Document Revision: 1.E

APPLICABILITY & EFFECTIVITY

Effective for all systems manufactured after June 2016.

ProtoNode Start-up Guide

FPC-N34, FPC-N35, FPC-N36, FPC-N37,

FPC-N38, FPC-N39, FPC-N40, FPC-N41 and FPC-N42

ProtoNode Start-Up Guide

Technical Support

Please call us for any technical support needs related to the FieldServer product.

Sierra Monitor Corporation

1991 Tarob Court

Milpitas, CA 95035

Website: www.sierramonitor.com

U.S. Support Information:

+1 408 262-6611

+1 800 727-4377

Email: support@sierramonitor.com

EMEA Support Information:

+44 2033 1813 41

Email: support.emea@sierramonitor.com

Contact Information

ProtoNode Start-Up Guide

TABLE OF CONTENTS

Table of Contents ........................................................................................................................................................ 3

List of Figures ............................................................................................................................................................. 4

1 Introduction .......................................................................................................................................................... 5

2 Certification .......................................................................................................................................................... 6

2.1 BTL Mark – BACnet Testing Laboratory ........................................................................................................ 6

2.2 LonMark Certification ...................................................................................................................................... 6

3 Bacnet/LONWorks Setup through Protonode .................................................................................................. 7

3.1 Features ......................................................................................................................................................... 7

3.2 Installation Steps for the Customer ................................................................................................................ 7

3.3 Record Identification Data .............................................................................................................................. 7

3.4 Configure the DIP Switches ........................................................................................................................... 8

3.4.1 Setting the Node/ID Device Instance (DIP Switch A0 – A7) ................................................................... 8

3.4.2 Setting the Serial Baud Rate (DIP Switch B0 – B3) ................................................................................ 8

3.4.3 Select and Load Configuration Files ....................................................................................................... 9

4 Interfacing ProtoNode to Host OEM Device ................................................................................................... 10

4.1 ProtoNode FPC-N34 and FPC-N35 Showing Connection Ports.................................................................. 10

4.2 Device Connections to ProtoNode ............................................................................................................... 11

4.3 Resistor and Power Jumper Information ...................................................................................................... 12

4.3.1 Bias Resistors ....................................................................................................................................... 12

4.3.2 Termination Resistor ............................................................................................................................. 13

4.3.3 Power Jumper Settings ......................................................................................................................... 14

4.4 Wiring Field Port to RS-485 BMS Network................................................................................................... 15

4.5 Wiring Field Port to a LonWorks Network .................................................................................................... 15

4.6 Power-Up ProtoNode ................................................................................................................................... 16

5 LonWorks (FPC-N35): Commissioning ProtoNode on a lonworks Network ............................................... 20

5.1 Commissioning ProtoNode FPC-N35 on a LonWorks Network ................................................................... 20

5.1.1 Instructions to Download XIF File from ProtoNode FPC-N35 Using Browser ...................................... 20

6 Connect the ProtoNode’s Web GUI to Setup IP Address for Ethernet Network ......................................... 17

6.1 Connect the PC to ProtoNode via the Ethernet Port .................................................................................... 17

6.2 Setting IP Address for Field Network ........................................................................................................... 18

Appendix A. Troubleshooting.................................................................................................................................. 22

Appendix A.1. Lost or Incorrect IP Address ............................................................................................................ 22

Appendix A.2. Viewing Diagnostic information........................................................................................................ 23

Appendix A.3. Check Wiring and Settings .............................................................................................................. 24

Appendix A.4. LED Diagnostics for Communications Between ProtoNode and Devices ....................................... 25

Appendix A.5. Take Diagnostic Capture With the FieldServer Toolbox ................................................................. 26

Appendix A.6. Update Firmware ............................................................................................................................. 29

Appendix A.7. BACnet: Setting Network_Number for more than one ProtoNode on Subnet ................................. 29

Appendix A.8. Passwords ....................................................................................................................................... 30

Appendix A.9. Reading Data Arrays ....................................................................................................................... 30

Appendix B. Vendor Information ............................................................................................................................. 31

Appendix B.1. Additional DIP switch settings ......................................................................................................... 31

Table of Contents

ProtoNode Start-Up Guide

Appendix C. Reference ............................................................................................................................................. 32

Appendix C.1. Specifications .................................................................................................................................. 32

Appendix C.1.1. Compliance with UL Regulations ........................................................................................... 33

Appendix D. Bank DIP Switch Settings .................................................................................................................. 34

Appendix D.1. “A” Bank DIP Switch Settings .......................................................................................................... 34

Appendix E. Limited 2 Year Warranty ..................................................................................................................... 37

LIST OF FIGURES

Figure 1: A0 - A7 DIP Switches .................................................................................................................................... 8

Figure 2: B0 – B3 DIP Switches.................................................................................................................................... 8

Figure 3: BMS Baud Rate ............................................................................................................................................. 9

Figure 4: S0 – S3 DIP Switches.................................................................................................................................... 9

Figure 5: ProtoNode BACnet FPC-N34 (upper) and ProtoNode FPC-N35 (lower) .................................................... 10

Figure 6: R2 Port ......................................................................................................................................................... 11

Figure 7: Power and RS-485 Connections ................................................................................................................. 11

Figure 8: Bias Resistors .............................................................................................................................................. 12

Figure 9: Termination Resistor.................................................................................................................................... 13

Figure 10: Power Jumper Switch ................................................................................................................................ 14

Figure 11: Connection from ProtoNode to RS-485 Field Network .............................................................................. 15

Figure 12: RS-485 BMS Network EOL Switch ............................................................................................................ 15

Figure 13: LonWorks Terminal.................................................................................................................................... 15

Figure 14: Required current draw for the ProtoNode ................................................................................................. 16

Figure 15: Power Connections.................................................................................................................................... 16

Figure 16: LonWorks Service Pin Location ................................................................................................................. 20

Figure 17: Sample of Fserver.XIF File Being Generated ........................................................................................... 21

Figure 18: Web Configurator screen with Active Profiles ........................................................................................... 18

Figure 19: Changing IP Address via Web GUI ........................................................................................................... 19

Figure 20: Ethernet Port Location ............................................................................................................................... 22

Figure 21: Error messages screen ............................................................................................................................. 23

Figure 22: Diagnostic LEDs ........................................................................................................................................ 25

Figure 23: Ethernet Port Location ............................................................................................................................... 26

Figure 24: Web Configurator – Setting Network Number for BACnet ........................................................................ 29

Figure 25: Additional DIP Switches ............................................................................................................................ 31

Figure 26: Specifications ............................................................................................................................................. 32

Table of Contents

ProtoNode Start-Up Guide

1

2

3

1 INTRODUCTION

ProtoNode is an external, high performance, Building and Industrial Automation multi-protocol

gateway for OEMs wanting to provide protocol translation between Serial and Serial, Serial-Ethernet and

Ethernet-Ethernet devices using LonWorks®1, BACnet®2, Metasys®3 N2 by JCI, Modbus, DNP3, and

more.

This manual provides installation information for 2 types of customers:

OEMs that have purchased the product to be used with their controllers and have not done a first

time start with their controller. When the OEM completes the programming of the ProtoNode with

their device, the ProtoNode will be vitually plug and play at the OEMs customer sites.

o The OEM follows all the steps in this guide to complete the first time start up.

End Users that have purchased the preprogrammed ProtoNode from one of our OEM customers

and need some instructions to configure the device.

The ProtoNode is always pre-configured by the OEM, requiring the end customer to only set of

DIP switches to load a configuration file and set the specific network setting of the device.

NOTE: Technical Support for the end‐user is provided by the device manufacturer and not Sierra

Monitor.

NOTE: For FieldPoP™ information, refer to the FieldPoP™ Device Cloud Start-up Guide online at

the Sierra Monitor.com Resource Center.

www.sierramonitor.com/customer-care/resource-center

LonWorks is a registered trademark of Echelon Corporation

BACnet is a registered trademark of ASHRAE

Metasys is a registered trademark of Johnson Controls Inc.

Page 5 of 37

ProtoNode Start-Up Guide

LonMark International is the recognized authority for certification, education,

and promotion of interoperability standards for the benefit of manufacturers,

integrators and end users. LonMark International has developed extensive

product certification standards and tests to provide the integrator and user with

confidence that products from multiple manufacturers utilizing LonMark

devices work together. Sierra Monitor has more LonMark Certified gateways

than any other gateway manufacturer, including the ProtoCessor, ProtoCarrier

and ProtoNode for OEM applications and the full featured, configurable

gateways.

2 CERTIFICATION

2.1 BTL Mark – BACnet Testing Laboratory

The BTL Mark on the BACnet Router is a symbol that indicates that a product

has passed a series of rigorous tests conducted by an independent laboratory

which verifies that the product correctly implements the BACnet features

claimed in the listing. The mark is a symbol of a high-quality BACnet product.

Go to http://www.BACnetInternational.net/btl/ for more information about the

BACnet Testing Laboratory. Click here for BACnet PIC Statement.

2.2 LonMark Certification

Page 6 of 37

ProtoNode Start-Up Guide

3 BACNET/LONWORKS SETUP THROUGH PROTONODE

3.1 Features

10/100BaseT Ethernet LAN interface (auto-sensing)

Multiple Protocol Support

Supports multiple configuration files and the ability to automatically load any of the stored files for

different OEM controllers or protocols supported.

ProtoNode- FPC-N34/N36/N38 – BACnet BTL Marked

o FPC-N34: 2 RS-485 ports and 1 Ethernet port

o FPC-N36: 1 RS-485 port, 1 Ethernet port and 1 RS-422

o FPC-N38: 1 RS-485 port, 1 Ethernet port and 1 RS-232

ProtoNode- FPC-N35/N37/N39 – LonMark Certified

o FPC-N35: 1 Ethernet Port, 1 LonWorks port and 1 RS-485 port

o FPC-N36: 1 Ethernet port, 1 LonWorks port and 1 RS-422 port

o FPC-N39: 1 Ethernet Port, 1 LonWorks port and 1 RS-232 port

ProtoNode- FPC-N40

o FPC-N40: 1 RS-485 port, 1 Ethernet port and KNX

ProtoNode- FPC-N42

o FPC-N42: 1 RS-485 port, 1 Ethernet port and M-Bus

3.2 Installation Steps for the Customer

1. Record the information about the unit. (Section 3.3)

2. Set the A, B, and S DIP Switch banks for Field Protocol baud rate, Node-ID/Device Instance, and

proper configuration. (Section 3.4)

3. Connect the ProtoNode to the Field Protocol port and customer’s port to the ProtoNode’s RS-485

interface. (Section 4.4)

4. Connect Power to ProtoNode. After power up, the device is installed on BACnet MS/TP or

Metasys N2.

5. Where the Field protocol is BACnet/IP or Modbus TCP/IP, refer to Section 4 to run the

ProtoNode Web GUI program to change the IP Address. No changes to the configuration file are

necessary.

3.3 Record Identification Data

Each ProtoNode has a unique part number located on the side or the back of the unit. The number format

is FPC-N34-XXX-XXX-XXXX. This number should be recorded, as it may be required for technical

support.

Part Number: __________________________________________________

Page 7 of 37

ProtoNode Start-Up Guide

A0

A1

A2

A3

A4

A5

A6

A7

Off On

B0

B1

B2

B3

Off

On

Figure 1: A0 - A7 DIP Switches

Figure 2: B0 – B3 DIP Switches

3.4 Configure the DIP Switches

3.4.1 Setting the Node/ID Device Instance (DIP Switch A0 – A7)

The A Bank DIP switches on the ProtoNode allow users to set the Node-ID/Device Instance on

the Field RS-485.

DIP switches A0 – A7 can also be used to set the MAC Address for BACnet MS/TP and

BACnet/IP.

NOTE: When setting DIP Switches, please ensure that power to the board is OFF.

Refer to Appendix B.1 for the full range of addresses to set Node-ID/Device Instance.

3.4.2 Setting the Serial Baud Rate (DIP Switch B0 – B3)

DIP Switches B0 – B3 can be used to set the serial baud rate to match the baud rate provided by

the interfaced systems.

Metasys N2 is always defaulted to 9600 baud and the B bank is disabled.

“B” bank DIP switches B0 – B3 are disabled on ProtoNode FPC-N35 (LonWorks).

Page 8 of 37

ProtoNode Start-Up Guide

Baud

B0

B1

B2

B3

9600

On

On

On

Off

19200

Off

Off

Off

On

38400*

On

On

Off

On

57600

Off

Off

On

On

76800

On

Off

On

On

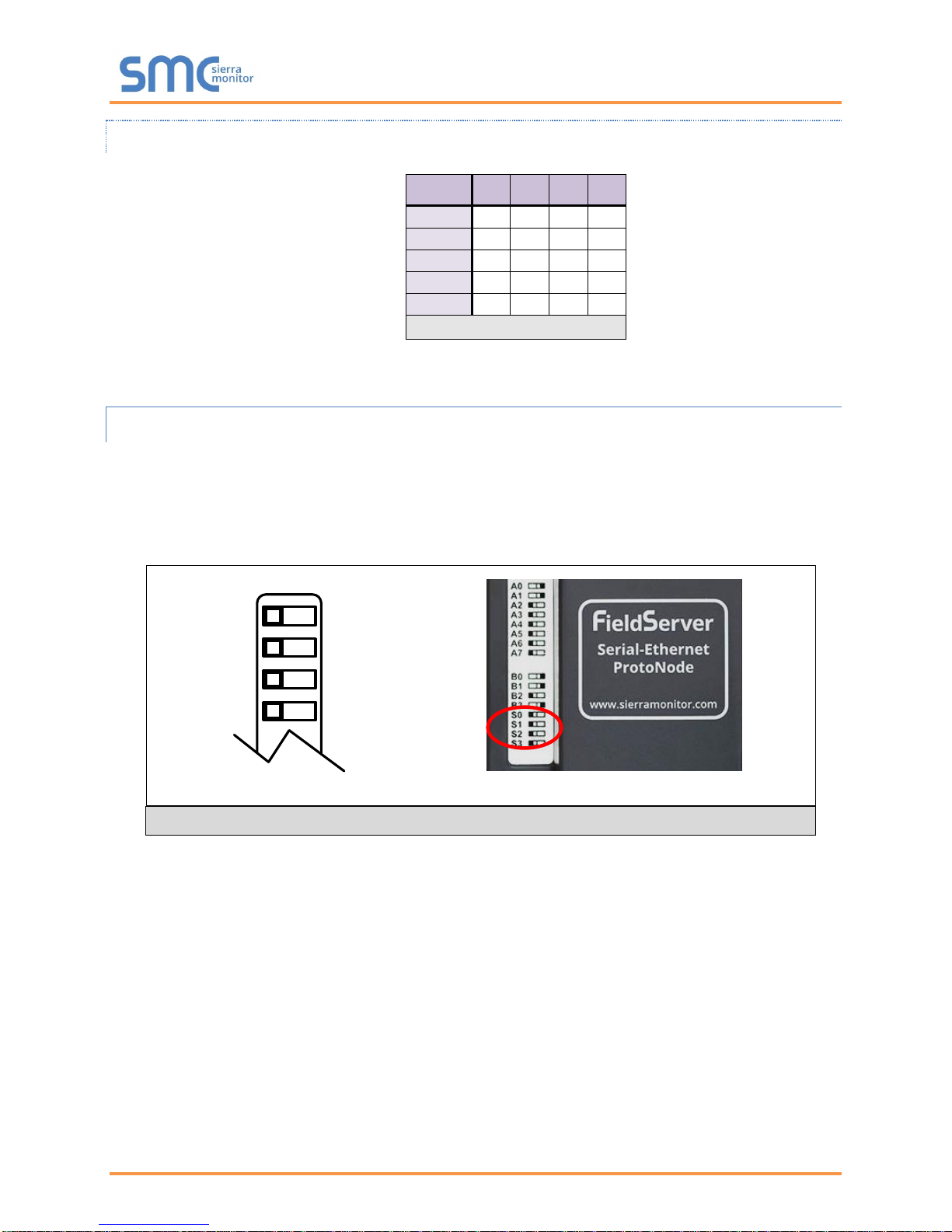

Figure 3: BMS Baud Rate

S Bank DIP Switch Location

Figure 4: S0 – S3 DIP Switches

S0

S1

S2

S3

Off On

S0 – S3 DIP Switches

3.4.2.1 Baud Rate Dip Switch Selection

* Factory default setting = 38400

3.4.3 Select and Load Configuration Files

The S bank of DIP switches, S0 - S3 is used to select and load a configuration file from a group of

pretested/preloaded configuration files that the OEM has programmed for their end users.

End customers will need to go back to the OEM of the device that they are installing to get the

DIP settings for the ProtoNode. The ProtoNode part number will need to be provided to identify

the unit.

Page 9 of 37

ProtoNode Start-Up Guide

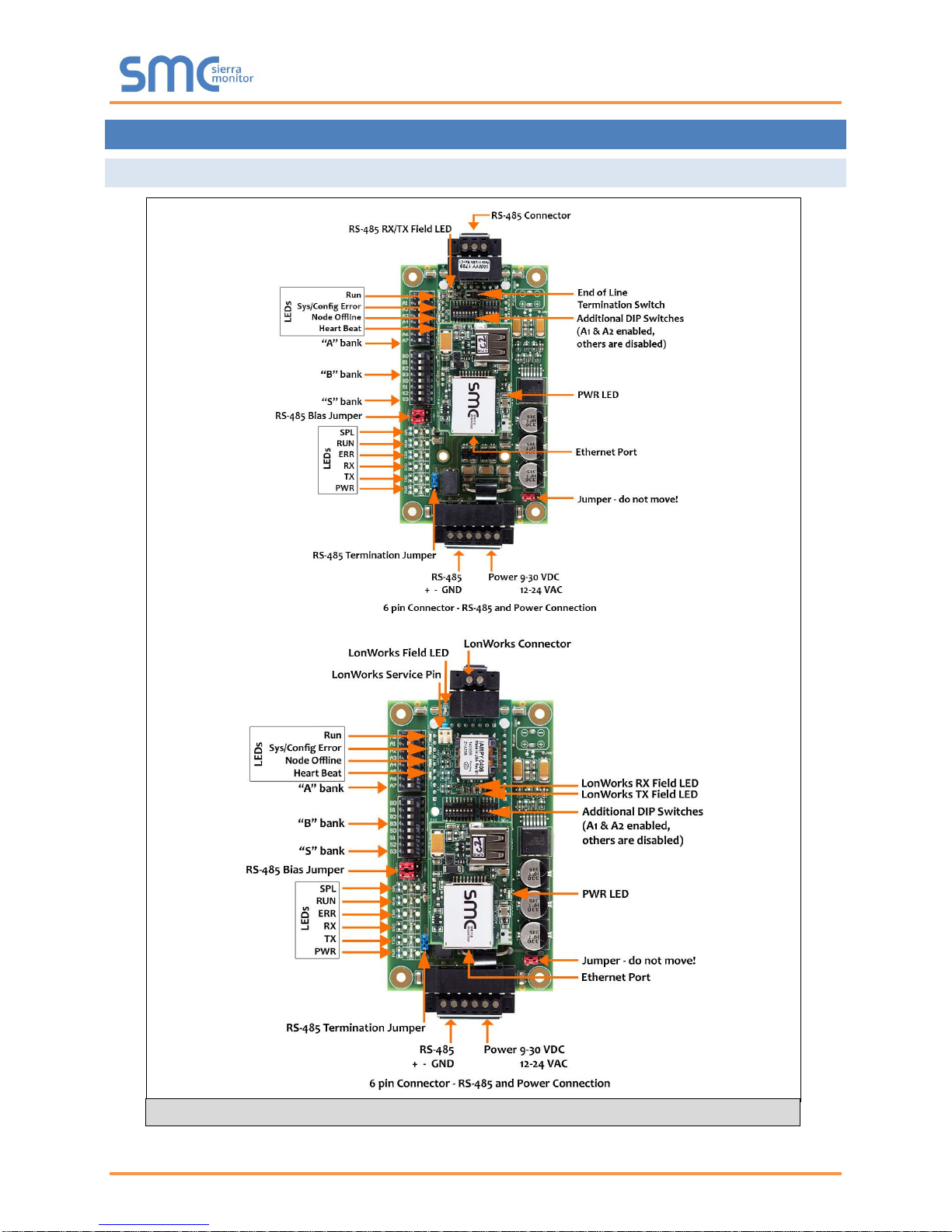

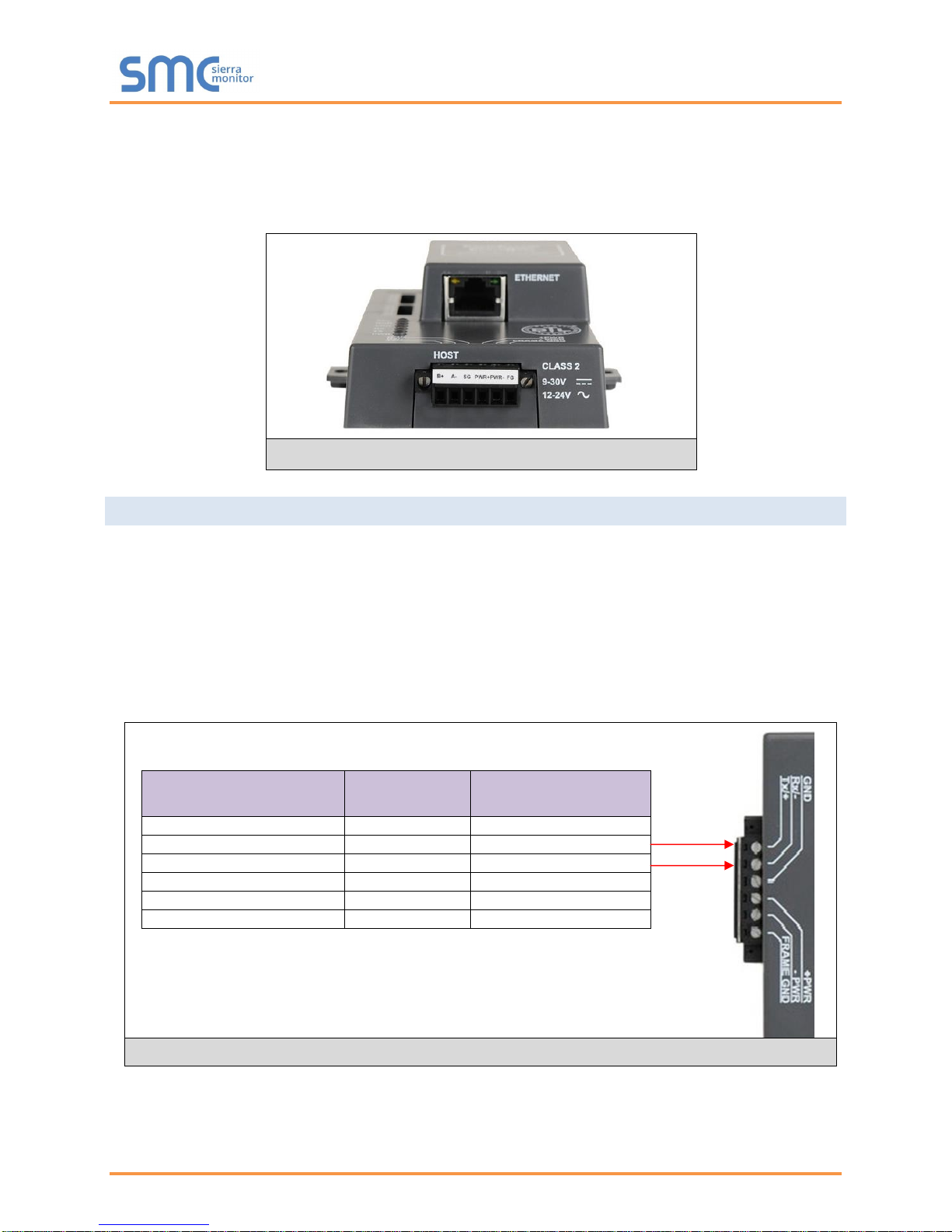

Figure 5: ProtoNode BACnet FPC-N34 (upper) and ProtoNode FPC-N35 (lower)

4 INTERFACING PROTONODE TO HOST OEM DEVICE

4.1 ProtoNode FPC-N34 and FPC-N35 Showing Connection Ports

Page 10 of 37

ProtoNode Start-Up Guide

Device Pins

ProtoNode Pin

#

Pin assignment

Pin RS-485 + / RS-232 Tx

Pin 1

RS-485 + / RS-232 Tx

Pin RS-485 - / RS-232 Rx

Pin 2

RS-485 - /RS-232 Rx

Pin GND

Pin 3

RS-485/RS-232 GND

Power In (+)

Pin 4

V +

Power In (-)

Pin 5

V -

Frame Ground

Pin 6

FRAME GND

Figure 6: R2 Port

Figure 7: Power and RS-485 Connections

The top 3 pin port will always be R1, unless it’s a LonWorks ProtoNode in which case the port designation

is LonWorks (and the port is 2 pins). The bottom 6 pin port will be R2.

NOTE: The 6 pin port can be RS-232, RS-485, RS-422 or KNX (and we use the left 3 pins for this as

currently shown).

4.2 Device Connections to ProtoNode

ProtoNode 6 Pin Phoenix connector for RS-485 Devices

The 6 pin Phoenix connector is the same for ProtoNode FPC-N34 (BACnet) and FPC-N35

(LonWorks).

Pins 1 through 3 are for Modbus RS-485 devices.

o The RS-485 GND (Pin 3) is not typically connected

Pins 4 through 6 are for power. Do not connect power until Section 4.6.

Page 11 of 37

ProtoNode Start-Up Guide

Bias Resistors

Figure 8: Bias Resistors

4.3 Resistor and Power Jumper Information

4.3.1 Bias Resistors

The ProtoNode bias resistors are used to keep the RS-485 bus to a known state, when there is no

transmission on the line (bus is idling), to help prevent false bits of data from being detected. The bias

resistors typically pull one line high and the other low - i.e. far away from the decision point of the logic.

In the RS-485 carrier, the bias resistor is 510 ohms which is in line with the BACnet spec. It should only

be enabled at one point on the bus (on the Brian field port were there are very weak bias resistors of

100k). Since there are no jumpers, many Brains can be put on network without running into the bias

resistor limit which is < 500 ohms.

NOTE: See www.ni.com/support/serial/resinfo.htm for additional pictures and notes.

Page 12 of 37

ProtoNode Start-Up Guide

Termination Resistor

Figure 9: Termination Resistor

4.3.2 Termination Resistor

Termination resistors are also used to reduce noise. These pull the two lines of an idle bus together.

However, they would override the effect of any bias resistors, if connected.

Page 13 of 37

ProtoNode Start-Up Guide

Power Jumper Switch

in position “A”

Figure 10: Power Jumper Switch

4.3.3 Power Jumper Settings

The ProtoNode Carrier Board power jumper is set to position A by default, but can be changed to position

B for other power supply requirements.

Position A: The Carrier makes use of a full-wave rectifying bridge. Can be used for 12-24 VAC input or

9 – 30 VDC input. At 9 VDC this becomes marginal.

Position B: The Carrier makes use of a half-wave rectifying bridge. Best position for Grounded AC

Transformers and for using DC voltage down to 9VDC.

Page 14 of 37

ProtoNode Start-Up Guide

BMS RS-

485 Wiring

ProtoNode

Pin #

Pin

Assignment

RS-485 +

Pin 1

RS-485 +

RS-485 -

Pin 2

RS-485 -

-

Pin 3

RS-485 GND

Figure 12: RS-485 BMS Network EOL Switch

Figure 11: Connection from ProtoNode to RS-485 Field Network

Figure 13: LonWorks Terminal

G

-

End-of-Line Switch

4.4 Wiring Field Port to RS-485 BMS Network

Connect the RS-485 network wires to the 3-pin RS-485 connector on ProtoNode FPC-N34 as

shown below in Figure 11.

o The RS-485 GND (Pin 3) is not typically connected

If the ProtoNode is the last device on the RS-485 trunk, then the End-Of-Line Termination

Switch needs to be enabled (Figure 12).

o The default setting from the factory is OFF (switch position = right side)

o To enable the EOL Termination, turn the EOL switch ON (switch position = left

side)

4.5 Wiring Field Port to a LonWorks Network

Connect ProtoNode to the field network with the LonWorks terminal using approved cable per the

FT-10 installation guidelines. LonWorks has no polarity.

Page 15 of 37

ProtoNode Start-Up Guide

Power Requirement for ProtoNode External Gateway

Current Draw Type

ProtoNode Family

12VDC/VAC

24VDC/VAC

30VDC

FPC – N34, N36, N38 (Typical)

170mA

100mA

80mA

FPC – N34, N36, N38 (Maximum)

240mA

140mA

100mA

FPC – N35, N37, N39 (Typical)

210mA

130mA

90mA

FPC – N35, N37, N39 (Maximum)

250mA

170mA

110mA

FPC – N40 (Typical)

170mA

100mA

80mA

FPC – N40 (Maximum)

240mA

140mA

100mA

FPC – N42 Slave (Maximum)

550mA

280mA

220mA

FPC – N42 Master (Maximum)

980mA

510mA

400mA

Note: These values are ‘nominal’ and a safety margin should be added to the power supply of the host

system. A safety margin of 25% is recommended.

Figure 14: Required current draw for the ProtoNode

Power to

ProtoNode

ProtoNode

Pin #

Pin

Assignment

Power In (+)

Pin 4

V +

Power In (-)

Pin 5

V -

Frame Ground

Pin 6

FRAME GND

Figure 15: Power Connections

4.6 Power-Up ProtoNode

Apply power to ProtoNode as show below in Figure 15. Ensure that the power supply used

complies with the specifications provided in Appendix C.1.

ProtoNode accepts either 9-30VDC or 12-24 VAC on pins 4 and 5.

Frame GND should be connected.

Page 16 of 37

ProtoNode Start-Up Guide

5 CONNECT THE PROTONODE’S W EB G UI TO SETUP IP ADDRESS FOR

ETHERNET NETWORK

5.1 Connect the PC to ProtoNode via the Ethernet Port

Connect a CAT5 Ethernet cable (Straight through or Cross-Over) between the PC and

ProtoNode.

The Default IP Address of ProtoNode is 192.168.1.24, Subnet Mask is 255.255.255.0. If the PC

and ProtoNode are on different IP Networks, assign a static IP Address to the PC on the

192.168.1.xxx network.

For Windows XP:

Go to > >

Right-click on Local Area Connection > Properties

Highlight >

For Windows 7 or later:

Go to > >

> >

Right-click on Local Area Connection > Properties

Highlight >

For Windows XP and Windows 7, use the following IP Address:

Click twice.

Page 17 of 37

ProtoNode Start-Up Guide

Figure 16: Web Configurator screen with Active Profiles

5.2 Setting IP Address for Field Network

After setting a local PC to be on the same subnet as the ProtoNode (Section 5.1), open a web

browser on the PC and enter the IP Address of the ProtoNode; the default address is

192.168.1.24.

The Web Configurator will be displayed as the landing page. (Figure 16)

NOTE: Below the “Active Profiles” heading are listed the profiles for connected devices. If no profiles are

present, then the wiring, baud rate, and DIP switch settings must be checked, because there is a

problem with device communications. All the active profiles must show the correct Node-ID’s

before proceeding.

NOTE: If multiple devices are connected to the ProtoNode and virtual server nodes are required,

set the BACnet Virtual Server Nodes field to “Yes”; otherwise leave the field on the default

“No” setting.

To access the Web GUI, click on the “Diagnostics & Debugging” button in the bottom right

side of the page.

Page 18 of 37

ProtoNode Start-Up Guide

Figure 17: Changing IP Address via Web GUI

From the Web GUI’s landing page, click on “Setup” to expand the navigation tree and then select

“Network Settings” to access the IP Settings menu. (Figure 17)

Modify the IP Address (N1 IP Address field) of the ProtoNode Ethernet port.

If necessary, change the Netmask (N1 Netmask field).

Type in a new Subnet Mask.

If necessary, change the IP Gateway (Default Gateway field).

Type in a new IP Gateway.

NOTE: If the ProtoNode is connected to a router, the IP Gateway of the ProtoNode should be set to the

IP Address as the router.

Reset ProtoNode.

Unplug Ethernet cable from PC and connect it to the network hub or router.

Record the IP Address assigned to the ProtoNode for future reference.

Page 19 of 37

ProtoNode Start-Up Guide

Figure 18: LonWorks Service Pin Location

6 LONWORKS (FPC-N35): COMMISSIONING PROTONODE ON A LONWORKS

NETWORK

Commissioning may only be performed by the LonWorks administrator.

6.1 Commissioning ProtoNode FPC-N35 on a LonWorks Network

The User will be prompted by the LonWorks Administrator to hit the Service Pin on the ProtoNode

FPC-N35 at the correct step of the Commissioning process which is different for each LonWorks

Network Management Tool.

If an XIF file is required, see steps in Section 6.1.1 to generate XIF.

6.1.1 Instructions to Download XIF File from ProtoNode FPC-N35 Using Browser

Connect a CAT5 Ethernet cable (Straight through or Cross-Over) between the PC and

ProtoNode.

The Default IP Address of ProtoNode is 192.168.1.24, Subnet Mask is 255.255.255.0. If the PC

and ProtoNode are on different IP Networks, assign a static IP Address to the PC on the

192.168.1.xxx network.

For Windows XP:

Go to > >

Right-click on Local Area Connection > Properties

Highlight >

For Windows 7 or later:

Go to > >

> >

Right-click on Local Area Connection > Properties

Highlight >

Page 20 of 37

ProtoNode Start-Up Guide

Figure 19: Sample of Fserver.XIF File Being Generated

For Windows XP and Windows 7, use the following IP Address:

Click twice.

Open a web browser and go to the following address: [IP Address of ProtoNode]/fserver.xif

o Example: 192.168.1.24/fserver.xif

If the web browser prompts to save the file, save the file onto the PC. If the web browser displays

the xif file as a web page, save the file on the local PC as “fserver.xif”.

Page 21 of 37

ProtoNode Start-Up Guide

Ethernet Port

Figure 20: Ethernet Port Location

Appendix A. Troubleshooting

Appendix A.1. Lost or Incorrect IP Address

Ensure that FieldServer Toolbox is Loaded on the PC that is currently being used, or download

FieldServer-Toolbox.zip on the Sierra Monitor webpage, under Customer Care: Resource Center,

Software Downloads:

www.sierramonitor.com/customer-care/resource-center?filters=software-downloads

Extract the executable file and complete the installation.

Disable any wireless Ethernet adapters on the PC/Laptop.

Disable firewall and virus protection software if possible.

Connect a standard CAT5 Ethernet cable between the PC and ProtoNode.

Double click on the FS Toolbox Utility.

Check IP Addresses from the Device listings.

Correct IP Address(es) by right clicking the settings icon and changing the IP Address.

Page 22 of 37

ProtoNode Start-Up Guide

Figure 21: Error messages screen

Appendix A.2. Viewing Diagnostic information

Type the IP Address of the ProtoNode into the local PC’s web browser or use the FieldServer

Toolbox to connect to the ProtoNode.

Click on Diagnostics and Debugging Button, then click on view, and then on connections.

If there are any errors showing on the Connection page, please refer to Appendix A.3 for the

relevant wiring and settings.

Page 23 of 37

ProtoNode Start-Up Guide

Appendix A.3. Check Wiring and Settings

No COMS on Modbus RTU side. If Tx/Rx are not flashing rapidly then there is a COM issue on

the Modbus side. To fix this problem, check the following:

o Visual observations of LEDs on ProtoNode. (Appendix A.4)

o Check baud rate, parity, data bits, stop bits

o Check Modbus device address

o Verify wiring

o Verify Modbus device is connected to the same subnet as the ProtoNode

o Verify all the Modbus devices were discovered in Web Configurator. (Section 5.2)

No COMS on Modbus TCP/IP side. To fix, check the following:

o Visual observations of LEDs on ProtoNode (Appendix A.4)

o Check device address

o Verify wiring

o Verify device is connected to the same subnet as the ProtoNode

o Verify all the Modbus TCP/IP devices were discovered in Web Configurator (Section 5.2)

Field COM problems:

o If Ethernet protocols are used, observe Ethernet LEDs on the ProtoNode (Appendix A.4)

o Visual dipswitch settings (using correct baud rate and device instance)

o Verify IP Address setting

o Verify wiring

If the problem still exists, a Diagnostic Capture needs to be taken and sent to Sierra Monitor

Corporation. (Appendix A.5)

Page 24 of 37

ProtoNode Start-Up Guide

Tag

Description

SPL

The SPL LED will light if the unit is not getting a response from one or more of the configured devices.

For LonWorks units, LED will light until the unit is commissioned on the LonWorks network.

RUN

The RUN LED will start flashing 20 seconds after power indicating normal operation.

ERR

The SYS ERR LED will go on solid 15 seconds after power up. It will turn off after 5 seconds. A steady

red light will indicate there is a system error on the unit. If this occurs, immediately report the related

“system error” shown in the error screen of the GUI interface to support for evaluation.

RX

If socket protocol is serial, the RX LED will flash when a message is received on the host port.

If socket protocol is Ethernet, this LED is not used.

TX

If socket protocol is serial, the TX LED will flash when a message is sent on the host port.

If socket protocol is Ethernet, this LED is not used.

PWR

This is the power light and should show steady green at all times when the unit is powered.

Figure 22: Diagnostic LEDs

Diagnostic LEDs

Appendix A.4. LED Diagnostics for Communications Between ProtoNode and Devices

Please see the diagram below for ProtoNode FPC-N34 and FPC-N35 LED Locations.

Page 25 of 37

ProtoNode Start-Up Guide

Ethernet Port

Figure 23: Ethernet Port Location

Appendix A.5. Take Diagnostic Capture With the FieldServer Toolbox

Once the Diagnostic Capture is complete, email it to support@sierramonitor.com. The

Diagnostic Capture will allow us to rapidly diagnose the problem.

Ensure that FieldServer Toolbox is Loaded on the PC that is currently being used, or download

FieldServer-Toolbox.zip on the Sierra Monitor Corporation webpage, under Customer Care:

Resource Center, Software Downloads:

www.sierramonitor.com/customer-care/resource-center?filters=software-downloads

Extract the executable file and complete the installation.

Disable any wireless Ethernet adapters on the PC/Laptop.

Disable firewall and virus protection software if possible.

Connect a standard CAT5 Ethernet cable between the PC and ProtoNode .

Double click on the FS Toolbox Utility.

Step 1: Take a Log

o Click on the diagnose icon of the desired device

Page 26 of 37

ProtoNode Start-Up Guide

o Select full Diagnostic

NOTE: If desired, the default capture period can be changed.

o Click on Start Diagnostic

o Wait for Capture period to finish, then the Diagnostic Test Complete window will appear

Page 27 of 37

ProtoNode Start-Up Guide

Step 2: Send Log

o Once the Diagnostic test is complete, a .zip file will be saved on the PC

o Choose Open to launch explorer and have it point directly at the correct folder

o Send the Diagnostic zip file to support@sierramonitor.com

Page 28 of 37

ProtoNode Start-Up Guide

Figure 24: Web Configurator – Setting Network Number for BACnet

Appendix A.6. Update Firmware

To load a new version of the firmware, follow these instructions:

1. Extract and save the new file onto the local PC.

2. Open a web browser and type the IP Address of the FieldServer in the address bar.

NOTE: Default IP Address is 192.168.1.24

NOTE: Use the FS Toolbox utility if the IP Address is unknown (Appendix A.1)

3. Click on the “Diagnostics & Debugging” button.

4. In the Navigation Tree on the left hand side, do the following:

a. Click on “Setup”

b. Click on “File Transfer”

c. Click on the “Firmware” tab

5. In the Firmware tab, click on “Choose Files” and select the firmware file extracted in step 1.

6. Click on the orange “Submit” button.

7. When the download is complete, click on the “System Restart” button.

Appendix A.7. BACnet: Setting Network_Number for more than one ProtoNode on Subnet

For both BACnet MS/TP and BACnet/IP, if more than one ProtoNode is connected to the same subnet,

they must be assigned unique Network_Number values.

On the main Web Configuration screen, update the Network Number with the “network_nr” field and click

submit. The default value is 50.

Page 29 of 37

ProtoNode Start-Up Guide

Appendix A.8. Passwords

Access to the ProtoNode can be restricted by enabling a password. There are 2 access levels defined by

2 account names: Admin and User.

The Admin account has unrestricted access to the ProtoNode.

The User account can view any ProtoNode information, but cannot make any changes or restart

the ProtoNode.

The password needs to be a minimum of eight characters and is case sensitive.

If the password is lost, click cancel on the password authentication popup window, and e-mail the

Password recovery token to support@sierramonitor.com to receive a temporary password from the Sierra

Monitor support team. Access the ProtoNode to set a new password.

Appendix A.9. Reading Data Arrays

Connect to the ProtoNode with a browser and click on the Diagnostics & Debugging button.

Select the User Messages branch.

Select the info tab.

See which profile has been loaded.

o Example: prof1b.csv

In the address bar of the browser, type the IP address/filename.

o Example: 192.168.1.24/prof1b.csv

Press the enter key and save the file.

Open the file and go to the server side map descriptors section.

The map_descriptor_name, data_array_name, and data array_offset will be shown for each point.

Go back to the browser and select the view branch.

Select the data arrays branch.

Select the data array that corresponds with the point that you want to monitor.

View the offset that corresponds with the point that you want to monitor.

Page 30 of 37

ProtoNode Start-Up Guide

S Bank DIP Switches

A1, A2, and A3 DIP Switches

Figure 25: Additional DIP Switches

Appendix B. Vendor Information

Appendix B.1. Additional DIP switch settings

When more configuration settings are needed than possible via the external S Bank DIP Switches, then

the user can access the A Bank DIP Switches internal to the ProtoNode.

NOTE: The lid on top of the ProtoNode has to be removed in order to select the A Bank of DIP switches.

Pull on the lid while holding the on to the 6 pin Phoenix connector. Please do not hold the wall

mount tabs as these are designed to break off if not required!

To set select these configurations, open the ProtoNode and select the A bank of switches (A1 or

A2 or A3) on the small ProtoCessor module that sits on top of the ProtoCarrier (inside the

ProtoNode).

Page 31 of 37

ProtoNode Start-Up Guide

ProtoNode FPC-N34/-N36/-N38

ProtoNode FPC-N35/-N37/-N39

Electrical Connections

One 6-pin Phoenix connector with:

RS-485 port (+ / - / gnd)

Power port (+ / - / Frame-gnd)

One 3-pin Phoenix connector with:

RS-485 port (+ / - / gnd)

One Ethernet 10/100 BaseT port

One 6-pin Phoenix connector with:

RS-485 port (+ / - / gnd)

Power port (+ / - / Frame-gnd)

One Ethernet 10/100 BaseT port

One FTT-10 LonWorks port

Approvals

CE Certified; TUV approved to UL 916, EN 60950-1,

EN 50491-3 and CSA C22-2 standards; FCC Class A Part 15;

DNP3 Conformance Tested; RoHS Compliant; CSA 205 Approved

BTL Marked

LonMark Certified

Power Requirements

Multi-mode power adapter: 9-30VDC or 12 - 24VAC

Physical Dimensions

11.5 cm L x 8.3 cm W x 4.1 cm H (4.5 x 3.2 x 1.6 in.)

Weight

0.2 kg (0.4 lbs)

Operating Temperature

-40°C to 75°C (-40°F to167°F)

Surge Suppression

EN61000-4-2 ESD EN61000-4-3 EMC EN61000-4-4 EFT

Humidity

5 - 90% RH (non-condensing)

(Specifications subject to change without notice)

Figure 26: Specifications

Interface Connections

RS-2321

RS-4852

RS-4223

Ethernet4

LonWorks5

KNX6

M-Bus7

ProtoNode

FPC-N34

2 1

FPC-N35

1 1 1

FPC-N36

1 1 1

FPC-N37

1 1 1

FPC-N38

1 1 1

FPC-N39

1 1 1

FPC-N40

1 1

1

FPC-N41

1 1

1

FPC-N42

1 1

1

1 Tx/Rx/GND

2 +/-/Frame Ground

3 +/-/Frame Ground

4 10/100 BaseT

5 FTT 10

6 +/-/Frame Ground

7 +/-/Frame Ground

Appendix C. Reference

Appendix C.1. Specifications

Page 32 of 37

ProtoNode Start-Up Guide

Appendix C.1.1. Compliance with UL Regulations

For UL compliance, the following instructions must be met when operating ProtoNode.

The units shall be powered by listed LPS or Class 2 power supply suited to the expected

operating temperature range.

The interconnecting power connector and power cable shall:

o Comply with local electrical code.

o Be suited to the expected operating temperature range.

o Meet the current and voltage rating for ProtoNode

Furthermore, the interconnecting power cable shall:

o Be of length not exceeding 3.05m (118.3”)

o Be constructed of materials rated VW-1 or FT-1 or better

If the unit is to be installed in an operating environment with a temperature above 65 °C, it should

be installed in a Restricted Access Area requiring a key or a special tool to gain access.

This device must not be connected to a LAN segment with outdoor wiring.

Page 33 of 37

ProtoNode Start-Up Guide

Address

A0

A1

A2

A3

A4

A5

A6

A7

1

On

Off

Off

Off

Off

Off

Off

Off 2 Off

On

Off

Off

Off

Off

Off

Off 3 On

On

Off

Off

Off

Off

Off

Off 4 Off

Off

On

Off

Off

Off

Off

Off 5 On

Off

On

Off

Off

Off

Off

Off 6 Off

On

On

Off

Off

Off

Off

Off 7 On

On

On

Off

Off

Off

Off

Off 8 Off

Off

Off

On

Off

Off

Off

Off 9 On

Off

Off

On

Off

Off

Off

Off

10

Off

On

Off

On

Off

Off

Off

Off

11

On

On

Off

On

Off

Off

Off

Off

12

Off

Off

On

On

Off

Off

Off

Off

13

On

Off

On

On

Off

Off

Off

Off

14

Off

On

On

On

Off

Off

Off

Off

15

On

On

On

On

Off

Off

Off

Off

16

Off

Off

Off

Off

On

Off

Off

Off

17

On

Off

Off

Off

On

Off

Off

Off

18

Off

On

Off

Off

On

Off

Off

Off

19

On

On

Off

Off

On

Off

Off

Off

20

Off

Off

On

Off

On

Off

Off

Off

21

On

Off

On

Off

On

Off

Off

Off

22

Off

On

On

Off

On

Off

Off

Off

23

On

On

On

Off

On

Off

Off

Off

24

Off

Off

Off

On

On

Off

Off

Off

25

On

Off

Off

On

On

Off

Off

Off

26

Off

On

Off

On

On

Off

Off

Off

27

On

On

Off

On

On

Off

Off

Off

28

Off

Off

On

On

On

Off

Off

Off

29

On

Off

On

On

On

Off

Off

Off

30

Off

On

On

On

On

Off

Off

Off

31

On

On

On

On

On

Off

Off

Off

32

Off

Off

Off

Off

Off

On

Off

Off

33

On

Off

Off

Off

Off

On

Off

Off

34

Off

On

Off

Off

Off

On

Off

Off

35

On

On

Off

Off

Off

On

Off

Off

36

Off

Off

On

Off

Off

On

Off

Off

37

On

Off

On

Off

Off

On

Off

Off

38

Off

On

On

Off

Off

On

Off

Off

39

On

On

On

Off

Off

On

Off

Off

40

Off

Off

Off

On

Off

On

Off

Off

41

On

Off

Off

On

Off

On

Off

Off

42

Off

On

Off

On

Off

On

Off

Off

43

On

On

Off

On

Off

On

Off

Off

44

Off

Off

On

On

Off

On

Off

Off

45

On

Off

On

On

Off

On

Off

Off

Address

A0

A1

A2

A3

A4

A5

A6

A7

46

Off

On

On

On

Off

On

Off

Off

47

On

On

On

On

Off

On

Off

Off

48

Off

Off

Off

Off

On

On

Off

Off

49

On

Off

Off

Off

On

On

Off

Off

50

Off

On

Off

Off

On

On

Off

Off

51

On

On

Off

Off

On

On

Off

Off

52

Off

Off

On

Off

On

On

Off

Off

53

On

Off

On

Off

On

On

Off

Off

54

Off

On

On

Off

On

On

Off

Off

55

On

On

On

Off

On

On

Off

Off

56

Off

Off

Off

On

On

On

Off

Off

57

On

Off

Off

On

On

On

Off

Off

58

Off

On

Off

On

On

On

Off

Off

59

On

On

Off

On

On

On

Off

Off

60

Off

Off

On

On

On

On

Off

Off

61

On

Off

On

On

On

On

Off

Off

62

Off

On

On

On

On

On

Off

Off

63

On

On

On

On

On

On

Off

Off

64

Off

Off

Off

Off

Off

Off

On

Off

65

On

Off

Off

Off

Off

Off

On

Off

66

Off

On

Off

Off

Off

Off

On

Off

67

On

On

Off

Off

Off

Off

On

Off

68

Off

Off

On

Off

Off

Off

On

Off

69

On

Off

On

Off

Off

Off

On

Off

70

Off

On

On

Off

Off

Off

On

Off

71

On

On

On

Off

Off

Off

On

Off

72

Off

Off

Off

On

Off

Off

On

Off

73

On

Off

Off

On

Off

Off

On

Off

74

Off

On

Off

On

Off

Off

On

Off

75

On

On

Off

On

Off

Off

On

Off

76

Off

Off

On

On

Off

Off

On

Off

77

On

Off

On

On

Off

Off

On

Off

78

Off

On

On

On

Off

Off

On

Off

79

On

On

On

On

Off

Off

On

Off

80

Off

Off

Off

Off

On

Off

On

Off

81

On

Off

Off

Off

On

Off

On

Off

82

Off

On

Off

Off

On

Off

On

Off

83

On

On

Off

Off

On

Off

On

Off

84

Off

Off

On

Off

On

Off

On

Off

85

On

Off

On

Off

On

Off

On

Off

86

Off

On

On

Off

On

Off

On

Off

87

On

On

On

Off

On

Off

On

Off

88

Off

Off

Off

On

On

Off

On

Off

89

On

Off

Off

On

On

Off

On

Off

90

Off

On

Off

On

On

Off

On

Off

Appendix D. Bank DIP Switch Settings

Appendix D.1. “A” Bank DIP Switch Settings

Page 34 of 37

ProtoNode Start-Up Guide

Address

A0

A1

A2

A3

A4

A5

A6

A7

91

On

On

Off

On

On

Off

On

Off

92

Off

Off

On

On

On

Off

On

Off

93

On

Off

On

On

On

Off

On

Off

94

Off

On

On

On

On

Off

On

Off

95

On

On

On

On

On

Off

On

Off

96

Off

Off

Off

Off

Off

On

On

Off

97

On

Off

Off

Off

Off

On

On

Off

98

Off

On

Off

Off

Off

On

On

Off

99

On

On

Off

Off

Off

On

On

Off

100

Off

Off

On

Off

Off

On

On

Off

101

On

Off

On

Off

Off

On

On

Off

102

Off

On

On

Off

Off

On

On

Off

103

On

On

On

Off

Off

On

On

Off

104

Off

Off

Off

On

Off

On

On

Off

105

On

Off

Off

On

Off

On

On

Off

106

Off

On

Off

On

Off

On

On

Off

107

On

On

Off

On

Off

On

On

Off

108

Off

Off

On

On

Off

On

On

Off

109

On

Off

On

On

Off

On

On

Off

110

Off

On

On

On

Off

On

On

Off

111

On

On

On

On

Off

On

On

Off

112

Off

Off

Off

Off

On

On

On

Off

113

On

Off

Off

Off

On

On

On

Off

114

Off

On

Off

Off

On

On

On

Off

115

On

On

Off

Off

On

On

On

Off

116

Off

Off

On

Off

On

On

On

Off

117

On

Off

On

Off

On

On

On

Off

118

Off

On

On

Off

On

On

On

Off

119

On

On

On

Off

On

On

On

Off

120

Off

Off

Off

On

On

On

On

Off

121

On

Off

Off

On

On

On

On

Off

122

Off

On

Off

On

On

On

On

Off

123

On

On

Off

On

On

On

On

Off

124

Off

Off

On

On

On

On

On

Off

125

On

Off

On

On

On

On

On

Off

126

Off

On

On

On

On

On

On

Off

127

On

On

On

On

On

On

On

Off

128

Off

Off

Off

Off

Off

Off

Off

On

129

On

Off

Off

Off

Off

Off

Off

On

130

Off

On

Off

Off

Off

Off

Off

On

131

On

On

Off

Off

Off

Off

Off

On

132

Off

Off

On

Off

Off

Off

Off

On

133

On

Off

On

Off

Off

Off

Off

On

134

Off

On

On

Off

Off

Off

Off

On

135

On

On

On

Off

Off

Off

Off

On

136

Off

Off

Off

On

Off

Off

Off

On

137

On

Off

Off

On

Off

Off

Off

On

138

Off

On

Off

On

Off

Off

Off

On

Address

A0

A1

A2

A3

A4

A5

A6

A7

139

On

On

Off

On

Off

Off

Off

On

140

Off

Off

On

On

Off

Off

Off

On

141

On

Off

On

On

Off

Off

Off

On

142

Off

On

On

On

Off

Off

Off

On

143

On

On

On

On

Off

Off

Off

On

144

Off

Off

Off

Off

On

Off

Off

On

145

On

Off

Off

Off

On

Off

Off

On

146

Off

On

Off

Off

On

Off

Off

On

147

On

On

Off

Off

On

Off

Off

On

148

Off

Off

On

Off

On

Off

Off

On

149

On

Off

On

Off

On

Off

Off

On

150

Off

On

On

Off

On

Off

Off

On

151

On

On

On

Off

On

Off

Off

On

152

Off

Off

Off

On

On

Off

Off

On

153

On

Off

Off

On

On

Off

Off

On

154

Off

On

Off

On

On

Off

Off

On

155

On

On

Off

On

On

Off

Off

On

156

Off

Off

On

On

On

Off

Off

On

157

On

Off

On

On

On

Off

Off

On

158

Off

On

On

On

On

Off

Off

On

159

On

On

On

On

On

Off

Off

On

160

Off

Off

Off

Off

Off

On

Off

On

161

On

Off

Off

Off

Off

On

Off

On

162

Off

On

Off

Off

Off

On

Off

On

163

On

On

Off

Off

Off

On

Off

On

164

Off

Off

On

Off

Off

On

Off

On

165

On

Off

On

Off

Off

On

Off

On

166

Off

On

On

Off

Off

On

Off

On

167

On

On

On

Off

Off

On

Off

On

168

Off

Off

Off

On

Off

On

Off

On

169

On

Off

Off

On

Off

On

Off

On

170

Off

On

Off

On

Off

On

Off

On

171

On

On

Off

On

Off

On

Off

On

172

Off

Off

On

On

Off

On

Off

On

173

On

Off

On

On

Off

On

Off

On

174

Off

On

On

On

Off

On

Off

On

175

On

On

On

On

Off

On

Off

On

176

Off

Off

Off

Off

On

On

Off

On

177

On

Off

Off

Off

On

On

Off

On

178

Off

On

Off

Off

On

On

Off

On

179

On

On

Off

Off

On

On

Off

On

180

Off

Off

On

Off

On

On

Off

On

181

On

Off

On

Off

On

On

Off

On

182

Off

On

On

Off

On

On

Off

On

183

On

On

On

Off

On

On

Off

On

184

Off

Off

Off

On

On

On

Off

On

185

On

Off

Off

On

On

On

Off

On

186

Off

On

Off

On

On

On

Off

On

Page 35 of 37

ProtoNode Start-Up Guide

Address

A0

A1

A2

A3

A4

A5

A6

A7

187

On

On

Off

On

On

On

Off

On

188

Off

Off

On

On

On

On

Off

On

189

On

Off

On

On

On

On

Off

On

190

Off

On

On

On

On

On

Off

On

191

On

On

On

On

On

On

Off

On

192

Off

Off

Off

Off

Off

Off

On

On

193

On

Off

Off

Off

Off

Off

On

On

194

Off

On

Off

Off

Off

Off

On

On

195

On

On

Off

Off

Off

Off

On

On

196

Off

Off

On

Off

Off

Off

On

On

197

On

Off

On

Off

Off

Off

On

On

198

Off

On

On

Off

Off

Off

On

On

199

On

On

On

Off

Off

Off

On

On

200

Off

Off

Off

On

Off

Off

On

On

201

On

Off

Off

On

Off

Off

On

On

202

Off

On

Off

On

Off

Off

On

On

203

On

On

Off

On

Off

Off

On

On

204

Off

Off

On

On

Off

Off

On

On

205

On

Off

On

On

Off

Off

On

On

206

Off

On

On

On

Off

Off

On

On

207

On

On

On

On

Off

Off

On

On

208

Off

Off

Off

Off

On

Off

On

On

209

On

Off

Off

Off

On

Off

On

On

210

Off

On

Off

Off

On

Off

On

On

211

On

On

Off

Off

On

Off

On

On

212

Off

Off

On

Off

On

Off

On

On

213

On

Off

On

Off

On

Off

On

On

214

Off

On

On

Off

On

Off

On

On

215

On

On

On

Off

On

Off

On

On

216

Off

Off

Off

On

On

Off

On

On

217

On

Off

Off

On

On

Off

On

On

218

Off

On

Off

On

On

Off

On

On

219

On

On

Off

On

On

Off

On

On

220

Off

Off

On

On

On

Off

On

On

221

On

Off

On

On

On

Off

On

On

222

Off

On

On

On

On

Off

On

On

223

On

On

On

On

On

Off

On

On

224

Off

Off

Off

Off

Off

On

On

On

225

On

Off

Off

Off

Off

On

On

On

226

Off

On

Off

Off

Off

On

On

On

227

On

On

Off

Off

Off

On

On

On

228

Off

Off

On

Off

Off

On

On

On

229

On

Off

On

Off

Off

On

On

On

230

Off

On

On

Off

Off

On

On

On

231

On

On

On

Off

Off

On

On

On

232

Off

Off

Off

On

Off

On

On

On

233

On

Off

Off

On

Off

On

On

On

234

Off

On

Off

On

Off

On

On

On

Address

A0

A1

A2

A3

A4

A5

A6

A7

235

On

On

Off

On

Off

On

On

On

236

Off

Off

On

On

Off

On

On

On

237

On

Off

On

On

Off

On

On

On

238

Off

On

On

On

Off

On

On

On

239

On

On

On

On

Off

On

On

On

240

Off

Off

Off

Off

On

On

On

On

241

On

Off

Off

Off

On

On

On

On

242

Off

On

Off

Off

On

On

On

On

243

On

On

Off

Off

On

On

On

On

244

Off

Off

On

Off

On

On

On

On

245

On

Off

On

Off

On

On

On

On

246

Off

On

On

Off

On

On

On

On

247

On

On

On

Off

On

On

On

On

248

Off

Off

Off

On

On

On

On

On

249

On

Off

Off

On

On

On

On

On

250

Off

On

Off

On

On

On

On

On

251

On

On

Off

On

On

On

On

On

252

Off

Off

On

On

On

On

On

On

253

On

Off

On

On

On

On

On

On

254

Off

On

On

On

On

On

On

On

255

On

On

On

On

On

On

On

On

Page 36 of 37

ProtoNode Start-Up Guide

Appendix E. Limited 2 Year Warranty

Sierra Monitor Corporation warrants its products to be free from defects in workmanship or

material under normal use and service for two years after date of shipment. Sierra Monitor

Corporation will repair or replace any equipment found to be defective during the warranty

period. Final determination of the nature and responsibility for defective or damaged equipment

will be made by Sierra Monitor Corporation personnel.

All warranties hereunder are contingent upon proper use in the application for which the product

was intended and do not cover products which have been modified or repaired without Sierra

Monitor Corporation’s approval or which have been subjected to accident, improper

maintenance, installation or application, or on which original identification marks have been

removed or altered. This Limited Warranty also will not apply to interconnecting cables or wires,

consumables or to any damage resulting from battery leakage.

In all cases Sierra Monitor Corporation’s responsibility and liability under this warranty shall be

limited to the cost of the equipment. The purchaser must obtain shipping instructions for the

prepaid return of any item under this warranty provision and compliance with such instruction

shall be a condition of this warranty.

Except for the express warranty stated above, Sierra Monitor Corporation disclaims all

warranties with regard to the products sold hereunder including all implied warranties of

merchantability and fitness and the express warranties stated herein are in lieu of all obligations

or liabilities on the part of Sierra Monitor Corporation for damages including, but not limited to,

consequential damages arising out of/or in connection with the use or performance of the

product.

Page 37 of 37

Loading...

Loading...