SMC Networks ZSE30A(F),ISE30A Operation Manual

No.PS##-OML0003-B

PRODUCT NAME

Digital Pressure Switch

MODEL / Series / Product Number

ZSE30A(F)

ISE30A

Table of Contents

Safety Instructions 2

Model Identification and how to order 8

Summary of Product parts 10

Definition and terminology 11

Mounting and Installation 14

Installation 14

Piping 17

Wiring 18

Pressure Setting 21

Measurement mode 21

Setting of Function 24

Function selection mode 24

Default setting 24

F0 Unit conversion function 26

F1 Setting of OUT1 27

F2 Setting of OUT2 30

F3 Setting of response time 30

F4 Setting of display resolution 31

F5 Setting of auto-preset 32

F6 Setting of fine adjustment of display value 34

F7 Setting of power saving mode 35

F8 Setting of security code 36

Special function setting 37

F90 Setting of all functions 37

F97 Selection of copy function 39

F98 Check of output 41

F99 Reset to the default setting 43

Other Settings 44

Maintenance 47

If the security code is forgotten 48

Troubleshooting 49

Specification 57

Specifications 57

Dimensions 59

-1-

No.PS##-OML0003-B

Safety Instructions

These safety instructions are intended to prevent hazardous situations and/or equipment damage.

These instructions indicate the level of potential hazard with the labels of "Caution", "Warning" or

"Danger". They are all important notes for safety and must be followed in addition to International

standards (ISO/IEC)

*1) ISO 4414: Pneumatic fluid power -- General rules relating to systems

ISO 4413: Hydraulic fluid power -- General rules relating to systems

IEC 60204-1: Safety of machinery -- Electrical equipment of machines (Part 1: General requirements)

ISO 10218-1: Manipulating industrial robots -Safety.

etc.

*1)

and other safety regulations.

CAUTION indicates a hazard with a low level of risk which, if not avoided,

Caution :

could result in minor or moderate injury.

WARNING indicates a hazard with a medium level of risk which, if not

Warning :

avoided, could result in death or serious injury.

DANGER indicates a hazard with a high level of risk which, if not avoided,

Danger :

will result in death or serious injury.

Warning

1. The compatibility of the product is the responsibility of the person who designs the

equipment or decides its specifications.

Since the product specified here is used under various operating conditions, its compatibility with specific

equipment must be decided by the person who designs the equipment or decides its specifications based on

necessary analysis and test results. The expected performance and safety assurance of the equipment will be

the responsibility of the person who has determined its compatibility with the product. This person should also

continuously review all specifications of the product referring to its latest catalog information, with a view to giving

due consideration to any possibility of equipment failure when configuring the equipment.

2. Only personnel with appropriate training should operate machinery and equipment.

The product specified here may become unsafe if handled incorrectly. The assembly, operation and

maintenance of machines or equipment including our products must be performed by an operator who is

appropriately trained and experienced.

3. Do not service or attempt to remove product and machinery/equipment until safety is confirmed.

1. The inspection and maintenance of machinery/equipment should only be performed after measures to prevent

falling or runaway of the driven objects have been confirmed.

2. When the product is to be removed, confirm that the safety measures as mentioned above are implemented

and the power from any appropriate source is cut, and read and understand the specific product precautions of

all relevant products carefully.

3. Before machinery/equipment is restarted, take measures to prevent unexpected operation and malfunction.

4. Contact SMC beforehand and take special consideration of safety measures if the product is

to be used in any of the following conditions.

1. Conditions and environments outside of the given specifications, or use outdoors or in a place exposed to direct

sunlight.

2. Installation on equipment in conjunction with atomic energy, railways, air navigation, space, shipping, vehicles,

military, medical treatment, combustion and recreation, or equipment in contact with food and beverages,

emergency stop circuits, clutch and brake circuits in press applications, safety equipment or other applications

unsuitable for the standard specifications described in the product catalog.

3. An application which could have negative effects on people, property, or animals requiring special safety

analysis.

4. Use in an interlock circuit, which requires the provision of double interlock for possible failure by using a

mechanical protective function, and periodical checks to confirm proper operation.

-2-

No.PS##-OML0003-B

Caution

The product is provided for use in manufacturing industries.

The product herein described is basically provided for peaceful use in manufacturing industries.

If considering using the product in other industries, consult SMC beforehand and exchange specifications or

a contract if necessary.

If anything is unclear, contact your nearest sales branch.

Limited warranty and Disclaimer/Compliance Requirements

The product used is subject to the following "Limited warranty and Disclaimer" and "Compliance

Requirements".

Read and accept them before using the product.

Limited warranty and Disclaimer

1. The warranty period of the product is 1 year in service or 1.5 years after the product is delivered.

Also, the product may have specified durability, running distance or replacement parts. Please

consult your nearest sales branch.

2. For any failure or damage reported within the warranty period which is clearly our responsibility, a

replacement product or necessary parts will be provided.

This limited warranty applies only to our product independently, and not to any other damage

incurred due to the failure of the product.

3. Prior to using SMC products, please read and understand the warranty terms and disclaimers noted

in the specified catalog for the particular products.

∗2)

∗2) Vacuum pads are excluded from this 1 year warranty.

A vacuum pad is a consumable part, so it is warranted for a year after it is delivered.

Also, even within the warranty period, the wear of a product due to the use of the vacuum pad or failure due to

the deterioration of rubber material are not covered by the limited warranty.

Compliance Requirements

1. The use of SMC products with production equipment for the manufacture of weapons of mass

destruction (WMD) or any other weapon is strictly prohibited.

2. The exports of SMC products or technology from one country to another are governed by the

relevant security laws and regulation of the countries involved in the transaction. Prior to the

shipment of a SMC product to another country, assure that all local rules governing that export are

known and followed.

-3-

No.PS##-OML0003-B

Operator

♦This operation manual is intended for those who have knowledge of machinery using pneumatic

equipment, and have sufficient knowledge of assembly, operation and maintenance of such

equipment. Only those persons are allowed to perform assembly, operation and maintenance.

♦Read and understand this operation manual carefully before assembling, operating or providing

maintenance to the product.

■Safety Instructions

Warning

■Do not disassemble, modify (including changing the printed circuit board) or repair.

An injury or failure can result.

■Do not operate the product outside of the specifications.

Do not use for flammable or harmful fluids.

Fire, malfunction, or damage to the product can result.

Verify the specifications before use.

■Do not operate in an atmosphere containing flammable or explosive gases.

Fire or an explosion can result.

This product is not designed to be explosion proof.

■Do not use the product in a place where static electricity is a problem.

Otherwise it can cause failure or malfunction of the system.

■If using the product in an interlocking circuit:

•Provide a double interlocking system, for example a mechanical system

•Check the product regularly for proper operation

Otherwise malfunction can result, causing an accident.

■The following instructions must be followed during maintenance:

•Turn off the power supply

•Stop the air supply, exhaust the residual pressure and verify that the air is released before performing

maintenance

Otherwise an injury can result.

Caution

■Do not touch the terminals and connectors while the power is on.

Otherwise electric shock, malfunction or damage to the product can result.

■After maintenance is complete, perform appropriate functional inspections and leak tests.

Stop operation if the equipment does not function properly or there is a leakage of fluid.

When leakage occurs from parts other than the piping, the product might be faulty.

Disconnect the power supply and stop the fluid supply.

Do not apply fluid under leaking conditions.

Safety cannot be assured in the case of unexpected malfunction.

-4-

No.PS##-OML0003-B

■NOTE

○Follow the instructions given below when designing, selecting and handling the product.

●The instructions on design and selection (installation, wiring, environment, adjustment, operation,

maintenance, etc.) described below must also be followed.

*Product specifications

•The direct current power supply to combine should be UL approved as follows.

Circuit (of Class2) which is of maximum 30 Vrms (42.4 V peak) or less, with UL1310 Class2 power supply unit or

UL1585 Class2 transformer.

•The Pressure switch is a approved product only if it has a mark on the body.

•Use the specified voltage.

Otherwise failure or malfunction can result.

•Do not exceed the specified maximum allowable load.

Otherwise it can cause damage or shorten the lifetime of the Pressure switch.

•Design the product to prevent reverse current when the circuit is opened or the product is forced to operate for

operational check.

Reverse current can cause malfunction or damage to the product.

•Input data to the Pressure switch is not deleted, even if the power supply is cut off.

(Writing time: 1,000,000 times, Data duration: 10 years after power off)

•For the details of compressed air quality, refer to ISO 8573-1, 1.1.2 to 1.6.2: 2001.

This can cause operating failure.

If compressed air containing condensate is used, install an air dryer or drain catch before the filter and perform

drainage regularly.

If drainage is not performed regularly and condensate enters the secondary side, it can cause operating failure of

pneumatic equipment.

If regular drainage is difficult, the use of a filter with an auto drain is recommended.

•Applicable fluid is air, inert gases and incombustible gases.

Do not use a fluid containing chemicals, synthetic oils including organic solvent, salt and corrosive gases.

Otherwise, damage to the product and malfunction can result.

Check the details of the specifications before using.

•Use the specified measurement flow rate and operating pressure.

Otherwise it can cause damage to the pressure switch or inability to measure correctly.

•Reserve a space for maintenance.

Allow sufficient space for maintenance when designing the system.

●Product handling

*Installation

•Tighten to the specified tightening torque.

If the tightening torque is exceeded the mounting screws and brackets may be broken.

If the tightening torque is insufficient, the product can be displaced and loosen the mounting screws.

(Refer to "Mounting and Installation" on page 14.)

•Do not apply excessive stress to the product when it is mounted with a panel mount.

Otherwise damage to the product and disconnection from the panel mount can result.

•Be sure to ground terminal FG when using a commercially available switch-mode power supply.

•Do not drop, hit or apply shock to the Pressure switch.

Otherwise damage to the internal parts can result, causing malfunction.

-5-

No.PS##-OML0003-B

•Do not pull the lead wire forcefully, not lift the product by pulling the lead wire. (Tensile force 35N or less)

Hold the body when handling to avoid the damage of the Pressure switch which lead to cause the failure and

malfunction.

•For piping of the Pressure switch, hold the piping with a spanner on the metal part of the piping (Piping

attachment).

Holding other part with spanner leads to damage the Pressure switch.

•Eliminate any dust left in the piping by air blow before connecting the piping to the product.

Otherwise it can cause damage or malfunction.

•Do not insert metal wires or other foreign matter into the pressure measurement port.

It can damage the pressure sensor causing failure or malfunction.

•Never mount a Pressure switch in a location that will be used as a foothold.

The product may be damaged if excessive force is applied by stepping or climbing onto it.

•If the entering of foreign material to the fluid is possible, install and pipe the filter or the mist separator to

the inlet to avoid failure and malfunction.

*Wiring

•Do not pull the lead wires.

In particular, never lift a Pressure switch equipped with fitting and piping by holding the lead wires.

Otherwise damage to the internal parts can result, causing malfunction or to be off the connector.

•Avoid repeatedly bending or stretching the lead wire, or placing heavy load on them.

Repetitive bending stress or tensile stress can cause the sheath of the wire to peel off, or breakage of the wire.

If the lead wire can move, fix it near the body of the product.

The recommended bend radius of the lead wire is 6 times the outside diameter of the sheath, or 33 times the

outside diameter of the insulation material, whichever is larger.

Replace the damaged lead wire with a new one.

•Wire correctly.

Incorrect wiring can break the Pressure switch.

•Do not perform wiring while the power is on.

Otherwise damage to the internal parts can result, causing malfunction.

•Do not route wires and cables together with power or high voltage cables.

Otherwise the product can malfunction due to interference of noise and surge voltage from power and high voltage

cables to the signal line. Route the wires (piping) of the product separately from power or high voltage cables.

•Confirm proper insulation of wiring.

Poor insulation (interference from another circuit, poor insulation between terminals, etc.) can lead to excess

voltage or current being applied to the product, causing damage.

•Design the system to prevent reverse current when the product is forced to operate for operational

check.

Depending on the circuit used, insulation may not be maintained when operation is forced, allowing reverse current

to flow, which can cause malfunction and damage the product.

•Keep wiring as short as possible to prevent interference from electromagnetic noise and surge voltage.

Do not use a cable longer than 10 m.

Wire the DC(-) line(blue) as close as possible to the power supply.

•When analog output is used, install a noise filter (line noise filter, ferrite element, etc.) between the

switch-mode power supply and this product.

*Environment

•Do not use the product in area that is exposed to corrosive gases, chemicals, sea water, water or steam.

Otherwise failure or malfunction can result.

•Do not use in a place where the product could be splashed by oil or chemicals.

If the product is to be used in an environment containing oils or chemicals such as coolant or cleaning solvent, even

for a short time, it may be adversely affected (damage, malfunction, or hardening of the lead wires).

•Do not use in an area where surges are generated.

If there is equipment which generates a large amount of surge (solenoid type lifter, high frequency induction furnace,

motor, etc.) close to the Pressure switch, this may cause deterioration or breakage of the internal circuit of the

Pressure switch. Avoid sources of surge generation and crossed lines.

-6-

No.PS##-OML0003-B

•Do not use a load which generates surge voltage.

When a surge-generating load such as a relay or solenoid is driven directly, use a Pressure switch with a built-in

surge absorbing element.

•The product is CE marked, but not immune to lightning strikes. Take measures against lightning strikes

in the system.

•Mount the product in a place that is not exposed to vibration or impact.

Otherwise failure or malfunction can result.

•Prevent foreign matter such as remnant of wires from entering the Pressure switch.

Take proper measures for the remnant not to enter the Pressure switch in order to prevent failure or malfunction.

•Do not use the product in an environment that is exposed to temperature cycle.

Heat cycles other than ordinary changes in temperature can adversely affect the inside of the product.

•Do not expose the product to direct sunlight.

If using in a location directly exposed to sunlight, shade the product from the sunlight.

Otherwise failure or malfunction can result.

•Keep within the specified fluid and ambient temperatures range.

The fluid and ambient temperatures should be 0 to 50 °C. Operation under low temperature (5 °C or less) leads to

cause damage or operation failure due to frozen moist in the fluid or air.

Protection against freezing is necessary. Air dryer is recommended for elimination of drain and water.

Avoid sudden temperature change even within specified temperature.

•Do not operate close to a heat source, or in a location exposed to radiant heat.

Otherwise malfunction can result.

*Adjustment and Operation

•Turn the power on after connecting a load.

Otherwise it can cause excess current causing instantaneous breakage of the Pressure switch.

•Do not short-circuit the load.

Although error is displayed when the Pressure switch load is short circuit, generated excess current lead to cause

the damage of the Pressure switch.

•Do not press the setting buttons with a sharp pointed object.

It may damage the setting buttons.

•If using the product to detect very small pressure rates, warm up the product for 10 to 15 minutes first.

There will be a drift on the display and the analog output of approximate ±1% immediately after the power supply is

turned on, within 10 minutes.

•Perform settings suitable for the operating conditions.

Incorrect setting can cause operation failure.

For details of each setting, refer to page 21 to 46 of this manual.

•The Pressure switch is compulsory turned off for 4 seconds after power supplied.

For 4 seconds after supplying power, the measurement output is turned off.

•Do not touch the LCD during operation.

The display can vary due to static electricity.

*Maintenance

•Turn off the power supply, stop the supplied air, exhaust the residual pressure and verify the release of

air before performing maintenance.

There is a risk of unexpected malfunction.

•Perform regular maintenance and inspections.

There is a risk of unexpected malfunction.

•Perform drainage regularly.

If condensate enters the secondary side, it can cause operating failure of pneumatic equipment.

•Do not use solvents such as benzene, thinner etc. to clean the Pressure switch.

They could damage the surface of the body and erase the markings on the body.

Use a soft cloth to remove stains. For heavy stains, use a cloth soaked with diluted neutral detergent and fully

squeezed, then wipe up the stains again with a dry cloth.

-7-

No.PS##-OML0003-B

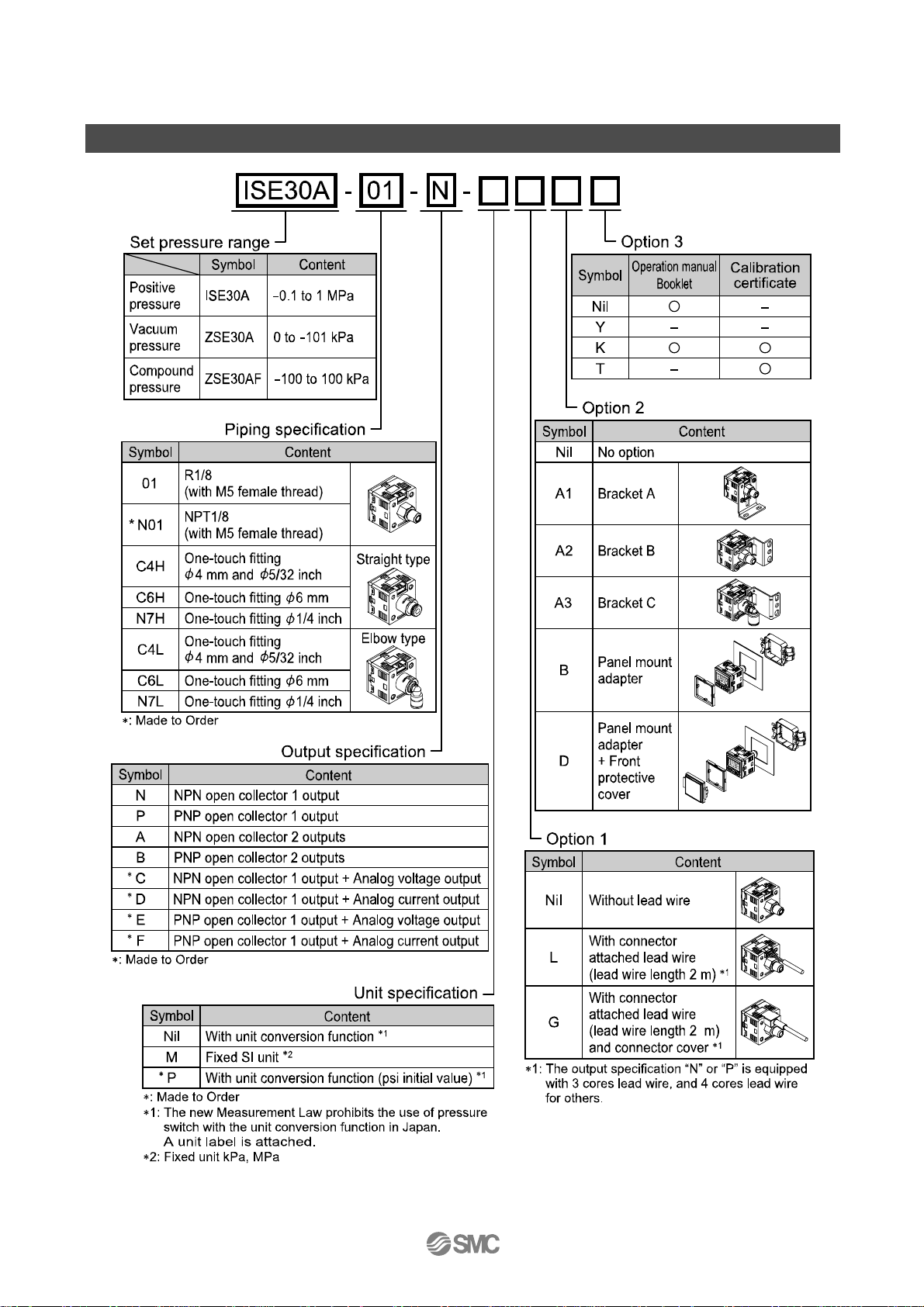

Model Identification and how to order

-8-

No.PS##-OML0003-B

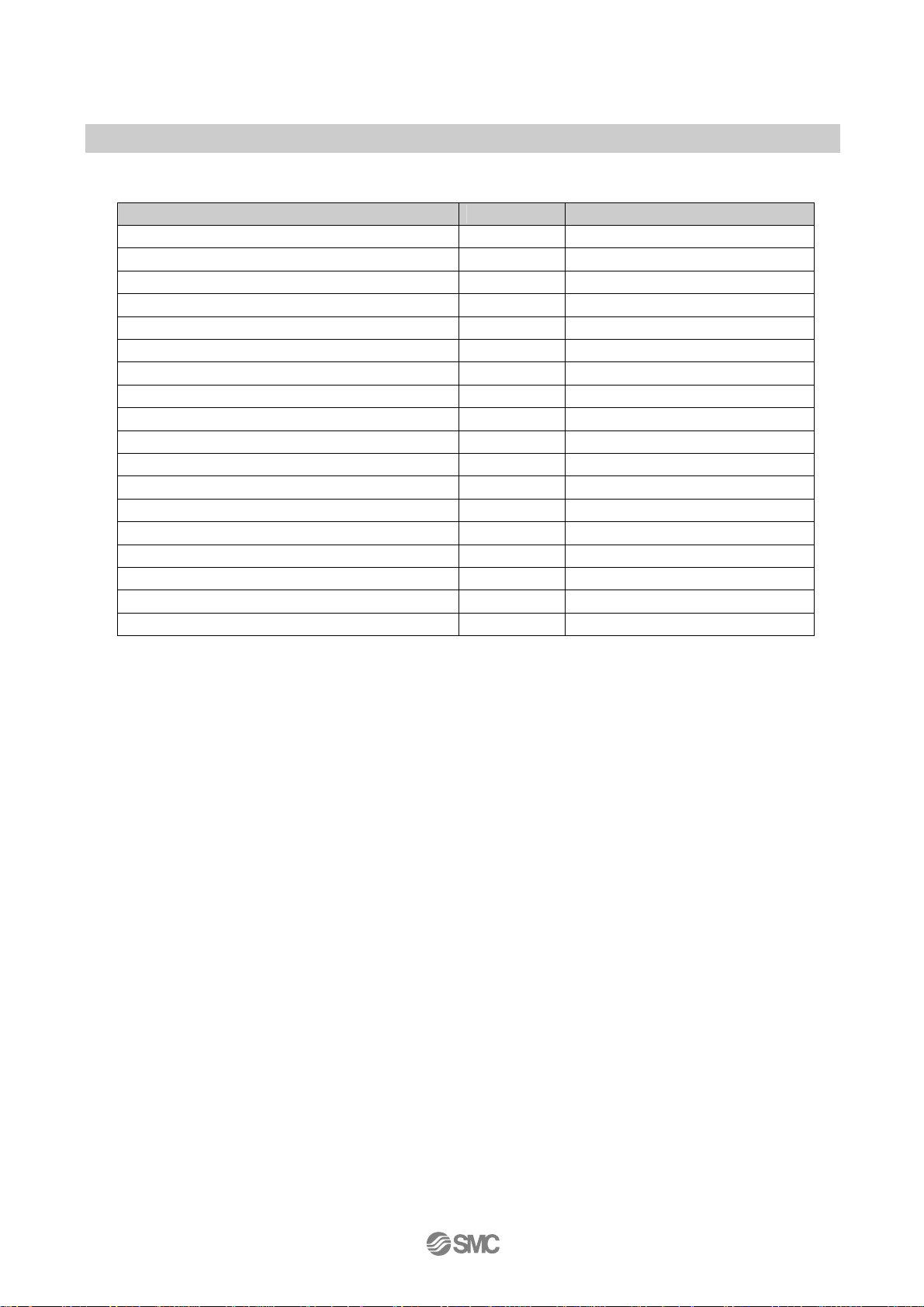

○Options/Part number

If an option is required independently, order with the following part number.

Description Part number Remarks

Bracket A ZS-38-A1 Mounting screw (M3 × 5 L, 2 pcs.)

Bracket B ZS-38-A2 Mounting screw (M3 × 5 L, 2 pcs.)

Bracket C ZS-38-A3 Mounting screw (M3 × 5 L, 2 pcs.)

Panel mount adapter ZS-27-C Mounting screw (M3 × 8 L, 2 pcs.)

Panel mount adapter + Front protective cover ZS-27-D Mounting screw (M3 × 8 L, 2 pcs.)

Connector attached lead wire ZS-38-3L 3 cores for 1 output, 2 m

Connector attached lead wire ZS-38-4L 4 cores for 2 outputs, 2 m

Connector attached lead wire and connector cover ZS-38-3G 3 cores for 1 output, 2 m

Connector attached lead wire and connector cover ZS-38-4G 4 cores for 2 outputs, 2 m

Connector attached lead wire for copy ZS-38-5L 3 cores for copy, 1 m

Connector attached lead wire unit for copy ZS-38-U For copy (For 10 slaves at the max.)

Front protective cover ZS-27-01 -

One-touch fitting φ4 mm straight ZS-38-C4H O-ring and One-touch clip enclosed

One-touch fitting φ6 mm straight ZS-38-C6H O-ring and One-touch clip enclosed

One-touch fitting φ1/4 inch straight ZS-38-N7H O-ring and One-touch clip enclosed

One-touch fitting φ4 mm elbow ZS-38-C4L O-ring and One-touch clip enclosed

One-touch fitting φ6 mm elbow ZS-38-C6L O-ring and One-touch clip enclosed

One-touch fitting φ1/4 inch elbow ZS-38-N7L O-ring and One-touch clip enclosed

-9-

No.PS##-OML0003-B

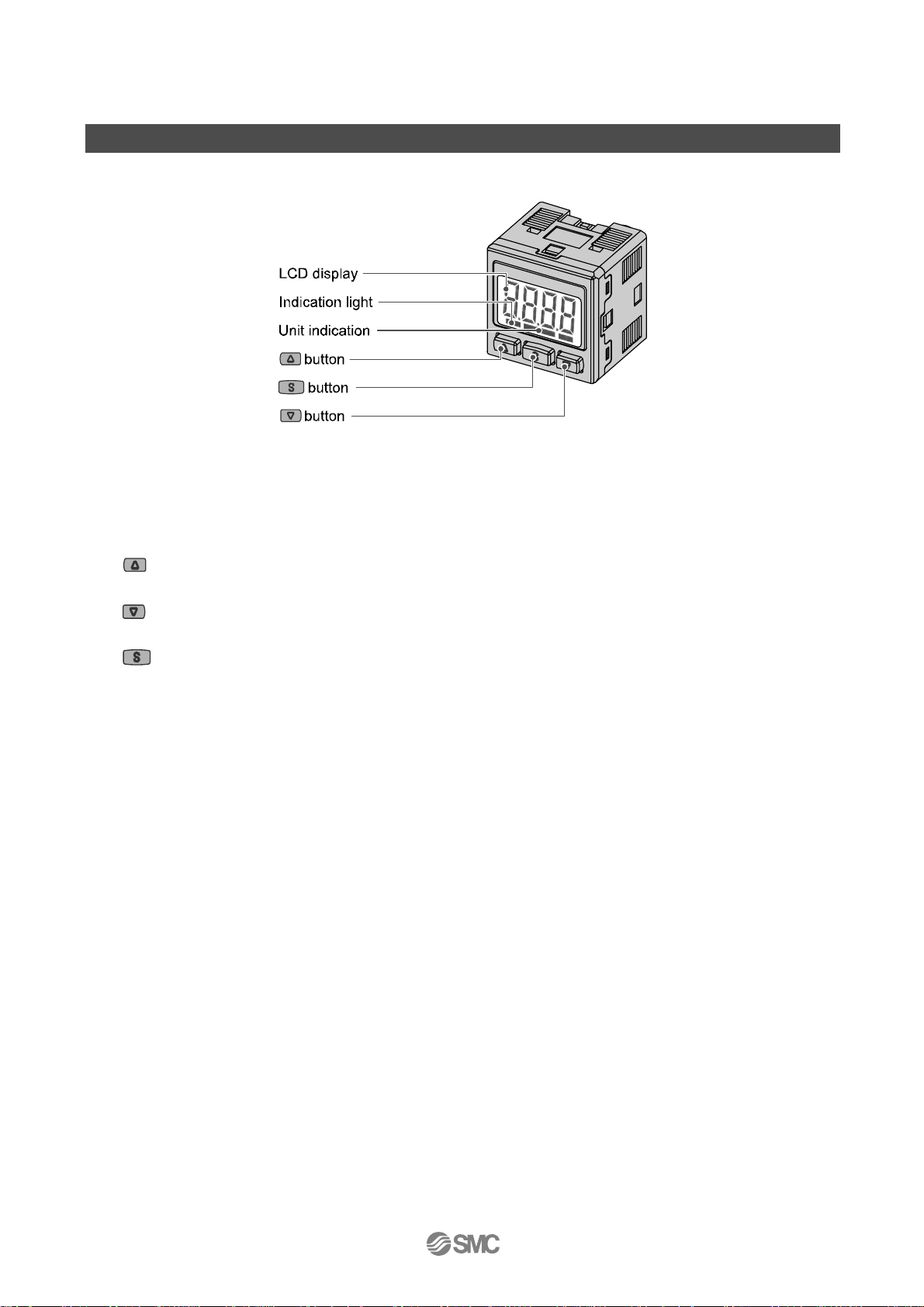

Summary of Product parts

○Names of individual parts

Indication light (Green OUT1 and Red OUT2): Displays switch operation condition.

LCD display: Displays the current status of pressure, setting mode, selected indication unit and error

code. Four display modes can be selected: display always in red or green only, or changing

from green to red, red to green linked to output.

button: Alters the mode or increases ON/OFF set value.

Press this button to change to the peak display mode.

button: Alters the mode or decreases ON/OFF set value.

Press this button to change to the bottom display mode.

button: Press this button to change to either mode and to set a set value.

Unit indication: Displays the current specification of unit. (Only for kPa and MPa indication unit)

-10-

No.PS##-OML0003-B

■Definition and terminology

Terms Meaning

2

2-color indication

7

7-segment indication

(Analog) current output See "Analog output (function)".

A

Analog output (function) Function to output the voltage or current in proportion to the pressure.

(Analog) voltage output See "Analog output (function)".

Auto preset

Bottom value indication (mode) Shows the minimum pressure reached at that moment.

B

C

Chattering

Chattering-preventing function

Copy function

D

Digit (Min. setting unit)

E

Error indication

Fine adjustment mode See "Fine adjustment of indicated value".

F

Fine adjustment of indicated

value

F.S. (full span/full scale)

Function selection mode

H

Hysteresis

Hysteresis mode Refer to "List of output mode" on page 29.

Indication accuracy Shows the deviation between displayed pressure value and the true pressure.

I

Indication color

There are two colors to indicate a value, changing in accordance with ON and

OFF of the switch output.

When "8" is shown on the display. It is called 7-segment because 8 consists of

7 pieces of "- (segments)".

A function of the Pressure switch to automatically setup pressure just by having

equipment hold and release a workpiece via vacuum adsorption. This function

is used in an application where vacuum adsorption of a workpiece needs to be

confirmed with a Pressure switch.

The phenomenon caused in the switch output type in which the output turns on

and off repeatedly at high frequency.

A function to delay the response time of switch output in order to prevent

chattering.

A function to copy a pressure setting value and function setting (excluding fine

adjustment of indication value).

Shows how precisely the pressure can be indicated or set by the digital

Pressure switch. When 1 digit

of 1kPa, e.g., 1, 2, 3, …, 99, 100.

With the self-diagnosis function given to the Pressure switch, it indicates that

there is a failure which could cause a switch failure.

An indicated pressure value can be adjusted within the range of ±5% R.D.

(±5% of the indicated value). It is used if a true pressure value is known or to

correct the difference of an indicated value of the measurement equipment

nearby that measures the same pressure as the Pressure switch.

Abbreviation for full span and full scale; means the maximum fluctuation range

of the Pressure switch rated value. For example, when the output voltage is 1

to 5[V], the F.S. will be 5-1

It is a mode with which each function is set up, and it is a separate menu from

the pressure setup. If the setting needs to be changed at factory, "F*", each

item can be set up. The items to be set up are: indication color, operation

mode, output type, response time, indication resolution, fine adjustment of

indicated value, use of auto preset, use of power-saving mode, and use of PIN

number.

Difference between the points at which the Pressure switch is turned on and

off.

The color of the digital display. There are four choices: usually green, usually

red, green (off) to red (on), and red (off) to green (on).

= 1 kPa, the pressure is given with an increment

= 4[V]. (Reference: 1%F.S. = 4 × 0.01 = 0.04[V])

-11-

No.PS##-OML0003-B

Terms Meaning

I

Insulation resistance

Indication resolution

Indication light The light that turns on when the switch output is on.

Indication unit The unit of pressure used in the display.

K

Key lock (function)

Load impedance See "Max. load impedance".

L

M

Manual setup

Master Pressure switch

Max. applied voltage

Max. load current The maximum current available to the output (output line) of the switch output.

Max. (Min.) load impedance

Measurement mode

Min. setting unit Refer to "digit".

N

Normal output

NPN (open collector) (output) The switch that uses the NPN transistor for output.

Operating mode There are two choices, hysteresis mode and window comparator mode.

O

Output impedance

Output style

Peak value indication (mode) Shows the maximum pressure reached at that moment.

P

Piping-port size

PNP (open collector) (output) The switch that uses the PNP transistor for output.

Insulation resistance of a product itself. The resistance between an electric

circuit and a body.

How fine the rated pressure range can be segmented. (Example: If a product

for 0 to 1 MPa can indicate pressure by 0.001 MPa, the indication resolution is

1/1000.)

Prohibits a change in the setting of the Pressure switch (locks button

operation).

Manual pressure setup without using auto preset. This term is used to

discriminate from the pressure setup using auto preset.

A Pressure switch which copies another Pressure switch's settings when using

the copy function.

The maximum value of applied voltage available to the output line of the NPN

output.

The maximum (minimum) load (resistance value and impedance) which can be

connected to the output (output line) of the analog current output.

The condition in which the pressure is being detected and indicated and switch

operation is enabled.

One of the switch output types, and means the operation in which a switch is

turned on when pressure equal to the switch output set value or more is

detected. In the (hysteresis mode) window comparator mode, it indicates the

operation in which a switch is turned on when pressure in the switch output

range (n1L to n1H or n2L to n2H) is detected.

(Refer to "List of output mode" on page 29.)

The resistance value of a component between the voltage outputting element

and the output line at the output of the analog voltage output. It is indicated as

a resistance value which is converted in accordance with the condition in which

resistance is directly connected to the voltage output element. There may be

an error in the output voltage depending on this output impedance and the

input impedance of customers' equipment. (Example: If the Pressure switch

with output impedance of 1kΩ is connected to the A/D converter to detect the

analog output of 5V, the detected voltage by the A/D converter becomes 5(V)

× 1(MΩ)/(1(kΩ) + 1(MΩ)) ≒ 4.995(V), and there is an error of approximate

0.005 V.)

The operation theory of the switch output. Either normal output or reversed

output can be selected.

Refer to "List of output mode" on page 29 for the operation status.

The size of the port on the switch body with which a device and the switch are

connected.

-12-

No.PS##-OML0003-B

Terms Meaning

P

Power saving mode

Pressure-sensing part A pressure-detecting part of a pressure-detecting element.

Pressure setting

Proof pressure The pressure beyond which the Pressure switch breaks.

R

Rated pressure range

R.D.

The condition in which the indicated value turns off and current consumption is

reduced.

The setting of pressure to determine the point at which the Pressure switch

turns on and off.

The pressure range in which the Pressure switch satisfies the specifications.

Values over this range can be set if they are within the set pressure range, but

cannot assured the specifications to be satisfied.

The value currently displayed.

For example, when the displayed value is 1.000, ±5%R.D. will be ±0.05,

which is ±5% of 1.000, while for a displayed value of 0.800 it will be 0.04.

Repeatability

Residual voltage

Resolution See "Indication resolution".

Response time

Reversed output

Ripple A type of chattering.

Setting of function See "Function selection mode".

S

Setting pressure range The pressure range within which switch output can be set.

Slave Pressure switch A Pressure switch whose settings are copied when using the copy function.

Switch output Alternatively called "ON-OFF output".

U

Unit conversion function

W

Wetted part

(or part exposed to gas)

Window comparator mode

Withstand voltage

Zero clear (function) Adjusts the displayed pressure value to "0".

Z

Reproducibility of the displayed value for pressure and ON-OFF output

operating point when the pressure changes at a temperature of 25

The difference between the ideal ON voltage and the actual voltage when the

switch output is on. It depends on present load current and ideally should be

"0".

The elapsed time until the ON-OFF output begins working since the pressure

supplied for the Pressure switch has reached the set value. Generally, the

shorter response time is, the better the performance is.

One of the switch output types, and means the operation in which a switch is

turned on when pressure equal to the switch output set value or less is

detected. In the (hysteresis mode) window comparator mode, it indicates the

operation in which a switch is turned on when pressure outside the switch

output range (n1L to n1H or n2L to n2H) is detected.

(Refer to "List of output mode" on page 29.)

Function to change the unit in which the value of pressure is indicated. Only a

product with this function can change the unit. A product with unit-changing

function cannot be purchased if it is used within Japan. Pressure is indicated

only by SI units in Japan.

That part of the Pressure switch which is in contact with detected fluid such as

a pressure sensor, seal, and fitting.

An output type that holds the output when the pressure is within a certain

range. (Refer to "List of output mode" on page 29.)

Durability to voltage applied between an electric circuit and a body. A product's

durability in withstanding voltage. If more voltage is applied to the product, the

product may be broken. (Voltage mentioned here is not power voltage to

activate the product.)

o

C.

-13-

No.PS##-OML0003-B

Mounting and Installation

■Installation

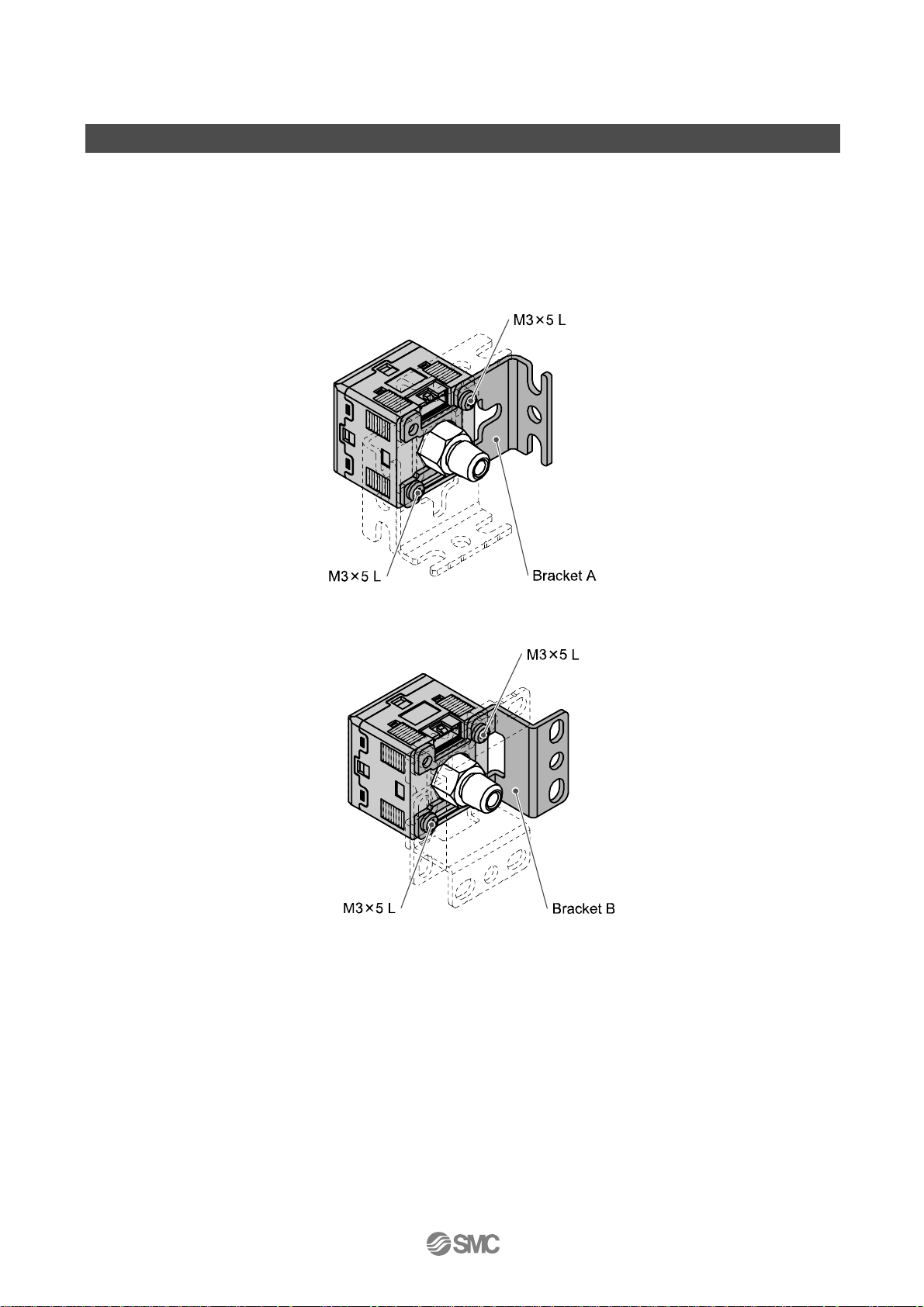

○Mounting by bracket

∗: The tightening torque of piping port must be 7 to 9 Nm.

The tightening torque of the mounting screw for the bracket must be 0.5 to 0.7Nm.

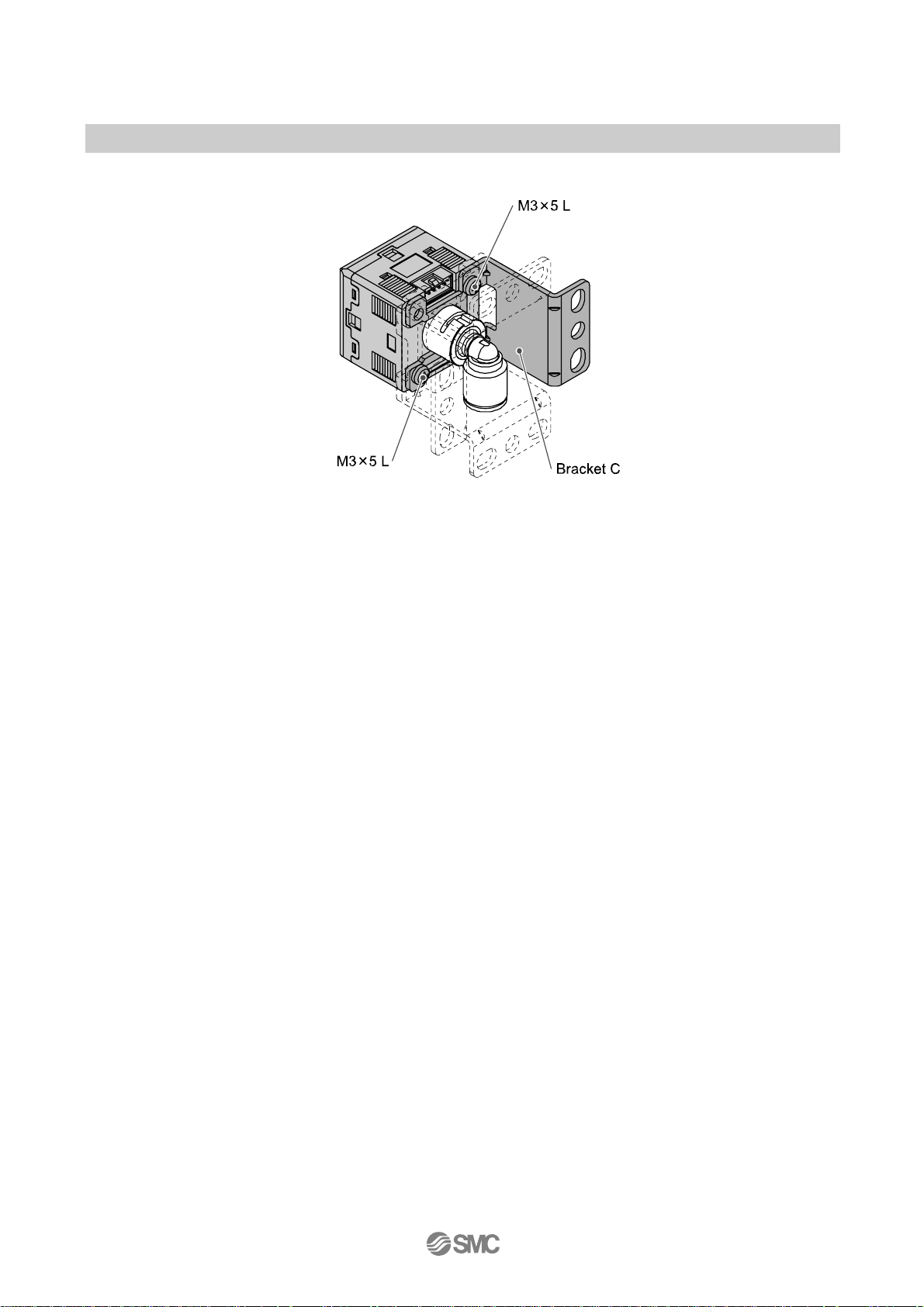

•Mount the bracket on the Pressure switch with the set screws M3 × 5 L (2 pcs.) and install on a machine.

•Bracket A (Model: ZS-38-A1)

•Bracket B (Model: ZS-38-A2)

-14-

No.PS##-OML0003-B

•Bracket C (Model: ZS-38-A3)

∗: The bracket A/B/C can be mounted in 4 ways.

-15-

No.PS##-OML0003-B

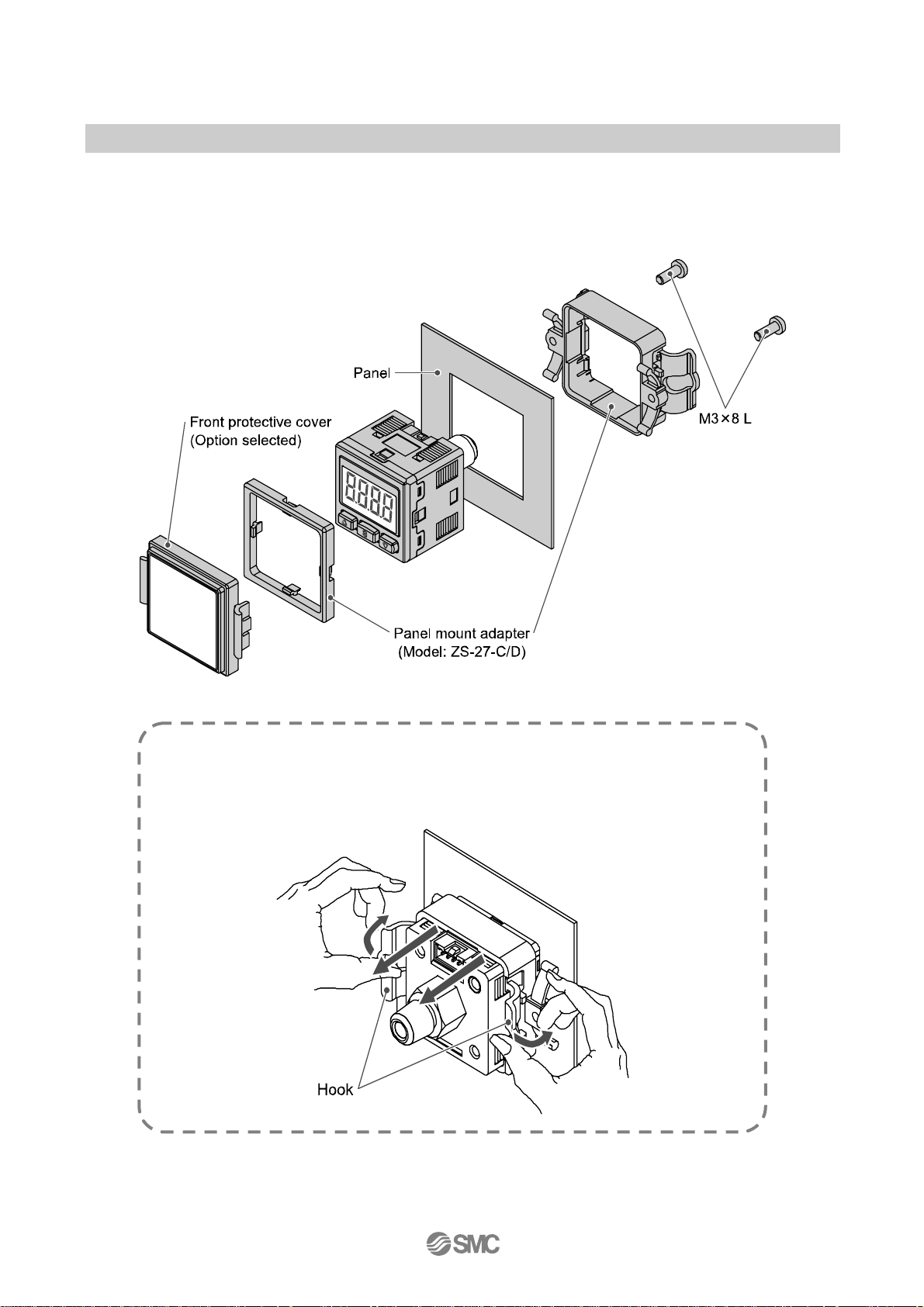

○Mounting by panel mount adapter

•Fix the panel mount adapter to the Pressure switch with the set screws M3 × 8 L (2 pcs.) as attached.

•Panel mount adapter (Model: ZS-27-C)

Panel mount adapter + Front protective cover (Model: ZS-27-D)

∗: The panel mount adapter can be rotated by 90 degrees for mounting.

Notice when removing the switch

•The Pressure switch with the panel mount adapter can be removed from facility

by widening the hook of the switch as following after removing two screws.

The Pressure switch and panel mount adapter may be damaged.

-16-

No.PS##-OML0003-B

■Piping

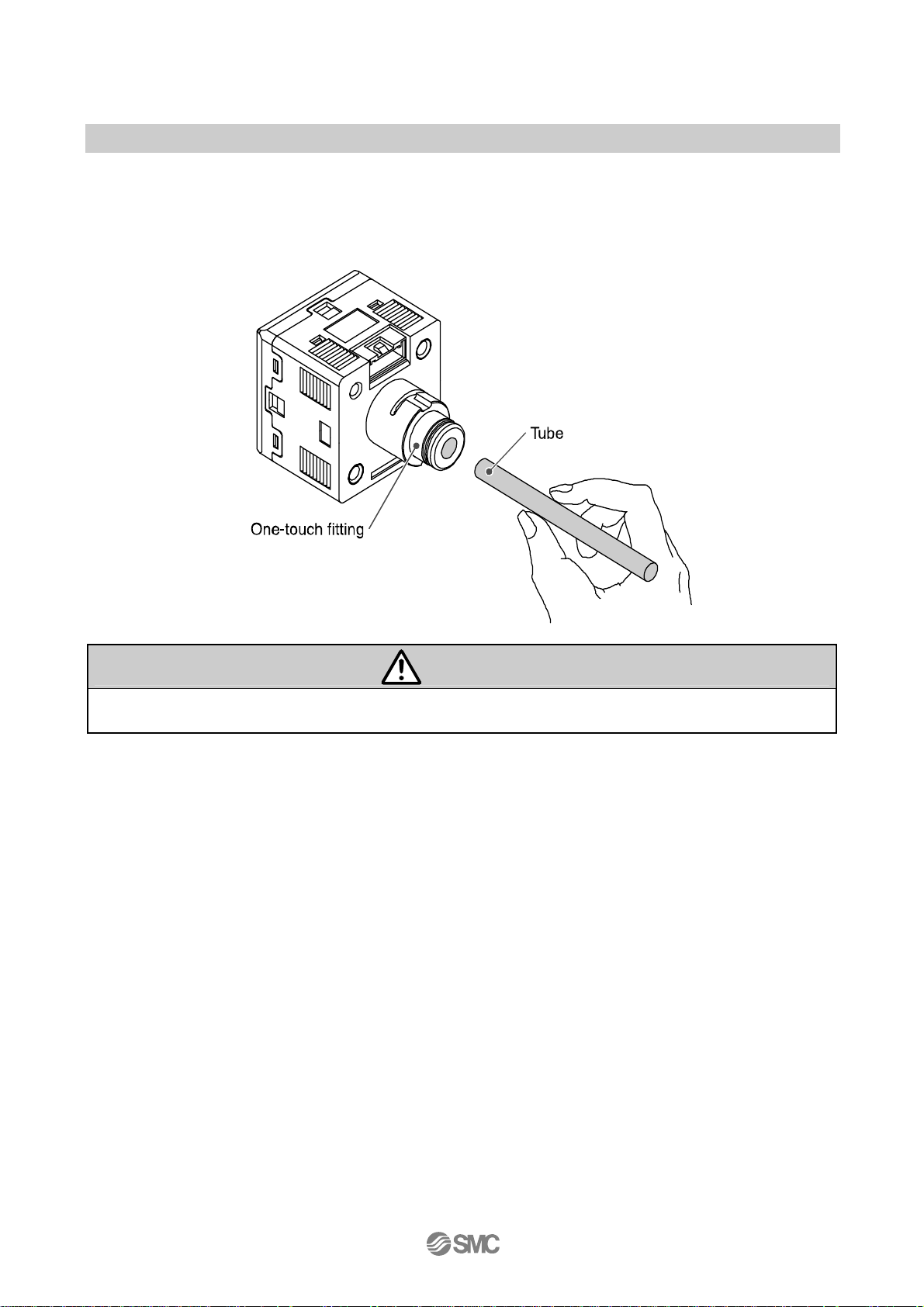

○Mounting by One-touch fitting

1. Cut the tube perpendicularly.

2. Hold the tube and insert it into the One-touch fitting slowly until it will bottom out.

Warning

■Do not use the Pressure switch in a place where electrical static charge will be problem.

It can cause the error and breakage of the system.

•Keep a margin for tube length to prevent twist, tensile and moment load from applying to the fitting and

tube.

•When using a tube manufactured by another company, check its outside diameter accuracy satisfies the

following value.

1) Nylon tube: ±0.1 mm at maximum

2) Soft nylon tube: ±0.1 mm at maximum

3) Polyurethane tube: +0.15 mm/-2 mm at maximum

-17-

No.PS##-OML0003-B

■Wiring

○Connection

•Connections should only be made with the power supply turned off.

•Use separate routes for the Pressure switch wiring and any power or high voltage wiring. Otherwise,

malfunction may result due to noise.

•Ensure that the FG terminal is connected to ground when using a commercially available switch-mode

power supply. When a switch-mode power supply is connected to the product, switching noise will be

superimposed and the product specification can no longer be met. This can be prevented by inserting a

noise filter, such as a line noise filter and ferrite core, between the switch-mode power supply and the

product, or by using a series power supply instead of a switch-mode power supply.

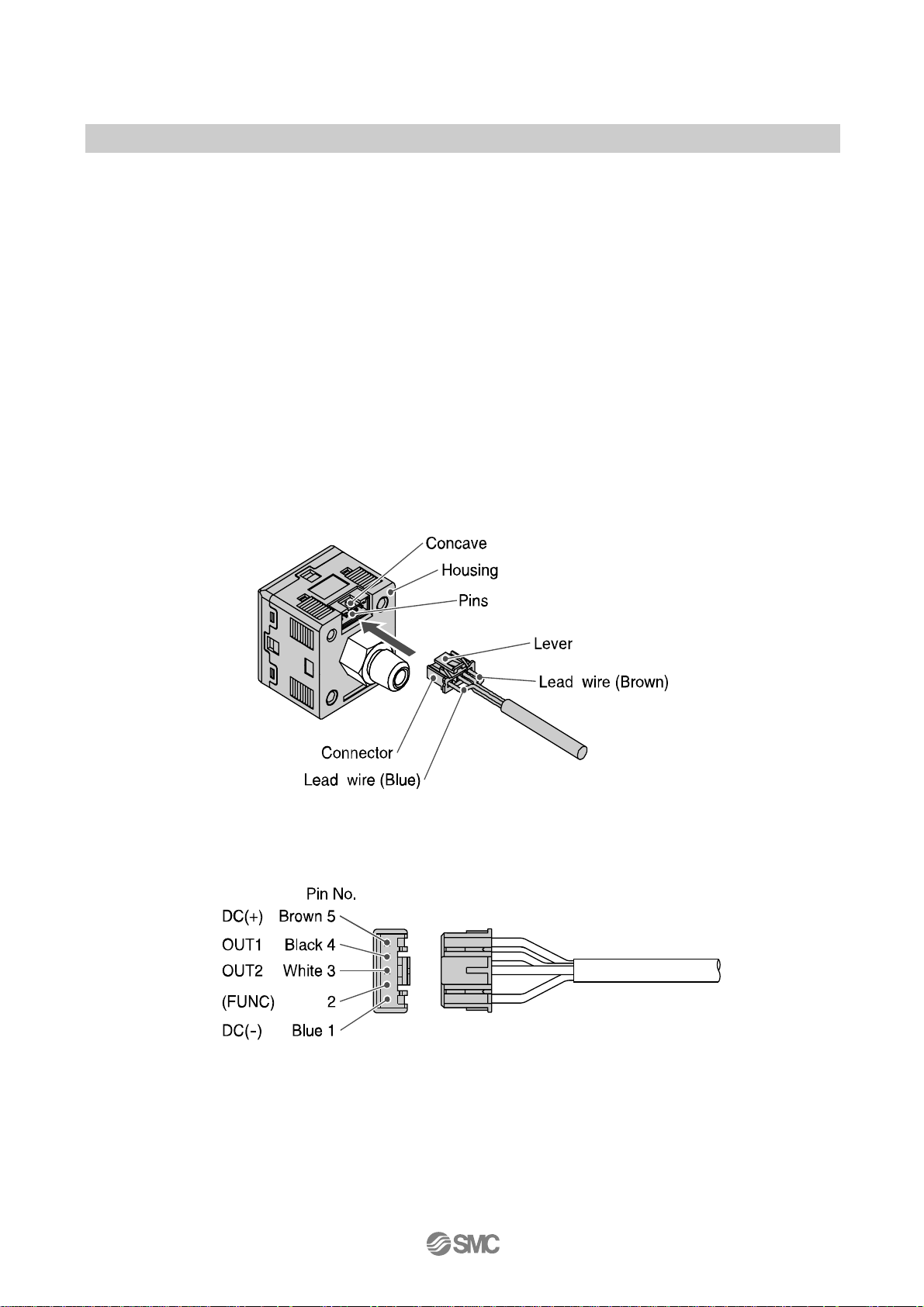

○Connector

Connecting/Disconnecting

•When mounting the connector, insert it straight into pins with holding the lever and connector body by

fingers and press fit the nook of the lever to the concave of the housing to lock.

•When removing the connector, press down the lever by thumb to let its nook come off from the concave

and pull out the connector straight.

Pin No. of the Connector

-18-

No.PS##-OML0003-B

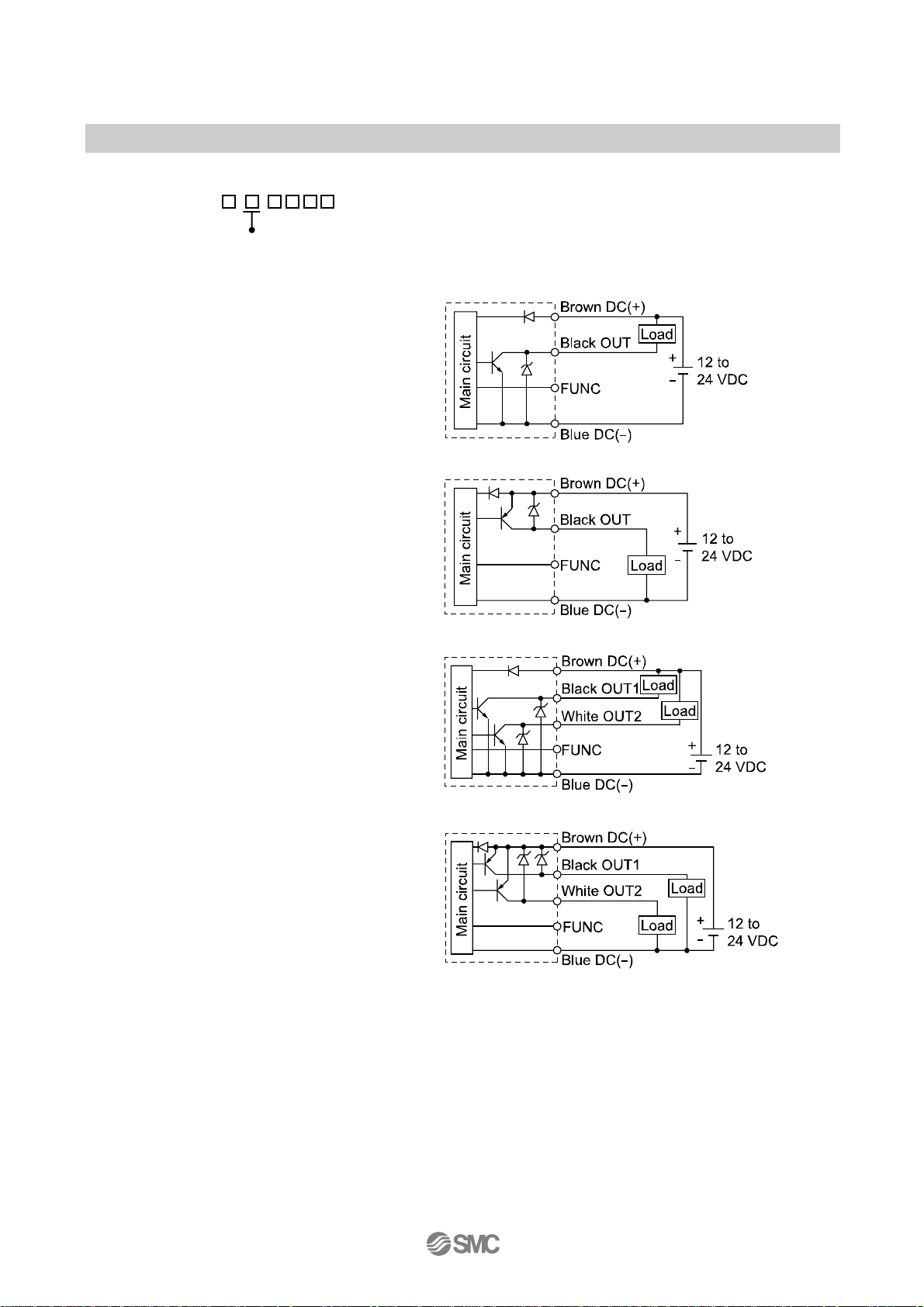

○Internal circuit and wiring example

Z/ISE30A(F)- - -

Output specification

-N

NPN open collector 1 output

Max. 28 V, 80 mA

Residual voltage 1 V or less

-P

PNP open collector 1 output

Max. 80 mA

Residual voltage 1 V or less

-A

NPN open collector 2 outputs

Max. 28 V, 80 mA

Residual voltage 1 V or less

-B

PNP open collector 2 outputs

Max. 80 mA

Residual voltage 1 V or less

-19-

No.PS##-OML0003-B

Loading...

Loading...