Page 1

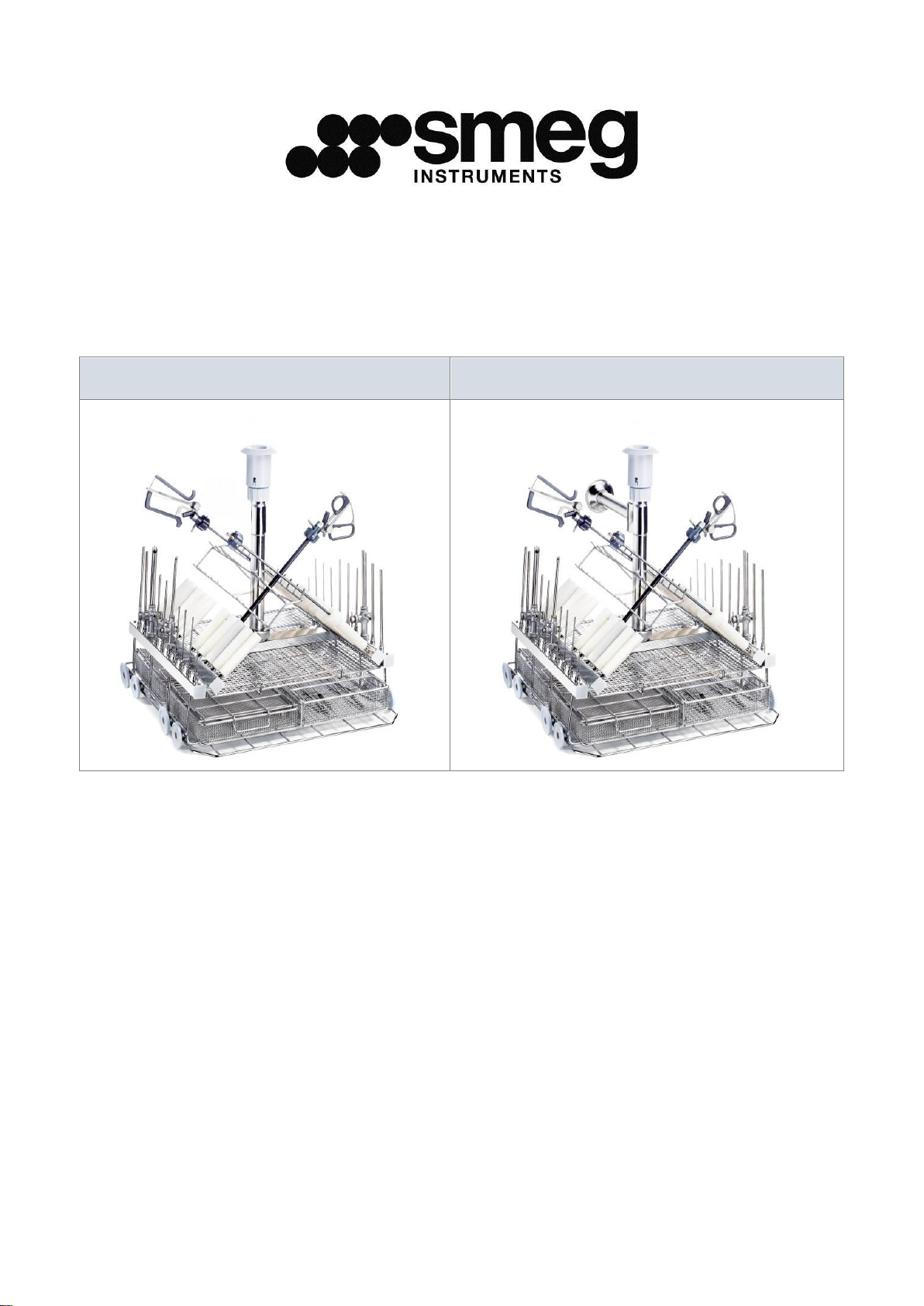

EF4

EF4DS

WASH CART FOR

THERMAL DISINFECTORS

OPERATING AND MAINTENANCE MANUAL

ORIGINAL INSTRUCTIONS

Page 2

EF4-EF4DS

OPERATING AND MAINTENANCE MANUAL

2

The manufacturer shall not be held liable for uses which are different from those specified in

this manual.

Installation, maintenance and possible repair operations must be carried out exclusively by

personnel authorized by the manufacturer.

In case the machine is used without complying with the specifications stated by the

manufacturer, its warranty might be impaired.

19 390 3425 04

23/02/2016

Rev.

Date

READ CAREFULLY

This document is related to Smeg’s devices “EF4” and “EF4DS”.

This appliance can be mounted and used exclusively on Smeg’s devices.

For a correct and safe use, this manual has to be used together with the manual of the device, instrument washer and

cart, on which the device is installed.

If not read, possible incomprehension or wrong interpretation of the instructions included in this manual might

damage the appliance, as well as represent a source of danger for the operator and considerably reduce the

machine’s performances.

The material included in this manual is meant for information. The content and the device described might be subject

to changes without any notification.

INFORMATION AND SUPPORT FOR THE PRODUCTS OF

SMEG INSTRUMENTS DEPARTMENT

Our Sales Department staff will give you information about prices and offers.

Our Technical Services Department will give you directions for a proper functioning of the appliance and will direct

you to the closest authorized service centre.

instruments@smeg.it – service.instruments@smeg.it

All of our product range can be viewed on the website:

www.smeg-instruments.com

International customers, please contact your local SMEG distributor.

Page 3

EF4-EF4DS

OPERATING AND MAINTENANCE MANUAL

3

TABLE OF CONTENTS

1 DESCRIPTION .............................................................................................................................................................. 4

1.1 DEFINITIONS ...................................................................................................................................................... 5

2 DIMENSIONS .............................................................................................................................................................. 5

3 COMPATIBILITY OF THE ACCESSORY – DEVICES ......................................................................................................... 5

4 EQUIPMENT IN THE BOX ............................................................................................................................................ 6

4.1 List the supplied parts ....................................................................................................................................... 6

5 ASSEMBLY INSTRUCTIONS ......................................................................................................................................... 7

5.1 Preliminary Operations ..................................................................................................................................... 7

6 NOZZLE ASSEMBLY DRAWING.................................................................................................................................... 7

7 ASSEMBLY SEQUENCE ................................................................................................................................................ 8

8 USE OF THE DEVICE .................................................................................................................................................. 10

9 RESOLUTION OF PROBLEMS .................................................................................................................................... 12

Page 4

EF4-EF4DS

OPERATING AND MAINTENANCE MANUAL

4

1 DESCRIPTION

The products “EF4” and “EF4DS” are wash carts which are built to process, through wash and thermal disinfection,

surgical accessories and instruments of various sizes and shapes. The carts can be used exclusively with wash devices

Smeg “WD” – washerdisinfector, tool washer for medical sector.

These are SPECIAL CARTS for MINIMALLY INVASIVE SURGERY:

Injection carts for internal wash and drying (drying only on “EF4DS”) of hollow-body instruments for minimally

invasive surgery.

Design and constructive characteristics: two external canals which have injectors and luerlock fast connectors for the

vertical placement of instruments of medium/small size, such as MIC detachable instruments.

Two internal lines of ULB connections, which are obliquely located, allow the insertion of canal instruments of large

size (maximum 500 mm of length).

The cart is equipped with:

n. 1 CSK2 half-level cart for instruments

n.2 CSMICRO1 carts for micro instruments

n. 10 ULBEF2 nozzles, threaded adapter

n. 20 ULP1 nozzles, pipette washing nozzle

n. 6 U4140 D4 L140 nozzles

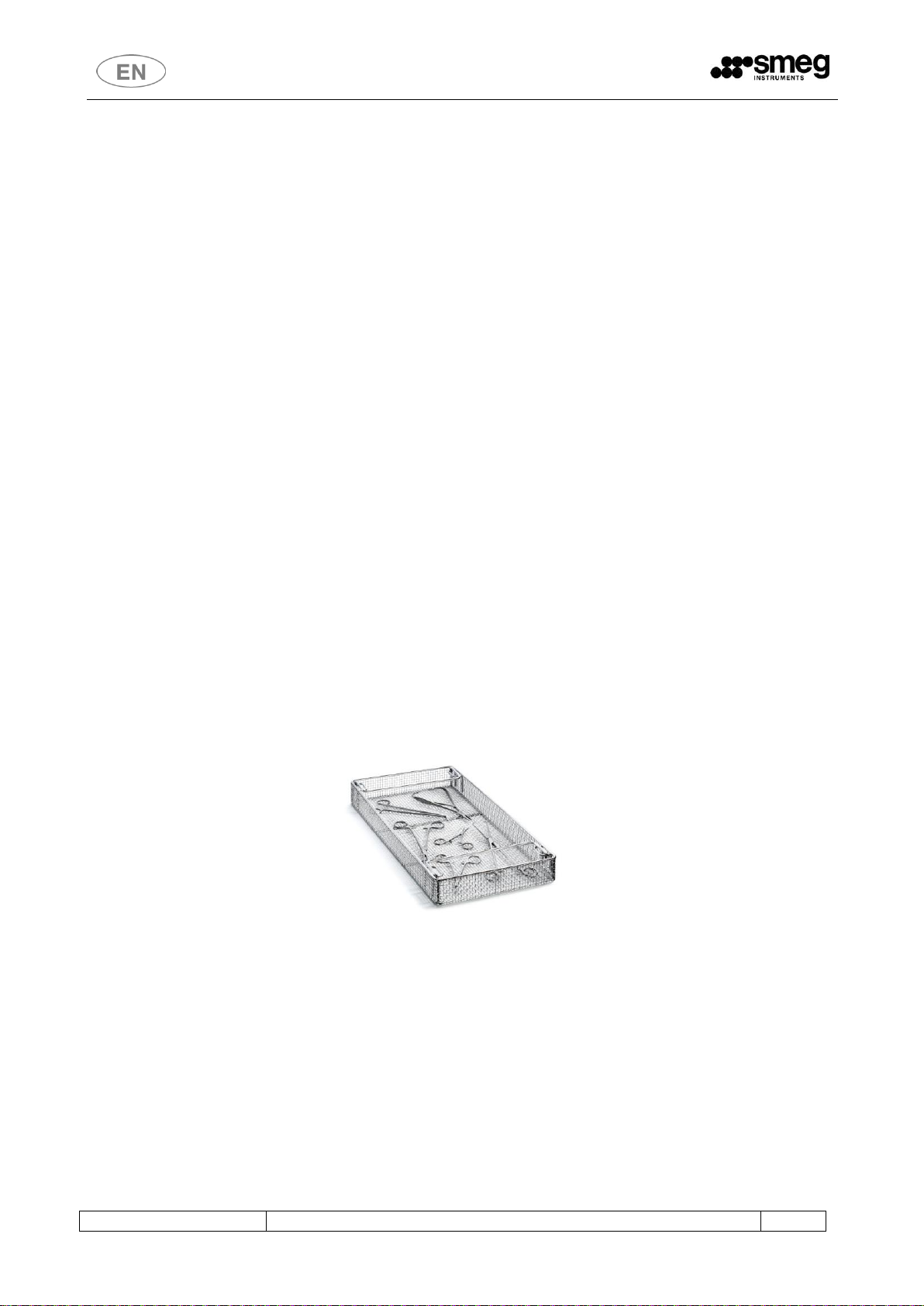

This device is built to host 1 “CSK2” cart and 2 csmics1 carts; as a reference the SMEG “CSKDIN” basket

(width x depth of the CSKDIN basket: 240 x 480 mm).

Baskets are not included in the device, you have to buy them separately. Please ask your local dealer for

information and special offers.

The cart is in two versions: EF4 and EF4DS.

- “EF4” is the cart with no manifold for the drying system air.

- “EF4DS” is the cart equipped with the manifold for the drying system air.

Figure 1 –Basket Smeg CSK2

Page 5

EF4-EF4DS

OPERATING AND MAINTENANCE MANUAL

5

EF4

EF4DS

WD RANGE – MEDICAL INSTRUMENTS WASHER

EF4

EF4DS

WD1160

WD4060

WD3060

WD4190

-

WD5090

1.1 DEFINITIONS

Cart: supporting structure, usually equipped with wheels, for the positioning of baskets which host

instruments. It is meant to insert and extract the load to be processed in the device.

Basket: container for hospital instruments, made in electro polished stainless steel wire. It can be equipped

with a lid to handle lighter instruments.

2 DIMENSIONS

3 COMPATIBILITY OF THE ACCESSORY – DEVICES

“EF4” is a cart with no manifold for the drying system air, recommended on machines with no Drying System.

“EF4DS” is a cart equipped with a manifold for drying system air, which can be used only on machines equipped with

Drying System.

The accessory can be used together with the following devices:

Page 6

EF4-EF4DS

OPERATING AND MAINTENANCE MANUAL

6

Q.ty

Description

1 CSK2 INSTRUMENT HOLDING BASKET, HALF FLOOR

2 CSMICO1 MICRO-INSTRUMENTS BASKET

20

ULP1 PIPETTE WASH NOZZLE

6 U6.170 NOZZLE D6 L170

6 U3110 NOZZLE D3 L110

6

U355 NOZZLE D3 L55

10

ULBEF2 LAPAROSCOPY NOZZLE

1 CENTRAL PIPE EF2 OR EF2DS

5 U3140 NOZZLE D3 L140

6 U4140 NOZZLE D4 L140

1 Nozzle blocking key

NOZZLE

(Ex.U4140 meaning

stainless steel noozle, D= 4mm

e H= 140mm)

ULP1

PIPETTE WASH

NOOZLE

ULBEF2

LAPAROSCOPY

NOZZLE

4 EQUIPMENT IN THE BOX

4.1 List the supplied parts

Page 7

EF4-EF4DS

OPERATING AND MAINTENANCE MANUAL

7

POSITION

NAME

1

ULP1

2

ULBEF2

3

U6170

4

U4140

5

U3110

6

U355

1

1

1

1

1

1

1

1

1

1

2

2

2

2

2

2

2

2

2

2

3

3

3

3

3

3

4

4

4

4

4

4

5

5

5

5

5

5

6

6

5 ASSEMBLY INSTRUCTIONS

5.1 Preliminary Operations

Unpack the device.

Remove, if present, cable ties from channels, sprayers or wires; they were tied to avoid shocks during

transportation

Place the cart / trolley inside the wash tank.

Perform a preliminary cycle before the effective use, with no load. Carry out a complete cycle of thermal

disinfection.

Before you process surgical instruments, consult the instructions supplied by the manufacturer of the

instruments, to verify they can undergo automatic cycles of thermal disinfection, and that they are resistant

to the temperatures reached during the washing cycle.

To avoid dirt drying on the instruments: make sure the time between the taking of the instruments and their

washing in the device is as short as possible.

During the operations of insertion and removal of the cart / trolley from the wash tank, please pay attention

not to excessively stress the product: let the cart run along the tracks and avoid bumps and carefully place

it, so that the water manifold is lined to the connections on the tank.

6 NOZZLE ASSEMBLY DRAWING

BACK

FRONT

Page 8

EF4-EF4DS

OPERATING AND MAINTENANCE MANUAL

8

Picture

Procedure

Picture 1

Insert the central pipe into its place and fasten

the ferrule so that everything is solid.

Picture 2

Picture 3

If the product is equipped with an “EF4DS”

device, you will not find the simple pipe (A) but

the pipe (B) in the box. The pipe B is mounted

as in the picture 3, e.g. facing the back of the

cart so that once it is inserted in the machine, it

fits in the air inlet (picture below).

A

B

7 ASSEMBLY SEQUENCE

Page 9

EF4-EF4DS

OPERATING AND MAINTENANCE MANUAL

9

Picture

Procedure

Picture 4

Assemble the different types of nozzles in the

positions recommended in the nozzle assembly

drawing. Fasten the nozzles with the supplied

key.

Picture 5

Carefully insert the cart in the machine, so that

the cart’s funnel is correctly positioned with the

tub’s one.

Page 10

EF4-EF4DS

OPERATING AND MAINTENANCE MANUAL

10

“CSK2” cart

Method

Insert the instruments inside the baskets so that they do

not stick out from the basket.

Instruments to be processed shall not overlap.

Instruments with joints shall be opened so that hidden

spots are reduced.

Picture

Method

Insert parts which shall be washed only externally in

the CSK2 cart (or similar one).

Place the basket in the lower part of the EF4DS cart.

The washing process is performed by the sprayer at

the bottom of the tub.

8 USE OF THE DEVICE

The following pictures are for explanatory purpose only.

Page 11

EF4-EF4DS

OPERATING AND MAINTENANCE MANUAL

11

Insert the hollow instruments, long and with small

diameter, in the vertical metallic nozzles or in the

plastic inclined ones, with silicon gasket with a

central hole.

Chose the most suitable support according to length

and diameter of the instrument to be processed

Rest long instruments on the central rack, inclined.

Page 12

EF4-EF4DS

OPERATING AND MAINTENANCE MANUAL

12

Insert trocars or other large diameter instruments in

the nozzles which have no cover nor silicon gasket.

Rest instruments on the central rack.

Silicon pipes can be washed with the metallic

vertical nozzles.

9 RESOLUTION OF PROBLEMS

In case of poor quality wash performance.

A) Verify the cleanliness of the nozzles / sprayers on the edges of the machine – according to the described

procedure.

B) Check the instructions for the correct procedure, as supplied by the manufacturer of the machinery.

C) Verify that the correct cycle has been selected.

D) Verify the functioning of the machine, check the manual.

E) Check the quantity and quality of the available detergent.

Via Leonardo da Vinci, 4 – 42016 Guastalla (RE) Italy

Tel. +39 0522 8211 – Fax +39 0522 821 592

E-Mail: instruments@smeg.it - service.instruments@smeg.it

Smeg S.p.A.

Instruments Division

www.smeg-instruments.com

Loading...

Loading...