Page 1

DEMI-One

INSTRUMENTS

Page 2

18

DEMI-One

DEMINERALIZER

User manual

INSTRUMENTS

Dear User,

We would like to thank you for purchasing our demineralizer DEMI-One.

We are pleased to provide information concerning the use of this equipment herewith.

We remind you that in order to use the demineralizer correctly, it is necessary to read

this manual carefully. All our products comply with the current safety norms and do not

involve any risk for the operator when used according to the instructions provided.

Whilst wishing you every success in your work, please note that the reproduction of this

manual is illegal and that, owing to continuous research and technological development,

the equipment specifications could change without prior notice.

Smeg Instruments

Page 3

19

Revision n° 2 User manual DEMI-One Editing: 03/2009

INSTRUMENTS

TABLE OF CONTENTS

INTRODUCTION .................................................................................................................20

GENERAL RECOMMENDATIONS ........................................................................................20

RESIN CARTRIDGES – SECURITY PRECAUTIONS ..............................................................21

INFORMATION ON WARRANTY ........................................................................................... 22

PACKAGE CONTENTS .......................................................................................................23

GENERAL NOTES ON DELIVERY .........................................................................................23

PACKAGE SIZE AND WEIGHT ............................................................................................. 23

DELIVERY CONTENT ........................................................................................................... 24

INSTALLATION AND USE ................................................................................................... 25

SYMBOLS ON THE NAMEPLATE .........................................................................................25

MOUNTING OF THE RESIN CARTRIDGES ...........................................................................26

INSTALLATION ..................................................................................................................... 27

REPLACEMENT OF THE RESIN CARTRIDGES ....................................................................28

PRECAUTIONS TO AVOID WATER CONTAMINATION ..........................................................28

OPERATION OF THE DEMINERALIZER ................................................................................28

MAINTENANCE ..................................................................................................................29

EXTERNAL CLEANING ......................................................................................................... 29

MAINTENANCE OF THE WATER BLOCK® SAFETY VALVE .................................................29

REGULAR CHECK OF THE WATER BLOCK® AND ONE-WAY VALVES ............................... 29

SPARE PART LIST ................................................................................................................ 30

TECHNICAL INFORMATION ...............................................................................................31

MAINTENANCE ISTRUCTIONS FOR THE SAFETY VALVE (WATER BLOCK®) ..............32

Page 4

20

Revision n° 2 User manual DEMI-One Editing: 03/2009

INSTRUMENTS

20

INTRODUCTION

This manual provides instructions for:

- Safe and efficient operation of the equipment

- Correct installation

- Continuous and scheduled maintenance.

The sizes mentioned in this manual are subject to change without notice.

Drawings and any other documents delivered with the equipment belong to the

manufacturer, who reserves all the rights; they cannot be made available to third

parties.

GENERAL RECOMMENDATIONS

• The equipment should be used in compliance with the procedures described in the

manual and never for purposes other than those detailed in the manual.

• The user is responsible for installing, operating and servicing the equipment in

accordance with the instructions listed in this manual.

• Only use genuine manufacturer resin cartridges dedicated for this product.

• Do not drink the water produced by DEMI-One.

• Do not block or crush the inlet or outlet pipes of the equipment or the sterilizer.

• In case the equipment is not operated according to the instructions in this manual or

is not properly maintained, the manufacturer cannot be held responsible for any fault,

damage or malfunctioning of the equipment.

• When used in conjunction with a sterilizer, replace resin cartridges immediately once

the water conductivity value exceed 15-20 μS (warning message appears on most

sterilizers) to avoid serious damage to the sterilizer.

Intended use: This manual is an integral part of the product and must be kept close to

the equipment for easy and quick reference. The equipment is to be used only for the

purpose for which it is designed.

DEMI-One: Device designed for the demineralization of drinking water and manual

supply to steam sterilizers Smeg.

Page 5

21

Revision n° 2 User manual DEMI-One Editing: 03/2009

INSTRUMENTS

English

Contact Hazards

Eye contact Irritation of the eyes (R36).

Skin contact Slight irritation of the skin.

First Aid procedures

Skin contact Take off the contaminated clothes.

contaminati. Remove the resin beads and flush the

contaminated area with water.

Eye contact Flush immediately with large amounts of

water and remove the resin beads.

Precautions in case material is spilled

People precautions Keep people away from the area of

spillage. Resin beads on the floor may

cause floor to be slippery. Take care not

to slip.

Cleaning methods Sweep the floor and transfer resin beads

to a plastic container for recovery or

disposal according to the appropriate

guidelines.

Notes for disposal

The used product is a special non hazardous waste.

The product must be disposed of in accordance with current local, regional

and country regulations.

The CER number for saturated or used ion-exchange resins used for the

production of drinking or service water is: 19 09 05.

RESIN CARTRIDGES – SECURITY PRECAUTIONS

!

Page 6

22

Revision n° 2 User manual DEMI-One Editing: 03/2009

INSTRUMENTS

The manufacturer grants warranty on your product, if used in accordance with the instructions described in

this manual, for a period of 24 months for mechanical and electrical components.

The warranty starts from the date of delivery to the customer, which must be proven by returning the

warranty form duly filled in and signed.

In case of dispute, the date on the delivery note relating to the equipment serial number will be valid. The

warranty does not cover defects or damage caused by:

• Incorrect installation

• Inadequate maintenance

• Tampering or unauthorized modifications

• Incorrect use of the equipment

• Non-compliance with the instructions included in this manual

The replacement of equipment or the extension of the warranty period because of breakdown is excluded.

Repair under warranty is carried out at judgment of the manufacturer and does not include packing and

shipment costs.

INFORMATION ON WARRANTY

DEMI-One

DEMI-One

CODE : 751202

SN : 90000D0010

IT

Questo apparecchio è stato realizzato con la massima cura di tecnici altamente specializzati. Attenersi esattamente

alle istruzioni di impiego. Guasti riconducibili a difetti dei materiali o a lavorazioni che dovessero manifestarsi nel

periodo di garanzia verranno riparati gratuitamente. L’apparecchio va inviato insieme alla cartolina di garanzia al

centro di Assistenza Tecnica Autorizzata. Utilizzare l’imballo originale o un imballo idoneo. Non si assume nessuna

responsabilità in caso di uso non conforme alle istruzioni o di spedizione in imballo non idoneo. Gli interventi di

garanzia vanno richiesti dal deposito dentale fornitore, fornendo la necessaria documentazione.

IT Purchase date :

GB Purchase date :

FR

Date de vente :

DE Verkauf Datum :

GB

The product has been manufactured with extreme care by highly qualified people. A wide variety of test and inspections guarantees fault-free operations. Please, pay particular attention to the enclosed User Manual. If deficiency

or damage occur during guarantee period which are caused by the material, these will be remedied free of charge.

The defective unit must be returned with this warranty certificates. Please request special transport packaging if

this is not available. Services under warranty are provided by the distributor or indirectly by its contractual partners.

We accept no responsibility for damage caused by improper handling or inadequate packaging during the return

of goods. Claims under warranty are submitted by the supply depot of the user to the manufacturer along with all

necessary documents

IT Distributore :

GB Supply depot :

FR

Cachet du depot :

DE Lieferdepot :

FR

Ce produit a été fabriqué avec le plus grand soin par des spécialistes hautement qualifiés. Divers contrôles et vérification garantissent un parfait fonctionnement. Veuillez lire attentivement la notice d’utilisation ci-jointe. Si des défaut

out détériorations liés au matériel apparaissent durant la période de garantie, il s seront entièrement pris en charge.

Utilisé impérativement un emballage spécial pour le transport si le carton d’origine n’est plus en votre possession.

Le frais de transport seront à la charge de l’expéditeur. Le détériorations consécutive à une mauvaise manipulation

où à un défaut d’emballage lors du retour ne seront pas prises en charge. Le demandes de prise en charge de

garantie n’interviennent pas directement entre l’utilisateur et le fabriquant. Celles-ci doivent être transmises à votre

fournisseur avec les justificatifs nécessaires.

IT Stadio medico

ospedaliero :

GB Clinic/Laboratory

address:

FR Nome t adresse

du client :

DE

Klinik/Labor adresse :

DE

Dieses Produkt wurde von hoch qualifizierten Fachleuten mit grosster Sorgfalt gefertigt. Vielfältige Prufungen und

Kontrollen garantieren eine einwandfreien Funktion. Beachten Sie bitte genau die beiliegende Gebrauchsanweisung. Sollten innerhalb der Garantie frist Mangel und Schade auftreten, die auf das Material zuruckzufuhren sind,

werden diese kostenlos behoben. Das defekte gerat muss mit diese Garantieschein eingesandt werden. Bitte

Spezial Transportverpackung anfordern, falls Originalverpackung nicht mehr verfügbar. Die Garantieleistung erfolgt

mittelbar durch das Lieferdepot oder unmittelbar durch deren Vertragspartner. Fur Schaden durch unsachgemasse

Behandlung oder unzureichende Verpackung bei der Einsendung haften wir nicht. Garantianspruche werden durch

Lieferdepot des Anwenders an den Fabrikanten unter Befugung aller dafür nötigen Unterlagen.

Smeg SpA

Via L.da Vinci, 4

42016 Guastalla (RE)

Page 7

23

Revision n° 2 User manual DEMI-One Editing: 03/2009

INSTRUMENTS

English

GENERAL NOTES ON DELIVERY

Upon delivery of the equipment, check the condition of the package and keep it in case of

future needs.

Open the package and check that:

- the contents correspond to the delivery note

- there is no evidence of any damage.

In the event of damage or missing items, inform the carrier and the supplier

immediately.

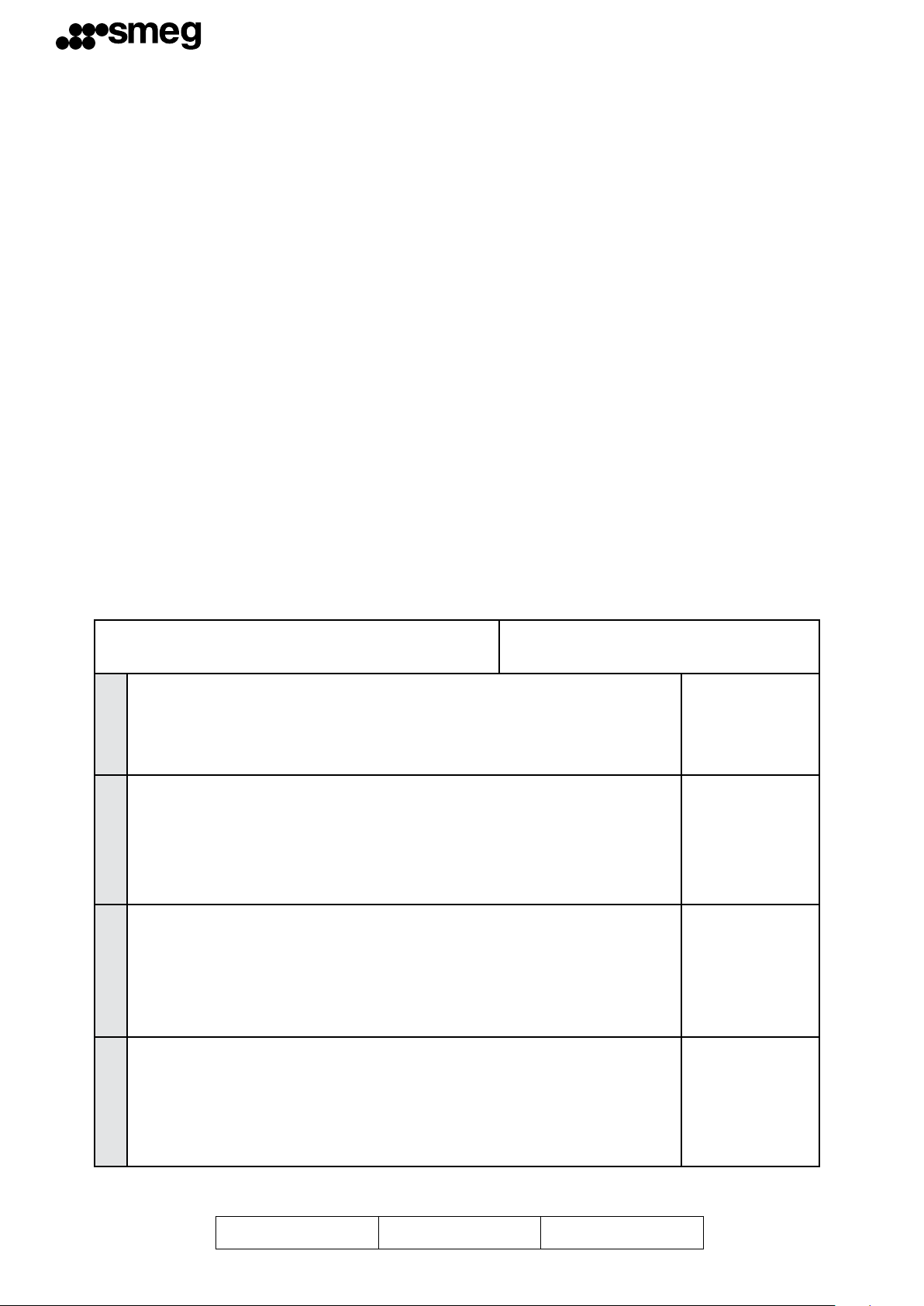

PACKAGE SIZE AND WEIGHT

Gross weight: 5 kg

Dimensions (mm)

PACKAGE CONTENTS

Page 8

24

Revision n° 2 User manual DEMI-One Editing: 03/2009

INSTRUMENTS

Item Description

1. Demineralizer

2. 2 resin cartridges + 2 sealing rings

3. Special key to replace cartridges

4. Water inlet tube (4m, Ø 6x4 mm)

5. Water Block valve (including filter and setting key)

6. Water gun

7. Warranty certificate and user manual

DELIVERY CONTENT

Figure 1

Page 9

25

Revision n° 2 User manual DEMI-One Editing: 03/2009

INSTRUMENTS

English

SYMBOLS ON THE NAMEPLATE

INSTALLATION AND USE

Model DEMI-One Code 751202

Pressure 1 ÷ 5 bar SN 90000D0010

Smeg SpA

Via L.da Vinci., 4 Made in EU

!

Model name

Tap water pressure

Manufacturer

Read the manual carefully

CE label

Product code

Serial number

Recycling symbol

Country of manufacture

Country of manufacture

Equipment provided

with protective

mechanical device

allowing only oneway water flow; in

accordance with EN

1717

Page 10

26

Revision n° 2 User manual DEMI-One Editing: 03/2009

INSTRUMENTS

1. Remove the filter head cover.

2. Remove the tubes from the two quick connectors (IN/OUT) and lift the entire

cartridge assembly from the demineralizer base.

3. Unscrew the two resin cartridge holders from the cartridge assembly by hand or

with the use of the supplied special key. Insert the two new cartridges.

4. Place the cartridge seals on the upper face side of the resin cartridges.

5. Place the o-rings in the groove of the resin cartridge holders and screw holders

onto the cartridge assembly by hand.

6. Slide the positioning rings up the cartridge holders and drop the entire cartridge

assembly onto the demineralizer base.

7. Reconnect the tubes to the quick connectors (IN/OUT).

8. Attach the filter head cover.

MOUNTING OF THE RESIN CARTRIDGES

Figure 2

Page 11

27

Revision n° 2 User manual DEMI-One Editing: 03/2009

INSTRUMENTS

English

1. Mount the security valve (Water Block®) to the tap water connection.

2. Connect the water inlet tube to the security valve and the demineralizer.

3. Connect the spiral tube to the front of the demineralizer.

WARNING

Use only original spare parts.

The Water Block® valve is fitted with a special one-way valve that prevents water from flowing back

and potentially polluting the main waterline.

For this reason the Water Block valve should be mounted vertically.

INSTALLATION

!

Page 12

28

Revision n° 2 User manual DEMI-One Editing: 03/2009

INSTRUMENTS

REPLACEMENT OF THE RESIN CARTRIDGES

When used with a sterilizer, replace the resin cartridges when the water conductivity reaches a value of 15

μS. Most sterilizers generate a display message once the water quality drops below a certain threshold.

1. Close the water supply tap at the front of the DEMI-One base.

2. Release the internal water pressure with the water gun.

3. Follow the steps as described in chapter “Mounting of the resin cartridges”.

4. Open the water supply tap.

PRECAUTIONS TO AVOID WATER CONTAMINATION

ATTENTION

In accordance with subsection 4.5 of EN1717, in order to avoid water quality

degradation and bacterial growth due to a tailback of water in the tubes, the

entire system must be drained before leaving it unused for a longer period of

time.

OPERATION OF THE DEMINERALIZER

Once installed and fitted correctly, the demineralizer is able to supply demineralized

water immediately.

ATTENTION

The demineralizer is equipped with a Water Block® valve that cuts off the water flow after a pre adjusted volume (5 liters) in order to prevent a large spillage of water in case of a broken tube.

When you take water from the demineralizer with the use of the spray gun and the volume goes

beyond 5 liters, the Water Block® valve will cut off the water supply. To reset the Water Block® valve

see hapter “Maintenance instructions for the safety valve”. To avoid a water cutoff, release the water

gun once every 30 seconds if quantities of more than 5 liters are taken from the demineralizer.

The quantity of demineralized water produced per set of resin cartridges depends on the quality and

hardness of the city water in your area. Refer to the table below for further details:

Conductivity of the tap water ( μS/cm ) Litres produced

!

!

Page 13

29

Revision n° 2 User manual DEMI-One Editing: 03/2009

INSTRUMENTS

English

MAINTENANCE

EXTERNAL CLEANING

Clean with a damp cloth using non-abrasive and non-corrosive detergents (neutral pH value).

MAINTENANCE OF THE WATER BLOCK® SAFETY VALVE

The inlet filter of the Water Block® valve should be cleaned on a regular basis, depending on the city water

quality and how often the demineralizer is used.

REGULAR CHECK OF THE WATER BLOCK® AND ONE-WAY VALVES

ATTENTION

To ensure compliance with subsection 4.6 of EN1717, have the Water Block® and the one-way valve

checked at least once a year; in case a sterilizer is attached to the system, this could be done during

the scheduled maintenance visits for the sterilizer.

It is further recommended to check all related devices fitted to the steriliser to ensure that the

hydraulic connection between demineralizer and sterilizer corresponds to category 2, in accordance

with EN 1717.

!

Page 14

30

Revision n° 2 User manual DEMI-One Editing: 03/2009

INSTRUMENTS

SPARE PART LIST

Nr Description

1

FILTER HEAD COVER

2

FILTER HEAD

3

CARTRIDGE HOLDER

4

RESIN CARTRIDGE KIT (4 CARTRIDGES + 4 SEALING RINGS + 4 O-RINGS)

5

PLASTIC KEY FOR CARTRIDGE HOLDER

6

WATER GUN

7

SPIRAL TUBE

8

TAP

9

WATER TUBE (4 m, Ø 6X4mm)

10

SECURITY VALVE (WATER BLOCK®) WITH FILTER AND ADJUSTING KEY

11

ONE WAY VALVE

12

O-RING

13

CENTERING RING

Page 15

31

Revision n° 2 User manual DEMI-One Editing: 03/2009

INSTRUMENTS

English

TECHNICAL INFORMATION

Operating temperature +5°C ÷ +30°C

Storage temperature

+5°C ÷ +35°C avoid direct sunlight and all

sources of heat

Size (WxDxH) 305x190x320 mm (LxPxH)

Weight (without cartridges) 2,8 Kg

Weight of two cartridges 1,5 Kg

Tap water pressure range 1 - 5 bar

Amount of demineralized water produced

with one set of cartridges with a conductivity value lower than 15÷20 μS

1

110÷130 liters

1

tested at: T=25°C; tap water quality 450 μS; water pressure 3 bar

Page 16

32

Revision n° 2 User manual DEMI-One Editing: 03/2009

INSTRUMENTS

MAINTENANCE ISTRUCTIONS FOR THE SAFETY VALVE

(WATER BLOCK®)

WATER BLOCK (WB) SAFETY VALVE

Indispensable device for washing machines, dishwashers and demineralizers as, under the conditions defined in the technical features

herewith described, it prevents a flow of water greater than the one for which it has been set by the adjustment pointer. This avoids

continuous leaking. The Water Block also has a particular non-return valve (antipollution). The device should be installed vertically (see

fig. 2) and following the instructions carefully.

TECHNICAL FEATURES

- Burst pressure: 500 N/cm²

- Max. static pressure: 100 N/cm²

- Max. controllable volume: about 50 lt.

- Min. operating capacity: 2 lt/min.

- Max. operating capacity: 30 lt/min

- Max. water temperature: 70° C

USER INSTRUCTIONS

WATER BLOCK should be installed between the tap and the supply hose of the demineralizer (fig. 2). Using the enclosed plastic key,

turn pointer ‘P’ (fig. 1) anticlockwise to the required setting (example, position 1,5).

CAUTION:

For use on other fixtures, set the pointer to a position suitable for that particular application, considering that each number on the scale

corresponds to a controlled volume of approx. 4-6 litres. In case of installation on fixtures which foresee dispensing of drinking water

for alimentary use it is advisable to let flow at least 10 litres of water inside the device before the connection, so as remove eventual

impurities banked during the storage.

INSTALLATION

1. Manually screw the WB to the tap having suitable thread (3/4” gas), inserting the filter

‘E’ with its convex side facing upwards (fig. 2). The WB will not operate properly if the

filter is not installed correctly. If the WB is tightened or loosened with the aid of a

wrench, the same must be applied to the appropriately octagonally shaped part of the

housing ‘A’.

2. Screw the supply hose ‘C’ to the lower end of the WB. If the supply hose is equipped

with a filter, the latter must be substituted by a flat rubber washer ‘F’. If the said hose

has to be tightened or loosened with the aid of a wrench, the same must be applied to

the appropriately octagonally shaped part of the WB housing ‘B’ so as to hold it firmly

while performing this operation. If a failure occurs causing a continuous water leak,

the WB will shut off when the volume of water flowing through equals the amount to

which it was previously set with the pointer ‘P’. To reset the Water Block again after

it has shut off, turn the tap off and carry out the necessary repair work. Remove the

supply hose ‘C’ from the Water Block and press the coloured plunger ‘H’ which is

located inside the lower housing of the device itself (fig. 1). It may be difficult to press

this plunger if there is high pressure at the inlet side of the WB. In this case, slacken the

device from the tap: the plunger ‘H’ can then be pressed with ease. Repeat the

operation as described in the section headed ‘Installation’.

CAUTION:

To avoid any possible damage that may be caused by water freezing inside the WB after its

installation, the ambient temperature should never be below 2° C. We decline all responsibility

deriving from the incorrect use of the WB or from its use for applications and/or solutions not

expressly foreseen by the above instructions.

MAINTENANCE:

Depending on the conditions and frequency of usage of the water block, it is recommended to clean out the inlet filter ‘E’

periodically and to replace the seal ‘F’.We reserve the right to modify any features without prior notice.

Page 17

33

Revision n° 2 User manual DEMI-One Editing: 03/2009

INSTRUMENTS

English

Do you need information or assistance for Smeg Instruments products?

You can reach us every day from 8:00 to 18:00:

Tel +39 0522-8211

Fax +39 0522-821592

instruments@smeg.it

www.smeg-instruments.com

Our Sales Department will inform you about prices and sales offers. You can also visit our website in order

to see the complete range of products.

Our Assistance department will inform you about the correct functioning of our products and will put you in

contact with the nearest Smeg Assistance centre.

Alternatively please contact your local SMEG Distributor on our website:

www.smeg-instruments.com

Page 18

Smeg SpA

via L.da Vinci,4

Instruments Division

via Circonvallazione, 36 - 42016 Guastalla (RE)

Tel. +39 0522 8211 - Fax +39 0522 821 592

E-mail: instruments@smeg.it - www.smeg-instruments.com

Loading...

Loading...