Page 1

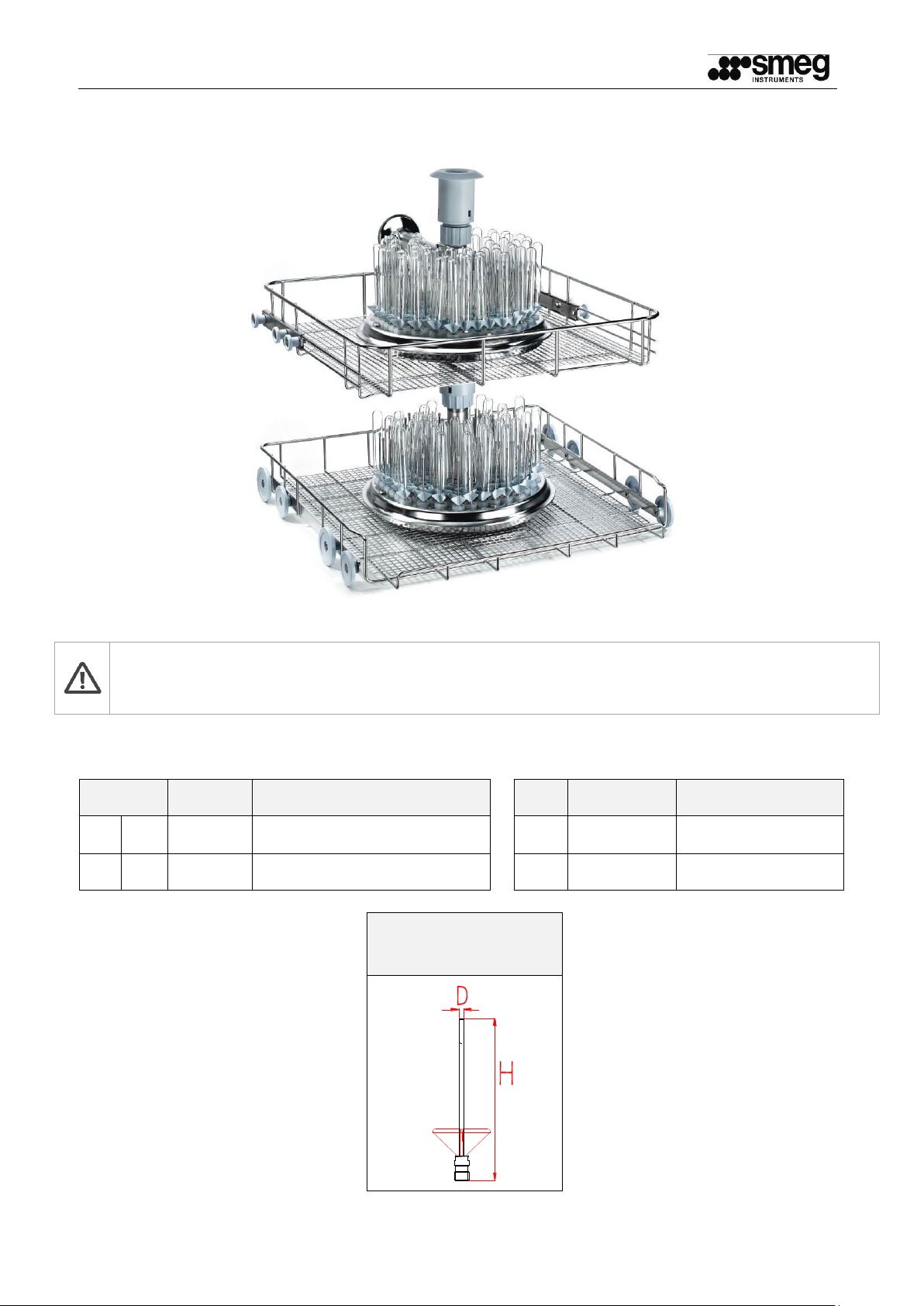

-EN- KP200/DS -

19390304000-KP200-DS_EN.doc

1

Rev. 01 - 03/01/2012

Read the safety warnings and instructions for the thermodisinfectors in which the rack is used with

care, together with the safety instructions of the producer of the glassware and any other item placed on the

rack. Badly positioned items or glass which shatters during washing may cause dangerous injuries. If

necessary, washing results must be checked and subjected to non-visual inspections.

Qt.y

PART

NUMBER

DESCRIPTION

Qt.y

PART

NUMBER

DESCRIPTION

1

0

TC80DS

LM80DS central pipe (only for

DS version)

208

U390

Stainless steel nozze

D=3 H=90 (mm)

1

2

TC80

LM80 central pipe (only one for

DS version)

NOZZLE

(E.g. U390 means

Stainless steel nozzle with

D= 3mm and H= 90mm)

KP200/DS - INSTRUCTIONS FOR ASSSEMBLY AND USE

1 LIST OF COMPONENTS SUPPLIED

Page 2

-EN- KP200/DS -

19390304000-KP200-DS_EN.doc

2

Rev. 01 - 03/01/2012

N.104

N.104

N.104

N.104

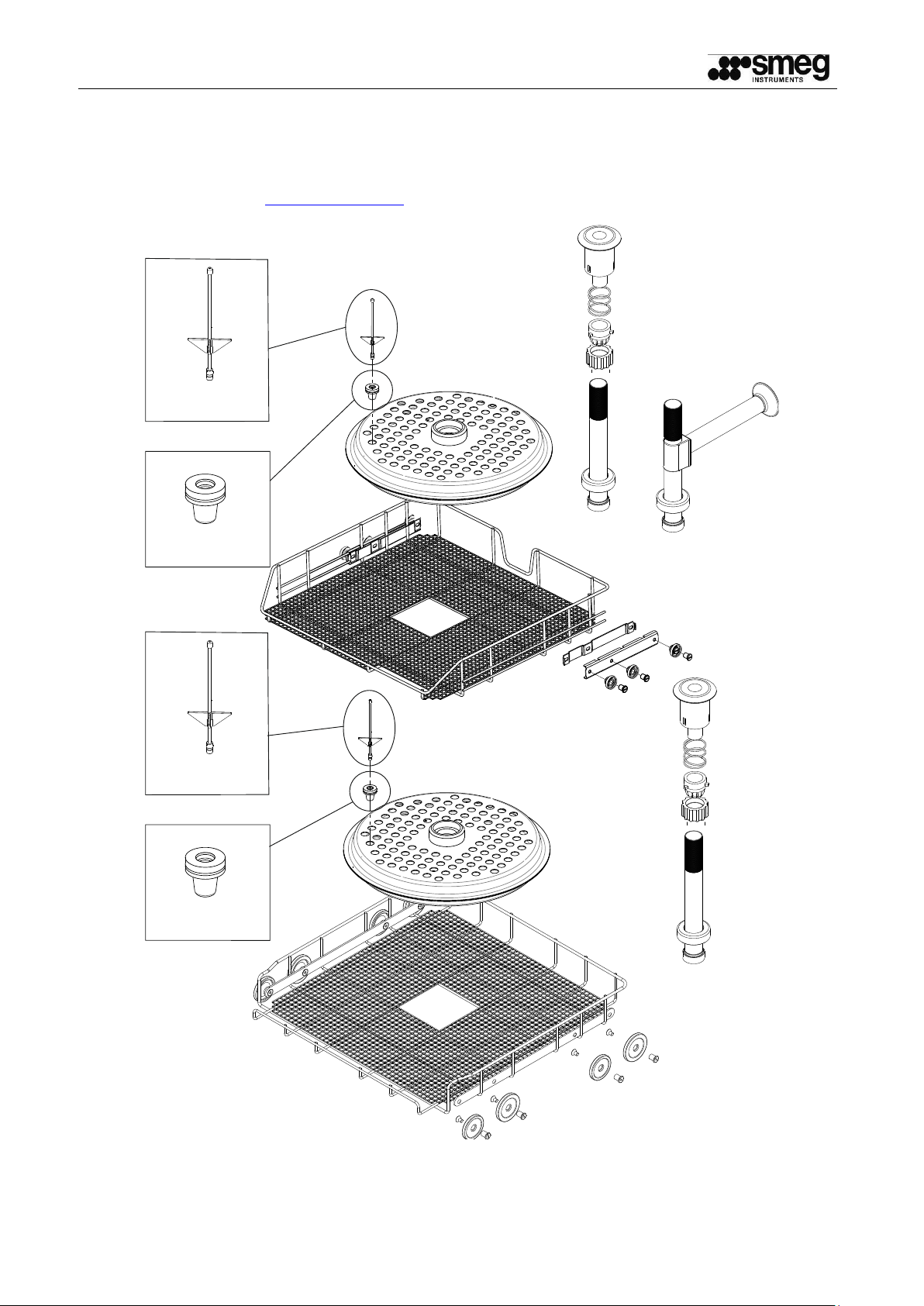

2 BLOW-UP DIAGRAM

The blow-up diagram below is guideline; request up-to-date information on spare parts from your Smeg

contact, with reference to www.smegtech.com.

Page 3

-EN- KP200/DS -

19390304000-KP200-DS_EN.doc

3

Rev. 01 - 03/01/2012

ILLUSTRATION

PROCEDURE

Fig. 1

Insert the central pipe into place and tighten

the ring-nut to fix all parts.

Fig. 2

Fig. 3

If your product is equipped with the DS device,

the pack contains pipe B (TC80DS) instead of

the ordinary pipe A (TC80), in which case the

pipe B must be fitted as shown in figure 3, i.e.

with the pipe projecting towards the rear of the

rack, so that once it is inside the disinfector it

will be aligned with the connection (illustration

below).

A

B

3 ASSEMBLY SEQUENCE

Page 4

-EN- KP200/DS -

19390304000-KP200-DS_EN.doc

4

Rev. 01 - 03/01/2012

ILLUSTRATION

PROCEDURE

Fig. 4

Fit the nozzles on all the rubber supports,

simply pressing them gently into place. If the

rack is fitted with the DS device, fit the black

caps into the holes underneath the tube (in the

top rack only).

Fig. 6

When inserting the rack in the disinfector, the

greatest care must be taken to ensure that the

tapered connection on the rack is aligned with

the one on the machine.

Page 5

-EN- KP200/DS -

19390304000-KP200-DS_EN.doc

5

Rev. 01 - 03/01/2012

PROCEDURE

PROCEDURE

Take care not to place pieces of glassware

touching each other.

Glass must not rest on the nozzle; it must

stand on the base support, allowing the

water to come out of the nozzle freely.

Move the spring underneath the support to

prevent it from descending.

Ensure that no glassware or any other item

for washing projects above the water intake.

Ensure that no item for washing projects from

the rack after loading.

4 USE AND PRECAUTIONS

Smeg S.p.A.

Instruments Division

Via Leonardo da Vinci, 4 – 42016 Guastalla (RE) Italy

E-Mail: instruments@smeg.it – www.smeg-instruments.com

Tel. +39 0522 8211 - Fax + 0522 821 592

Loading...

Loading...