Smeg GW4190 Installation manual [GB]

Rev. 19 561 0151 08 - EN

1 - 18

INSTALLATION REQUIREMENTS

SMEG S.p.A. thanks you for having chosen this product.

In a constant quest for complete Customer satisfaction throughout the lifecycle of the product,

SMEG S.p.A. ensures the start-up and after sales service of its machines across the National territory by

SMEG Authorized Centers.

Preliminary operations for Start-up, at Customer's care:

any necessary work of room preparation

prearrangement of properly operating systems, in compliance with the requirements and

regulations in force

machine positioning

Refer to the instructions in this manual for detailed instructions on the above.

SMEG S.p.A. disclaims any liability for damage to persons or property resulting from defective systems or

not compliant with the regulations, for improper installation of the appliance and/or accessories made by

unauthorized personnel.

Any operation on the appliance by unauthorized personnel will invalidate the warranty.

08

26/02/2020

Update of environmental conditions and references to backflow devices.

06

10/12/2019

WD1160P4, WD4060P4 dimensions. GW6290 air vent prescriptions.

REV. DOC.

DATE

NOTES

REQUEST FOR START-UP

Rev. 19 561 0151 08 - EN

2 - 18

CONTENTS

INSTALLATION REQUIREMENTS .................................................................................................................................................... 3

1 PRODUCT DIMENSIONS – UNITS IN mm ................................................................................................................................ 3

2 AMBIENT CONDITIONS ........................................................................................................................................................... 5

3 MACHINE POSITIONING ......................................................................................................................................................... 5

4 ELECTRICAL SYSTEM REQUIREMENTS .................................................................................................................................... 7

5 HYDRAULIC ARRANGEMENT ................................................................................................................................................ 10

5.1 WATER FILLING ........................................................................................................................................................... 10

5.1.1 WATER INLETS CONNECTION ................................................................................................................................. 10

5.1.2 FILLING TAPS POSITIONING .................................................................................................................................... 11

5.1.3 SYSTEM REQUIREMENTS ........................................................................................................................................ 12

5.1.4 CHARACTERISTICS OF WATER SUPPLY.................................................................................................................... 12

5.1.5 “PAD” ACCESSORY FOR DEMINERALIZED WATER NOT UNDER PRESSURE ............................................................ 13

5.2 WATER DRAIN ............................................................................................................................................................. 15

5.3 STEAM DRAIN CONNECTION – GW6290 MODELS ONLY ............................................................................................ 17

REQUEST FOR START-UP

Rev. 19 561 0151 08 - EN

3 - 18

INSTALLATION REQUIREMENTS

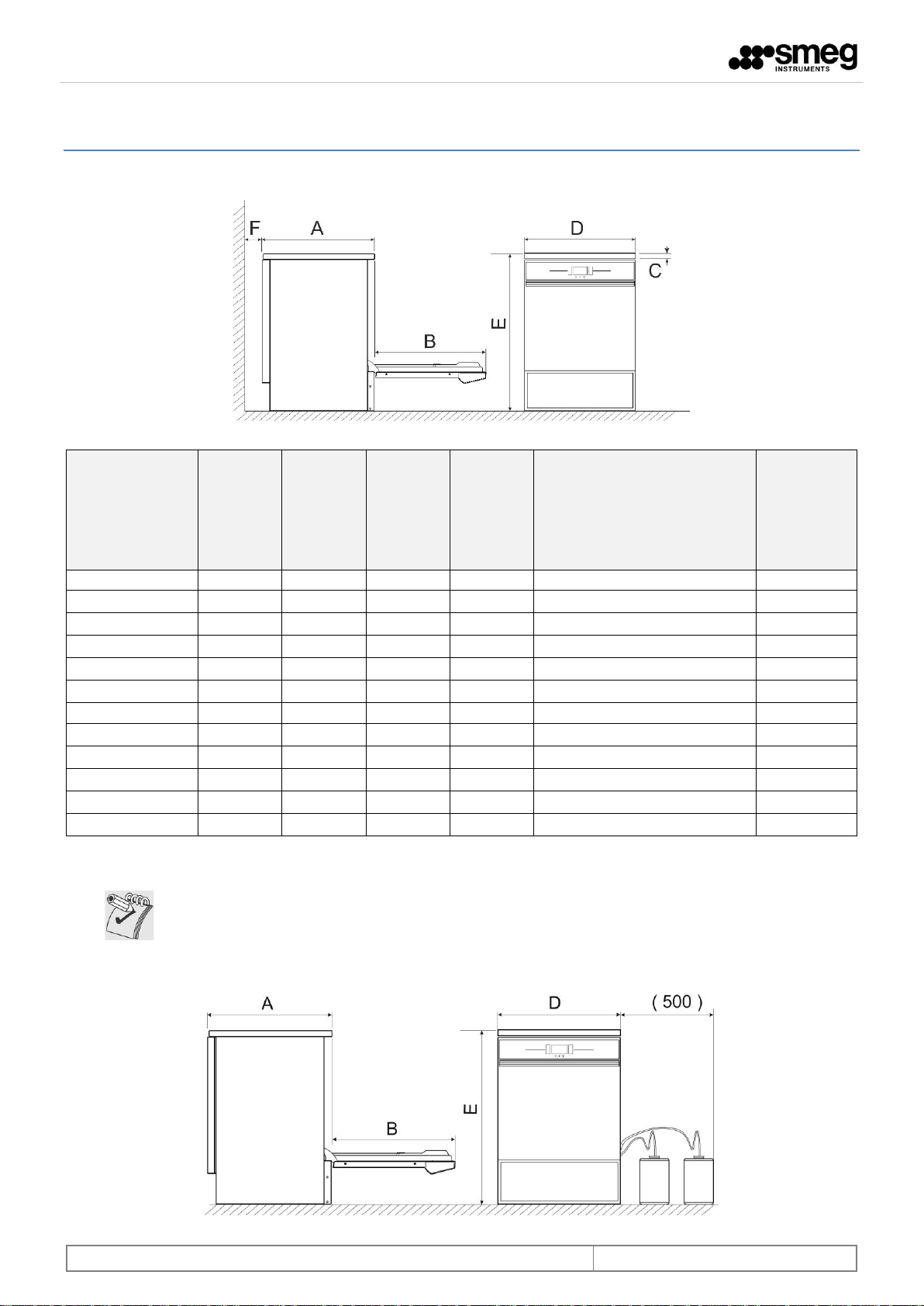

1 PRODUCT DIMENSIONS – UNITS IN mm

fig. 1 – Schematic drawing 45CM and 60CM, overall dimensions of the product

FAMILY

A B C

D

E

(in brackets the height with built-in top)

[Only for the GW0160, GW1160,

GW4060, WD1160, WD4060 series: the

height, with the optional “Aquastop

system”, is indicated between square

brackets]

F

GW2145

620

600

30

450

850 (830)

> 10

GW0160

600

600

30

600

850 (820) [857]

> 10

GW1160

600

600

30

600

850 (820) [857]

> 10

GW3060

640

600

30

600

850 (820)

> 10

GW4060

600

600

30

600

850 (820) [857]

> 10

PW4060

600

600

30

600

850 (820) [857]

> 10

WD2145

620

600

30

450

850 (830)

> 10

WD1160

600

600

30

600

850 (820) [857]

> 10

WD1160P4

660

600

30

600

850 (820) [857]

> 10

WD3060

640

600

30

600

850 (820)

> 10

WD4060

600

600

30

600

850 (820) [857]

> 10

WD4060P4

660

600

30

600

850 (820) [857]

> 10

Note:

For all devices that are not equipped with the cabinet for detergents jerry cans, you must consider

an extra space for lateral positioning of the detergents (the jerry cans can be positioned both left

and right of the device).

See the image below - guideline for n.2 jerry cans.

REQUEST FOR START-UP

Rev. 19 561 0151 08 - EN

4 - 18

fig. 2 – Schematic drawing GW4090 and WD5090 overall dimensions of the product 90CM.

FAMILY

A B C

D1

D2

E

(in brackets the

height with built-

in top)

F

GW4090

640

600

30

900

600

850 (820)

> 10

GW4190

600

600

30

900

600

850 (820)

> 10

WD4190

600

600

30

900

600

850 (820)

> 10

WD5090

640

600

30

900

600

850 (820)

> 10

fig. 3 – Schematic drawing GW6290, overall dimensions of the product

FAMILY

A B C

D1

D2

E

F

GW6290DS

800

980

245

900

754

1950

> 10

REQUEST FOR START-UP

Rev. 19 561 0151 08 - EN

5 - 18

2 AMBIENT CONDITIONS

AMBIENT CONDITIONS

USE

Indoor

ALTITUDE

Up to 1000m

AMBIENT TEMPERATURE

From 5°C to 40°C

MINIMUM LIGHTING LEVEL

REQUIRED

300 lx

MAX RELATIVE HUMIDITY

80% for temperatures up to 31°C with linear decrease to 50% at the

temperature of 40°C

INSTALLATION CATEGORY (OR

SURGE CATEGORY or

INSTALLATION CATEGORY)

II

ELECTRICAL INSULATION CLASS

(ref. IEC 61140)

I

DEGREE OF POLLUTION

2

MODEL

GW2145,

WD2145

GW0160, GW1160, WD1160,

GW4060, WD4060, PW4060,

GW4190, WD4190

GW3060, GW4090, WD5090

GW6290

HEAT EMISSION INTO THE ROOM CYCLE RUNNING

(Assessed considering a cycle containing a

93°C thermal disinfection cycle - not

including the heat emitted by the steam

vent)

600 W

(2050

BTU/h)

900 W

( 3070 BTU/hr )

1000 W

(3400 BTU/h)

3 MACHINE POSITIONING

IMPORTANT

The machine must be positioned with its back against a wall (minimum distance 10 mm) and must be installed by an authorized

SMEG technician. The machine, when suitably prepared, can be placed under a work top

The technician who installs the machine is responsible for the appliance correct operation after it has been installed. The

technician must also provide all the necessary information to the user for correct use.

During installation, it is necessary to remove the scratchproof film on the outer steel surfaces.

The kit of installation accessories (seals and clamps) is located inside the wash chamber.

The machine can be placed up against the sides to the adjacent units, taking care to leave free venting of the steam on the

back: it is therefore advisable that the wall at the back is made of brickwork or some other impermeable material.

Furthermore ensure the heat does not reach any electrical circuits or sockets on the back of the appliance.

The machine is equipped with hoses to supply and drain off the water. These can be positioned towards the right or left,

depending on the installation requirements.

LEVELLING

After positioning the machine, adjust the feet by screwing or unscrewing them in order to adjust the height and level it using

a spirit level so that it is to be horizontal (max angle tolerance allowed: 0.5°).

Correct levelling will ensure that the machine operates in the right way.

CAUTION

Any adjustment, maintenance, etc.. must be performed with the device switched off and disconnected from power sources.

LIFTING AND TRANSPORT

The base of the machine, before leaving the factory, is fixed on a pallet which serves both for lifting and for the transport.

The machine must be handled with a fork-lift truck or transpallet.

REQUEST FOR START-UP

Rev. 19 561 0151 08 - EN

6 - 18

INSTALLATION WITH BASE - MACHINE SUPPORT

If the device is installed on a support (e.g. product Smeg B6040) with height "HB" (base height), all the dimensions of the height

with respect to the support surface outlined in this document are to be increased of the same "HB" amount.

HMi = Hi + HB

Where:

Hi = generic dimension indicated in the document

HB = height of the machine base support

HMi = dimension recalculated for machine installed on the base

fig. 4 – Base Smeg B6040L.

Loading...

Loading...