Page 1

19 592 0371 00

GW6290 - PROGRAM TABLE

1

GW6290

GW6290: glassware washers with forced-air drying system.

Hinged door.

- PROGRAM TABLE – (GW)

WARNING

This document is an appendix to the appliance's user manual and must be consulted together with the manual for proper, safe use of the device.

It contains up-to-date information concerning the characteristics of the washing programs installed in the appliance.

Programs may vary depending on the firmware version installed in the appliance. If in doubt, have authorised staff check on the appliance that the installed version is the same as the

version stated in the table at the back of this document.

ABBREVIATIONS USED IN THE TABLE

Demi, DW: demineralised water, the type of water used in a specific phase of the program.

Cold, CW: cold mains water, the type of water used in a specific phase of the program.

Hot, HW: hot mains water, the type of water used in a specific phase of the program.

K_TEST: indicates the predisposition in the phase of the “conductivity check” (active only if present and activated the option for the control of the water conductivity, “IC6290”).

ID_prog: identity number of the washing program; it is not necessarily bonded to the program name. (E.g. the program “ custom 1 ” has ID_prog = 21).

Int.: “Intensive” – use this program to process dirty elements.

N.C.: "NOT CONTROLLED" - refers to the relatively short heating phases during which the heating elements are “on” but no target temperature value is set.

P1, ... P5: the code refers to the activation of the relative peristaltic pump, with dispensing of the liquid detergent associated to it.

Each pump has a default dispensing rate set in the factory.

P1b, P2a: the code refers to dispensing by pump P1, P2 at a rate different from the default rate, used in special cases, as specified in the program table.

PUMP DOSAGE ID.

DEFAULT DOSAGE LABORATORY PROGRAMS GLASSWARE WASHER GW [ml/litro]

P1

5

P1b

3

P2

3

P2a

4

P3

10

P4

0.4

P1(20), P2(20), P3(20), P4(20), P5(20)

20 (dosage for service purpose only – peristaltic pump service program)

TD: thermal disinfection - phase during which the target temperature is kept above a target value for a specified time. The efficacy of the thermal disinfection process is indicated by

means of parameter A0. In preset programs, the target value for a thermal disinfection process is always at least 80°C.

Temp. T [°C]: Target temperature of the current phase. The temperature inside the tank is kept constant around the specified value for the time shown in the table. The phase during

which the temperature is held at the target value is called the EXTENSION phase. When no target temperature is indicated or the indication is (“0”), the heating elements are not

activated (e.g. during a cold prewash or for cold rinses).

Page 2

19 592 0371 00

GW6290 - PROGRAM TABLE

2

VARIOUS NOTES

WATER FILLING: at each step corresponds a load of water. The quantity are specified in the table.

GW6290

40 liters

PHASE NUMBERING: the display of the machine, during the progression of the cycle, provides information on the various stages in progress. The first phase assumes the identity of

"Phase 1", the second phase "Phase 2", etc.

CYCLE TIME: the stated time (on the display) for the complete cycle is completely indicative and refers to standard test conditions: intake water pressure 3bar, cold water temperature

25°C, hot water 55°C, electrical connection 3/N/PE 400V. Pressures and temperatures lower impact on cycle duration.

PARAMETER A0

Parameter A0 is used by product standard EN ISO 15883-1 to assign a numerical value to the thermal disinfection process.

It is calculated mathematically using the formula:

z = 10°C - t = duration of time interval considered in seconds - T = load temperature in °C.

When calculating the parameter, only the time intervals during which the temperature is above 65°C are considered.

For our thermal disinfection programs, the calculation is simplified by only including the “extension” phase, when the temperature is kept constant with reference to the target value set.

DRYING: Drying stage at the end of the cycle are present only on the models equipped with a drying system.

CHAMBER RECOVERY DRAIN: Only if installed the optional "WD-VDS": according to the default factory programs settings, the first two phases of the cycle are marked as "recovery

drain" (potentially contaminated).

FACTORY AND CUSTOM PROGRAMS

Programs from n.1 to 20 (ID_prog from 1 to 20) are defined as Factory non-editable programs.

Custom programs: programs from n. 21 to 40 (ID_prog from 21 to 40) are predisposed to be personalized, with a maximum of n.10 washing phases.

The change can be made through the touch-screen interface of the device, using the updated firmware.

If parameters are modified from the default settings, a record should be kept of the various phases and the new program settings.

ATTENTION: The editing of a washing program requires specific knowledge in relation to the load-treatment process, and to the device parameters. For this reason, the

function is protected by password.

Always proceed according to the rules in force in the place of installation: a custom program, used to process the load, must be validated according to the standards and

regulations applicable.

Consult the authorized technical service for clarification. Warning: when creating a custom program, do not include more than two thermal disinfection phases at 93°C for

10min.

SERVICE PROGRAMS

Programs 200, 201, 202, 203 are service programs, not to be used for the processing of the load.

Page 3

19 592 0371 00

GW6290 - PROGRAM TABLE

3

LABORATORY – PROGRAM TABLE

ID_prog

Laboratory programs

Prewashing / Washing / NAOH

washing

Washing / NAOH washing /

Thermo disinfection

Neutralization

Mains rinsing

Demi rinsing

Rins. Demi hot

Drying phase

H2O load

Temp °C

Extension (min)

H2O load

Temp °C

Extension (min)

H2O load

Temp °C

Extension (min)

H2O load

Temp °C

Extension (min)

H2O load

Temp °C

Extension (min)

H2O load

Temp

°C

Extension (min)

Temperature °C

Extension (min)

A0

Cycle time std

empty chamber

[min]

1

1 Prewash GW

Cold

0

5

-

11

2

2 Plastic

Cold

0 3 Cold

75 3 Hot

NC 3 Hot

NC 1 Demi

NC 1 Demi [K_TEST]

75 1 80

30

-

108

P1 P2

3

3 Glassware - quick

Hot

75 3 Hot

NC 2

Demi

NC 1 Demi [K_TEST]

75 1 80

30

-

81

P1 P2

4

4 Glassware - med.

Hot

75 5 Hot

NC 2

Demi

NC 1 Demi [K_TEST]

75 1 80

30

-

83

P1 P2

5

5 Glassware - std.

Hot

80 5 Hot

NC 2 Hot

NC 1 Demi

NC 1 Demi [K_TEST]

75 1 90

30

-

91

P1 P2

6

6 Glassware - int.

Hot

NC 3 Hot

90 3 Hot

NC 2 Hot

NC 1 Demi

NC 2 Demi [K_TEST]

75 1 100

30

1800

103

P1

P1 P2a

7

7 Glassware (blood)

Cold

3 Cold

93 3 Hot

NC 3 Hot

NC 1 Demi

NC 2 Demi [K_TEST]

75 1 100

30

3600

117

P1

P1 P2

8

8 Glassware AGAR

Hot

NC 3 Hot

93 3 Hot

NC 3 Hot

NC 1 Demi

NC 2 Demi [K_TEST]

75 1 100

30

3600

104

P1

P1 P2

9

9 AGAR Intensive

Hot

80 3 Hot

93 5 Hot

NC 2 Hot

NC 1 Demi

NC 2 Demi [K_TEST]

75 1 100

30

6000

112

P1

P3

P4

P1

P3

P4 P2

10

10 Thermal disin. GW 93°C

3'

Hot

93 3 Hot

NC 2

Demi

NC 2 Demi [K_TEST]

75 1 100

30

3600

88

P1 P2

11

11 Thermal disin. GW 93°C

10'

Hot

93

10

Hot

NC 2

Demi

NC 2 Demi [K_TEST]

75 1 100

30

12000

95

P1 P2

12

12 Thermal disin. GW int.

93°C 5'

Cold

NC 2 Cold

93 5 Hot

NC 2 Hot

NC 2 Demi

NC 1 Demi [K_TEST]

75 1 100

30

6000

120

P1

P1 P2

13

13 Thermal disin. GW int.

93°C 10'

Cold

NC 2 Cold

93

10

Hot

NC 2 Hot

NC 2 Demi

NC 1 Demi [K_TEST]

75 1 100

30

12000

123

P1

P1 P2

14

14 Stained Oil

Hot

NC 2 Hot

93 1 Hot

NC 2 Hot

NC 2 Demi

NC 1 Demi [K_TEST]

75 1 100

30

1200

102

P1

P3

P4 P2

15

15 Stained oil - int.

Hot

NC 2 Hot

93 5 Hot

NC 2 Hot

NC 2 Demi

NC 1 Demi [K_TEST]

75 1 100

30

6000

107

P1b

P1

P3

P4 P2

16

16 Oil grease

Hot

50 2 Hot

93 1 Hot

NC 2 Hot

NC 2 Demi

NC 1 Demi [K_TEST]

75 1 100

30

1200

104

P1

P3

P4

P1

P3

P4 P2

17

17 Mineral Oil

Hot

75 1 Hot

93

10

Hot

NC 2 Hot

NC 2 Demi

NC 1 Demi [K_TEST]

75 1 100

30

12000

116

P1

P3

P4

P1

P3

P4 P2

Page 4

19 592 0371 00

GW6290 - PROGRAM TABLE

4

ID_prog

Laboratory programs

Prewashing / Washing / NAOH

washing

Washing / NAOH washing /

Thermo disinfection

Neutralization

Mains rinsing

Demi rinsing

Rins. Hot demi

Drying phase

H2O load

Temp °C

Extension (min)

H2O load

Temp °C

Extension (min)

H2O load

Temp °C

Extension

(min)

H2O load

Temp °C

Extension (min)

H2O load

Temp °C

Extension (min)

H2O load

Temp °C

Extension (min)

Temperature °C

Extension (min)

A0

Cycle time std

empty chamber

[min]

18

18 Petrol

Hot

93 5 Hot

NC 2 Hot

NC 2 Demi

NC 2 Demi [K_TEST]

75 1 100

30

6000

102

P1

P3

P4 P2

19

19 Diesel

Hot

NC 3 Hot

93 1 Hot

NC 2 Hot

NC 2 Demi

NC 2 Demi [K_TEST]

75 1 100

30

1200

103

P1

P3

P4

P1

P3

P4 P2

20

20 Universal Petrol

Hot

93

10

Hot

93

10

Hot

NC 2 Hot

NC 2 Demi

NC 1 Demi [K_TEST]

75 1 100

30

12000

127

P1

P3

P4

P1

P3

P4 P2a

CUSTOM PROGRAMS

On laboratory glassware washers, all the 20 pre-set custom programs have the same structure (as shown in the table below).

Prewashing / Washing /

NAOH washing

Washing / NAOH washing / Thermo

disinfection

Neutralization

Mains rinsing

Demi rinsing

Rins. Hot demi

Drying phase

Ao

ID_prog

Custom:

Program name

H2O load

Temp °C

Extension (min)

H2O load

Temp °C

Extension (min)

H2O load

Temp °C

Extension (min)

H2O load

Temp °C

Extension (min)

H2O load

Temp °C

Extension (min)

H2O load

Temp °C

Extension (min)

Temperature °C

Extension (min)

H2O load

Temp °C

21

Custom 1

DW (32)

-

1

- - -

22

Custom 2

DW (32)

-

1

- - -

23

Custom 3

DW (32)

-

1

- - -

…

…

DW (32)

-

1

- - -

40

Custom 20

DW (32)

-

1

- - -

Page 5

19 592 0371 00

GW6290 - PROGRAM TABLE

5

SERVICE PROGRAMS

Prewashing / Washing

/ NAOH washing

Washing / NAOH washing / Thermo disinfection

Neutralization

Mains rinsing

Demi rinsing

Rins. Hot demi

Drying phase

Ao

Cycle time std

empty chamber

[min]

ID_prog

Service Programs:

Program name

H2O load

Temp °C

Extension (min)

H2O load

Temp °C

Extension (min)

H2O load

Temp °C

Extension (min)

H2O load

Temp °C

Extension (min)

H2O load

Temp °C

Extension (min)

H2O load

Temp °C

Extension (min)

Temperature °C

Extension (min)

H2O load

Temp °C

201

Drying

90

30

-

30

202

Service 1

(peristaltic pump test)

CW (10)

- 0 HW(10)

- 0

CW(10)

- 0 DW(40)

-

1

-

-

-

15

P1(20)+P3(20)+P5(20)

P2(20)

P4(20)

203

Probes calibration

(TL, TCL)

DW

93

10

CW - 3

DW

93

10

100

10

-

80

Recommended use of the service programs:

- Program "201 Drying": performs a drying step in itself - to be used if the load drying was partial / not completely effective.

- Program “202 Service 1” It performs a loading of all installed peristaltic pumps - can be used to fill the circuit of detergents in case of first installation or to check the

proper functioning of the peristaltic (detergents) pumps.

- Program "203 Probes calibration" to verify the good calibration of temperature probes in chamber.

Please note:

These programs can be disabled by the Superuser to facilitate the choice of the basic operator for the everyday programs.

Page 6

19 592 0371 00

GW6290 - PROGRAM TABLE

6

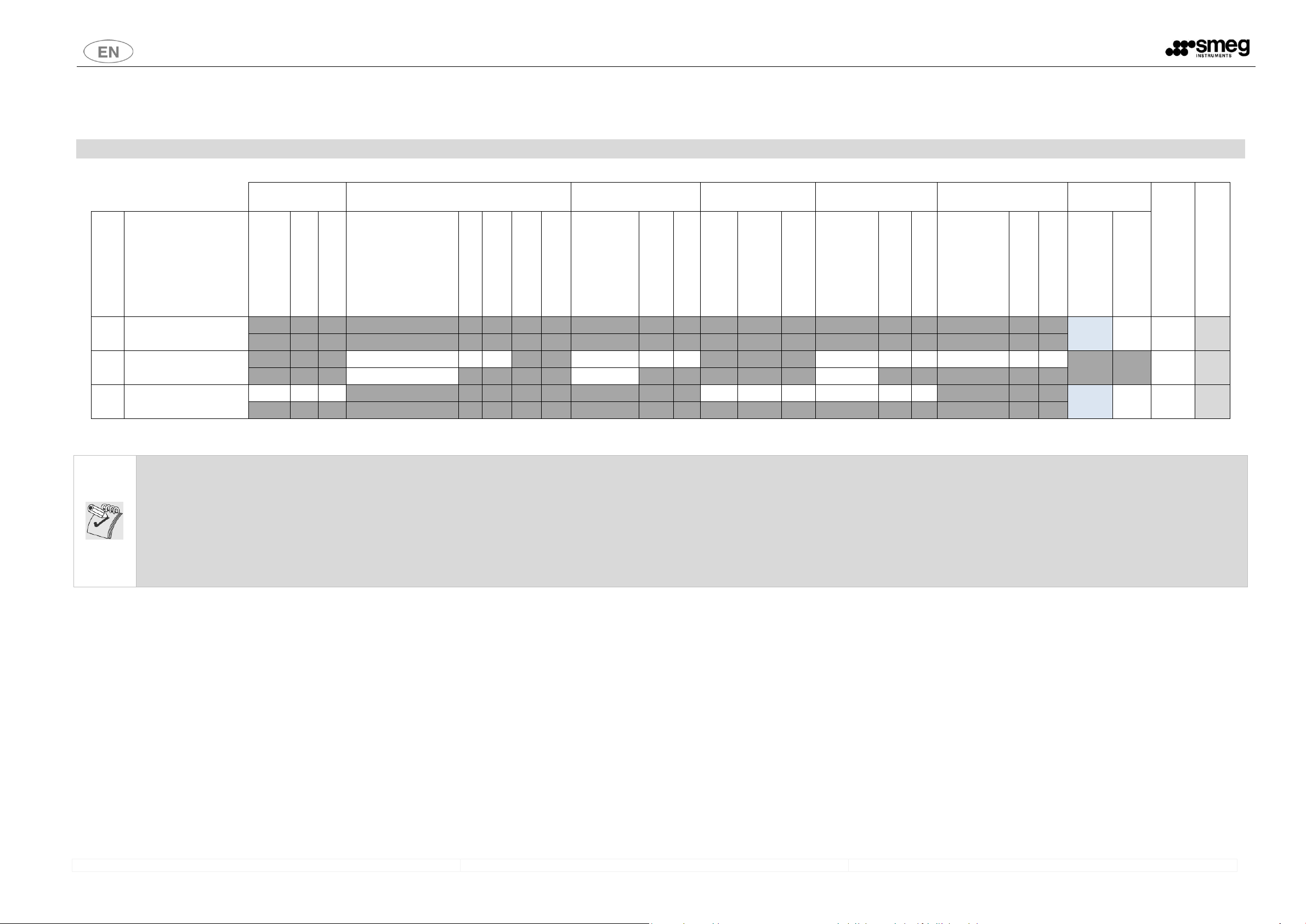

CUSTOM PROGRAM RECORD TEMPLATE

Phase 1

Phase 2

Phase 3

Phase 4

Phase 5

Phase 6

Phase 7

Phase 8

Phase 9

Phase 10

Drying

A0 value

Name

Water Filling

T target [°C]

Holding Time [min]

Water

Filling

T target [°C]

Holding Time [min]

Water Filling

T target [°C]

Holding Time [min]

Water Filling

T target [°C]

Holding Time [min]

Water Filling

T target [°C]

Holding Time [min]

Water Filling

T target [°C]

Holding Time [min]

Water Filling

T target [°C]

Holding Time [min]

Water Filling

T target [°C]

Holding Time [min]

Water Filling

T target [°C]

Holding Time [min]

Water Filling

T target [°C]

Holding Time [min]

Drying Temperature [°C]

Holding Time [min]

Page 7

19 592 0371 00

GW6290 - PROGRAM TABLE

7

19 592 0371 - EN

00

Program set cod. 16812002900

11/04/2019

First issue.

Custom program set

cod. 16 813 0007 02

Doc.

rev.

Firmware Main

Date

Note

Smeg S.p.A. - Instruments Division

Via Leonardo da Vinci, 4 – 42016 Guastalla (RE) Italy

Tel. +39 0522 8211 – Fax +39 0522 821 592

E-Mail: instruments@smeg.it - service.instruments@smeg.it

www.smeg-instruments.com

Loading...

Loading...