1

GW6090

– TABLE OF PROGRAMS –

ATTENTION

This document is complementary to the user manual of the equipment and must be used in conjunction with the manual for the correct and safe use of the device.

The laboratory programs are installed on the "GW" machines.

The programs may vary depending on the firmware version installed. Check on the machine the correspondence between the installed version and this version, as shown in the table at

the bottom of the document.

ABBREVIATIONS USED

P1, ..., P5: the acronym refers to the activation of the corresponding peristaltic pump. Each pump doses the default preset values.

Depending on the machine model you choose, some peristaltic pumps can be absent.

P5 pump is always optional.

N.C.: "NOT CONTROLLED" - refers to the stages of heating, relatively short, in which the heaters are turned on but it is not set a target value of temperature to be reached.

TD: Thermal disinfection.

INT: intense

INS: Instruments

AGG: aggressive

ENC: very dirty

Cold, Hot, Demi: cold, hot, demineralised water, the type of water used in a specific phase of the program.

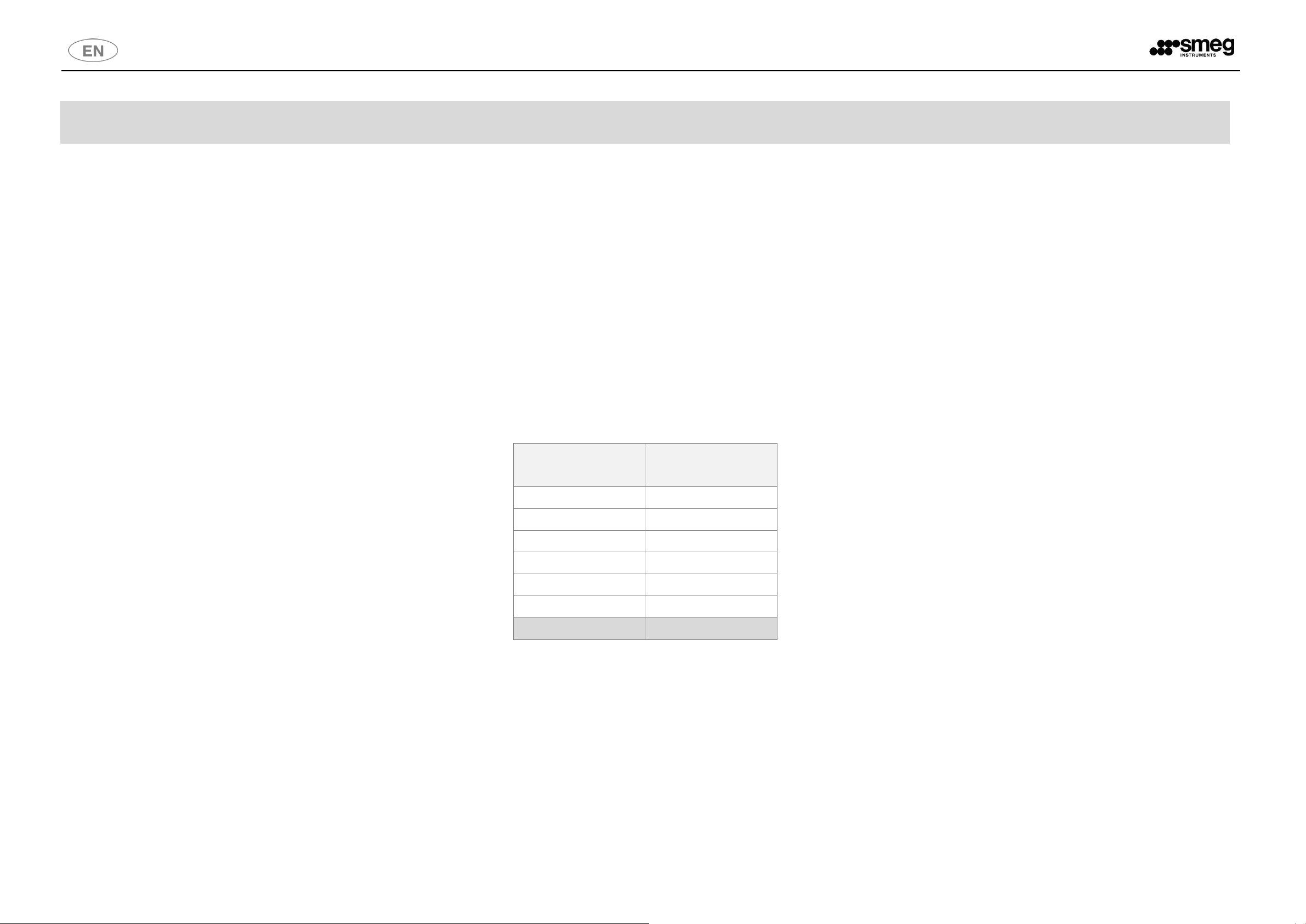

PUMP

GW - DEFAULT

VALUES [ml/liter]

P1

5

P1b

3

P2

3

P2a

4

P3

10

P4

0.4

P5

-

2

NOTES

WATER FILLING: at each step corresponds a load equal to 40 liters of water.

NUMBER OF THE PHASES: the display of the machine, during the progression of the cycle, provides information on the various stages in progress. The first phase assumes the identity of

"Phase 0", the second phase "Phase 1", etc..

CYCLE DURATION: The given duration is indicative and refers to standardized test conditions (inlet water pressure: 3 bar, cold water temperature 25 °C, electrical connection 3/N/PE 400V

50Hz). Pressures and temperatures lower impact on cycle duration. The total time reported is indicative, it can vary significantly depending on the inlet water pressure, of the total weight

of the load and of the oscillations of the mains voltage power supply.

DRYING: Drying stage at the end of the cycle are present only on the models equipped with a drying system, “DS” models.

A0 PARAMETER

A0 parameter is used by the international standard UNI EN ISO 15883-1 in order to associate a numerical value to the disinfection performed.

z = 10°C - t = time in seconds - T = temperature °C.

For the calculation of the parameter, the 15883 standard considers only the intervals at which the temperature is greater than 65 °C.

For thermal disinfection programs the calculation is simplified by counting only the "extension" phase, where the temperature is kept constantly around the target value set.

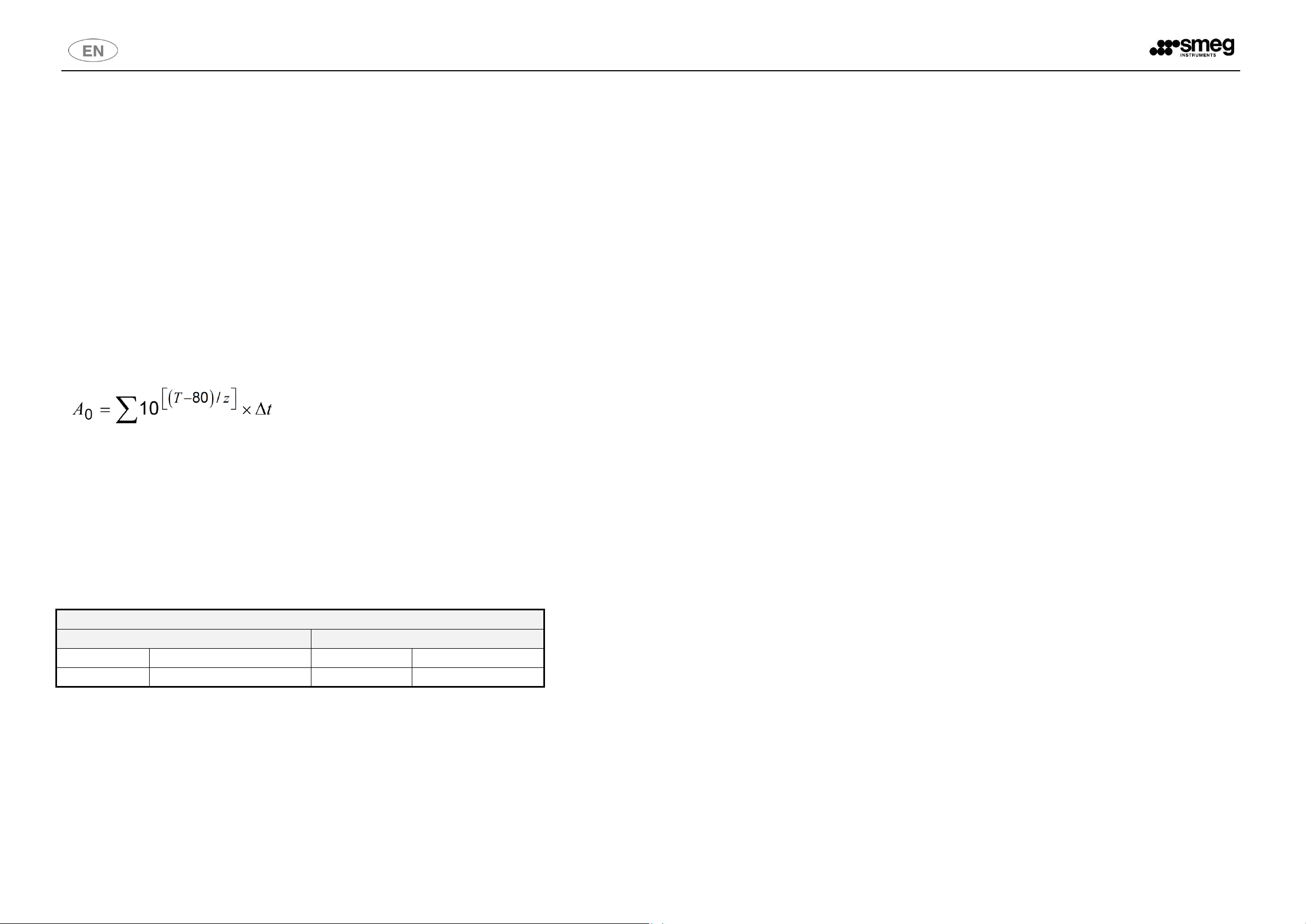

The drying phase meets the requirements of the standard when the following minimum requirements are met.

Greater values in the extension time and / or temperature are to be considered as improvements.

Times and temperatures lower than those listed here do not guarantee the compliance of the drying phase to the regulatory requirements (ref. par. 6.12 standard 15883-1).

Drying parameters, Time and temperature

Thermodisinfections at 90°C or 93°C

Thermodisinfection at 80°C

T [°C]

110

T [°C]

110

t [minutes]

35

t [minutes]

45

The values refer to a dry test load of 30kg properly positioned, with no overlapping of instruments (ref. M12x100 stainless hex head screws, see Section 6.3.2.2 EN ISO 15883-2).

The drying is only available on "DS" models (eg. WD6090DS).

The total cycle time shown is indicative, can vary significantly depending on the incoming water pressure, the total weight of the load and fluctuations in the mains voltage. The times

refer to the conditions listed in the operating instruction manual, empty chamber.

3

Prewash / Washing / NAOH

Washing

Washing / NAOH Washing /

Thermodisinfection

Neutralization

Mains water Rinse

Demi Rinse

Hot Demi Rinse

Drying

GW

LABORATORY

PROGRAMS

Load H2O

Temp °C

Extension

[min]

Load H2O

Temp °C

Extension

[min]

Load H2O

Temp °C

Extension

[min]

Load H2O

Temp °C

Extension

[min]

Load H2O

Temp °C

Extension

[min]

Load H2O

Temp °C

Extension

[min]

Temperture

°C

Extension

[min]

Ao

CYCLE

DURATION

[min]

1 PREWASH

Cold

0 5

-

9

2 PLASTIC WASH

Cold

0 3 Cold

75 3 Hot

NC 3 Hot

NC

1

Demi

NC

1

Demi

75 1 80

30

-

116

P1 P2

3 GLSW.QK.WASH

Hot

75 3 Hot

NC 2

Demi

NC

1

Demi

75 1 80

30

-

95

P1 P2

4 GLSW.MD.WASH

Hot

75 5 Hot

NC 2

Demi

NC

1

Demi

75 1 80

30

-

93

P1 P2

5 GLSW.STNDARD

Hot

80 5 Hot

NC 2 Hot

NC

1

Demi

NC

1

Demi

75 1 90

30

-

102

P1 P2

6 GLSW.INTENS

Hot

NC 3 Hot

90 3 Hot

NC 2 Hot

NC

1

Demi

NC

2

Demi

75 1 100

30

1800

112

P1

P1 P2a

7 BLOOD GLSW.

Cold

3 Cold

93 3 Hot

NC 3 Hot

NC

1

Demi

NC

2

Demi

75 1 100

30

3600

126

P1

P1 P2

8 AGAR GLSWARE

Hot

NC 3 Hot

93 3 Hot

NC 3 Hot

NC

1

Demi

NC

2

Demi

75 1 100

30

3600

114

P1

P1 P2

9 AGAR INTENS.

Hot

80 3 Hot

93 5 Hot

NC 2 Hot

NC

1

Demi

NC

2

Demi

75 1 100

30

6000

121

P1

P3

P4

P1

P3

P4 P2

10 TD 93C 3'

Hot

93 3 Hot

NC 2

Demi

NC

2

Demi

75 1 100

30

3600

96

P1 P2

11 TD 93C 10'

Hot

93

10

Hot

NC 2

Demi

NC

2

Demi

75 1 100

30

12000

106

P1 P2

12 INT T.93C5'

Cold

NC 2 Cold

93 5 Hot

NC 2 Hot

NC

2

Demi

NC

1

Demi

75 1 100

30

6000

128

P1

P1 P2

13 INT T.93C10

Cold

NC 2 Cold

93

10

Hot

NC 2 Hot

NC

2

Demi

NC

1

Demi

75 1 100

30

12000

137

P1

P1 P2

14 STAINED OIL

Hot

NC 2 Hot

93 1 Hot

NC 2 Hot

NC

2

Demi

NC

1

Demi

75 1 100

30

1200

111

P1

P3

P4 P2

15 INT.STN.OIL

Hot

NC 2 Hot

93 5 Hot

NC 2 Hot

NC

2

Demi

NC

1

Demi

75 1 100

30

6000

116

P1b

P1

P3

P4 P2

16 OIL-GREASE

Hot

50 2 Hot

93 1 Hot

NC 2 Hot

NC

2

Demi

NC

1

Demi

75 1 100

30

1200

112

P1

P3

P4

P1

P3

P4 P2

17 MINERAL OIL

Hot

75 1 Hot

93

10

Hot

NC 2 Hot

NC

2

Demi

NC

1

Demi

75 1 100

30

12000

129

P1

P3

P4

P1

P3

P4 P2

18 PETROL

Hot

93 5 Hot

NC 2 Hot

NC

2

Demi

NC

2

Demi

75 1 100

30

6000

109

P1

P3

P4 P2

19 DIESEL

Hot

NC 3 Hot

93 1 Hot

NC 2 Hot

NC

2

Demi

NC

2

Demi

75 1 100

30

1200

114

P1

P3

P4

P1

P3

P4 P2

20 PETROL UNIV

Hot

93

10

Hot

93

10

Hot

NC 2 Hot

NC

2

Demi

NC

1

Demi

75 1 100

30

12000

137

P1

P3

P4

P1

P3

P4 P2a

19592035500 – EN

7.7.6 – 13/05/2015

31/03/2016

Rev.

Firmware Master

Date

Smeg S.p.A.

Instruments Division

Via Leonardo da Vinci, 4 – 42016 Guastalla (R.E.) - Italy

Tel +39 0522 8211 – Fax +39 0522 821 592

E-mail: instruments@smeg.it – www.smeg-instruments.com

Loading...

Loading...