Page 1

TABLE OF CONTENTS

1 PRECAUTIONS FOR SAFETY AND USE ........................................................................... 3

2 TECHNICAL DATA ......................................................................................................... 4

3 INSTALLATION AND POSITIONING................................................................................ 6

4 INSTRUCTIONS FOR TECHNICAL STAFF ......................................................................... 7

4.1 lumbing hookup ..................................................................................................... 7

4.2 Electrical connection .............................................................................................. 8

5 FIRST START-UP............................................................................................................ 9

5.1 Using the water softener (on models with this feature only) ................................. 9

6 SET-UP ....................................................................................................................... 10

6.1 Glasswasher parameter modification procedure: ................................................ 10

6.2 Quit “SET-UP” menu ............................................................................................ 12

6.3 Rinsing temperature setup .................................................................................. 13

6.4 Washing temperature setup ................................................................................ 13

6.5 Rinse aid dispensing setup ................................................................................... 13

6.6 Detergent dispensing setup ................................................................................. 13

6.7 Autostart function ............................................................................................... 14

6.8 Regeneration frequency setup (models with softener) ........................................ 14

6.9 tStP (minimum rinsing temperature) function ..................................................... 15

6.10 Rinse aid pump (display and if required reset during maintenance) ................ 15

6.11 Detergent pump (display and if required reset during maintenance) .............. 15

6.12 Energy consumption – Display and reset if required ......................................... 16

6.13 Customisation of duration of program P4. ........................................................ 16

6.14 Service setting (for After-Sales Service only) ..................................................... 16

6.15 Starting the peristaltic pumps – rapid filling of detergent and rinse aid delivery

circuit. 16

7 MALFUNCTIONS SHOWN ON THE DISPLAY (FOR THE TECHNICIAN) ........................... 17

8 INSTRUCTIONS FOR THE USER ................................................................................... 19

Page 2

CWG 520-530

These are intended for the qualified staff who are to install, commission and test

the appliance and carry out any servicing and repairs.

These provide recommendations for use, a description of the controls and the

correct procedures for cleaning and maintaining the glasswasher.

8.1 Control panel ....................................................................................................... 19

8.2 Before washing .................................................................................................... 20

8.3 First use each day (tank and boiler empty) .......................................................... 20

8.4 Changing the Program ......................................................................................... 22

9 CHOOSING THE PROGRAM ........................................................................................ 22

10 SUPPLEMENTARY FUNCTIONS ................................................................................ 23

10.1 Selecting the crys“glassware” function (available in P1-P2) .............................. 23

10.2 Selecting the erin “extra rinse” function (available in P1-P2-P3-P4) ................. 23

10.3 Selecting the “sanitisation” function (only available in P3) ............................... 23

11 MAINTENANCE AND CLEANING .............................................................................. 26

11.1 Daily cleaning .................................................................................................... 26

11.2 Routine inspection of the spray arms ............................................................... 27

11.3 Lengthy periods out of use ............................................................................... 27

12 TROUBLESHOOTING ................................................................................................ 28

13 MALFUNCTIONS SHOWN ON THE DISPLAY (FOR THE USER) ................................... 29

SMEG thanks you for choosing one of its products.

Read all the instructions in this manual carefully to become familiar with the right conditions for the

proper use of your glasswasher.

TECHNICAL INSTRUCTIONS

INSTRUCTIONS FOR THE USER

2

Page 3

CWG 520-530

THIS MANUAL IS AN INTEGRAL PART OF THE GLASSWASHER AND MUST ALWAYS BE

KEPT INTACT TOGETHER WITH THE APPLIANCE.

POSITIONING, HOOKUP, COMMISSIONING, TROUBLESHOOTING AND REPLACING THE

POWER CABLE MUST ALWAYS BE CARRIED OUT BY QUALIFIED STAFF.

THE APPLIANCE MUST BE GROUNDED AS REQUIRED BY ELECTRICAL EQUIPMENT

SAFETY STANDARDS.

THE SYMBOL OF THE RUBBISH BIN WITH A BAR ACROSS IT ON THE PRODUCT OR IN THE

TECHNICAL DOCUMENTATION INDICATES THAT THIS PRODUCT MUST NOT BE TREATED

AS ORDINARY DOMESTIC WASTE BUT MUST BE CONSIGNED TO THE SPECIAL

COLLECTION POINT FOR THE RECYCLING OF ELECTRICAL AND ELECTRONIC EQUIPMENT.

NEVER PLACE SOLVENTS SUCH AS ALCOHOL OR TURPENTINE, WHICH MIGHT CAUSE AN

EXPLOSION, INSIDE THE APPLIANCE. NEVER LOAD DISHES DIRTY WITH ASH, WAX OR

PAINTS.

NEVER USE THE GLASSWASHER OR ANY PART OF IT AS A LADDER, SUPPORT OR STAND

FOR PEOPLE, ANIMALS OR ANY OBJECT. LEANING OR SITTING ON THE OPEN DOOR OF

THE GLASSWASHER MIGHT CAUSE IT TO TIP OVER, PUTTING PEOPLE IN DANGER. NEVER

LEAVE THE GLASSWASHER DOOR OPEN SINCE PEOPLE MIGHT TRIP OVER IT.

DO NOT DRINK ANY WATER LEFT IN THE DISHES OR GLASSWASHER AT THE END OF THE

WASHING PROGRAM.

THE APPLIANCE IS NOT SUITABLE FOR USE BY JUVENILES OR PERSONS WITH REDUCED

PHYSICAL, SENSORIAL OR MENTAL CAPACITIES, OR THOSE WITHOUT THE NECESSARY

KNOWLEDGE AND EXPERIENCE. SUCH PERSONS MAY ONLY USE THE APPLIANCE UNDER

THE SUPERVISION OF A PERSON RESPONSIBLE FOR THEIR SAFETY.

1 PRECAUTIONS FOR SAFETY AND USE

THE GLASSWASHER IS INTENDED FOR PROFESSIONAL USE ONLY AND MUST ONLY BE USED BY

AUTHORISED STAFF. IT IS DESIGNED TO WASH TABLEWARE (GLASS, CUPS, BOWLS, OVEN DISHES

AND CUTLERY) AND SIMILAR ITEMS IN THE RESTAURANT AND INSTITUTIONAL CATERING SECTOR,

AND COMPLIES WITH THE INTERNATIONAL STANDARDS ON ELECTRICAL AND MECHANICAL SAFETY

(CEI-EN-IEC 60335-2-58/61770) AND ELECTROMAGNETIC COMPATIBILITY (CEI-IEC-EN 55014-1/-2,

61000-3;4, 50366). THE MANUFACTURER DECLINES ALL RESPONSIBILITY FOR INJURY OR DAMAGE

CAUSED BY FAILURE TO COMPLY WITH THE INSTRUCTIONS IN THE MANUAL, BY INCORRECT USE, BY

TAMPERING WITH EVEN JUST ONE PART OF THE APPLIANCE AND BY THE USE OF NON-ORIGINAL

SPARE PARTS . THIS APPLIANCE IS TAGGED UNDER EUROPEAN DIRECTIVE 2002/96/EC ON WASTE

ELECTRICAL AND ELECTRONIC EQUIPMENT (WEE). BY MAKING SURE THAT THIS PRODUCT IS

DISPOSED OF CORRECTLY THE USER HELPS TO PREVENT POTENTIAL DETRIMENTAL EFFECTS ON

HEALTH AND THE ENVIRONMENT. WHEN DECOMMISSIONING THE APPLIANCE COMPLY WITH THE

LOCAL WASTE DISPOSAL REGULATIONS. FOR FURTHER INFORMATION ON THE TREATMENT,

RECOVERY AND RECYCLING OF THIS PRODUCT, CONTACT THE COMPETENT LOCAL OFFICE, THE

DOMESTIC WASTE COLLECTION SERVICE, OR THE SHOP WHERE THE PRODUCT WAS PURCHASED.

3

Page 4

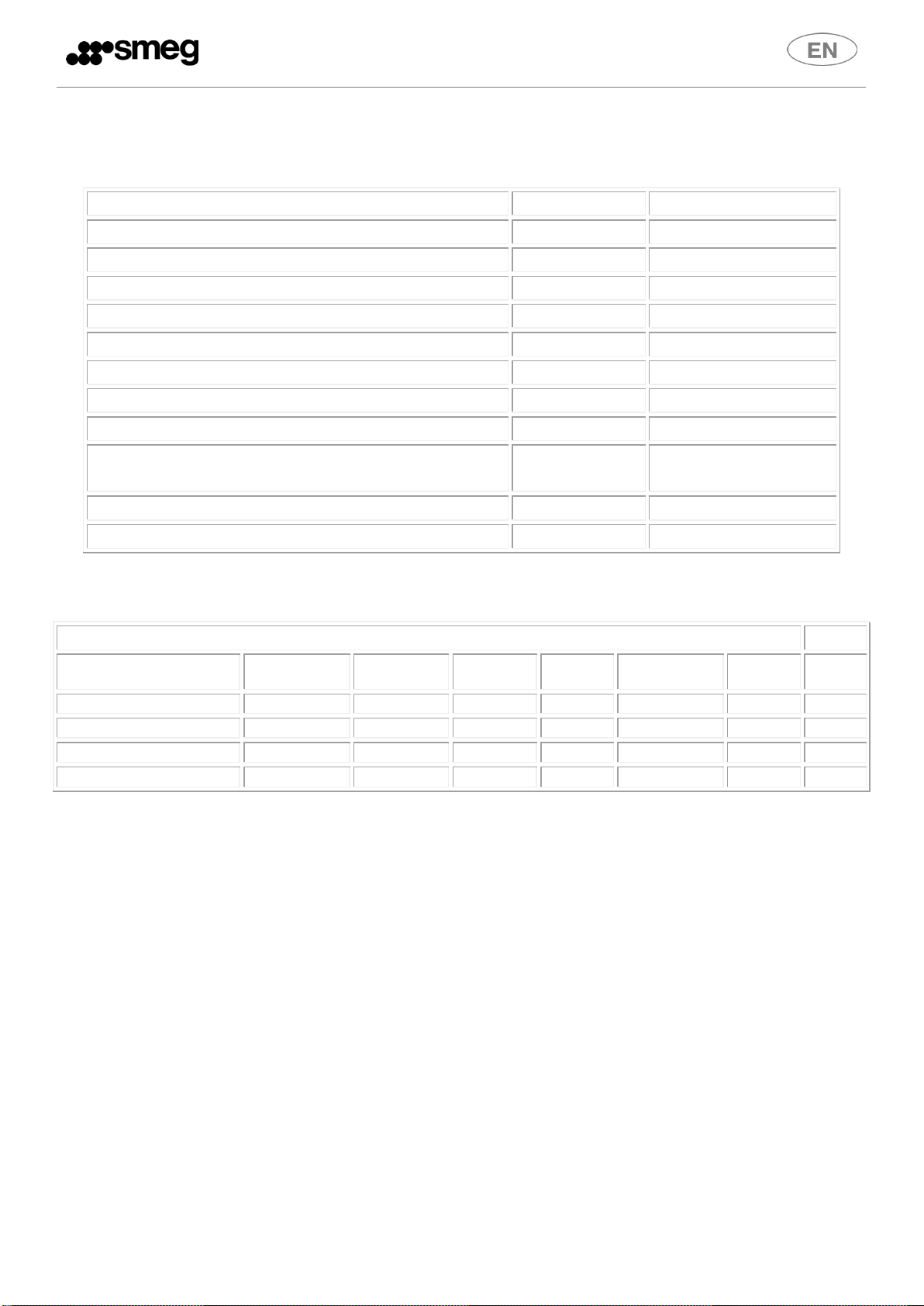

CWG 520-530

Water intake pressure

kPa (bar)

100-600 (1 ÷ 6)

Water intake temperature

°C

15°C – 60°C

Intake water hardness (models with softener)

°f

15°f-60°f

Rinse cycle water consumption

l

3.2

Boiler capacity

l

6

Tank capacity

l

11

Standard cycle duration with intake water at 50°C

s

90/150/240

Noise level

dB(A)

50

Degree of protection

IPX

4/5

Net weight

Kg

CWG 60-63

CWH 84-87

Power supply cable type

◄HAR►

H07RN-F

Fuse

A

4

SEE APPLIANCE LABEL

VOLTAGE

FUSE

PROTECTION

TANK

HEATING

MOTOR

BOILER

(1.5X3)

TOTAL

CONNECTION

Current

POWER

CABLE

400V-50Hz/3/N/PE

13A

0.8kW

0.7kW

5kW

5.7kW

11A

5X2.5

230V-50Hz/3/PE

25A

0.8kW

0.7kW

5kW

5.7kW

16A

5X2.5

230V-50Hz/1/N/PE (2RR)

25A

0.8kW

0.7kW

3.3kW

4.7KW

18A

3X4

230V-50Hz/1/N/PE

13A

0.8kW

0.7kW

1.7kW

2.4kW

11A

3X2.5

2 TECHNICAL DATA

4

Page 5

CWG 520-530

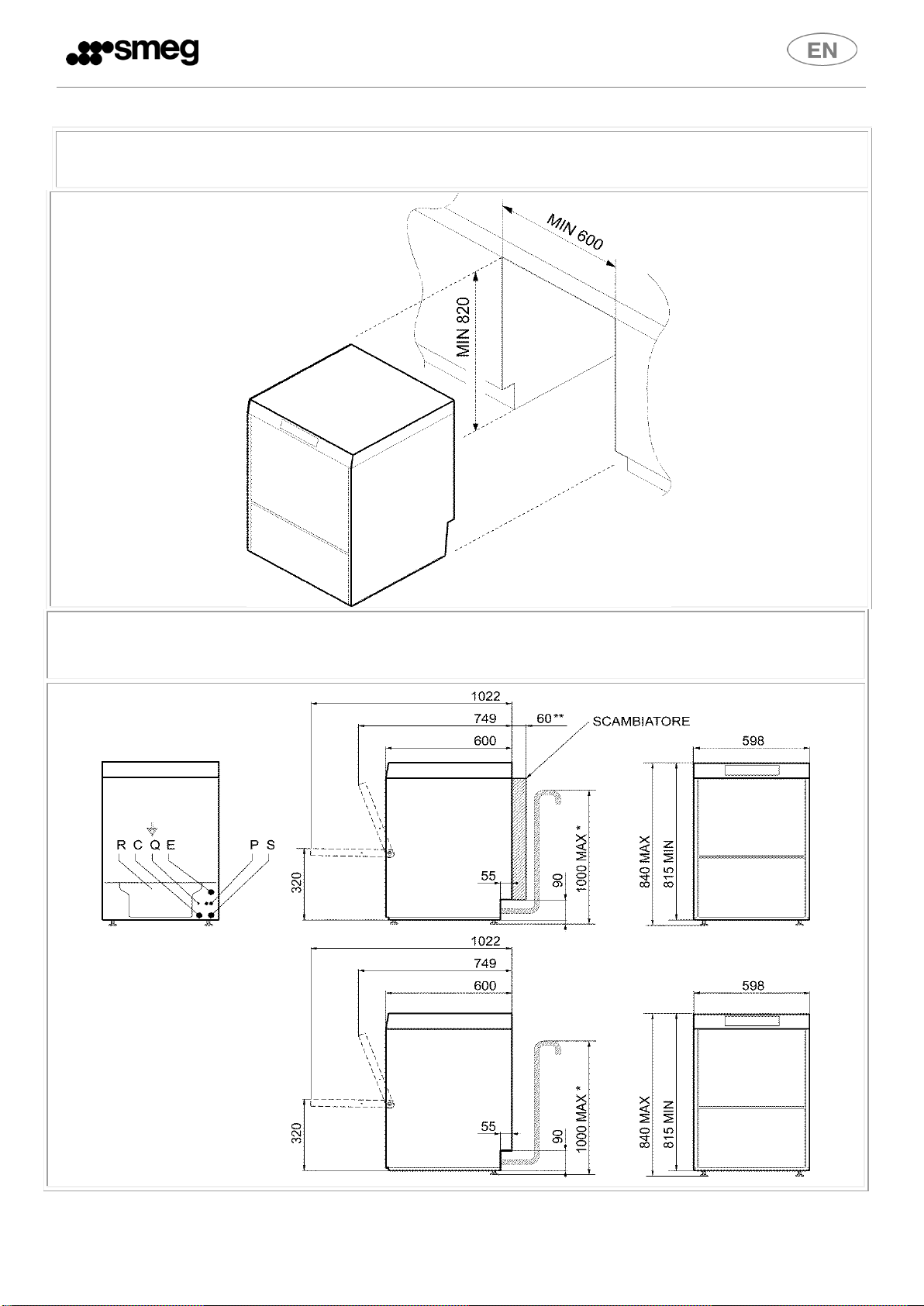

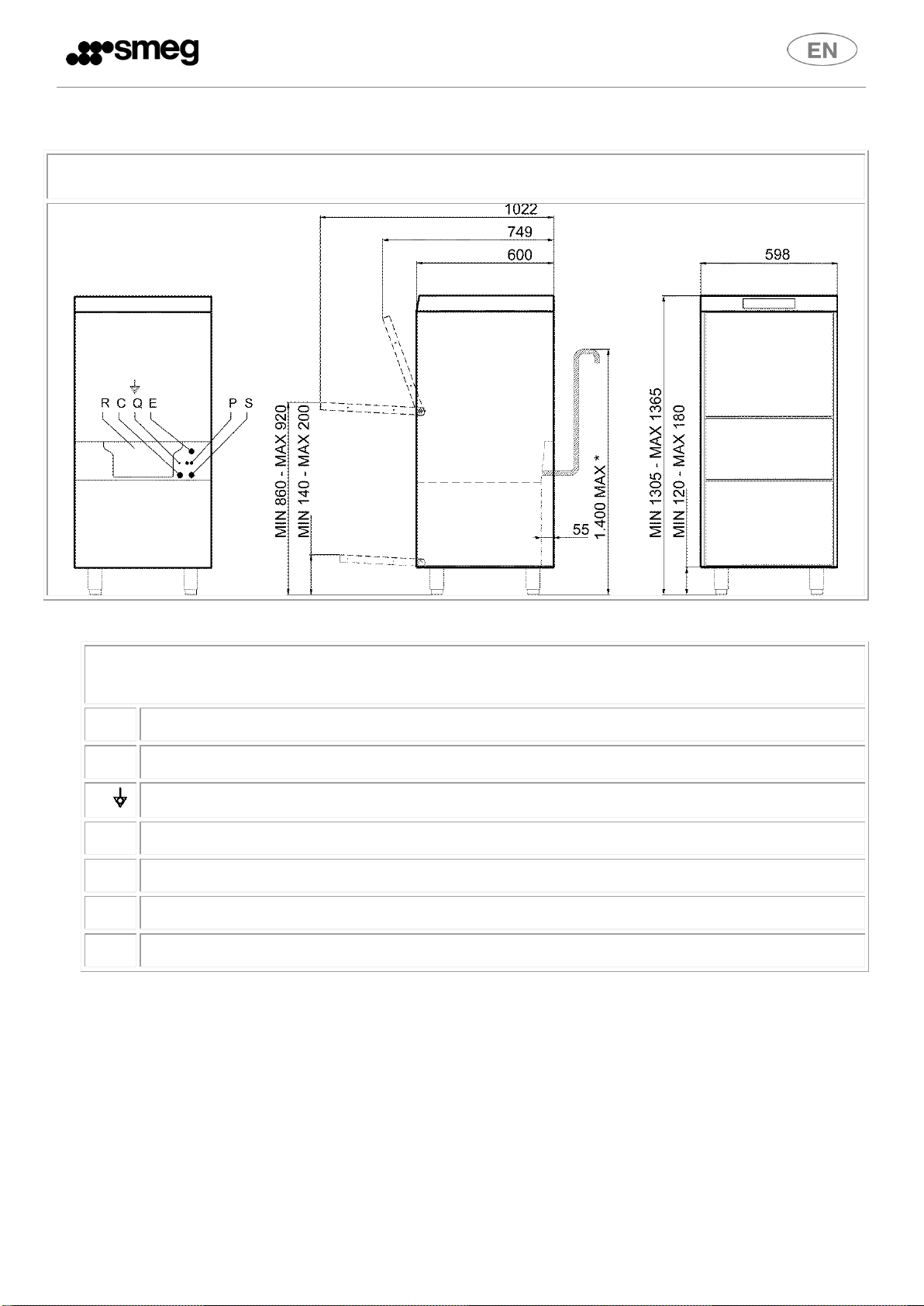

CAVITY DIMENSIONS FOR BUILT-UNDER INSTALLATION

APPLIANCE DIMENSIONS AND CONNECTION POSITIONS

(*N.B. : VALUE “1000” - max 600 if siphon with valve is used)

(**N.B. : VALUE - max 60 - heat exchanger )

5

Page 6

CWG 520-530

APPLIANCE DIMENSIONS AND CONNECTION POSITIONS

(**N.B. – VALUE “1400” WITH ASTERISK: max 1000 if siphon with valve is used)

KEY TO LETTERS USED IN DIAGRAM

R

LOWER BACK PANEL

C

FILLER HOSE

Q

EARTH TERMINAL

E

ELECTRICITY SUPPLY CABLE

P

PERISTALTIC HOSES

S

DRAIN HOSE

T

EXTERNAL DISPENSER POWER CABLE ENTRY POINT

3 INSTALLATION AND POSITIONING

INSTALLATION and POSITIONING

Bring the glasswasher to the installation site, remove the packaging and check the appliance and components for

damage; any damage found must be reported to the transporter in writing. The packaging components (plastic

bags, expanded polystyrene, nails, etc.) must not be left within reach of children and pets since they are

potentially dangerous. All packaging materials used are environment-friendly. They can be kept without

constituting any hazard, or may be disposed of at a specialist waste disposal centre. The plastic components

suitable for recycling are marked as follows: PE polyethylene: external packaging film, bag containing the

instructions, protective bags. PP polypropylene: straps. PS expanded polystyrene: corner guards, top of packaging.

6

Page 7

CWG 520-530

Water supply and drain connection

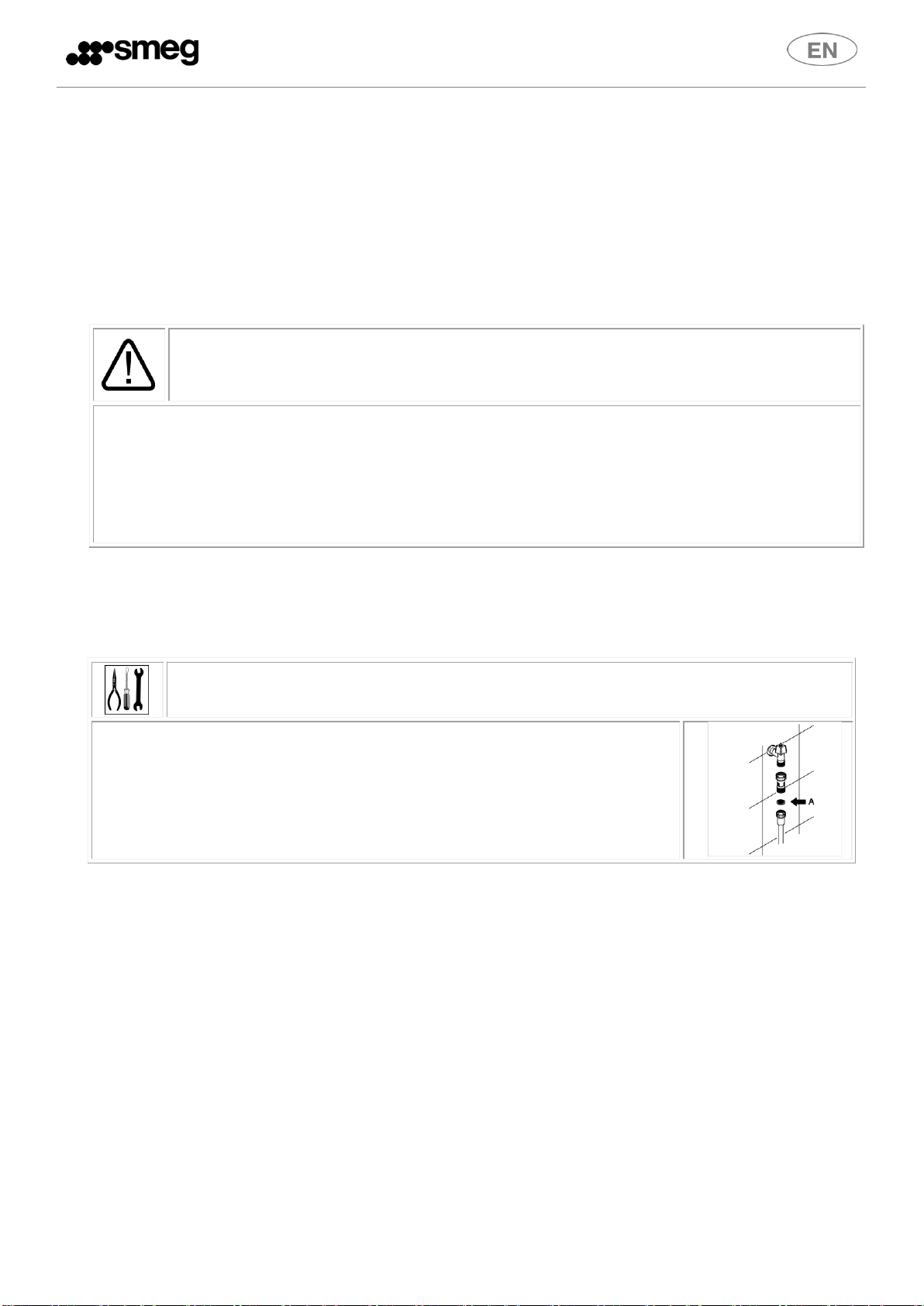

The water pipelines and electricity supply cable lead out of the bottom

right-hand corner of the appliance. Connect the water intake hose to a

connector with ¾” threaded fitting, fitting the filter A provided (in models

with acquastop, the filter and ring-nut form a single unit).

The connection to the water mains must only be made with new hoses; the

use of old or worn hoses is not permitted.

Caution: the indoor system and premises in which equipment for institutions is installed

must comply with the relevant regulations.

The manufacturer declines all liability for direct or indirect injury or damage deriving from failure

to comply with these regulations. Before installation, check that there are no objects or materials

in the vicinity which may be damaged by steam or splashes of washing solution, or that any such

items are suitably protected. Place the glasswasher in the chosen point and remove the protective

film. Level the glasswasher (with the aid of a spirit level) on its adjustable feet to ensure that it is

stable; all other mounting solutions must be approved by the manufacturer.

Wooden and cardboard components can be disposed of in accordance with the relevant regulations. When the

product is decommissioned it must not be dumped in the environment; it must be disposed of in accordance with

the relevant regulations. All metal parts are in stainless steel and can be removed. The plastic parts are marked

with the symbol identifying the material used and must be disposed of in accordance with the relevant

regulations. When the product is decommissioned it must not be dumped in the environment; it must be

disposed of in accordance with the relevant regulations. All metal parts are in stainless steel and can be removed.

POSITIONING:

4 INSTRUCTIONS FOR TECHNICAL STAFF

4.1 lumbing hookup

FOR MODELS WITH A WATER SOFTENER

AN ‘APPROVED’ DOUBLE CHECK VALVE OR SOME OTHER NO LESS EFFECTIVE DEVICE PROVIDING

BACKFLOW PREVENTION PROTECTION TO AT LEAST FLUID CATEGORY TWO SHALL BE FITTED AT THE

POINT OF CONNECTION BETWEEN THE WATER SUPPLY AND THE FITTING OR APPLIANCE.

FOR MODELS WITHOUT A WATER SOFTENER

AN ‘APPROVED’ SINGLE CHECK VALVE OR SOME OTHER NO LESS EFFECTIVE DEVICE PROVIDING

BACKFLOW PREVENTION PROTECTION TO AT LEAST FLUID CATEGORY TWO SHALL BE FITTED AT THE

POINT OF CONNECTION BETWEEN THE WATER SUPPLY AND THE FITTING OR APPLIANCE.

The dynamic water supply pressure must be between 1 and 6 bar; if it is higher a pressure reducer

must be installed. It is essential to fit a main stop tap on the water intake deliver pipeline; the tap

must be accessible after installation of the appliance, so do not install it behind the warewasher. The

stated cycle duration applies to appliances supplied with hot water >50°C<60°C If the warewasher is

supplied with cold water, the cycle duration might increase depending on the intake water

temperature. The warewasher is fitted with a drain pump and can operate with drain connections

7

Page 8

CWG 520-530

Caution: make sure that the intake and drain hoses are not bent, constricted or crushed

after installation.

The glasswasher and any additional equipment must be connected to the electrical

system by authorised, skilled staff, in accordance with the relevant regulations; also

comply with the technical instructions for the connection.

The total rated power is stated on the appliance’s technical data plate.

The electrical protection devices fitted for the glasswasher must serve this appliance

only.

The user must have a master switch and a differential safety breaker, with rating

suitable for the appliance’s characteristics, installed on the electricity supply line in

accordance with the relevant regulations.

These switches must be installed close to the glasswasher, be easily accessible after

installation, and provide complete disconnection from the electrical mains in

overvoltage class III conditions.

Warning !!!

The glasswasher is always powered up unless the master switch is turned off.

Connect the appliance to the user’s earth system. The terminal for the connection is

in the bottom right-hand corner of the appliance.

The earth wire (PE) is yellow-green in colour, the neutral wire (N) is blue and the live

wires (L1, L2, L3) are black, grey and brown.

In the event of single-phase connection (230V-1N~), the connection to the electrical

mains must be made using a cable with plug compliant with the relevant regulations.

THE POWER SUPPLY CABLE, AS PROVIDED, MUST BE REPLACED BY THE

MANUFACTURER OR AN AUTHORIZED SERVICE CENTER IN COMPLIANCE WITH THE

SPECIFICATIONS PROVIDED ON ELECTRICAL DIAGRAM SUPPLIED IN THE MACHINE IN

ORDER TO PREVENT ALL RISKS.

on the floor or wall. Refer to the connection diagram for the maximum permitted height of wall

drains – (see TECHNICAL DATA)

When installing the drain hose to a siphon with valve, the maximum height of the drain outlet is

reduced to 600 mm.

4.2 Electrical connection

8

Page 9

CWG 520-530

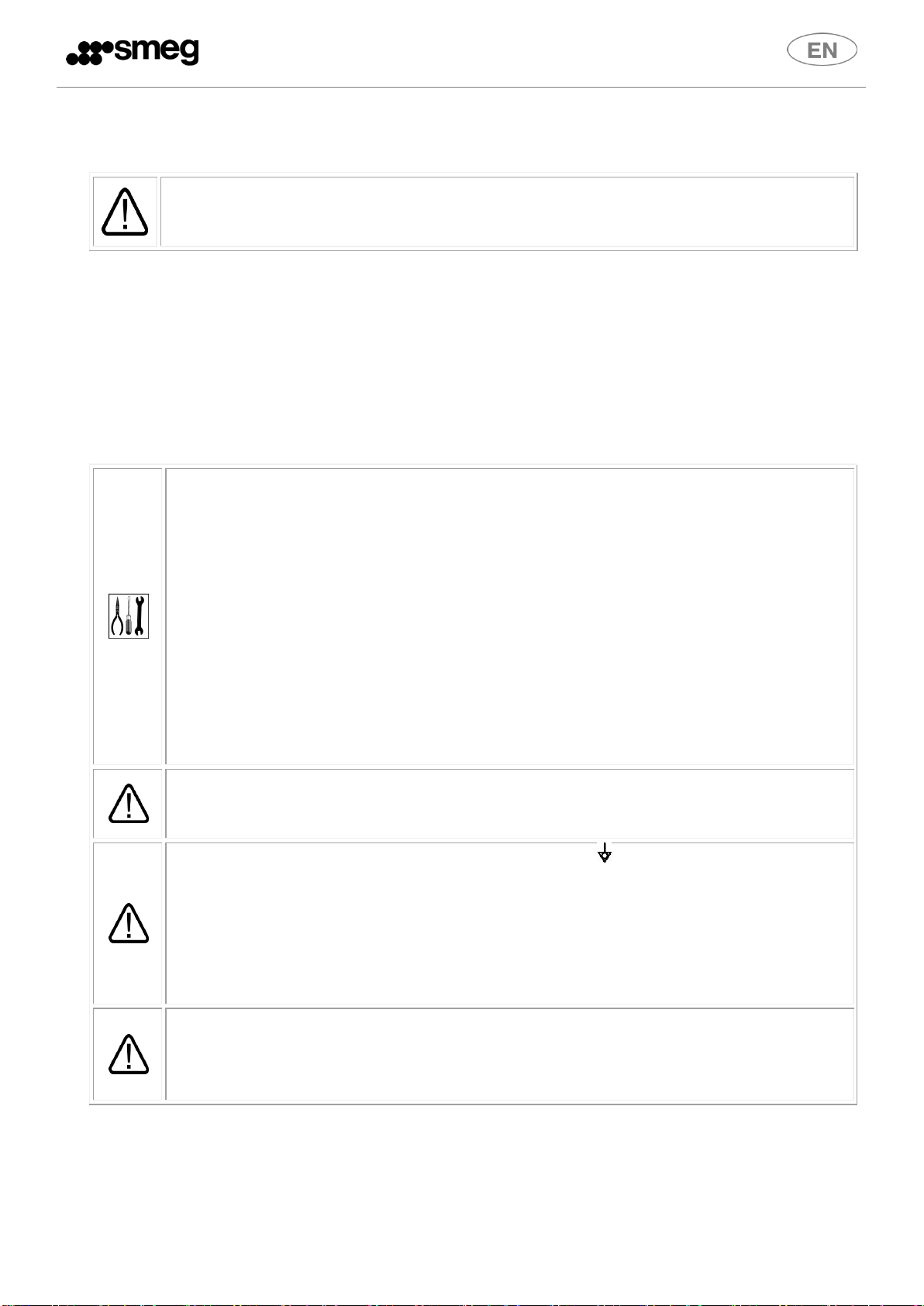

Before inserting the hoses into the containers, fit the weights (needed

to ensure that they always draw in liquid from the bottoms of the

containers) and the filters onto their ends as shown.

If the detergent dispenser is not factory-fitted, it can be retrofitted

after ordering the relative kit.

The quantity of lime in the water (which indicates its hardness) causes whitish

marks on dry dishes and dishes also tend to lose their shine over time.

The glasswasher is equipped with an automatic water softener which removes

the substances that cause hardness from the water with the aid of regenerating

salt.

The first time the glasswasher is used, a litre of water must be poured into the

tank with the salt. Whenever the tank is filled, always take care to ensure that the

cap is firmly closed.

The mixture of water and detergent must not get into the salt tank, as this would

impair operation of the regeneration system.

In this case warranty cover will be forfeited.

5 FIRST START-UP

First start-up

The electrical protection system must undergo a functional test before the appliance is put into

operation.

The appliance must be installed and/or inspected by qualified staff, who will start it up for the first

time and provide the relevant operating instructions.

Preparing for use (important)

The rinse aid dispenser is fitted on all models, the detergent dispenser only on some.

If both dispensers are present put the external detergent and rinse aid containers in place and

insert the respective intake hoses on the rear of the appliance into them.

Red hose: detergent

blue hose: rinse aid

NOTE: It takes about 10-15 wash cycles before they arrive in detergent and rinse tank and boiler

As an alternative an external dispenser can be fitted, making the electrical connection by means of

an H05 RN-F 2x0.5 mm electrical cable, which can be laid along the route shown in the TECHNICAL

DATA diagram and connected as shown in the wiring diagram supplied with the glasswasher.

The dispenser must operate on 230V/50 Hz with maximum power absorption of 15 W.

Connect to the detergent dispenser outside the glasswasher using the red hose mentioned above.

5.1 Using the water softener (on models with this feature only)

9

Page 10

CWG 520-530

Access “programming mode” by pressing the button for

a few seconds with the appliance on with the door open

and the tank empty (after the filling and heating phases).

The display shows UnLo1:58; when the beep sounds,

release the button and press it again at once. Keep

pressing the button again to scroll through all the

modifiable parameters in the following order:

Rinsing temperature (boiler temperature)

Washing temperature (tank temperature)

IMPORTANT:

Whenever the type of detergent or rinse aid is changed, it is ABSOLUTELY ESSENTIAL to flush out

the peristaltic pumps by placing the external intake pipes in water for a few cycles. Always use

only products specifically recommended for use in a glasswasher. Failure to comply with this

recommendation leads to forfeiture of the warranty entitlement on the appliance’s water system.

The internal pipes of the detergent and rinse aid pumps should be replaced by the After-Sales

Service every 12 months or 15,000 wash cycles and operation of the diaphragm can be disposed

of in accordance with the relevant regulations rinse aid pump should be checked.

Set-up

During first start-up, the functions/parameters listed below must be set or adjusted:

6 SET-UP

6.1 Glasswasher parameter modification procedure:

Only accessible after filling is complete or with the door open.

Indicator lights showing: off; green; orange; flashing.

10

Page 11

CWG 520-530

Quantity of rinse aid dispensed, OPT, only if installed (the

number indicates the number of seconds for which the

peristaltic pump is operated)

Quantity of detergent dispensed, OPT, only if installed (the

number indicates the number of seconds for which the

peristaltic pump is operated)

Start-on/start-off

Set at “on” to start the cycle when the door is closed.

Set at “off” for cycle start after confirmation with the start

button

Water hardness setting (OPT, on models with softener

only)

tStP on/off “on” = minimum rinsing temperature as set,

regardless of intake water temperature.

If the intake water is not hot; the cycle duration might be a

few seconds longer than the nominal timing, “off” = the

minimum rinsing temperature might be a few degrees

lower than the setting

Rinse aid pump total operating minutes display.

This value can be reset during pump maintenance - see

below.

11

Page 12

CWG 520-530

Detergent pump total operating minutes display.

This value can be reset during pump maintenance - see

below.

Energy consumption (kW) display

The Pc option indicates the total kW consumed since

installation of the glasswasher or since the latest reset.

Display of the number of cycles performed

When scrolling through the appliance parameters, the “tc

88888” item will also appear; this is the count of the total

cycles performed by the glasswasher since installation.

This parameter cannot be modified or reset unless the

software is reprogrammed.

Customisation of duration of program P4.

This submenu and the relative functions can only be

accessed with the aid of a password available on

SmegTech and only by technical staff.

6.2 Quit “SET-UP” menu

Wait more than 10 seconds without pressing any button and the appliance quits this menu

automatically,

or press the on/off button to exit.

Indicator lights showing: off; green; orange; flashing.

Caution: the tank and boiler temperatures shown on the display may be differ from the actual

temperatures by a few degrees, especially in transient phases (just after the FILL is completed, just after

the end of the cycle, etc.) due to the inertia of the measurement probe.

12

Page 13

CWG 520-530

Modify the value of the parameter by pressing .

(Default value: 71°C)

Min. 71°C – max. 85°C

Modify the value of the parameter by pressing .

(Default value: 62 °C)

Min. 52°C – max. 62°C

Modify the value of the

parameter by pressing .

RINSE AID

Delivery time

(s)

Delivery

quantity (c.c.)

0

0,0 6 0,7

* default value (factory preset)

12

1,3

18

2,0

24

2,7

30*

3,3

36

4,0

42

4,7

Modify the value of the

parameter by pressing

.

DETERGENT

Delivery time

(s)

Delivery

quantity (c.c.)

0

0,0 4 1,7

8

3,3

12*

5,0

6.3 Rinsing temperature setup

6.4 Washing temperature setup

Indicator lights showing: off; green; orange; flashing.

6.5 Rinse aid dispensing setup

6.6 Detergent dispensing setup

13

Page 14

CWG 520-530

* default value (factory preset)

16

6,7

20

8,3

24

10,0

30

11,7

36

13,3

42

15,0

Modify the parameter (ON/OFF) by pressing .

Modify the

value of the

parameter by

pressing .

Hardness

(°dH German

degrees)

Hardness

(°dF French

degrees)

Setting

level

Regeneration

off

Regeneration

off

H00

8,5

15

H01

11

20

H02

17

30

H03

22,5

40

H04

28

50

H05

Regeneration cycle duration: 12 minutes

33,5

60

H06

6.7 Autostart function

Set at “on” to start the cycle when the door is closed.

Set at “off” for cycle start after confirmation with the start button

6.8 Regeneration frequency setup (models with softener)

(Default value: H03; modify the parameter to suit the mains water hardness.

At first use, the salt tank has to be filled. It is subsequently sufficient simply to fill up with

regenerating salt when necessary.

With values over 60°dF an external water treatment device must be used and the regeneration

frequency must be set on H00.

14

Page 15

CWG 520-530

Modify the parameter (ON/OFF) by pressing .

To reset, press for 3 seconds.

To reset, press for 3 seconds.

6.9 tStP (minimum rinsing temperature) function

Set at “on” for minimum rinsing temperature as set; set at “off” for rinsing regardless of boiler

temperature.

If the parameter is set as “off” and hot intake water is not used, the minimum rinsing temperature

might be a few degrees lower than the setting.

If the termostop device is set “off” the rinsing is no longer monitored and the user is responsible

for ensuring that the minimum correct T° are maintained for the tank and boiler. It is particularly

important to check the intake water temperature.

Also refer to the insufficient washing/drying / foam in tank point of the “troubleshooting” section:

restore T Stop ON and/or connect the appliance to a hot water supply

6.10 Rinse aid pump (display and if required reset during maintenance)

6.11 Detergent pump (display and if required reset during maintenance)

15

Page 16

CWG 520-530

To reset, press for 3 seconds.

Access the programming procedure and scroll through to

“ınF” using the button, then to 03:00 and press the

button to set the time required (from 3 to 10 minutes)

After a few seconds without the user pressing any buttons,

the display will return to the normal operating status and the

modifications will be saved.

See information on Smegtech

6.12 Energy consumption – Display and reset if required

6.13 Customisation of duration of program P4.

The duration of program P4 can be customised from 3 to 10 minutes

6.14 Service setting (for After-Sales Service only)

6.15 Starting the peristaltic pumps – rapid filling of detergent and rinse aid

delivery circuit.

Perform after the parameter modification procedure explained in the previous point.

Indicator lights showing: off; green; orange; flashing.

16

Page 17

CWG 520-530

With the glasswasher powered up, access “programming

mode” by pressing the on/off button for a few seconds; at

the “beep”, release the button and press it again quickly

within 0.5 seconds.

The peristaltic pumps continue to operate until the same

button is pressed again. The rinse aid and detergent symbol

lights remain on as long as the pumps are on; bear in mind

that the rinse aid peristaltic pump fills the circuit in about 7

minutes, while for the detergent it only takes 2 minutes.

Err01

The anti-flooding system has

been activated (for the

relevant models only).

Large water leak: check the origin of the problem.

Err04

Tank temperature probe

malfunction

Tank temperature probe disconnected or not working.

Err05

Tank water filling malfunction

The tank does not fill within the allowed time: check water intake

tap, dynamic pressure in intake system, cleaning of water intake

filter, possible damage to water intake hose or cleaning of rinsing

nozzles. If the problem persists during FILL:

- tank pressure switch has failed (continuous empty reading: check

whether tank safety pressure switch is tripped)

- leak from pipe connected to air trap

If the problem occurs during work cycle

- filler hose bleeder valve fouled: tank empties completely at end

of a wash cycle due to siphon effect.

Err06

Water pump-out malfunction

Inspect the filters for dirt and check that the drain hose is not

blocked, bent or crushed.

Check that the drain pump is not blocked by dirt by removing the

insert on the sump (from inside the tank).

If it persists, check in this order:

- with tank empty: constant “tank full” signal: tank pressure switch

faulty or leak from connections of air trap connection pipe (water

entering pipe)

- with tank full: drain pump failure

Err09

Too much water in tank

With tank full:

see above (water pump-out malfunction)

With tank empty: constant “tank full” signal: safety pressure switch

faulty or leak from connections of air trap connection pipe (water

7 MALFUNCTIONS SHOWN ON THE DISPLAY (FOR

THE TECHNICIAN)

The glasswasher is able to identify a number of malfunctions and show them on the display. If the

problem persists after the glasswasher has been switched off and back on, proceed as described below:

17

Page 18

CWG 520-530

entering pipe)

Err23

Boiler does not heat up as

expected

The problem might occur because water is continually entering the

tank (the causes are as for Err5 – see above)

If it persists, check in this order:

- damaged boiler heating element

- contactor failure,

- boiler safety thermostat failure,

- boiler temperature probe faulty or incorrectly positioned

- motherboard relay failure,

Important: if the boiler heating element is damaged, this might be

due to operation with no water in the boiler - the pressure switch

is indicating full even with the boiler empty: check and if necessary

replace the boiler air trap and/or the relative pressure switch: the

problem is generally preceded by “boiler overheating E28”

Err24

Boiler temperature probe

malfunction

boiler temperature probe disconnected or not working

Err25

Boiler water filling

malfunction

The boiler does not fill within the allowed time: check water intake

tap, dynamic pressure in intake system, cleaning of water intake

filter, possible damage to water intake hose

Or check in this order:

- boiler pressure switch has failed (continuous empty reading)

- pipe leaking/disconnected (water entering pipe)

Err26

Boiler emptying malfunction

- check that rinsing spray arm nozzles are clean

- boiler pressure switch has failed (continuous full reading)

- pipe leaking/disconnected (water entering pipe)

- rinsing pump not working

Err27

Boiler emptying malfunction –

with tank full

Boiler pressure switch has failed (continuous full reading)

Err28

Boiler heating malfunction

(overheating)

First check:

- boiler pressure switch has failed (continuous full reading)

- pipe leaking/disconnected: water entering pipe connected to air

trap, pressure switch continues to give full reading even with boiler

empty, heating element operating dry

Or:

- circuit board relay failure, or

- contactor failure

18

Page 19

CWG 520-530

On-off button

Program selection button

Start CONFIRM/PAUSE button

Total emptying button (tank and boiler)

Additional function selection button

L1 Mains power on light

L2 Intake/standby cycle in progress light (red/green)

L3 Pump-out in progress light

No rinse-aid symbol (if a system for monitoring outside the glasswasher is provided)

Tank heating element on symbol

No salt symbol (if softener is fitted)

Boiler element on symbol

No detergent symbol (if a system for monitoring outside the glasswasher is provided)

8.1 Control panel

8 INSTRUCTIONS FOR THE USER

19

Page 20

CWG 520-530

Turn on the

mains water

tap (user)

Check:

Switch on the

master switch

(user): the word

“OFF” appears on

the display.

The level of

detergent and

rinse aid in the

containers.

That there is

regenerating salt

in the relative

container (if

fitted).

That the filters are in

place, the spray arms

rotate, and there are

no foreign bodies in

the glasswasher.

Display shows

Actions and what happens

With the door closed:

Press and hold it down, with word FILL appears.

the glasswasher fills the tank after the water in the boiler

has heated up; light L2 shows orange and the boiler

heating element symbol appears on the display.

Wait for P1 to appear and LED L1 to change from red to

green; the tank heating element light comes on until the

set temperature is reached. The duration of this stage may

vary depending on the mains water temperature and on

When topping up the tanks, take care not to swap the products; this might damage the

glasswasher and cause malfunctions.

Do not mix different detergents; this would damage the dispenser device.

Industrial glasswasher detergents may cause serious irritation. Comply carefully with the instructions

provided by the detergent producer on the pack.

8.2 Before washing

Use only detergents and rinse aids for industrial glasswashers.

Do not use detergents intended for hand washing.

We recommend the use of Smeg products, specially developed for this glasswasher.

8.3 First use each day (tank and boiler empty)

Indicator lights showing: off; green; orange; flashing.

20

Page 21

CWG 520-530

the single-phase connection.

Press the button quickly to display the tank (left) and

boiler (right) temperatures for a short time.

Load the dishes

Select the program required by pressing .

Confirm the program start by pressing and holding it

down for 1 second (light L2 changes from green to

orange).

Cycle in progress, the progress of the cycle is displayed by

vertical bars which illuminate in sequence. If the door is

opened “CLOSE” flashes and the program stops; when it is

closed again the program restarts from the beginning.

At the end of the program “End” flashes

Unload the dishes

When the door is closed again, the system offers the last program run.

21

Page 22

CWG 520-530

With the door closed, to change to a fresh program

instead of repeating the last one, press the button.

The programs available are displayed.

If a program has already started, press and hold it

down to interrupt it.

change the program by pressing

Confirm the program start by pressing and holding it

down for 1 second (light L2 changes back to orange).

PROGRAM

TYPE OF DIRT

DURATION (*)

P1

Glasses and cups

Short, about 1’ 30”;

1’ with glassware function active.

P2

Glasses, cups with light dirt

Average, about 2’ 30”;

2’ with glassware function active.

P3

Very dirty glasses and cutlery

Long, about 4’;

5’30” with sani function active.

P4

Depending on the duration set.

As required from 5 to 20'.

8.4 Changing the Program

N.B.:

During heating of the water in the boiler and tank with the cycle running, the tank heating element

and boiler heating element symbols may appear on the display.

Filter presence sensor (on some models only)

The filter is fitted with a sensor which checks that it is properly fitted; if it is not in the correct position,

the word “FiLter” appears on the display.

9 CHOOSING THE PROGRAM

(*) The cycle duration stated above refers to three-phase appliances supplied with hot water at

50°C. If the appliance is supplied with cold water, the cycle duration might increase depending

22

Page 23

CWG 520-530

After selecting the "Crys” function, perform a cycle with the appliance empty to stabilise the boiler

temperature

Press and hold it down to select the glassware function

then press to confirm the program start.

Press and hold it down to select the extra rinse

function then press to confirm the program start.

on the intake water temperature, since the glasswasher is fitted with the HTR system, which

requires set temperature and pressure for rinsing.

10 SUPPLEMENTARY FUNCTIONS

Indicator lights showing: off; green; orange; flashing.

To select a supplementary function, when the program required is shown on the display (P1, P2, P3 or

P4) press the button. Only one supplementary function can be selected for each program.

10.1 Selecting the crys“glassware” function (available in P1-P2)

Reduces the program’s rinsing temperature and duration

10.2 Selecting the erin “extra rinse” function (available in P1-P2-P3-P4)

Extends the duration of the rinse

During performance of cycles with Extra Rinse, the cycle duration increases by about 30" because of the

increased duration of the rinsing phase and the time consequently required to restore the level and

temperature in the boiler. If the Termostop is OFF and the glasswasher is connected to cold water, this

function will be less effective

10.3 Selecting the “sanitisation” function (only available in P3)

Increases the program’s washing and rinsing temperatures and duration

23

Page 24

CWG 520-530

Press to select the sanitisation function then to

confirm the program start.

Press the pump-out button and the display shows

“UnLo” and the duration.

N.B.:

- the supplementary function remains selected until the program is changed or the glasswasher is

switched off by pressing the button.

- During execution of the selected program, the display alternates between showing the

supplementary function and the duration.

Glasses

Load glasses upside down.

Cutlery

Use the basket(s) provided. Load cutlery loose, preferably with the handle at the bottom, taking care not

to injure yourself with fork prongs or knife blades.

TOTAL PUMP-OUT AT THE END OF THE DAY

The glasswasher is able to perform an automatic cleaning cycle at the end of the day.

24

Page 25

CWG 520-530

Confirm by pressing ; light L2 turns orange.

When pump-out is complete the appliance switches to

“OFF” status.

Never switch the glasswasher off with water in the tank; always pump out first.

Press the pump-out button ; “rEgE” and the duration

appear on the display.

Confirm by pressing ; light L2 turns orange.

When pump-out is complete the appliance switches to

“OFF” status.

After a total pump-out the filters should be cleaned as described above.

TOTAL PUMP-OUT AT THE END OF THE DAY + RESIN REGENERATION

(for models with water softener)

From time to time, on models with water softener, before the total pump-out at the end of the day the

user will automatically be reminded to carry out the resin regeneration cycle, required after a number of

washes which depends on the hardness of the water (about 30 for average setting H03). In this case the

sequence will be as follows:

Topping up with regenerating salt (for models with water softener)

Salt must be added when the “no salt” light ( ) appears on the display.

Top up with salt when there is no water in the tank to prevent washing water from getting into the

water softener device.

Caution: use only salt of the specific type, do not use cooking salt.

The salt tank has a capacity of about 1 kg of coarse-grained salt .

25

Page 26

CWG 520-530

Press the button, and hold it down, until “P0” and the

duration of 1’ appear on the display.

Confirm by pressing ; light L2 turns orange.

At the end of the pump-out the word “End” flashes on

the display. The display returns to showing “P1”. Clean

the filter; the glasswasher automatically fills the tank

when the door is closed.

The salt tank is in the bottom of the appliance's tank. After removing the basket, undo the cap and pour

the salt in using the funnel supplied. Remove any salt residues around the opening before screwing the

cap back on.

11 MAINTENANCE AND CLEANING

Although no particular scheduled maintenance is required, users are advised to have the glasswasher

checked by a specialist technician twice a year.

N.B. the manufacturer accepts no liability for wilful damage or damage deriving from carelessness,

neglect, failure to comply with instructions, regulations and standards or incorrect connections.

11.1 Daily cleaning

The glasswasher has IPX4 protection, but the use of direct water jets for cleaning is forbidden.

Cleaning the filter during the day

In case of particularly heavy-duty working conditions, the filter should be cleaned every 30-40 cycles,

keeping the machine in operating conditions; to do this, carry out the “partial tank pump-out” routine

(program “P0”).

26

Page 27

CWG 520-530

Remove the filters (simply lift them out as shown here), taking care

that no large residues fall into the sump underneath. Clean them to

remove residues and rinse with plenty of water, then put them

correctly back in place; do not use sharp or pointed tools.

Clean away any limescale deposits to prevent excessive build-ups;

- If possible, leave the door ajar when not in use;

- Clean surfaces thoroughly and often with a damp cloth; use

neutral, non-abrasive detergents which do not use chlorine

compounds, which corrode and damage stainless steel.

Do not use the products mentioned above even when cleaning the floor underneath or in the vicinity of

the glasswasher, to ensure that fumes or drops cannot damage the steel surfaces.

IMPORTANT: The glasswasher automatically performs program “P0” at the start of the day if water has

been left in the tank and has dropped below the temperature of 40°C

11.2 Routine inspection of the spray arms

Remove the washing and rinsing (top and bottom) spray arms by unscrewing the central screw; remove

the rinsing spray arms 3 and remove the screws 2 as shown. Do not unscrew the nozzles. Clean the

holes and nozzles under a jet of clean running water; do not use tools which might cause damage.

Reassemble the spray arms with care.

Clean the outside of the appliance with a damp cloth and neutral soap, rinsing and drying thoroughly.

11.3 Lengthy periods out of use

If the glasswasher is to be out of use for a fairly long period of time, the detergent and rinse aid

dispenser devices must be emptied to prevent crystallisation and damage to the pumps: Remove the

intake hoses from the detergent and rinse aid containers and place them in a container of clean water,

then perform a few wash cycles followed by a complete pump-out. Finally, turn off the master switch,

close the water intake valve and leave the door ajar until the interior is completely dry. The detergent

and rinse aid intake hoses must be put back into the containers when the glasswasher is returned to

service, taking care not to swap them over (red hose = detergent, blue hose = rinse aid).

27

Page 28

CWG 520-530

If the system fails to pump out because the drain pump is

fouled (as a result of incorrect filter positioning), proceed as

follows:

Bale out the glasswasher with a basin and disconnect it from

the electrical mains.

Unscrew the screw A, release the tang B and lift it.

Check that the impeller of the drain pump underneath the

cover turns freely, and is free from dirt, limescale residues, or

pieces of glass. Never use tools, screwdrivers, scissors, etc.

PROBLEM

POSSIBLE CAUSE

POSSIBLE REMEDY

LIGHT S1 DOES NOT COME ON

Mains power failure

Check electrical mains connection.

WASHING PROGRAM DOES

NOT START

The glasswasher has not

yet finished filling.

Wait for the word FILL to go out.

The word CLOSE remains

on the display

If the word CLOSE remains on the display even

with the door closed, call the after-sales service.

POOR WASHING RESULTS

Spray arm washing holes

blocked by dirt or

limescale

Remove spray arms and clean them

(10.2 Periodic checks)

Filter fouled

See “Cleaning the filter during the day”

Too little or unsuitable

detergent or rinse aid

Check type and quantity of detergent.

No or not enough

detergent or rinse aid

being supplied: detergent

or rinse aid not being

taken from the relative

container.

Pipe inside detergent and/or rinse aid peristaltic

pump worn or broke, have it replaced by the

After-Sales Service.

glasses badly arranged

Arrange glasses correctly.

Low washing

temperature

Check temperature shown on the display, call

the after-sales service if less than 50℃

Inappropriate cycle set

Increase washing duration, especially if dishes

are very dirty or dirt has dried on.

Spray arm nozzles fouled

Limescale in boiler

- Check that nozzles are clean, and ensure that

the softener is working properly (if installed).

- Check that the filter of the hose inserted in the

rinse aid tank is not fouled.

INADEQUATE RINSING

Rinse aid unsuitable or

not being delivered

correctly.

Rinsing temperature too

Check container of rinse aid and whether it is

suitable for the type of mains water.

Check boiler temperature setting

If the problem persists, contact the after-sales

12 TROUBLESHOOTING

28

Page 29

CWG 520-530

low

service.

DISHES NOT PROPERLY

DRIED

Rinse aid unsuitable or

not being delivered

correctly.

Water hardness above

12°dF or large amounts

of dissolved salts

Check container of rinse aid and whether it

is suitable for the type of mains water.

Restore T Stop ON and/or connect the

appliance to a hot water supply.

If the problem persists, contact the aftersales service.

STAINS ON GLASSES AND

CUTLERY

Drain hose incorrectly

positioned or partially

obstructed.

Check that the glasswasher drain hose and

rain are unobstructed and the drain is not

too high up; see connection diagram.

WATER IN TANK AFTER

PUMP-OUT

Drain hose incorrectly

positioned or partially

obstructed.

Check that the glasswasher hose and drain

are unobstructed and the drain is not too

high up; see connection diagram.

Err01

The anti-flooding system has been

activated (for the relevant models

only).

Contact the After-Sales Service.

Err04

Tank temperature probe malfunction

Contact the After-Sales Service

Err05

Tank water filling malfunction

Check that the water intake tap is on and the dynamic

pressure in intake system, inspect water intake filter and

clean if necessary. If the problem persists, contact the AfterSales Service.

Err06

Water pump-out malfunction

(glasswasher is left full of water)

Inspect the filters for dirt and check that the drain hose is not

blocked, bent or crushed.

Check that the drain pump is not blocked by dirt; proceed as

described in point “10.2 Periodic checks”. If the problem

persists, contact the After-Sales Service.

Err09

Tank water level too high

Contact the After-Sales Service.

Err23

Boiler heating malfunction (does not

heat up)

Contact the After-Sales Service.

Err24

Boiler temperature probe malfunction

Contact the After-Sales Service.

Err25

Boiler water filling malfunction

Check that the water intake tap is on and the dynamic

13 MALFUNCTIONS SHOWN ON THE DISPLAY (FOR

THE USER)

The glasswasher is able to identify a number of malfunctions and show them on the display.

If the problem persists after the glasswasher has been switched off and back on, proceed as described

below:

(TO ALLOW THE AFTER-SALES SERVICE TO TAKE THE APPROPRIATE ACTION, ALWAYS MAKE A NOTE OF

THE ERROR INDICATED)

29

Page 30

CWG 520-530

pressure in intake system, inspect water intake filter and

clean if necessary. If the problem persists, contact the AfterSales Service.

Err26

Boiler emptying malfunction

Check that the rinsing spray arm nozzles are not fouled If the

problem persists, contact the After-Sales Service.

Err27

Boiler emptying malfunction – with

tank full

Contact the After-Sales Service.

Err28

Boiler heating malfunction

(overheating)

Contact the After-Sales Service.

19.390.4918.00

17/12/2013

Manual Ed.

Date

INFORMATION AND AFTER-SALES SERVICE FOR SMEG PRODUCTS

COMMERCIAL GLASSWASHERS

Our Sales Department staff will be able to provide you with information about prices and special offers.

Our After-Sales Department will be able to provide you with guidance about keeping your appliance

functioning correctly and put you in touch with your nearest authorised Service Centre.

Our whole product offering can be viewed at:

www.smegfoodservice.com

International customers, please contact your local SMEG distributor.

Smeg S.p.A.

Via Leonardo da Vinci, 4 - 42016 Guastalla (Reggio Emilia)

Tel. +39 0522 8211 - Fax + 39 0522 821453

email foodservice@smeg.it

30

Loading...

Loading...