SMC Networks ZVB Series, ZVB40 Operation Manual

Document No: ZVB-OM00201

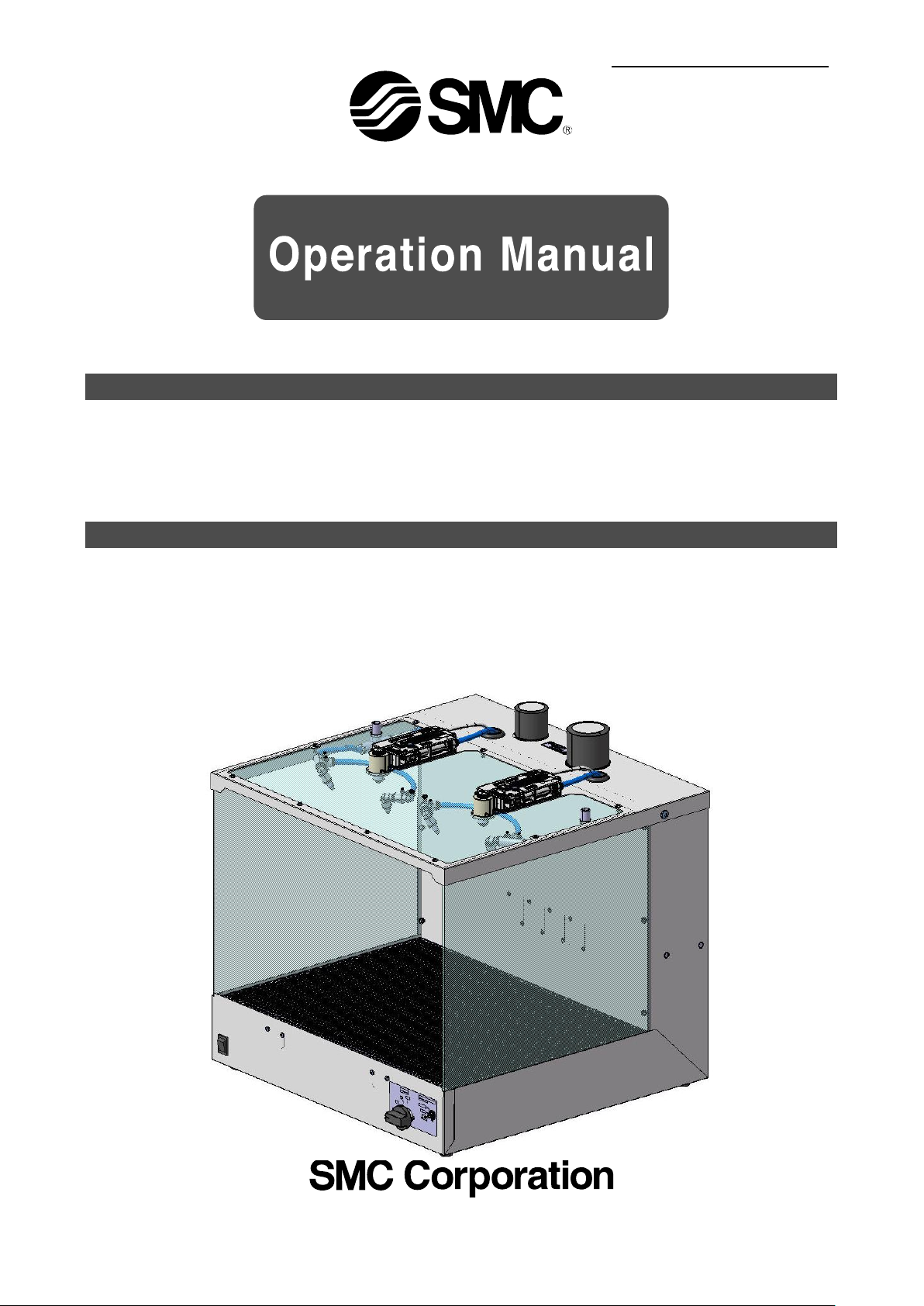

PRODUCT NAME

Desktop Duster Box

MODEL/ Series/ Product Number

ZVB Series

Applicable model: ZVB40

Contents

Safety Instructions ..................................................... 2

1. How to Operate ....................................................... 5

2. Desktop Duster Box/ ZVB Series ........................ 10

1.1 Outline ....................................................................... 5

1.2 Installation and Piping .............................................. 5

1.3 Wiring of the DC plug ............................................... 6

1.4 Terminal Block .......................................................... 7

1.5 Operation Method ..................................................... 7

1.6 Operation step (with photoelectric sensor) ............ 8

1.7 Removal of side cover .............................................. 9

2.1 Specifications.......................................................... 10

2.2 How to Order ........................................................... 10

2.3 Construction ........................................................... 11

2.4 Dimensions ............................................................. 12

2.5 Offset Voltage and Discharge Time ....................... 13

3. Ionizer Functions .................................................. 14

3.1 Functions ................................................................. 14

4. Maintenance.......................................................... 15

4.1 Maintenance of Ionizer ........................................... 15

4.2 Valve Maintenance .................................................. 16

-1-

Caution

Caution indicates a hazard with a low level of risk, which if not avoided, could result in

minor or moderate injury.

Warning

Warning indicates a hazard with a medium level of risk,

which if not avoided, could result in death or serious injury.

Danger

Danger indicates a hazard with a high level of risk which, if not avoided, will result in

death or serious injury.

Warning

1. The compatibility of the product is the responsibility of the person who designs the equipment or

decides its specifications.

Since the product specified here is used under various operating conditions, its compatibility with specific

equipment must be decided by the person who designs the equipment or decides its specifications based on

necessary analysis and test results. The expected performance and safety assurance of the equipment will be the

responsibility of the person who has determined its compatibility with the product. This person should also

continuously review all specifications of the product referring to its latest catalog information, with a view to giving

due consideration to any possibility of equipment failure when configuring the equipment.

2. Only personnel with appropriate training should operate machinery and equipment.

The product specified here may become unsafe if handled incorrectly.

An operator who is appropriately trained and experienced must perform the assembly, operation and maintenance

of machines or equipment.

3. Do not service or attempt to remove product and machinery/equipment until safety is confirmed.

1. The inspection and maintenance of machinery/equipment should only be performed after all energy

sources have been isolated and put into a safe mode.

2. Additionally, all driven objects should be contained in a safe manner. Follow all lock out procedures

necessary for the machinery.the power from allsources is cut. Read and understand the specific product

precautions of all relevant products carefully.

3. Before machinery/equipment is restarted, take measures to prevent unexpected operation and malfunction.

4. Contact SMC beforehand and take special consideration of safety measures if the product is to be

used in any of the following conditions.

1. Conditions and environments outside of the given specifications, or use outdoors or in a location exposed to

direct sunlight.

2. Installation on equipment in conjunction with atomic energy, railways, air navigation, space, shipping, vehicles,

military, medical treatment, combustion and recreation, or equipment in contact with food and beverages,

emergency stop circuits, clutch and brake circuits in press applications, safety equipment or other applications

unsuitable for the standard specifications described in the product catalog.

3. An application which could have adverseeffects on people, property, or animals especially those requiring special

safety requirements.

4. If used in an interlock circuit, consider using a mechanical function as a redundant safety measure..

Perform periodical checks to confirm proper operation. Check the product regularly in order to confirm

normal operation.

ZVB Series

Safety Instructions

These safety instructions are intended to prevent hazardous situations and/or equipment damage.

These instructions are categorized into three groups, "Caution", "Warning" and "Danger" depending on the

level of hazard and damage, and the degree of emergency. They are all important notes for safety and

must be followed in addition to International Standards (ISO/IEC), Japan Industrial Standards (JIS)

other safety regulations

*1) ISO 4414: Pneumatic fluid power – General rules relating to systems

ISO 4413: Hydraulic fluid power -- General rules relating to systems.

IEC 60204-1: Safety of machinery --Electrical equipment of machines. (Part1: General requirements)

ISO 10218-1992: Manipulating industrial robots -Safety.

JIS B 8370: General rules for pneumatic equipment.

JIS B 8361: General rules for hydraulic equipment.

JIS B 9960-1: Safety of machinery – Electrical equipment for machines. (Part 1: General requirements)

JIS B 8433-1993: Manipulating industrial robots - Safety, etc.

*2) Labor Safety and Sanitation Law, etc。

*2)

.

*1)

and

-2-

Caution

1. The product is provided for use in manufacturing industries.

The product herein described is basically provided for use in manufacturing industries.

If the product is being considered for use in other industries, consult SMC beforehand and exchange specifications

or a contract if necessary.

If anything is unclear, contact your nearest sales branch.

1. The warranty period of the product is 1 year in service or within 1.5 years after the product is

delivered. *

Also, the product may have specified durability, running distance or replacement parts. Please

consult your nearest sales branch.

2. For any failure or damage reported within the warranty period, which is clearly SMC’s responsibility,

a replacement product or necessary parts will be provided.

This limited warranty applies only to the SMC product independently, and not to any other damage

incurred due to the failure of the product.

3. Prior to using SMC products, please read and understand the warranty terms and disclaimers noted

in the specified catalog for the particular products.

*: Vacuum pads are excluded from this 1 year warranty.

A vacuum pad is a consumable part, so it is warranted for a year after it is delivered.

Also, even within the warranty period, the wear of a product due to the use of the vacuum pad

or failure due to the deterioration of rubber material are not covered by the limited warranty.

When the product is exported, compliancy to applicable laws must be followed as required by each

individual country and its applicable agencies such as the Ministry of Economy, Foreign Exchange, and

Foreign Trade Law.

ZVB Series

Safety Instructions

Limited Warranty and Disclaimer/Compliance Requirements

The product used is subject to the following “Limited Warranty and Disclaimer” and “Compliance

Requirements”.

Read and accept them before using the product.

Limited Warranty and Disclaimer

Compliance Requirements

-3-

Selection

Handling

ZVB Series

Safety Instructions

Warning

1. Use within the specified voltage and temperature range.

Operation with a voltage other than that specified can cause malfunction, damage to the product, electric

shock or fire.

2. Use clean compressed air as fluid.

Never use flammable or explosive gas as fluid. This may lead to fire or explosion. If fluid other than

compressed air is used, consult SMC.

3. The product is not designed to be explosion proof.

Never use in an atmosphere of potential dust explosion, flammable gas or explosive gas. It may cause

fire.

Caution

1. This product has not been cleaned. When using this product in a clean room environment, flush

and confirm the product’s purification level before use.

Caution

1. Do not drop, hit or apply excessive shock to the product.

Even if the body is not damaged, the internal components may be damaged, leading to a malfunction.

-4-

1. How to Operate

*

Mesh is

removable

1.1 Outline

1. This is equipment used to remove dust that is stuck to a workpiece due to static and to remove static

electricity and collect dust to prevent dust from sticking to the workpiece again.

2. Ionized air from IZN10E ionizer neutralizes static electricity and blows dust away from the workpiece.

1.2 Installation and Piping

1. This product must be installed on a stable horizontal surface.

2. Avoid using in a place where noise (electromagnetic wave and surge) is generated.

It may cause failure or damage to the product. Take measures to prevent noise at source and avoid

power and signal lines from coming into close contact.

3. Do not allow foreign matter, workpiece or tool to enter the ionizer nozzle.

There is an emitter inside the nozzle. If the emitter gets in contact with metallic workpieces or tools,

electrical shock may cause injury. If emitter is damaged, it may interfere with the specified function and

performance, and may also cause operation failure and accident.

4. Mounting, wiring or adjustments should never be done without shutting off the power supply to the

product.

5. Make sure to confirm the effect of static elimination after installation.

6. Power supply required to the product is 24 VDC and 1A.

When power is supplied to the product without using the exclusive AC adapter, make sure to use a

stabilization power supply and connect wiring to the DC plug that is provided with the product as an

accessory.

- Refer to P6 for wiring.

7. AC power supply cable of the exclusive AC adapter has a socket configuration that is for 100 VAC.

The AC adapter is applicable to 100 to 240V. Replace it with a socket that is applicable to other voltage if

necessary. The socket needs to be prepared by the user.

8. D-class ground connection (ground with a resistance of less than 100Ω) MUST be used to the product.

Without grounding, the product will not provide the designed performance.

9. Operate in an environement in the specified ambient temperature and fluid temperature ranges

(0 to 55oC).

Avoid sudden temperature changes even within specified temperature range, as it may cause

condensation.

10. For air piping, use SMC tubing of diameter 10 mm or equivalent.

11. It is recommended to use supply air which purity class is 2:4:3 2:5:3 2:6:3 of ISO08573-1:2010(JIS

B8392-1:2012) or higher. The air containing mist or dust will cause the performance to decrease and

shorten the maintenance cycle. Install a dryer (IDF series), air filter (AF/AFF series), and/or mist

separator (AFM/AM series) to the upstream of the product to obtain clean compressed air.

12. Air connections should only be made with the pressure supply turned off.

Flush the system before piping to prevent foreign matter from entering inside the product.

13. Do not allow humans or objects to touch the ionizer while power is being supplied.

Otherwise, the offset voltage may change or the HV LED may turn ON.

14. Do not make a rapid pressure change while power is being supplied to the ionizer.

It will cause the NDL LED to turn ON.

15. Do not use this product in an enclosed space.

This product utilizes the corona discharge phenomenon. Although the amount is very small, Ozone and

NOx are generated. Ozone condensation can increase if used in an enclosed space, which can affect

the human body, so ventilation is necessary. Even when the room is ventilated, operating more than one

product in a small space may increase the ozone density. Confirm that

the ozone density in the operating environment is not more

than the standard value of 0.1 ppm before starting operation.

16. When the dust collector is operating, air is discharged

vigorously from the exhaust port.

Prevent exhausted air from contacting people or objects.

Piping (I.D. 32mm) or dust collecting bag must be connected

to the exhaust port.

17. Read and understand the Operation Manual of this product

before using. Confirm safety before starting operation.

18. If anything such as a part drops through to the bottom in the

static elimination area, remove the mesh and take it away.

-5-

Loading...

Loading...