Page 1

Table of contents

1. PRECAUTIONS FOR USE ...................................................................................................... 4

2. INSTALLING THE APPLIANCE .............................................................................................. 6

3. ADAPTATION TO DIFFERENT TYPES OF GAS ................................................................ 10

4. FINAL OPERATIONS ...........................................................................................................13

5. GETTING TO KNOW YOUR COOKER ................................................................................. 14

6. DESCRIPTION OF FRONT PANEL CONTROLS ................................................................ 15

7. USING THE HOB .................................................................................................................. 17

8. USING THE OVEN ................................................................................................................ 18

9. AVAILABLE ACCESSORIES ............................................................................................... 20

10. CLEANING AND MAINTENANCE ...................................................................................... 21

11. EXTRAORDINARY MAINTENANCE .................................................................................. 23

12. PROBLEMS AND CAUSES ................................................................................................ 24

Thank you for choosing our product.

We advise you to read this manual carefully. It contains all necessary instructions for maintaining

unaltered the appearance and functional qualities of the cooker.

INSTRUCTIONS FOR THE INSTALLER: these are intended for the authorized person who is to check

the gas supply system and install, commission and test the appliance.

INSTRUCTIONS FOR THE USER: these provide recommendations for use, a description of the controls

and the correct procedures for cleaning and maintaining the appliance.

3

Page 2

Precautions for use

1. PRECAUTIONS FOR USE

THIS MANUAL IS AN INTEGRAL PART OF THE APPLIANCE. TAKE GOOD CARE OF IT AND KEEP IT

TO HAND THROUGHOUT THE COOKER'S LIFE CYCLE. WE URGE YOU TO READ THIS MANUAL

AND ALL THE INFORMATION IT CONTAINS CAREFULLY BEFORE USING THE APPLIANCE. ALSO

KEEP ALL THE NOZZLES PROVIDED IN A SAFE PLACE. INSTALLATION MUST BE CARRIED OUT

BY QUALIFIED PERSONNEL IN ACCORDANCE WITH THE REGULATIONS IN FORCE. THIS

APPLIANCE IS INTENDED FOR HOUSEHOLD USE AND COMPLIES WITH THE RELEVANT

REGULATIONS. THE APPLIANCE HAS BEEN BUILT TO CARRY OUT THE FOLLOWING

FUNCTIONS: COOKING AND HEATING FOODS; ALL OTHER USES ARE CONSIDERED

IMPROPER.

THE MANUFACTURER DECLINES ALL RESPONSIBILITY FOR IMPROPER USE.

TO BE INSTALLED ONLY BY AN AUTHORIZED PERSON.

NEVER LEAVE PACKAGING RESIDUES UNATTENDED IN THE HOME. SEPARATE WASTE

PACKAGING MATERIALS BY TYPE AND CONSIGN THEM TO THE NEAREST SEPARATE DISPOSAL

CENTRE.

REPLACED APPLIANCES MUST BE TAKEN TO A SPECIAL GARBAGE COLLECTION CENTRE.

THE APPLIANCE MUST BE CONNECTED TO EARTH IN COMPLIANCE WITH ELECTRICAL

SYSTEM SAFETY REGULATIONS.

THE PLUG TO BE CONNECTED TO THE POWER SUPPLY LEAD AND THE RELATIVE SOCKET MUST BE

OF THE SAME TYPE AND COMPLY WITH THE RELEVANT REGULATIONS.

THE SOCKET MUST BE ACCESSIBLE AFTER THE APPLIANCE IS BUILT IN.

NEVER DISCONNECT THE PLUG BY PULLING ON THE POWER SUPPLY LEAD.

IMMEDIATELY AFTER INSTALLATION, CARRY OUT A QUICK TEST ON THE APPLIANCE FOLLOWING

THE INSTRUCTIONS PROVIDED LATER IN THIS MANUAL. SHOULD THE APPLIANCE NOT FUNCTION,

DISCONNECT IT FROM THE SUPPLY AND CALL THE NEAREST TECHNICAL ASSISTANCE CENTRE.

NEVER ATTEMPT TO REPAIR THE APPLIANCE YOURSELF.

AFTER EACH USE OF THE APPLIACE, ALWAYS CHECK THAT THE CONTROL KNOBS ARE TURNED TO

(OFF)

NEVER PLACE FLAMMABLE OBJECTS IN THE OVEN: IF IT SHOULD ACCIDENTALLY BE SWITCHED

ON, THIS MIGHT CAUSE A FIRE.

THE NAMEPLATE WITH THE TECHNICAL DATA, SERIAL NUMBER AND MARK IS IN A VISIBLE

POSITION INSIDE THE STORAGE COMPARTMENT.

THE PLATE MUST NEVER BE REMOVED.

NEVER PLACE PANS WITH BOTTOMS WHICH ARE NOT PERFECTLY FLAT AND SMOOTH ON THE HOB

GRIDS.

DURING USE THE APPLIANCE BECOMES VERY HOT. TAKE CARE NEVER TO TOUCH THE HEATING

ELEMENTS INSIDE THE OVEN. TO AVOID BURNS AND SCALDS CHILDREN SHOULD BE KEPT AWAY.

IF THE APPLIANCE IS TO BE POSITIONED ON A PLATFORM IT MUST BE INSTALLED IN SUCH A WAY

AS TO PREVENT IT FROM SLIPPING OFF THE FORMER.

INSTALL THE APPLIANCE SO THAT WHEN DRAWERS OR DOORS OF UNITS INSTALLED AT HOB

HEIGHT ARE OPENED, ACCIDENTAL CONTACT WITH PANS ON THE HOB IS NOT POSSIBLE.

4

Page 3

Precautions for use

WAR NIN G - IN ORDER TO PREVENT ACCIDENTAL TIPPING OF THE APPLIANCE, FOR EXAMPLE

BY A CHILD CLIMBING ONTO THE OPEN OVEN DOOR, THE STABILIZING MEANS MUST BE

INSTALLED.

PLEASE REFER TO INSTRUCTIONS FOR INSTALLATION.

NEVER USE PANS OR GRIDDLE PLATES WHICH PROJECT BEYOND THE OUTSIDE EDGE OF THE

HOB.

THE APPLIANCE IS NOT INTENDED FOR USE BY YOUNG CHILDREN OR INFIRM PERSONS UNLESS

THEY HAVE BEEN ADEQUATELY SUPERVISED BY A RESPONSIBLE PERSON TO ENSURE THEY CAN

USE THE APPLIANCE SAFELY. YOUNG CHILDREN SHOULD BE SUPERVISED TO ENSURE THAT THEY

DO NOT PLAY WITH THE APPLIANCE.

DO NOT SPRAY AEROSOLS IN THE VICINITY OF THIS APPLIANCE WHILE IT IS IN OPERATION.

WHERE THIS APPLIANCE IS INSTALLED IN MARINE CRAFT OR CARAVANS, IT SHALL NOT

USED AS A SPACE HEATER.

BEFORE THE APPLIANCE IS PUT INTO OPERATION, ALL THE LABELS AND PROTECTIVE FILMS

APPLIED INSIDE OR OUTSIDE MUST BE REMOVED.

DO NOT MODIFY THIS APPLIANCE.

DO NOT STORE FLAMMABLE MATERIALS IN THE APPLIANCE STORAGE DRAWER OR NEAR

THIS APPLIANCE.

THE INSTRUCTIONS PACKAGED WITH THIS APPLIANCE CONTAIN IMPORTANT INFORMATION

ABOUT INSTALLATION AND USE.

UNSUITABLE FOR USE IN MARINE CRAFT, CARAVANS OR MOBILE HOMES, UNLESS EACH

BURNER IS FITTED WITH A FLAME SAFEGUARD

IN CASE OF SERVICE, CONTACT YOUR NEAREST SERVICE AGENT OR DISTRIBUTOR LISTED

ON THE WARRANTY CARD.

BE

The manufacturer declines all responsibility for injury or damage caused by failure to comply with the

above regulations or deriving from tampering with even just one part of the appliance and the use of

non-original spare parts.

5

Page 4

Instructions for the installer

2. INSTALLING THE APPLIANCE

IIt is the law that all gas appliances are installed by authorised persons. Clearance around the cooker

must comply with the requirements of AS5601.

2.1 Electrical connection

After making the electrical and gas connections, level the the appliance on the ground by means of its

four adjustable feet. For good cooking results, the appliance must be properly levelled. Depending on the

model you have purchased, the foot height adjustment range may vary from 70 to 95 mm and from 110

to 160 mm. These heights refer to the distance between the highest point of the foot (fixed part) and the

lowest point (movable part which rests on the floor).

2.2 Electrical connection

Make sure that the power line voltage matches the specifications indicated on the rating plate located

inside the storage compartment.

This rating plate must never be removed.

The plug on the end of the power supply cable and the wall socket must be of the same type (in

compliance with the relevant national standards). Check that the power supply line is properly earthed.

The use of reductions, adapters or junctions is not recommended.

The appliance's power supply line must be fitted with an omnipolar breaking device with contact gap of at

least 3 mm, located in an easily accessible position close to the appliance itself.

The manufacturer declines all responsibility for damage to persons or things caused by nonobservance of the above prescriptions.

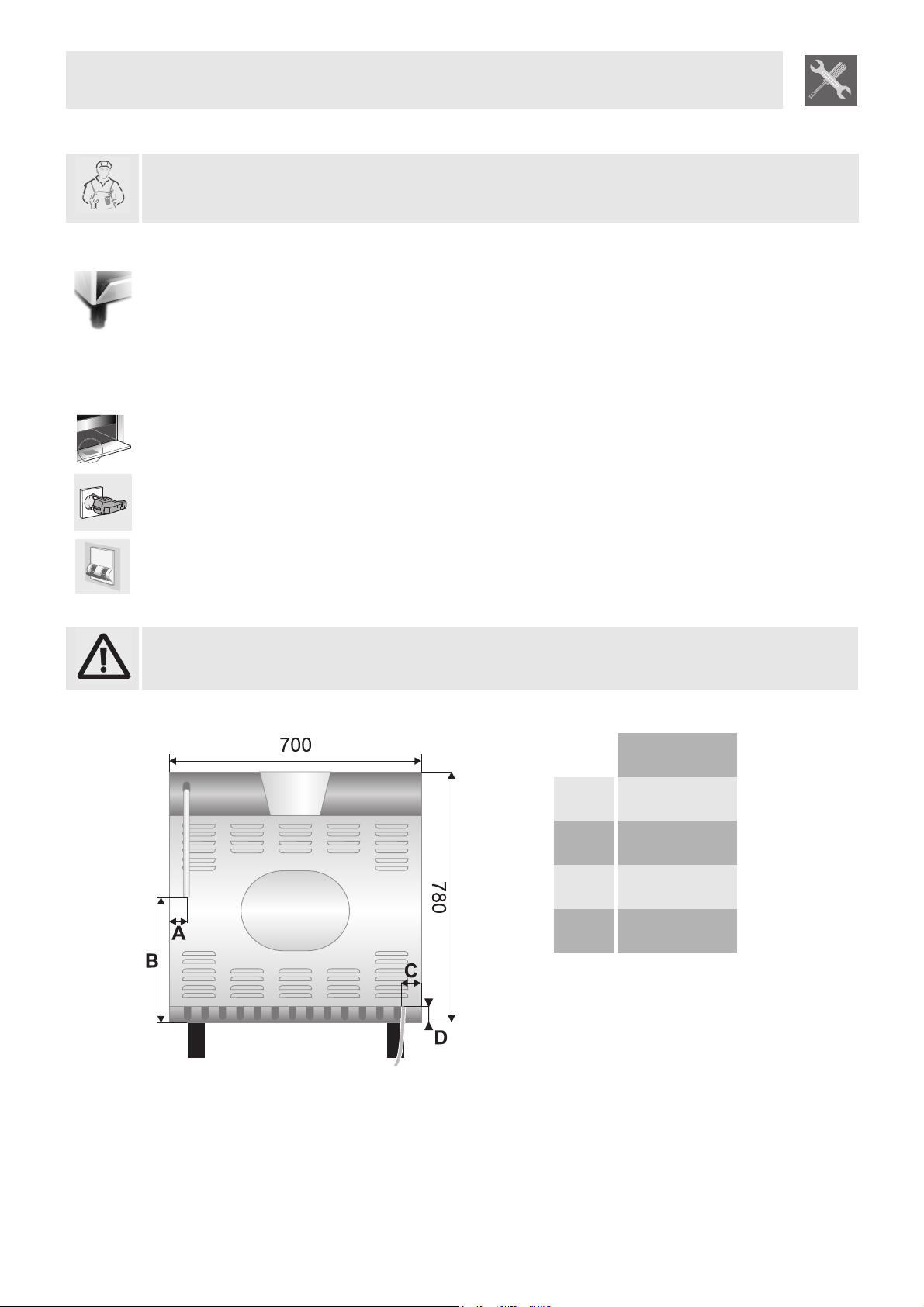

Overall dimensions: location of gas and electrical connection points (all measures in mm).

70 cm

A 110

B 600

C 157

D 145

6

Page 5

Instructions for the installer

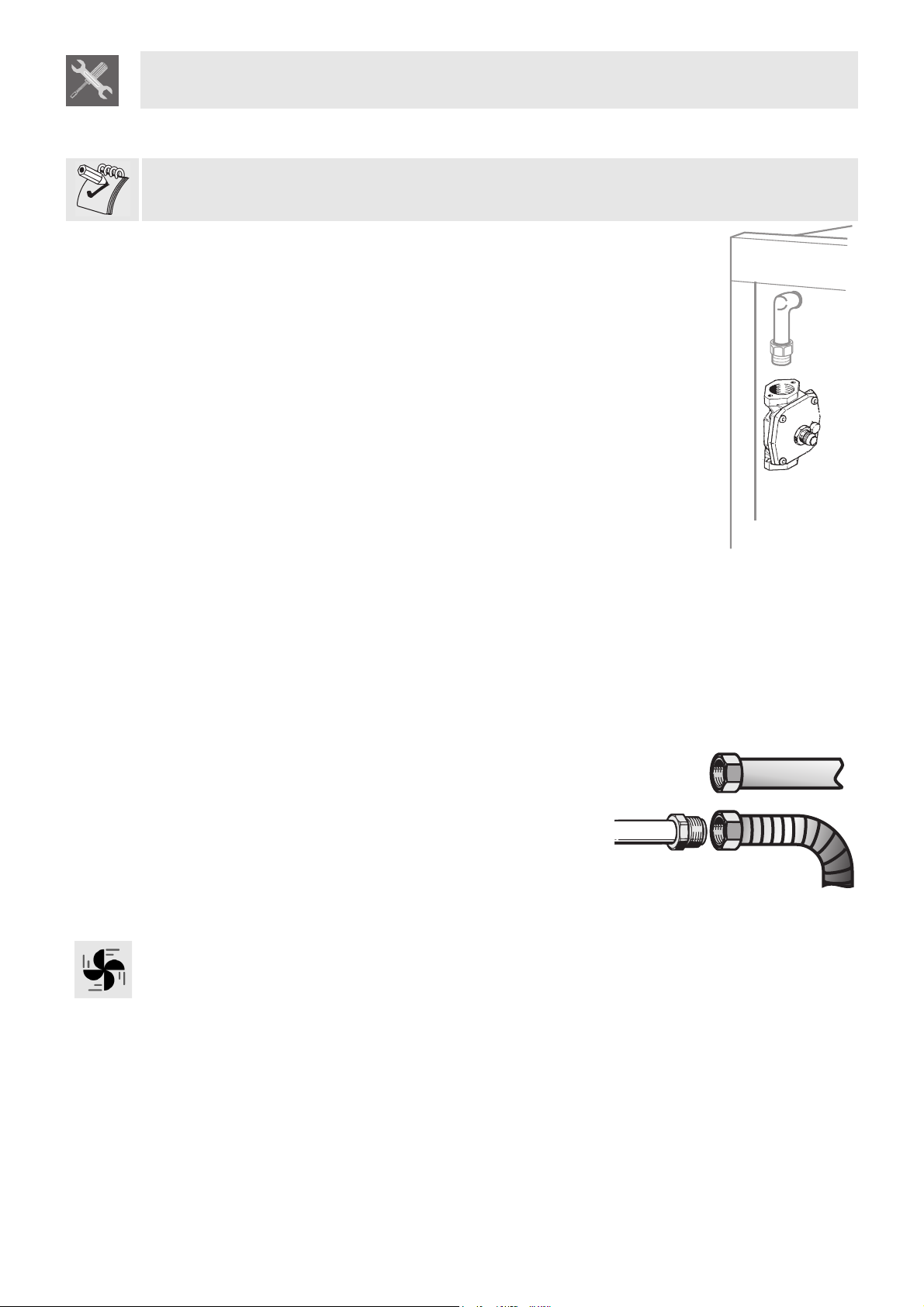

2.3 Gas connection

Always use a suitable sealing substance (such as teflon tape) between the gas connection.

This appliance is suitable for installation with Natural Gas or ULPG (propane). Refer

to page 13 for the relevant burner pressure and appropriate injector sizes. When the

appliance is to be connected to Natural Gas then the pressure regulator supplied

must be fitted to the gas inlet. A test point (for checking the gas pressure) is supplied

either with the regulator or as a separate fitting in the case of LPG (propane)

appliances.

Connection of the appliance to the gas supply must be in accordance with the

requirements of AS5601. A ½” BSP connector at the inlet is recommended and the

gas supply line to the appliance must be of adequate length to allow sufficient

withdrawal of appliance for service or disconnection and be:

1 annealed copper pipe or;

2 Flexible hose according to AS/NZ1869 & be at least Class “B”, 10 mm diameter,

max length 1000 mm.

The cooker must be installed with provision to allow the gas to be turned off and

disconnected for servicing and removal of the appliance as required from the gas

supply.

Before the cooker is operated make certain all relevant parts are placed in the correct

position.

When the installation is completed the installation connections of cooker will require

to be leak tested, the burner operating pressure and flame checked and adjusted.

Warranty service calls do not cover these adjustments!

To check the operating pressure of the appliance it is recommended at least 2 large

size burners are used. Ensure appliance is secured to wall when installation is

completed.

N.G. A regulator must be fitted to the ½ BSP thread at the rear of the appliance. An

approved manual shut-off valve must be installed. The N.G. regulator must be

checked and adjusted to 1.0kPa after installation.

U.L.P.G. Can be connected to the inlet fitting directly. The pressure

must be checked to ensure it is operating at 2.75kPa. A separate

test point fitting must be installed between the piping & the

appliance for the pressure to be checked to ensure it is operating at

2.75kPa.

2.4 Ventilation requirements

Caution – This cooker may only be installed and operated in rooms permanently ventilated in

accordance with current regulations. For proper operation of a gas appliance it is essential for the air

necessary for combustion of the gas to be able to flow naturally into the room. Air must flow directly into

the room through openings in its outside walls. This (these) opening (s) must have a free passage crosssection of at least 100 cm2, or 200 cm2 for appliances not equipped with gas safety device. These

openings must be constructed so that they cannot be obstructed indoors or outdoors, and should

preferably be close to the floor on the side opposite to the combustion gas discharge point. If it is not

possible to make the openings in the room where the cooker is installed, the necessary air may be taken

from an adjoining room, proveded it is not a bedroom or a room with fire risk.

7

Page 6

Instructions for the installer

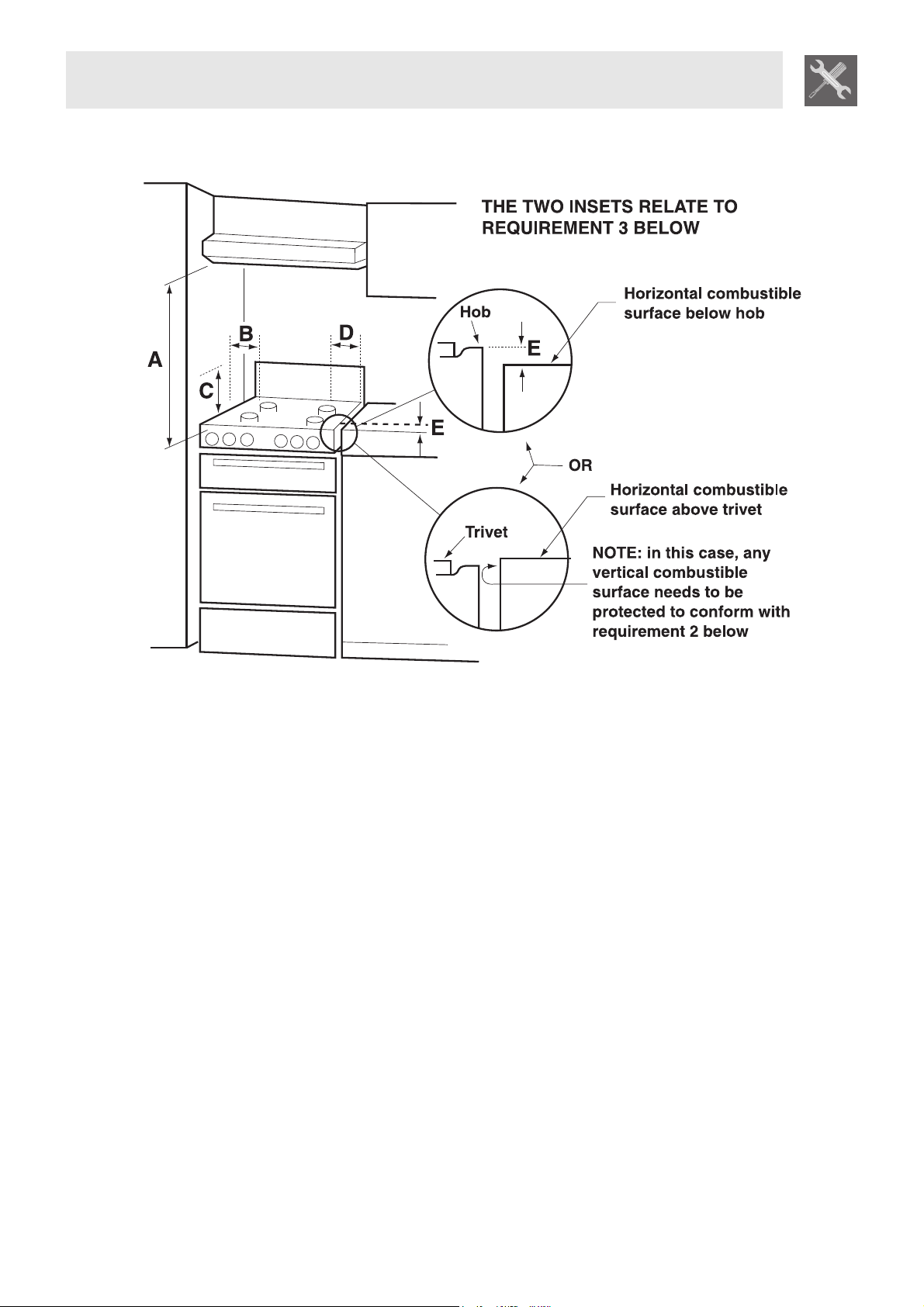

2.5 Clearance above and around domestic cookers

Extract from AS5601

REQUIREMENTS

1 Overhead clearances – (Measurement A)

Range hoods and exhaust fans shall be installed in accordance with the manufacturer’s instructions.

However, in no case shall the clearance between the highest part of the hob of the cooking appliance

and a range hood be less than 600 mm or, for an overhead exhaust fan, 750 mm.

Any other downward facing combustible surface less than 600 mm above the highest part of the hob

shall be protected for the full width and depth of the cooking surface area in accordance with Clause

5.12.1.2. However, in no case shall this clearance to any surface be less than 450 mm.

2 Side clearances – (Measurements B & C)

Where B, measured from the periphery of the nearest burner to any vertical combustible surface, is

less than 200 mm, the surface shall be protected in accordance with Clause 5.12.1.2 to a height C of

not less than 150 mm above the hob for the full dimension (width or depth) of the cooking surface

area. Where the cooking appliance is fitted with a ‘splashback’, protection of the rear wall is not

required.

3 Additional requirements for Freestanding and Elevated Cooking Appliaces – (Measurements D & E)

Where D, the distance from the periphery of the nearest burner to a horizontal combustible surface is

less than 200 mm, then E shall be 10 mm or more, or the horizontal surface shall be above the trivet.

See insets above.

NOTES

1 Requirement 3 does not apply to a freestanding or elevated cooking appliance which is designed to

prevent flames or the cooking vessels from extending beyond the periphery of the appliance.

2 The ‘cooking surface area’ is defined as that part of the appliance where cooking normally takes

place and does not include those parts of the appliance containing control knobs.

3 For definition of hob, see Clause 1.4.64. 4 For definition of trivet, see Clause 1.4.109. 5 Consideration is to be given to window treatments when located near cooking appliances. See

Clause 5.3.4.

8

Page 7

Instructions for the installer

A

A

170

900

BB

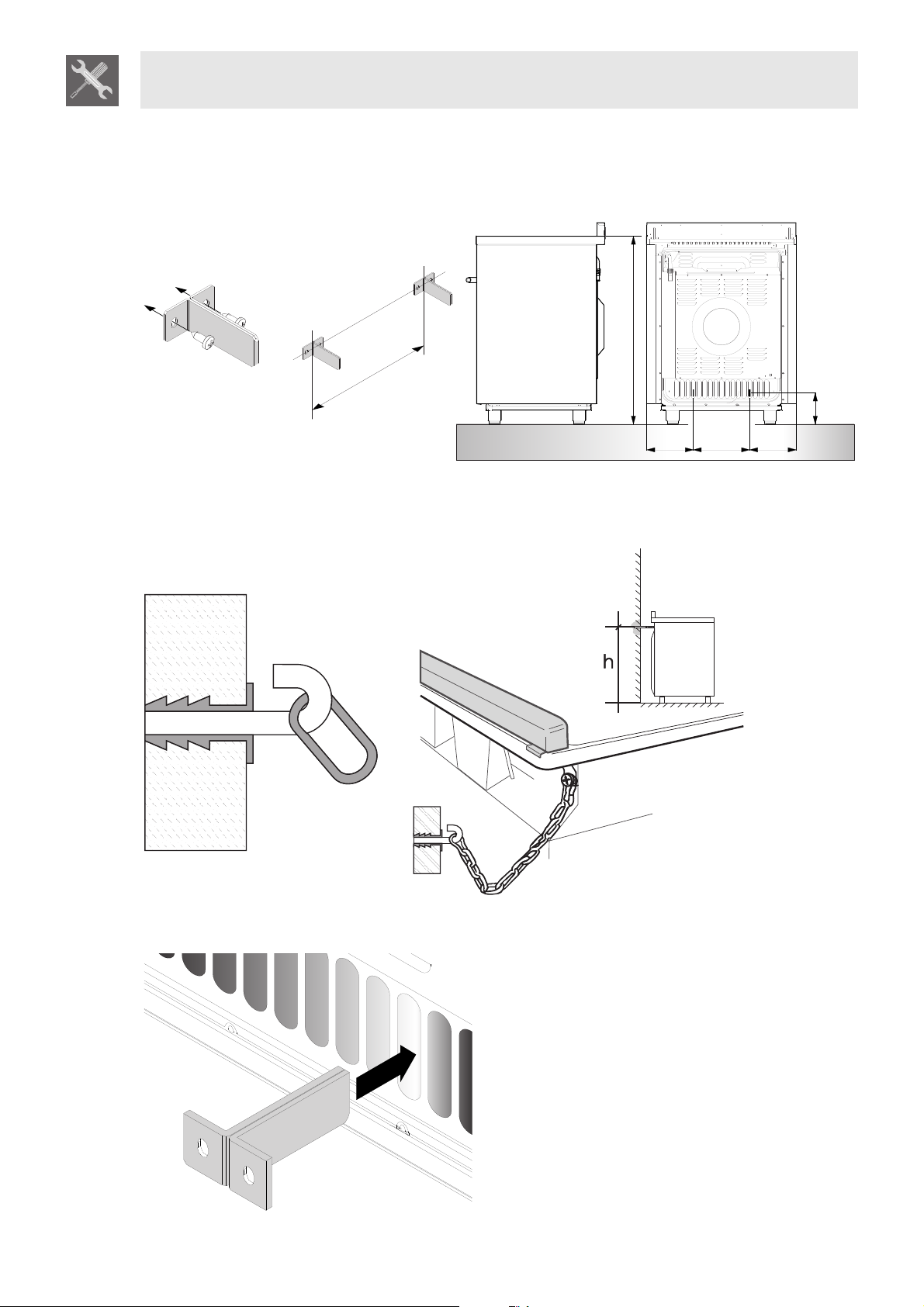

2.6 Instruction for wall fixing

1 Fasten the two wall brackets to the wall taking care to comply with the centre distances and

measurements indicated in the images below. The dimensions are given in mm.

A= 262 / B = 218

2 Attach the chain to the cooker 3 Stretch out the chain attached to the cooker horizontally so that the other end touches the wall. 4 Mark the wall in the position where the hole is to be drilled. 5 Drill the hole, insert a wall plug and attach the chain.

6 Once these operations are completed, push the appliance against the wall taking care to insert the

wall brackets correctly in the slots on the back of the cooker.

9

Page 8

Instructions for the installer

3. ADAPTATION TO DIFFERENT TYPES OF GAS

Before performing any operations requiring access to powered parts, switch off the power supply to the

appliance.

The cooker hob is preset for natural gas at a pressure of 1.0 KPa. In the case of operation with other

types of gas the burner nozzles must be changed and the minimum flame adjusted on the gas taps. To

change the nozzles, proceed as described below.

3.1 Changing nozzles

This operation does not require the primary air to be adjusted.

1 Extract the grids and remove all the caps and flame-spreader crowns; 2 Unscrew the burner nozzles with a 7 mm socket wrench; 3 Replace the nozzles according to the type of gas to be used and the description in paragraph "3.2

Burner and nozzle characteristics table";

4 Replace the burners in the correct position.

10

Page 9

Instructions for the installer

3.2 Burner and nozzle characteristics table

Burner ULPG (PROPANE) – 2.75 KPa

Nominal gas consumption

(MJ/h)

Auxiliary (1) 3.9 1.5 0.54

Semi rapid (2) 6.3 1.5 0.68

Rapid (3) 10.8 2.7 0.88

Ultra-rapid (4) 15.0 5.4 1.05

Oven 11.5 - 0.94

Burner NG (NATURAL GAS) – 1.0 KPa

Nominal gas consumption

(MJ/h)

Auxiliary (1) 3.9 1.5 0.90

Semi rapid (2) 7.5 1.5 1.20

Rapid (3) 12.0 2.7 1.55

Ultra-rapid (4) 15.8 5.4 1.85

Oven 11.5 - 1.55

Turn-down gas

consumption (MJ/h)

Turn-down gas

consumption (MJ/h)

Injector

(mm)

Injector

(mm)

3.3 Arrangement of the burners on the hob

BURNERS

1. Auxiliary

2. Semi-rapid

3. Rapid

4. Ultra-rapid

min. and max. Ø (in cm)

12 - 14

16 - 24

18 - 26

18 - 26

11

Page 10

Instructions for the installer

3.4 Oven burner adjustment

To adjust the oven burner you need to open the oven door and carry out

the following operations:

• Remove the oven basin and its rack.

• Lift up the oven surface and pull it outwards.

3.4.1 Replacing the oven burner nozzle

• Loosen the oven burner fixing screw A.

• Push the burner B towards the right until the nozzle is

accessible.

• Using a 13 socket wrench, replace the nozzle, inserting

a new nozzle suitable for the type of gas to be used (see

paragraph "3.2/3.3 Burner and nozzle characteristics

table").

3.4.2 Replacing the oven burner nozzle

• Loosen the adjustment screw "A" of the air regulation sleeve.

• Turn the adjustment sleeve "B" to the position that corresponds to the

type of gas to be used according to the table below.

• Tighten the adjustment screw and restore the seals.

• When the operation is completed, reassemble the burner correctly.

NATURAL GAS ULPG

X= 10 mm 10 mm

12

Page 11

Instructions for the installer

4. FINAL OPERATIONS

After changing the nozzles, put the pan stands, the burner caps and flame diffuser rings back in place.

After adjusting for use of a gas other than the gas used for testing the appliance, replace the gas setting

label on the appliance with the label for the new gas. The label is supplied in the bag with the nozzles.

4.1 Regulation of the hob burner minimum level for natural gas

Light the burner and turn it to the minimum position . Extract the gas tap knob

and turn the adjustment screw at the side of the tap rod until the correct minimum

flame is achieved.

Refit the knob and verify that the burner flame is stable (turning the knob rapidly

from the maximum to the minimum position the flame must not go out). Repeat

the operation on all the gas taps.

For models with valves, keep the knob at minimum level for about 1 minute to keep the flame lit and to

activate the safety device.

4.2 Regulation of the hob burner minimum level for ULPG

In order to adjust the minimum with ULPG, the screw at the side of the tap rod must be turned clockwise

all the way. The bypass diameters for each individual burner are shown in paragraph "3.2 Burner and

nozzle characteristics table". Once the regulation has been completed, restore the seal on the bypasses using paint or similar materials.

4.3 Adjustment of the oven burner minimum

Light the burner and turn it to the minimum position .

Extract the gas tap knob and turn the adjustment screw

at the side of the tap rod until the correct minimum

flame is achieved.

Refit the knob and verify that the burner flame is stable

(turning the knob rapidly from the maximum to the

minimum position the flame must not go out). Repeat

the operation on all the gas taps.

13

Page 12

Instructions for the user

225

125

150

175

200

275

250

0

30

55

50

45

40

35

5

10

15

20

25

omega

4

3

2

5. GETTING TO KNOW YOUR COOKER

HOB

CONTROL PANEL

OVEN/MAIN OVEN

FOOD WARMER

COMPARTMENT

14

Page 13

Instructions for the user

225

125

150

175

200

275

250

30

55

50

45

40

35

5

10

15

20

25

omega

6. DESCRIPTION OF FRONT PANEL CONTROLS

All the cooker controls are grouped together on the front panel. The symbols used are described in the

table below.

OVEN THERMOSTAT KNOB REAR LEFT-HAND BURNER

OVEN FUNCTIONS KNOB CENTRAL BURNER

TIMER KNOB REAR RIGHT-HAND BURNER

FRONT LEFT-HAND BURNER FRONT RIGHT-HAND BURNER

HOB BURNERS CONTROL KNOB

To light the flame, press the knob and turn it counterclockwise to the minimum flame

symbol . To adjust the flame, turn the knob to the zone between the maximum ( )

and minimum ( ) settings. To turn off the burner, turn the knob to the position.

TIMER KNOB

In order to use the timer, the buzzer must be set by turning the knob in a clockwise

direction. The numbers correspond to minutes (maximum 55 minutes). Adjustment is

progressive and intermediate positions between the figures can be used. The end of

cooking buzzer does not interrupt operation of the oven.

GAS OVEN THERMOSTAT KNOB

This knob allows the gas burner inside the oven to be lit. The cooking temperature is

selected by turning the knob counterclockwise to the desired setting, between 125°C.

and 275°C.

To learn how to light the gas oven, see paragraph “8.3 Using the gas oven”.

15

Page 14

Instructions for the user

4 FUNCTIONS SELECTION KNOB

This control lets you access the various functions of the oven. The lighting ( ), grill

( ) and thawing ( ) functions can be used when the oven is off. The fan-assisted

function ( ) can only be used if the gas oven is lit. Ventilation will start working when

the oven has reached a temperature of about 120-130 °C.

GRILL ELEMENT FAN-ASSISTED HEATING ELEMENT

GRILL ELEMENT THAWING

16

Page 15

Instructions for the user

7. USING THE HOB

7.1 Lighting the hob burners

Before lighting the hob burners, check that the flame-spreader crowns are correctly in place with their

respective burner caps, making sure that the holes A in the flame-spreaders are aligned with the plugs

and thermocouples. Before lighting the burners lift the glass lid; before closing it again, turn off all the

burners and wait for them to cool.

The optional grid B is for use with woks. To prevent damage to the hob, the cooker comes complete with

a raised pan stand C for use underneath pans more than 26 cm in diameter. The pan stand C supplied is

for use even with small pans.

The burner each knob controls is shown next to the knob. The appliance is equipped

with an electronic ignition device. Simply press the knob and turn it anti-clockwise to

the minimum flame symbol , until the burner lights. Keep the knob pressed down

for a few seconds to allow the thermocouple to heat up. The burner may go out when

the knob is released: in this case, the thermocouple has not heated up sufficiently.

Repeat the operation, keeping the knob pressed down for longer. This is not

necessary on burners not equipped with thermocouple.

If the burners should go out accidentally a safety device will be tripped about 20 seconds later, cutting off

the gas supply even if the gas tap is open.

7.2 Practical hints for using the hob burners

For better burner efficiency and to minimise gas consumption, use pans with lids and of suitable size for

the burner, so that flames do not reach up the sides of the pan (see paragraph “7.3 Pan diameters”).

Once the contents come to the boil, turn down the flame far enough to prevent the liquid from boiling

over. To prevent burns or damage to the hob during cooking, all pans or griddle plates must be placed

inside the perimeter of the hob. All pans must have smooth, flat bottoms. Take the greatest care when

using fats or oils since they may catch fire if overheated. If the flame accidentally goes out, turn off the

control knob and wait at least 1 minute before trying to re-light the burner.

7.3 Pan diameters

BURNERS

1. Auxiliary

2. Semi-rapid

3. Rapid

4. Ultra-rapid

min. and max. Ø (in cm)

12 - 14

16 - 24

18 - 26

18 - 26

17

Page 16

Instructions for the user

8. USING THE OVEN

8.1 Warnings and general advice

When using the oven and the various heating elements for the first time, they should be heated to the

maximum temperature (275°C) for long enough to burn off any oily residues left by the manufacturing

process, which might contaminate foods with unpleasant smells.

WARNING: The appliance becomes very hot during use. oven gloves should always be worn.

WARNING: the gas oven must be lit with the oven door open. The oven is equipped with a safety

system that blocks ignition of the burner if the door is closed. If you make a mistake in the

lighting procedure, open the oven door and wait a few moments before trying to light it again.

WHILE COOKING DESSERTS AND VEGETABLES DRIPPING FROM THE BOTTOM OF THE DOOR

COULD OCCUR. THIS IS A NATURAL PHYSICAL PHENOMENON WHICH MAINLY OCCURS WHEN

PREHEATING HAS NOT TAKEN PLACE. IN ORDER TO AVOID THIS, OPEN THE DOOR A COUPLE

OF TIMES WHILE COOKING, TAKING GREAT CARE.

To prevent any steam in the oven from creating problems, open the door

in two stages: half open (5 cm approx.) for 4-5 seconds and then fully open. To

access food, always leave the door open as short a time as possible to prevent

the temperature in the oven from falling and ruining the food.

8.2 Cooling fan

This system keeps the door and internal components of the oven at a lower temperature through forced

recirculation of cool air, guaranteeing increased safety and a longer life for the electrical appliance.

The tangential cooling system remains active even after cooking has finished and continues working

when the oven has been switched off in order to disperse all the heat that has built up in side. This

mechanism allows all the furniture units surrounding the appliance to be protected, preventing them from

overheating.

8.3 Using the gas oven

8.3.1 Electronic spark ignition

Open the oven door fully, press the thermostat knob and turn it counterclockwise to

the maximum temperature; the electrical spark ignition is activated automatically.

When the oven is lit, keep the knob pressed down for a few seconds to allow the

thermocouple to heat up.

If the burner does not ignite after 15 seconds, interrupt the attempt to light it, open

the oven door completely and do not try to light it again for at least 1 minute.

8.3.2 Manual ignition

Open the oven door fully and turn the thermostat knob while keeping it pressed in.

Bring a lighted match close to the mouth of the flame pipe

oven surface and press the thermostat knob. Once it is lit, keep the knob pressed

down for a few seconds to allow the thermocouple to heat up and make sure that it

has remained lit by looking through the inspection hole

temperature is selected by turning the knob clockwise to the desired setting,

between

125°C

and

275° C

.

A

at the centre of the

B

. The cooking

18

If the burner is extinguished accidentally, a safety valve will be activated to interrupt the flow of gas. To light

it again, first turn the knob to the OFF position ( ) and wait for about one minute. Then relight the gas

following the normal procedures.

Page 17

Instructions for the user

8.4 Using the electric grill

To use this function you must first extinguish the oven burner by moving the relevant

knob to the position and then turning the selector to the position.

It is not possible to operate the gas oven and the grill at the same time.

8.4.1 How to use the grill

When the oven has come on, confirmed by the red light switching on, leave it to heat up for 5 minutes

before placing foods inside.

Foods must be seasoned before cooking. Foods should also be coated with oil or melted butter before

cooking. Use the oven tray to collect juice.

The foods to be cooked must be placed on the oven rack, which must then be placed on one of the

runners fitted in the various types of ovens, following the guidelines below:

FOODS RACK ON THE SHELF

Flat, thin pieces of meat 3

Rolled roasts 2 - 3

Poultry 2 - 3

PRECAUTIONS

Grilling processes must never last more than 60 minutes.

• In models with an electric or gas oven, the oven door must be closed during grill cooking

operations.

• To prevent hazardous overheating, the appliance's glass lid must always be raised when using

the oven or grill.

• Accessible parts may be very hot during and after use of the grill; keep children well away

from the appliance.

• When using the oven, remove all unused plates and racks from its interior.

• During cooking, do not cover the bottom of the oven with aluminium or tin foil and do not

place pans or oven plates on it as this may damage the enamel coating. If you wish to use

greaseproof paper, place it so that it will not interfere with the hot air circulation inside the

oven.

8.5 Storage compartment (only on some models)

The storage compartment is in the bottom of the cooker, underneath

the oven. To open it, pull on the top of the door.

Never use it to store flammable materials such as rags, paper, etc.; it

is intended to take the appliance's metal accessories only.

Do not open the storage compartment when the oven is on and still hot. The temperatures inside it may

be very high.

Never use it to store flammable materials such as rags, paper, etc.; it is intended for storing the

appliance's metal accessories only.

19

Page 18

Instructions for the user

9. AVAILABLE ACCESSORIES

The oven features 4 runners for placing trays and shelves at different

heights.

Oven shelf: for cooking food on plates, small cakes or roasts or foods

requiring light grilling.

Tray g r i d: for placing on top of a tray for cooking foods which may

drip.

Oven tray: useful for collecting fat from foods placed on the grid

above.

Baking tray: useful for cooking cakes, pizza and confectionery.

Not all accessories are provided on some models.

Accessories available on request

Original optional accessories can be ordered through our Authorised Service Centres.

20

Page 19

Instructions for the user

10. CLEANING AND MAINTENANCE

Before carrying out any operation involving access to live parts, disconnect the appliance from

the electricity supply.

Do not use a steam cleaner to clean a hob, oven or range.

10.1 Cleaning stainless steel

To keep stainless steel in good condition, it must be cleaned regularly, after each use of the cooker, after

allowing it to cool.

10.2 Routine daily cleaning

When cleaning and caring for stainless steel surfaces, always use only specific products which do not

contain abrasives or chlorine-based acids.

Instructions for use: pour the product onto a damp cloth and wipe over the surface, then rinse

thoroughly and dry with a soft cloth or chamois leather.

Do not use harsh abrasive cleaners or sharp metal scrapers to clean the oven glass door since they can

scratch the surface, wich may result in shattering of the glass

10.3 Food stains or residues

Never use metal scouring pads or sharp scrapers; they will damage surfaces.

Use ordinary non-abrasive products for steel, with the aid of wooden or plastic utensils if

necessary.

Rinse thoroughly and dry with a soft cloth or chamois leather.

Do not allow spills of foods with high sugar content (e.g. jam) to dry inside the oven. If they dry

for too long, they might damage the enamel coating of the inside of the oven.

10.4 The burner caps, flame diffuser rings and burners

The burner caps and flame diffuser rings can be removed for easier cleaning; wash

them in hot water and non-abrasive detergent, taking care to remove all deposits, and

wait for them to dry completely.

Replace the burner caps on their rings, making sure that the holes A are perfectly

centered with the circular projections B on the burners.

Never wash these components in the dishwasher.

10.5 The plugs and thermocouples

For best performance, the ignition plugs and thermocouples must always be kept

thoroughly clean. Check them frequently and if necessary clean them with a wet cloth.

Remove any dry residues with a wooden toothpick or a needle.

21

Page 20

Instructions for the user

10.6 Cleaning the oven

For best oven upkeep clean regularly after having allowed to cool. Take out all removable parts.

Clean the oven grill and side guides with hot water and non-abrasive detergent. Rinse and dry.

10.7 Cleaning the door glazing

The glass in the door should always be kept thoroughly clean. Use absorbent kitchen roll; remove

stubborn dirt with a damp sponge and ordinary detergent.

When cleaning, dry the appliance thoroughly to prevent water or detergent drips from interfering with its

operation or creating unsightly marks.

Do not use abrasive or corrosive cleaners for cleaning the door glazing. (e.g. powder products, ovencleaner sprays, stain removers and metal scouring pads).

Do not use rough or abrasive materials or sharp metal scrapers to clean the oven's glass doors since

they may scratch the surface and cause the glass to shatter.

22

Page 21

Instructions for the user

11. EXTRAORDINARY MAINTENANCE

The oven may require extraordinary maintenance or replacement of parts subject to wear such as seals,

bulbs, and so on. The following instructions describe how to carry out these minor maintenance

operations.

Before performing any operations requiring access to powered parts, switch off the power supply to the

appliance.

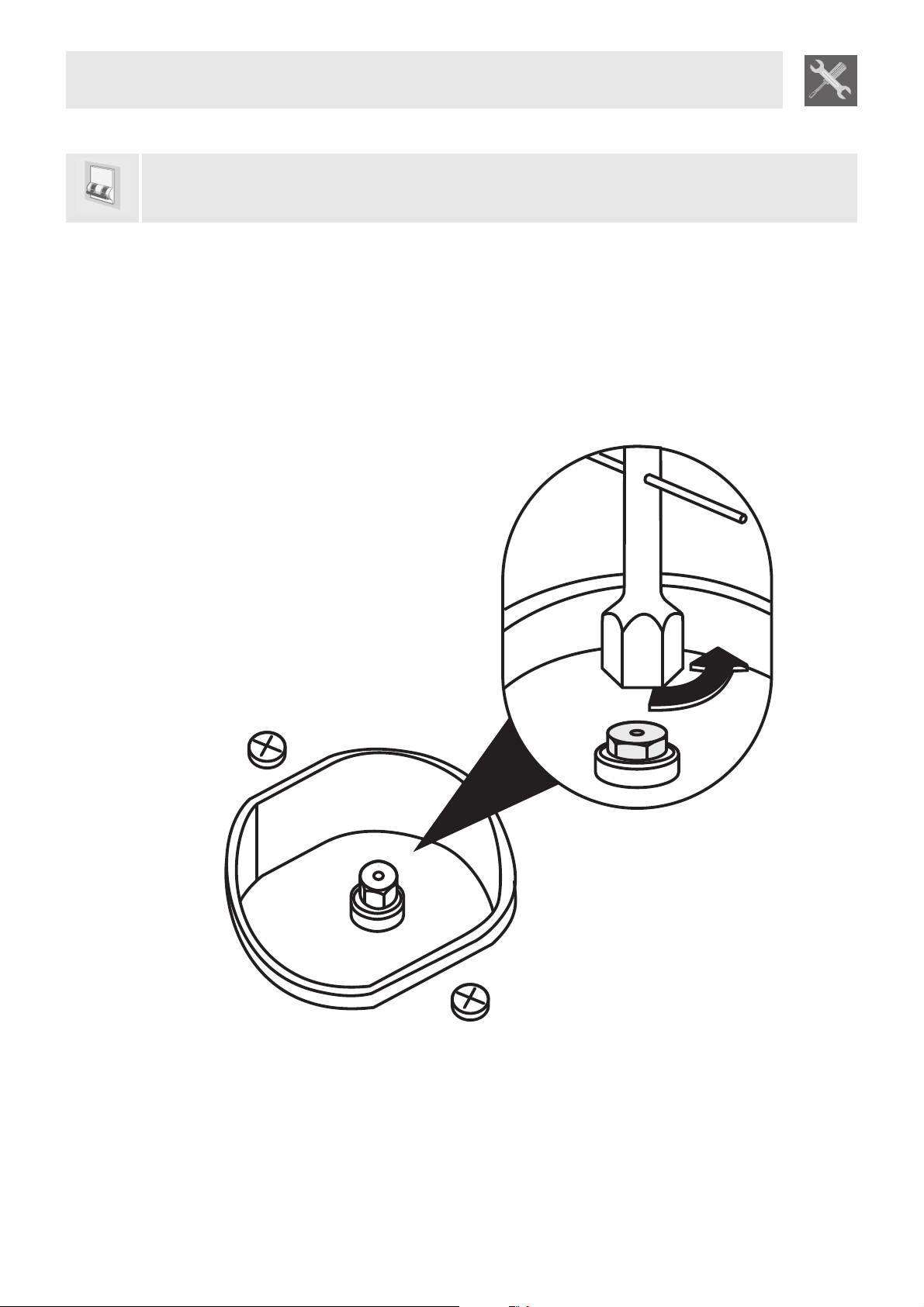

11.1 Changing the light bulb

Remove the protective cover A by unscrewing it anti-clockwise; replace the bulb B with another of the

same type (25 W). Re-fit the bulb protector A.

WARNING : Ensure the appliance is switched off before replacing the lamp to avoid the

possibility of electric shock.

Use only oven bulbs (T 300°C).

11.2 Removing the door

Lift the levers B and Take hold of the two sides of the door

with both hands near to the hinges A. Raise the door to an

angle of about 45° and remove it. To reassemble, fit the

hinges A into their grooves, then lower the door into place

and release the levers B.

11.3 Removing the door seal

To permit thorough cleaning of the oven, the seal may be removed.

Before removing the seal, take off the door as described above. Once the

door has been taken off, lift the tabs at the corners as shown in the figure.

23

Page 22

Instructions for the user

12.PROBLEMS AND CAUSES

Each of the following cases is caused by abnormal operation of the appliance and should be dealt with

by a authorised person: please contact your local dealer or Service Center in case you detect any of

these malfunctioning.

PROBLEM CAUSE WHAT TO DO

The flame is very long with bright

yellow tips.

Black deposits on the bottom of

the pans.

The flame is very short and noisy.

The flame moves away from the

burner ports.

The flame extinguishes when the

burner knob is set to the low

flame position.

The valve knob is hard to rotate. Gas valve worn out or needs

The cooker suddenly stops

working during operation of the

oven.

Defect of comburent air or

incorrect injectors.

Excess of comburent air. Call service Center.

Incorrect adjustement of the

minimum heat input or excess of

comburent air.

lubrification.

Overheating of the appliance Let the appliance cool down: the

Call service Center.

Call service Center.

Call service Center.

safety thermal cut-out will self-

reset when the temperature has

decreased to correct value.

Should the problem arise again,

call the Service Center.

24

Page 23

Page 24

914774105/ B

Loading...

Loading...