Page 1

Important Safety Instruction

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS – Your safety and the safety of others are very important.

We have provided many important safety messages throughout this manual and on the appliance.

Read all instructions before using the appliance and always obey all safety messages.

RECOGNIZE SAFETY INFORMATION

This is a safety alert symbol. This symbol alerts you to potential hazards that can kill or hurt you and

others.

UNDERSTAND SIGNAL WORDS

A signal word – DANGER, WARNING, or CAUTION – is used with the safety-alert symbol. DANGER

identifies the most serious hazards. It means you can be killed or seriously injured if you do not

immediately

follow the instructions. CAUTION indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

All safety messages will inform you of potential hazards, on how to reduce the risk of injury and what

can occur if the instructions are not followed.

IMPORTANT: Observe all governing codes and ordinances.

follow the instructions. WARNING means you can be killed or seriously injured if you do not

WARNING: For your safety, the information in this manual must be followed to minimize the risk

of fire or explosion, or to prevent property damage, personal injury or death.

- This conversion kit must be installed by a qualified service agency in accordance with the

manufacturer's instructions and all applicable codes and requirements of the authority

having jurisdiction.

- The qualified service agency is responsible for the proper installation of this kit.

- The installation shall not be considered to be correct and completed until the operation of the

converted appliance is checked as specified in the manufacturer's instructions supplied with

this kit.

FIRE HAZARD

WARNING

Securely tighten all gas connections. If connected to LP, have a qualified

person ensure that the gas pressure does not exceed 14" water column.

Examples of a qualified person include licensed heating personnel,

authorized gas company personnel, and authorized service personnel.

FAILURE TO DO SO CAN RESULT IN DEATH, EXPLOSION, OR FIRE.

3

Page 2

1)

2)

Conversion Kit

Check that the main gas supply line to the range is shut off and that the

power supply cord is disconnected.

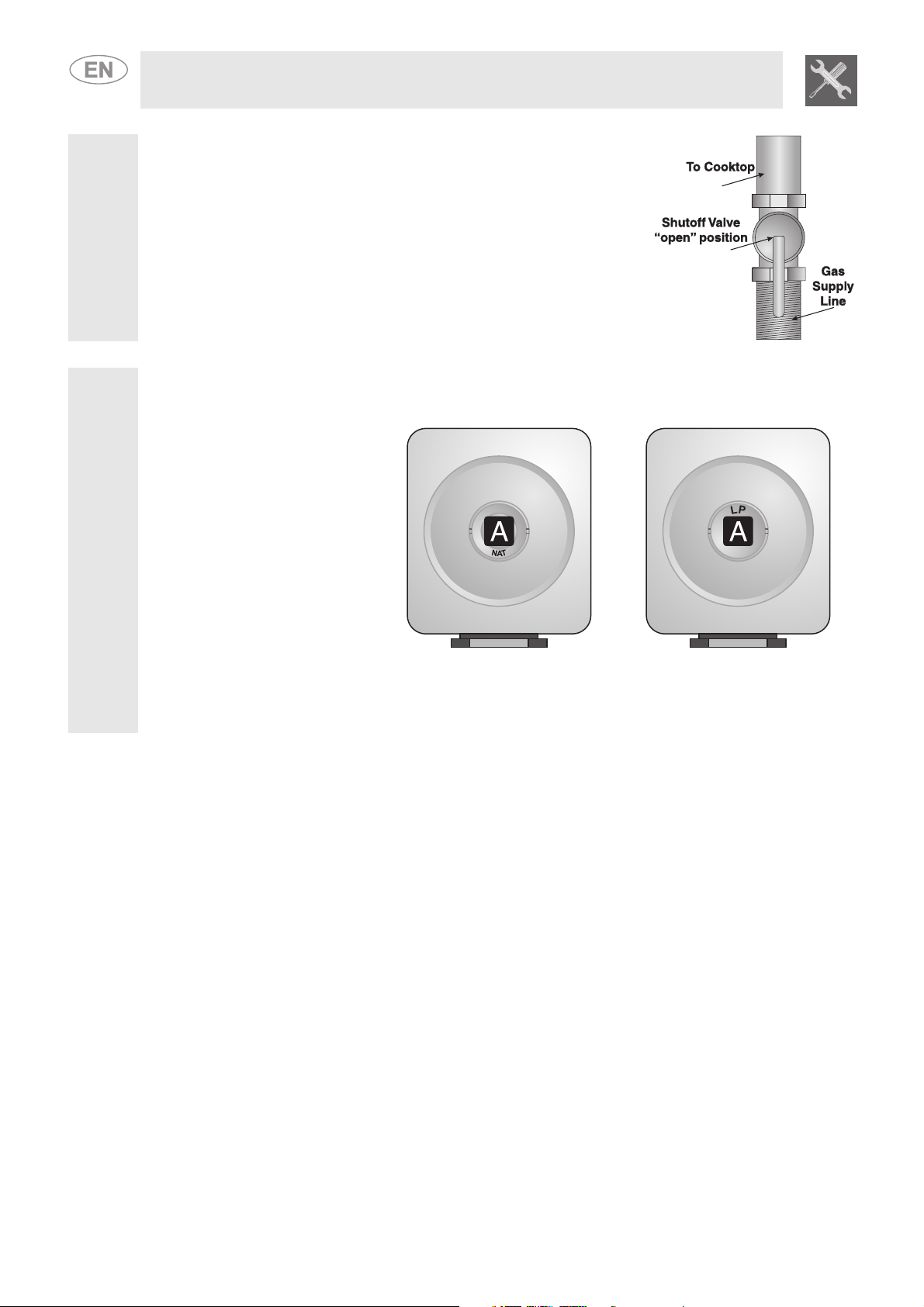

Remove access cap “A” by using a screwdriver or a quarter, turning the access cap counter-clockwise.

The gas pressure regulator has two settings which are indicated on two sides of the cap. Turn the cap

and reinstall it in the regulator with "LP" visible from the outside of the regulator.

The regulator must be checked at

a minimum water column of 1 inch

(2.5 cm) above the set pressure.

The inlet pressure to the regulator

should be as follows for operation

and checking the regulator

setting: - NATURAL GAS: Set

pressure at 4” W.C. Supply

pressure of 3

maximum; - LP GAS: Set

pressure at 11” W.C. Supply

pressure of 8” - 13” W.C.

maximum.

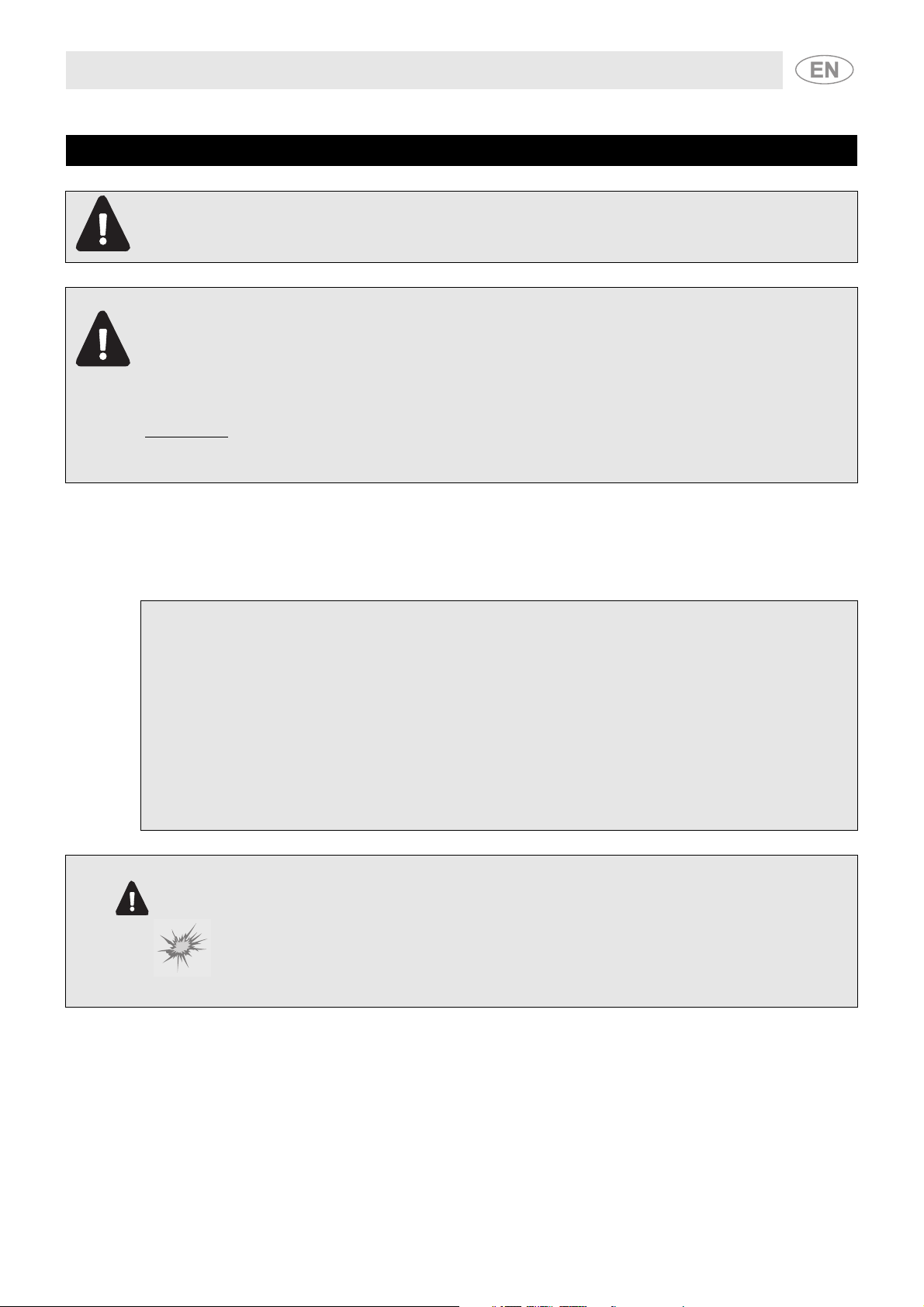

The range must be isolated from the gas supply piping system by closing the respective manual shut-off

valve during any pressure testing of the gas supply piping system at test pressures equal to or greater

than 1/2 psig (3.5 kPa).

1

/2” - 10 1/2” W.C.

4

Page 3

3)

Conversion Kit

This operation requires no primary air regulation.

1 Extract the grids and remove all the caps and flame-spreader crowns;

2 Unscrew the burner nozzles with a 7 mm socket wrench;

3 Replace the nozzles according to the type of gas to be used and the description in paragraph 3.2

“Burner and nozzle characteristics table”.

Put the burners back in their correct position.

5

Page 4

4)

Conversion Kit

To adjust the cooktop for LP gas or to return to

Natural Gas use, refer to the tables below.

Natural gas

Qt Injector Qr

BTU Ø mm BTU

Front Right 5200 1.10 1500

Front Left 3400 0.90 1200

Central

Rear Right 10000 1.52 2600

Rear Left 10000 1.52 2600

Front Right 5200

Front Left 3400

Central

Rear Right 10000

Front Left 10000

Inner 3000 0.85 1200

Outer 12000 1.17-1.17 4500

LP

Qt Injector Qr By-pass

BTU Ø mm BTU mm

Inner 3000

Outer 12000

0.65

(drw.0222)

0.54

(drw.0222)

0.50

(drw.0222)

0.70-0.70

(drw.0222)

0.90

(drw.0222)

0.90

(drw.0222)

1500 0.39

1200 0.33

1000 0.33

4000 0.65

2400 0.45

2400 0.45

NOTE: Save the nozzles removed from the appliance for future use.

FIRE HAZARD

WARNING

6

- Use a soapy solution to check for proper tightness.

- Never test for gas leaks with a match or other flames.

- Failure to follow this instruction can result in death or fire

Page 5

5)

6)

Conversion Kit

Minimum adjustment for Natural Gas

Light the burner and take it to the minimum.

Remove the gas tap knob and turn the adjustment screw inside or at the side of the tap

shaft (depending on the model) until there is a regular minimum flame.

Replace the knob and check burner flame stability: (rapidly turning the knob from

maximum to minimum position, the flame should not go out).

Repeat the operation on all the gas taps.

Minimum adjustment for LP

For regulating the minimum with LP, the screw at the side of the tap rod must be turned clockwise all the

way.

The bypass diameters for each individual burner are shown in point 4.

Once the regulation has been completed, replace the seal on the by-passes using paint or similar

materials.

7)

8)

9)

Completely fill out conversion label (part no. 91849A078) and attach the label in the storage

compartment beside the rating tag. Do not cover the rating tag with the conversion label.

At higher altitudes, no further adjustments are necessary. Derating the burners is also unnecessary.

Save the nozzles removed from the unit along with these instructions for possible future use.

NATURAL GAS:

To convert back to Natural Gas: Follow steps 3 through 5 and replace the nozzles in the order in which

they were removed.

7

Loading...

Loading...