Page 1

Contents

1. INSTRUCTIONS FOR SAFE AND PROPER USE _____________________ 18

2. INSTALLATION OF THE OVEN ___________________________________ 20

3. DESCRIPTION OF CONTROLS __________________________________ 22

4. USE OF THE OVEN ____________________________________________ 24

5. CLEANING AND MAINTENANCE _________________________________ 27

6. EXTRAORDINARY MAINTENANCE _______________________________ 29

INSTRUCTIONS FOR THE INSTALLER: these are intended for the

qualified technician who must install the appliance, set it functioning

and carry out an inspection test.

INSTRUCTIONS FOR THE USER: these contain user advice,

description of the commands and the correct procedures for cleaning

and maintenance of the appliance.

17

Page 2

Introduction

1. INSTRUCTIONS FOR SAFE AND PROPER USE

THIS MANUAL IS AN INTEGRAL PART OF THE APPLIANCE AND

THEREFORE MUST BE KEPT IN ITS ENTIRETY AND IN AN ACCESSIBLE

PLACE FOR THE WHOLE WORKING LIFE OF THE OVEN. WE ADVISE

READING THIS MANUAL AND ALL THE INSTRUCTIONS THEREIN BEFORE

USING THE OVEN. INSTALLATION MUST BE CARRIED OUT BY QUALIFIED

ENGINEERS IN ACCORDANCE WITH THE REGULATIONS IN FORCE. THIS

OVEN IS INTENDED FOR COMMERCIAL USES AND CONFORMS TO

CURRENT REGULATIONS IN FORCE. THE APPLIANCE HAS BEEN BUILT TO

CARRY OUT THE FOLLOWING FUNCTIONS: COOKING AND HEATING-UP

OF FOOD. ALL OTHER USES ARE CONSIDERED IMPROPER.

THE MANUFACTURER DECLINES ALL RESPONSIBILITY FOR IMPROPER

USE.

DO NOT LEAVE THE PACKING IN THE HOME ENVIRONMENT. SEPARATE

THE VARIOUS WASTE MATERIALS AND TAKE THEM TO THE NEAREST

SPECIAL GARBAGE COLLECTION CENTRE.

IT IS OBLIGATORY FOR THE ELECTRICAL SYSTEM TO BE GROUNDED

ACCORDING TO THE METHODS REQUIRED BY SAFETY RULES.

WHEN LINKING UP TO MAINS BY PLUG AND SOCKET, MAKE SURE THAT

BOTH ARE COMPATIBLE AND CONNECT BY MEANS OF A POWER CABLE

COMPLYING WITH APPLICABLE REGULATIONS.

THE SOCKET MUST BE ACCESSIBLE AFTER THE APPLIANCE HAS BEEN

BUILT IN.

NEVER UNPLUG BY PULLING ON THE CABLE.

DO NOT OBSTRUCT VENTILATION OPENINGS AND HEAT DISPERSAL

SLITS.

18

IMMEDIATELY AFTER INSTALLATION CARRY OUT A BRIEF INSPECTION

TEST OF THE OVEN, FOLLOWING THE INSTRUCTIONS BELOW. SHOULD

THE APPLIANCE NOT FUNCTION, DISCONNECT IT FROM THE SUPPLY AND

CALL THE NEAREST TECHNICAL ASSISTANCE CENTRE.

NEVER ATTEMPT TO REPAIR THE APPLIANCE.

ALWAYS CHECK THAT THE CONTROL KNOBS ARE IN THE 0 (OFF)

POSITION WHEN YOU FINISH USING THE OVEN.

Page 3

Introduction

NEVER PUT INFLAMMABLE OBJECTS IN THE OVEN: THEY COULD BE

ACCIDENTALLY LIGHTED AND CAUSE FIRES.

THE APPLIANCE BECOMES VERY HOT DURING USE. SUITABLE HEATPROOF GLOVES SHOULD BE WORN FOR ALL OPERATIONS.

THE I.D. PLATE WITH TECHNICAL DATA, REGISTRATION NUMBER AND

BRAND NAME IS LOCATED IN AN EXPOSED POSITION AT THE REAR OF

THE OVEN.

THE PLATE MUST NOT BE REMOVED.

THE APPLIANCE IS INTENDED FOR COMMERCIAL USE BY

APPROPRIATELY TRAINED PERSONNEL. CHILDREN SHOULD ALWAYS BE

KEPT OUT OF ITS REACH AND NEVER BE ALLOWED TO PLAY WITH IT.

THE HARDNESS OF THE WATER USED IN THE OVEN WATER RESERVOIR

FOR STEAMING MUST NOT EXCEED 10-11°F. USE NATURAL MINERAL

WATER, OR TAP WATER THAT HAS BEEN TREATED WITH A WATER

PURIFICATION OR SOFTENING SYSTEM.

REPLACED APPLIANCES MUST BE TAKEN TO A SPECIAL GARBAGE

COLLECTION CENTRE.

The manufacturer declines all responsibility for damage to persons

or things caused by non-observance of the above prescriptions or by

interference with any part of the appliance or by the use of non-original

spares.

19

Page 4

Instructions for the installer

2. INSTALLATION OF THE OVEN

The oven must be set up on a perfectly flat surface and left standing

free. Make sure to allow enough room at the sides for easy access to the

terminal strip for connection of the power cable to mains.

Installation must be carried out by a qualified technician in compliance

with applicable regulations in force.

2.1 Electrical connection

Make sure that the power line voltage matches the specifications

indicated on the rating plate located to the rear of the oven. This rating

plate must never be removed.

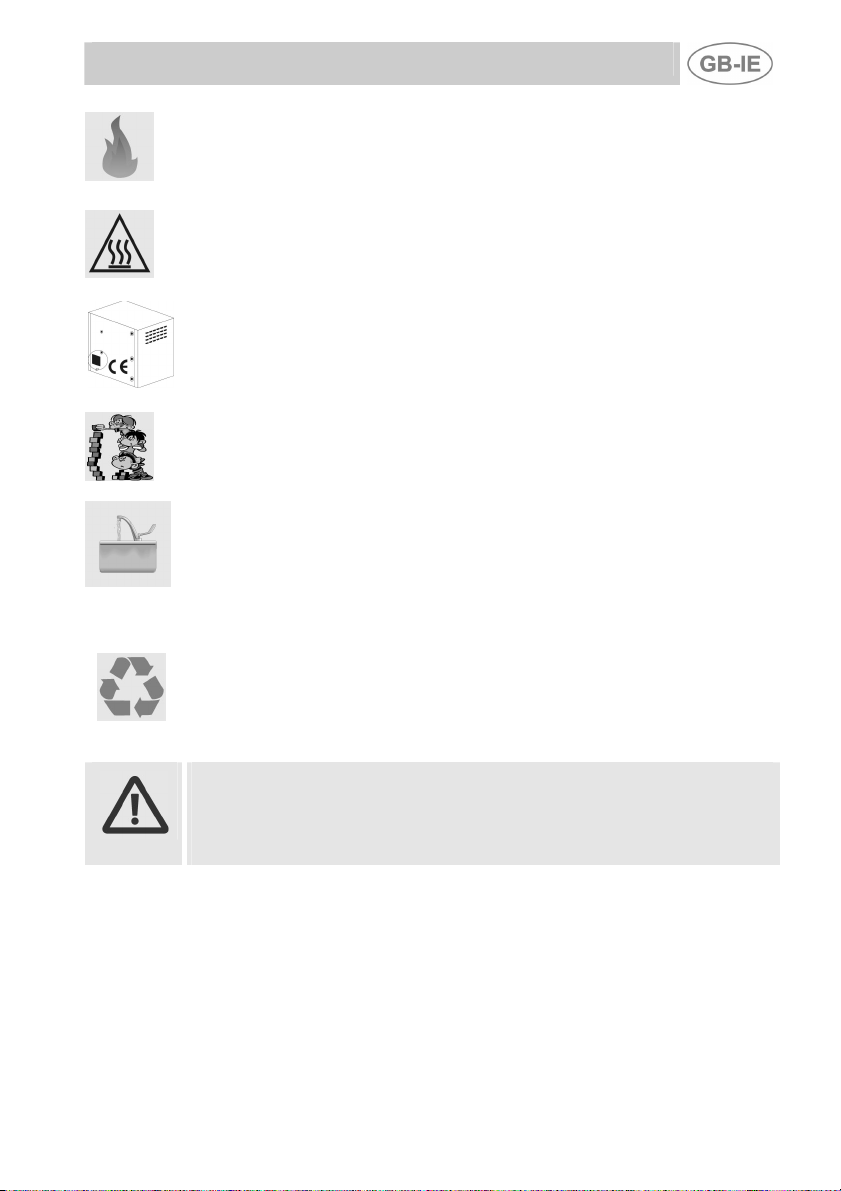

For operation on 400-415V 3N∼: use

an H07RN-F-type five-core cable (5 x

1.5 mm2).

20

Make sure that plug and wall socket are of the same type and are in

conformity with regulations in force. Also check that the power supply

line is provided with adequate earthing. Avoid using adapters or

shunters.

In case of permanent connection, ensure that power cable is equipped

with an easily accessible omnipolar switch fitted in proximity to the

apparatus and with a gap between contacts equal to or greater than

3 mm.

Page 5

Instructions for the installer

The power supply connector on the back of the oven may be used only

for supplying the optional extractor hood, which has maximum power

absorption of 300W.

2.1.1 Safety thermostat

The oven is fitted with a safety device which trips in case of serious

malfunction. To reset, contact the nearest servicing centre.

The manufacturer declines all responsibility for damage to persons

or things caused by non-observance of the above prescriptions or by

interference with any part of the oven.

2.2 Levelling

Adjust the four feet so as to set the oven on a perfectly level plane. For

this purpose, loosen the lock nut and unscrew the foot. The range of

adjustment of the screw is 10 mm.

2.3

Water line connection

Connect the water intake valve on the back to the water supply using a

hose with a ¾ gas thread, making sure that the connections are secured

tightly.

If the water hose is new or has not been used for a long period of time,

run the water to ensure that the water is clear and free of impurities

before you connect it. This is a precautionary measure serving to avoid

the risk of the water causing blockage and thus damaging the appliance.

You are advised to supply the oven with a water pressure ranging

between a minimum of 50 KPa and a maximum of 500 KPa.

An exhaust pipe is fitted on the top of the

oven to allow the discharge of steam

during cooking. Make sure that it's no

way obstructed.

21

Page 6

Instructions for the user

3. DESCRIPTION OF CONTROLS

All oven knobs and controls are

located on the side panels.

STEAM REGULATION KNOB

This knob with two positions allows the elimination of steam

during cooking that is formed during the cooking phase. The

outlet values go from 0 to 1 and all intermediate zones can be

used.

THERMOSTAT KNOB

This permits selection of the ideal cooking temperature.

Rotate clockwise to the desired temperature (50° to 250°C).

Adjustment is progressive so that the oven also operates at

any intermediate value.

ORANGE LIGHT

When on, indicates that oven is heating up. When the set

temperature is reached, the light goes off. During the cooking

cycle, the light comes on and goes off various times signalling

that the temperature in the oven is being kept constant as per

the set value.

GREEN LIGHT

When off, indicates that timed cooking is in progress. When

on, indicates that the timed cooking cycle has been

completed.

TIMER KNOB

This permits to select manual or timer-controlled cooking with

automatic turning off of the oven at end of the cooking cycle.

To set to manual, turn the knob anticlockwise to .

To set cooking time, turn the knob clockwise. Time is

expressed in minutes (5 to 60). Adjustment is progressive so

that time can also be set to any intermediate value. Upon

22

Page 7

Instructions for the user

completion of the cooking cycle, the knob automatically

returns to 0, the oven turns off and a buzzer signal is set off,

which switches off automatically after 20 seconds.

STEAM EROGATION KNOB

This serves for selecting the amount of steam most suited to

the foods to be cooked.

Turning the knob clockwise, the selection options range from

the 0 setting (no steam is supplied), to the 1 setting (maximum

steam supply). Steam continues to be supplied until the knob

is released; once released the knob automatically returns to

the 0 setting.

N.B.: The oven thermostat knob must be set between 150°

and 250°C for steaming.

23

Page 8

Instructions for the user

4. USE OF THE OVEN

4.1 Warnings and general advice

When using for the first time, it is advisable to

heat up the oven to its maximum temperature

(250°C) for enough time to burn off any

possible oily manufacturing residues.

It should be borne in mind that when the oven

door is opened, the heating elements and the

fan are automatically switched off. This means

that, if the food being cooked needs to be

checked, it is best to leave the door open for as

short a time as possible in order to avoid the

temperature inside the oven from dropping too

much and thus compromising cooking results.

To prevent any problems that could be caused

from the steam in the oven, open the door in

two stages: keep the door ajar (about 5-6 cm)

for 4-5 seconds and then open it fully.

4.2 Oven lights

The lights inside the oven come on automatically upon turning the

Moving air at ambient temperature causes frozen food to quickly thaw.

thermostat knob.

4.3 Cooking hints

THE OVEN DIMENSIONS ARE DESIGNED FOR A OVERALL LOAD

OF 15 KG.

4.3.1 Defrosting

TIMER KNOB

SET TO MANUAL

THERMOSTAT KNOB

SET TO VENTILATION

This type of thawing is ideal as the taste and appearance of the defrozen food, whether previously deep-frozen or frozen in the domestic

freezer, remain unaltered.

24

Page 9

Instructions for the user

The oven heats up as signalled by the orange light going on. Upon the

The oven heats up as signalled by the orange light going on. Upon the

4.3.2 Pre-heating

Before cooking, it is advisable to pre-heat the oven to the desired

temperature for at least 15 minutes.

4.3.3 Manual cooking

TIMER KNOB

SET TO MANUAL

THERMOSTAT KNOB

SET TO BETWEEN 50° AND 250°C

EX.

set temperature being reached, the light goes off. The orange light

comes on and goes off various times during the cooking cycle indicating

that the temperature in the oven is being kept constant.

4.3.4 Timed cooking

TIMER KNOB

SET TO BETWEEN 5' AND 60'

THERMOSTAT KNOB

SET TO BETWEEN 50° AND 250°C

set temperature being reached, the light goes off. The orange light

comes on and goes off various times during the cooking cycle indicating

that the temperature in the oven is being kept constant. Upon completion

of the cooking cycle, the oven automatically turns off, the green light

comes on and the buzzer sounds for a few seconds. To completely turn

off, set the thermostat knob to 0.

EX.

25

Page 10

Instructions for the user

4.3.5 Steaming foods

STEAM DISTRIBUTION KNOB

THERMOSTAT KNOB

TIMER KNOB

On pos. 1

(max. 10 sec. a time)

BETWEEN 150° AND 250°C

No steam is created at temperatures lower than 150°C: temperatures

below 150°C give rise to condensation and consequent dripping.

Therefore, turn the thermostat knob to 150°C and wait until the (orange)

thermostat indicator light switches off before opening the steam supply.

26

Page 11

Instructions for the user

5. CLEANING AND MAINTENANCE

Important:

never spray water directly on to the oven. Never use pressure nozzles.

Before any intervention, disconnect the power supply of the oven.

5.1 Cleaning stainless steel parts

To maintain stainless steel parts in perfect condition, clean regularly at

the end of the work day. Allow to cool first.

To clean and preserve the stainless steel surfaces, always use only

specific products that do not contain abrasives or chlorine-based acids.

How to use: pour the product on a damp cloth and wipe the surface,

rinse thoroughly and dry with a soft cloth or deerskin.

Do not use metallic sponges or sharp scrapers: they will

damage the surface.

Use normal non-abrasive products for steel, and a wooden or

plastic tool if necessary.

Rinse thoroughly and dry with a soft cloth or deerskin.

Do not allow residues of sugary foods (such as jam) to set

inside the oven. If left to set for too long, they might damage

the enamel lining of the oven.

27

Page 12

Instructions for the user

5.2 Cleaning the inside of the oven

To maintain the oven in perfect condition, clean it regularly at the end of

the work day. Allow to cool first. Take off all removable parts.

Remove the side guides by lifting them and extracting them from the

supporting pins (as shown in the diagram).

28

• Clean oven grill and side guides with warm water and non-abrasive

detergents. Rinse and dry.

• Clean the inside walls of the oven with a soft cloth soaked in an

ammonia solution; rinse and dry. In case of persistent spots or dripoffs, place an ammonia-imbibed cloth on the bottom of the oven,

close the door and after a few hours wash the oven with warm water

and a liquid detergent. Rinse and dry.

5.3 Door glass

The door glass should always be kept clean. Use absorbent kitchen

paper to clean. In case of tough spots, clean with a damp sponge using

regular detergent.

Page 13

Instructions for the user

6. EXTRAORDINARY MAINTENANCE

The oven may require extraordinary maintenance or replacement of parts

subject to wear such as seals, bulbs, and so on. The following

instructions describe how to carry out these minor maintenance

operations.

Before any intervention, disconnect the power supply of the oven.

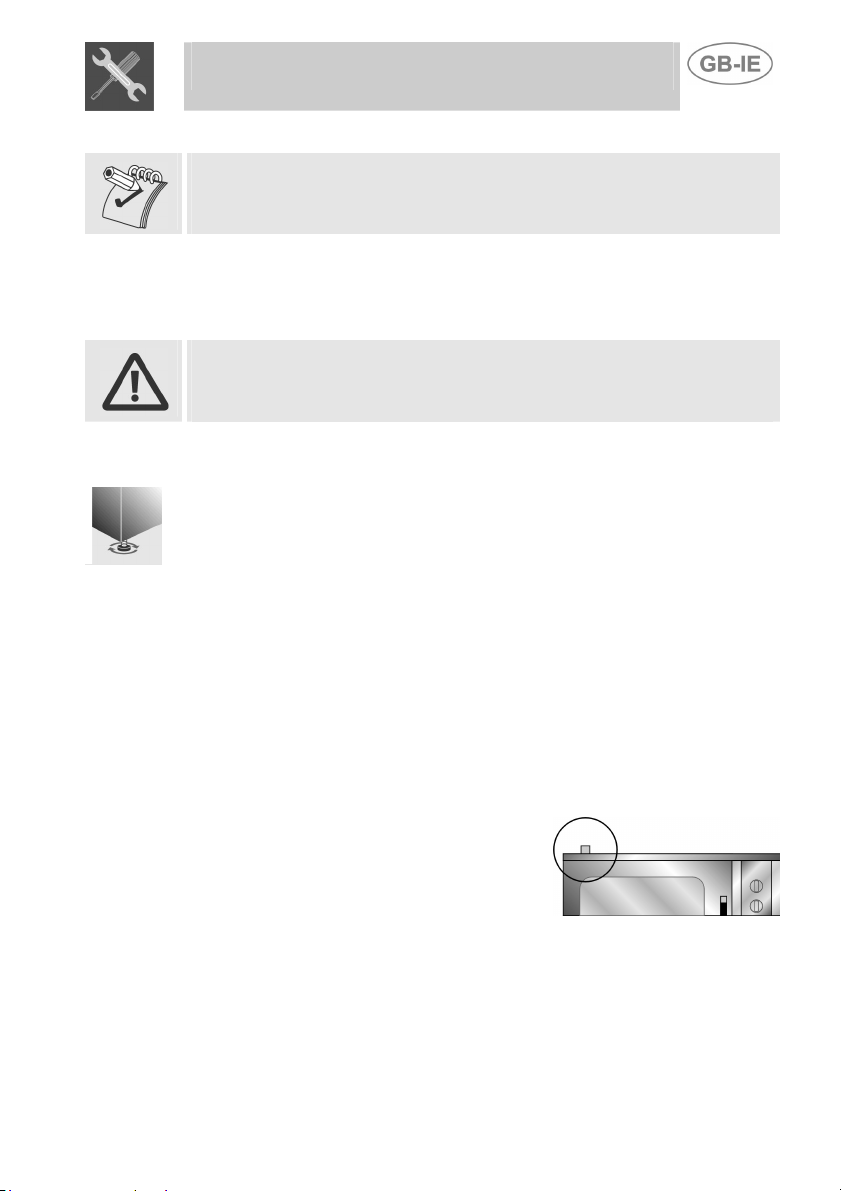

6.1 Replacing the light bulb

Remove protection cover A using a screwdriver

to pry open. Replace bulb B with a similar one.

Remount protection cover A.

Use only oven light bulbs (suitable for a temperature of up to

300°C).

29

Page 14

Instructions for the user

6.2 If the oven is not working properly

This product meets the current safety regulations in force for

electrical appliances. To prevent safety hazards for users, all

technical inspections or repairs must be carried out by qualified

persons.

If the appliance is not working properly, before calling Customer Service,

ensure that the procedures listed below have been performed. This will

help to avoid unnecessary expenses.

PROBLEM

The oven is not working

Foods either take too long

or too little to cook

No steam is being supplied

Moisture forms inside the

oven and on the foods

There is water inside the

oven

PROBABLE SOLUTION

• The minute minder knob is positioned on 0.

• The plug is not properly inserted in the socket.

• The electrical system is damaged or not

working properly.

• The fuses have blown or the circuit breakers

have been activated.

The temperature setting is incorrect.

• The control knobs have not been positioned

correctly.

• The oven door has not been closed properly.

• There is something that does not allow water to

enter inside the oven (closed tap or bent tube)

The foods are being left in the oven for too long

after cooking. Do not leave them in the oven for

more than 15-20 minutes after the end of the

cooking time.

• The device controlling the supply of water to

the water reservoir is not working properly.

• A temperature of less than 150° has been

selected.

30

Loading...

Loading...