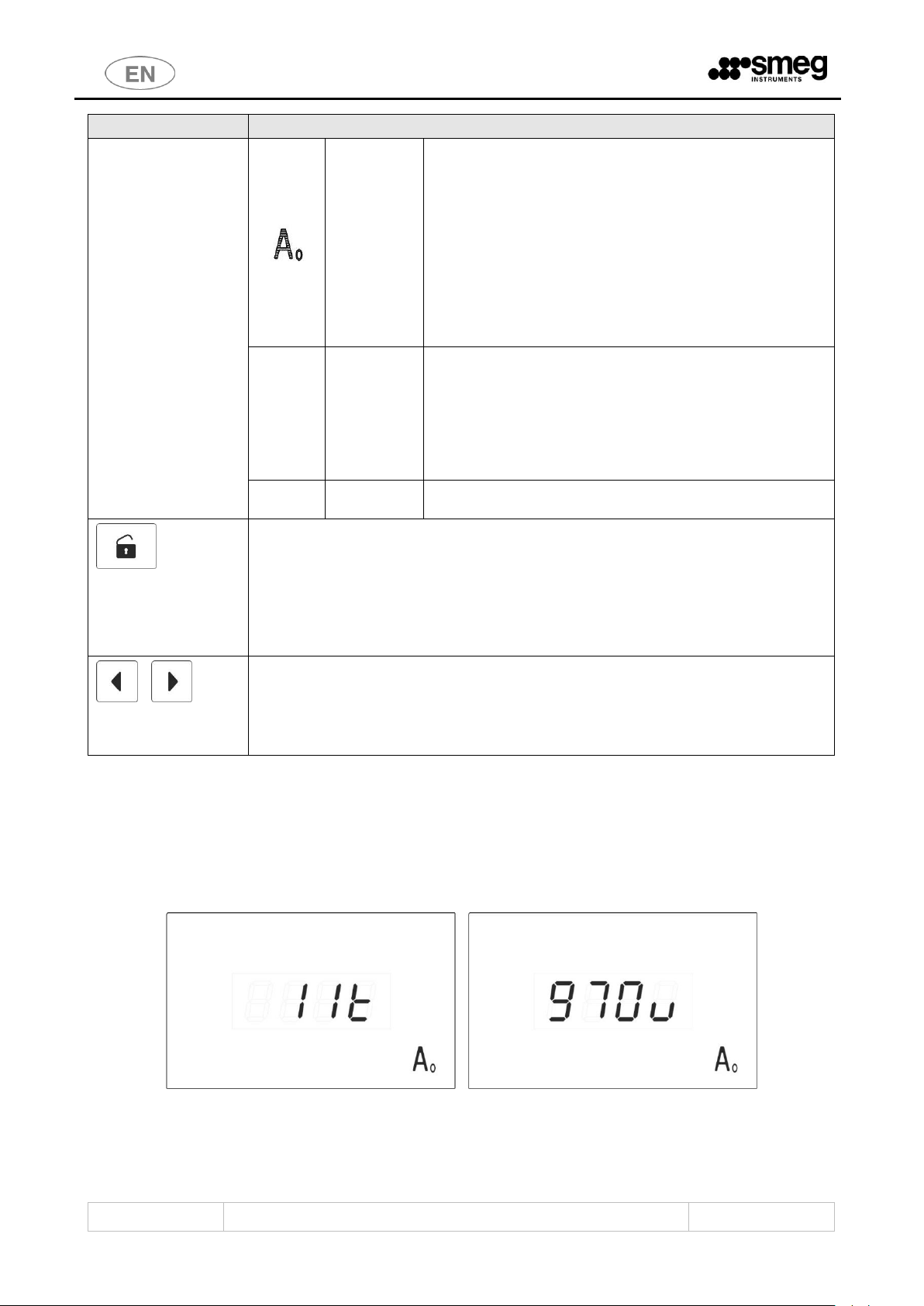

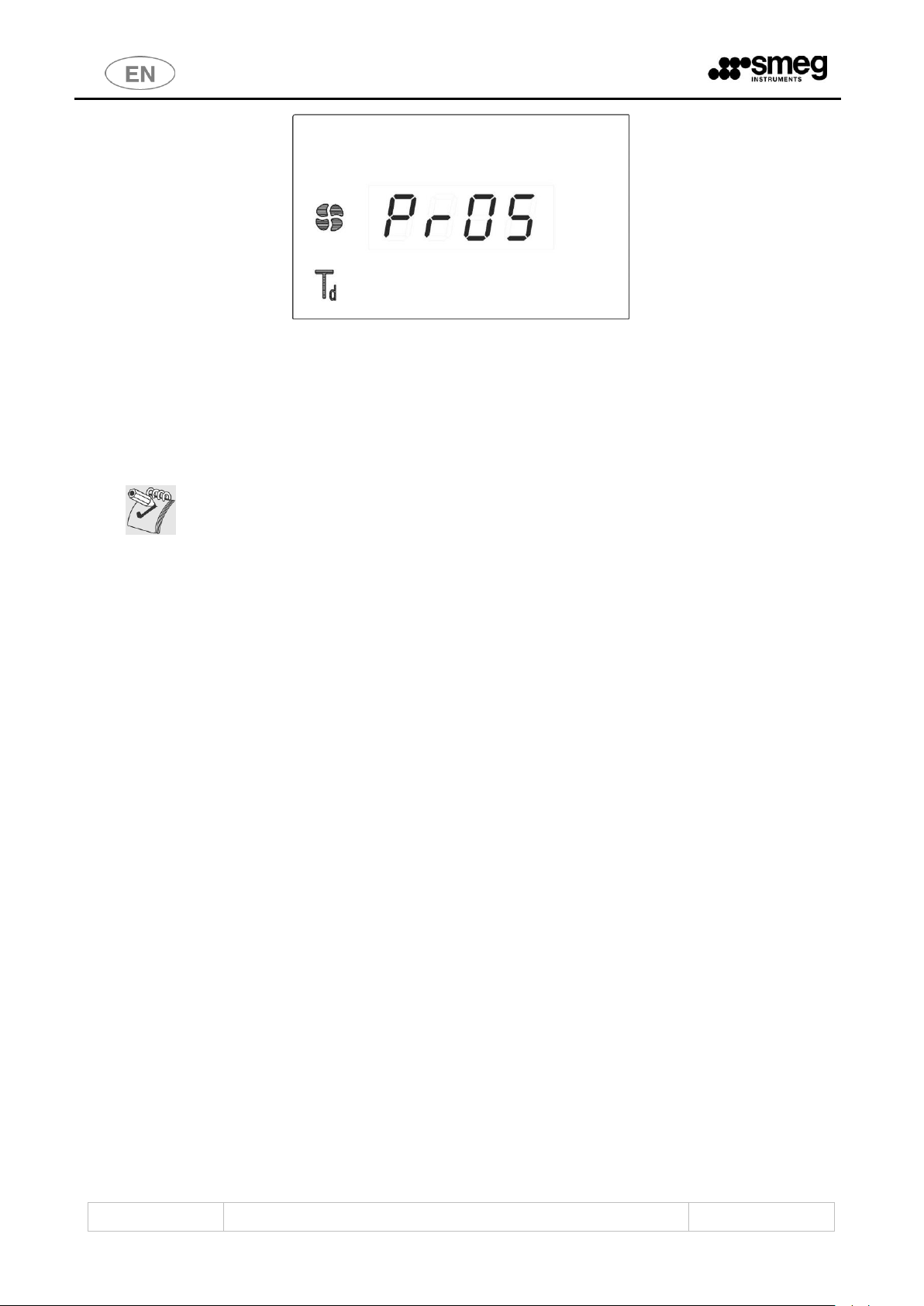

4.2.1 DISPLAY OF PARAMETER A0

Displayed on two screens from firmware version 1.11.0.33 (May 2013).

The values of parameter A0 may be high (typical example A0=12000) and it is displayed on two consecutive screens,

the thousands(t-thousands) screen and the units (u-units) screen; the value in thousands appears with the suffix “t”,

the units with suffix “u”. The switch between screens takes place automatically after 3 seconds, or can be triggered by

a short press on the “Functions” button.

fig. 7 – Display of A0 on two consecutive screens; the suffix “t” stands for thousands.

User Manual

PW4060 Series

Page 18 - 78

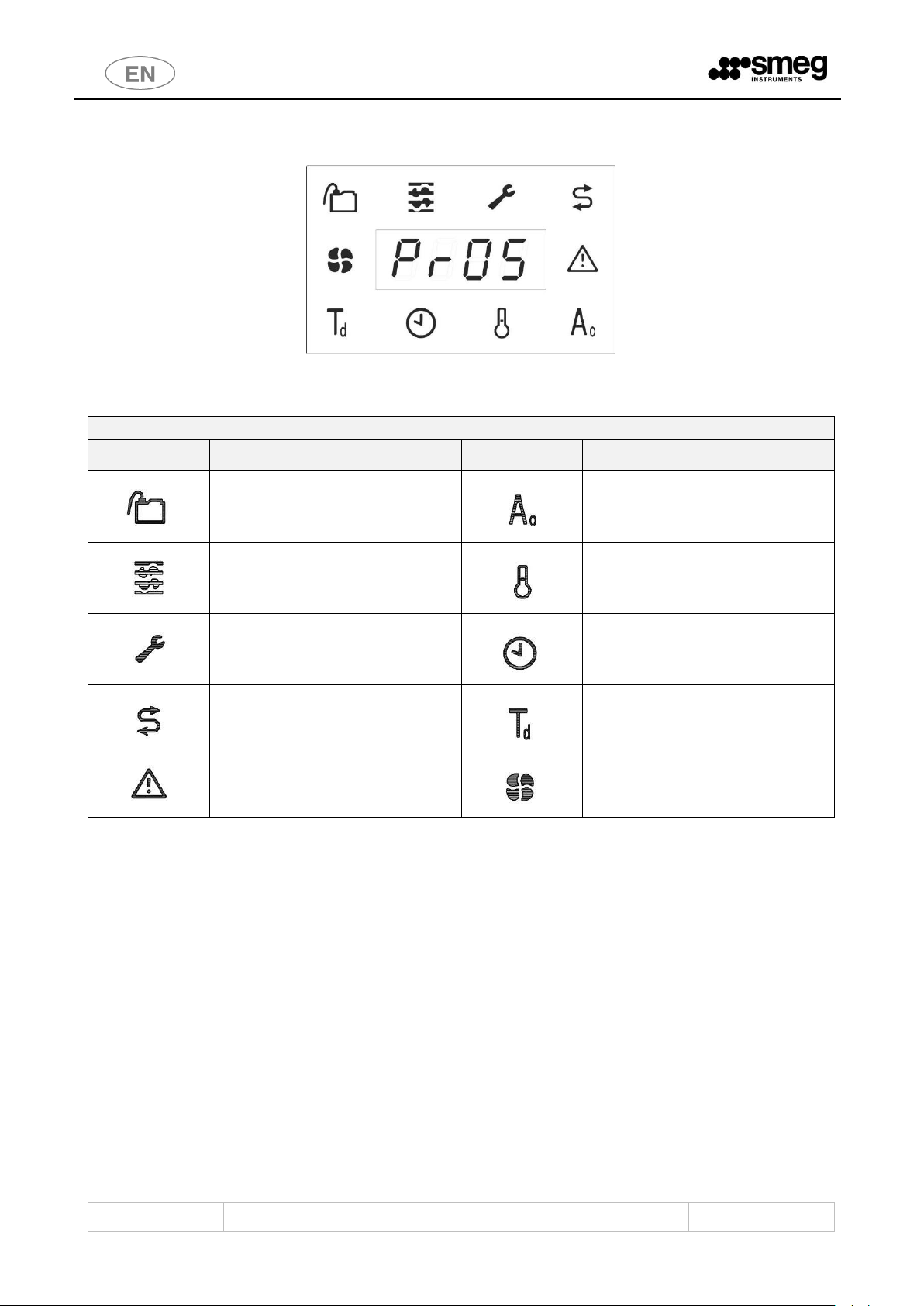

4.3 INDICATOR LEDS - INTRODUCTION

fig. 8 – In the front panel display area: digit area in the centre with indicator LEDs around the perimeter.

LED SYMBOLS

SYMBOL

MEANING

SYMBOL

MEANING

Lack of detergent

A0, thermal disinfection

Maintenance: filter

replacement

(only if absolute filter is installed)

Temperature

Appliance maintenance

Time: time left on display

No salt

Thermal disinfection,

identifies cycles with thermal

disinfection

Alarm

Drying

User Manual

PW4060 Series

Page 19 - 78

4.4 INDICATOR LEDS - DETAILED EXPLANATION

1 - Symbols associated to a warning

SYMBOL

MEANING

Lack of detergent

Lights up if the detergent level sensors are installed and one of them is at "minimum" level.

The warning is displayed at the end of the cycle and, in combination with the LED, the segment

display shows the code of the detergent to which the warning refers:

P1: code “A- : 68”

P2: code “A- : 69”

P3: code “A- : 70”

Activated at the end of the cycle and when the user attempts to start a new program.

The washing cycle can be started with this light on by pressing the Start/Stop button again.

If both alarms are present (cans P1 and P2 both empty), the Start/Stop button has to be pressed

twice to start the cycle. (The appliance’s internal memory records the event).

Replace the can of detergent which is running out with a new can as soon as possible.

Maintenance: filter replacement

For PW4060 series only; active if the dryer is present and the absolute filter is installed. (The

absolute filter is optional). The LED indicates that the absolute filter needs to be replaced.

Operation of the light is triggered by the number of drying operating hours, set at 500h when the

filter is new. The filter must be replaced by Smeg authorised staff.

Appliance maintenance

The appliance counts the number of cycles performed and the LED comes on to alert the user that

maintenance is required.

These are inspection and maintenance operations, scheduled every 1000 cycles, which must be

performed by Smeg authorised staff to keep the appliance safe and in good working order.

No Salt

Salt must be added to the water softener reservoir in the tank.

Salt is necessary to enable the softener to reduce the hardness of the intake water.

Alarm

The machine displays an anomaly, which can be generated by a fault or by the detection of abnormal

conditions. The displays shows the number of the alarm. In the alarms table in this manual, each

code is matched with the components which may have caused the event as an aid to

troubleshooting.

A record should be kept of any alarms to allow the After-Sales Service to be provided with a detailed

description of the malfunction.

User Manual

PW4060 Series

Page 20 - 78

2 - Symbols associated to a washing cycle parameter

When the LEDs listed below light up, the value shown on the display is a parameter of the

washing cycle in progress or being selected.

When the cycle has not yet started: pressing the Functions button displays the cycle

parameters.

When the operating cycle is in progress: pressing the Functions button displays the value

reached by the parameter associated to the LED.

SYMBOL

MEANING

A0, thermal disinfection

With cycle running: The LED is on when the digits in the middle of the screen show the A0 value

reached.

With appliance in standby: when the LED is on the digits in the middle of the screen show the A0

value associated to the cycle being selected.

Parameter calculation and display are only enabled if the cycle has a thermal disinfection phase with

temperature of at least 80°C.

Temperature

With cycle running: The LED lights up when the display shows the temperature in the tank.

With drying in progress: The LED lights up when the display shows the temperature in the dryer

pipe (function introduced from firmware version 4.6.xx.yy).

With appliance in standby: The value on the display shows the max. temperature associated to the

cycle being selected.

Thermal disinfection

Identifies a cycle with thermal disinfection; the LED flashes when a thermal disinfection phase is in

progress.

Drying

For PW4060 series only. The LED comes on to identify a cycle with drying phase, even during

selection. The LED flashes when the drying phase is in progress.

Remaining time

With cycle running: The LED lights up when the display shows the time remaining.

With appliance in standby: the value on the display shows the estimated time for performance of

the program.

fig. 9 – Functions button. With the cycle in progress or being selected, pressing the Functions button displays the parameters of the wash cycle: A0

value, Temperature and Time Remaining.

User Manual

PW4060 Series

Page 21 - 78

4.5 SELECTING THE WASHING PROGRAMME

The device has an interface, with segment display and 10 LED-lit symbols, for user-device communications.

To run a program:

1. Close the door by shutting it against the appliance until the lock clicks shut. The buttons are only enabled with

the door closed.

2. If the appliance is off, switch it on by pressing the On/Off key (hold down for 2 seconds)

3. Use the Selection buttons to select the program.

4. Once the selection has been made, the Functions button can be used to scroll through the program

parameters.

5. If the program includes a drying phase, its duration can be adjusted using the Drying Decrease and Drying

Increase buttons.

6. Press the Start/Stop button to start the cycle (hold it down for 2 seconds).

7. Two beeps sound to indicate the start of the program.

8. Once the selected program has been successfully completed, the display shows “End“.

9. Interrupting the cycle: A cycle in progress can be interrupted by pressing the Start/Stop button. A

After the cycle has been interrupted, the options available vary depending on conditions in the tank:

i. If the temperature in the tank is below 40°C: the door can be opened. If the door is closed

again within 1 minute, the cycle can be restarted from the phase where it was interrupted by

holding down the Start/Stop button.

ii. If the temperature in the tank is above 40°C: a reset cycle is required since the door cannot

be opened.

2

3

1

fig. 10 – Standard procedure for starting a cycle. 1 Select the program using the Selection buttons. 2 Check the program parameters: Functions

button. 3 Start the program: hold down the Start/Stop button.

CONTROL PANEL SYMBOLS

SYMBOL

MEANING

SYMBOL

MEANING

On/Off

Functions

Drying Decrease

Drying Increase

Start / Stop

Open door

Select

Select

User Manual

PW4060 Series

Page 22 - 78

fig. 11 – Example of a Display screen. Program 5 selected

The program includes a drying phase – Drying LED on.

The program includes a thermal disinfection phase– ”Td” LED on.

NOTE - CYCLE COMPLETION TIMES

The completion times shown on the display are guideline: they may vary due to factors such as

the intake water temperature and pressure.

At the end of each program, a resin regeneration phase may be automatically tripped, followed

by resin washing, to ensure that the integral softener operates correctly. These procedures do

not take place at every cycle but are triggered as needed, depending on the intake water hardness

and the amount of water used.

The procedures are not included in the theoretical cycle time shown initially on the display.

In order for the real times to be close to the theoretical stated times, the appliance parameters

must be set appropriately, so that the time passed is calculated on the basis of the electrical

connection as made.

User Manual

PW4060 Series

Page 23 - 78

4.6 BRIEF TABLE OF THE PROGRAMS INSTALLED

For details of the various washing program phases, always refer to the enclosed “PW4060 Programs Table”.

The brief table below is purely guideline. The programs listed below may be subject to modification for the purposes

of improvement.

The drying phase – phase finale of the programme - is included in the Smeg PW4060 series.

All programmes can be modified to meet specific requirements.

Programs can only be modified using the Smeg TRACELOG software; contact Smeg for

information concerning the use and installation of the program.

ID

PW - PUNCH WASHER

PR 1

Light [+ Drying]

PR 2

Medium [ + Drying ]

PR 3

Strong [ + Drying ]

PR 4

Light demi [ + Drying ]

PR 5

Medium demi [ + Drying ]

PR 6

Strong demi [ + Drying ]

PR 7

Light demi* [ + Drying ]

PR 8

Medium demi* [ + Drying ]

PR 9

Strong demi* [ + Drying ]

PR 10

Custom 1 (default: rinse demi)

PR 11

Custom 2 (default: rinse demi)

PR 12

Custom 3 (default: rinse demi)

PR 13

Custom 4 (default: rinse demi)

PR 14

Custom 5 (default: rinse demi)

PR 15

Custom 6 (default: rinse demi)

PR 16

Service - operation of peristaltic pumps, intake of detergent + rinsing

Tab. 1 – Brief table of the programs installed.

PUMP

PW DEFAULT

DOSAGE

[ml/litre]

DOSAGE FOR SERVICE

PROGRAM 16 ONLY

[ml/litre]

P1 5 12

P2 3 12

P3

2 (equivalent to

0.3ml/l)

12 (equivalent to

1.8ml/l)

Operating PARAMETERS for P3

Display shows

“SEt – 3”

ml dispensed by pump per

litre of water

1

0.14

2

0.29

3

0.43

4

0.57

5

0.71

6

0.86

7

1.00

8

1.14

9

1.29

10

1.43

Tab. 2 – Brief table of doses and water intakes per phase.

User Manual

PW4060 Series

Page 24 - 78

MAINS WATER - DEMINERALISED WATER in PROGRAMS

The enclosed table indicates when a specific phase takes in cold water and when demineralised

water.

If demineralised water is deselected by means of the appliance setup parameters, the

appliance will always take in cold water.

Whenever possible, connection to demineralised water is recommended, for better final rinsing

results and to avoid the formation of limescale.

4.6.1 RESINS - SOFTENER, REGENERATION AND WASHING PHASE

The softener incorporated in the device removes calcium compounds from the intake water to reduce its hardness.

The softener comprises a container of ion exchanger resins, which must be regenerated regularly.

The appliance decides when a resin regeneration and washing cycle is needed depending on the hardness set and the

quantity of water treated.

Resin regeneration and washing cycles are performed at the start of a washing cycle, to avoid the risk that standing

brine (salt and water) might cause corrosion.

4.6.2 DRYING PHASE

The drying phase is included in the washing cycle, except in programs

“CUSTOM” and “16 Service”.

If the current program includes drying, the respective indicator light turns on.

ADJUSTING THE DRYING SETTINGS

The specific buttons for this function allow the effectiveness of the drying process to be regulated by increasing or

decreasing the total time of this phase. 3 dashes light up on the display if the default drying settings are active, while 2

dashes or 1 dash indicate gradually shorter times.

STANDARD STRUCTURE OF THE DRYING PHASE, IN 3 STEPS

Drying

total time:

t_d = t_1 + t_2 + t_3

Step 1

Step 2

Step 3

Characteristics:

The fan speed is reduced

(1/4 - 1/2 of full speed) to

aid the controlled venting

of steam from the tank.

Time and temperature

equal to target values set

by the program. Fan at full

speed.

Cooling phase for load and

heating elements.

Duration, with 3 steps

t_1 = 10 minutes

t_2 = target_time

t_3 = 4 minutes

Duration, with 2 steps

t_1 = 10 minutes

t_2 = 0.5 x target_time

t_3 = 4 minutes

Duration, with 1 step

t_1 = 10 minutes

t_2 = 0

t_3 = 4 minutes

Duration, with 0 steps

t_1 = 4 minutes

t_2 = 0

t_3 = 4 minutes

NOTES

The “target time” stated in the table refers to the time specified in the annexed “PROGRAM TABLE” document.

In a standard program, e.g. with drying having t_target=25min, the total time of the phase is calculated as follows:

t_d = t_1 + t_2 + t_3 = 10 + 25 + 4 = 39minutes.

If the final temperature is below 40°C during the last phase of the washing cycle, step 1 is completely omitted, since

there is no need to expel steam: t_1=0.

Target temperature: the temperature value in the program table, which refers to the temperature reached by the

monitoring probe TA in the drying duct. The temperature in the tank during drying is about 30°C below the target

value. For example, for a drying program with T_target=110°C,

T_tank≈ T_target - 30°C = 110°C – 30°C = 80°C.

User Manual

PW4060 Series

Page 25 - 78

SEPARATE DRYING PHASE

Users can also select a SEPARATE DRYING CYCLE by pressing the “Drying Decrease” button for 2 seconds: the

message “PdrY” appears on the display.

The drying time can still be adjusted as described above.

fig. 12 – Display screen: separate drying program.

Drying Decrease

Drying Increase

fig. 13 – Buttons used to Decrease and Increase the Drying Time.

fig. 14 – Display during Drying setting adjustment.

N.B. - important for selecting the cycle and max. cycle temperature

The drying temperature stated in the programs table (e.g. 110°C) refers to the value measured at

a specific point of the Dryer duct and does not correspond to the temperature reached by the

load.

Temperatures in the tank during drying never exceed 90°C.

User Manual

PW4060 Series

Page 26 - 78

4.6.3 CUSTOM PROGRAMS

All programmes can be modified to meet specific requirements, except for programme "16 service"

Modifications can be made using the Smeg TRACELOG software (not part of the standard package) or by Smeg

authorised engineers on request.

For details of how to purchase the software and minimum installation requirements, contact your local dealer or mail

Smeg directly at instruments@smeg.it .

If parameters are modified from the default settings, a record should be kept of the various phases and the new

program settings.

Warning: when creating a custom program, do not include more than two thermal disinfection

phases at 93°C for 10 min.

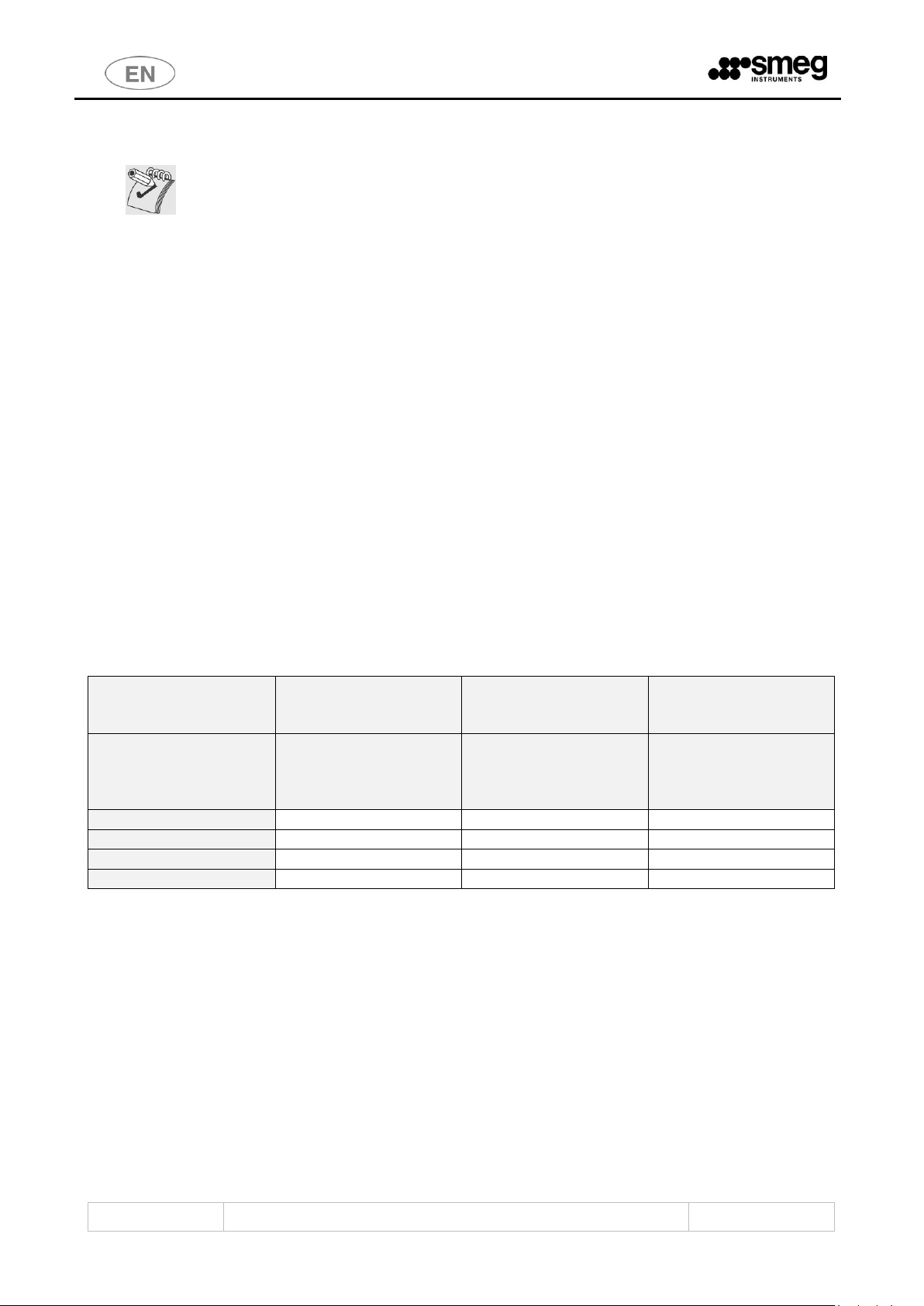

CUSTOM PROGRAM RECORD TEMPLATE

Program

1. Prewash /

Wash (cold)

2. Wash /

Enzymatic Wash

3. Chemical

Disinfection

4. Neutralisation

5. Mains Water

Rinse

6. Demi Rinse

7. Hot Demi Rinse

8. Thermal

Disinfection / Td +

lubrication

9. Drying

A0

Cycle time (except

drying)

ID.

Name

H2O Intake

Temp. [°C]

Duration [min]

H2O Intake

Temp. [°C]

Duration [min]

H2O Intake

Temp. [°C]

Duration [min]

H2O Intake

Temp. [°C]

Duration [min]

H2O Intake

Temp. [°C]

Duration [min]

H2O Intake

Temp. [°C]

Duration [min]

H2O Intake

Temp. [°C]

Duration [min]

H2O Intake

Temp. [°C]

Duration [min]

Temp. [°C]

Duration [min]

User Manual

PW4060 Series

Page 27 - 78

4.7 A0 THERMAL DISINFECTION PARAMETER

The A0 parameter (introduced by the EN 15883 standard1) allows a numerical value to be assigned to the thermal

disinfection carried out - shown by Td in the interface LEDs.

When calculating the parameter, only the time intervals during which the temperature is above 65°C are considered.

For SMEG thermal disinfection programs, the calculation is simplified by only including the “extension” phase, when the

temperature is kept constant at close to the target value set.

Programs that include thermal disinfection have therefore been designed to offer the following A0. values:

Temperature [°C] and time [min]

A0

90°C - 1’

600

90°C - 5’

3000

93°C - 5’

6000

93°C - 10’

12000

The formula for calculating A0. is given below.

10

80

0

10

T

A

= Time in seconds for which the disinfection temperature must be maintained.

T

= Disinfection temperature in °C.

If the temperature is 80°C, A0 is equal to the temperature maintenance time.

1

EUROPEAN STANDARD EN 15883 “Washer-Disinfectors”, with particular reference to section 3 Terms and Definitions and annex B, A0 concept. of

part 1 of the standard, 15883-1.

User Manual

PW4060 Series

Page 28 - 78

4.8 PREPARING THE LOAD FOR WASHING AND DISINFECTION

Loading instructions are provided in compliance with 5.4.4-k of IEC61010-2-040:2005.

The load for processing must be arranged appropriately on the most suitable supports for machine-washing.

Effective washing starts with preparation of the objects for processing.

Therefore, before placing the items of the load the specific baskets, it is necessary to remove any

large residues deriving from previous use, by soaking, treatment or rinsing.

Stainless steel items cannot be immersed in physiological solutions of sodium chloride, as prolonged contact causes

corrosion and damage to the surface due to stress corrosion cracking.

Do not overload the washing baskets to ensure effective mechanical action of the water across the entire surface.

To allow effective cleaning and prevent damage to the objects for processing, they must be properly arranged on the

most suitable supports for machine-washing.

Contact Smeg for advice about the washing trolleys best suited to your needs instruments@smeg.it

Items which can be dismantled must be prepared and stowed as instructed by the manufacturer.

For effective cleaning, items with hinged joints must be opened to minimise the overlapped surfaces. The instrument

holder devices used and the fixing devices must be designed so that no shadow zones are created during subsequent

cleaning and disinfection.

Make sure that there no labels on the objects for washing which may detach during the process.

WASHING SUPPORTS - TROLLEYS

The appliance comes without washing trolleys.

Refer to the washing trolley manuals for guidance on their correct use.

Avoid direct, repeated contact with dirty material.

Always take the greatest care and use suitable personal protection equipment, both before and after

treatment.

Before processing an object, check on the manufacturer’s instructions that it is are approved for

automatic treatment and also check the recommended maximum washing temperature.

User Manual

PW4060 Series

Page 29 - 78

4.9 END OF CYCLE

Once the selected program has been successfully completed, the display shows “End“.

“End” only appears if the washing phases have been performed and been completed correctly; it does not appear if the

program has been interrupted or if an error which may affect the cycles’ effectiveness has occurred.

A beep sounds to indicate the end of the cycle.

AUTOMATIC OPENING AT END OF CYCLE

If auto open is enabled, the door opens automatically and 4 horizontal dashes display.

Automatic opening is not enabled if alarms occur during washing.

Drying LED: When a program which includes the drying phase is selected, at the end of the cycle, the

relative LED is:

1. on and steady if the process has been completed correctly,

2. flashing if drying has been interrupted (e.g. due to a power blackout or forced interruption of the

program by the user).

fig. 15 – End of cycle, display screen. The word End indicates that the washing process has been completed correctly. If automatic opening is enabled:

the door is released automatically and the 4 dashes appear on the display.

AUTOMATIC OPENING AT END OF CYCLE

At the end of the cycle, the door may open automatically to allow the remaining steam to disperse and help the

processed material to cool and dry more quickly.

If the temperature inside the tank is above 80°C, a delay of 10 minutes is automatically calculated before the door

opens.

During this delay, the lock can be released by pressing the Door opening button.

Automatic door opening at the end of the cycle is a parameter which can be enabled or disabled: refer to the specific

point: SETUP MODE - “FUNCTIONS”.

Wait about 10 minutes with the door open before removing the processed load, to allow the material in the washing

chamber to cool, and if necessary to dry.

User Manual

PW4060 Series

Page 30 - 78

4.10 HALTING A PROGRAM IN EXECUTION

SUSPENDING A PROGRAM

A cycle in progress can be interrupted by pressing the Start/Stop button.

During the “Suspension” of the program, the letter “S” appears on the display, followed by the

code of the current program.

fig. 16 – Interrupting a Program: hold down the Start/Stop button

For PW - Punch Washer series products, SUSPENSION phase:

1. If the temperature in the tank is below 40°C: the door can be opened. If the door is closed again within 1

minute, the cycle can be restarted from the phase where it was interrupted. The cycle is always restarted by

holding down the Start/Stop button for 2 seconds.

2. If the temperature in the tank is above 40°C: a reset cycle is required since the door cannot be opened.

3. If the cycle is interrupted and the user does not press any buttons within 1 minute: the appliance automatically

switches to Reset mode

fig. 17 – Display screen, Suspension of program 5: S 05 “.

User Manual

PW4060 Series

Page 31 - 78

4.11 PROGRAM SPECIAL OPTIONS

The following functions are defined as “Special Options”:

1. Temporary disabling of demi water

2. Delayed start (function introduced from firmware version 4.6.xx.yy).

The “Special Options” menu is accessed by pressing the “Start/Stop” and “Door Opening” buttons simultaneously.

To scroll through the special functions: press the "Functions" button and release at once.

The special options only apply for 1 single cycle, executed after selection of the option. After execution of the cycle,

the default values are restored.

Special options must be confirmed by pressing the “Start/Stop” button; after confirmation, the program display

returns to the screen.

If the option is not confirmed, after 10 seconds without any action the system quits the option and the last parameter

set is maintained.

N.B.: the current date and time must be set to allow the “delayed start” setting to function

correctly.

4.11.1 DELAYED START - Setting the hours

Delayed start: initially, the display shows “dh:00”.

The selection keys can be pressed to set up to a max of 12 hours (“dh:12”).

The “clock” LED remains on while the selection is made and the value set flashes until confirmed.

fig. 18 – Delayed start setting screen.

4.11.2 DELAYED START - Starting the program and display

To start a program with delayed start set: Hold down the “Start/Stop” (as when starting the cycle normally).

The display shows, in alternation (switching every 2 seconds):

the time remaining before the start of the program (format “hh:mm”) / the program selected (“Pr:XX”).

The “clock” LED remains steady when the time remaining is displayed.

At the end of the delay time: the program starts and from this point onward the contents of the display are the same

as for a normal cycle.

fig. 19 – Once the cycle start command is given, the display alternates the program selected with the time remaining before it actually starts.

User Manual

PW4060 Series

Page 32 - 78

fig. 20 – Example of use of the delayed start to set a delay of 1 h

4.11.3 TEMPORARY DISABLING OF DEMI WATER

Press the “Start/Stop” and “Door opening” buttons simultaneously for a moment to display the

status of the “demineralised water disabling” option.

The Selection buttons can be used to deselect the use of demineralised water.

If the option is active, the message “no dE ”, meaning “No demi”, temporary disabling of demineralised water,

appears on the screen.

If the option is disabled by pressing the two keys mentioned above, the message “dE” is shown on the screen.

This option can only be used if the use of demineralised water has been activated.

The disabling option can be activated before starting the selected program, and remains active

for only one cycle, at the end of which it is deactivated automatically.

When the option is active, demi water is replaced with cold water in all the phases where it

would normally be used.

User Manual

PW4060 Series

Page 33 - 78

1

1

2

fig. 21 – Demi water disabling buttons. To access the function: hold down the Start/Stop + Door opening buttons together. To select demi water

disabling: Selection buttons.

fig. 22 – Display screen: TEMPORARY disabling of demi water; the option can be enabled and disabled using the selection buttons.

4.11.4 Deleting “Delayed start” - “No Demi” settings

To delete a setting:

1. return the parameter to zero (e.g. “dh:00” for delayed start, “ dE” for demi water);

2. switch the device off and back on (the default value is restored: e.g. “dh:00”);

3. by opening the door of the device (for “delayed start” only) once the cycle start command has been given.

User Manual

PW4060 Series

Page 34 - 78

4.12 RESET PROCEDURE

The RESET procedure performs water pump-out and intake cycles to return the device to conditions

of safety in the event of a malfunction.

A RESET cycle can and should be started if an alarm occurs.

The Reset cycle can also be started independently, regardless of whether or not an alarm is present.

N.B.: the RESET procedure can only be started with the door CLOSED.

When an error occurs, generally the device manages the anomaly itself: in this case the alarm code

flashes on the display until the problem has been dealt with: no reset commands are accepted

during this time.

Any RESET forced by the user will not be accepted until the problem has been dealt with and the

alarm code on the display is “steady”.

STARTING A RESET

After an alarm or with the appliance at a standstill, press the Functions and Start/Stop buttons and hold them down for

about 2 seconds, until a beep is heard.

"P-" appears on the display and the RESET procedure starts.

At the end of the procedure, "E-“ flashes on the display, alternating with the program which was running and has been

interrupted, if any.

Depending on the appliance’s status, the RESET command may not be accepted: in this case, open and close the door

and then repeat the procedure.

ATTENTION

If it is not possible to perform the RESET cycle, before calling the After-Sales Service switch the

appliance off and back on and then try again.

fig. 23 – RESET cycle selection buttons: hold down the Start/Stop + Functions buttons together.

fig. 24 – RESET: during the RESET the display shows “ P- “. At the end of the RESET cycle, “ E- “ appears on the display.

User Manual

PW4060 Series

Page 35 - 78

4.13 PRINTING THE CYCLE AND APPLIANCE PARAMETERS

If the Smeg “WD-PRINTE” accessory has been installed, it is possible to force printing of the data relating:

1. To the last cycle performed: by pressing the 1 On/Off and 2 Functions keys simultaneously.

2. To setup parameters: by pressing the 3 Functions and 4 - L selection keys simultaneously.

Print last cycle

+

Print parameters

+

Commands are only accepted if the door of the device is closed.

1

2 - 3

4

fig. 25 – Standard procedure for forcing printing.

Last cycle data: use “On/Off”+”Functions” keys; Parameters: use “Functions”+”LH Selection” keys.

5 SETUP MODE - “FUNCTIONS”

The device has setup procedures for modifying its operating parameters.

The setup mode is accessed by pressing the “Functions” button and requires a password.

For reasons of security and responsibility, 4 levels of password are available for access to more and more complex

functions:

1. USER Level (1111)

2. SUPERUSER Level (provided by the installation engineer)

3. ENGINEER Level

4. SMEG Level

5.1 ACCESSING THE SETUP MODE / ENTERING THE PASSWORD

a. Hold button 5 - Functions down for 5 seconds. 4 dashes appear on the display.

b. Use the Selection buttons 4 and 8 to modify the individual characters of the password.

c. Press button 5 - Functions quickly to move on to the next character

d. Once the 4 characters of the password have been entered, confirm by holding down button 3 - Start/Stop.

a. If the password entered is correct, the system accesses the first menu item

User Manual

PW4060 Series

Page 36 - 78

b. If the password is not correct, two beeps signal the error.

c. 5 seconds after the last button is pressed, the system automatically quits the Setup menu.

e. Once the Setup mode has been accessed, the various items available can be scrolled using button 5 -

Functions.

f. To quit the SETUP mode, hold down button 7 - Open door.

g. N.B.: a short press on button 6 – Drying + has the same effect as a short press on button 5 – Functions in the

following cases:

a. During typing of the Password, to move on to the next digit

b. Once the Setup mode has been accessed, for scrolling the various options available.

fig. 26 – 5 - Functions button: hold down to access the Setup mode.

The items accessible from the SETUP menu are shown in the table below. To move on from one item to the next,

press button 5 - Functions quickly.

Setup Item

Description

Set

Appliance parameter setup - detailed explanation provided below in “Set“ PARAMETERS

Cloc

Time and date – see Par.“CLOC” – DATE AND TIME PARAMETERS

Filt

Drying filter counter. (Only if absolute filter is installed)

Press the Start/Stop button to display the number of absolute filter hours left before

the maintenance message appears. The initial default setting is 500. The value is in

units. (Display only parameter, cannot be modified).

Tec

Appliance operating hour counter for maintenance. Press the Start/Stop button to

display the number of cycles left before the maintenance message appears. The initial

default setting is 900. The value is in units. (Display only parameter, cannot be

modified).

Coun

Device total operation counter. (Display only parameter, cannot be modified)

This parameter displays on two consecutive screens. The thousands value is followed by

“t”, the units value by “u”.

PrEn

Setting which allows display and selection only of the washing programs actually of

interest.

User Manual

PW4060 Series

Page 37 - 78

5.2 ACCESS AND PARAMETER MODIFICATION

The three options referred to above - Set, Cloc and PrEn – are used for accessing and modifying:

1. Appliance parameters, Set.

2. Date and Time parameters, Cloc.

3. setting to allow display and use of a subset of programs only, PrEn (PrEn: “Program Enable”).

The following basic procedure applies to every item.

Step

Button

Action

1

Start/Stop – hold down to access the option required.

To access the Set parameters, hold down until the “Set” option appears on the

display.

To access the Cloc (date and time setting) parameters, hold down until the “Cloc”

option appears on the display. Similarly, for the “PrEn” option

2

Functions– short press - Selection of the parameter required. (A short press on

button 6 – Drying + has the same effect as a short press on button 5 – Functions so

either can be used).

3

-

Selection buttons - Modification of the selected parameter.

During modification, the parameter concerned flashes on the display.

4

Start / Stop – hold down to confirm the modification.

Once the modification has been confirmed the parameter stops flashing and appears

on the display with steady light.

5

Door opening – hold down to quit the screen for display/modification of the current

parameter.

2

1 - 4

5

3

fig. 27 – Access for display and modification of the Set and Cloc parameters:

Access the parameter: by pressing the Start/Stop button

Quit the parameter: by pressing the Door opening button.

fig. 28 – Set parameters. Hold down the Start/Stop button to access the parameters. Parameter -1 sets to the dose dispensed by peristaltic pump P1.

Use the Selection buttons to modify the parameter. Press the Function button quickly to move to another parameter. Confirm changes using the

Start/Stop button.

User Manual

PW4060 Series

Page 38 - 78

fig. 29 – Cloc parameters. Hold down the Start/Stop button to access the parameters, in this case identified as C1, C2, etc. Parameter C1 sets the

current year. Use the Selection buttons to modify the parameter. Press the Function button quickly to move to another parameter. Confirm changes

using the Start/Stop button.

User Manual

PW4060 Series

Page 39 - 78

5.3 “SET“ PARAMETERS

The display reads Set.

To access this item press the Start/Stop button.

The Set option has a variety of individual settings.

User level operators can only display the parameters and cannot modify any “Set” parameters.

Set

PARAMETER

DESCRIPTION

POSSIBLE SUPERUSER ACTION

With set

parameter

“-d=0”

With set

parameter

“-d=1”

-1

Detergent pump P1 batching.

Setting in ml/litre, the default value of this parameter is

3ml/litre.

Maximum recommended quantity with Smeg

detergents: 10ml/litre. (Max setting 10ml/litre)

Increase/decrease the setting with the Select buttons.

Display and

Modification

Display shows

-2

Detergent pump P2 dispensing rate.

Setting in ml/litre, the default value of this parameter is

3ml/litre.

Maximum recommended quantity with Smeg

detergents: 10ml/litre. (Max setting 20ml/litre)

Increase/decrease the setting with the Select buttons.

Display and

Modification

Display shows

-3

Detergent pump P3 dispensing rate.

The default value of this parameter is 2ml.

NB: consider the table of dispensing rates for this pump

Display and

Modification

Display shows

-4

Water hardness

Set the hardness in °f, in steps of 5. Range: 5-65°f. The

default setting is 40°f.

Attention: Make sure that the value corresponds to the

actual hardness of the water supply.

Display and

Modification

Display and

Modification

-5

Automatic opening at end of cycle

The default setting on PW appliances is “On”, but

automatic door opening can be disabled by changing the

parameter to “Off”.

If the option is enabled, the device door is opened

automatically at the end of the cycle.

Display and

Modification

Display and

Modification

-6

Printer language

English by default, the language can be chosen from the

various options available

Display and

Modification

Display and

Modification

German

French

Spanish

Italian

English

dE

Fr

ES

It

En

-7

Demineralised water

The use of demineralised water can be activated or

deactivated depending on whether or not the relative

connection has been made (Activated: dn, Deactivated: --)

Display and

Modification

Display and

Modification

-8

Filter hours left (only installed on PW4060)

The parameter indicates the number of fan operating

hours left before filter replacement. Initial value 50 (“-

8:50” on the display means 500 hours). The value can be

reset by a Smeg authorised engineer.

Display Only

Display Only

User Manual

PW4060 Series

Page 40 - 78

Set

PARAMETER

DESCRIPTION

POSSIBLE SUPERUSER ACTION

With set

parameter

“-d=0”

With set

parameter

“-d=1”

-9

Cycles left before service

Indicates, to the nearest ten, the number of cycles left

before the routine service (e.g. “-9.20” on the display

indicates that there are 200 cycles left before the service

alert).

The value can be reset by a Smeg authorised engineer.

Display Only

Display Only

-A

Power Supply

The parameter indicates whether the connection is:

- single-phase: parameter setting “1”

- three-phase: parameter setting “3”

N.B.: the value “3” refers to both 400V 3N~ / 50 Hz and

230V 3~ / 50Hz connections.

Warning: this parameter is only used for the correct

setting of times remaining.

Display Only

Display Only

-b

Memory Data Overwriting

- Overwriting enabled: parameter setting “1”

- Overwriting disabled: parameter setting “0”

The parameter refers to whether or not the device’s

internal memory, which keeps a record of all the cycles

performed and the alarms which have occurred, can be

overwritten.

WARNING

If overwriting is disabled, alarm AF:91 is triggered once

the memory is full. In this case the appliance will not

perform any more cycles until the data from the memory

are downloaded; this can only be done using the

TRACELOG software.

Display and

Modification

Display and

Modification

-C

Use of powder dispenser

(Parameter introduced from Main Firmware version

1.11.0.33).

Parameter for use by authorised engineers.

This parameter only appears on some models, which are

fitted with the powder detergent dispenser on the door

liner. It may assume the following values:

“-C:dd”, means that the powder dispenser (DD) is fitted

and activated; the dispending rate set using parameter

P1: “Set -1” is not considered.

“-C:P1”, for presence of peristaltic pump P1. Detergent is

dispensed at the rate set in parameter "Set -1”.

Display Only

Display Only

-d

Superuser dosage setting disabling parameter.

(Parameter introduced from Main Firmware version

4.6.xx.yy).

If “-d: 0” the superuser is able to modify the dosages

If “-d: 1” the superuser is not able to modify the dosages

but can display them.

Default value: “-d: 0”.

This Parameter can only be modified by the authorised

engineer.

Display Only

Display Only

User Manual

PW4060 Series

Page 41 - 78

Set

PARAMETER

DESCRIPTION

POSSIBLE SUPERUSER ACTION

With set

parameter

“-d=0”

With set

parameter

“-d=1”

-E

Parameter for setting presence or absence of the WDLANE accessory.

(Parameter introduced from Main Firmware version

4.6.xx.yy).

Sets the serial port communication speed

“-E: Pr” = 9600 bps (for Printer connection)

“-E: Ln” = 11500 bps (for connection to WD-LANE - LAN

accessory).

Display and

Modification

Display and

Modification

-t

Test cycle

(Parameter introduced from Main Firmware version

1.11.0.33).

The parameter, for use by authorised engineers only,

displays and starts a Test Programme; the display shows “

Pr t ”. When it is started, the programme performs a short

wash cycle and activates all the appliance's user devices:

this cycle is for use for checking after components have

been replaced.

- parameter value “ - -“, no access to “ Pr t ” cycle

- parameter value “on”, accesso Test programme “ Pr t ”.

To abort the Test programme "Pr t": switch the appliance

off and back on.

Display Only

Display Only

In the images which follow: example screens relating to some Set parameters.

fig. 30 – Parameter “Set – C”. The setting, indicating the presence of the powder dispenser or peristaltic pump P1, may be “dd” or “P1” as specified

above. “dd” implies use of the powder dispenser, so the dispensing rate set in parameter “Set -1” is not considered.

fig. 31 – Parameter “Set – t”. The setting may be “--” or “on” as specified above, for activation of a test cycle.

User Manual

PW4060 Series

Page 42 - 78

5.3.1 APPLIANCE DATA STORAGE, OVERWRITING, PARAMETER Set -b

The appliance stores the data relating to the cycles performed and all the alarms which have occurred in its own

internal memory, on a PCB.

The data in the appliance’s memory can be read using the Smeg TRACELOG software.

Overwriting of the data in the appliance’s memory can be enabled or disabled using a setup parameter, Set: -b – ; for

details, refer to the SETUP MODE - “FUNCTIONS” section.

Parameter Set -b has two possible values:

- “0” meaning “overwriting disabled”

- “1” meaning “overwriting enabled” – 1 is the default value for the parameter; overwriting is permitted and no alarm

is triggered when the appliance’s memory is full.

WARNING

If overwriting is disabled, parameter “-b=0”, alarm AF:91 is triggered once the memory is full.