Document Revision: 7.E

Web Configurator

Template Revision: 71

T17022

ProtoNode FPC-N34 and ProtoNode FPC-N35

Start-up Guide

For Interfacing Weil-McLain Products:

SlimFit 1000-2000 Series 1 (SOLA), Evergreen, SlimFit 550-750 Series 2 & 3,

SlimFit 1000-2000 Series 2 and SVF Models

To Building Automation Systems:

BACnet MS/TP, BACnet/IP, Modbus TCP/IP, Metasys N2, LonWorks and

SMC Cloud

APPLICABILITY & EFFECTIVITY

Explains ProtoNode hardware and how to install it.

The instructions are effective for the above as of May 2019.

Weil-McLain ProtoNode Start-up Guide

Page 2 of 61

Technical Support

Thank you for purchasing the ProtoNode for Weil-McLain.

Please call Weil-McLain for technical support of the ProtoNode product.

Sierra Monitor Corporation does not provide direct support. If Weil-McLain needs to escalate the concern,

they will contact Sierra Monitor Corporation for assistance.

Support Contact Information:

Weil-McLain

500 Blaine Street

Michigan City IN

46360

Customer Service:

1.800.654.2109, Option 2

Email: wmtechnicalservices@weil-mclain.com

Website: www.Weil-McLain.com

Weil-McLain ProtoNode Start-up Guide

Page 3 of 61

Quick Start Guide

1. Record the information about the unit. (Section 3.1)

2. Configure the COM settings and Node-ID for any device to connect to the ProtoNode. (Section 3.3)

3. FPC-N34: Select the protocol configuration on the S Bank DIP switches. (Section 3.4)

4. BACnet MS/TP (FPC-N34): Set the MAC Address on the A Bank DIP switches. (Section 3.5.1)

5. BACnet MS/TP (FPC-N34): Set the baud rate of the BACnet MS/TP field protocol on the B Bank DIP

switches. (Section 3.5.2)

6. Connect the ProtoNode 6 pin RS-485 connector to the RS-485 network that is connected to each of

the devices. (Section 4.2)

7. Connect the ProtoNode FPC-N34 3 pin RS-485 port to the field protocol cabling, (Section 4.3)

or connect the ProtoNode FPC-N35 2 pin LonWorks port to the field protocol cabling. (Section 4.4)

8. Connect power to the ProtoNode 6 pin port. (Section 4.5)

9. Use a web browser to access the ProtoNode Web Configurator page to select the profiles of the devices

attached to the ProtoNode and enter any necessary device information. Once the devices are selected,

the ProtoNode automatically builds and loads the appropriate configuration. (Section 5)

10. Ethernet Network (FPC-N34): Use a web browser to access the ProtoNode Web Configurator page to

change the IP Address. No changes to the configuration are necessary. (Section 5.4)

11. LonWorks (FPC-N35): The ProtoNode must be commissioned on the LonWorks Network. This needs

to be done by the LonWorks administrator using a LonWorks commissioning tool. (Section 8)

Weil-McLain ProtoNode Start-up Guide

Page 4 of 61

TABLE OF CONTENTS

1 Certifications ........................................................................................................................................ 7

1.1 BTL Mark – BACnet® Testing Laboratory ....................................................................................... 7

1.2 LonMark Certification ...................................................................................................................... 7

2 Introduction .......................................................................................................................................... 8

2.1 ProtoNode Gateway ....................................................................................................................... 8

3 Setup for ProtoNode .......................................................................................................................... 10

3.1 Record Identification Data ............................................................................................................ 10

3.2 Point Count Capacity and Registers per Device .......................................................................... 10

3.3 Configuring Device Communications ........................................................................................... 11

3.3.1 Input COM Settings on Any Serial Device Connected to the ProtoNode ............................... 11

3.3.2 Set Node-ID for Any Device Attached to the ProtoNode ........................................................ 11

3.4 Selecting the Desired Protocol Configuration ............................................................................... 12

3.5 BMS Network Settings: MAC Address, Device Instance and Baud Rate .................................... 13

3.5.1 BACnet MS/TP (FPC-N34): Setting the MAC Address for BMS Network .............................. 13

3.5.2 BACnet (FPC-N34): Calculating the Default Device Instance ................................................ 14

3.5.3 BACnet MS/TP (FPC-N34): Setting the Baud Rate for BMS Network .................................... 14

3.5.3.1 Baud Rate DIP Switch Selection ..................................................................................... 14

4 Interfacing ProtoNode to Devices .................................................................................................... 15

4.1 ProtoNode FPC-N34 and FPC-N35 Showing Connection Ports .................................................. 15

4.2 Serial Device Connections to the ProtoNode ............................................................................... 16

4.2.1 Biasing the RS-485 Device Network ....................................................................................... 17

4.2.2 End of Line Termination Switch for the RS-485 Device Network ........................................... 18

4.3 Serial Network (FPC-N34): Wiring Field Port to RS-485 Network ............................................... 19

4.4 LonWorks (FPC-N35): Wiring LonWorks Devices to the LonWorks Terminal ............................. 20

4.5 Power-Up ProtoNode.................................................................................................................... 21

5 Use the ProtoNode Web Configurator to Setup the Gateway ....................................................... 22

5.1 Connect the PC to the ProtoNode via the Ethernet Port .............................................................. 22

5.1.1 Changing the Subnet of the Connected PC ............................................................................ 22

5.1.2 Changing the IP Address of the ProtoNode with FieldServer Toolbox ................................... 23

5.2 Connecting to the ProtoNode Web Configurator .......................................................................... 24

5.3 Selecting Profiles for Devices Connected to ProtoNode .............................................................. 24

5.3.1 Verify Device Communications ............................................................................................... 25

5.4 Ethernet Network: Setting IP Address for the Field Network ....................................................... 26

5.5 Change ProtoNode COM Settings........................................................................................ 28

6 BACnet: Setting Node_Offset to Assign Specific Device Instances ........................................... 29

7 How to Start the Installation Over: Clearing Profiles ..................................................................... 30

8 LonWorks (FPC-N35): Commissioning ProtoNode on a LonWorks Network.............................. 31

8.1 Commissioning ProtoNode FPC-N35 on a LonWorks Network ................................................... 31

8.1.1 Instructions to Upload XIF File from ProtoNode FPC-N35 Using Browser ............................. 31

Appendix A. Troubleshooting .................................................................................................................. 33

Lost or Incorrect IP Address ............................................................................................ 33

Viewing Diagnostic Information ....................................................................................... 34

Check Wiring and Settings............................................................................................... 35

LED Diagnostics for Communications Between ProtoNode and Devices ....................... 36

Take a FieldServer Diagnostic Capture ........................................................................... 37

Appendix A.5.1. Using the FieldServer Toolbox .................................................................................. 37

Appendix A.5.2. Using FS-GUI ............................................................................................................ 40

Appendix B. Additional Information ........................................................................................................ 41

Update Firmware ............................................................................................................. 41

BACnet: Setting Network_Number for More Than One ProtoNode on the Subnet ......... 41

Securing ProtoNode with Passwords .............................................................................. 42

Weil-McLain ProtoNode Start-up Guide

Page 5 of 61

Appendix C. Vendor Information – Weil-McLain .................................................................................... 43

SlimFit 1000-2000 Series 1 (SOLA) Modbus RTU Mappings to BACnet, Metasys N2 and

LonWorks ................................................................................................................................................ 43

Evergreen/SlimFit 550-750 Series 2 & 3/SlimFit 1000-2000 Series 2/SVF Models

Modbus RTU Mappings to BACnet, Metasys N2 and LonWorks ............................................................ 45

Appendix D. “A” Bank DIP Switch Settings ........................................................................................... 57

“A” Bank DIP Switch Settings .......................................................................................... 57

Appendix E. Reference ............................................................................................................................. 60

Specifications ................................................................................................................... 60

Appendix E.1.1. Compliance with UL Regulations .............................................................................. 60

Appendix F. Limited 2 Year Warranty ..................................................................................................... 61

Weil-McLain ProtoNode Start-up Guide

Page 6 of 61

LIST OF FIGURES

Figure 1: ProtoNode Part Numbers ............................................................................................................ 10

Figure 2: Supported Point Count Capacity ................................................................................................. 10

Figure 3: Registers per Device ................................................................................................................... 10

Figure 4: COM Settings ............................................................................................................................... 11

Figure 5: S Bank DIP Switches ................................................................................................................... 12

Figure 6: MAC Address DIP Switches ........................................................................................................ 13

Figure 7: Baud Rate DIP Switches ............................................................................................................. 14

Figure 8: BMS Baud Rate ........................................................................................................................... 14

Figure 9: ProtoNode FPC-N34 (Top) and ProtoNode FPC-N35 (Bottom) .................................................. 15

Figure 10: Device and Power Connections................................................................................................. 16

Figure 11: RS-485 Biasing Switch on the ProtoNode N34 (Left) and ProtoNode N35 (Right) ................... 17

Figure 12: RS-485 End-Of-Line Termination Switch on the ProtoNode N34 (Left) and ............................. 18

Figure 13: Connection from ProtoNode to RS-485 Field Network .............................................................. 19

Figure 14: RS-485 EOL & Bias Resistor Switches ..................................................................................... 19

Figure 15: LonWorks Terminal .................................................................................................................... 20

Figure 16: Required Current Draw for the ProtoNode ................................................................................ 21

Figure 17: Power Connections .................................................................................................................... 21

Figure 18: Ethernet Port Location ............................................................................................................... 22

Figure 19: Web Configurator Showing no Active Profiles ........................................................................... 24

Figure 20: Web Configurator Showing Available Profile Selection ............................................................. 25

Figure 21: Web Configurator Showing Active Profile Additions .................................................................. 25

Figure 22: Web Configurator Screen with Active Profiles ........................................................................... 26

Figure 23: Changing IP Address via FS-GUI .............................................................................................. 27

Figure 24: Web Configurator ProtoNode COM Settings ............................................................................. 28

Figure 25: Device COM Settings ................................................................................................................ 28

Figure 26: Web Configurator Node Offset Field.......................................................................................... 29

Figure 27: Active Profiles ............................................................................................................................ 29

Figure 28: LonWorks Service Pin Location ................................................................................................. 31

Figure 29: Sample of Fserver.XIF File Generated ...................................................................................... 32

Figure 30: Ethernet Port Location ............................................................................................................... 33

Figure 31: Error Messages Screen ............................................................................................................. 34

Figure 32: Diagnostic LEDs ........................................................................................................................ 36

Figure 33: Ethernet Port Location ............................................................................................................... 37

Figure 34: Web Configurator – Network Number Field ............................................................................... 41

Figure 35: FS-GUI Passwords Page ........................................................................................................... 42

Figure 36: Password Recovery Page ......................................................................................................... 42

Figure 37: Specifications ............................................................................................................................. 60

Weil-McLain ProtoNode Start-up Guide

Page 7 of 61

1 CERTIFICATIONS

1.1 BTL Mark – BACnet

®

1

Testing Laboratory

1.2 LonMark Certification

1

BACnet is a registered trademark of ASHRAE

The BTL Mark on ProtoNode is a symbol that indicates that a product has

passed a series of rigorous tests conducted by an independent laboratory

which verifies that the product correctly implements the BACnet features

claimed in the listing. The mark is a symbol of a high-quality BACnet product.

Go to www.BACnetInternational.net for more information about the BACnet

Testing Laboratory. Click here for the BACnet PIC Statement.

LonMark International is the recognized authority for certification, education,

and promotion of interoperability standards for the benefit of manufacturers,

integrators and end users. LonMark International has developed extensive

product certification standards and tests to provide the integrator and user

with confidence that products from multiple manufacturers utilizing LonMark

devices work together. Sierra Monitor has more LonMark Certified gateways

than any other gateway manufacturer, including the ProtoCessor,

ProtoCarrier and ProtoNode for OEM applications and the full featured,

configurable gateways.

Weil-McLain ProtoNode Start-up Guide

Page 8 of 61

2 INTRODUCTION

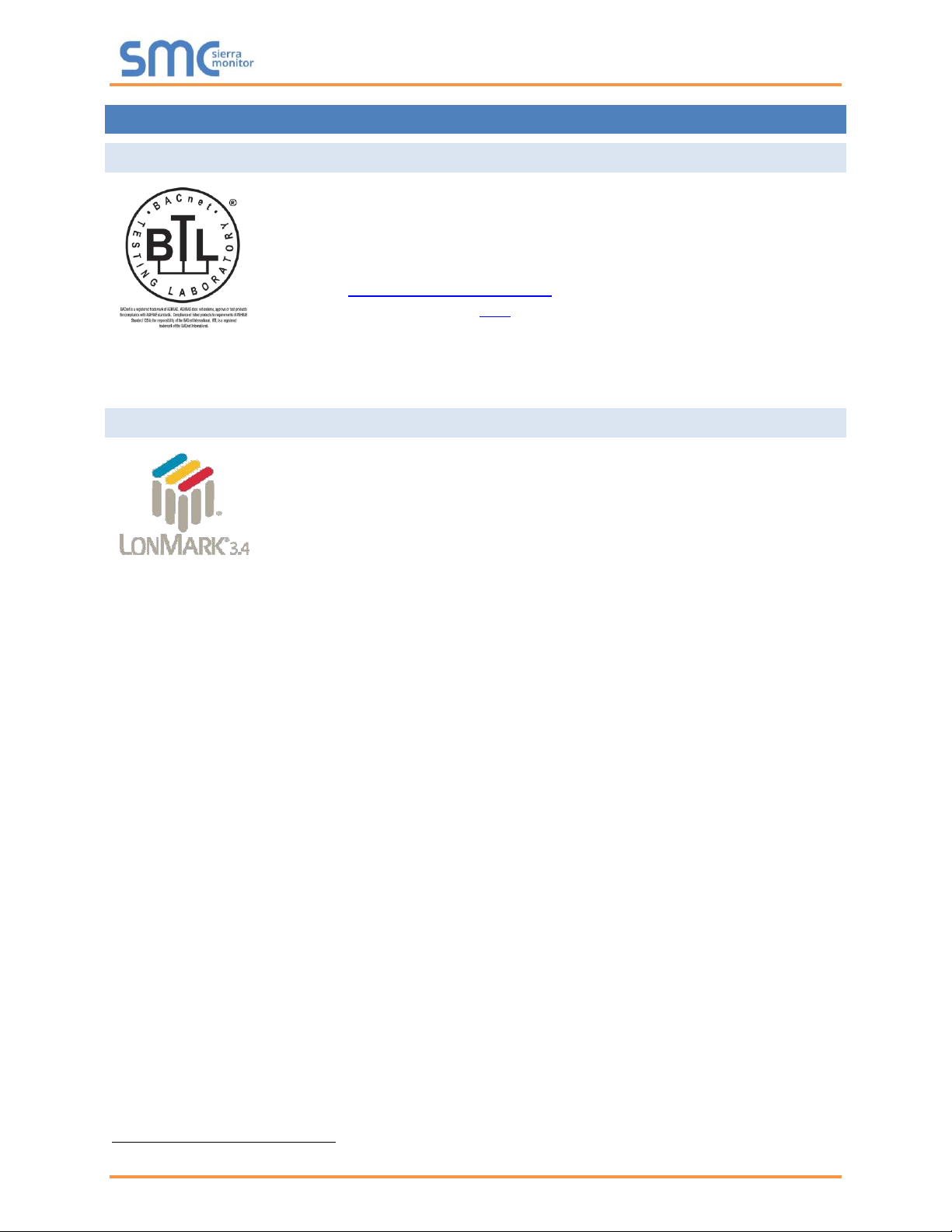

2.1 ProtoNode Gateway

The ProtoNode is an external, high performance building automation multi-protocol gateway that is

preconfigured to automatically communicate between Weil-McLain’s products (hereafter called “device”)

connected to the ProtoNode and automatically configures them for BACnet MS/TP, BACnet/IP, Metasys

®

2

N2 by JCI, Modbus TCP/IP or LonWorks

®

3

.

It is not necessary to download any configuration files to support the required applications. The ProtoNode

is pre-loaded with tested profiles/configurations for the supported devices.

WARNING: Only use screws supplied by SMC in the holes found on the back of the unit when

attaching the optional DIN rail bracket. Use of any other screws may damage the unit.

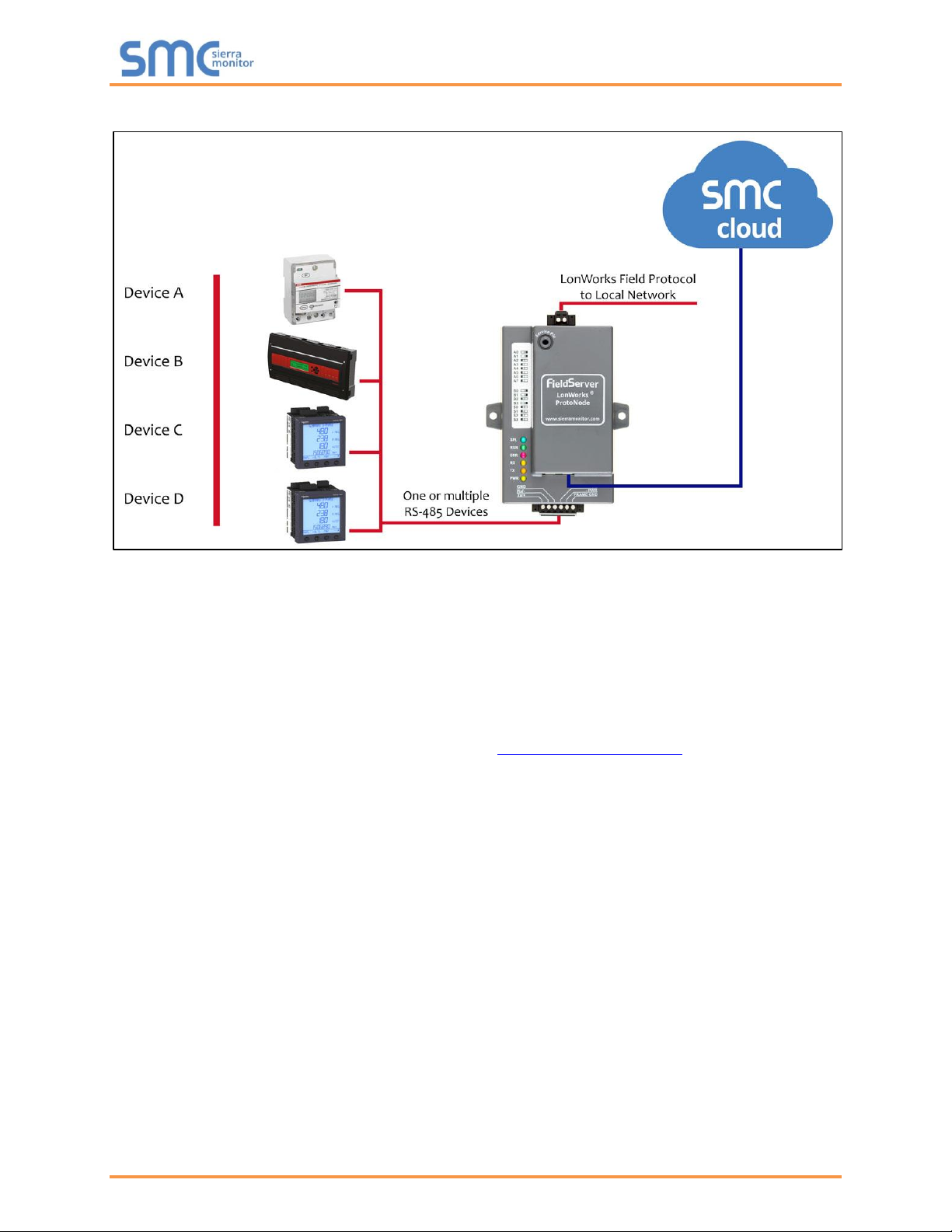

FPC-N34 Connectivity Diagram:

2

Metasys is a registered trademark of Johnson Controls Inc.

3

LonWorks is a registered trademark of Echelon Corporation

Weil-McLain ProtoNode Start-up Guide

Page 9 of 61

FPC-N35 Connectivity Diagram:

The ProtoNode can connect with Sierra Monitor’s SMC Cloud. The SMC Cloud allows technicians, the

OEM's support team and Sierra Monitor's support team to remotely connect to the ProtoNode. The SMC

Cloud provides the following capabilities for any registered devices in the field:

• Remotely monitor and control devices.

• Collect device data and view it on the SMC Cloud Dashboard and the SMC Smart Phone App.

• Create user defined device notifications (alarm, trouble and warning) via SMS and/or Email.

• Generate diagnostic captures (as needed for troubleshooting) without going to the site.

For more information about the SMC Cloud, refer to the SMC Cloud Start-up Guide.

Weil-McLain ProtoNode Start-up Guide

Page 10 of 61

3 SETUP FOR PROTONODE

3.1 Record Identification Data

Each ProtoNode has a unique part number located on the side or the back of the unit. This number should

be recorded, as it may be required for technical support. The numbers are as follows:

Model

Part Number

ProtoNode FPC-N34

FPC-N34-0970

ProtoNode FPC-N35

FPC-N35-0991

Figure 1: ProtoNode Part Numbers

• FPC-N34 units have the following 3 ports: RS-485 + Ethernet + RS-485

• FPC-N35 units have the following 3 ports: LonWorks + Ethernet + RS-485

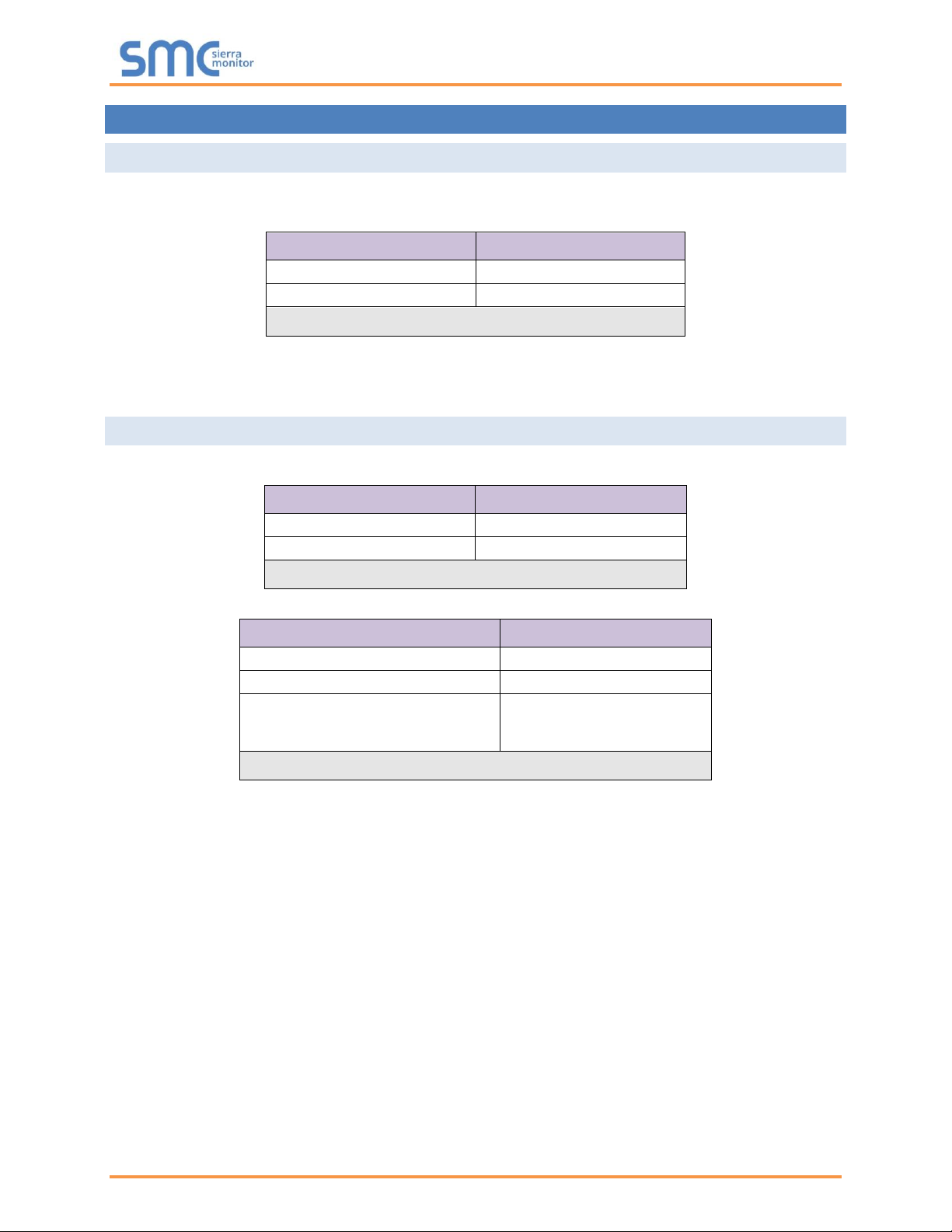

3.2 Point Count Capacity and Registers per Device

The total number of registers presented by the device(s) attached to the ProtoNode cannot exceed:

Part number

Total Registers

FPC-N34-0970

5,000

FPC-N35-0991

5,000

Figure 2: Supported Point Count Capacity

Devices

Registers Per Device

SlimFit 1000-2000 Series 1 (SOLA)

144

Evergreen

831

SlimFit 550-750 Series 2 & 3

SlimFit 1000-2000 Series 2

SVF Models

831

Figure 3: Registers per Device

Weil-McLain ProtoNode Start-up Guide

Page 11 of 61

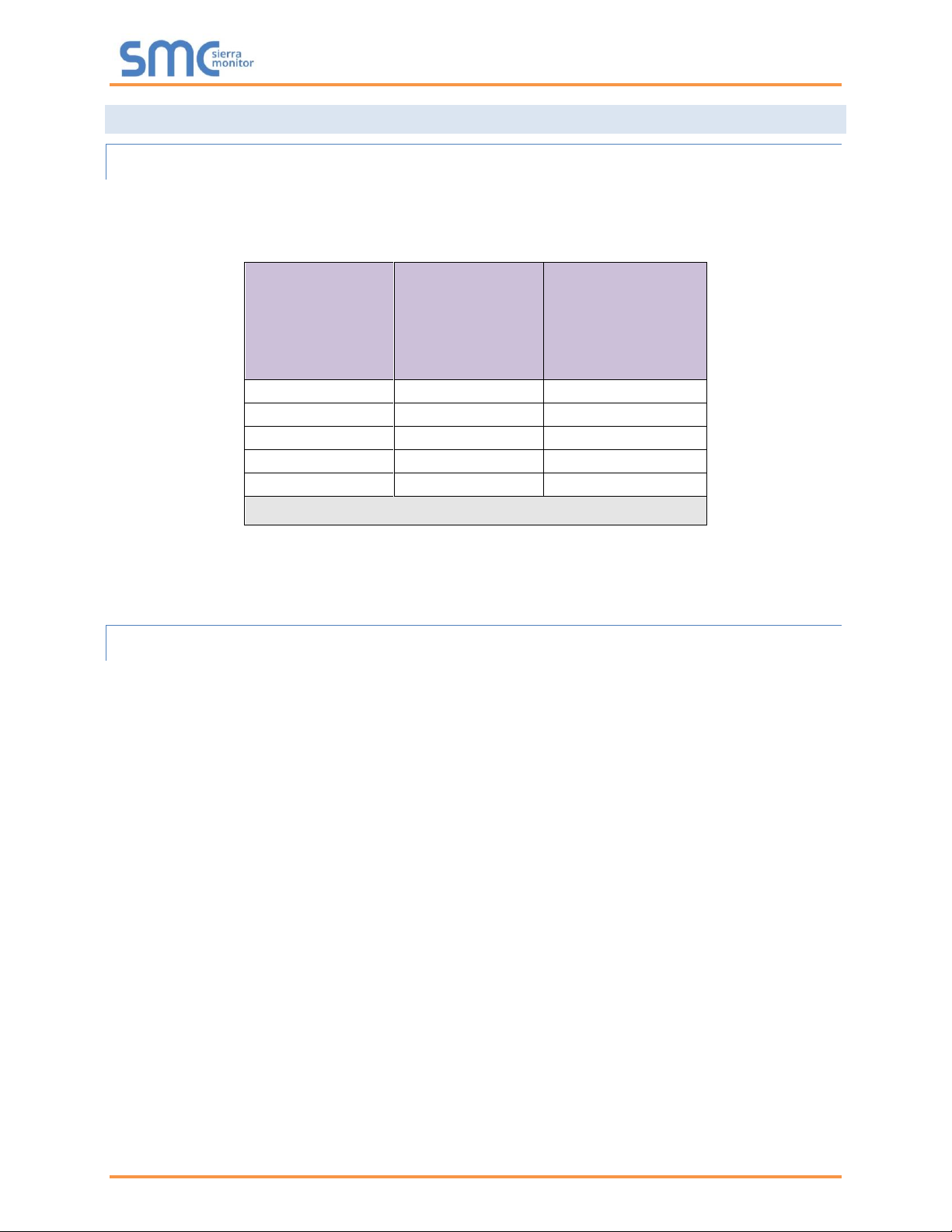

3.3 Configuring Device Communications

3.3.1 Input COM Settings on Any Serial Device Connected to the ProtoNode

• Any connected serial device MUST have the same baud rate, data bits, stop bits, and

parity settings as the ProtoNode.

• Figure 4 specifies the device serial port settings required to communicate with the ProtoNode.

Port Setting

SlimFit 1000-2000

Series 1 (SOLA)

Evergreen/

SlimFit 550-750

Series 2 & 3/

SlimFit 1000-2000

Series 2/

SVF Models

Protocol

Modbus RTU

Modbus RTU

Baud Rate

38400

19200

Parity

None

None

Data Bits

8

8

Stop Bits

1

2

Figure 4: COM Settings

NOTE: The ProtoNode default setting for the Modbus RTU serial baud rate is 19200. When

connecting devices with a different baud rate (SlimFit 1000-2000 Series 1), the baud rate

must be changed via the ProtoNode Web Configurator (Section 5.5).

3.3.2 Set Node-ID for Any Device Attached to the ProtoNode

• Set Node-ID for any device attached to ProtoNode. The Node-ID needs to be uniquely assigned

between 1 and 255.

• Document the Node-ID that is assigned to any device. The Node-ID assigned is used for deriving

the Device Instance for BACnet/IP and BACnet MS/TP. (Section 3.5.2)

NOTE: The Metasys N2 and Modbus TCP/IP field protocol Node-ID is automatically set to be the

same value as the Node-ID of the device.

Weil-McLain ProtoNode Start-up Guide

Page 12 of 61

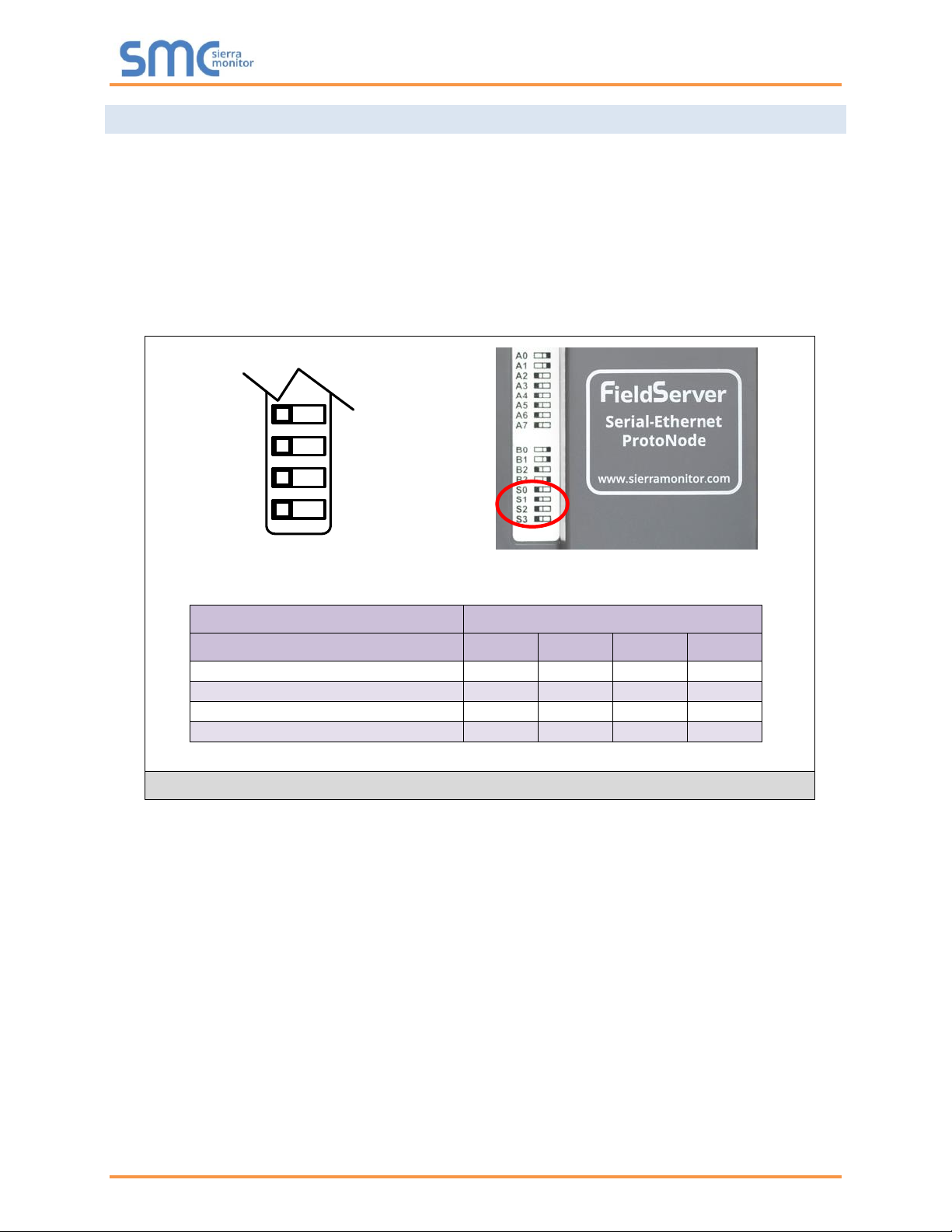

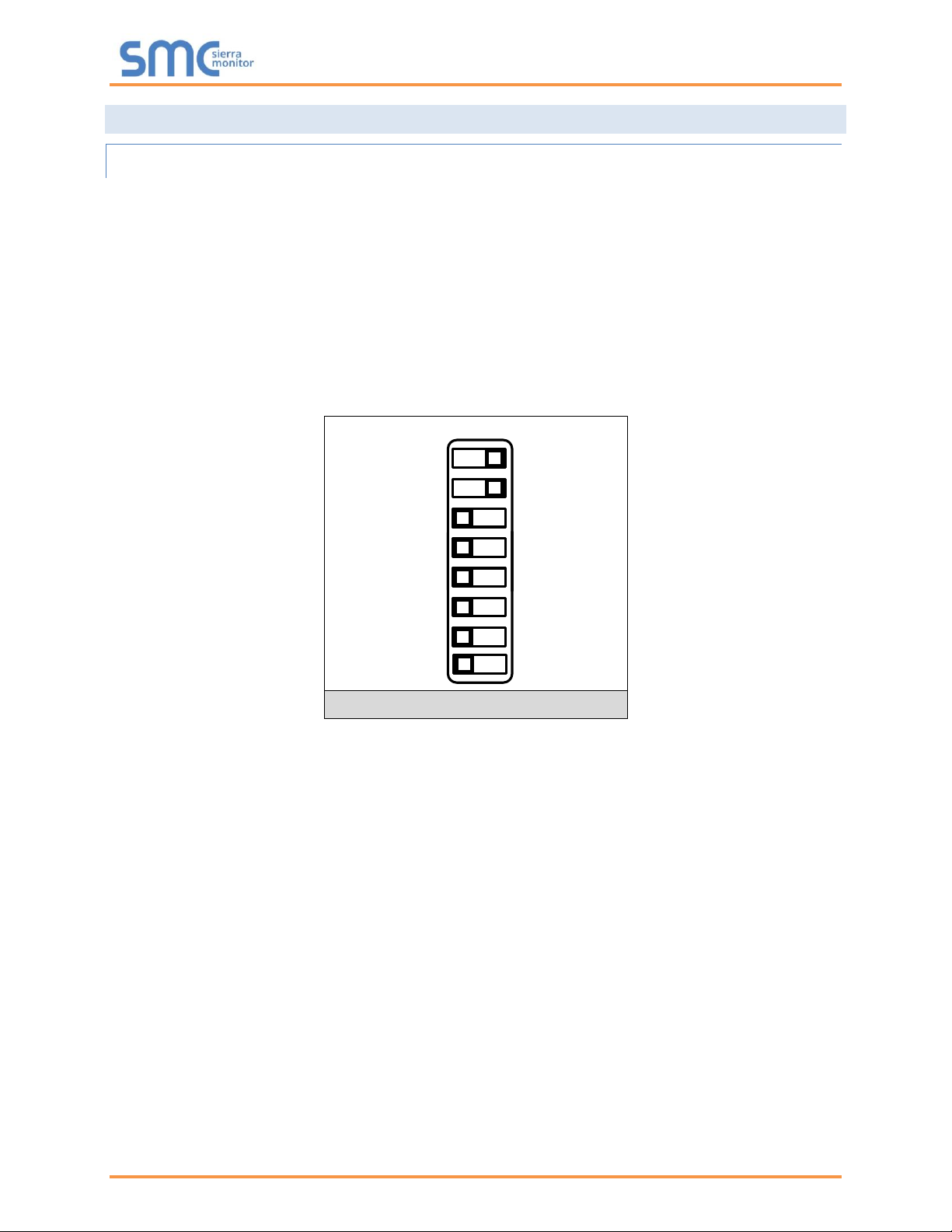

3.4 Selecting the Desired Protocol Configuration

• ProtoNode FPC-N34 units use the “S” bank of DIP switches (S0 – S3) to select the protocol

configuration.

o See the table in Figure 5 for the switch settings to select

o The OFF position is when the DIP switches are set closest to the outside of the box

• ProtoNode FPC-N35 units do not use the “S” bank DIP switches (S0 – S3) to select a field protocol.

o On ProtoNode FPC-N35 units, these switches are disabled; the field protocol is always

LonWorks

ProtoNode FPC-N34

S Bank DIP Switches

Profile

S0

S1

S2

S3

BACnet/IP

Off

Off

Off

Off

BACnet MS/TP

On

Off

Off

Off

Metasys N2

Off

On

Off

Off

Modbus TCP/IP

On

On

Off

Off

NOTE: When setting DIP switches, ensure that power to the board is OFF.

S0 – S3 DIP

Switches

S Bank DIP Switch Location

Profile Settings for ProtoNode

Figure 5: S Bank DIP Switches

S3

S2

S1

S0

Off On

Weil-McLain ProtoNode Start-up Guide

Page 13 of 61

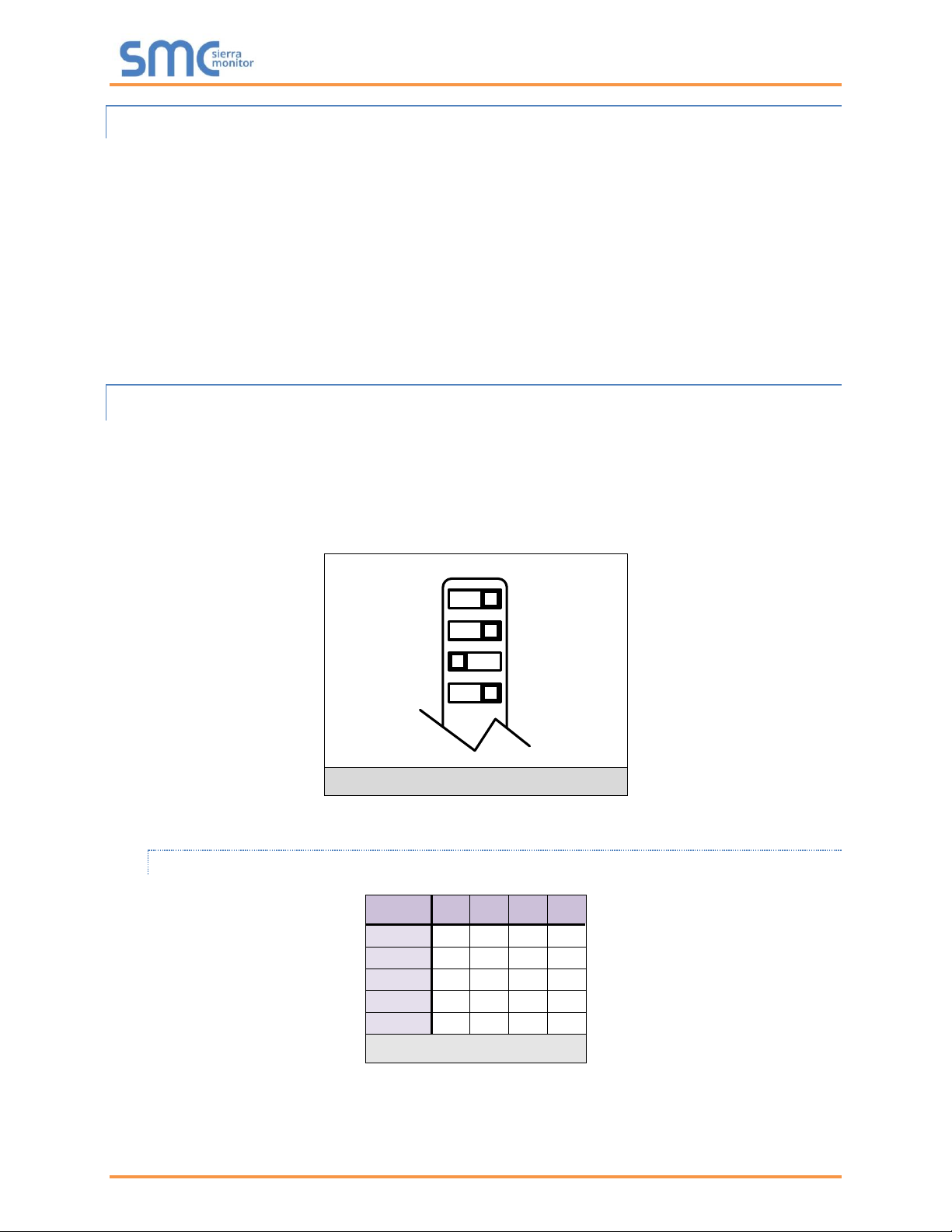

3.5 BMS Network Settings: MAC Address, Device Instance and Baud Rate

3.5.1 BACnet MS/TP (FPC-N34): Setting the MAC Address for BMS Network

• Only 1 MAC Address is set for ProtoNode regardless of how many devices are connected to

ProtoNode.

• Set the BACnet MS/TP MAC Address of the ProtoNode to a value between 1 to 127 (Master MAC

Address); this is so that the BMS front end can find ProtoNode via BACnet Auto-Discovery.

NOTE: Never set a BACnet MS/TP MAC Address of the ProtoNode to a value from 128 to 255.

Addresses from 128 to 255 are Slave Addresses and cannot be discovered by BMS front

ends that support Auto-Discovery of BACnet MS/TP devices.

• Set “A” bank DIP switches A0 – A7 to assign a MAC Address to the ProtoNode for BACnet MS/TP.

• Refer to Appendix D.1 for the complete range of MAC Addresses and DIP switch settings.

A0

A1

A2

A3

A4

A5

A6

A7

Off On

NOTE: When setting DIP switches, ensure that power to the board is OFF.

Figure 6: MAC Address DIP Switches

Weil-McLain ProtoNode Start-up Guide

Page 14 of 61

3.5.2 BACnet (FPC-N34): Calculating the Default Device Instance

• The Device Instance value is automatically generated using the following formula:

BACnet Device Instance = (Device Node ID) + (Default Node Offset)

NOTE: The default Node Offset is 50,000.

For example, if Device A has a Node ID of 1 and Device B has a Node ID of 2, then:

BACnet Device Instance A = (1) + (50000) = 50001

BACnet Device Instance B = (2) + (50000) = 50002

NOTE: The Node ID is set in Section 5.3.

• To reach a specific BACnet Device Instance result, refer to Section 6.

3.5.3 BACnet MS/TP (FPC-N34): Setting the Baud Rate for BMS Network

• DIP switches B0 – B3 can be used to set the field baud rate of the ProtoNode to match the baud

rate required by the BMS for BACnet MS/TP.

• The ProtoNode baud rate for Metasys N2 is set for 9600. DIP switches B0 – B3 are disabled for

Metasys N2 on the ProtoNode FPC-N34.

• DIP switches B0 – B3 are disabled on the ProtoNode FPC-N35 (LonWorks).

B0

B1

B2

B3

Off

On

NOTE: When setting DIP switches, ensure that power to the board is OFF.

3.5.3.1 Baud Rate DIP Switch Selection

Baud

B0

B1

B2

B3

9600

On

On

On

Off

19200

Off

Off

Off

On

38400*

On

On

Off

On

57600

Off

Off

On

On

76800

On

Off

On

On

Figure 8: BMS Baud Rate

* Factory default setting = 38400

Figure 7: Baud Rate DIP Switches

Weil-McLain ProtoNode Start-up Guide

Page 15 of 61

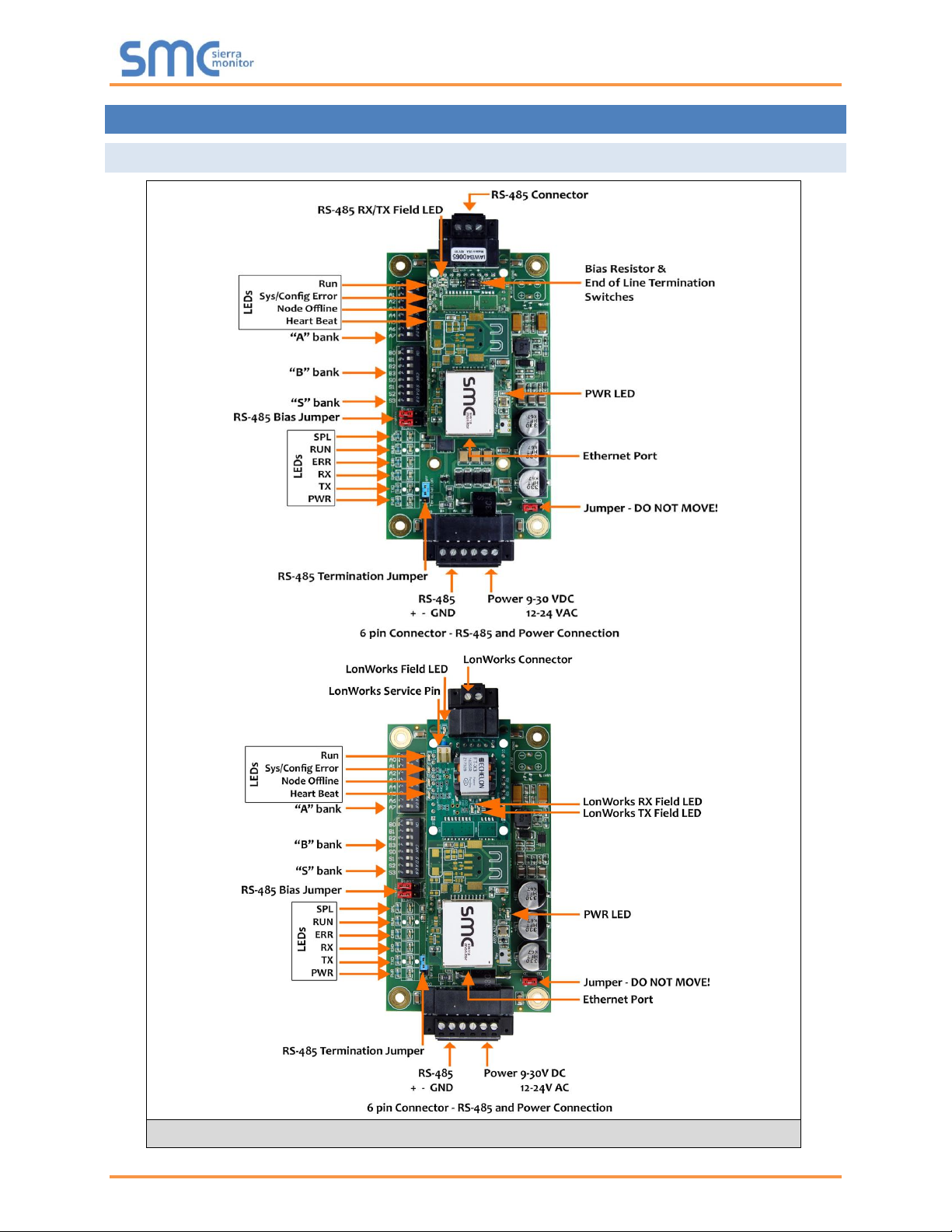

4 INTERFACING PROTONODE TO DEVICES

4.1 ProtoNode FPC-N34 and FPC-N35 Showing Connection Ports

Figure 9: ProtoNode FPC-N34 (Top) and ProtoNode FPC-N35 (Bottom)

Weil-McLain ProtoNode Start-up Guide

Page 16 of 61

4.2 Serial Device Connections to the ProtoNode

ProtoNode 6 Pin Phoenix connector:

• The 6 pin Phoenix connector is the same for ProtoNode FPC-N34 and FPC-N35 (LonWorks).

• Pins 1 through 3 are for RS-485 devices.

o Use standard grounding principles for RS-485 GND

• Pins 4 through 6 are for power. Do not connect power until Section 4.5.

Device Pins

ProtoNode Pin

#

Pin

Assignment

Pin RS-485 +

Pin 1

RS-485 +

Pin RS-485 -

Pin 2

RS-485 -

Pin GND

Pin 3

RS-485 GND

Power In (+)

Pin 4

V +

Power In (-)

Pin 5

V -

Frame Ground

Pin 6

FRAME GND

Figure 10: Device and Power Connections

Weil-McLain ProtoNode Start-up Guide

Page 17 of 61

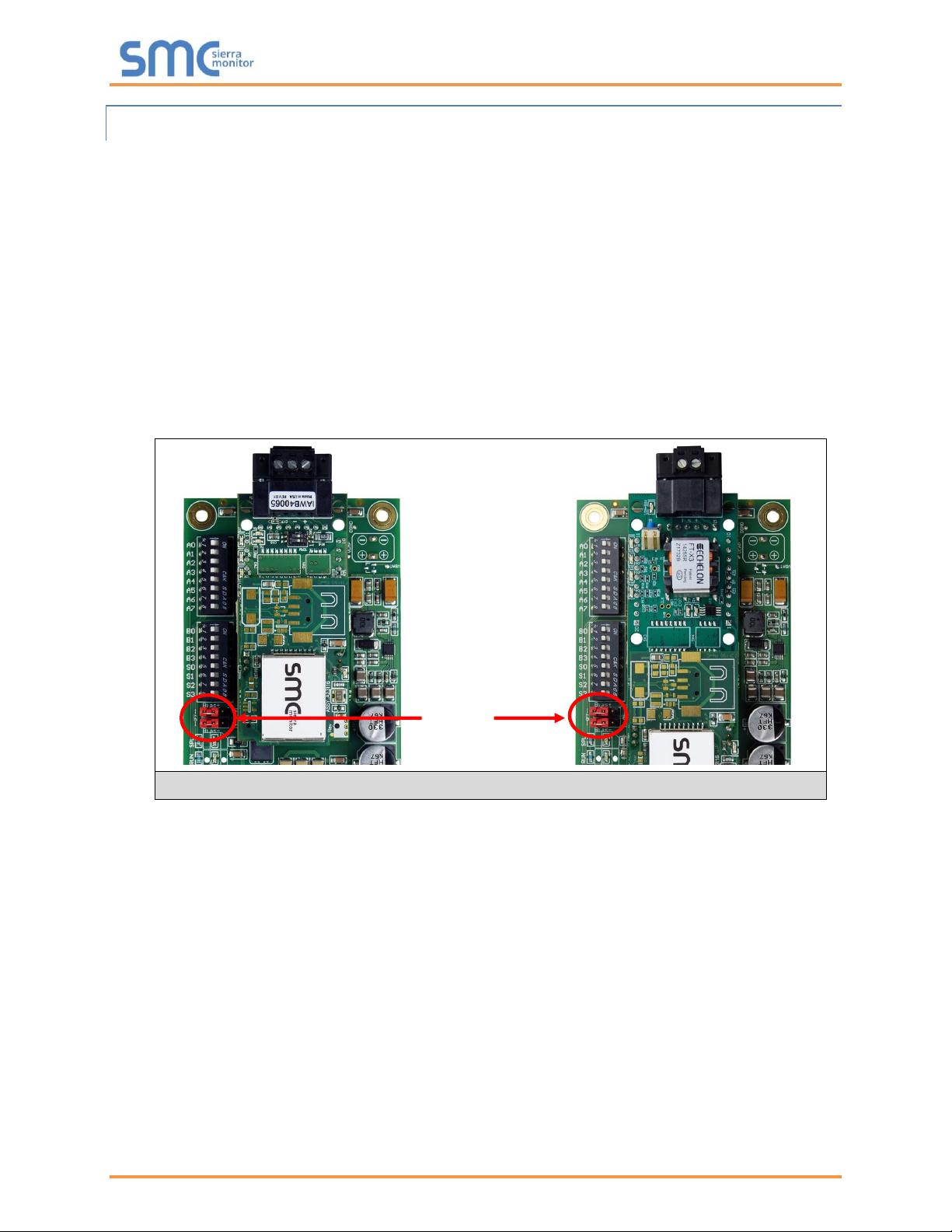

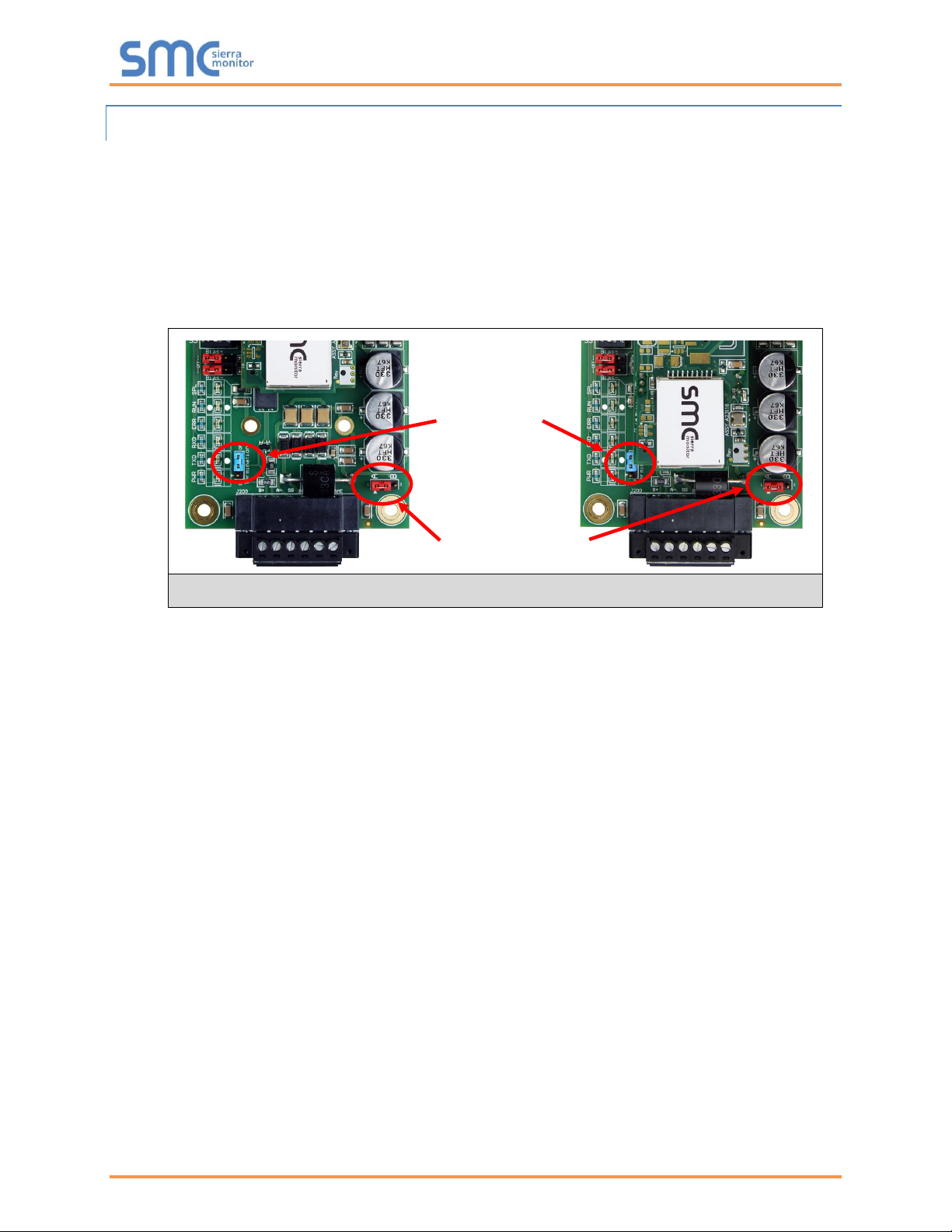

4.2.1 Biasing the RS-485 Device Network

• An RS-485 network with more than one device needs to have biasing to ensure proper

communication. The biasing only needs to be done on one device.

• The ProtoNode has 510 ohm resistors that can be used to set the biasing. The ProtoNode’s default

positions from the factory for the biasing jumpers are OFF.

• The OFF position is when the 2 red biasing jumpers straddle the 4 pins closest to the outside of

the board of the ProtoNode. (Figure 11)

• Only turn biasing ON:

o IF the BMS cannot see more than one device connected to the ProtoNode

o AND all the settings (COM settings, wiring, and DIP switches) have been checked

• To turn biasing ON, move the 2 red biasing jumpers to straddle the 4 pins closest to the inside of

the board of the ProtoNode.

RS-485 Bias

Switch

(off)

Figure 11: RS-485 Biasing Switch on the ProtoNode N34 (Left) and ProtoNode N35 (Right)

Weil-McLain ProtoNode Start-up Guide

Page 18 of 61

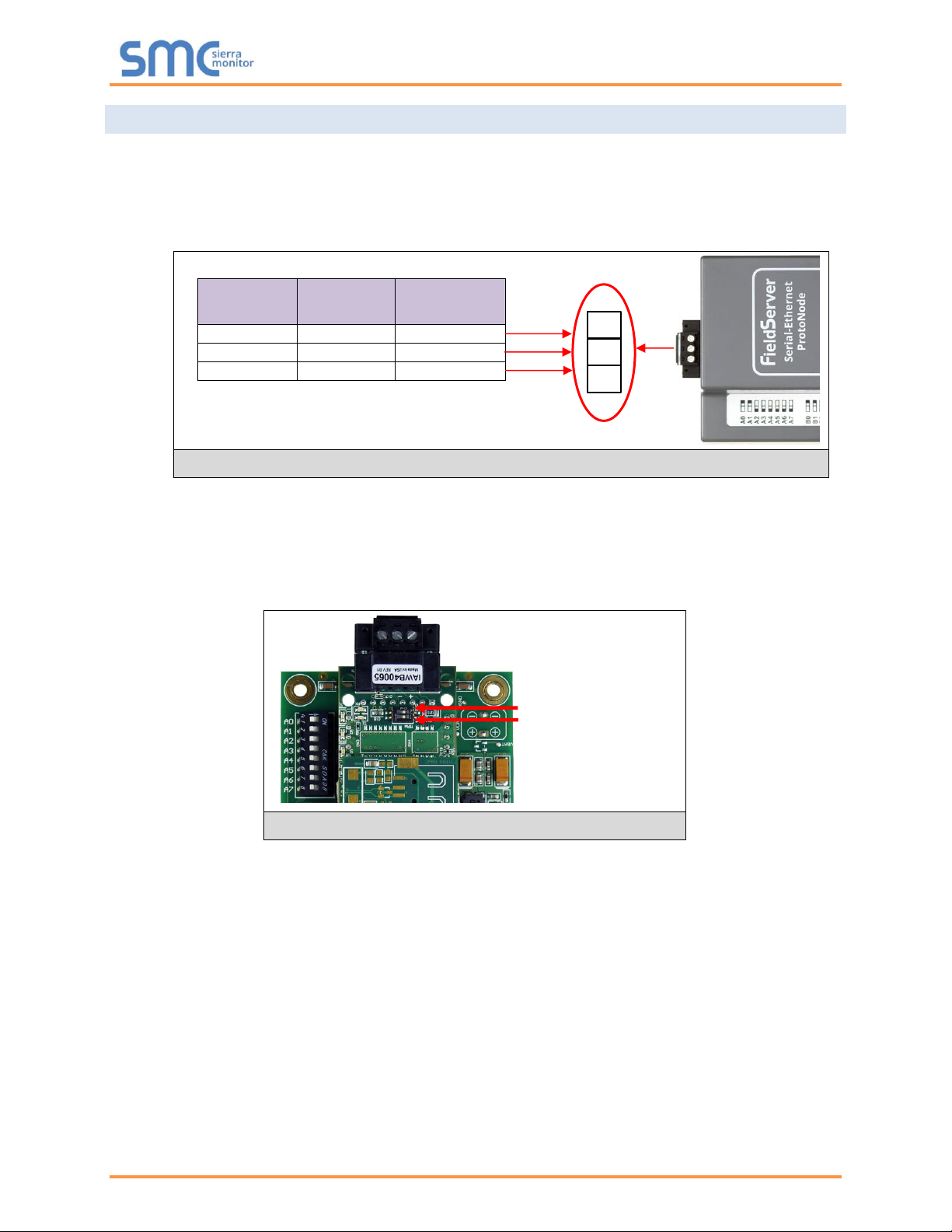

4.2.2 End of Line Termination Switch for the RS-485 Device Network

• On long RS-485 cabling runs, the RS-485 trunk must be properly terminated at each end.

• The ProtoNode has an end of line (EOL) blue jumper. The default setting for this blue EOL switch

is OFF with the jumper straddling the pins closest to the inside of the board of the ProtoNode.

o On short cabling runs the EOL switch does not to need to be turned ON

• If the ProtoNode is placed at one of the ends of the trunk, set the blue EOL jumper to the ON

position straddling the pins closest to the outside of the board of the ProtoNode.

• Always leave the single red jumper in the A position (default factory setting).

RS-485 EOL

Switch

(off)

Leave in Position A

Figure 12: RS-485 End-Of-Line Termination Switch on the ProtoNode N34 (Left) and

ProtoNode N35 (Right)

Weil-McLain ProtoNode Start-up Guide

Page 19 of 61

4.3 Serial Network (FPC-N34): Wiring Field Port to RS-485 Network

• Connect the RS-485 network wires to the 3-pin RS-485 connector on ProtoNode FPC-N34 as

shown below in Figure 13.

o Use standard grounding principles for RS-485 GND

• See Section 5.4 for information on connecting to an Ethernet network.

• If the ProtoNode is the last device on the trunk, then the end of line (EOL) termination switch needs

to be enabled. See Figure 14 for the orientation of switch positions referenced below.

o The default setting from the factory is OFF (switch position = right side)

o To enable the EOL termination, turn the EOL switch ON (switch position = left side)

• If more than one RS-485 device is connected to the network, then the field bias resistor switch

needs to be enabled to ensure proper communication. See Figure 14 for the orientation of switch

positions referenced below.

o The default factory setting is OFF (switch position = right side)

o To enable biasing, turn the bias switch ON (switch position = left side)

NOTE: Biasing only needs to be enabled on one device. The ProtoNode has 510 ohm resistors

that are used to set the biasing.

BMS

Wiring

ProtoNode

Pin #

Pin

Assignment

RS-485 +

Pin 1

RS-485 +

RS-485 -

Pin 2

RS-485 -

-

Pin 3

RS-485 GND

Bias Resistor Switch

End of Line Switch

Figure 14: RS-485 EOL & Bias Resistor Switches

Figure 13: Connection from ProtoNode to RS-485 Field Network

G

-

Weil-McLain ProtoNode Start-up Guide

Page 20 of 61

4.4 LonWorks (FPC-N35): Wiring LonWorks Devices to the LonWorks Terminal

• Wire the LonWorks device network to the ProtoNode LonWorks Terminal.

o Use approved cable per the FT-10 installation guidelines

• LonWorks has no polarity.

Figure 15: LonWorks Terminal

Weil-McLain ProtoNode Start-up Guide

Page 21 of 61

4.5 Power-Up ProtoNode

Check power requirements in the table below:

Power Requirement for ProtoNode External Gateway

Current Draw Type

ProtoNode Family

12VDC/AC

24VDC/AC

30VDC

FPC – N34 (Typical)

170mA

100mA

80mA

FPC – N34 (Maximum)

240mA

140mA

100mA

FPC – N35 (Typical)

210mA

130mA

90mA

FPC – N35 (Maximum)

250mA

170mA

110mA

NOTE: These values are ‘nominal’ and a safety margin should be added to the power supply of

the host system. A safety margin of 25% is recommended.

Figure 16: Required Current Draw for the ProtoNode

Apply power to the ProtoNode as shown below in Figure 17. Ensure that the power supply used complies

with the specifications provided in Appendix E.1.

• ProtoNode accepts either 9-30VDC or 12-24VAC on pins 4 and 5.

• Frame GND should be connected.

Power to

ProtoNode

ProtoNode

Pin #

Pin

Assignment

Power In (+)

Pin 4

V +

Power In (-)

Pin 5

V -

Frame Ground

Pin 6

FRAME GND

Figure 17: Power Connections

Weil-McLain ProtoNode Start-up Guide

Page 22 of 61

5 USE THE PROTONODE WEB CONFIGURATOR TO SETUP THE GATEWAY

5.1 Connect the PC to the ProtoNode via the Ethernet Port

First, connect a Cat-5 Ethernet cable (straight through or cross-over) between the local PC and ProtoNode.

There are two methods to access the ProtoNode via Ethernet connection, either by changing the

subnet of the connected PC (Section 5.1.1) or using the FieldServer Toolbox to change the IP

Address of the ProtoNode (Section 5.1.2).

NOTE: Only perform one method or the other.

5.1.1 Changing the Subnet of the Connected PC

The default IP Address for the ProtoNode is 192.168.1.24, Subnet Mask is 255.255.255.0. If the PC and

ProtoNode are on different IP networks, assign a static IP Address to the PC on the 192.168.1.xxx network.

For Windows 10:

• Find the search field in the local computer’s taskbar (usually to the right of the windows icon )

and type in “Control Panel”.

• Click “Control Panel”, click “Network and Internet” and then click “Network and Sharing Center”.

• Click “Change adapter settings” on the left side of the window.

• Right-click on “Local Area Connection” and select “Properties” from the dropdown menu.

• Highlight and then click the Properties button.

• Select and enter a static IP Address on the same subnet. For example:

• Click the Okay button to close the Internet Protocol window and the Close button to close the

Ethernet Properties window.

Ethernet Port

Figure 18: Ethernet Port Location

Weil-McLain ProtoNode Start-up Guide

Page 23 of 61

5.1.2 Changing the IP Address of the ProtoNode with FieldServer Toolbox

• Ensure that FieldServer Toolbox is loaded onto the local PC. Otherwise, download the

FieldServer-Toolbox.zip via the Sierra Monitor website’s Software Downloads.

• Extract the executable file and complete the installation.

• Double click on the FS Toolbox Utility and click Discover Now on the splash page.

• Find the desired gateway and click the Configure Device button (gear icon) to the right of the

gateway information.

NOTE: If connectivity status is green, then the IP Address doesn’t need to be changed (the

ProtoNode is already on the same subnet). Skip to the next section.

• Select Network Settings in the Configure Device window.

• Modify the IP Address (N1 IP Address field) of the gateway Ethernet port.

o Change additional fields as needed

NOTE: If the gateway is connected to a router, the Default Gateway field of the gateway should be

set to the IP Address of the connected router.

NOTE: Do not change the DHCP Server State (N1 DHCP Server State field).

NOTE: If DNS settings are unknown, set DNS1 to “8.8.8.8” and DNS2 to “8.8.4.4”.

• Click Update IP Settings, then click on the “Change and restart” button to reboot the gateway and

activate the new IP Address. See the FieldServer Toolbox and GUI Manual for more information.

Weil-McLain ProtoNode Start-up Guide

Page 24 of 61

5.2 Connecting to the ProtoNode Web Configurator

After setting a local PC on the same subnet as the ProtoNode (Section 5.1), open a web browser on the

PC and enter the IP Address of the ProtoNode; the default address is 192.168.1.24.

NOTE: If the IP Address of the ProtoNode was changed, the assigned IP Address can be

discovered using the FS Toolbox utility. See Appendix A.1 for instructions.

5.3 Selecting Profiles for Devices Connected to ProtoNode

NOTE: If Modbus TCP/IP was selected in Section 3.4 for the Field/BMS protocol, skip this section.

Device profiles are NOT used for Modbus TCP/IP.

• In the Web Configurator, the Active Profiles are shown below the Configuration Parameters.

• The Active Profiles section lists the currently active device profiles, including previous Web

Configurator additions. This list is empty for new installations, or after clearing all configurations.

(Figure 19)

Figure 19: Web Configurator Showing no Active Profiles

Weil-McLain ProtoNode Start-up Guide

Page 25 of 61

• To add an active profile to support a device, click the Add button under the Active Profiles heading.

Select a profile from the drop-down menu field that appears underneath the Current profile column.

(Figure 20)

• For every device that is added, assign a unique Node-ID. This specification must match the device’s

network settings.

NOTE: If multiple devices are connected to the ProtoNode, set the BACnet Virtual Server Nodes

field to “Yes”; otherwise leave the field on the default “No” setting.

• Once the Profile for the device has been selected from the drop-down list, enter the value of the

device’s Node-ID which was assigned in Section 3.3.2.

• Then press the “Submit” button to add the Profile to the list of devices to be configured.

• Repeat this process until all the devices have been added.

• Completed additions are listed under “Active profiles” as shown in Figure 21.

5.3.1 Verify Device Communications

• Check that TX and RX LEDs are rapidly flashing. See Appendix A.4 for information and images.

• Confirm the software shows communication without errors. Go to Appendix A.2 for instructions.

Figure 20: Web Configurator Showing Available Profile Selection

Figure 21: Web Configurator Showing Active Profile Additions

Weil-McLain ProtoNode Start-up Guide

Page 26 of 61

5.4 Ethernet Network: Setting IP Address for the Field Network

• After setting a local PC to the same subnet as the ProtoNode (Section 5.1), open a web browser

on the PC and enter the IP Address of the ProtoNode; the default address is 192.168.1.24.

• The Web Configurator is displayed as the landing page. (Figure 22)

Figure 22: Web Configurator Screen with Active Profiles

Weil-McLain ProtoNode Start-up Guide

Page 27 of 61

• To access the FS-GUI, click on the “Diagnostics & Debugging” button in the bottom right corner of

the page.

• From the FS-GUI landing page, click on “Setup” to expand the navigation tree and then select

“Network Settings” to access the IP Settings menu. (Figure 23)

• Modify the IP Address (N1 IP Address field) of the ProtoNode Ethernet port.

• If necessary, change the Netmask (N1 Netmask field).

• If necessary, change the IP Gateway (Default Gateway field).

NOTE: If the ProtoNode is connected to a managed switch/router, the IP Gateway of the

ProtoNode should be set to the IP Address of that managed switch/router.

• Click the “System Restart” button at the bottom of the page to apply changes and restart the

ProtoNode.

• Unplug Ethernet cable from PC and connect it to the network switch or router.

• Record the IP Address assigned to the ProtoNode for future reference.

NOTE: The FieldPoP™ button (see Figure 23) allows users to connect to the SMC

Cloud, Sierra Monitor’s device cloud solution for IIoT. The SMC Cloud enables secure

remote connection to field devices through a FieldServer and its local applications for

configuration, management, maintenance. For more information about the SMC Cloud,

refer to the SMC Cloud Start-up Guide.

Figure 23: Changing IP Address via FS-GUI

Weil-McLain ProtoNode Start-up Guide

Page 28 of 61

5.5 Change ProtoNode COM Settings

• In the Web Configurator, the ProtoNode COM Settings are the first parameters displayed.

NOTE: The ProtoNode default setting for the Modbus RTU serial baud rate is 19200 and the

default stop bits setting is 1. When connecting devices with different baud rate and stop

bits settings (SlimFit 1000-2000 Series 1), these values must be changed via the

ProtoNode Web Configurator to match the device.

• Change the ProtoNode COM Settings if needed. See Figure 25 for the correct device settings.

Device Settings

SlimFit 1000-2000

Series 1 (SOLA)

Evergreen/

SlimFit 550-750

Series 2 & 3/

SlimFit 1000-2000

Series 2/

SVF Models

Baud Rate

38400

19200

Parity

None

None

Data Bits

8

8

Stop Bits

1

2

Figure 25: Device COM Settings

• If new values are entered in the text field, click Submit then reset the ProtoNode.

Figure 24: Web Configurator ProtoNode COM Settings

Weil-McLain ProtoNode Start-up Guide

Page 29 of 61

6 BACNET: SETTING NODE_OFFSET TO ASSIGN SPECIFIC DEVICE

INSTANCES

• After setting a local PC to the same subnet as the ProtoNode (Section 5.1), open a web browser

on the PC and enter the IP Address of the ProtoNode.

o If the IP Address of the ProtoNode has been changed by previous configuration, the assigned

IP Address must be gathered from the network administrator

o The Web Configurator is displayed as the landing page

• Node_Offset field shows the current value (default = 50,000).

o The values allowed for a BACnet Device Instance can range from 1 to 4,194,303

• To assign a specific Device Instance (or range); change the Node_Offset value as needed using

the calculation below:

Device Instance (desired) = Node_Offset + Node_ID

For example, if the desired Device Instance for the device 1 is 50,001 and the following is true:

- Device 1 has a Node-ID of 1

- Device 2 has a Node-ID of 22

- Device 3 has a Node-ID of 33

Then plug the device 1’s information into the formula to find the desired Node_Offset:

50,001 = Node_Offset + 1

➢ 50,000 = Node_Offset

Once the Node_Offset value is input, it will be applied to all devices as shown below:

- Device 1 Instance = 50,000 + Node_ID = 50,000 + 1 = 50,001

- Device 2 Instance = 50,000 + Node_ID = 50,000 + 22 = 50,022

- Device 3 Instance = 50,000 + Node_ID = 50,000 + 33 = 50,033

• Click “Submit” once the desired value is entered.

Figure 27: Active Profiles

Figure 26: Web Configurator Node Offset Field

Weil-McLain ProtoNode Start-up Guide

Page 30 of 61

7 HOW TO START THE INSTALLATION OVER: CLEARING PROFILES

• After setting a local PC to the same subnet as the ProtoNode (Section 5.1), open a web browser

on the PC and enter the IP Address of the ProtoNode; the default address is 192.168.1.24.

• If the IP Address of the ProtoNode has been changed by previous configuration, the assigned IP

Address must be gathered from the network administrator.

• The Web Configurator is displayed as the landing page.

• At the bottom-left of the page, click the “Clear Profiles and Restart” button.

• Once restart is complete, all past profiles discovered and/or added via Web configurator are

deleted. The unit can now be reinstalled.

Weil-McLain ProtoNode Start-up Guide

Page 31 of 61

8 LONWORKS (FPC-N35): COMMISSIONING PROTONODE ON A LONWORKS

NETWORK

Commissioning may only be performed by the LonWorks administrator.

8.1 Commissioning ProtoNode FPC-N35 on a LonWorks Network

During the commissioning process, the LonWorks administrator may prompt the user to hit the service pin

on the ProtoNode FPC-N35 at a specific point (this step occurs at different points of the commissioning

process for each LonWorks network management tool).

• If an XIF file is required, see steps in Section 8.1.1 to generate XIF.

8.1.1 Instructions to Upload XIF File from ProtoNode FPC-N35 Using Browser

• Connect a Cat-5 Ethernet cable (straight through or cross-over) between the PC and ProtoNode.

• The default IP Address for the ProtoNode is 192.168.1.24, Subnet Mask is 255.255.255.0. If the

PC and ProtoNode are on different IP networks, assign a static IP Address to the PC on the

192.168.1.xxx network.

For Windows 10:

• Find the search field in the local computer’s taskbar (usually to the right of the windows icon )

and type in “Control Panel”.

• Click “Control Panel”, click “Network and Internet” and then click “Network and Sharing Center”.

• Click “Change adapter settings” on the left side of the window.

• Right-click on “Local Area Connection” and select “Properties” from the dropdown menu.

• Highlight and then click the Properties button.

• Select and enter a static IP Address on the same subnet. For example:

• Click the Okay button to close the Internet Protocol window and the Close button to close the

Ethernet Properties window.

Figure 28: LonWorks Service Pin Location

Weil-McLain ProtoNode Start-up Guide

Page 32 of 61

• Open a web browser and go to the following address: [IP Address of ProtoNode]/fserver.xif

o Example: 192.168.1.24/fserver.xif

• If the web browser prompts to save the file, save the file onto the PC. If the web browser displays

the xif file as a web page, save the file onto the local PC as “fserver.xif”.

Figure 29: Sample of Fserver.XIF File Generated

Weil-McLain ProtoNode Start-up Guide

Page 33 of 61

Appendix A. Troubleshooting

Lost or Incorrect IP Address

• Ensure that FieldServer Toolbox is loaded onto the local PC. Otherwise, download the

FieldServer-Toolbox.zip via the Sierra Monitor website’s Software Downloads.

• Extract the executable file and complete the installation.

• Connect a standard Cat-5 Ethernet cable between the user’s PC and ProtoNode.

• Double click on the FS Toolbox Utility and click Discover Now on the splash page.

• Check for the IP Address of the desired gateway.

• If correcting the IP Address of the gateway: click the settings icon on the same row as the

gateway, then click Network Settings, change the IP Address and click Update IP Settings to save.

Ethernet Port

Figure 30: Ethernet Port Location

Weil-McLain ProtoNode Start-up Guide

Page 34 of 61

Viewing Diagnostic Information

• Type the IP Address of the ProtoNode into the web browser or use the FieldServer Toolbox to

connect to the ProtoNode.

• Click on Diagnostics and Debugging Button, then click on view, and then on connections.

• If there are any errors showing on the Connection page, refer to Appendix A.3 for the relevant

wiring and settings.

Figure 31: Error Messages Screen

Weil-McLain ProtoNode Start-up Guide

Page 35 of 61

Check Wiring and Settings

• No COMS on Modbus RTU side. If the Tx/Rx LEDs are not flashing rapidly then there is a COM

issue. To fix this, check the following:

o Visual observations of LEDs on the ProtoNode (Appendix A.4)

o Check baud rate, parity, data bits, stop bits

o Check device address

o Verify wiring

o Verify device is connected to the same subnet as the ProtoNode

o Verify the Modbus device(s) were listed in the Web Configurator (Section 5.2)

• Field COM problems:

o If Ethernet protocols are used, observe Ethernet LEDs on the ProtoNode (Appendix A.4)

o Check dipswitch settings (using correct baud rate and device instance)

o Verify IP Address setting

o Verify wiring

NOTE: If the problem persists, a Diagnostic Capture needs to be taken and sent to support.

(Appendix A.5)

Weil-McLain ProtoNode Start-up Guide

Page 36 of 61

LED Diagnostics for Communications Between ProtoNode and Devices

See the diagram below for ProtoNode FPC-N34 and FPC-N35 LED Locations.

Tag

Description

SPL

The SPL LED will light if the unit is not getting a response from one or more of the configured devices.

For LonWorks units, LED will light until the unit is commissioned on the LonWorks network.

RUN

The RUN LED will start flashing 20 seconds after power indicating normal operation.

ERR

A steady red light will indicate there is a system error on the unit. If this occurs, immediately report the

related “system error” shown in the error screen of the FS-GUI interface to support for evaluation.

RX

The RX LED will flash when a message is received on the serial port on the 6-pin connector.

If the serial port is not used, this LED is non-operational.

TX

The TX LED will flash when a message is sent on the serial port on the 6-pin connector.

If the serial port is not used, this LED is non-operational.

PWR

This is the power light. It should always show a steady green light when powered.

Figure 32: Diagnostic LEDs

Diagnostic LEDs

Weil-McLain ProtoNode Start-up Guide

Page 37 of 61

Take a FieldServer Diagnostic Capture

When there is a problem on-site that cannot easily be resolved, perform a diagnostic capture before

contacting support so that support can quickly solve the problem. There are two methods for taking

diagnostic captures:

• FieldServer Toolbox:

This method requires installation of the FS Toolbox program. A FS Toolbox diagnostic capture

takes a snapshot of the loaded configuration files and a log of all the communications on the

serial ports over a specified period of time. If the problem occurs over an Ethernet connection,

then take a Wire Shark capture.

• Gateway’s FS-GUI Page:

This method doesn’t require downloading software. The diagnostic capture utilities are embedded

in the FS-GUI web interface. Starting a diagnostic capture takes a snapshot of the loaded

configuration files and a log of all the communications over a specified period of time. This works

for both serial and Ethernet connections.

NOTE: The information in the zipped files contains everything support needs to quickly resolve

problems that occur on-site.

Appendix A.5.1. Using the FieldServer Toolbox

Once the Diagnostic Capture is complete, email it to technical support. The Diagnostic Capture will

accelerate diagnosis of the problem.

• Ensure that FieldServer Toolbox is loaded onto the local PC. Otherwise, download the

FieldServer-Toolbox.zip via the Sierra Monitor website’s Software Downloads.

• Extract the executable file and complete the installation.

• Connect a standard Cat-5 Ethernet cable between the PC and ProtoNode.

• Double click on the FS Toolbox Utility.

Ethernet Port

Figure 33: Ethernet Port Location

Weil-McLain ProtoNode Start-up Guide

Page 38 of 61

• Step 1: Take a Log

o Click on the diagnose icon of the desired device

o Ensure “Full Diagnostic" is selected (this is the default)

NOTE: If desired, the default capture period can be changed.

Weil-McLain ProtoNode Start-up Guide

Page 39 of 61

o Click on “Start Diagnostic”

o When the capture period is finished, the “Diagnostic Test Complete” window will appear

• Step 2: Send Log

o Once the diagnostic test is complete, a .zip file is saved on the PC

o Choose “Open” to launch explorer and have it point directly at the correct folder

o Send the diagnostic zip file to wmtechnicalservices@weil-mclain.com

Weil-McLain ProtoNode Start-up Guide

Page 40 of 61

Appendix A.5.2. Using FS-GUI

Diagnostic Capture via FS-GUI is only available on FieldServers with a bios updated/released on November

2017 or later. Completing a Diagnostic Capture through the FieldServer allows network connections (such

as Ethernet and Wi-Fi) to be captured.

Once the Diagnostic Capture is complete, email it to technical support. The Diagnostic Capture will

accelerate diagnosis of the problem.

• Open the FieldServer FS-GUI page.

• Click on Diagnostics in the Navigation panel.

• Go to Full Diagnostic and select the capture period.

• Click the Start button under the Full Diagnostic heading to start the capture.

o When the capture period is finished, a Download button will appear next to the Start button

• Click Download for the capture to be downloaded to the local PC.

• Send the diagnostic zip file to wmtechnicalservices@weil-mclain.com.

NOTE: Diagnostic captures of BACnet MS/TP communication are output in a “.PCAP” file

extension which is compatible with Wireshark.

Weil-McLain ProtoNode Start-up Guide

Page 41 of 61

Appendix B. Additional Information

Update Firmware

To load a new version of the firmware, follow these instructions:

1. Extract and save the new file onto the local PC.

2. Open a web browser and type the IP Address of the FieldServer in the address bar.

o Default IP Address is 192.168.1.24

o Use the FS Toolbox utility if the IP Address is unknown (Appendix A.1)

3. Click on the “Diagnostics & Debugging” button.

4. In the Navigation Tree on the left hand side, do the following:

a. Click on “Setup”

b. Click on “File Transfer”

c. Click on the “General” tab

5. In the General tab, click on “Choose Files” and select the web.img file extracted in step 1.

6. Click on the orange “Submit” button.

7. When the download is complete, click on the “System Restart” button.

BACnet: Setting Network_Number for More Than One ProtoNode on the Subnet

For both BACnet MS/TP and BACnet/IP, if more than one ProtoNode is connected to the same subnet,

they must be assigned unique Network_Number values.

On the main Web Configuration screen, update the BACnet Network Number field and click submit. The

default value is 50.

Figure 34: Web Configurator – Network Number Field

Weil-McLain ProtoNode Start-up Guide

Page 42 of 61

Securing ProtoNode with Passwords

Access to the ProtoNode can be restricted by enabling a password on the FS-GUI Passwords page –

click Setup and then Passwords in the navigation panel. There are 2 access levels defined by 2 account

names: Admin and User.

• The Admin account has unrestricted access to the ProtoNode.

• The User account can view any ProtoNode information but cannot make any changes or restart

the ProtoNode.

The password needs to be a minimum of eight characters and is case sensitive.

If the password is lost, click cancel on the password authentication popup window, and email the

password recovery token to technical support to receive a temporary password from the support team.

Access the ProtoNode to set a new password.

Figure 35: FS-GUI Passwords Page

Figure 36: Password Recovery Page

Weil-McLain ProtoNode Start-up Guide

Page 43 of 61

Appendix C. Vendor Information – Weil-McLain

NOTE: All Modbus TCP/IP registers are the same as the Modbus RTU registers for the serial

device. If this point list is needed, contact Weil-McLain technical support. The Modbus

TCP/IP node address of the device is also the same as the Modbus RTU node address.

SlimFit 1000-2000 Series 1 (SOLA) Modbus RTU Mappings to BACnet, Metasys

N2 and LonWorks

Point Name

BACnet

Object

Type

BACnet

Object

ID

N2

Data

Type

N2

Address

LonWorks Name

LonWorks SNVT

4-20mA Remote Control Input Status

AV

1

AO 1 nvoRemCtInSt_XXX

SNVT_count_f

Active CH Setpoint

AV

2

AO 2 nvoActCHSP_XXX

SNVT_temp_p

Active DHW Setpoint Status

AV

3

AO 3 nvoAcDHWSPSt_XXX

SNVT_temp_p

Active LL Operating Point Status

AV

4

AO 4 nvoALLOpPtSt_XXX

SNVT_temp_p

Active LL Setpoint Status

AV

5

AO 5 nvoActLLSPS_XXX

SNVT_temp_p

Active System Operating Point Status

AV

6

AO 6 nvoASyOpPtSt_XXX

SNVT_temp_p

Active System Setpoint Status

AV

7

AO 7 nvoAcSysSPSt_XXX

SNVT_temp_p

Alarm Record 1 Status

AV

8

AO 8 nvoAlmRec1St_XXX

SNVT_count_f

Alarm Record 2 Status

AV

9

AO 9 nvoAlmRec2St_XXX

SNVT_count_f

Alarm Record 3 Status

AV

10

AO

10

nvoAlmRec3St_XXX

SNVT_count_f

Alarm Record 4 Status

AV

11

AO

11

nvoAlmRec4St_XXX

SNVT_count_f

Alarm Record 5 Status

AV

12

AO

12

nvoAlmRec5St_XXX

SNVT_count_f

Annunciator First Out Status

AV

13

AO

13

nvoAn1stOtSt_XXX

SNVT_count_f

Auxiliary 2 Pump Cycle Count

AV

14

AO

14

nvoAx2PpCyCt_XXX

SNVT_count_f

Auxiliary 2 Pump Cycle Count Status

AV

15

AO

15

nvoAx2PCyCSt_XXX

SNVT_count_f

Auxiliary Pump Cycle Count

AV

16

AO

16

nvoAxPmpCyCt_XXX

SNVT_count_f

Auxiliary Pump Cycle Count Status

AV

17

AO

17

nvoAxPpCyCSt_XXX

SNVT_count_f

Boiler Pump Cycle Count

AV

18

AO

18

nvoBlPmpCyCt_XXX

SNVT_count_f

Boiler Pump Cycle Count Status

AV

19

AO

19

nvoBlPpCyCSt_XXX

SNVT_count_f

Burner Control State Status

AV

20

AO

20

nvoBrnCtStSt_XXX

SNVT_count_f

Burner Control Status

AV

21

AO

21

nvoBrnCtlSt_XXX

SNVT_count_f

Burner Cycle Count

AV

22

AO

22

nvoBrnCycCnt_XXX

SNVT_count_f

Burner Cycle Count Status

AV

23

AO

23

nvoBrnCyCtSt_XXX

SNVT_count_f

Burner Run Time

AV

24

AO

24

nvoBrnRnTme_XXX

SNVT_time_hour

Burner Run Time Status

AV

25

AO

25

nvoBrnRnTmSt_XXX

SNVT_time_hour

CH Burner Demand Status

AV

26

AO

26

nvoCHBrnDmSt_XXX

SNVT_count_f

CH Heat Demand Status

AV

27

AO

27

nvoCHHtDemSt_XXX

SNVT_count_f

CH ODR Low Water Temperature (W)

AV

28

AO

28

nvi/nvoCHODLoWtT_XXX

SNVT_temp_p

CH ODR Low Water Temperature Status

AV

29

AO

29

nvoCHODLoWTS_XXX

SNVT_temp_p

CH ODR Max Outdoor Temperature (W)

AV

30

AO

30

nvi/nvoCHODMxWtT_XXX

SNVT_temp_p

CH ODR Max Outdoor Temperature Status

AV

31

AO

31

nvoCHODMxWTS_XXX

SNVT_temp_p

CH ODR Min Outdoor Temp (W)

AV

32

AO

32

nvi/nvoCHODMnWtT_XXX

SNVT_temp_p

CH ODR Min Outdoor Temp Status

AV

33

AO

33

nvoCHODMnWTS_XXX

SNVT_temp_p

CH Pump Cycle Count

AV

34

AO

34

nvoCHPmpCyCt_XXX

SNVT_count_f

CH Pump Cycle Count Status

AV

35

AO

35

nvoCHPCyCtSt_XXX

SNVT_count_f

CH Requested Rate Status

AV

36

AO

36

nvoCHReqRtSt_XXX

SNVT_lev_percent

CH Setpoint (W)

AV

37

AO

37

nvi/nvoCH_SP_XXX

SNVT_temp_p

CH Setpoint Status

AV

38

AO

38

nvoCH_SPStat_XXX

SNVT_count_f

CH Setpoint Source Status

AV

39

AO

39

nvoCHSPSrcSt_XXX

SNVT_temp_p

CH Status

AV

40

AO

40

nvoCH_Status_XXX

SNVT_count_f

CH Time of Day Setpoint (W)

AV

41

AO

41

nvi/nvoCH_TOD_SP_XXX

SNVT_temp_p

CH Time of Day Setpoint Status

AV

42

AO

42

nvoCHTODSPSt_XXX

SNVT_temp_p

Controller Cycle Count Status

AV

43

AO

43

nvoCtCycCtSt_XXX

SNVT_count_f

Controller Run Time Status

AV

44

AO

44

nvoCtRunTmSt_XXX

SNVT_time_hour

Demand Source Status

AV

45

AO

45

nvoDemSrcSt_XXX

SNVT_count_f

DHW Status

AV

46

AO

46

nvoDHWStatus_XXX

SNVT_count_f

DHW Burner Demand Status

AV

47

AO

47

nvoDHWBrDmSt_XXX

SNVT_count_f

DHW Heat Demand Status

AV

48

AO

48

nvoDHWHtDmSt_XXX

SNVT_count_f

DHW Priority Count Status

AV

49

AO

49

nvoDHWPrCtSt_XXX

SNVT_count_f

DHW Pump Cycle Count

AV

50

AO

50

nvoDHWPpCyCt_XXX

SNVT_count_f

DHW Pump Cycle Count Status

AV

51

AO

51

nvoDHWPCyCtS_XXX

SNVT_count_f

DHW Sensor Status

AV

52

AO

52

nvoDHWSenSta_XXX

SNVT_temp_p

DHW Setpoint

AV

53

AO

53

nvoDHW_SP_XXX

SNVT_temp_p

DHW Setpoint Source Status

AV

54

AO

54

nvoDHWSPSrSt_XXX

SNVT_count_f

DHW Setpoint Status

AV

55

AO

55

nvoDHWSPStat_XXX

SNVT_temp_p

Weil-McLain ProtoNode Start-up Guide

Page 44 of 61

DHW Time of Day Setpoint (W)

AV

56

AO

56

nvi/nvoDHWTODSP_XXX

SNVT_temp_p

DHW Time of Day Setpoint Status

AV

57

AO

57

nvoDHWTDSPSt_XXX

SNVT_temp_p

DHW requested Rate Status

AV

58

AO

58

nvoDHWRqRtSt_XXX

SNVT_count_f

Fan Speed Status

AV

59

AO

59

nvoFanSpdSt_XXX

SNVT_count_f

Firing Rate Status

AV

60

AO

60

nvoFirRtStat_XXX

SNVT_count_f

Flame Signal Status

AV

61

AO

61

nvoFlmSigSt_XXX

SNVT_count_f

Inlet Sensor Status

AV

62

AO

62

nvoInSenStat_XXX

SNVT_temp_p

Lead Boiler Address Status

AV

63

AO

63

nvoLdBlAddSt_XXX

SNVT_count_f

Lead Lag Active Service Status

AV

64

AO

64

nvoLLAcSrvSt_XXX

SNVT_count_f

Lead Lag CH 20mA Water Temp (W)

AV

65

AO

65

nvi/nvoLLCH20WTp_XXX

SNVT_temp_p

Lead Lag CH 20mA Water Temp Status

AV

66

AO

66

nvoLLCH20WTS_XXX

SNVT_temp_p

Lead Lag CH 4mA Water Temp (W)

AV

67

AO

67

nvi/nvoLLCH4WtTp_XXX

SNVT_temp_p

Lead Lag CH 4mA Water Temp Status

AV

68

AO

68

nvoLLCH4WTpS_XXX

SNVT_temp_p

Lead Lag CH ODR Low Water Temperature (W)

AV

69

AO

69

nvi/nvoLLODRLoWT_XXX

SNVT_temp_p

Lead Lag CH ODR Low Water Temperature

Status

AV

70

AO

70

nvoLLODRLWTS_XXX

SNVT_temp_p

Lead Lag CH ODR Max Outdoor Temperature

(W)

AV

71

AO

71

nvi/nvoLLODRMxTp_XXX

SNVT_temp_p

Lead Lag CH ODR Max Outdoor Temperature

Status

AV

72

AO

72

nvoLLODRMxTS_XXX

SNVT_temp_p

Lead Lag CH ODR Min Outdoor Temperature

(W)

AV

73

AO

73

nvi/nvoLLODRMnTp_XXX

SNVT_temp_p

Lead Lag CH ODR Min Outdoor Temperature

Status

AV

74

AO

74

nvoLLODRMnTS_XXX

SNVT_temp_p

Lead Lag CH Setpoint Source (W)

AV

75

AO

75

nvi/nvoLLCHSPSrc_XXX

SNVT_count_f

Lead Lag CH Setpoint Source Status

AV

76

AO

76

nvoLLCHSPSSt_XXX

SNVT_count_f

Lead Lag DHW Setpoint

AV

77

AO

77

nvoLLDHW_SP_XXX

SNVT_temp_p

Lead Lag DHW Setpoint Status

AV

78

AO

78

nvoLLDHWSPSt_XXX

SNVT_temp_p

Lead Lag Master Enable Status

AV

79

AO

79

nvoLLMstEnSt_XXX

SNVT_count_f

Lead Lag Master Setpoint Source Status

AV

80

AO

80

nvoLLMsSPSrS_XXX

SNVT_count_f

Lead Lag Master Status

AV

81

AO

81

nvoLLMstStat_XXX

SNVT_count_f

Lead Lag Modulation Backup Sensor

AV

82

AO

82

nvoLLModBkSn_XXX

SNVT_count_f

Lead Lag Modulation Backup Sensor Status

AV

83

AO

83

nvoLLMdBkSnS_XXX

SNVT_count_f

Lead Lag Setpoint (W)

AV

84

AO

84

nvi/nvoLLSP_XXX

SNVT_temp_p

Lead Lag Setpoint Status

AV

85

AO

85

nvoLLSPStat_XXX

SNVT_temp_p

Lead Lag Slave Enable Status

AV

86

AO

86

nvoLLSlEnSt_XXX

SNVT_count_f

Lead Lag Slave Status

AV

87

AO

87

nvoLLSlStat_XXX

SNVT_count_f

Lead Lag Time of Day Setpoint (W)

AV

88

AO

88

nvi/nvoLL_TOD_SP_XXX

SNVT_temp_p

Lead Lag Time of Day Setpoint Status

AV

89

AO

89

nvoLLTODSPSt_XXX

SNVT_temp_p

Lockout Status

AV

90

AO

90

nvoLkotStat_XXX

SNVT_count_f

Lockout Status1

AV

91

AO

91

nvoLkotStat1_XXX

SNVT_count_f

Lockout Status2

AV

92

AO

92

nvoLkotStat2_XXX

SNVT_count_f

Lockout Status3

AV

93

AO

93

nvoLkotStat3_XXX

SNVT_count_f

Lockout Status4

AV

94

AO

94

nvoLkotStat4_XXX

SNVT_count_f

Lockout Status5

AV

95

AO

95

nvoLkotStat5_XXX

SNVT_count_f

Outdoor Frost Protection Setpoint (W)

AV

96

AO

96

nvi/nvoOdrFrPrSP_XXX

SNVT_temp_p

Outdoor Frost Protection Setpoint Status

AV

97

AO

97

nvoOdFrPrSPS_XXX

SNVT_temp_p

Outdoor Sensor Status Status

AV

98

AO

98

nvoOdrSnStat_XXX

SNVT_count_f

Outdoor Temperature Status

AV

99

AO

99

nvoOdrTmpSta_XXX

SNVT_temp_p

Outlet Sensor Status

AV

100

AO

100

nvoOutSenSta_XXX

SNVT_temp_p

Password (W)

AV

101

AO

101

nvi/nvoPassword_XXX

SNVT_count_f

PSWD Status

AV

102

AO

102

nvoPSWDStat_XXX

SNVT_count_f

S5 (Header) Sensor Status

AV

103

AO

103

nvoS5SenStat_XXX

SNVT_temp_p

Slave 1 Firing Rate Status

AV

104

AO

104

nvoS1FirRtSt_XXX

SNVT_lev_percent

Slave 1 State Status

AV

105

AO

105

nvoS1StatSt_XXX

SNVT_count_f

Slave 2 Firing Rate Status

AV

106

AO

106

nvoS2FirRtSt_XXX

SNVT_lev_percent

Slave 2 State Status

AV

107

AO

107

nvoS2StatSt_XXX

SNVT_count_f

Slave 3 Firing Rate Status

AV

108

AO

108

nvoS3FirRtSt_XXX

SNVT_lev_percent

Slave 3 State Status

AV

109

AO

109

nvoS3StatSt_XXX

SNVT_count_f

Slave 4 Firing Rate Status

AV

110

AO

110

nvoS4FirRtSt_XXX

SNVT_lev_percent

Slave 4 State Status

AV

111

AO

111

nvoS4StatSt_XXX

SNVT_count_f

Slave 5 Firing Rate Status

AV

112

AO

112

nvoS5FirRtSt_XXX

SNVT_lev_percent

Slave 5 State Status

AV

113

AO

113

nvoS5StatSt_XXX

SNVT_count_f

Slave 6 Firing Rate Status

AV

114

AO

114

nvoS6FirRtSt_XXX

SNVT_lev_percent

Slave 6 State Status

AV

115

AO

115

nvoS6StatSt_XXX

SNVT_count_f

Slave 7 Firing Rate Status

AV

116

AO

116

nvoS7FirRtSt_XXX

SNVT_lev_percent

Slave 7 State Status

AV

117

AO

117

nvoS7StatSt_XXX

SNVT_count_f

Slave 8 Firing Rate Status

AV

118

AO

118

nvoS8FirRtSt_XXX

SNVT_lev_percent

Slave 8 State Status

AV

119

AO

119

nvoS8StatSt_XXX

SNVT_count_f

Stack Sensor Status

AV

120

AO

120

nvoStkSenSta_XXX

SNVT_temp_p

Weil-McLain ProtoNode Start-up Guide

Page 45 of 61

System Pump Cycle Count

AV

121

AO

121

nvoSysPpCyCt_XXX

SNVT_count_f

System Pump Cycle Count Status

AV

122

AO

122

nvoSyPpCyCtS_XXX

SNVT_count_f

Warm Weather Shutdown Setpoint

AV

123

AO

123

nvoWmWtShDSP_XXX

SNVT_temp_p

Warm Weather Shutdown Setpoint Status

AV

124

AO

124

nvoWmWtSDSPS_XXX

SNVT_temp_p

CH Enable (W)

BV

1

DO 1 nvi/nvoCH_Enable_XXX

SNVT_switch

CH Enable Status

BV

2

DO 2 nvoCHEnblSt_XXX

SNVT_switch

CH Frost Protection Enable (W)

BV

3

DO 3 nvi/nvoCHFrPrEn_XXX

SNVT_switch

CH Frost Protection Enable Status

BV

4

DO 4 nvoCHFrPrEnS_XXX

SNVT_switch

CH Outdoor Reset Enable (W)

BV

5

DO 5 nvoCHOdrRsEn_XXX

SNVT_switch

CH Outdoor Reset Enable Status

BV

6

DO 6 nvoCHOdrRsES_XXX

SNVT_switch

CH Remote Stat (W)

BV

7

DO 7 nvi/nvoCHRemStat_XXX

SNVT_switch

CH Remote Status

BV

8

DO 8 nvoCHRemSts_XXX

SNVT_switch

DHW Enable

BV

9

DO 9 nvoDHWEnab_XXX

SNVT_switch

DHW Enable Status

BV

10

DO

10

nvoDHWEnStat_XXX

SNVT_switch

DHW Frost Protection Enable

BV

11

DO

11

nvoDHWFrPrEn_XXX

SNVT_switch

DHW Frost Protection Enable Status

BV

12

DO

12

nvoDHWFPrEnS_XXX

SNVT_switch

Htemp HI Alarm

BV

13

DO

13

nvoHTmpHiAlm_XXX

SNVT_switch

Htemp Low Alarm

BV

14

DO

14

nvoHTmpLoAlm_XXX

SNVT_switch

Lead Lag Operation Switch (W)

BV

15

DO

15

nvi/nvoLLOpSw_XXX

SNVT_switch

Lead Lag Operation Switch Status

BV

16

DO

16

nvoLLOpSwSt_XXX

SNVT_switch

ODRTemp Hi Alarm

BV

17

DO

17

nvoODRTpHiAl_XXX

SNVT_switch

ODTTemp Low Alarm

BV

18

DO

18

nvoODTTpLoAl_XXX

SNVT_switch

Warm Weather Shutdown Enable

BV

19

DO

19

nvoWmWtShEn_XXX

SNVT_switch

Warm Weather Shutdown Enable Status

BV

20

DO

20

nvoWmWtShEnS_XXX

SNVT_switch

Evergreen/SlimFit 550-750 Series 2 & 3/SlimFit 1000-2000 Series 2/SVF Models

Modbus RTU Mappings to BACnet, Metasys N2 and LonWorks

Point Name

BACnet

Object

Type

BACnet

Object

ID

N2

Data

Type

N2

Address

LonWorks Name

LonWorks

SNVT

Boiler Model

AI 2 AI 2 nvoBlrModel_XXX

SNVT_count_f

Relay Output Status

AI 6 AI 6 nvoRelOutSt_XXX

SNVT_count_f

Boiler Out 1 Temperature

AI 7 AI 7 nvoBlOut1Tmp_XXX

SNVT_count_f

Active Target Supply Temperature

AI

10

AI

10

nvoActTrSpTp_XXX

SNVT_count_f

Boiler Status 2

AI

13

AI

13

nvoBlrSt2_XXX

SNVT_count_f

Fan Speed

AI

15

AI

15

nvoFanSpd_XXX

SNVT_count_f

Flame Sense Value

AI

16

AI

16

nvoFlmSenVal_XXX

SNVT_count_f

Outdoor Temp

AI

19

AI

19

nvoOutdrTmp_XXX

SNVT_count_f

System Time (Minutes)

AV

20

AO 1 nvi/nvoSysTmMin_XXX

SNVT_count_f

System Time (Hours)

AV

21

AO 2 nvi/nvoSysTmHr_XXX

SNVT_count_f

System Date (Day)

AV

22

AO 3 nvi/nvoSysDtDay_XXX

SNVT_count_f

System Date (Month)

AV

23

AO 4 nvi/nvoSysDtMnt_XXX

SNVT_count_f

System Date (Year)

AV

24

AO 5 nvi/nvoSysDtYr_XXX

SNVT_count_f

0-10V Input

AI

27

AI

27

nvo0_10VInp_XXX

SNVT_count_f

Circulator Exercise/Freeze Protection

AV

30

AO 6 nvi/nvoCircExcer_XXX

SNVT_count_f

Priority 1 Settings

AI

32

AI

32

nvoPr1Set_XXX

SNVT_count_f

Priority 1 Supply Max Target

AV

33

AO 7 nvi/nvoPr1SpMxTr_XXX

SNVT_count_f

Priority 1 Supply Min Target

AV

34

AO 8 nvi/nvoPr1SpMnTr_XXX

SNVT_count_f

Priority 1 OD Reset/Volts Max

AV

35

AO 9 nvi/nvoPr1ODRVMx_XXX

SNVT_count_f

Priority 1 OD Reset/Volts Min

AV

36

AO

10

nvi/nvoPr1ODRVMn_XXX

SNVT_count_f

Priority 1 Max Boiler Temperature

AV

37

AO

11

nvi/nvoPr1MxBlTp_XXX

SNVT_count_f

Priority 3 Max Rate Volts

AV

38

AO

12

nvi/nvoPr3MxRtVl_XXX

SNVT_count_f

Active Network Priority's Boiler Off Diff

AI

40

AI

40

nvoAcNtPrBOD_XXX

SNVT_count_f

Priority 1 System On Diff

AV

41

AO

13

nvi/nvoPr1SyOnDf_XXX

SNVT_count_f

Priority 1 Max On Time Setting

AV

42

AO

14

nvi/nvoPr1MxOnTS_XXX

SNVT_count_f

Priority 1 Post Pump Time

AV

43

AO

15

nvi/nvoPr1PsPpTm_XXX

SNVT_count_f

Priority 1 Boost Time

AV

44

AO

16

nvi/nvoPr1BstTm_XXX

SNVT_count_f

Input 1 Priority

AI

45

AI

45

nvoIn1Pr_XXX

SNVT_count_f

Priority 1 Pre Pump Time

AV

46

AO

17

nvi/nvoPr1PrPpTm_XXX

SNVT_count_f

Priority 1 Boiler On Diff

AV

48

AO

18

nvi/nvoPr1BlOnDf_XXX

SNVT_count_f

Priority 1 Boiler Off Diff

AV

49

AO

19

nvi/nvoPr1BlOfDf_XXX

SNVT_count_f

Priority 1 Max Rate

AV

50

AO

20

nvi/nvoPr1MxRt_XXX

SNVT_count_f

Priority 1 Min Rate

AV

51

AO

21

nvi/nvoPr1MnRt_XXX

SNVT_count_f

Active Network Priority's Max BLR Temp

AI

52

AI

52

nvoANPMxBlTp_XXX

SNVT_count_f

Active Network Priority's Boiler On Diff

AI

53

AI

53

nvoANPBlOnDf_XXX

SNVT_count_f

Priority 2 Setting

AI

55

AI

55

nvoPr2Set_XXX

SNVT_count_f

Weil-McLain ProtoNode Start-up Guide

Page 46 of 61

Priority 2 Supply Max Target

AV

56

AO

22

nvi/nvoPr2SpMxTr_XXX

SNVT_count_f

Priority 2 Supply Min Target

AV

57

AO

23

nvi/nvoPr2SpMnTr_XXX

SNVT_count_f

Priority 2 OD Reset/Volts Max

AV

58

AO

24

nvi/nvoPr2ODRVMx_XXX

SNVT_count_f

Priority 2 OD Reset/Volts Min

AV

59

AO

25

nvi/nvoPr2ODRVMn_XXX

SNVT_count_f

Active Network Prepump Time

AI

60

AI

60

nvoAcNPrPpTm_XXX

SNVT_count_f

Priority 2 Min On Time Setting

AV

62

AO

26

nvi/nvoPr2MnOnTS_XXX

SNVT_count_f

Priority 2 Max On Time Setting

AV

63

AO

27

nvi/nvoPr2MxOnTS_XXX

SNVT_count_f

Priority 2 Post Pump Time

AV

64

AO

28

nvi/nvoPr2PsPpTm_XXX

SNVT_count_f

Priority 2 Boost Time

AV

65

AO

29

nvi/nvoPr2BstTm_XXX

SNVT_count_f

Boiler Control Type

AI

66

AI

66

nvoBlrCtrTyp_XXX

SNVT_count_f

Priority 1 Pre Pump Time

AV

67

AO

30

nvi/nvoPr1PrPpT2_XXX

SNVT_count_f

Priority 2 System Off Diff

AV

68

AO

31

nvi/nvoPr2SyOfDf_XXX

SNVT_count_f

Network Minimum On Time

AI

69

AI

69

nvoNetMnOnTm_XXX

SNVT_count_f

Priority 2 Boiler On Diff

AV

70

AO

32

nvi/nvoPr2BlOnDf_XXX

SNVT_count_f

Priority 2 Boiler Off Diff

AV

71

AO

33

nvi/nvoPr2BlOfDf_XXX

SNVT_count_f

Priority 2 Max Rate