Page 1

19510091200 Fogl.IT-EN DIS.6010 - 20150731

Smeg S.p.A. - Instruments Division - instruments@smeg.it

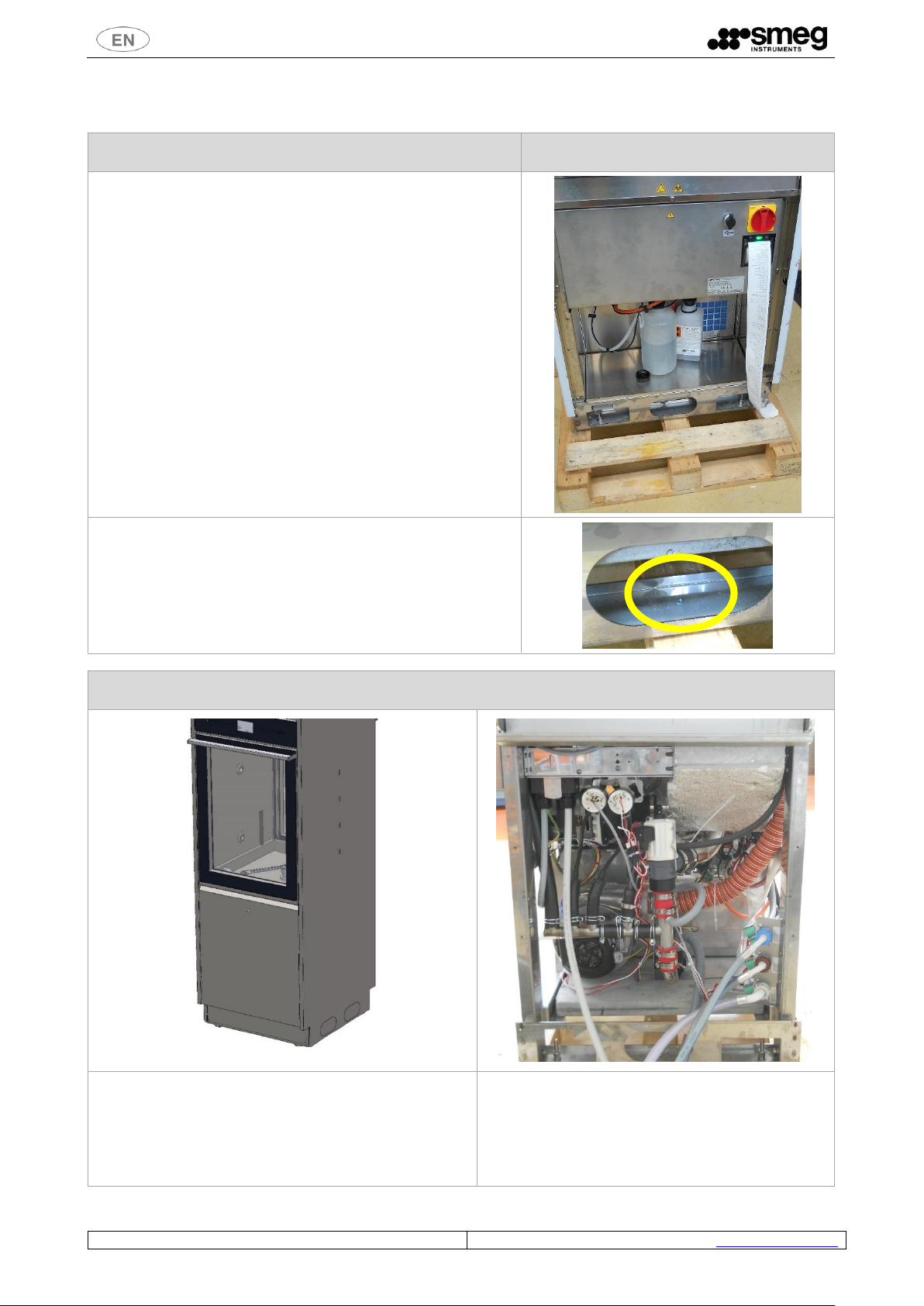

First operations

Images

When moving the appliance around, a forklift truck must be used.

Before leaving the factory, the base of the appliance is secured to

a pallet, which is used for lifting and transporting it.

Do not use appliances which have been damaged in transit!

Open the lower metallic panels (both the loading side and the

unloading side) to have access to the fixing screws.

The fixing screws to the pallet, both on the loading side ("unclean

side") that on the unloading side ("clean side"), must be

unscrewed in order to remove the machine from the pallet.

Access to the power cord and water connections

“Double door” machine: The lower metal door, on the

"clean side" (unloading side), must be removed to access

the water connections and the power cord. Loosen the

screws, then remove the lower doors.

“Single door” machine: the back metal panel has to be

removed to gain access to the connections.

Remove the backside metal door, on the left side: the

power cord of the device.

WD6010 – GW6010

GETTING STARTED – REFER TO THE INSTRUCTION MANUAL FOR COMPLETENESS

Page 2

19510091200 Fogl.IT-EN DIS.6010 - 20150731

Smeg S.p.A. - Instruments Division - instruments@smeg.it

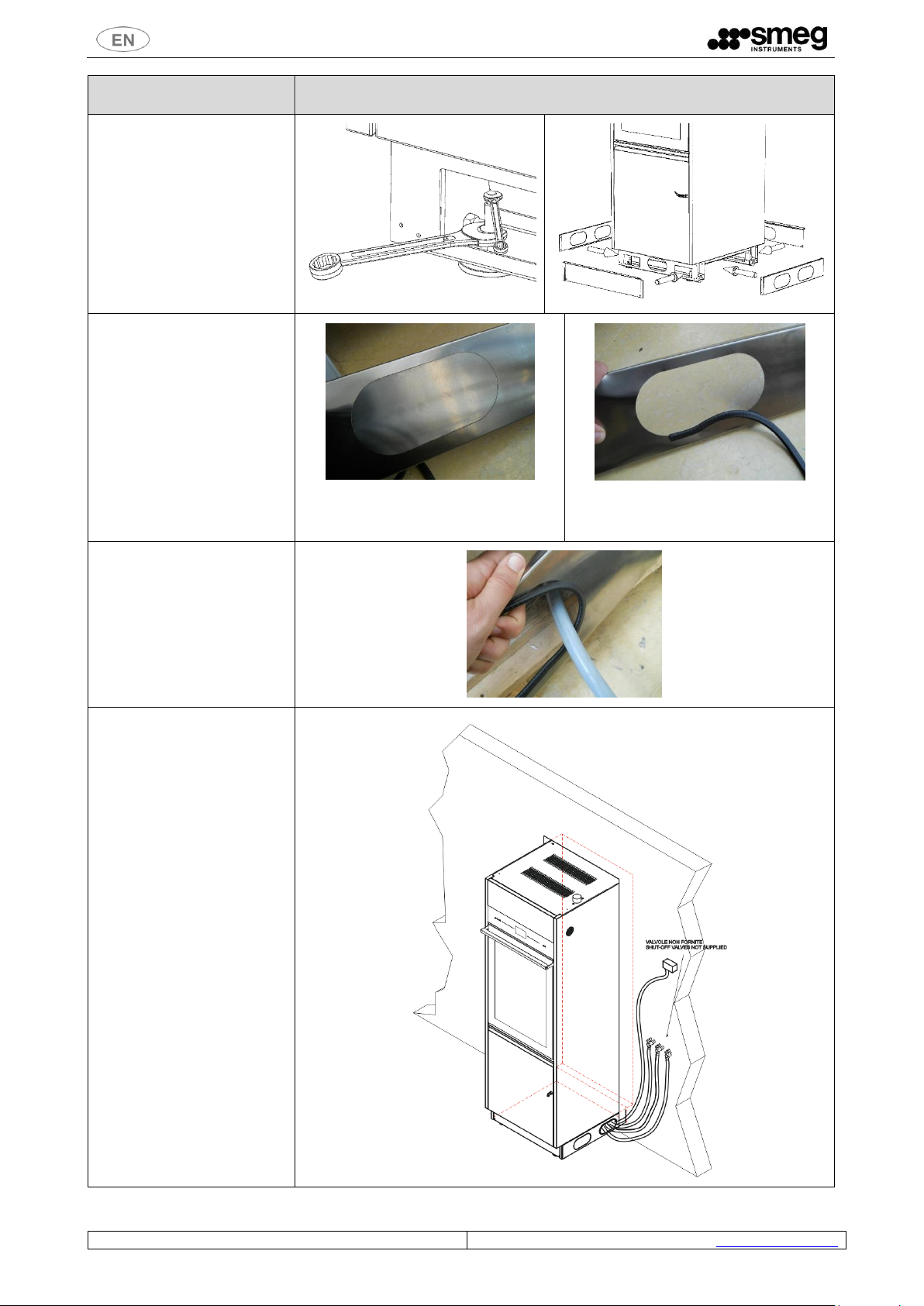

Description first steps and

key elements

Images

Adjustment and fixing of the

feet for leveling of the device.

Lower metal panels

application, to be fixed with

screws.

Lower metal panels: “presheared” for the water

loading pipes, water

discharge pipe and power

cord.

After removing the

preblanking: use protection

rubber on metal rim to

protect the tubes that can be

cut.

The pipes and cables must be

positioned correctly, using

the rubber protection on

sharp metal edges.

Example of correct

positioning of the pipes and

of the power cord.

The device doors are

equipped with automatic

door locking system: do not

force the door manually,

refer to the instruction

manual.

Loading...

Loading...