Page 1

SST60S

60cm secret telescopic with retractable cantilevered visor

ID030608

code 3040/3

FINISH

SIZE

INSTALLATION

MOTOR

AIR EXTRACTION

SPEED

NOISE RATING

DUCTING

ILLUMINATION

AUTOMATION

CAPACITY

FILTRATION

OPTION

WARRANTY

PERFORMANCE

High efcient air extraction of up to 280 cubic metres net an

hour. Designed for the more vigorous styles of cooking, such as

stir frying, prolonged boiling and griddle cooking and can be

turned down to cater for the gentlest of simmers.

AUTOMATION

The fan extraction speed and lights can be preset to start

automatically once the rail is moved forward. At all times this

can be overridden and operated manually.

SECRET INSTALLATION

Completely concealed when not in use, the front rail cantilevers

downward and forward to create an effective catchment area

of vapours. The SST installation is via suspension from the shelf in

cabinet cavity.

QUIETNESS

48–58 dBA — minimum noise with smooth-walled motor

encasements and internal uing for low air drag and effect. All

metal joins are welded for no vibration.

SAFETY

Thermal overload protector or motor, re-retardant hardened

metal and mesh. VO self-extinguishing polycarbonate for motor

housing and internal ue.

silverfrost

562mm wide suits 60cm application

built into overhead cabinetry

2 x 100 watt single shaded pole motors with impellor

exhaust direct to atmosphere or recirculate to kitchen

three: low, medium and high, OFF separate rocker switches

48–58 dBA

125mm or (5”) diameter duct pipe required. (NB: ducting is not

supplied)

two 20 watt halogen recessed lamps, separate switch

preset fan speed and lights

280m³/hour net

removable aluminium mesh piece (4-ply), washable

activated charcoal lter, part number 08999875

two years parts and labour

DUCTING

Ideally, the extracted air is ducted direct to the atmosphere

via the top exit. This direct ducting ensures maximum removal

of the grease, oil particle-laden vapour and, importantly,

the removal of the heat and odours, resulting in a more

comfortable cooking environment.

RECIRCULATION

When the cooking vapours cannot be ducted, simply redirect

the extracted and ltered air into the kitchen via a duct pipe

through the overhead cabinetry. A more frequent inspection

and cleaning of the grease lter is recommended.

DUCTING MATERIAL

Smooth internal walled duct pipe lengths ensure the most

efcient air movement and quieter operation. Consider either

high temperature rated PVC or galvanised sheet metal piping.

The exible ducting can be ideal for a very short, tight run.

CHARCOAL FILTERS

This is a purchasable accessory and easily tted within the

grease lter. It effectively diminishes cooking odours in the

recirculation mode. These lters are not to be washed, but are

replaceable.

WARRANTY

Two years parts and labour.

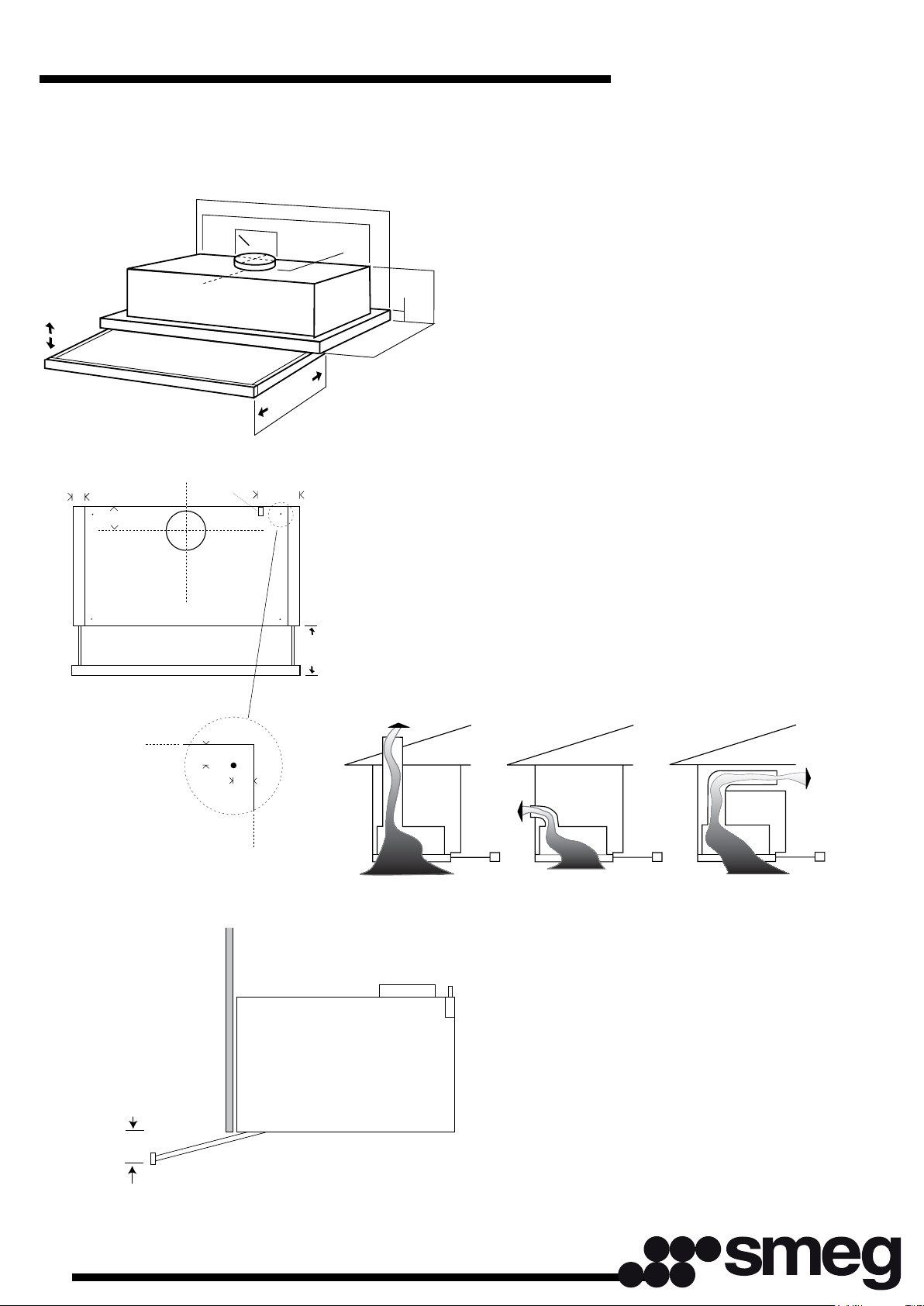

Page 2

SST60S rangehood

ducted ducted

recirculated

562

498

O123

80

0 -150

280

40

170

glass visor

130

32

power cord

1.3m

80

22

20

pickup

points for

shelf

suspension

cabinet

removable spigot

(collar)

1.3m

power cord

60

60cm secret telescopic with retractable cantilevered visor

ID030608

code 3040/3

height

width

depth

packaged dimensions

gross weight

net weight

capacity

noise rating

electrical supply

electrical connection

motor

maximum current

lights

air exit aperture

duct size

supplied

170mm

562mm

280mm closed, 430mm open

645mm x 380mm x 265mm = 0.65m³

9.1kg

8.6kg

3

280m

/hr net

48–58 dB

240 volt, 50 Hz

1.3m connected power cord with 3-pin plug suits

standard 10 amp GPO

2 x 100 watt single shaded pole with 1.2 impellor

1.0 amp

two x 20-watt halogen

123mm diameter collar supplied (spigot)

125mm diameter duct piece required

• template for mounting

• spigot for duct piece

• screws

• one-way buttery valve for spigot (removable)

• instructions for installation, operation and

maintenance

NB: drawings are not to scale

— they are to assist only

WARNING: technical specications and product sizes can be varied by the manufacturer

without notice. Cutouts for appliances should only be by physical product measurements.

The above information is indicative only.

Loading...

Loading...