Contents

1. INSTRUCTIONS FOR USE .............................................................. 26

2. SAFETY PRECAUTIONS ................................................................. 28

3. ENVIRONMENTAL RESPONSIBILITY............................................. 30

4. DESCRIPTION OF CONTROLS ...................................................... 31

5. USING THE HOB.............................................................................. 32

6. CLEANING AND MAINTENANCE.................................................... 36

7. POSITIONING IN THE COUNTER TOP .......................................... 38

8. ELECTRICAL CONNECTION........................................................... 40

9. GAS CONNECTION ......................................................................... 41

10. ADAPTATION TO DIFFERENT TYPES OF GAS ........................... 43

THESE INSTRUCTIONS ARE VALID ONLY FOR THE DESTINATION COUNTRIES

WHOSE IDENTIFYING SYMBOLS ARE INCLUDED ON THE COVER OF THIS

MANUAL. THIS IS A CLASS 3 BUILT-IN HOB.

INSTRUCTIONS FOR THE USER: these contain user advice, the description

of the controls and the correct procedures for cleaning and maintenance of

the appliance.

INSTRUCTIONS FOR THE INSTALLER: these are intended for the qualified

technician who must install the appliance, set it functioning and carry out

an inspection test.

25

General instructions

1. INSTRUCTIONS FOR USE

THIS MANUAL IS AN INTEGRAL PART OF THE APPLIANCE. IT MUST BE KEPT IN ITS

ENTIRETY AND IN AN ACCESSIBLE PLACE FOR THE WHOLE WORKING LIFE OF

THE HOB. WE ADVISE YOU TO READ THIS MANUAL AND ALL THE INFORMATION IT

CONTAINS CAREFULLY BEFORE USING THE HOB. ALSO KEEP THE SERIES OF

NOZZLES PROVIDED. INSTALLATION MUST BE CARRIED OUT BY QUALIFIED

PERSONNEL IN ACCORDANCE WITH THE REGULATIONS IN FORCE. THIS

APPLIANCE IS INTENDED FOR HOUSEHOLD USE AND COMPLIES WITH THE EEC

DIRECTIVES CURRENTLY IN FORCE. THE APPLIANCE HAS BEEN BUILT TO CARRY

OUT THE FOLLOWING FUNCTION: COOKING AND HEATING FOODS; ALL OTHER

USES ARE TO BE CONSIDERED IMPROPER.

THE MANUFACTURER CANNOT BE HELD LIABLE FOR USE OTHER THAN AS

INDICATED.

IF THE APPLIANCE IS INSTALLED ON BOATS OR IN CARAVANS, DO NOT USE IT AS

A ROOM HEATER.

DO NOT USE THIS APPLIANCE FOR HEATING ROOMS.

THIS APPLIANCE IS MARKED ACCORDING TO EUROPEAN DIRECTIVE 2002/96/EC

ON WASTE ELECTRICAL AND ELECTRONIC EQUIPMENT (WEEE).

THIS DIRECTIVE DETERMINES THE STANDARDS FOR THE COLLECTION AND

RECYCLING OF WASTE ELECTRICAL AND ELECTRONIC EQUIPMENT APPLICABLE

THROUGHOUT THE EUROPEAN UNION.

BEFORE THE APPLIANCE IS PUT INTO OPERATION, ALL PROTECTIVE FILMS

MUST BE REMOVED.

26

SUITABLE HEAT-PROOF GLOVES SHOULD BE WORN FOR ALL OPERATIONS.

DO NOT USE STEEL SPONGES AND SHARP SCRAPERS AS THEY WILL

DAMAGE THE SURFACE.

USE NORMAL NON-ABRASIVE PRODUCTS, INCLUDING WOODEN OR

PLASTIC UTENSILS IF NECESSARY. RINSE THOROUGHLY AND DRY

USING A SOFT CLOTH OR A MICROFIBRE CLOTH.

DO NOT LEAVE THE APPLIANCE UNATTENDED DURING COOKING OPERATIONS

WHERE FATS OR OILS COULD BE RELEASED.

FATS AND OILS MAY CATCH FIRE.

General instructions

ALWAYS CHECK THAT THE CONTROL KNOBS ARE IN THE (OFF) POSITION

WHEN YOU FINISH USING THE HOB.

NEVER PLACE PANS WITH BOTTOMS WHICH ARE NOT PERFECTLY FLAT AND

SMOOTH ON THE COOKING HOB RACKS.

NEVER USE CONTAINERS WHICH PROJECT BEYOND THE OUTSIDE EDGE OF THE

HOB.

27

General instructions

2. SAFETY PRECAUTIONS

REFER TO THE INSTALLATION INSTRUCTIONS FOR THE SAFETY REGULATIONS

FOR ELECTRIC OR GAS APPLIANCES AND VENTILATION FUNCTIONS.

IN YOUR INTERESTS AND FOR YOUR SAFETY IT HAS BEEN ESTABLISHED BY LAW

THAT THE INSTALLATION AND SERVICING OF ALL ELECTRICAL APPLIANCES IS TO

BE CARRIED OUT BY QUALIFIED PERSONNEL IN ACCORDANCE WITH THE

REGULATIONS IN FORCE.

OUR APPROVED INSTALLERS GUARANTEE A SATISFACTORY JOB.

GAS OR ELECTRICAL APPLIANCES MUST ALWAYS BE DISCONNECTED BY

SUITABLY SKILLED PEOPLE.

BEFORE CONNECTING THE APPLIANCE TO THE POWER GRID, CHECK THE DATA

ON THE PLATE AGAINST THE DATA FOR THE GRID ITSELF.

THE IDENTIFICATION PLATE CONTAINING THE TECHNICAL DATA, SERIAL NUMBER

AND BRAND NAME IS IN A VISIBLE POSITION UNDER THE CASING.

DO NOT REMOVE THE PLATE ON THE CASING FOR ANY REASON.

BEFORE CONNECTING THE APPLIANCE, ENSURE THAT IT IS SET TO THE TYPE

OF GAS THAT IT WILL BE SUPPLIED WITH, CHECKING THE LABEL APPLIED UNDER

THE CASING.

BEFORE CARRYING OUT INSTALLATION/MAINTENANCE WORK, MAKE SURE THAT

THE APPLIANCE IS NOT CONNECTED TO THE POWER GRID.

THE PLUG TO BE CONNECTED TO THE POWER SUPPLY CABLE AND ITS SOCKET

MUST BE OF THE SAME TYPE AND CONFORM TO THE REGULATIONS IN FORCE.

THE SOCKET MUST BE ACCESSIBLE AFTER THE APPLIANCE HAS BEEN BUILT IN.

NEVER DISCONNECT THE PLUG BY PULLING ON THE CABLE.

IF THE POWER SUPPLY CABLE IS DAMAGED, CONTACT THE TECHNICAL

SUPPORT SERVICE IMMEDIATELY AND THEY WILL REPLACE IT.

28

IT IS OBLIGATORY FOR ALL ELECTRICAL EQUIPMENT TO BE EARTHED

ACCORDING TO THE METHODS LAID DOWN BY SAFETY REGULATIONS.

IMMEDIATELY AFTER INSTALLATION, CARRY OUT A BRIEF INSPECTION TEST,

FOLLOWING THE INSTRUCTIONS BELOW. SHOULD THE APPLIANCE NOT

FUNCTION, DISCONNECT IT FROM THE POWER SUPPLY AND CALL THE NEAREST

TECHNICAL SUPPORT CENTRE.

NEVER ATTEMPT TO REPAIR THE APPLIANCE.

DURING USE THE APPLIANCE BECOMES VERY HOT. TAKE CARE NOT TO TOUCH

THE HEATING ELEMENTS.

THE USE OF THIS APPLIANCE IS NOT PERMITTED TO PEOPLE (INCLUDING

CHILDREN) OF REDUCED PHYSICAL AND MENTAL ABILITY, OR LACKING IN

EXPERIENCE IN THE USE OF ELECTRICAL APPLIANCES, UNLESS THEY ARE

SUPERVISED OR INSTRUCTED BY ADULTS OR PEOPLE RESPONSIBLE FOR THEIR

SAFETY.

General instructions

DO NOT LET CHILDREN GO NEAR THE APPLIANCE WHEN IT IS IN OPERATION OR

PL AY W ITH I T AT ANY T I ME.

DO NOT INSERT POINTED METAL OBJECTS (CUTLERY OR UTENSILS) INTO THE

SLITS IN THE APPLIANCE.

DO NOT USE STEAM JETS FOR CLEANING THE APPLIANCE.

THE STEAM COULD REACH THE ELECTRONICS, DAMAGING THEM AND CAUSING

SHORT-CIRCUITS.

DO NOT MODIFY THIS APPLIANCE.

DO NOT SPRAY ANY SPRAY PRODUCTS NEAR THE ELECTRICAL APPLIANCE

WHILE IT IS IN OPERATION.

DO NOT USE SPRAY PRODUCTS WHILE THE PRODUCT IS STILL HOT.

The manufacturer declines all responsibility for damage to persons or things

caused by non-observance of the above prescriptions or by interference with any

part of the appliance or by the use of non-original spare parts.

29

Instructions for disposal

3. ENVIRONMENTAL RESPONSIBILITY

3.1 Our environmental responsibility

Pursuant to Directives 2002/95/EC, 2002/96/EC and 2003/108/EC relating to

the reduction of the use of hazardous substances in electrical and electronic

appliances, as well as to the disposal of refuse, the crossed out bin symbol on

the appliance indicates that the product, at the end of its useful life, must be

collected separately from other refuse. Therefore, the user must consign the

product that has reached the end of its working life to the appropriate selective

collection centres for electrical and electronic refuse, or deliver it back to the

retailer when purchasing an equivalent product, on a one for one basis.

Adequate differentiated collection for the subsequent forwarding of the

decommissioned product to recycling, processing and ecologically compatible

disposal contributes to avoiding possible negative effects on the environment

and on health, and promotes recycling of the appliance's constituent materials.

The illicit disposal of the product by the user results in the application of

administrative sanctions.

The product does not contain substances in quantities sufficient to be

considered hazardous to health and the environment, in accordance with

current European directives.

30

3.2 Your environmental responsibility

Our product's packaging is made of non-polluting materials, therefore

compatible with the environment and recyclable. Please help by disposing of the

packaging correctly. You can obtain the addresses of collection, recycling and

disposal centres from your retailer or from the competent local organisations.

Do not discard the packaging or any part of it, or leave it unattended. It can

constitute a suffocation hazard for children, especially the plastic bags.

Your old appliance also needs to be disposed of correctly.

Important: hand over your appliance to the local agency authorised for the

collection of household appliances no longer in use. Correct disposal enables

intelligent recovery of valuable materials.

Before disposing of your appliance it is important to remove doors and leave

shelves in the same position as for use, to ensure that children cannot

accidentally become trapped inside during play. It is also necessary to cut the

connecting cable to the power supply, removing it along with the plug.

Instructions for the user

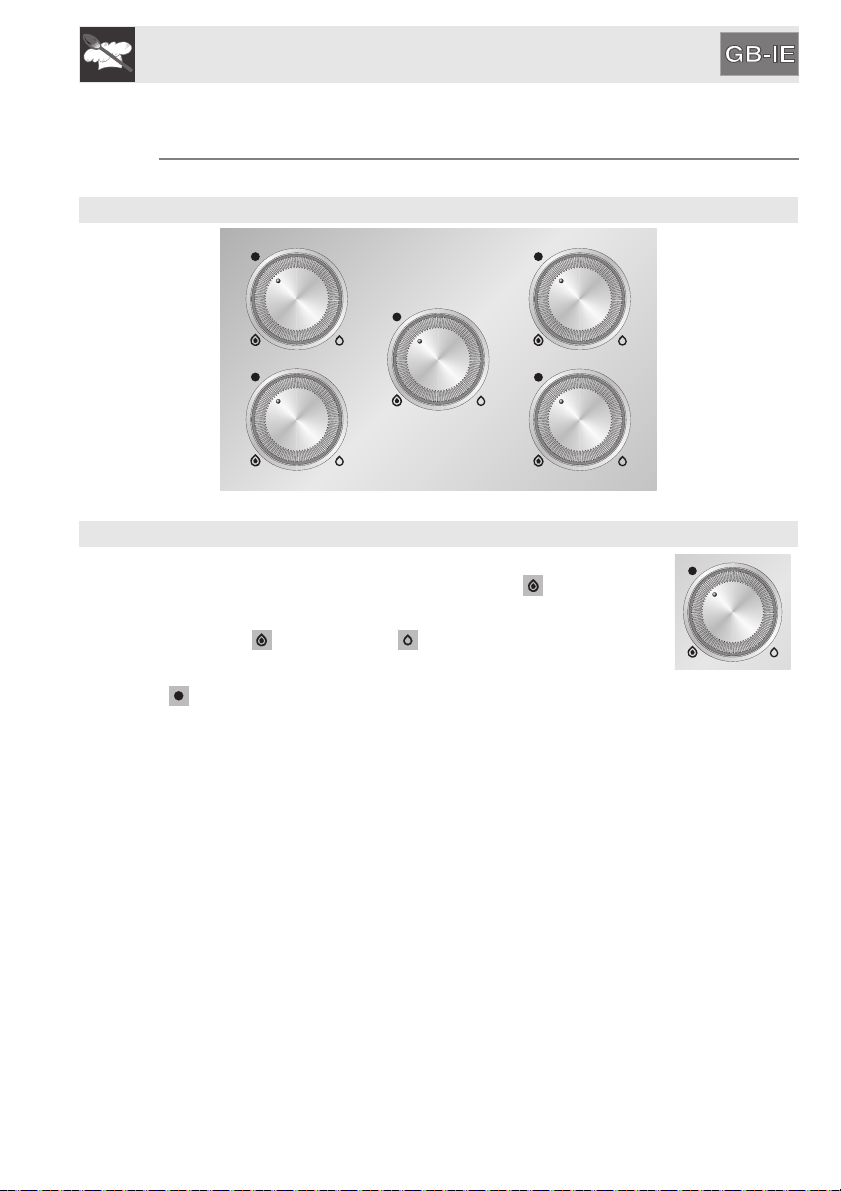

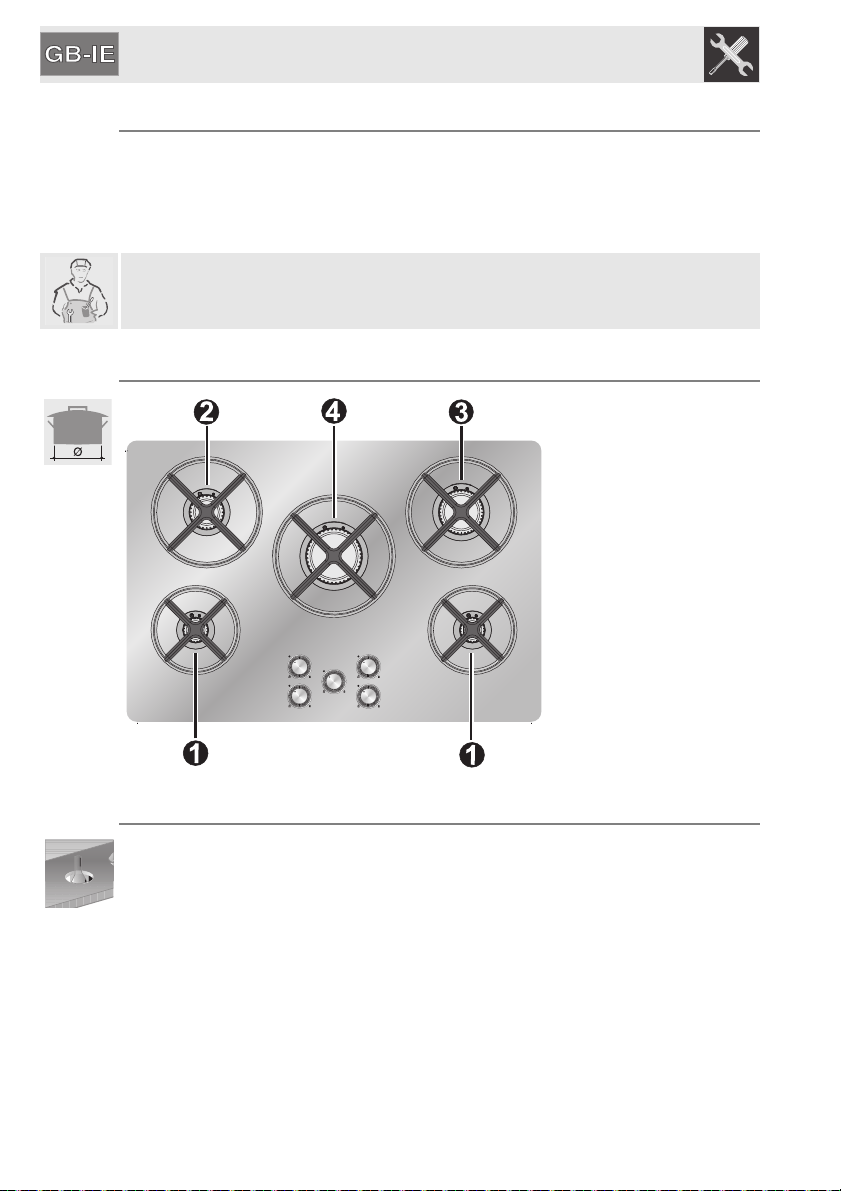

4. DESCRIPTION OF CONTROLS

4.1 Control zone

All the hob controls are grouped together at the centre front.

CONTROL ZONE

KNOB DESCRIPTION

To light the flame, press the knob and, at the same time, turn it

anticlockwise to the maximum flame symbol .

To adjust the flame, turn the knob to the zone between the

maximum and minimum settings.

To turn off the burner, turn the knob to the zero position to the

symbol.

31

Instructions for the user

5. USING THE HOB

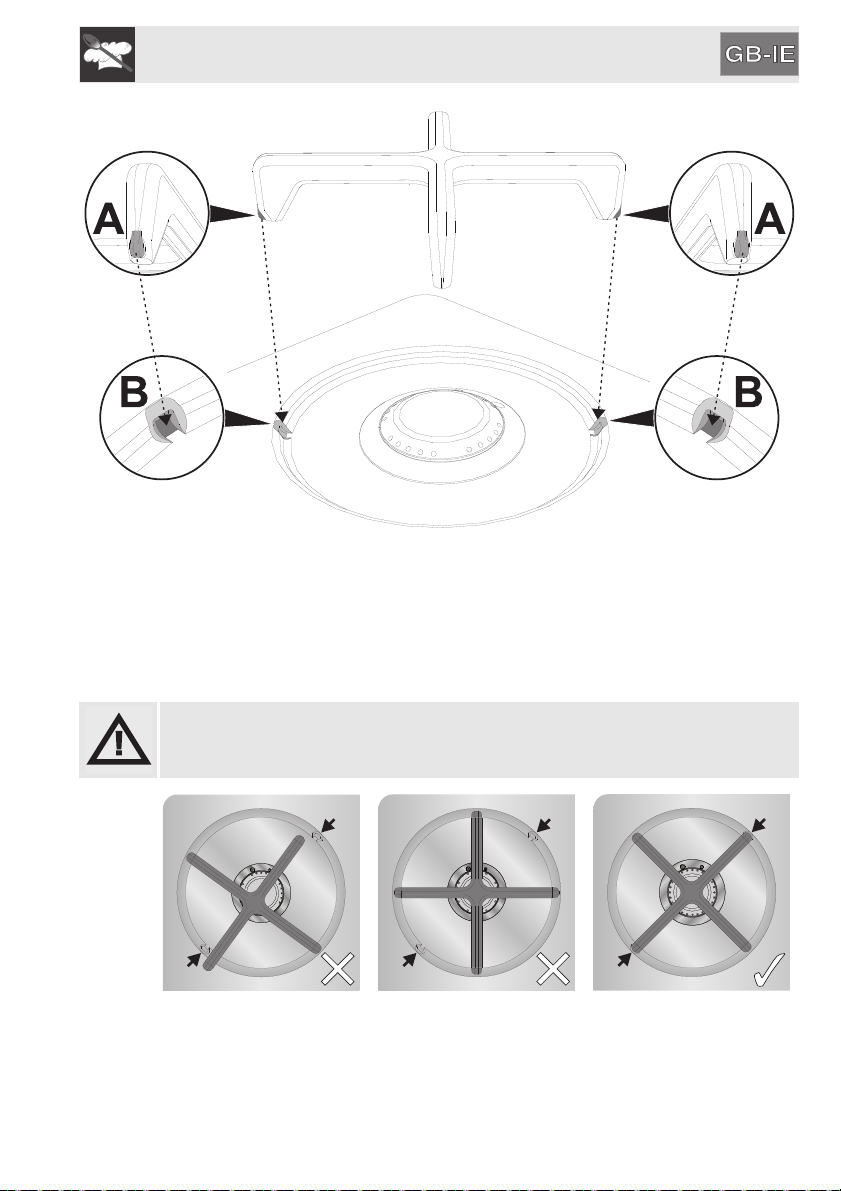

Make sure that the burners, flame-spreader crowns and

racks are fitted correctly.

The notches A of the flame-spreader crowns must be

inserted into the housings B of the burner. The igniter

and thermocouple on the hob should fit into the 2 holes

on the burner.

5.1 Positioning the racks

The racks are provided unassembled on the hob. To position each rack correctly

on its burner, follow the instructions below:

32

Each rack must be positioned on the corresponding burner in order to guarantee

proper operation. Be very careful to match the different central diameters of the

racks to the flame-spreader crowns.

Instructions for the user

All the racks have two reference notches (A).

To position the racks correctly, align the reference notches (A) with the cavities

(B) on the hob.

After positioning, check that the rack feet are all resting on the same level.

Make sure that the racks are simply centred on their respective burners,

without forcing the burners to be raised or tilted. If they are, repeat the

positioning procedure.

INCORRECT INCORRECT CORRECT

33

Instructions for the user

5.2 Lighting the burners using a safety device

The appliance is equipped with electronic ignition. Simply press the knob and

simultaneously turn it anticlockwise to the minimum flame symbol , until it

lights. Hold down the knob for about 2 seconds to keep the flame lit and to

activate the safety device. The burner may go out when the knob is released. If

this happens, repeat the procedure, holding the knob down for longer.

If the burners should go out accidentally, after about 20 seconds a safety device

will be tripped, cutting off the gas supply, even if the gas tap is open.

5.3 Practical tips for using the burners

For better burner performance and minimum gas

consumption, pans with flat, even bases and with lids should

be used, and their size should be in proportion to the burner

(see “5.4 Pan diameters”).

During cooking, in order to avoid burns or damage to the hob

top, all pans or griddles must be positioned inside the outer

edge of the hob and at a minimum distance of 5-7 cm must be

maintained from the knobs.

If the burner flame accidentally goes out, turn off the control

knob and wait at least 1 minute before trying to re-light the

burner.

34

Instructions for the user

5.4 Pan diameters

BURNERS

1 Auxiliary

2. Semi-rapid

3 Medium Rapid

4 Large Rapid

min. and max. Ø (in cm)

7-18

10-24

18-24

20-26

35

Instructions for the user

6. CLEANING AND MAINTENANCE

Before performing any operations requiring access to powered parts, disconnect

the appliance from the power supply.

6.1 Cleaning the hob

To keep the hob in good condition it should be cleaned regularly after use.

Let it cool first.

6.1.1 Ordinary daily cleaning

To clean and preserve the stainless steel surfaces, always use only specific

products that do not contain abrasives or chlorine-based acids.

How to use: pour the product onto a damp cloth and wipe the surface, rinse

thoroughly and dry with a soft cloth or chamois leather.

6.1.2 Food stains or residues

Do not use metallic sponges or sharp scrapers: they will damage the

surface.

Use ordinary non-abrasive products for steel, together with antiscratch sponges and wooden or plastic utensils if necessary.

Rinse thoroughly and dry with a soft cloth or chamois leather.

36

Instructions for the user

6.2 Cleaning the components

6.2.1 Knobs

The knobs should be cleaned with a soft cloth dampened with lukewarm water,

then dried carefully. For easier cleaning they can be removed by pulling them

upwards.

Do not use aggressive products containing alcohol or products for cleaning steel

and glass when cleaning the knobs, as these products could cause permanent

damage.

6.2.2 Racks

Remove the racks and clean them with lukewarm water and nonabrasive detergent, making sure to remove any encrustations.

Replace them on the cooking hob.

These components must not be washed in the dishwasher.

6.2.3 Flame-spreader crowns

The flame-spreader crowns are removable. Wash them with

lukewarm water and non-abrasive detergent, making sure to

remove any encrustations.

To remove burned on food residue, use Puliforno with a scourer

sponge.

For less stubborn residue and for polishing, use stainless steel

cream cleaner Crema Inox with a microfiber cloth.

After cleaning ensure they are perfectly dry and reposition them

correctly.

6.2.4 Igniters and thermocouples

For correct operation the igniters and thermocouples must always

be perfectly clean. Check them frequently and clean them with a

damp cloth if necessary. Remove any dry residues with a wooden

toothpick or a needle.

37

Instructions for the installer

7. POSITIONING IN THE COUNTER TOP

The following operation requires building and/or carpentry work so must be

carried out by a competent tradesman.

Installation can be carried out on various materials such as masonry, metal,

solid wood or plastic laminated wood as long as they are heat resistant (T 90°C).

7.1 Fixing to the supporting structure

Create an opening with the dimensions shown in the figure in the top surface of

the counter, keeping a minimum distance of 50 mm from the rear edge. This

appliance can be mounted against walls higher than the work surface on

condition that a distance of "X" be kept between the appliance and the wall as

shown in the figure so as to avoid damage from overheating. Make sure that

there is a minimum distance of 750 mm between the hob and any shelf that may

be installed directly above it.

38

Do not use aggressive products containing alcohol or products for cleaning steel

and glass when cleaning the knobs, as these products could cause permanent

damage.

If installing over an empty kitchen unit with doors, a separation panel must be

placed under the hob. Keep a minimum distance of 10 mm between the bottom

of the appliance and the surface of the panel, which must be easily extractable

to allow sufficient access for any technical assistance.

Instructions for the installer

Carefully position the supplied insulating seal on the outer perimeter of the hole

made in the counter top as shown in the figures below, trying to make it stick on

the entire surface by applying light pressure on it with your hands. Depending

on the hob model being installed refer to the dimensions in the figure, bearing in

mind that for both models the long front side must brush against the hole. Fix

the hob to the unit using the appropriate brackets A supplied. Carefully trim the

surplus away from edge B beyond the seal. The dimensions given in the

following drawing refer from the hole to the inside of the seal.

The figure to the side shows the exact

holes to be used to correctly attach

the hob to the work surface with

brackets.

IMPORTANT: If installing the hob over an oven, ensure that the latter is

equipped with a cooling fan.

39

Instructions for the installer

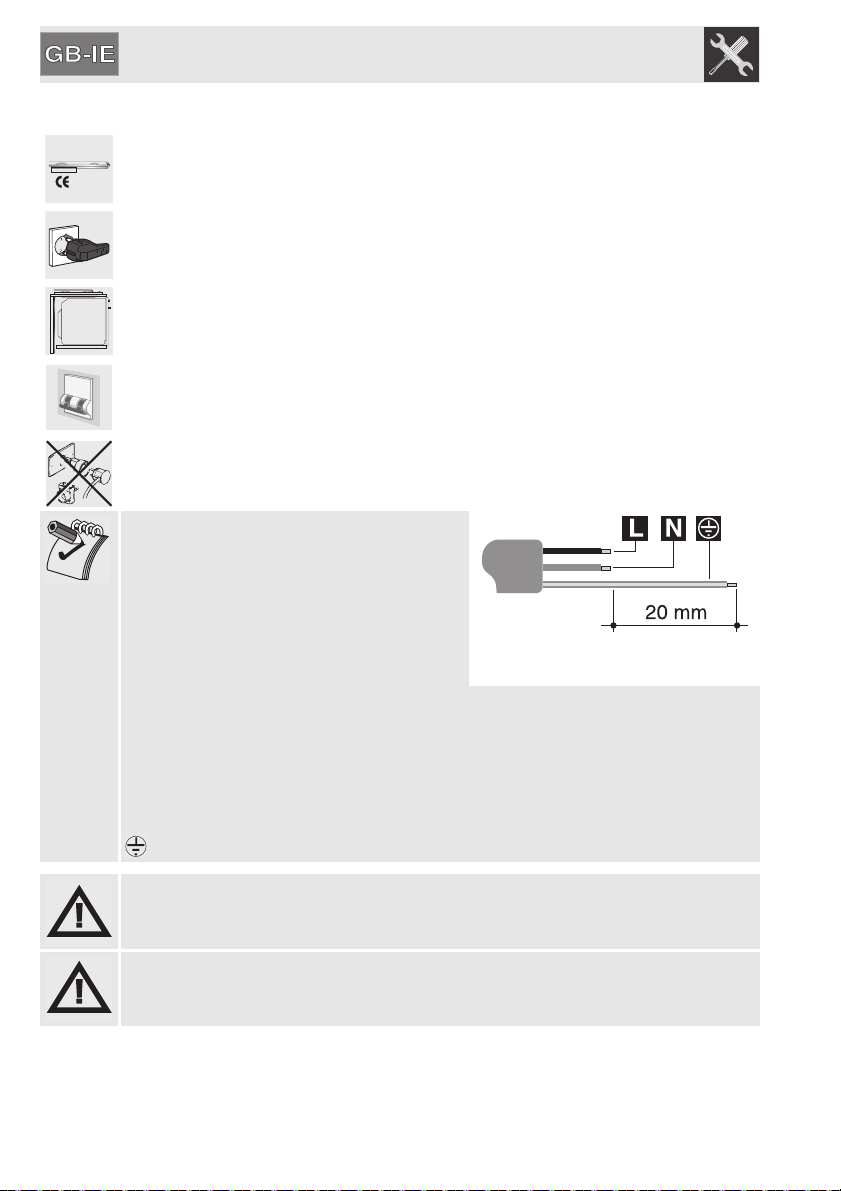

8. ELECTRICAL CONNECTION

Make sure that the voltage and capacity of the power supply line conform to the

data shown on the plate located under the casing. Do not remove this plate

for any reason.

The plug at the end of the supply cable and the wall socket must be of the same

type and must conform to the applicable legislation on electrical installations.

Make sure that the supply line is suitably earthed.

Pass the power supply cable through the back of the unit, taking care that it

does not touch the bottom casing of the hob or the oven (if any) installed

underneath it.

Fit the power supply line with an omnipolar circuit breaker with a contact

opening gap equal to or greater than 3 mm in an easily accessible position close

to the appliance.

Avoid use of adapters and shunts.

If the power cable is replaced, the crosssection of wires in the new cable must be

no less than 0.75 mm

remembering that the end for connection to

the appliance must have an earth wire

(yellow/green) which is at least 20 mm

longer.

Only use a H05V2V2-F or similar cable resistant to the maximum temperature of

90°C. Its replacement must be carried out be a specialised technician who must

carry out the connection to the power grid following the diagram below.

2

(3 x 0.75 cable),

40

L = brown

N = blue

= yellow/green

The power supply cable must be replaced by an authorised service centre to

prevent any risks.

The manufacturer declines all responsibility for damage to persons or things

caused by non-observance of the above prescriptions or by interference with

any part of the appliance.

Instructions for the installer

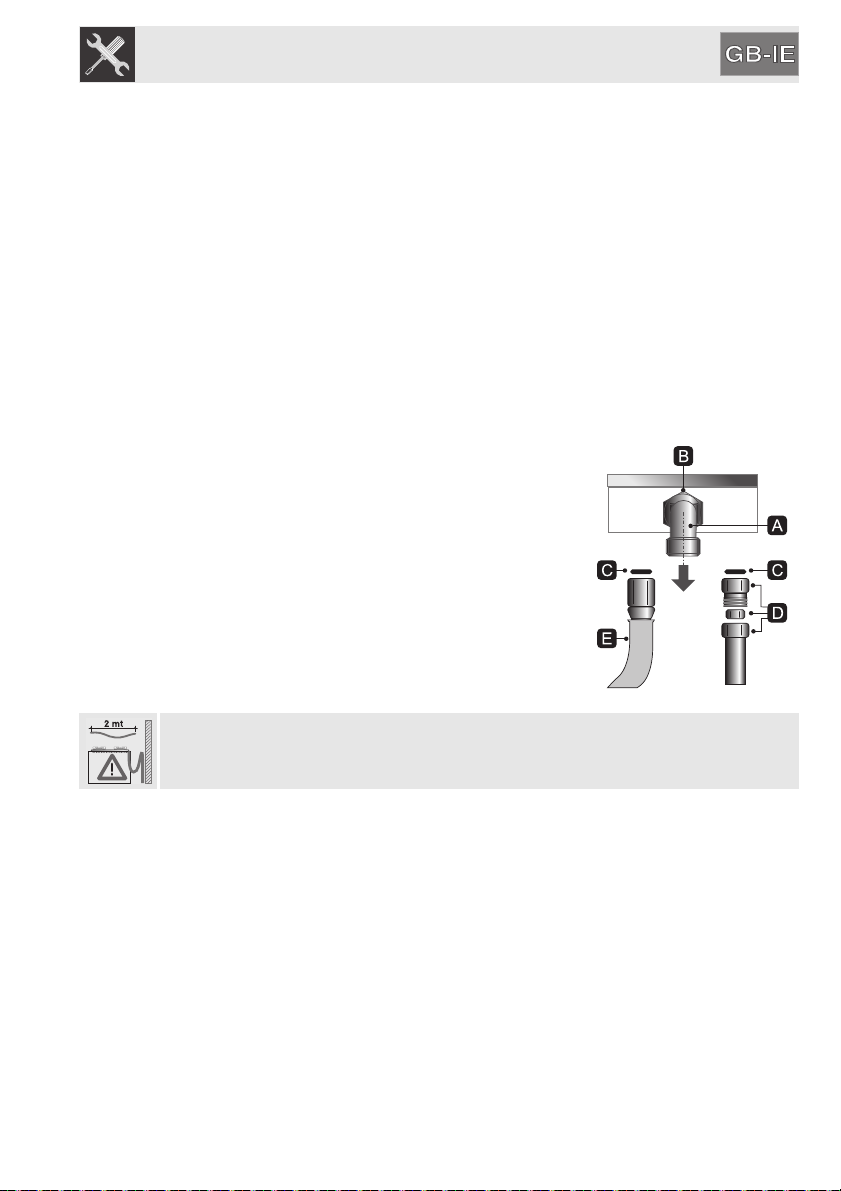

9. GAS CONNECTION

If the appliance is installed on an oven, you must avoid running the gas tube

round the back of the oven in order to avoid overheating.

Connection to the gas supply network can be made using a rigid copper hose or

a flexible steel hose with a continuous wall and in compliance with the

guidelines established by the applicable standard. To facilitate the connection,

connector A on the back of the appliance can be orientated laterally; loosen

hexagonal nut B, twist connector A into the desired position then retighten

hexagonal nut B (it is sealed with a rubber gasket). Once the operation is

complete, check the hose fittings for leaks using a soapy solution; never use a

flame. The hob is preset for natural gas G20 (2H) at a pressure of 20 mbar. To

set it up for supply using other types of gas, see Chapter “10. ADAPTATION TO

DIFFERENT TYPES OF GAS”. The gas inlet connection is threaded ½” for

external gas (ISO 228-1).

Connection with a rigid copper hose: The

connection to the gas supply network must be made

in such a way that it does not cause stresses of any

type on the appliance. The connection can be made

using the adapter unit D with double cone, always

inserting gasket C (provided) in between.

Connection with a flexible steel hose: use only

continuous wall stainless steel hoses that comply

with the applicable standards, making sure to always

insert gasket C (provided) between connector A and

flexible hose B.

Installation with flexible hose must be carried out so that the length of the piping

does not exceed 2 metres when fully extended; make sure that the hoses do not

come into contact with moving parts and that they are not crushed in any way.

41

Instructions for the installer

9.1 Connection to liquid gas

Use a pressure regulator and make the connection on the gas cylinder following

the guidelines set out in the regulations in force.

Make sure that the supply pressure complies with the values indicated in the

paragraph “10.3 Burner and nozzle characteristics tables”.

9.2 Room ventilation

The room containing the appliance should have an air supply in accordance with

the standards in force. The room where the appliance is installed must have

enough air flow needed for the regular combustion of gas and the necessary air

change in the room itself. The air vents, protected by grills, must be the right

size to comply with current regulations and positioned so that no part of them is

obstructed, not even partially.

The room must be kept adequately ventilated in order to eliminate the heat and

humidity produced by cooking: in particular, after prolonged use, you are

recommended to open a window or to increase the speed of any fans.

9.3 Extraction of the combustion products

The combustion products may be extracted by means of hoods connected to a

natural draught chimney whose efficiency is certain or via forced extraction. An

efficient extraction system requires precision planning by a specialist qualified in

this area and must comply with the positions and distances indicated by the

regulations. When the job is complete, the installer must issue a certificate of

conformity.

42

Instructions for the installer

10. ADAPTATION TO DIFFERENT TYPES OF GAS

Before carrying out the following operations, disconnect the appliance from the

power supply.

The hob is preset for natural gas G20 (2H) at a pressure of 20 mbar. If other

types of gas are to be used, the nozzles must be replaced and the primary air

must be adjusted.

In order to replace the nozzles and adjust the burners, the hob top must be

removed as described below.

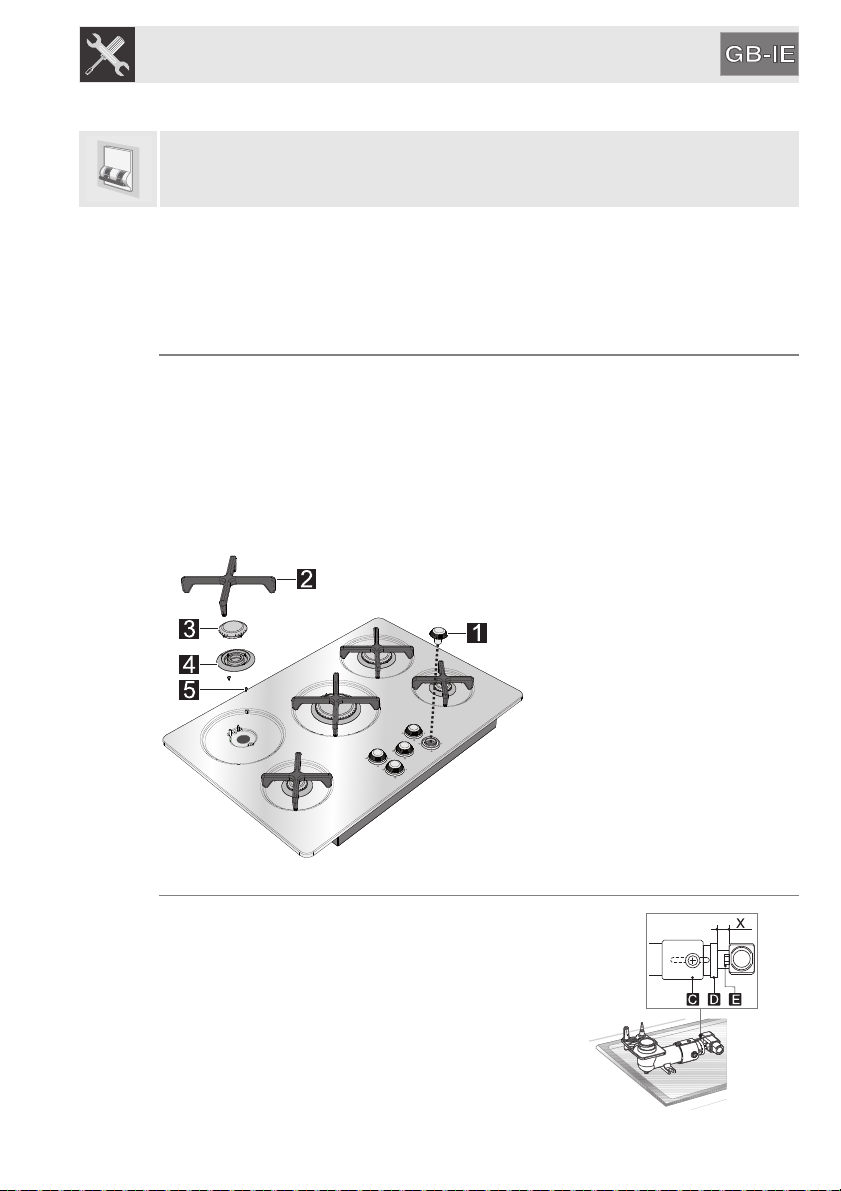

10.1 Removing the hob top

Remove all the burner components, following the numerical sequence in the

figures below:

• Take out all the knobs (1) by pulling them upwards;

• Remove the racks (2) by lifting them upwards;

• Lift all the burner components off the hob (3 - 4);

• Unscrew the screws (5) that secure the burner supports;

• Having removed all the components described above, lift the hob top

upwards to access the burners and gas taps.

10.2 Replacement of the cooking hob nozzles

Unscrew screw C and push air regulator D as far as

it will go. Using a 7-mm wrench, remove nozzle E

and replace it with the appropriate nozzle, following

the instructions in the tables for the type of gas to be

used. The nozzle tightening torque must be no more

than 3 Nm. Adjust the air by sliding regulator D until

distance “X” is reached, as indicated in the table in

paragraph “10.4 Primary air adjustment”.

Lock regulator D by tightening screw C.

43

Instructions for the installer

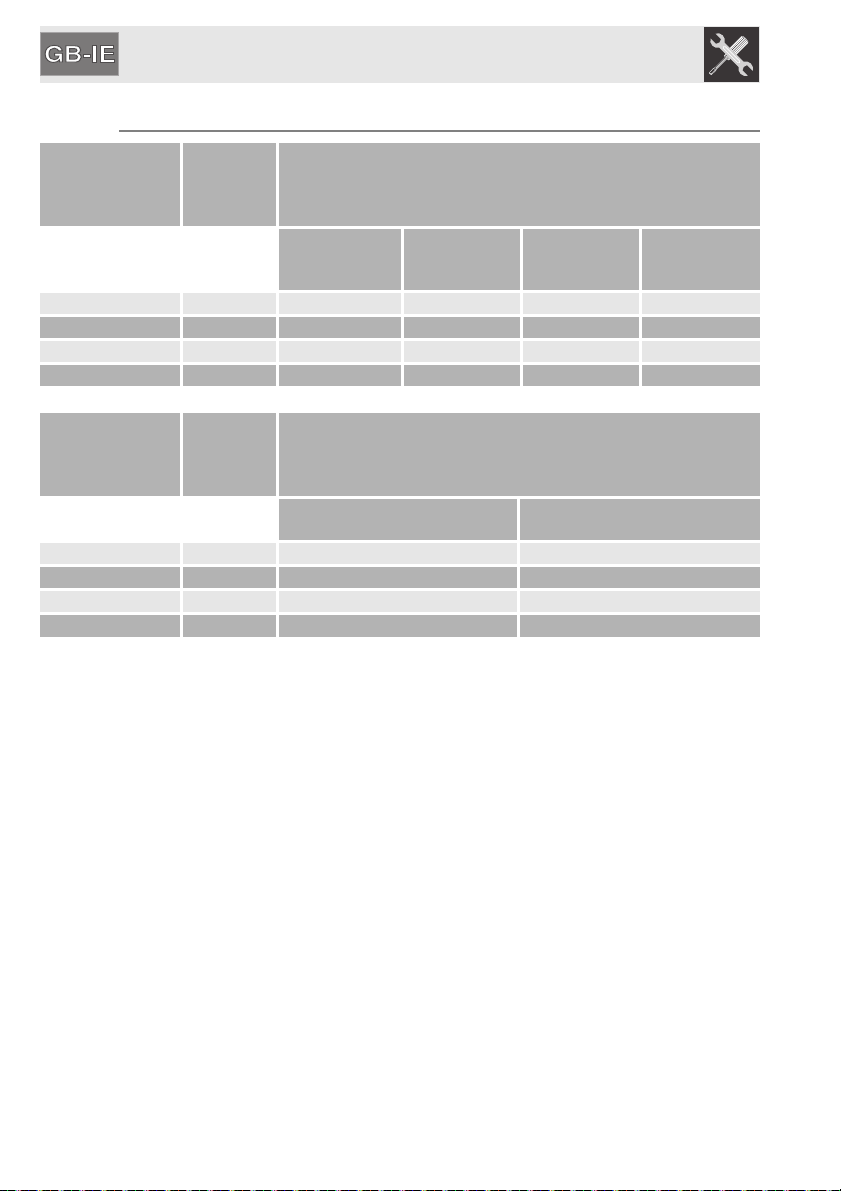

10.3 Burner and nozzle characteristics tables

Rated

Burner

Auxiliary 1.05 48 400 76 75

Semi-rapid 1.65 62 500 120 118

Medium Rapid 2.5 76 750 182 179

Large Rapid 3.4 87 1050 247 243

Burner

Auxiliary 1.05 76 400

Semi-rapid 1.7 95 500

Medium Rapid 2.6 117 750

Large Rapid 3.5 135 1050

heating

capacity

(kW)

Rated

heating

capacity

(kW)

Nozzle

diameter

1/100 mm

Nozzle diameter

1/100 mm

LPG – G30/G31 28/37 mbar

Reduced

capacity

(W)

Natural gas – G20 20 mbar

Capacity

g/h G30

Reduced capacity

Capacity

g/h G31

(W)

44

Instructions for the installer

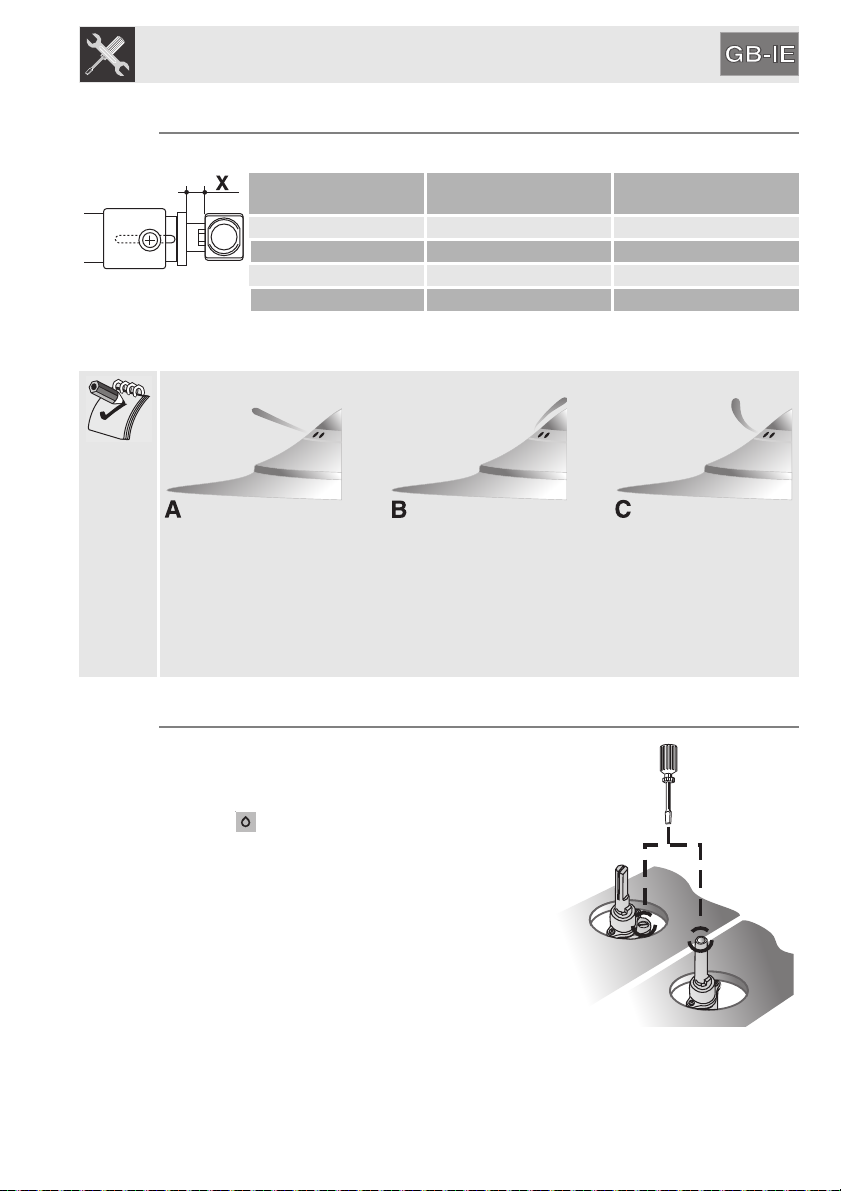

10.4 Primary air adjustment

Refers to distance “X” in mm.

BURNER

Auxiliary 7 1

Semi-rapid 2 0.5

Medium Rapid 2 1

Large Rapid 10 1.5

G30/G31

28/37 mbar

To identify the burners on your hob, please refer to the illustrations in paragraph

“10.7 Arrangement of the burners on the hob”.

If having adjusted the air the flame appears as illustrated in the figure:

the following modifications must be made:

A: the flame is "noisy", unstable or "detaches" from the burner: the primary air is

too high.

B: The flame is opaque, dull or has yellow tips and "wraps around" the burner:

the primary air is too low.

C: The flame is blue, clear and stable, does not "detach" or "wrap around" the

burner: the air is adjusted correctly.

G20

20 mbar

10.5 Adjusting the minimum for natural gas

Reposition the components on the burner and

slide the knobs onto the tap rods.

Light the burner and set it to the minimum

position .

Extract the knob again and turn the adjustment

screw inside or next to the tap rod (depending

on the model) until the correct minimum flame

is achieved.

Refit the knob and verify that the burner flame

is stable (when turning the knob rapidly from

the maximum to the minimum position the

flame must not go out).

45

Instructions for the installer

10.6 Adjusting the minimum setting for LPG

To adjust the minimum setting with LPG, you must tighten the screw inside or

next to the tap rod (depending on the model) fully in a clockwise direction.

The diameters of the by-passes for the individual burners are given in the table

“10.3 Burner and nozzle characteristics tables”.

After adjustment with a gas other than the preset one, replace the label on the

casing of the appliance with the label corresponding to the new gas. The label is

inserted inside the pack together with the nozzles.

10.7 Arrangement of the burners on the hob

Type of burner

1 Auxiliary

2. Semi-rapid

3 Medium Rapid

4 Large Rapid

46

10.8 Lubrication of gas taps

Over time the gas taps may become difficult to turn and get blocked. Clean them

internally and replace the lubrication grease.

This procedure must be carried out by a specialised technician.

Loading...

Loading...