Page 1

Instructions for the Installer

CONVERSION INSTRUCTIONS

THIS MANUAL IS AN INTEGRAL PART OF THE APPLIANCE. TAKE GOOD CARE

OF IT AND KEEP IT TO HAND THROUGHOUT THE APPLIANCE'S LIFE CYCLE.

INSTALLATION MUST BE CARRIED OUT BY QUALIFIED STAFF IN

COMPLIANCE WITH THE RELEVANT REGULATIONS. THE MANUFACTURER

DECLINES ALL LIABILITY FOR IMPROPER USES OTHER THAN THOSE

STATED ABOVE.

This kit, for separate sale, has been specially designed to convert the

barbecue from LPG to NATURAL GAS.

It contains all the components and instructions necessary for the

conversion procedure.

The appliance is set in the factory to operate on LPG. The conversion

procedure (requiring the kit described below) involves replacement of all

the burner nozzles, adjustment of the primary air flow of the barbecue

section burners only, and adjustment of the minimum flame setting on the

gas taps.

On completion of these operations, replace the “regulated for gas” label on

the rear of the barbecue with the one supplied in the kit.

The installation work must be carried out by a skilled technician.

WARNING: Keep all the nozzles factory-fitted on the appliance, the union

supplied and the “regulated for gas” label. It might be necessary to convert

the appliance back from NATURAL GAS to LPG in the future.

When converting back to LPG the conversion procedure is exactly the

same as that described below for NATURAL GAS.

CONTENTS OF THE KIT

The contents of the natural gas conversion kit are listed below:

• NATURAL GAS NOZZLES.

• 5/8" TO 1/2" GAS MALE UNION.

• SEAL.

• "REGULATED FOR" LABEL

(TO BE APPLIED AFTER CONVERSION).

9

Page 2

Instructions for the Installer

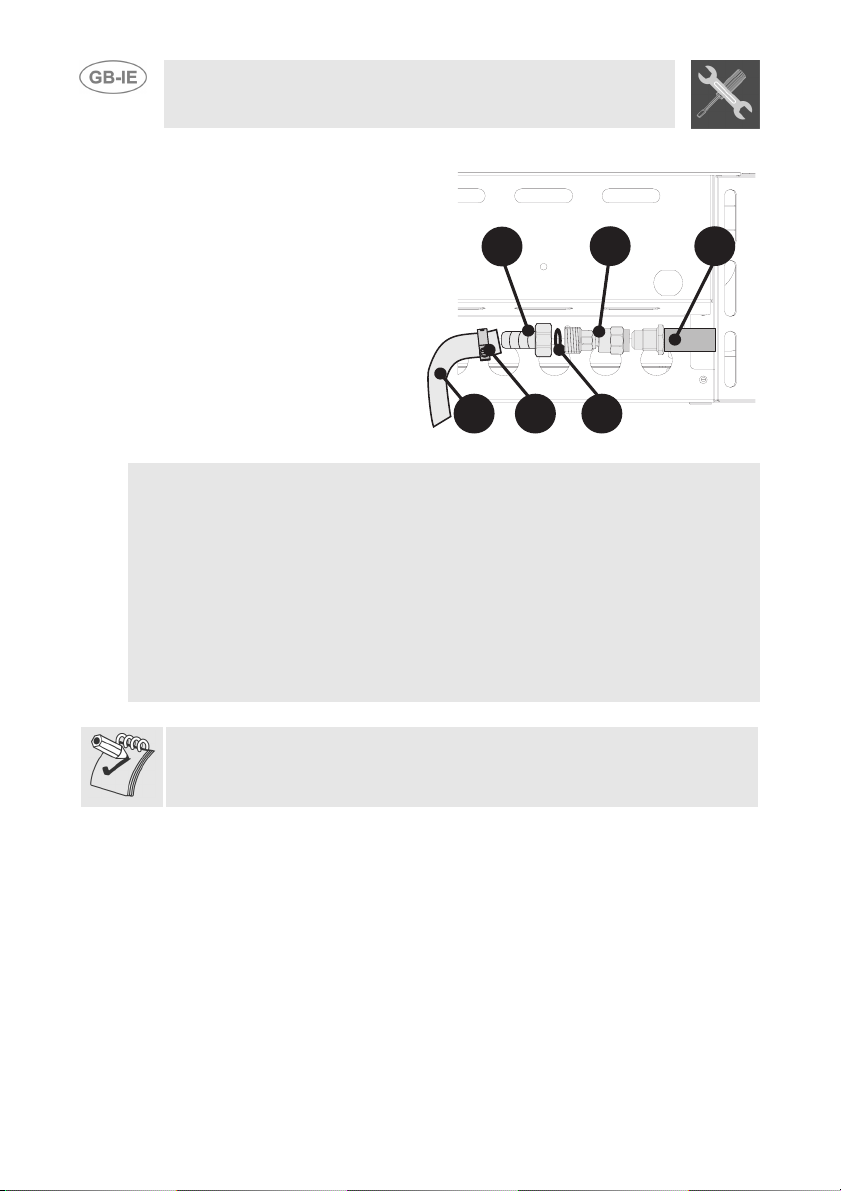

CONNECTION TO THE MAINS GAS SUPPLY

Connect the appliance to the mains

natural gas supply using a rubber or

steel hose in accordance with the

relevant regulations.

Screw the 5/8”-1/2” union (B)

supplied onto the barbecue's gas

inlet (C).

Screw the union (A) onto the union

(B) fitting the seal (D) between

them, as shown. Fit the hose (F)

onto the union (A) and secure it with

a band clamp (E).

Check that all the conditions listed below are met:

• the hose must be fixed to the hose connector with a safety band clamp;

• the hose must be accessible for inspection along its entire length (max. 1.5 m).

• the hose must not touch hot surfaces at any point (max. 50°C).

• there must not be any traction forces or stresses acting on the hose or any

tight bends or kinks in it.

• the hose must not touch sharp components or edges.

• if the hose is not perfectly gastight and causes gas leaks, do not attempt

to repair it ; replace it with a new hose.

• check that the hose's expiration date has not been passed.

A

EF

B

D

C

10

If the appliance has been mounted on the optional trolley, lock the wheels

using the clamps provided. Any pulling or tension on the hose might

reduce the appliance's safety level.

Page 3

Instructions for the Installer

BURNER, NOZZLE AND GAS CONSUMPTION DATA TABLES

Rated

Burner

Left 4.5 closed 100

Central

(BQ90T)

Right 4.5 closed 100

Radiant grill 3.8 1 + 1/4 95

Radiant grill

(BQ90T)

Ultrarapid

(BQ6030T)

heat

capacity

(kW)

n. turns

by-pass

4.5 closed 100

4.5 1 + 1/4 105

3.5 closed 94

In the by-pass n. of turns column, closed means fully screwed down.

Bottled gas – G30/G31 30/37 mbar

Nozzle

diameter

1/100

mm

By-pass

1/100

mm

85

85

85

Adj.

Adj.

65

Reduced

heat

capacity

(W)

2200

2200

2200

2500

2700

1500

Capacity

g/h G30

327 321

327 321

327 321

276 271

327 321

254 250

Capacity

g/h G31

Rated heat

Burner

Left 4.5 1 + 1/4 150 2200

Central (BQ90T) 4.5 1 + 1/4 150 2200

Right 4.5 1 + 1/4 150 2200

Radiant grill 3.8 2 145 2500

Radiant grill (BQ90T) 4.5 2 + 1/2 155 2700

Ultrarapid (BQ6030T) 3.5 1 133 1500

capacity

(kW)

n. turns

by-pass

Natural gas - G20 20 mbar

Nozzle diameter

1/100 mm

Reduced heat

capacity

(W)

11

Page 4

Instructions for the Installer

CHANGING THE NOZZLES

REPLACING THE BURNER SECTION NOZZLES

1 Remove the grids and refractory plates inside the

barbecue section.

2 Undo the screws (for each burner) on the rear

cross-member.

3 Remove the burners from the barbecue section. 4 Using a 7 mm socket wrench, undo the nozzles on

the taps (replace the nozzles as specified in the

table above).

5 Adjust the primary air flows (see adjusting primary

air flows section).

6 Put the burners back into place correctly and

tighten the fixing screws.

REPLACING THE RADIANT GRILL NOZZLES (ON

TOP VERSIONS ONLY)

1 Remove the rear of the barbecue by undoing the

supporting screws.

2 Using a 7 mm spanner, unscrew the nozzle (1). 3 Replace the nozzles as specified in the table

above. To make it easier to fit the nozzle, the nut

(2) can be unscrewed.

4 Retighten the nut (2) with great care. 5 Fit the rear part back into place and screw on with

the fixing screws.

REPLACING THE ULTRARAPID BURNER NOZZLE

(BQ6030 MODELS ONLY)

1 Remove the grid, the burner cap and the flame

diffuser ring.

2 Using a 7 mm socket wrench, unscrew the burner

nozzle.

3 Replace the nozzle as specified in the table above. 4 Put the burner, the burner cap and the flame

diffuser ring back into place correctly.

5 Fit the rear part back into place and screw on with

the fixing screws.

1 2

12

Page 5

Instructions for the Installer

ADJUSTING THE PRIMARY AIR FLOWS

The operations below must be carried out for every

burner in the barbecue section:

ADJUSTING THE PRIMARY AIR FLOW FOR "U"SHAPED BURNERS

1 Undo the adjuster screw A of the air regulator

sleeve.

2 Turn the regulator sleeve B into the position for the

type of gas to be used, consulting the table below.

3 Tighten the regulator screw, making sure that the

distance X is correct (see table below).

ADJUSTING THE PRIMARY AIR FLOW FOR

"PARALLEL FLAME" BURNERS

1 Undo the adjuster screw A of the air regulator

sleeve.

2 Pull the regulator sleeve B out or push it in to

achieve the position for the type of gas to be used,

consulting the table below.

3 Tighten the regulator screw, making sure that the

distance X is correct (see table below).

X

X

A

B

A

B

NATURAL GAS

(N) U-shaped

burners

X = 4 mm 8 mm 2 mm 8 mm

G30/G31 (LPG)

U-shaped

burners

NATURAL GAS (N)

Parallel flame

burners

G30/G31 (LPG)

Parallel flame

burners

13

Page 6

Instructions for the Installer

ADJUSTING THE BURNER MINIMUM SETTING

CONVERTING FROM LPG TO NATURAL GAS

Perform the operations described below on all the gas

taps.

1 Pull off the knob. 2 Make sure that the by-pass inside is screwed fully

down. Use a screwdriver inside or on the side of

the rod (see right).

3 Turn the bypass as stated in the BURNER

CHARACTERISTICS, NOZZLES AND GAS

CONSUMPTION table (see page 10).

4 When adjustments are complete, fit the knob, light

the relative burner and turn it to the minimum

setting . The flame should be even at the

minimum setting.

5 Check that the flame remains stable when the

knob is turned quickly from the maximum to the

minimum setting. The flame must not go out.

6 If the minimum flame is not even, remove the knob

and make small clockwise or anti-clockwise

adjustments to the bypass then check stability

again. Otherwise the minimum flame has been

adjusted successfully.

CONVERTING FROM NATURAL GAS TO LPG.

Perform the operations described below on all the gas

taps.

1 Pull off the knob. 2 Turn the by-pass inside, screwing it fully down.

Use a screwdriver inside or on the side of the rod

(see right).

3 For the grill tap, after screwing the bypass fully

down back it off by 1+1/4 turn.

14

Loading...

Loading...