Page 1

Instructions for the installer

INSTRUCTIONS FOR TRANSFORMATION

THIS MANUAL IS AN INTEGRAL PART OF THE APPLIANCE. IT MUST BE KEPT

IN ITS ENTIRETY AND IN AN ACCESSIBLE PLACE FOR THE WHOLE

WORKING LIFE OF THE PRODUCT. INSTALLATION MUST BE CARRIED OUT

BY QUALIFIED PERSONNEL IN ACCORDANCE WITH THE REGULATIONS IN

FORCE. THE MANUFACTURER DECLINES ALL RESPONSIBILITY FOR

IMPROPER USE.

This kit sold separately is designed specifically for transformation of

barbecue fuelling from GPL gas to METHANE gas.

The kit includes all the components and the instructions necessary in

order to make the modification.

The appliance is factory set to run on GPL gas; to transform it (using the

following kit) you must change the nozzles on all the burners, regulate the

primary air only of the barbecue compartment burners and also regulate

the minimum flame on the gas taps.

At the end of these operations, replace the label “regulated for gas” on the

back of the barbecue with the label provided in the kit.

The installation must be carried out by a specialised technician.

WARNING: Keep the product's standard installation nozzles and the

“regulated for gas” label, since reconversion from METHANE gas to GPL

gas could be necessary in the future.

In the case of reconversion to GPL gas, the conversion procedure is

identical to that described below for METHANE gas.

KIT CONTENTS

The contents of the methane gas transformation kit are listed below:

• NOZZLES FOR METHANE GAS.

• SEALING GASKET.

• LABEL “REGULATED FOR GAS”

TRANSFORMATION).

10

(TO BE APPLIED AFTER THE

Page 2

Instructions for the installer

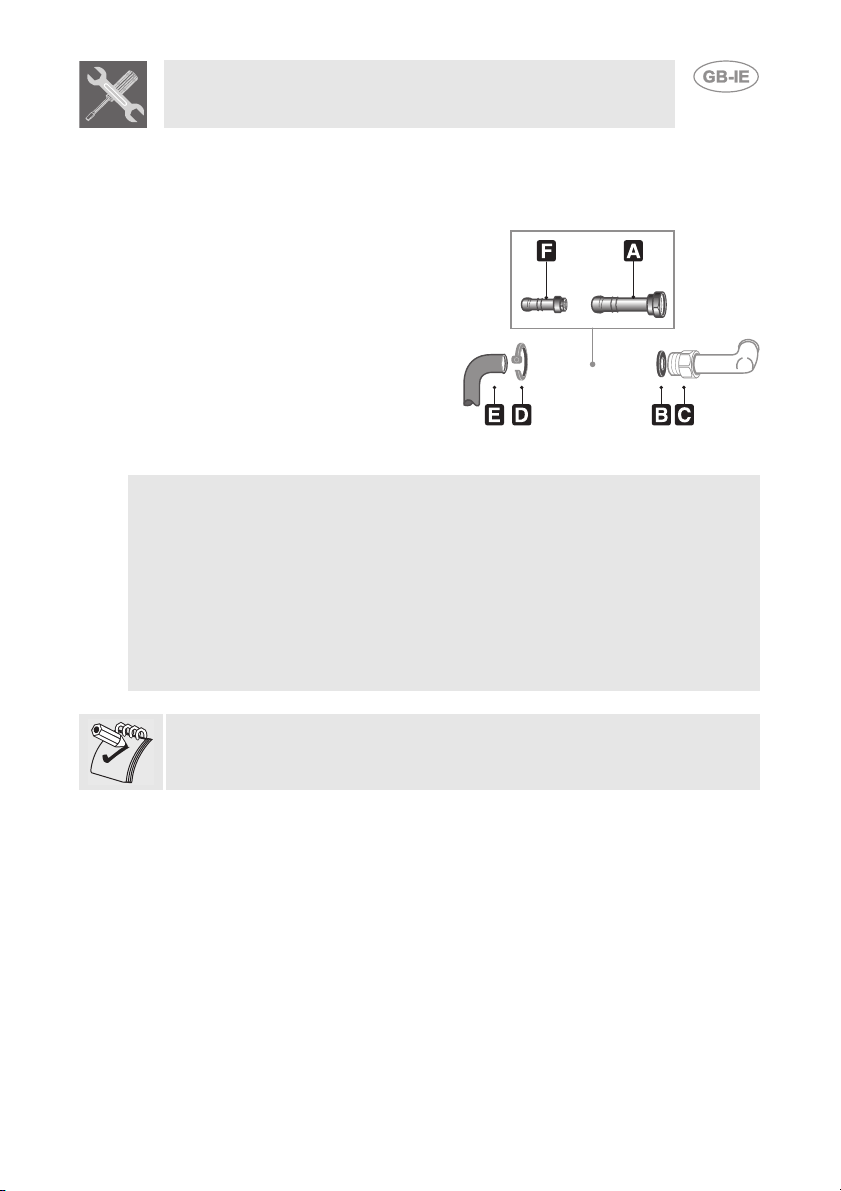

GAS MAINS CONNECTION

The product must be connected to the

methane gas mains by means of a

standards-compliant rubber or flexible

steel hose.

Screw the connector (A) inserting the

sealing gasket (B) at the barbecue inlet

connector (C); see the drawing at the

side. Depending on the diameter of the

hose, you may or may not need to attach

smaller connector (F) to the connector

(A) attached previously.

Push the hose (E) onto the connector (A)

or (F) and secure it to the connector by

means of a clamp (D).

Verify that the following conditions are met:

• the hose is fixed to the hose connection with safety clamps.

• it is possible to inspect the entire length of the hose (max 1.5 m).

• no part of the hose is in contact with the hot walls (max. 50°C).

• the hose is not under traction or tension and has no tight curves or twists.

• the hose is not in contact with sharp objects or sharp corners.

• if the hose is not perfectly airtight and leaks gas, do not try to repair it;

replace it with a new tube.

• verify that the hose is not beyond its life cycle.

If the product was installed on a trolley (optional) lock the wheels using the

appropriate stops. Any traction or tension forces exerted on the hose

could jeopardise the safety of the product.

11

Page 3

Instructions for the installer

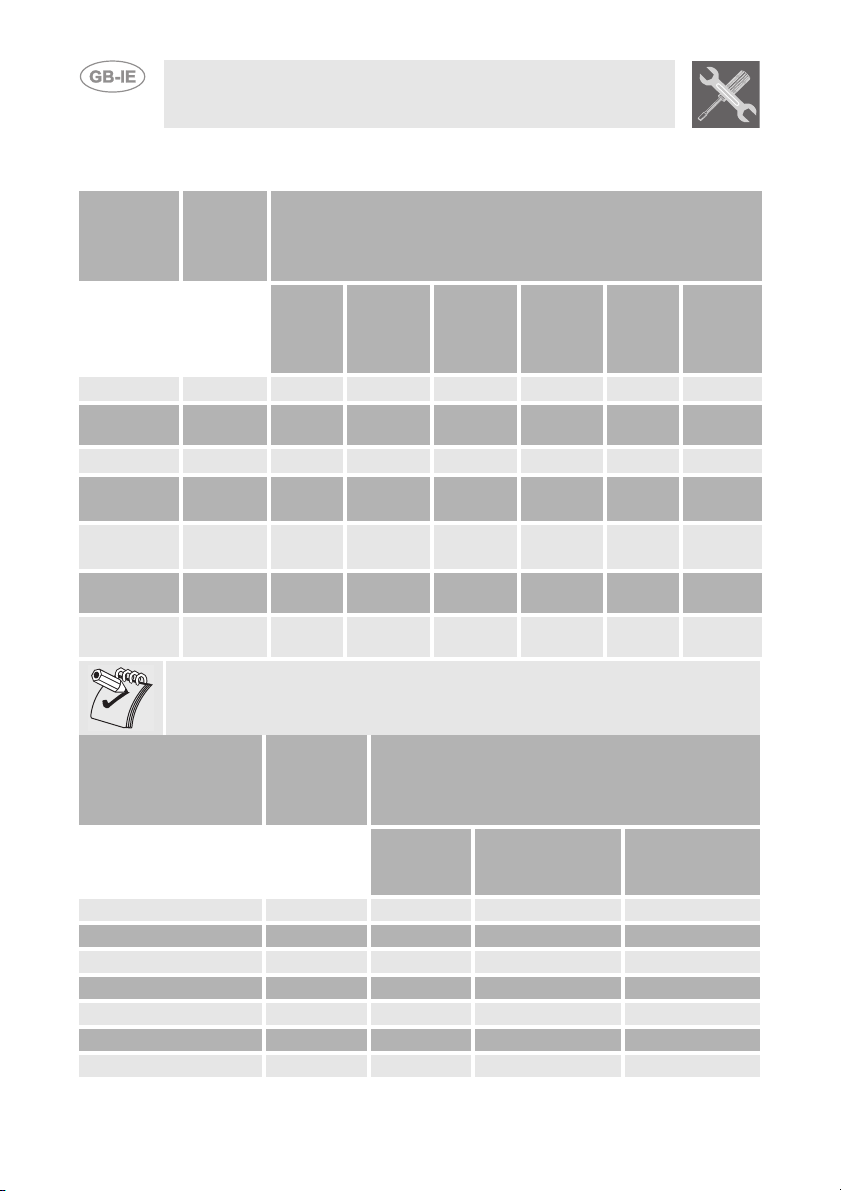

BURNER, NOZZLE AND GAS CONSUMPTION CHARACTERISTICS

BQ61T - BQ6130T - BQ91T

Rated

Burner

Left 4.5 closed 100

Centre

(BQ91T)

Right 4.5 closed 100

Radiating

grill

Radiating

grill (BQ91T)

Rapid

(BQ6130T)

Auxiliary

(BQ6130T)

heating

capacity

(kW)

no.

turns

by-pass

4.5 closed 100

3.8 1 + 1/4 95

4.5 1 + 1/4 105

3.0 closed 85

1.05 closed 50

In the column no. turns by-pass, closed means screwed in fully.

LPG – G30/G31 30/37 mbar

Nozzle

diameter

1/100

mm

By-pass

1/100

mm

85

85

85

Reg.

Reg.

45

30

Reduced

flowrate

(W)

2200

2200

2200

2500

2700

800

400

Flow-

rate

g/h G30

327 321

327 321

327 321

276 271

327 321

218 214

76 75

Flow-

rate

g/h G31

Rated

Burner

Left 4.5 360° + 90° 150 2200

Centre (BQ91T) 4.5 360° + 90° 150 2200

Right 4.5 360° + 90° 150 2200

Radiating grill 3.8 360° + 360° 145 2500

Radiating grill (BQ91T) 4.5 720° + 180° 155 2700

Rapid (BQ6130 - S) 3.0 180° 108 800

Auxiliary (BQ6130 - S) 1.05 180° 72 400

12

heating

capacity

(kW)

Methane gas – G20 20 mbar

no. turns

by-pass

Nozzle diameter

1/100 mm

Reduced

flowrate

(W)

Page 4

Instructions for the installer

BQ61 - BQ6130 - BQ91 - BQ61S - BQ6130S - BQ91S

Rated

Burner

Left 3.0 closed 80

Centre left

(BQ91S - BQ91)

Centre 3.0 closed 80

Centre right

(BQ91S - BQ91)

Right 3.0 closed 80

Rapid

(BQ6130 - S)

Auxiliary

(BQ6130 - S)

heating

capacity

(kW)

no.

turns

by-pass

3.0 closed 80

3.0 closed 80

3.0 closed 85

1.05 closed 50

In the column no. turns by-pass, closed means screwed in fully.

Nozzle

diameter

1/100

mm

LPG – G30/G31 30/37 mbar

By-pass

1/100

mm

75

75

75

75

75

45

30

Reduced

flowrate

(W)

1800

1800

1800

1800

1800

800

400

g/h G30

Flow-

rate

Flowrate

g/h G31

218 214

218 214

218 214

218 214

218 214

218 214

76 75

Rated

Burner

Left 3.0 315° 123 1800

Centre left (BQ91S - BQ91) 3.0 315° 123 1800

Centre 3.0 315° 123 1800

Centre right (BQ91S - BQ91) 3.0 315° 123 1800

Right 3.0 315° 123 1800

Rapid (BQ6130 - S) 3.0 180° 115 800

Auxiliary (BQ6130 - S) 1.05 180° 72 400

heating

capacity

(kW)

Methane gas – G20 20 mbar

rotation

by-pass

Nozzle diameter

1/100 mm

Reduced

flowrate

(W)

13

Page 5

Instructions for the installer

CHANGING THE NOZZLES

CHANGING THE BURNER COMPARTMENT

NOZZLES

1 Remove the grills and refractory plates (where

present) located inside the barbecue compartment.

2 Unscrew the screw(s) (for each burner) located on

the rear crosspiece.

3 Remove the burners from the barbecue

compartment.

4 Using a 7mm socket wrench, unscrew the nozzles

positioned on the taps (Change the nozzles

according to the table provided above).

5 Regulate the air (see primary air adjustment). 6 Replace the burners correctly and screw the

holding screws.

CHANGING THE RADIATING GRILL NOZZLES

(ONLY ON MODELS BQ61T - BQ6130T - BQ91T)

1 Remove the rear part of the barbecue by

unscrewing the support screws.

2 Using a 7mm wrench unscrew the nozzle (1). 3 Change the nozzles according to the table

provided above. To facilitate the nozzle insertion

operations the nut can be unscrewed (2).

4 Screw back the nut (2) taking great care. 5 Replace the rear part, screwing it into place with

the holding screws.

REPLACING RAPID - AUXILIARY BURNER

NOZZLES

(

ONLY ON MODELS BQ6130T - BQ6130S - BQ6130)

1 2

1 Remove the grids, the caps and the flame-

spreader crowns;

2 Using a 7mm wrench unscrew the nozzle of the

burner.

3 Change the nozzles according to the table

provided above.

4 Replace the burners, the caps and the flame-

spreader crowns correctly in their appropriate

positions.

14

Page 6

Instructions for the installer

PRIMARY AIR ADJUSTMENT

Carry out the following operations for every burner

present in the barbecue compartment:

PRIMARY AIR ADJUSTMENT WITH “SINGLE

PARALLEL FLAME” BURNERS

1 Loosen the adjustment screw A of the air

regulation sleeve.

2 Turn the registration sleeve B to the position that

corresponds to the type of gas to be used

according to the table below.

3 Tighten the adjustment screw making sure that the

distance X is correct (See table below).

PRIMARY AIR ADJUSTMENT WITH “DUAL

PARALLEL FLAME” BURNERS

1 Loosen the adjustment screw A of the air

regulation sleeve.

2 Extract or insert the registration sleeve B to the

position that corresponds to the type of gas to be

used according to the table below.

3 Tighten the adjustment screw making sure that the

distance X is correct (See table below).

X

A

B

METHANE (N)

Single parallel

flame burners

X= 1.5 mm 4 mm 4 mm 8 mm

G30/G31 (GPL)

Single parallel

flame burners

METHANE (N)

Dual parallel

flame burners

G30/G31 (GPL)

Dual parallel

flame burners

15

Page 7

Instructions for the installer

BURNER MINIMUM ADJUSTMENT

CONVERSION FROM GPL GAS TO METHANE

GAS

Carry out the following operations on all the gas taps.

1 Extract the knob. 2 Make sure that the by-pass inside is fully screwed

in. Use a screw driver inside the tap rod or at the

side (See the drawing at the side).

3 Turn the by-pass according to the table BURNER,

NOZZLE AND GAS CONSUMPTION

CHARACTERISTICS (see page 11).

4 When the adjustments are completed, insert the

knob and light the relative burner bringing it to the

minimum position . The flame at minimum

should be regular.

5 Check the stability of the flame by rapidly turning

the knob from the maximum to the minimum

position. The flame should not go out.

6 If the minimum flame is not regular, remove the

knob and move the by-pass with small clockwise

or counter-clockwise turns and repeating the flame

stability check. If the flame is regular, the minimum

adjustment operation has been successful.

CONVERSION FROM METHANE GAS TO GPL

GAS

Carry out the following operations on all the gas taps.

1 Extract the knob. 2 Turn the by-pass inside, screwing it in fully. Use a

screw driver inside the tap rod or at the side (See

the drawing at the side).

3 In the case of the grill tap, after having screwed

the by-pass fully in, unscrew it 360° + 90 °.

16

Loading...

Loading...