Compact/Light weight (compared to series VX)

Single valve volume: Reduced 75% (VDW20)

100g: Reduced approx. 50%

(for orifice size equivalent to ø2)

CAT.ES70-20 A

Compact Direct Operated

2/3 Port Solenoid Valve for Water and Air

Series VDW

VDW10/20/30: 2 Port, VDW200/300: 3 Port

Series of compact designs

VDW10 VDW20 VDW30 VDW200 VDW300

ø17

ø20.5

ø28

ø20.5

ø28

High flow rate: Cv factor

0.03 to 0.44 (2 port)

Universal porting

VDW200/300 (3 port)

Compact (compared to series VX)

Single valve volume: Reduced 75% (VDW20)

Manifold length: Reduced 18% (VDW30, 7 stations)

Light weight (compared series VX)

100g: Reduced approx. 50% (for orifice size equivalent to ø2)

Clip type

Bottom mounting threads

Mounting bracket also available

Compact Direct Operated 2/3 Port Solenoid Valve

for Water and Air

Improved durability (nearly twice the life of the previous series)

The use of a unique magnetic material reduces the operating resistance of moving parts, while

improving service life, wear and corrosion resistance.

ø17

ø20.5

ø28

ø20.5

ø28

2 port 3 port

Threaded assembly

Simplifies maintenance

Improved corrosion resistance

Special material introduced

SeriesVDW

SeriesVDW

Quick change coils

Clip design makes coil

replacement easy (2 port)

Brass/Stainless steel

manifolds added to

series (2 port)

Features 1

How to Order Valves (Single Type)

For water, air and vacuum

1

2

3

10

20

30

Series

VDW 2 1 1 G 2 01

Nil

F

None

Foot type bracket

Option

Nil

F

N

Rc

G

NPT

Thread type

Symbol

M5

01

02

Port size

M5

1/8 (6A)

1/4 (8A)

10

—

Series

20

—

30

—

Port size

Symbol

1

2

1

2

3

2

3

4

Orifice size

mm

ø1

ø1.6

ø1.6

ø2.3

ø3.2

ø2

ø3

ø4

Series

10

20

30

Orifice size

Symbol

Nil

A

G

H

L

Body material

Coil insulation

Seal material

NBR

FKM

NBR

FKM

FKM

Brass

Class B

Stainless

steel

Materials and insulation type

1

2

3

4

5

6

100VAC (50/60Hz)

200VAC (50/60Hz)

110VAC (50/60Hz)

210VAC (50/60Hz)

24VDC

12VDC

Voltage

1

N.C.

OUT

(2)

(1)

IN

Valve type

Electrical entry

∗ Contact SMC regarding other voltages.

G – Grommet

Note) Foot brackets are packed with valves.

Note)

—

Note) For pure water: Armature assembly is a

corrosion resistant construction.

1

Compact Direct Operated

2 Port Solenoid Valve for Water and Air

Series VDW10/20/30

Standard Specifications

Valve construction

Fluid

Note 2)

Withstand pressure MPa

Ambient temperature °C

Fluid temperature °C

Environment

Valve leakage cm

3

/min

Mounting orientation

Vibration/Impact m/s

2

Note 4)

Rated voltage

Allowable voltage fluctuation

%

Coil insulation type

Enclosure

Note 5)

Power consumption W

Note 3)

Direct operated poppet

Water (except waste water or agricultural water), Air, Low vacuum

2.0

–10 to 50

1 to 50 (with no freezing)

Location without corrosive or explosive gases

0 (with water pressure)

Unrestricted

30/150

24VDC, 12VDC, 100VAC, 110VAC, 200VAC, 220VAC (50/60Hz)

±10% of rated voltage

Class B

Dust proof (equivalent to IP40)

2.5 (VDW10), 3 (VDW20/30)

Characteristic Specifications

VDW10

VDW20

VDW30

Model

ø1

ø1.6

ø1.6

ø2.3

ø3.2

ø2

ø3

ø4

0.9

0.4

0.7

0.4

0.2

0.8

0.4

0.2

0.54 (0.03)

1.2 (0.07)

1.2 (0.07)

3.2 (0.18)

5.8 (0.3)

2.8 (0.16)

5.0 (0.28)

8.0 (0.44)

0.4

0.2

0.2

0.1

0.05

0.2

0.1

0.05

Orifice

size

mm

Weight

kg

Port size

M5

M5

1/8 (6A)

1/8 (6A)

1/4 (8A)

Maximum operating

pressure

differential MPa

Note 1)

Pressure port 1 Pressure port 2

0.08

0 to 1.0

0.1

1/8: 0.23

1/4: 0.26

Valve specifications

Coil

Specifications

Operating

pressure

range

MPa

Note 2)

Effective area

mm²

(Cv factor)

Note 1) Consult SMC when used under conditions which may cause condensation on the exterior of the product.

Note 2) When used with pure water, select "L" (stainless steel, FKM) for the material type.

Note 3) Since AC coil specifications include a rectifying device, there is no difference in power consumption for starting and

holding.

In case of 110/220VAC, VDW10 is 3W and VDW20/30 is 3.5W.

Note 4) Vibration resistance … No malfunction when tested with one sweep of 5 to 200Hz in the axial direction and at a

right angle to the armature, in both energized and deenergized states.

Impact resistance … No malfunction when tested with a drop tester in the axial direction and at a right angle to

the armature, one time each in energized and deenergized states

Note 5) Consult SMC regarding drip-proof specifications (equivalent to IP54).

Note 1) The maximum operating pressure differential changes depending on the flow direction of the fluid. Refer to page

21 for details.

Note 2) For low vacuum specifications, the operating pressure range is 1Torr (1.33 x 10

² Pa) to 1.0MPa.

Consult SMC if used below 1Torr (1.33 x 10

² Pa).

Series

VDW10/20/30

2

VDW11

VDW31

VDW21

No.

1

2

3

4

5

6

7

8

Body

Tube assembly

Coil assembly

O-ring (body)

Return spring

Cover

Clip

Description

Material

Optional

Stainless steel

—

—

FKM

—

—

—

Parts list

Standard

Brass

Stainless steel

—

NBR

Stainless steel

SPCE

Stainless steel

VDW11/21:

Stainless steel, PPS,

FKM

VDW31:

Stainless steel, FKM

VDW11/21:

Stainless steel, PPS,

NBR

VDW31:

Stainless steel, NBR

Amature assembly

Construction

3

Compact Direct Operated

2 Port Solenoid Valve for W ater and Air Series VDW10/20/30

Dimensions

VDW11 VDW21

VDW31

Lead wire

l approx. 300

2– ø3.2

21

27

14

20

20

ø17

485

11

6

4–ø5

2–ø3.5

Rectifying device

AC type

M5

1 (IN) port

2-M2.5 x 0.45

Thread depth 3.5

M5

2 (OUT) port

Lead wire

l approx. 300

Rectifying device

AC type

Lead wire

l approx. 300

Rectifying device

AC type

M5, 1/8

1 (IN) port

M5, 1/8

2 (OUT) port

1/8, 1/4

1 (IN) port

Dimensions inside ( ) are for port size 1/8.

2-M4 x 0.7

Thread depth 6

1/8, 1/4

2 (OUT) port

2-M3 x 0.5

Thread depth 5

ø20.5

54

8

15

22

5

20

27

20

27

1

SMC

66 (62.5) 6

12.8

25

34

ø28

30

40

36 (27.6)

1

SMC

8.5 (6.3)

1

1

VDW 0 15A 12

1

2

10

20

Series

Bracket assembly part no.

Types

10, 20

VCW20 12 01A

Type 30

Series

VDW10/20/30

4

How to Order Valves (for Manifold)

Manifold Options

How to Order Manifolds

VV2DW 2 05 01

How to Order Manifold Assemblies (Example)

Enter the valve and option models to be mounted

under the manifold base part number.

<Example>

VV2DW2-0501 ……...

∗VDW23-5G-2 ………...

1 set Manifold part no.

5 sets Valve part no.

(Stations 1 to 5)

Enter together in

order, counting

from station 1

on the D side.

1

2

3

10

20

30

Series

Materials

Nil

F

N

Rc

G

NPT

Thread type

Nil

F

None

With bracket

Option

Symbol

M5

01

02

Port

size

M5

1/8 (6A)

1/4 (8A)

10

—

—

Series

20

—

30

Note) IN port sizes are as follows.

10: 1/8 (6A)

20: 1/4 (8A)

30: 3/8 (10A)

OUT port size

Stations

VVDW 0 3A2

1

2

10

20

Series

Materials

VDW 2 35 2G

1

2

3

10

20

30

Series

3

N.C. for Manifold

Valve type

1

2

3

4

5

6

9

100VAC (50/60Hz)

200VAC (50/60Hz)

110VAC (50/60Hz)

220VAC (50/60Hz)

24VDC

12VDC

Other

Voltage

Symbol

Nil

A

G

H

L

Symbol

1

2

1

2

3

2

3

4

Body material

Brass

Stainless

steel

Seal material

NBR

FKM

NBR

FKM

FKM

Coil insulation

Materials and insulation type

G

Grommet

Electrical entry

Orifice size

mm

ø1

ø1.6

ø1.6

ø2.3

ø3.2

ø2

ø3

ø4

10

20

30

Series

Orifice size

Class B

Blanking plate assembly

Note)

Symbol

Nil

A

G

H

Manifold material

Brass

Stainless steel

Seal material

NBR

FKM

NBR

FKM

Symbol

G

H

Plate material

Stainless

steel

∗ Plate material is stainless steel only.

Seal material

NBR

FKM

Types 10, 20

VVCW20 3A

Materials

Symbol

Nil

A

G

H

Plate material

Brass

Stainless

steel

Seal material

NBR

FKM

NBR

FKM

Type 30

1

D side

2

3

4

5

U side

02

:

10

2 stations

:

10 stations

—

"∗" is the symbol for

mounting. Add "∗" in front

of the part numbers for

solenoid valves, etc., to

be mounted.

Note) For pure water: The armature is a corrosion

resistant construction.

Note) Type 30 is available

only with bracket.

5

Compact Direct Operated

2 Port Solenoid Valve for W ater and Air Series VDW10/20/30

Dimensions

2

35

45

52

2 stns. x 1

Dimensions

L1

L2

L3

L dimensions

3

52.5

62.5

69.5

3 stns. x 1

4

70

80

87

2 stns. x 2

5

87.5

97.5

104.5

2 stns. + 3 stns.

6

105

115

122

3 stns. x 2

7

122.5

132.5

139.5

2 stns. x 2 + 3 stns.

8

140

150

157

2 stns. + 3 stns. x 2

9

157.5

167.5

174.5

3 stns. x 3

10

175

185

192

2 stns. x 2 + 3 stns. x 2

(mm)

n (stations)

Manifold composition

Note) Manifold bases are composed by connecting 2 station and 3 station bases.

Refer to pages 9 and 10 regarding manifold additions.

VV2DW1

4-M3 x 0.5

8.1

n-M5 x 0.8

(OUT port)

L1

L3

L2

13.4

3.4

1

R1.7

16.3

2-∗1/8 (IN port)

(∗: Thread type)

16

VDW13-*G-*VDW13-*G-*VDW13-*G-*VDW13-*G-

*

1

D side

2345

n

U side

8.8 P = 17.5

8.8

(19.6)

11.57.7

(16.3)

5

7.7 11.5

61

7.7 P = 17.5

1.5

13

19.6

24.4

2.8

22.5

40 7.5

26.5

(2.8)

34

(4.4)

9.4 Approx. 300

30

(1.5)

Stations

∗ When not equipped with bracket,

the M3 threads at both ends (4

positions) can be used for other

purposes.

Series

VDW10/20/30

6

Dimensions

2

44

53

62

2 stns. x 1

Dimensions

L1

L2

L3

L dimensions

3

66

75

84

3 stns. x 1

4

88

97

106

2 stns. x 2

5

110

119

128

2 stns. + 3 stns.

6

132

141

150

3 stns. x 2

7

154

163

172

2 stns. x 2 + 3 stns.

8

176

185

194

2 stns. + 3 stns. x 2

9

198

207

216

3 stns. x 3

10

220

229

238

2 stns. x 2 + 3 stns. x 2

(mm)

2-∗1/4 (IN port)

(∗: Thread type)

n-M5 x 0.8

n-∗1/8

(OUT port)

4-M4 x 0.7

n (stations)

Manifold composition

Note) Manifold bases are composed by connecting 2 station and 3 station bases.

Refer to pages 9 and 10 regarding manifold additions.

10 24

10

46

119.5

11

9.5

( 19.5)

632

6

54

L1

L2

L3

11

Approx. 300

16

4.6

24

33

R2.3

9

4.5

19.5

11

P = 22

11

1.5

4.5

68

21

15 ( 25.5)

1

31.5

VDW23-*G-*VDW23-*G-*VDW23-*G-*VDW23-*G-*

1

Stations

D side

2345

n

U side

18.5

1

(19.5)

VV2DW2

∗ When not equipped with bracket, the M3

threads at both ends (4 positions) can be

used for other purposes.

7

Compact Direct Operated

2 Port Solenoid Valve for W ater and Air Series VDW10/20/30

2

69

81

93

2 stns. x 1

Dimensions

L1

L2

L3

Manifold composition

L dimensions

3

103.5

115.5

127.5

3 stns. x 1

4

138

150

162

2 stns. x 2

5

172.5

184.5

196.5

2 stns. + 3 stns.

6

207

219

231

3 stns. x 2

7

241.5

253.5

265.5

2 stns. x 2 + 3 stns.

8

276

288

300

2 stns. + 3 stns. x 2

9

310.5

322.5

334.5

3 stns. x 3

10

345

357

369

2 stns. x 2 + 3 stns. x 2

(mm)

n (stations)

Note) Manifold bases are composed by connecting 2 station and 3 station bases.

Refer to pages 9 and 10 regarding manifold additions.

VV2DW3

1

Stations

D side

2345n

U side

2

5.5 21

5.5 10.5

(26.5)

23

L1

L2

L3

2.5

28

4.5

(24.5)

38

20 14.7

Approx. 300

24.5

2-∗3/8 (IN port)

(∗:

Thread type)

16

VDW33-*G-

*

VDW33-*G-

*

VDW33-*G-

*

VDW33-*G-

*

P = 34.5

83

34

n-∗1/8

n-∗1/4

(OUT port)

R2.25

17.25

17.25

49

Dimensions

Series

VDW10/20/30

8

Bracket assembly Passage pipe assembly

2 station manifold base

3 station manifold base

Bracket assembly

Manifold Exploded View

Connecting

plate assembly

Connecting

plate assembly

∗ Figure shows VV2DW2.

Manifold additions

1

2

3

Install a passage pipe assembly in between the manifold bases to be added.

Connect the respective manifold bases with a connecting plate assembly. (Tightening torque: 0.9±0.1N⋅ m)

Attach brackets to the manifold bases. {when equipped with brackets} (Tightening torque: 0.9±0.1N⋅ m)

Note) Manifold station additions can be made in units of 2 or 3 stations.

Order one set each of manifold base, connection plate assembly and passage pipe assembly.

9

Compact Direct Operated

2 Port Solenoid Valve for W ater and Air Series VDW10/20/30

VVDW

<Manifold bases>

Material

02C 1 012

C

S

Brass

Stainless steel

Stations

1

2

For 2 stations

For 3 stations

OUT port size

Symbol

M5

01

Port size

M5

1/8 (6A)

1210

20

Series

1210

20

Series

VVDW

<Connecting plate assembly>

20 4A

Types 10, 20

VVCW20

Material

2C 1 01

C

S

Brass

Stainless steel

Stations

1

2

For 2 stations

For 3 stations

OUT port size

Symbol

01

02

Port size

1/8 (6A)

1/4 (8A)

Type 30

Types 10, 20

VVCW20-4A

Type 30

1210

20

Series

VVDW

<Bracket assembly>

20 5A

Types 10, 20

VVCW20-5A

Type 30

Note) Consists of a set for the D and U sides.

Note) Two sets of connecting plate and mounting screws.

∗ Type 10 is M5 only.

1210

20

Series

VVDW

<Passage pipe assembly>

2

Materials

06A

VVCW20 6A

Types 10, 20

Type 30

Symbol

Nil

A

G

H

Pipe material

Brass

Stainless

steel

Seal material

NBR

FKM

NBR

FKM

Materials

Symbol

Nil

A

G

H

Pipe material

Brass

Stainless

steel

Seal material

NBR

FKM

NBR

FKM

Nil

F

N

Rc

G

NPT

Thread type

Nil

F

N

Rc

G

NPT

Thread type

Series

VDW10/20/30

10

How to Order Valves (Single Type)

For water,

air and vacuum

2

3

200

300

Series

VDW 2 50 1 G 2 01

Nil

F

None

Foot type bracket

Option

Nil

F

N

Rc

G

NPT

Thread type

Symbol

M5

01

02

Port size

M5

1/8 (6A)

1/4 (8A)

200

—

300

—

Port size

1

2

2

3

4

Symbol

N.C.

Orifice size

mm

ø1

ø1.6

ø2

ø3

ø4

N.O.

Orifice size

mm

ø1

ø1.8

Series

200

300

Orifice size

Symbol

Nil

A

G

H

L

Body material

Coil insulation

Seal material

NBR

FKM

NBR

FKM

FKM

Brass

Class B

Stainless

steel

Materials and insulation type

1

2

3

4

5

6

100VAC (50/60Hz)

200VAC (50/60Hz)

110VAC (50/60Hz)

210VAC (50/60Hz)

24VDC

12VDC

Voltage

50

C.O.

Valve type

Electrical entry

∗ Consult SMC regarding other voltages.

G – Grommet

Note) Foot brackets are packed with valves.

Note)

Series

N.C.

(2)

N.O.

(3)

(1)

IN

Note) For pure water: The armature assembly is a

corrosion resistant construction.

11

Compact Direct Operated

3 Port Solenoid Valve for Water and Air

Series VDW200/300

Standard Specifications

Characteristic Specifications

VDW200

VDW300

Model

ø1

ø1.6

ø2

ø3

ø4

0.9

0.7

0.8

0.4

0.2

0.54 (0.03)

1.2 (0.07)

2.8 (0.16)

5.0 (0.28)

8.0 (0.44)

0.3

0.1

0.2

0.1

0.05

Orifice

size

mm

Weight

kg

Port size

M5

1/8 (6A)

1/8 (6A)

1/4 (8A)

0.12

0 to 1.0

1/8: 0.27

1/4: 0.30

Note 2)

Note 1) Effective area is for the case when IN is normally closed (N.C.).

Note 2) Indicates the maximum operating pressure differential of pressure ports 2 and 3.

Note 3) The maximum operating pressure differential changes depending on the flow direction of the fluid.

Refer to page 21 for details.

Note 4) For low vacuum specifications, the operating pressure range is 1Torr (1.33 x 10

²Pa) to 1.0MPa.

Consult SMC if used below 1Torr (1.33 x 10

²Pa).

Valve specifications

Coil

specifications

Valve construction

Fluid

Note 2)

Withstand pressure MPa

Ambient temperature °C

Fluid temperature °C

Environment

Valve leakage cm

3

/min

Mounting orientation

Vibration/Impact m/s

2

Note 4)

Rated voltage

Allowable voltage fluctuation %

Coil insulation type

Enclosure

Note 5)

Power consumption W

Note 3)

Maximum operating

pressure

differential MPa

Note 3)

Effective area

mm²

(Cv factor)

Note 1)

Operating

pressure

range

MPa

Note 4)

Pressure port 1

Pressure ports 2, 3

Direct operated poppet

Water (except waste water or agricultural water), Air, Low vacuum

2.0

–10 to 50

1 to 50 (with no freezing)

Location without corrosive or explosive gases

0 (with water pressure)

Unrestricted

30/150

24VDC, 12VDC, 100VAC, 110VAC, 200VAC, 220VAC (50/60Hz)

±10% of rated voltage

Class B

Dust proof (equivalent to IP40)

3

Note 1) Consult SMC when used under conditions which may cause condensation on the exterior of the product.

Note 2) When used with pure water, select "L" (stainless steel, FKM) for the material type.

Note 3) Since AC coil specifications include a rectifying device, there is no difference in power consumption for starting

and holding.

3.5W in case of 110/220VAC.

Note 4) Vibration resistance …No malfunction when tested with one sweep of 5 to 200Hz in the axial direction and at a

right angle to the armature, in both energized and deenergized states.

Impact resistance ….. No malfunction when tested with a drop tester in the axial direction and at a right angle to

the armature, one time each in energized and deenergized states.

Note 5) Consult SMC regarding drip-proof specifications (equivalent to IP54) .

Series

VDW200/300

12

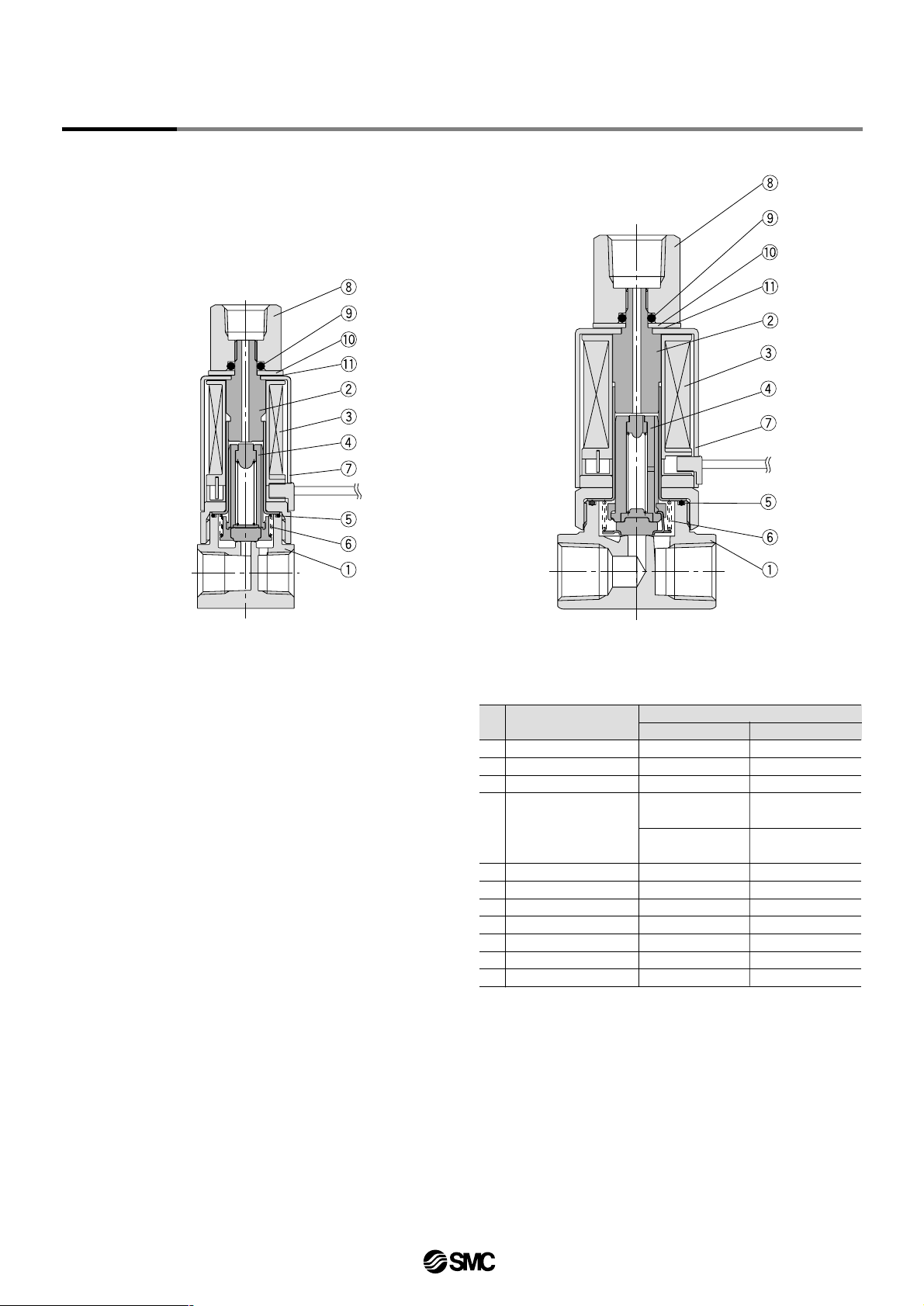

Construction

VDW250

VDW350

No.

1

2

3

4

5

6

7

8

9

10

11

Body

Tube assembly

Coil assembly

O-ring (body)

Return spring

Cover

Socket

O-ring

Plate

Wave washer

Description

Material

Optional

Stainless steel

—

—

FKM

—

—

Stainless steel

FKM

—

—

Parts list

Standard

Brass

Stainless steel

—

NBR

Stainless steel

SPCE

Brass

NBR

SPCC

Stainless steel

VDW250:

Stainless steel, PPS,

FKM

VDW350:

Stainless steel, FKM

VDW250:

Stainless steel, PPS,

NBR

VDW350:

Stainless steel, NBR

Amature assembly

13

Compact Direct Operated

3 Port Solenoid Valve for Water and Air Series VDW200/300

Dimensions

VDW250 VDW350

Lead wire

l approx. 300

2–ø3.5

4–ø5

Rectifying device

AC type

M5, 1/8

1 (IN) port

1/8, 1/4

1 (IN) port

2-M3

Thread depth 5

M5, 1/8

2 (N.C.) port

Lead wire

l approx. 300

Rectifying device

AC type

M5, 1/8

3 (N.O.) port

1/8, 1/4

3 (N.O.) port

1/8, 1/4

2 (N.C.) port

2-M4 x 0.7

Thread depth 6

ø20.5

22

69

8

5

15

20

27

20

27

1

SMC

6

12.8

25

34

ø28

30

40

36 (27.6)

1

SMC

Dimensions inside ( ) are for port size 1/8.

86 (82.5)

8.5 (6.3)

3

3

1

VDW20 15A 1

Bracket part no.

Type 200

VCW20 12 01A

Type 300

Series

VDW200/300

14

For air

For water

How to find the flow rate for water

• Formula based on Cv factor

Q = 14.2⋅ Cv⋅ 10.2⋅ ∆P … l/min

• Formula based on effective area (Smm²)

Q = 0.8⋅ S⋅ 10.2⋅ ∆P …… l/min

How to find the flow rate for air

1. For subsonic range

Where P1 + 0.1013 = (1 to 1.8941) (P2 + 0.1013)

• Formula based on Cv factor

Q = 4073.4⋅Cv⋅ ∆P (P2 + 0.1013) … l/min (ANR)

• Formula based on effective area

Q = 226.3⋅S⋅ ∆P (P2 + 0.1013) …… l/min (ANR)

2. For sonic range

Where P1 + 0.1013≥1.8941 (P2 + 0.1013)

• Formula based on Cv factor

Q = 1972.8⋅ Cv⋅ (P1 + 0.1013) … l/min (ANR)

• Formula based on effective area

Q = 109.6⋅S⋅ (P1 + 0.1013) ….… l/min (ANR)

Q: Flow rate (l/min), ∆P: Pressure differential (P1—P2), P1: Upstream pressure (MPa)

P2: Downstream pressure (MPa), S: Effective area (mm²), Cv: Cv factor

100

10

5.0

1.0

0.1

0.001 0.01 0.1 1 10

Pressure differential ∆P = (P

₁ – P₂)

MPa

Flow rate Ql /min

1. Materials

NBR: Nitrile rubber

FKM: Fluoro rubber – Trade names: Viton®, Dai-el, etc.

Other

Viewing

the graph

VDW30 ø2 CV = 0.16ø2 CV = 0.16

VDW20 ø2.3 CV = 0.18ø2.3 CV = 0.18

VDW30 ø4 CV = 0.39ø4 CV = 0.39

VDW20 ø3.2 CV = 0.3ø3.2 CV = 0.3

VDW30

ø2 CV = 0.16

VDW10 ø1 CV = 0.03ø1 CV = 0.03

VDW VDW

ø1.6 CV = 0.07ø1.6 CV = 0.07

10

20

VDW10

ø1 CV = 0.03

VDW

ø1.6 CV = 0.07

10

20

VDW20

ø2.3 CV = 0.18

VDW30 ø3 CV = 0.28ø3 CV = 0.28VDW30

ø3 CV = 0.28

VDW30

ø4 CV = 0.44

VDW20

ø3.2 CV = 0.3

The sonic range pressure to generate a flow rate of 300l/min (ANR)

for orifice ø2.3 (VDW20) is P1 approx. 0.77MPa,

for orifice ø3 (VDW30) is P1 approx. 0.45MPa,

for orifice ø4 (VDW30) is P1 approx. 0.24MPa.

Viewing

the graph

Explanation of Terminology

Pressure Terminology

1. Maximum operating pressure differential

This indicates the maximum pressure differential (upstream

and downstream pressure differential) which can be allowed

for operation with the valve closed or open. When the

downstream pressure is 0MPa, this becomes the maximum

operating pressure.

2. Maximum operating pressure

This indicates the limit of pressure that can be applied inside

the pipelines. (line pressure)

(The pressure differential of the solenoid valve unit must be no

more than the maximum operating pressure differential.)

3.

Withstand pressure

The pressure which must be withstood without a drop in

performance after returning to the operating pressure range.

(the value under the prescribed conditions)

Electrical Terminology

1. Surge voltage

A high voltage which is momentarily generated in the shut-off unit

by shutting off the power.

To generate a water flow of 4l/min at a differential pressure of

0.1MPa, an effective area with Cv factor 0.28 (VDW30ø3) or

more is required.

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

0

.95

0.95

0

.90.9

0.850.85

0.80.8

0

.7

5

0.75

0.70.7

0.650.65

0.60.6

0.5

5

0.55

0.50.5

0.30.3

0.250.25

0.20.2

0.10.1

0.050.05

0

.95

0

.9

0.85

0.8

0

.7

5

0.7

0.65

0.6

0.5

5

0.5

0.450.450.45

0.40.40.4

0.350.350.35

0.3

0.25

0.2

0.150.150.15

0.1

0.05

S = 0.54

S = 1.2

S = 3.2

S = 5.8

S = 2.8

S = 5.0

S = 8.0

VDW10ø1

VDW ø1.6

VDW20ø2.3

VDW20ø3.2

VDW30ø2

VDW30ø3

VDW30ø4

6050403020

1251007550

10

35030025020015010050

600500400300200100

30025020015010050

600500

400300200100

900800700

600500400300200

10

20

Downstream pressure of valve (P2) MPa

Upstream pressure of valve P

₁ = 1.0MPa

Critical

pressure

Subsonic

Sonic

Flow rate Q l/min (ANR)

Series VDW

Model Selection

15

Series VDW

Safety Instruction s

These safety instructions are intended to prevent a hazardous situation and/or

equipment damage. These instructions indicate the level of potential hazard by a

label of "Caution", "Warning" or "Danger". To ensure safety, be sure to observe

ISO 4414

Note 1)

and other safety practices.

1. The compatibility of equipment is the responsibility of the person who designs

the system or decides its specifications.

Since the products specified here are used in various operating conditions, their compatibility for the

specific system must be based on specifications or after analysis and/or tests to meet your specific

requirements. Be particularly careful in determining the compatibility of the fluid to be used.

2. Only trained personnel should operate machinery and equipment.

The fluid can be dangerous if handled incorrectly. Assembly, handling or repair of systems should be

performed by trained and experienced operators.

3. Do not service machinery/ equipment or attempt to remove components until

safety is confirmed.

1. Inspection and maintenance of machinery/equipment should only be performed after confirmation of safe

locked-out control positions and measures to prevent danger from the fluid.

2. When equipment is to be removed, confirm the safety process as mentioned above and be certain there

is no danger from fluid leakage or fluid remaining in the system.

3. Restart machinery carefully, confirming that safety measures are being implemented.

4. Contact SMC if the product is to be used in any of the following conditions:

1. Conditions and environments beyond the given specifications, or if product is used outdoors.

2. With fluids whose application causes concern due to the type of fluid or additives, etc.

3. An application which has the possibility of having negative effects on people, property, or animals,

requiring special safety analysis.

Note 1) ISO 4414 : Pneumatic fluid power -- Recommendations for the application of equipment to transmission and control

systems

Warning

Cauti on :

Operator error could result in injury or equipment damage.

Warning

:

Operator error could result in serious injury or loss of life.

Danger :

In extreme conditions, there is a possible result of serious injury or loss of life.

16

1. Confirm the specifications.

Give careful consideration to operating conditions such as the

application, fluid and environment, and use within the operating

ranges specified in this catalog.

2. Fluid temperature

Operate within the prescribed fluid temperature range.

3. Fluid quality

For water

The use of fluid which contains foreign matter can cause

problems such as malfunction and seal failure by promoting

wear of the valve seat and core, and by sticking to the sliding

parts of the armature, etc. Install a suitable filter (strainer)

immediately upstream from the valve. As a general rule, use 80

to 100 mesh.

For air

Use general purpose compressed air (except dry air) and

provide a filter of 40µm or less in the upstream piping.

2. Low temperature operation

1. The valve can be used at ambient temperatures as low as

–10°C, but take measures to prevent freezing or

solidification of impurities, etc.

2. When used in cold areas with water, etc., adopt freeze

prevention measures such as draining the water from

pipelines after pump operation has been stopped. If

warmed with a heater, etc., avoid the coil unit. Also,

implement warming or other freeze prevention measures

for the body.

OFF

CR

1. Cannot be used as an emergency shutoff

valve, etc.

The valves presented in this catalog are not designed for safety applications such as an emergency shutoff valve. If the

valves are used in this type of system, other reliable safety assurance measures should also be adopted.

2. Extended periods of continuous energization

Consult SMC if valves will be continuously energized for extended periods of time.

3. Liquid seals

In cases with a flowing liquid, provide a by-pass valve in the

system to prevent the liquid from entering the liquid seal circuit.

4. This solenoid valve cannot be used for explosion protection.

5. Maintenance space

The installation should allow sufficient space for maintenance

activities (removal of valve, etc.).

Warning

Precautions on Design Selection

Warning

Caution

1. Leakage voltage

Particularly when using a resistor in parallel with a switching

element and using a C-R element (surge voltage suppressor)

to protect the switching element, take note that leakage current

will flow through the resistor and C-R element, etc., creating a

danger that the valve may not shut OFF.

Switching element

Leakage voltage

Valve

Leakage current

Power supply

10% or less of rated voltage

AC coil

2% or less of rated voltage

DC coil

Series VDW

2/3 Port Solenoid Valve for Fluid Control/Precautions 1

Be sure to read before handling.

17

1. If air leakage increases or equipment does

not operate properly, stop operation.

After mounting is completed, confirm that it has been done

correctly by performing a suitable function test.

2. Do not apply external force to the coil

section.

When tightening is performed, apply a wrench or other tool to

the outside of the piping connection parts.

3. Do not warm the coil assembly with a heat

insulator, etc.

Use tape and heaters, etc., for freeze prevention on the piping

and body only. They can cause the coil to burn out.

4. Secure the product except in the case of steel

piping and copper fittings.

5. Avoid sources of vibration, or set the arm

from the body to the minimum length so that

resonance will not occur.

6. Instruction manual

Mount the product after reading the manual carefully and

understanding its contents. Also keep the manual where it can

be referred to as necessary.

7. Painting and coating

Warnings and specifications printed or pasted on the product

should not be erased, removed or covered up.

Mounting

Warning

1. Preparation before piping

Before piping is connected, it should be thoroughly blown out

with air (flushing) or washed to remove chips, cutting oil and

other debris from inside the pipe.

2. Wrapping of pipe tape

When connecting pipes and fittings, etc., be sure that chips from

the pipe threads and sealing material do not get inside the

valve.

Furthermore, when pipe tape is used, leave 1.5 to 2 thread ridges exposed at the end of the threads.

3. Avoid connection of ground lines to piping,

as this may cause electric corrosion of the

system.

4. Always tighten threads with the proper

tightening torque.

When screwing fittings into valves, tighten with the proper tightening torque as shown below.

Piping

Caution

5. Connection of piping to the product

When connecting piping to the product, refer to its instruction

manual to avoid mistakes regarding the supply port, etc.

Winding

direction

Pipe tape

Expose approx. 2 threads

Connection threads

M5

Rc 1/8

Rc 1/4

Rc 3/8

1.5 to 2

7 to 9

12 to 14

22 to 24

∗ Reference

Tightening of M5 fitting threads

After tightening by hand, tighten approximately 1/6 turn further with a tightening

tool. However, when using miniature fittings, tighten an additional 1/4 turn after

tightening by hand. (In cases where there is a gasket in two places such as a

universal elbow or universal tee, double the additional tightening to 1/2 turn.)

Proper tightening torque N⋅m

Tightening torque for piping

Series VDW

2/3 Port Solenoid Valve for Fluid Control/Precautions 2

Be sure to read before handling.

18

Wiring

DC circuit AC circuit

1 (+)

2 (–)

SOL. SOL.

1

2

Caution

Rectifying device

ZNR

Operating Environment

1. Perform maintenance in accordance with the

procedures in the instruction manual.

Improper handling can cause damage or malfunction of equipment and devices, etc.

2. Demounting of the product

1. Shut off the fluid supply and release the fluid pressure in the

system.

2. Shut off the power supply.

3. Demount the product.

3. Low frequency operation

Switch valves at least once every 30 days to prevent

malfunction. In addition, perform maintenance inspections once

every six months to ensure optimum performance.

Warning

1. Filters and strainers

1. Be careful regarding clogging of filters and strainers.

2. Replace filter elements after one year of use, or earlier if the

amount of pressure drop reaches 0.1MPa.

3. Clean strainers when the amount of pressure drop reaches

0.1MPa.

4.

Flush drainage from filters periodically.

2. Storage

In case of long term (approx. one month or more) storage after

use with water, first thoroughly remove all moisture to prevent

rust and deterioration of rubber materials, etc.

Caution

1. As a rule, use electrical wire of 0.5 to

1.25mm² or more.

Furthermore, do not allow excessive force to

be applied to the lines.

2. Use electrical circuits which do not generate

chattering in their contacts.

3. Use voltage which is within ±10% of the rated

voltage. In cases of a DC power supply where

emphasis is placed on responsiveness, stay

within ±5% of the rated value. The voltage

drop is the value in the lead wire section connecting the coil.

Caution

Electrical Connections

Caution

Rated voltage

DC

100VAC

200VAC

Other AC

Black

Blue

Red

Gray

Red

Blue

Red

Gray

Lead wire color

∗ DC does not have polarity.

1 ( )

2 ( )

Electrical Circuits

1. Do not use valves in atmospheres of corrosive

gases, chemicals, salt water, water or steam, or

where there is direct contact with same.

2. Do not use in explosive atmospheres.

3. Do not use in locations subject to vibration or

impact.

4. Do not use in locations where radiated heat will be

received from nearby heat sources.

5. Employ suitable protective measures in locations

where there is contact with water droplets, oil or

welding spatter, etc.

Warning

Maintenance

Series VDW

2/3 Port Solenoid Valve for Fluid Control/Precautions 3

Be sure to read before handling.

19

Replacement of the Solenoid Coil

Caution

Clip

Cover

Cover

Flat head screw driver

2 port valve 3 port valve

Tube assembly

Socket

O-ring

Plate

Wave washer

Cover

Coil assembly

Fixed armature threads

Coil assembly

Push the clip in direction (1) with

a flat head screw driver, etc.,

and remove it from the tube

assembly groove.

1

2

3

Remove the cover in direction (2),

and replace the coil assembly.

In case of types 10 and 30, the

cover alone cannot be removed

because it is integrated with the

coil assembly.

After replacing the coil, insert the

clip into the tube assembly

groove from direction (3). After

inserting it into the groove,

confirm the position and condition

of the clip.

Tube assembly groove

Center of clip

OK NG

Inserted position

Inserted condition

After removing the socket with a wrench, etc., lift off the plate, wave

washer and cover, and replace the coil assembly. After replacing the

coil, first tighten the socket by hand while holding down the plate and

wave washer, and then tighten it further with a torque of 0.8 to 1N⋅ m .

∗ Precautions when attaching and removing the socket

• Be careful that the O-ring installed on the bottom (plate side) of the socket does

not fall out or become chewed up, etc.

• Be sure to hold the body with a wrench, etc., and tighten the socket within the

tightening torque range given above. If excessive torque is applied, there is a

danger of damaging the threads.

Note

In case of type 300, the cover

alone cannot be removed because

it is integrated with the coil

assembly.

Note

Series VDW/Specific Product Precautions 1

Be sure to read before handling.

Refer to pages 16 through 19 for safety instructions and precautions for 2/3 port solenoid valve for

fluid control.

20

Replacement Parts Fluid Flow Direction

Solenoid coil part numbers

1

2

3

10

20, 200

30, 300

Series

VDW

Nil

L1

Note)

300mm

600mm

Lead wire length

1

2

3

4

5

6

100VAC

200VAC

110VAC

220VAC

24VDC

12VDC

Voltage

B

C1

C2

20, 200

10, 30

300

Type

Note 1)

Clip part numbers (2 port)

AZ-T-VDW

How to Order Valves

(Refer to pages 1, 5 and 11.)

01B1

Note) Type L1 is optional.

2

3

10, 20

30

Series

VDW 20 102

Piping to 3 Port Valve N.O. Port

Caution

Socket

Cover

When piping to an N.O. port, be sure to perform piping work

while holding the socket with a wrench or other tool. Refer to

page 18 for other precautions related to piping.

Caution

The maximum operating pressure differential differs depending

on the flow direction of the fluid. If the pressure differential at

each port exceeds the values in the table below, valve

leakage may occur.

Model

VDW10

VDW20

VDW30

ø1

ø1.6

ø1.6

ø2.3

ø3.2

ø2

ø3

ø4

Orifice size

mm

Maximum operating pressure

differential MPa

Pressure port 1

0.9

0.4

0.7

0.4

0.2

0.8

0.4

0.2

Pressure port 2

Note 1)

0.4

0.2

0.2

0.1

0.05

0.2

0.1

0.05

2 port valve

Note) When applying pressure from port 2, be careful to avoid vibration and impacts, etc.

OUT

(2)

(1)

IN

Model

VDW200

VDW300

ø1

ø1.6

ø2

ø3

ø4

Orifice size

mm

Maximum operating pressure

differential MPa

Pressure port 1

0.9

0.7

0.8

0.4

0.2

Pressure ports 2, 3

Note 1 & 2)

0.3

0.1

0.2

0.1

0.05

3 port valve

N.C.

(2)

N.O.

(3)

(1)

IN

2

Note 1) In case of a type C coil (for 10, 30, 300), the cover will be an integrated

type.

To have a label on the cover, enter the part number below together with

the coil part number.

Note 1) Indicates the maximum operating pressure differential for pressure ports 2 and 3.

Note 2) When the port 2 pressure is the higher pressure, be careful to avoid vibration and

impacts, etc.

21

Series VDW/Specific Product Precautions 2

Be sure to read before handling.

Refer to pages 16 through 19 for safety instructions and precautions for 2/3 port solenoid valve for

fluid control.

EUROPE

SPAIN/PORTUGAL

SMC España, S.A.

SWEDEN

SMC Pneumatics Sweden AB

SWITZERLAND

SMC Pneumatik AG.

UK

SMC Pneumatics (U.K.) Ltd.

ASIA

CHINA

SMC (China) Co., Ltd.

HONG KONG

SMC Pneumatics (Hong Kong) Ltd.

INDIA

SMC Pneumatics (India) Pvt. Ltd.

MALAYSIA

SMC Pneumatics (S.E.A.) Sdn. Bhd.

PHILIPPINES

SMC Pneumatics (Philippines), Inc.

SINGAPORE

SMC Pneumatics (S.E.A.) Pte. Ltd.

SOUTH KOREA

SMC Pneumatics Korea Co., Ltd.

TAIWAN

SMC Pneumatics (Taiwan) Co., Ltd.

THAILAND

SMC Thailand Ltd.

NORTH AMERICA

CANADA

SMC Pneumatics (Canada) Ltd.

MEXICO

SMC Corporation (Mexico) S.A. de C.V.

USA

SMC Pneumatics, Inc.

SOUTH AMERICA

ARGENTINA

SMC Argentina S.A.

BOLIVIA

SMC Pneumatics Bolivia S.R.L.

BRAZIL

SMC Pneumaticos Do Brazil Ltda.

CHILE

SMC Pneumatics (Chile) S.A.

VENEZUELA

SMC Neumatica Venezuela S.A.

OCEANIA

AUSTRALIA

SMC Pneumatics (Australia) Pty. Ltd.

NEW ZEALAND

SMC Pneumatics (N.Z.) Ltd.

EUROPE

AUSTRIA

SMC Pneumatik GmbH

CZECH

SMC Czech s.r.o.

DENMARK

SMC Pneumatik A/S

FINLAND

SMC Pneumatiikka OY

FRANCE

SMC Pneumatique SA

GERMANY

SMC Pneumatik GmbH

HUNGARY

SMC Hungary Kft.

IRELAND

SMC Pneumatics (Ireland) Ltd.

ITALY

SMC Italia S.p.A.

NETHERLANDS

SMC Pnuematics BV.

NORWAY

SMC Pneumatics Norway A/S

ROMANIA

SMC Romania s.r.l.

RUSSIA

SMC Pneumatik LLC.

SLOVAKIA

SMC Slovakia s.r.o.

SLOVENIA

SMC Slovenia d.o.o.

SMC'S GLOBAL MANUFACTURING, DISTRIBUTION AND SERVICE NETWORK

1-16-4 Shimbashi, Minato-ku, Tokyo 105-0004, JAPAN

Tel: 03-3502-2740 Fax: 03-3508-2480

URL http://www.smcworld.com

© 1999 SMC CORPORATION All Rights Reserved

Specifications are subject to change without prior notice

and any obligation on the part of the manufacturer.

Printed in Japan.

1st printing December, 1999 D-SMC.L.A. P-80 (D)

Loading...

Loading...