Contents

1 Instructions 4

1.1 General safety instructions 4

1.2 Manufacturer liability 7

1.3 Appliance purpose 7

1.4 Disposal 7

1.5 Identification plate 8

1.6 How to read the user manual 8

2 Description 9

2.1 General Description 9

2.2 Symbols 9

2.3 Available accessories 9

3 Use 10

3.1 Instructions 10

3.2 First use 10

3.3 Using the hob 10

4 Cleaning and maintenance 13

4.1 Instructions 13

4.2 Cleaning the appliance 13

5 Installation 15

5.1 Safety instructions 15

5.2 Section cut from the countertop 15

5.3 Mounting 16

5.4 Gas connection 17

5.5 Adaptation to different types of gas 19

5.6 Electrical connection 26

EN

These instructions apply only for the destination countries listed on the appliance’s data plate.

This is a class 3 built in hob.

We advise you to read this manual carefully, which contains all the instructions for

maintaining the appliance’s aesthetic and functional qualities.

For further information on the product: www.smeg.com

3

Instructions

1 Instructions

1.1 General safety instructions

Risk of personal injury

• During use the appliance and its

accessible parts become very hot.

Never touch the heating elements

during use.

• Protect your hands by wearing

oven gloves when moving food

inside the oven.

• Never try to put out a fire or

flames with water: turn off the

appliance and smother the flames

with a fire blanket or other

appropriate cover.

• This appliance can be used by

children aged from 8 years and

above and persons with reduced

physical, sensory or mental

capabilities or lack of experience

and knowledge if they have been

given supervision or instruction

concerning use of the appliance in

a safe way and understand the

hazards involved.

• Children must never play with the

appliance.

• Keep children under the age of 8

at a safe distance unless they are

constantly supervised.

• Keep children under the age of 8

away from the appliance when it

is in use.

• Cleaning and maintenance must

not be carried out by unsupervised

children.

• Make sure that the flamespreader crowns are correctly

positioned in their seats with their

respective burner caps.

• Be aware of how rapidly the

cooking zones heat up. Do not

place empty pans on the heat.

Danger of overheating.

• Fats and oils can catch fire if they

overheat. Do not leave the

appliance unattended while

preparing foods containing oils or

fats. If fats or oils catch fire, never

put water on them. Place the lid on

the pan and turn off the relevant

cooking zone.

• Cooking process should always

be kept under control. A short

cooking process must be

continuously surveyed.

• While cooking do not place

metal objects, such as cutlery or

dishes on the hob surface as they

may overheat.

• Do not insert pointed metal

objects (cutlery or utensils) into the

slots in the appliance.

• Do not pour water directly on very

hot trays.

4

Instructions

• Do not use aerosols in the vicinity

of this appliance whilst it is in use.

• Switch off the appliance after use.

• Do not modify this appliance.

• Do not try to repair the appliance

yourself or without the intervention

of a qualified technician.

• Do not pull the cable to remove

the plug.

• In order to avoid hazard, if the

power supply cable is damaged,

contact technical support and they

will replace it.

Risk of damaging the appliance

• Do not sit on the appliance.

• Do not use steam jets to clean the

appliance.

• Do not obstruct ventilation

openings and heat dispersal slots.

• Never leave the appliance

unattended during cooking

operations where fats or oils could

overheat and take fire. Be very

careful.

• Danger of fire: do not store items

on the cooking surfaces.

• Do not use the appliance to heat

rooms for any reason.

• Do not spray any spray products

near the oven.

• Cooking vessels or griddle plates

should be placed inside the

perimeter of the hob.

• All pans must have smooth, flat

bottoms.

• If any liquid does boil over or spill,

remove the excess from the hob.

• Take care not to spill acid

substances such as lemon juice or

vinegar on the hob.

• Do not put empty pans or frying

pans on switched on cooking

zones.

• Do not use steam jets to clean the

appliance.

• Do not use rough or abrasive

materials or sharp metal scrapers.

• Do not use cleaning products

containing chlorine, ammonia or

bleach on parts made of steel or

that have metallic surface finishes

(e.g. anodizing, nickel- or

chromium-plating).

• Do not use abrasive or corrosive

detergents (e.g. scouring

powders, stain removers and

metallic sponges) on glass parts.

• Do not wash the removable

components such as the hob grids,

flame-spreader crowns and

burner caps in a dishwasher.

EN

• Do not use plastic cookware or

containers for cooking.

5

Instructions

Installation

• This appliance must not be

installed in a boat or caravan.

• This appliance must not be

installed on a pedestal.

• Position the appliance into the

cabinet cut-out with the help of a

second person.

• To prevent any possible

overheating, the appliance should

not be installed behind a

decoration door or a panel.

• Before any operation on the

appliance (installation,

maintenance, positioning or

movement) always wear PPM.

• Before performing any operation

on the appliance, switch off the

power supply.

• Have qualified personnel carry

out installation and assistance

interventions according to the

standards in force.

• Have the gas connection

performed by authorised staff.

• Installation using a hose must be

carried out so that the length of the

hose does not exceed 2 metres

when fully extended for steel hoses

and 1.5 metres for rubber hoses.

• The hoses should not come into

contact with moving parts and

should not be crushed in any way.

• If required, use a pressure

regulator that complies with

current regulations.

• After carrying out any operation,

check that the tightening torque of

gas connections is between

10 Nm and 15 Nm.

• At the end of the installation,

check for any leaks with a soapy

solution, never with a flame.

• Have the electrical connection

performed by authorised

technicians.

• The appliance must be connected

to ground in compliance with

electrical system safety standards.

• Use cables withstanding a

temperature of at least 90°C.

• The tightening torque of the

screws of the terminal board leads

must be 1.5 - 2 Nm.

• If it is necessary to replace the

power cable, this must only be

performed by a qualified

technician.

• Before installation, make sure that

the local distribution conditions

(nature and pressure of the gas)

and the adjustment of the

appliance are compatible;

• The adjustment conditions for this

appliance are shown on the gas

setting label.

6

Instructions

• This appliance is not connected to

an exhaust system for combustion

products. It must be installed and

connected in compliance with the

current installation regulations.

Special attention should be paid

to the relevant requirements as for

ventilation.

For this appliance

• The glass ceramic surface is

highly resistant to impact.

However, prevent hard, solid

objects from falling on the

cooking surface as they may

cause it to break if they are sharp.

• The glass ceramic cooking

surface must not be used as a

surface for placing objects.

• If cracks or fissures form, or if the

glass ceramic cooking surface

breaks, turn off the appliance

immediately. Disconnect the

power supply and call Technical

Support.

• use of non-original spare parts.

1.3 Appliance purpose

• This appliance is intended for

cooking food in the home

environment. Every other use is

considered inappropriate.

• The appliance is not designed to

operate with external timers or with

remote-control systems.

1.4 Disposal

This appliance conforms to the

WEEE European directive

(2012/19/EU) and must be

disposed of separately from other

waste at the end of its service life.

The appliance does not contain

substances in quantities sufficient to

be considered hazardous to health

and the environment, in accordance

with current European directives.

To dispose of the appliance:

Power voltage

Danger of electrocution

EN

1.2 Manufacturer liability

The manufacturer declines all liability

for damage to persons or property

caused by:

• use of the appliance other than

the one envisaged,

• failure to comply with the

instructions in the user manual,

• tampering with any part of the

appliance,

• Disconnect the mains power

supply.

• Unplug the appliance.

• Cut the power supply cable and

remove it along with the plug.

7

Instructions

• Deliver the appliance to the

appropriate recycling centre for

electrical and electronic

equipment waste, or return it to the

retailer when purchasing an

equivalent product, on a one for

one basis.

Our appliances are packaged in

non-polluting and recyclable

materials.

• Deliver the packing materials to

the appropriate recycling centre.

Plastic packaging

Danger of suffocation

• Do not leave the packaging or

any part of it unattended.

• Do not let children play with the

packaging plastic bags.

1.5 Identification plate

1.6 How to read the user manual

This user manual uses the following reading

conventions:

Instructions

General information on this user

manual, on safety and final

disposal.

Description

Description of the appliance and its

accessories.

Use

Information on the use of the

appliance and its accessories,

cooking advice.

Cleaning and maintenance

Information for proper cleaning and

maintenance of the appliance.

Installation

Information for the qualified

technician: Installation, operation

and inspection.

The identification plate bears the

technical data, serial number and

brand name of the appliance. Do not

remove the identification plate for

any reason.This user manual

This user manual is an integral part of

the appliance and must therefore be

kept in its entirety and within the

user’s reach for the whole working

life of the appliance. Read this user

manual carefully before using the

appliance.

8

Safety instructions

Information

Advice

1. Sequence of instructions for use.

• Standalone instruction.

2 Description

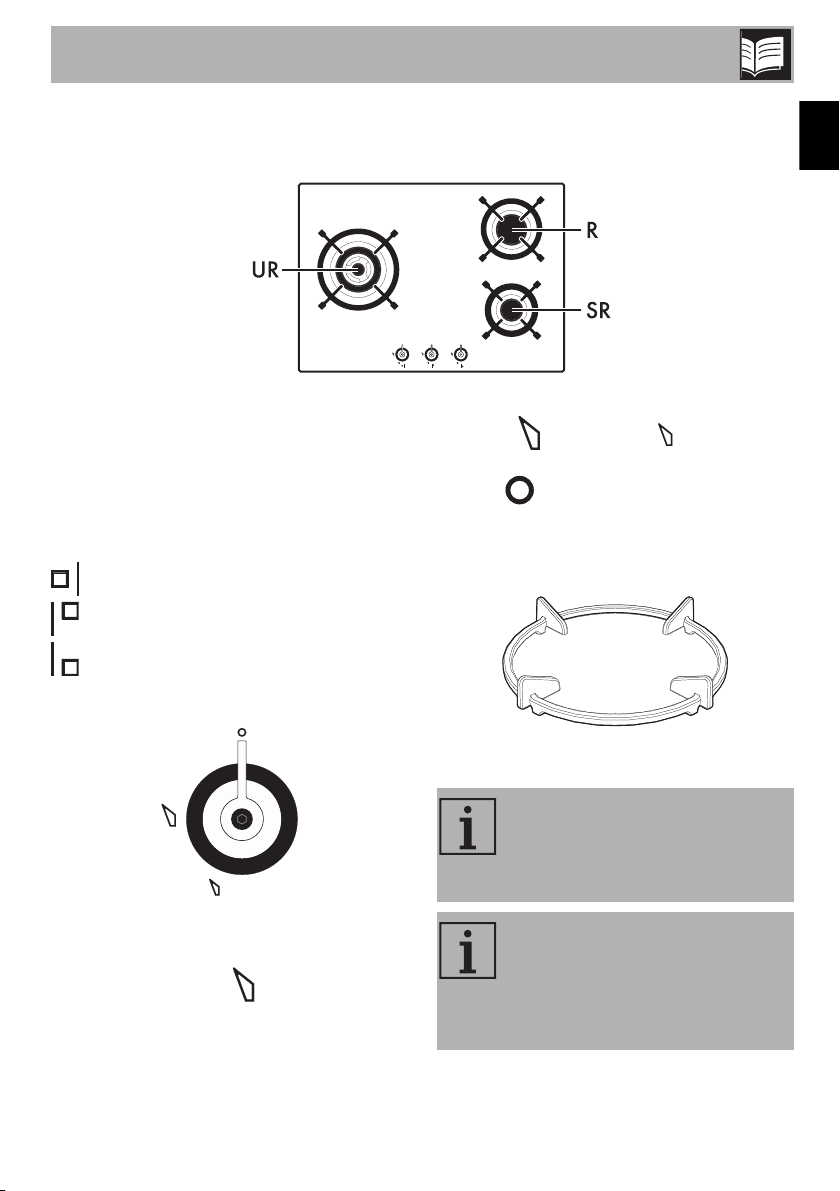

2.1 General Description

SR = Semi-rapid

R = Rapid

UR = Ultra rapid

2.2 Symbols

Description

EN

Turn the knobs to the zone between the

maximum and minimum setting to

adjust the flame. Return the knobs to the

position to turn off the burners.

Cooking zones

Centre left

Rear right

Front right

Burner knobs

Useful for lighting and adjusting the hob

burners. Press and turn the knobs anti-

clockwise to the value to light the relative

burners.

2.3 Available accessories

WOK ring

Useful when using a wok.

The accessories intended to come

into contact with food are made of

materials that comply with the

provisions of current legislation.

Supplied original and optional

accessories can be requested to

Authorised Assistance Centres.

Use only original accessories

supplied by the manufacturer.

9

Use

3 Use

3.1 Instructions

Improper use

Danger of burns

• Make sure that the flame-spreader

crowns are correctly positioned in their

seats with their respective burner caps.

• Oils and fats could catch fire if

overheated. Be very careful.

• Do not leave the appliance unattended

during cooking operations where fats or

oils could be released.

• Do not spray any spray products near

the appliance.

• Do not touch the appliance's heating

elements when it is running. Leave them

to cool before cleaning.

• Keep children under the age of eight

away from the appliance when it is in

use.

Improper use

Risk of damage to surfaces

• Do not use aluminium foil to cover the

burners or hob body.

• Cooking vessels or griddle plates

should be placed inside the perimeter of

the hob.

• All pans must have smooth, flat bottoms.

• If any liquid does boil over or spill,

remove the excess from the hob.

• It is not recommended to use

earthenware or steatite (soapstone)

pans to cook or heat food.

3.2 First use

1. Remove any protective film from the

outside or inside of the appliance,

including accessories.

2. Remove any labels (apart from the

technical data plate) from accessories.

3. Remove and wash all the appliance

accessories (see 4 Cleaning and

maintenance).

3.3 Using the hob

All the appliance’s control and monitoring

devices are located together on the front

panel. The burner controlled by each knob

is shown next to the knob. The appliance is

equipped with an electronic ignition device.

Simply press the knob and turn it anticlockwise to the maximum flame symbol,

until the burner ignites. If the burner does not

light in the first 15 seconds, turn the knob

to and wait 60 seconds before trying

again. After lighting, keep the knob pressed

in for a few seconds to allow the

thermocouple to heat up. The burner may

go out when the knob is released: In this

case, the thermocouple has not heated up

sufficiently. Wait a few moments and repeat

the operation. Keep the knob pressed in

longer.

In case of an accidental switching

off, a safety device will be tripped,

cutting off the gas supply, even if

the gas cock is open. Return the

knob to and wait at least 60

seconds before lighting it again.

10

Use

Correct positioning of the grids

Under the grids there are silicone rests with

a hole that must be centred onto the

matching fixing pins on the surface.

Make sure that the grids are simply centred

on their respective burners, without forcing

the burners to be raised or tilted. If they are,

repeat the positioning procedure.

If you find that a pan is particularly unstable,

make sure that the grids have not been

positioned incorrectly.

Ring reducers

The ring reducers must be rested on the hob

grid. Make sure they are properly

positioned.

Correct positioning of the flamespreader crowns and burner caps

Before lighting the hob burners, make sure

that the flame-spreader crowns are

correctly positioned in their housings with

their respective burner caps. Make sure that

the holes in the burners are aligned with the

igniters and thermocouples. Also ensure that

the flame-spreader crowns are correctly

engaged in the burner holes.

Practical tips for using the hob

For better burner efficiency and to minimise

gas consumption, use pans with lids and of

suitable size for the burner, so that flames

do not reach up the sides of the pan. Once

the contents come to the boil, turn down the

flame far enough to ensure that the liquid

does not boil over.

EN

Cookware diameters:

• SR: 10 - 24 cm.

• R: 12 - 24 cm.

• UR: 12 - 26 cm

11

To prevent burns or damage to the hob or

the counter top during cooking, all pans or

griddles (not provided) must be placed

inside the perimeter of the hob.

Using a griddle

Use

A few precautions are necessary if you wish

to use a griddle:

• The griddle can be pre-heated with the

burner on maximum power for no more

than 10 minutes.

• It is recommended you reduce the

power during cooking;

• Do not allow the burner flames to extend

beyond the edge of the griddle;

• Leave a gap of at least 150 mm

between the edge of the griddle and the

side wall;

• Do not place the griddle over more than

one burner at the same time.

12

Cleaning and maintenance

4 Cleaning and maintenance

4.1 Instructions

Improper use

Risk of damage to surfaces

• Do not use steam jets to clean the

appliance.

• Do not use cleaning products containing

chlorine, ammonia or bleach on parts

made of steel or that have metallic

surface finishes (e.g. anodizing, nickelor chromium-plating).

• If it comes into contact with aggressive

detergents, hard water or spills (cooking

water, sauces, coffee, etc.), clean

immediately after having let the hob cool

down.

• Do not use abrasive or corrosive

detergents (e.g. scouring powders, stain

removers and metallic sponges) on

glass parts.

• Do not use rough or abrasive materials

or sharp metal scrapers.

• Do not wash the removable

components such as the hob grids,

flame-spreader crowns and burner caps

in a dishwasher.

4.2 Cleaning the appliance

To keep the surfaces in good condition,

they should be cleaned regularly after use.

Let them cool first.

Ordinary daily cleaning

Always use only specific products that do

not contain abrasives or chlorine-based

acids.

Pour the product onto a damp cloth and

wipe the surface, rinse thoroughly and dry

with a soft cloth or a microfibre cloth.

Food stains or residues

Do not use steel sponges and sharp

scrapers as they will damage the surface.

Use normal, non-abrasive products and a

wooden or plastic tool, if necessary. Rinse

thoroughly and dry with a soft cloth or a

microfibre cloth.

Do not allow residues of sugary foods (such

as jam) to set inside the oven. If left to set for

too long, they might damage the enamel

lining of the oven.

Cooking hob grids

Remove the grids and clean them in

lukewarm water and non-abrasive

detergent. Make sure to remove any

encrustations. Dry them thoroughly and

return them to the hob.

The continuous contact between

the grids and the flame can cause

modifications to the enamel over

time in those parts exposed to

heat. This is a completely natural

phenomenon which has no effect

on the operation of this

component.

EN

13

Cleaning and maintenance

Igniters and thermocouples

For correct operation the igniters and

thermocouples must always be perfectly

clean. Check them frequently and clean

them with a damp cloth if necessary.

Remove any dry residues with a wooden

toothpick or a needle.

Flame-spreader crowns and burner caps

For easier cleaning, the flame-spreader

crowns and the burner caps can be

removed. Wash them in hot water and nonabrasive detergent. Carefully remove any

encrustation, then wait until they are

perfectly dry.

14

Installation

5 Installation

5.1 Safety instructions

Heat production during appliance

operation

Risk of fire

• Check that the carcase material is heat

resistant.

• Check that the carcase has the required

openings.

Veneers, adhesives or plastic coatings on

adjacent furniture should be temperatureresistant (>90°C), otherwise they might

warp over time.

The minimum clearance between a

ventilation hood and the cooking

surface must be at least the

distance indicated in the ventilation

hood installation instructions.

The minimum clearances must also be

respected for the edges of the hob on the

back as indicated in the mounting

illustrations.

5.2 Section cut from the countertop

The following operation requires

building and/or carpentry work

and must therefore be carried out

by a competent tradesman.

Installation can be carried out on

various materials such as masonry,

metal, solid wood or plastic

laminated wood as long as they

are heat resistant (>90°C).

Create an opening with the dimensions

shown in the figure in the countertop of the

piece of furniture.

L (mm) X (mm) Y (mm)

720 555 - 560 478 - 482

EN

A (mm) B (mm) C (mm) D (mm) E (mm)

min 200 min 460 min 750 20 - 60 min 50

15

Installation

5.3 Mounting

Over built-in oven unit

The clearance between the hob and the

kitchen furniture or other installed

appliances must be enough to ensure

sufficient ventilation and air discharge.

If installed above an oven, a space must be

left between the bottom of the hob and the

top of the appliance installed below.

opens on bottom

Over empty kitchen unit or drawers

If there are other pieces of furniture (lateral

walls, drawers, etc.), dishwashers or fridges

under the hob, a double-layer wooden

base must be installed at least 20 mm from

the bottom of the hob to avoid any

accidental contact. It must only be possible

to remove the double-layer base using

suitable equipment.

150 x 150 (mm)

required for gas connection

16

opens on bottom and on rear

If installed on top of an oven, the

latter must be equipped with a

cooling fan.

opens on bottom

opens on rear

Failure to install the double-layer

wooden base exposes the user to

possible accidental contact with

sharp or hot parts.

Installation

Fixing brackets

Screw the fixing brackets (A) into the holes

on the sides of the bottom casing to

properly fasten the hob to the structure.

Do not use silicone to secure the

hob. This would make it impossible

to remove the hob, if necessary,

without damaging it.

Hob seal

To prevent leakage of liquid between the

frame of the hob and the countertop, place

the adhesive seal provided along the entire

outer edge of the hob before assembly.

5.4 Gas connection

Gas leak

Danger of explosion

• After carrying out any operation, check

that the tightening torque of gas

connections is between 10 Nm and

15 Nm.

• If required, use a pressure regulator that

complies with current regulations.

• At the end of the installation, check for

any leaks with a soapy solution, never

with a flame.

• The hoses should not come into contact

with moving parts and should not be

crushed in any way.

• The adjustment conditions for this

appliance are shown on the gas setting

label.

General information

Connection to the gas mains can be made

using a rigid copper pipe or a continuous

wall steel hose in compliance with the

provisions established by the applicable

standard.

For supplying it with other types of gas, see

chapter ““Adaptation to different types of

gas””. The gas inlet connection is threaded

½” external gas (ISO 228-1).

EN

17

Installation

Connection with a steel hose

Make the connection to the gas mains

using a continuous wall steel hose whose

specifications comply with the applicable

standard. Carefully screw the connector 3

to the gas connector 1 of the appliance,

placing the seal 2 between them.

Connection with a steel hose with conical

fitting

Make the connection to the gas mains

using a continuous wall steel hose whose

specifications comply with the applicable

standard. Carefully screw the hose

connector 3 to the appliance’s gas

connector 1 (½” thread ISO 228-1),

placing the supplied seal 2 between them.

Apply insulating material to the thread of

connector 3, then tighten the steel hose 4 to

the connector 3.

Connection to LPG

Use a pressure regulator and make the

connection on the gas cylinder following

the guidelines set out in the standards in

force.

The supply pressure must comply with the

values indicated in the table in “Burner and

nozzle characteristics tables”.

Room ventilation

The appliance should be installed in rooms

that have a permanent air supply in

accordance with the standards in force. The

room where the appliance is installed must

have enough air flow for the regular

combustion of gas and the necessary air

change in the room itself. The air vents,

protected by grilles, must be the right size to

comply with current regulations and

positioned so that no part of them is

obstructed, not even partially.

The room must be kept adequately

ventilated in order to eliminate the heat and

humidity produced by cooking: In

particular, after prolonged use, you are

recommended to open a window or to

increase the speed of any fans.

18

Installation

Extraction of the combustion products

This appliance is not connected to

an exhaust system for combustion

products. It must be installed and

connected in compliance with the

current installation regulations.

Special attention should be paid to

the relevant requirements as for

ventilation.

The combustion products may be extracted

by means of hoods connected to a natural

draught chimney whose efficiency is certain

or via forced extraction. An efficient

extraction system requires precision

planning by a specialist qualified in this

area and must comply with the positions

and clearances indicated by the applicable

standards.

When the job is complete, the installer must

issue a certificate of conformity.

1 Extraction using a hood

2 Extraction without a hood

A Single natural draught chimney

B Single chimney with extractor fan

C Directly outdoors with wall- or window-

mounted extractor fan

D Directly outdoors through wall

Air

Combustion products

Extractor fan

5.5 Adaptation to different types of

gas

If other types of gas are to be used, the

nozzles must be replaced and the primary

air must be adjusted. In order to replace the

nozzles and adjust the burners, the hob top

must be removed.

EN

Removing the hob top

1. Remove the grids from the hob.

19

Installation

2. Remove the flame-spreader crowns and

relative burner caps.

3. Pull the knobs upwards to remove them.

4. Remove the screws fastening the top and

the plates corresponding to each burner

zone.

5. Remove the fastening plates and the hob

top.

20

Installation

Replacing nozzles

1. Unscrew screw A and push air regulator

B as far as it will go.

2. Use a spanner to remove the nozzles C

and install the new ones for the required

gas supply, following the indications

given in the relevant table (see “Burner

and nozzle characteristics tables”).

Adjusting the minimum setting for natural

or town gas

1. Light the burner and turn it to the minimum

position.

2. Extract the gas cock knob and turn the

adjustment screw next to the tap rod

(depending on the model) until the

correct minimum flame is achieved.

3. Refit the knob and verify that the burner

flame is stable.

4. Turn the knob rapidly from the maximum

to the minimum setting: The flame should

not go out.

5. Repeat the operation on all gas cocks.

EN

The nozzle tightening torque must

be no more than 3 Nm.

3. Adjust the air flow by moving the air

regulator B to obtain the distance D

given in the corresponding table (see

“Burner and nozzle characteristics

tables”).

4. After adjusting each burner, reassemble

the appliance correctly.

21

Installation

Adjusting the minimum setting for LPG

• Tighten the screw located at the side of

the tap rod clockwise all the way.

Following adjustment to a gas

other than the one originally set in

the factory, replace the gas setting

label on the appliance with the

one corresponding to the new gas.

The label is inserted inside the

nozzle pack (where present).

Lubricating the gas cocks

Over time the gas taps may become difficult

to turn and get blocked. Clean them

internally and replace the lubrication

grease.

Lubrication of the gas taps should

be performed by a specialised

technician.

22

Gas types and Countries

Gas types IT GB-IE FR-BE DE AT NL ES PT SE RU DK PL HU

1 Natural gas G20

G20 20 mbar

G20/25 20/25 mbar

2 Natural gas G20

G20 25 mbar

3 Natural gas G25

G25 25 mbar

4 Natural gas G25.1

G25.1 25 mbar

5 Natural gas G25

G25 20 mbar

6 Natural gas G2.350

G2.350 13 mbar

7 LPG G30/31

G30/31 28/37 mbar

G30/31 30/37 mbar

G30/31 30/30 mbar

8 LPG G30/31

G30/31 37 mbar

9 LPG G30/31

G30/31 50 mbar

10 Town gas G110

G110 8 mbar

Installation

EN

• • •• ••••••

•

•

•

•

•

•

•• • •

••

•••

•

••

•••

It is possible to identify the

available gas types based on the

country the appliance is to be

installed in. Refer to the heading

number to identify the correct

values in the “Burner and nozzle

specifications tables”.

23

Installation

Burner and nozzle characteristics tables

1 Natural Gas G20 - 20 mbar SR R UR

Rated heating capacity (kW)

Nozzle diameter (1/100 mm)

Reduced flow rate (W)

Primary air (mm)

2 Natural Gas G20 - 25 mbar SR R UR

Rated heating capacity (kW)

Nozzle diameter (1/100 mm)

Reduced flow rate (W)

Primary air (mm)

3 Natural Gas G25/G25.3 - 25 mbar SR R UR

Rated heating capacity (kW)

Nozzle diameter (1/100 mm)

Reduced flow rate (W)

Primary air (mm)

4 Natural Gas G25.1 - 25 mbar SR R UR

Rated heating capacity (kW)

Nozzle diameter (1/100 mm)

Reduced flow rate (W)

Primary air (mm)

5 Natural Gas G25 - 20 mbar SR R UR

Rated heating capacity (kW)

Nozzle diameter (1/100 mm)

Reduced flow rate (W)

Primary air (mm)

6 Natural Gas G2.350 - 13 mbar SR R UR

Rated heating capacity (kW)

Nozzle diameter (1/100 mm)

Reduced flow rate (W)

Primary air (mm)

1.7 3.1 6.0

92 126 175

500 900 1800

111

1.7 3.1 5.7

87 120 160

500 900 1800

1 1 0.5

1.7 3.1 6.0

95 130 185

500 900 1800

1 1 0.5

1.7 3.1 5.9

98 135 190

500 900 1800

1 1 0.5

1.7 3.1 6.0

100 140 200

500 900 1800

1 1 0.5

1.7 3.1 6.0

126 175 280

500 900 1800

113

24

Installation

7 LPG G30/31 - 30/37 mbar SR R UR

Rated heating capacity (kW)

Nozzle diameter (1/100 mm)

Reduced flow rate (W)

Primary air (mm)

Rated flow rate G30 (g/h)

Rated flow rate G31 (g/h)

8 LPG G30/31 - 37 mbar SR R UR

Rated heating capacity (kW)

Nozzle diameter (1/100 mm)

Reduced flow rate (W)

Primary air (mm)

Rated flow rate G30 (g/h)

Rated flow rate G31 (g/h)

9 LPG G30/31 - 50 mbar SR R UR

Rated heating capacity (kW)

Nozzle diameter (1/100 mm)

Reduced flow rate (W)

Primary air (mm)

Rated flow rate G30 (g/h)

Rated flow rate G31 (g/h)

10 Town Gas G110 SR R UR

Rated heating capacity (kW)

Nozzle diameter (1/100 mm)

Reduced flow rate (W)

Primary air (mm)

1.7 3.1 6.0

62 85 115

500 1100 1800

2212

124 225 436

121 221 429

1.7 3.1 6.0

60 80 110

550 1100 1900

226

124 225 436

121 221 429

1.7 3.1 6.0

54 76 102

500 1100 1900

1 1 2.5

124 225 436

121 221 429

1.7 3.0 3.8

165 250 310

500 900 1400

0.5 1 1

EN

The nozzles not provided are available at Authorised Service Centres.

25

Installation

5.6 Electrical connection

Power voltage

Danger of electrocution

• Have the electrical connection

performed by authorised technical

personnel.

• Use personal protective equipment.

• The appliance must be connected to

earth in compliance with electrical

system safety standards.

• Disconnect the mains power supply.

• Do not pull the cable to remove the

plug.

• Use cables withstanding a temperature

of at least 90°C.

• The tightening torque of the screws of the

terminal supply wires must be 1.5 - 2 Nm.

General information

Check the grid characteristics against the

data indicated on the plate.

The identification plate bearing the

technical data, serial number and brand

name is visibly positioned on the appliance.

Do not remove this plate for any reason.

Perform the ground connection using a wire

that is 20 mm longer than the other wires.

The appliance can work in the following

modes:

• 220-240 V 1N~

20 mm

Use a 3 x 0.75 mm² three-core cable.

The values indicated above refer

to the cross-section of the internal

conductor.

Fixed connection

Fit the power line with an omnipolar circuit

breaker in compliance with installation

regulations.

The circuit breaker should be located near

the appliance and in an easily reachable

position.

Connection with plug and socket

Make sure that the plug and socket are of

the same type.

Avoid using adapters and shunts as these

could cause overheating and a risk of

burns.

26

Loading...

Loading...