Page 1

Document No.ZL-OM01001

PRODUCT NAME

Multistage Ejector

MODEL / Series / Product Number

ZL112A Series

Page 2

Document No.ZL-OM01001

- 1 -

Contents

Safety Instructions 2

Model Indication and How-to-Order 7

Names of Parts 8

Operating Environment 9

Mounting and Installation 10

Air Supply 11

Piping 12

Electrical wiring 14

Solenoid valve 15

Vacuum pressure switch 15

Construction 16

Maintenance and Inspection 17

Exhaust from ejector 21

Specifications 22

Circuit diagram 24

Exhaust characteristics, flow characteristics,

time required to reach the specified vacuum, release flow characteristics 25

Flow characteristics curve 26

Troubleshooting 27

Page 3

Document No.ZL-OM01001

- 2 -

These safety instructions are intended to prevent hazardous situations and/or equipment damage.

These instructions are categorized into three groups, "Caution", "Warning" and "Danger" depending on the level

of hazard and damage, and the degree of emergency. They are all important notes for safety and must be

followed in addition to International Standards (ISO/IEC), Japan Industrial Standards (JIS)

*1)

and other safety

regulations

*2)

.

*1) ISO 4414: Pneumatic fluid power -- General rules relating to systems.

ISO 4413: Hydraulic fluid power -- General rules relating to systems.

IEC 60204-1: Safety of machinery --Electrical equipment of machines. (Part1: General requirements)

ISO 10218-1992: Manipulating industrial robots -Safety.

JIS B 8370: General rules for pneumatic equipment.

JIS B 8361: General rules for hydraulic equipment.

JIS B 9960-1: Safety of machinery – Electrical equipment for machines. (Part 1: General requirements)

JIS B 8433-1993: Manipulating industrial robots - Safety, etc.

*2) Labor Safety and Sanitation Law, etc.

Caution

Caution indicates a hazard with a low level of risk, which if not avoided, could result in

minor or moderate injury.

Warning

Warning indicates a hazard with a medium level of risk,

which if not avoided, could result in death or serious injury.

Danger

Danger indicates a hazard with a high level of risk which, if not avoided, will result in

death or serious injury.

Warning

1. The compatibility of the product is the responsibility of the person who designs the equipment or

decides its specifications.

Since the product specified here is used under various operating conditions, its compatibility with specific

equipment must be decided by the person who designs the equipment or decides its specifications based on

necessary analysis and test results. The expected performance and safety assurance of the equipment will be the

responsibility of the person who has determined its compatibility with the product. This person should also

continuously review all specifications of the product referring to its latest catalog information, with a view to giving

due consideration to any possibility of equipment failure when configuring the equipment.

2. Only personnel with appropriate training should operate machinery and equipment.

The product specified here may become unsafe if handled incorrectly.

An operator who is appropriately trained and experienced must perform the assembly, operation and maintenance

of machines or equipment.

3. Do not service or attempt to remove product and machinery/equipment until safety is confirmed.

1. The inspection and maintenance of machinery/equipment should only be performed after measures to prevent

dropping of driven objects or run-away of machinery/equipment have been confirmed.

2. When the product is to be removed, confirm that the safety measures as mentioned above are implemented and

the power from any appropriate source is cut. Read and understand the specific product precautions of all

relevant products carefully.

3. Before machinery/equipment is restarted, take measures to prevent unexpected operation and malfunction.

4. Contact SMC beforehand and take special consideration of safety measures if the product is to be

used in any of the following conditions.

1. Conditions and environments outside of the given specifications, or use outdoors or in a location exposed to

direct sunlight.

2. Installation on equipment in conjunction with atomic energy, railways, air navigation, space, shipping, vehicles,

military, medical treatment, combustion and recreation, or equipment in contact with food and beverages,

emergency stop circuits, clutch and brake circuits in press applications, safety equipment or other applications

unsuitable for the standard specifications described in the product catalog.

3. An application which could have negative effects on people, property, or animals requiring special safety

analysis.

4. Use in an interlock circuit, which requires the provision of double interlock for possible failure by using a

mechanical protective function, and periodical checks to confirm proper operation. Check the product regularly in

order to confirm normal operation.

Safety Instructions

Page 4

Document No.ZL-OM01001

- 3 -

Safety Instructions

Caution

1. The product is provided for use in manufacturing industries.

The product herein described is basically provided for use in manufacturing industries.

If the product is being considered for use in other industries, consult SMC beforehand and exchange specifications

or a contract if necessary.

If anything is unclear, contact your nearest sales branch.

Limited Warranty and Disclaimer/Compliance Requirements

The product used is subject to the following “Limited warranty and Disclaimer” and “Compliance Requirements”.

Read and accept them before using the product.

Limited Warranty and Disclaimer

1. The warranty period of the product is 1 year in service or within 1.5 years after the product is

delivered. *3)

Also, the product may have specified durability, running distance or replacement parts. Please

consult your nearest sales branch.

2. For any failure or damage reported within the warranty period, which is clearly our responsibility,

a replacement product or necessary parts will be provided.

This limited warranty applies only to the SMC product independently, and not to any other damage

incurred due to the failure of the product.

3. Prior to using SMC products, please read and understand the warranty terms and disclaimers noted

in the specified catalog for the particular products.

*3) Vacuum pads are excluded from this 1 year warranty.

A vacuum pad is a consumable part, so it is warranted for a year after it is delivered.

Also, even within the warranty period, the wear of a product due to the use of the vacuum pad

or failure due to the deterioration of rubber material are not covered by the limited warranty.

Compliance Requirements

When the product is exported, strictly follow the laws required by the Ministry of Economy, Trade and

Industry (Foreign Exchange and Foreign Trade Control Law).

Page 5

Document No.ZL-OM01001

- 4 -

■Explanation of Symbols

Symbol

Definition

Things you must not do.

Instructions are provided as a drawing or sentence next to the symbol.

Things you must do

Instructions are provided as a drawing or sentence next to the symbol.

■Operator

1. This Operation Manual is intended for those who have knowledge of machinery using pneumatic equipment, and

have sufficient knowledge of assembly, operation and maintenance of such equipment.

Only those persons are allowed to perform assembly, operation and maintenance.

2. Read and understand this Operation Manual carefully before assembling, operating or providing maintenance to

the product.

Page 6

Document No.ZL-OM01001

- 5 -

■Safety Instructions

Warning

Disassembly

prohibited

Do not disassemble, modify (including the replacement of board) or repair other than

instructed in this manual.

Otherwise, an injury or failure can result.

Do not

Do not operate the product outside of the specifications.

Do not use for flammable or harmful fluids.

Fire, malfunction, or damage to the product can result.

Please check the specifications before use.

Do not

Do not use in an atmosphere containing flammable or explosive gases.

Fire or an explosion can result.

The product is not designed to be explosion proof.

Do not

Do not use the product in a place where static electricity is a problem.

Otherwise failure or malfunction of the system can result.

Do not

Do not cut off the power and compressed air supplied to this product while it is operating.

Otherwise it can cause injury due to dropping of workpieces or damage to the system.

Instruction

If using the product in an interlocking circuit

- Provide a double interlocking system, for example a mechanical system.

- Check the product for proper operation.

Otherwise malfunction can result, causing an accident.

Instruction

The following instructions must be followed during maintenance

- Turn off the power supply

- Stop the air supply, exhaust the residual pressure in piping and verify that the air is

released before performing maintenance work.

It may cause an injury.

Page 7

Document No.ZL-OM01001

- 6 -

Caution

Do not touch

Do not touch the terminals and connectors while the power is on.

Otherwise electric shock, malfunction or damage to the switch can result.

Instruction

Perform sufficient trial run.

Otherwise, injury or damage to the system can result due to suction failure depending on

the conditions of the suction of the workpiece or the pressure switch settings.

Perform sufficient verification before using this product.

Instruction

After maintenance is complete, perform appropriate functional inspections and leak test.

Stop operation if the equipment does not function properly or there is leakage of fluid.

If there is leakage from parts other than the piping, the product might be broken.

Cut off the power supply and stop the fluid supply.

Do not supply fluid if there is leakage.

Safety cannot be assured in the case of an unexpected malfunction.

Page 8

Document No.ZL-OM01001

- 7 -

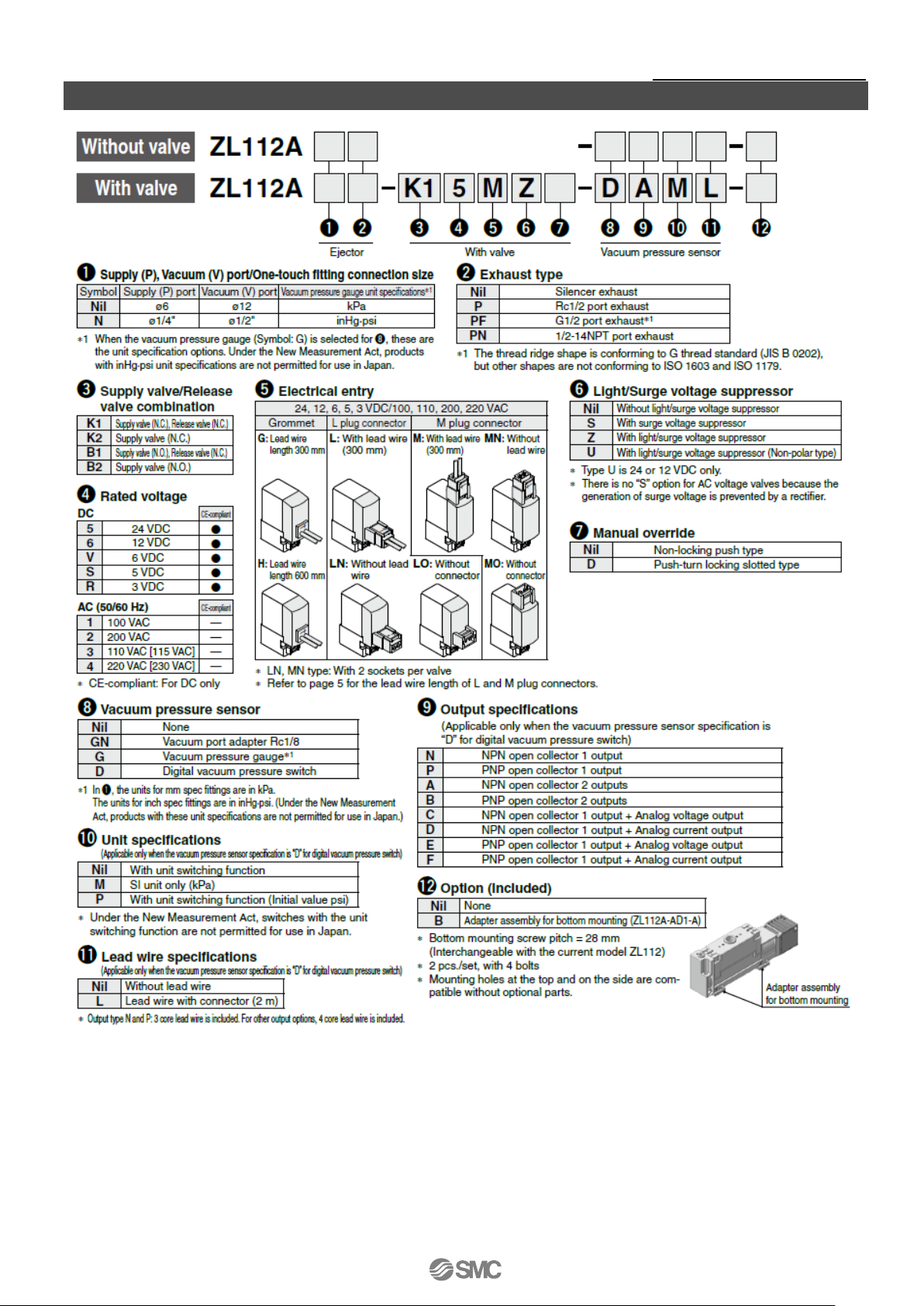

Model Indication and How to Order

Page 9

Document No.ZL-OM01001

- 8 -

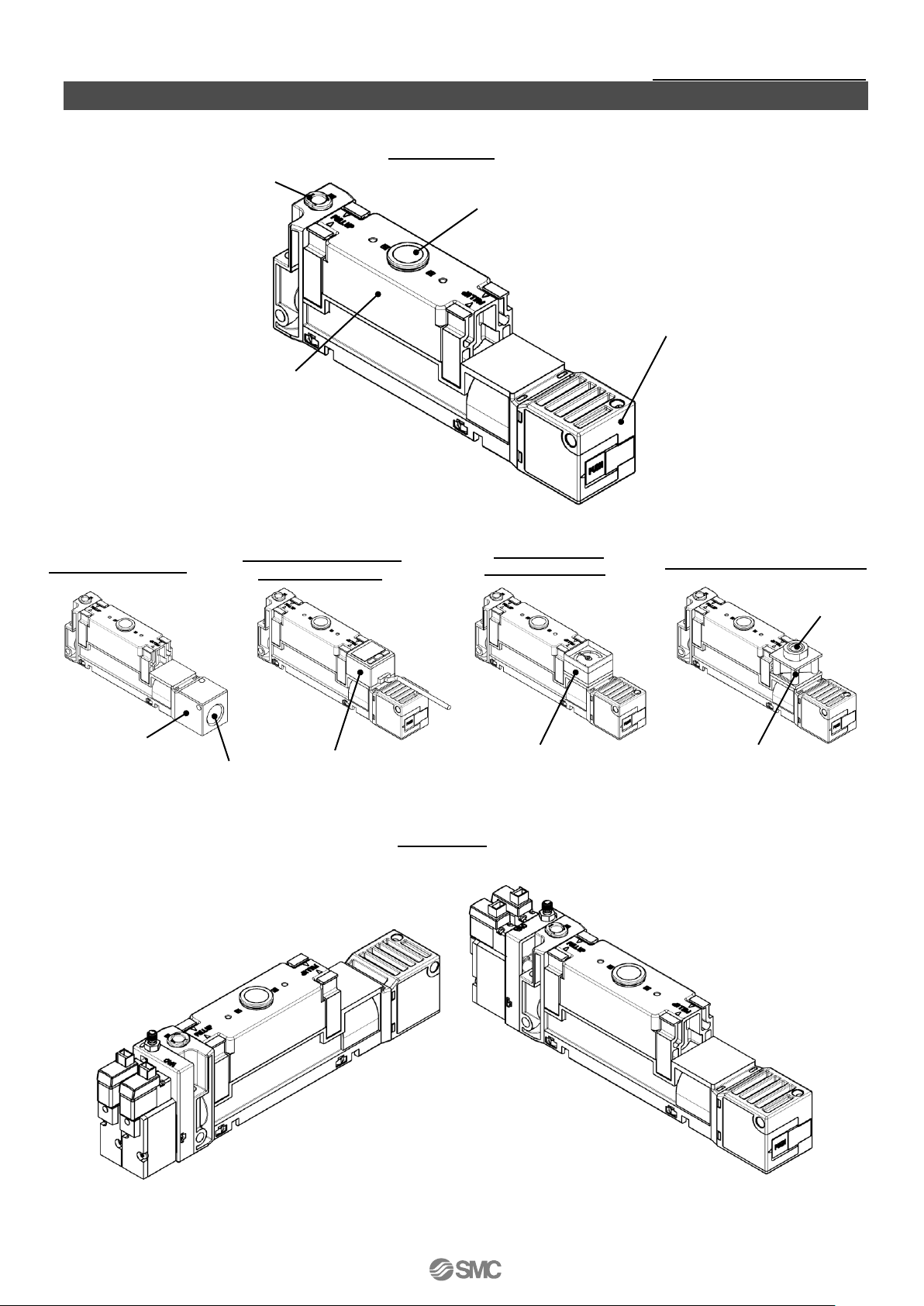

Names of Parts

With valves

Port block

Digital vacuum

pressure switch

Vacuum pressure gauge

Vacuum port

adapter

With port exhaust

With digital vacuum

pressure switch

With Vacuum

pressure gauge

With Vacuum port adapter

Exhaust port

Vacuum pressure

detection port

Supply ( P ) Port

Vacuum ( V ) Port

Suction cover

Silencer case ( Exhaust )

Without valve

Release valve

Supply valve

Vacuum break flow

adjusting needle

Lock nut

Page 10

Document No.ZL-OM01001

- 9 -

Operating Environment

- Do not use in an environment where corrosive gases, chemicals, sea water, water or steam are

present. These can cause failure or malfunction.

- Do not use the product in a place where the product could be splashed by oil or chemicals.

If the product is to be used in an environment containing oils or chemicals such as coolant or

cleaning solvent, even for a short time, it may be adversely affected (damage, malfunction, or

hardening of the lead wires).

- Keep the ambient temperature of the product between 5 and 50°C. In environments such as

inside a panel where heat radiation efficiency is poor, the ambient temperature will rise due to

the heat generation of the coil of the solenoid valve, causing malfunction. At the same time,

avoid rapid temperature changes even within the specified temperature range.

- Do not use this product in places where there are cyclic temperature changes. Heat cycles other

than ordinary changes in temperature can adversely affect the inside of the product.

- Do not use where the product is exposed to direct sunlight. Shade the sunlight in locations

where the product is exposed to direct sunlight. Failure and malfunction can result.

- Do not use in a location where the product is exposed to radiant heat from surrounding heat

sources. This can cause operating failure.

-Do not use the product in an area where surge is generated. When there are machines or

equipment that generate large surge near the pressure switch (magnetic type lifter, high

frequency inductive furnace, motor, etc.), this can result in deterioration and damage of the

internal elements. Take measures against the surge sources, and prevent the lines from coming

into close contact.

- Do not let foreign matter, such as wire debris, get inside the product. In order to avoid failure and

malfunction, do not let foreign matter, such as wire debris, get inside the product.

- The use of resin piping can cause static electricity to be generated, depending on the fluid.

Therefore, when connecting the vacuum pressure switch assembly, take appropriate measures

against static electricity at the customer’s equipment side, and separate the grounding for the

product from the grounding for any equipment which generates a strong electromagnetic noise

or high frequency. Otherwise, static electricity can break the vacuum pressure switch assembly.

Page 11

Document No.ZL-OM01001

- 10 -

Mounting and Installation

1. Tighten the body to the recommended tightening torque (For top and side mounting: 1.2 to

1.5N・m, for bottom mounting: 0.60 to 0.74 Nm ). If the recommended tightening torque is

exceeded, the body, mounting screws and brackets may be damaged. Insufficient torque can

cause displacement of the body from its proper position and the looseness of the mounting

screws.

2. If air leakage increases or the equipment does not operate properly, stop operation. After

installation and maintenance, apply air and power supplies to the equipment and perform

appropriate functional and leakage inspections to make sure the equipment is mounted

properly.

3. Do not drop, hit or apply excessive shock to the product. The inner parts can be damaged

leading to malfunction even if the sensor body is not damaged.

4. Mount the product in a location that is not affected by vibration or impact.

Failure and malfunction can occur.

5. Do not fix the product such that a load is always applied to the air pressure supply port, vacuum

port, vacuum pressure detection port and exhaust port in a bending or pulling direction. This

can damage this product.

6. Do not pull the lead wire forcefully, or lift the product by the lead wire (Lead wire tensile

strength: within 30N). Hold the product body when handing.

7. Do not obstruct the exhaust port of the ejector. Do not cover the exhaust port. Otherwise,

vacuum is not generated. Do not block the exhaust port to release the work piece. This can

damage the vacuum ejector.

8. If the product is operated in a dusty environment or if there is dust on the surface of the work

pieces, it can cause clogging of the silencing material as well as the suction filter. Secure

space necessary for the maintenance checks and replacement of the silencer when the ejector

performance decreases.

9. Be sure to connect the ground terminal F.G. to ground when using a commercially available

switch-mode power supply.

10. Although this product is interchangeable with the ZL112 multistage ejector (old product),

adapter assembly for bottom porting (ZL112A-AD1-A) is required only for the bottom porting.

When the adapter assembly for bottom porting is

mounted to the product, please follow the

direction specified on the right side.

(Recommended tightening torque:

0.60 to 0.74 Nm)

Adapter assembly

for bottom mounting

Page 12

Document No.ZL-OM01001

- 11 -

Supply air

1. For the compressed air quality, refer to 2.4.3, 2.5.3 and 2.6.3 of ISO8573-1:2001 (JIS

B8392-1:2003).

2. It is recommended that an air filter and a mist separator are connected to the upstream side of

the ejector and the pump system. (Refer to Air Preparation Equipment Selection Guide in Best

Pneumatics 5 for detail.)

3. Using compressed air which contains chemicals, synthetic oils containing organic solvents,

salts or corrosive gases, etc. can cause damage or malfunction. Do not use compressed air

containing toxic impurities.

4. If the compressed air contains excessive moisture or carbon powder, it can stick to the vacuum

parts (the nozzle diffuser), inside of the solenoid valve or the pressure switch and cause a

decrease in performance or operation failure. An air dryer, mist separator, and filter should be

installed upstream from filters.

If condensation in the drain bowl and air filter is not emptied on a regular basis, the bowl will

overflow and allow the condensation to enter the compressed air lines. This causes malfunction

of pneumatic equipment. If the drain bowl is difficult to check and remove, installation of a drain

bowl with an auto drain option is recommended.

5. Use the product within the specified supply pressure range (0.2 to 0.5 MPa). Operation over the

specified supply pressure range can cause damage to the product.

Page 13

Document No.ZL-OM01001

- 12 -

Wrap this way.

Sealant tape

Leave 1 thread exposed.

Piping

■ Piping for Air Pressure Supply and Vacuum Pressure Supply

(1) Preparation before piping

Before piping, perform air blow (flushing) or cleaning to remove any cutting chips, cutting oil,

dust, etc. from the piping.

(2) Wrapping of pipe tape

When installing piping or a tube fitting into a port, prevent cutting

chips and sealant material from getting inside the product.

If a sealant tape is used, leave 1 thread exposed at the end of threads.

(3) When connecting tubing, consider factors such as changes in the tubing length due to

pressure, and allow a sufficient margin.

Otherwise, it can damage the fitting and cause the tube to come off. Refer to Fittings & Tubing

Precautions from 1 to 4 shown in Best Pneumatics 6 on SMC’s website (URL

http://www.smcworld.com) for the recommended piping conditions.

■ Piping to the Exhaust Port, Vacuum Port Adapter

Piping to the Exhaust Port

When mounting or removing the piping to or from

the exhaust port, hold the exhaust block with

a wrench (across the flats 36).

Recommended tightening torque:20 to 25 N·m

The product may break, if it is held by hand.

Piping to the Vacuum Port Adapter

When mounting or removing the fitting,

etc. to or from the vacuum port adapter,

hold the vacuum port adapter with a wrench

(across the flats 19).

Recommended tightening torque:3 to 5 N·m

The product may break, if it is held by hand.

When piping is connected to the exhaust port block and vacuum port adapter, pay attention

that no twisting, tensile, moment loads, vibration or impact should be applied to the piping.

This can cause displacement or damage of the port.

Port block

Vacuum port adapter

Page 14

Document No.ZL-OM01001

- 13 -

■ Piping to the Vacuum (V) Port

(1) Allow a sufficient margin of tube length when piping, in order to prevent twisting, tensile,

moment loads, vibration or impact being applied to the tubes and fittings. This can cause

damage to the tube fittings and crushing, bursting or disconnection of tubing.

(2) Piping to the product is assumed to be static piping. If the tube moves, it may become worn,

elongated or torn due to tensile forces, or disconnected from the fitting. Ensure the tube is in a

static condition at all times before using.

(3) Prevent the connected tube from being rotated. If the fittings are used in this way, the fitting

may fail.

(4) Do not lift the product by holding the piping after the tube is connected to the vacuum (V) port.

■ One-touch Fittings Precautions

1. Insertion of tube

1) Cut the tube perpendicularly, being careful not to damage the external surface. Use SMC’s

tube cutter TK-1, 2 or 3 for cutting. Do not cut the tube with pliers, nippers, scissors, etc. If the

tube is cut by any tools other than a tube cutter, the cut surface of the tube will be slanted or flat,

making it impossible to be connected securely, or causing the tube to come off or air leakage

after the tube is connected. Also, allow a sufficient margin of tube length.

2) Hold the tube and push it in slowly, inserting it securely all the way into the fitting.

3) After inserting the tubing, pull on it gently to confirm that it will not come out. If it is not installed

securely all the way into the fitting, problems such as leakage or disconnection of the tube can

occur.

2. Removal of the tube

1) KQ2 series is used for the vacuum (V) port. For this series, the tube can be removed by

pushing one part of the release button.

2) Hold down the release button while pulling out the tube. If the release button is not held down

fully, there will be more bite so it will be more difficult to pull out the tube.

3) If the removed tubing is to be used again, cut off the section of the tubing which has been

gripped. Using the gripped portion of the tube as it is can cause problems such as air leakage or

difficulty in removing the tube.

Precautions for Use of Other Manufacturers' Tubes

If tubes of brands other than SMC are used, confirm that the materials and tolerance of the

tubing outside diameter will satisfy the following specifications.

1) Nylon tube within +/-0.1mm

2) Soft nylon tube within +/-0.1mm

3) Polyurethane tube within +/-0.15mm and -0.2mm

Do not use tubing which does not meet these outside diameter tolerances. Connection to the

fitting may fail, causing disconnection of the tube and air leakage.

Page 15

Document No.ZL-OM01001

- 14 -

Electrical wiring

1. Use the specified voltage. Otherwise failure or malfunction can occur.

2. Do not exceed the specified maximum allowable load. Otherwise it can cause damage or

shorten the life of the product.

3. Design the product to prevent reverse current when the circuit is opened or the product is

forced to operate for operational check. Reverse current can cause malfunction or damage the

product.

4. Do not pull the lead wire forcefully, or lift the product by the lead wire (Lead wire tensile

strength: within 30N). Hold the product body when handing.

5. Avoid repeatedly bending or stretching the lead wires, or placing a heavy load or applying force

to them. If the bending stress and tensile force is repeatedly applied to the lead wires, sheath

might be removed. If the lead wire can move, fix it near the body of the product. The

recommended bending radius of the lead wire is R40 mm or more. For details, please contact

SMC. Replace the damaged lead wire with a new one.

6. Incorrect wiring can damage the switch and cause malfunction. Connections should be done

while the power supply is turned off.

7. Do not perform wiring while the power is on. Otherwise damage to the solenoid valve or the

internal parts of the pressure switch/sensor can result, causing malfunction.

8. Do not attempt to insert or pull out the connector from the pressure switch while the power is on.

This may cause switch output malfunction.。

9. Malfunctions stemming from noise may occur if the wire is installed in the same route as that of

power or high-voltage cable. Wire the pressure switch independently.

10. Confirm proper insulation of wiring. Poor insulation (interference with other circuits, poor

insulation between terminals etc.) can apply excessive voltage or current to the solenoid valve

or the pressure sensor, causing damage.

11. Keep wiring as short as possible to prevent interference from electromagnetic noise and surge

voltage. Do not use a cable longer than 10 m. Wire the DC (-) line (solenoid valve: black,

pressure switch: blue) as close as possible to the power supply.

12. Do not use the product in an area where surge is generated. When there are machines or

equipment that generate large surge near the pressure switch (magnetic type lifter, high

frequency inductive furnace, motor, etc.), this can result in deterioration and damage of the

internal elements. Take measures against the surge sources, and prevent the lines from

coming into close contact.

Page 16

Document No.ZL-OM01001

- 15 -

Solenoid Valve

1. Avoid energizing the solenoid valve for long periods of time. If a solenoid valve is continuously

energized for an extended period of time, the heat generated by the coil assembly may reduce

performance and life of the valve or have adverse effects on peripheral equipment. Therefore,

when it is continuously energized for an extended period of time or when the energized period

per day is longer than the de-energized period, use N.O. (normally open) type product.

When the valve is mounted onto a control panel, take measures to radiate heat in order to keep

the product temperature within the specified range.

2. For details of the SYJ500 3-port solenoid valve other than the above-mentioned series, please

refer to the SMC website URL: http://www.smcworld.com.

Digital Pressure Switch for Vacuum

1. Connect a load before turning the power supply on. If the power supply is turned on with no

load, over current may flow, causing the pressure switch to break instantly.

2. Do not short circuit the load. An error is displayed when the load of the pressure switch is short

circuited, but over current may flow, causing damage to the pressure switch.

3. Do not press the setting buttons with a sharp pointed object. This may damage the setting

buttons.

4. If using the product to detect very small pressures, warm up the product for 10 to 15 minutes

first.

There will be a drift on the display of approx. 1% for 10 minutes after the power supply is turned

on.

5. Perform settings suitable for the operating conditions. Incorrect setting can cause operation

failure.

For details of each setting, refer to the Operation Manual of the pressure switch.

6. Do not touch the LED during operation. The display can vary due to static electricity.

7. For details of the ZSE30A 2-Color Display High-Precision Digital Pressure Switch other than

the above-mentioned series, please refer to the SMC website URL: http://www.smcworld.com.

Page 17

Document No.ZL-OM01001

- 16 -

Construction

Components

The components other than (1) and (6) are available as service parts. Refer to “Maintenance and Check” on the

next pages for details.

Without valves and switch

With valves and switch

No. Description Material Note

1 Body assembly Resin, NBR, Steel

2

Suction cover assembly

(Filter element included)

Resin, NBR, Steel,

Non-woven fabric

Silencer case assembly (Sound absorbing

material and clip included)

Resin, Steel For silencer exhaust

Port block assembly

(Clip included)

Aluminum alloy, NBR, Steel For port exhaust

4 Ejector assembly Resin, NBR, Fluororubber

5

Valve plate assembly (Needle is included

for models with release valves.)

Resin, NBR, HNBR, Steel

6

Vacuum break flow

adjusting needle

Brass (Electroless nickel

plating),

Resin, NBR, Steel

7 Filter element Non-woven fabric

8 Sound absorbing material Resin

9 Supply valve, Release valve -

Digital vacuum pressure

switch

- For Digital vacuum pressure switch

Vacuum port adapter assembly

Resin, Aluminum alloy, NBR,

Steel

For Vacuum port adapter

Pressure gauge assembly - For Vacuum pressure gauge

11 O-ring NBR

3

10

Page 18

Document No.ZL-OM01001

- 17 -

Maintenance and Inspection

■ Implement the maintenance and check shown below in order to use the ejector and the

vacuum system safely and in an appropriate way for a long period of time.

1. Maintenance should be performed according to the procedure indicated in the Operation

Manual. Improper handling can cause damage and malfunction of equipment and machinery.

2. Maintenance work

Compressed air can be dangerous when handled incorrectly. Therefore, in addition to observing

the product specifications, replacement of elements and other maintenance activities should be

performed by personnel with sufficient knowledge and experience pertaining to pneumatic

equipment.

3. Draining

Remove condensate from air filters and mist separators regularly. If the collected drainage is

drained to the downstream side, it can stick inside of the product, causing operation failure and

failure to reach the specified vacuum pressure.

4. Replace the filter element built into the ejector and the vacuum pump system and the silencer

regularly. (Refer to the replacement procedure below.)

It is recommended to replace the filter element and the silencer when the pressure drop reaches

5kPa as a guideline. The replacement cycle varies depending on the operating conditions,

operating environment and supply air quality.

However, if there is a vacuum pressure drop and/or delay in the vacuum (adsorption) response

time which causes problem with the settings during operation, stop the operation of the product

and replace the element regardless of the above mentioned replacement guideline.

5. Operation in an environment where there is a lot of dust in the air

The processing capacity of the filter element built into the product may be insufficient. It is

recommended to use SMC's air suction filter (ZFA, ZFB, ZFC series) in order to avoid problems

beforehand.

6. Check before and after the maintenance work

When the product is to be removed, turn off the power supply, and be sure to cut off the supply

pressure and exhaust the compressed air. Confirm that the air is released to atmosphere.

When mounting the product after the maintenance work, supply compressed air, connect to the

power, check if it functions properly and have a leakage inspection. Especially for the latching

type supply valve, be sure to check that the supply valve is OFF in the initial condition because

it is possible that it is ON due to vibration.

7. Do not disassemble or modify the product, other than the replacement parts specified in this

manual.

8. Do not use solvents such as benzene and thinner for cleaning. These can damage the surface

and erase the marking on the pressure switch. Use a soft cloth to remove stains. For heavy

stains, use a damp cloth that has been soaked with diluted neutral detergent and fully

squeezed, then wipe up the stains again with a dry cloth.

Page 19

Document No.ZL-OM01001

- 18 -

Replacement parts list

No. Description Part number Note

2

Suction cover assembly

(Filter element included)

ZL112A-FC1□-A □: Vac uum por t s ize Nil : ø 12, N: ø1/2"

Silencer case assembly (Sound absorbing

material and clip included)

ZL112A-SC1-A For silencer exhaust

Port block assembly

(Clip included)

ZL112A-EP1□-A

For port exhaust

□: Exh aust po rt size Ni l: Rc1/ 2, G: G1/2 , N : 1/2-1 4NP T

4 Ejector assembly ZL112A-EJ1-A

5

Vacuum break flow

adjusting needle

ZL112A-VP□-A

□: Sup ply val ve/ Release va lve com binatio n∗1

1: Supply valve + Release valve, 2: Supply valve only

7 Filter element ZL112A-FE1-A 1 pc. (page 17)

8 Sound absorbing material ZL112A-SE1-A

1 pc. of each/set: Sound absorbing material 1 and 2

(page 17)

9 Supply valve, Release valve SYJ5 □4 -□□□ □- □

Refer to how to order the supply valve and release valve.

(page 16)∗1

Digital vacuum pressure

switch

ZL-ZSE30A-00-□-□□

Vacuum pressure sensor: Digital vacuum pressure switch

Refer to how to order the digital vacuum pressure switch.

(page 16)

Vacuum port adapter assembly ZL112A-AD2-A Vacuum pressure sensor: Vacuum port adapter

Pressure gauge assembly ZL112A-PG□-A

Vacuum pressure sensor: Vacuum pressure gauge

□: Uni ts for pre ssure 1 = kPa, 2 = inHg· psi ∗2

11 O-ring ZL112A-OR1-A 5 pcs./set

3

10

1 It is not possible to switch between models without valves and with valves.

2 Under the New Measurement Act, products with inHg・psi unit specifications are not permitted for use in Japan.

Page 20

Document No.ZL-OM01001

- 19 -

リード

How to Order Replacement Parts

Digital vacuum pressure switch

Supply valve/Release valve

How to order connector assembly

Lead wire assembly with connector

How to order

Page 21

Document No.ZL-OM01001

- 20 -

■Replacement Procedure for Filter element (ZL112A-FE1-A)

■Replacement procedure for Sound absorbing material (ZL112A-SE1-A)

Replacement Procedure

The suction cover can be attached or detached at

a touch.

Suction cover can be removed by pushing the

suction cover levers (2 pcs.) on the side. (It can be

removed from the opposite side as well.)

Replace the filter element assembled in the filter

case.

Check that the gasket is correctly fit in the groove

before mounting the suction cover.

Check that the lever hook is locked in the correct

position when mounting the suction cover. If the

hook or the lever is damaged or deformed, replace

the suction cover assembly.

The sound absorbing material can be replaced with a single operation.

Push the area where word “PUSH” is printed on the silencer cover in direction shown in Fig. 1.

The silencer cover will come out. (See Fig. 2) Remove the sound absorbing material 1 and 2 and

replace with the new ones. (See Fig. 3)

After replacing the sound absorbing material, place the end surface of the sound absorbing

material 1 to the end surface of the diffuser while engaging the hooks to the hook holes and

push the silencer cover back into the place. (See Fig. 4)

* When the product is mounted

with the silencer cover side facing

to the wall, maintenance shown in

the figures above is not possible.

Remove the product from the wall

for maintenance.

Page 22

Document No.ZL-OM01001

- 21 -

■Removal/Mounting of the Solenoid Valve or Pressure Switch Connector

Do not attempt to insert or pull out the connector while the power is on. Otherwise, it may cause

switch output malfunction.

Before removal or mounting of the pressure switch connector, it is necessary to remove the

silencer assembly (exhaust block assembly). Remove the silencer assembly (exhaust block

assembly) following the procedure below in order to remove or to mount the pressure switch

connector.

Exhaust from Ejector

1. The exhaust resistance should be as small as possible to obtain the full ejector performance.

There should be no shield around the exhaust port for the silencer exhaust specification. For the

port exhaust specification, the back pressure should be 5 kPa or less, as exhaust resistance is

generated with some piping bore sizes and piping lengths.

DO NOT block the exhaust port. The product will fracture or break.

2. If the sound absorbing material is clogged, it will cause a reduction in the ejector performance.

In particular, if it is used in a dusty environment, not only the filter element, but also the sound

absorbing material can be clogged. It is recommended to replace the sound absorbing material

periodically.

3. Air is exhausted from the connecting part between the silencer case and silencer cover. This

does not affect the performance of the product.

Remove the clip using flat blade

screwdriver from the bottom of the

product. Remove the silencer assembly

(exhaust block assembly) from the body.

Remove or mount the pressure switch

connector.

Page 23

Document No.ZL-OM01001

- 22 -

Specifications

■Ejector Specifications

*1 Values are at the standard supply pressure and based on SMC’s measurement standards.

They depend on atmospheric pressure (weather, altitude, etc.) and the measurement method.

*2 10 to 500 Hz for 2 hours in each direction of X, Y, and Z (De-energized, Initial value)

*3 3 times in each direction of X, Y, and Z (De-energized, Initial value)

■Weight

■Supply Valve/Release Valve Specifications

*1 Based on JIS B 8419: 2010 dynamic performance test (Standard type: Coil temperature 20°C, at rated voltage, without surge

voltage suppressor)

* Refer to the Web Catalog for details on valves.

■Vacuum Pressure Gauge Specifications

Page 24

Document No.ZL-OM01001

- 23 -

■Digital Vacuum Pressure Switch Specifications

Note 1) If the applied voltage fluctuates around the set value, the hysteresis must be set to a value more than the

fluctuating width, otherwise chattering will occur.

Note 2) When the analog voltage output is selected, the analog current output cannot be selected simultaneously.

Note 3) When the analog current output is selected, the analog voltage output cannot be selected simultaneously.

Note 4) For details of the pressure switch, please visit the SMC website URL: http://www.smcworld.com.

Page 25

Document No.ZL-OM01001

- 24 -

Circuit diagram

Without valve

ZL112A

With vacuum port adapter

ZL112A-GN

With vacuum pressure gauge

ZL112A-G

With digital vacuum pressure switch

ZL112A-D□□□

Port exhaust

ZL112AP□

Page 26

Document No.ZL-OM01001

- 25 -

Exhaust Characteristics/Flow Rate Characteristics/Time to Reach Vacuum

Vacuum Break Flow Adjusting Needle

With supply valve

ZL112A-K2□□□□

ZL112A-B2□□□□

With supply valve and release valve

ZL112A-K1□□□□

ZL112A-B1□□□□

Page 27

Document No.ZL-OM01001

- 26 -

Flow Characteristics Curve

■ How to read the flow characteristics curves of ejector

The flow characteristics curve shows the relationship

between the vacuum pressure and the suction flow of

the ejector/vacuum pump system. It shows that the

vacuum pressure changes when the suction flow

changes.

Generally, the curve shows the relationship at the

standard supply pressure of the ejector. In the graph on

the right, Pmax means the maximum vacuum pressure

and Qmax means the maximum suction flow.

The value shown in this graph is what is shown in this operation manual and the catalogs as the specifications.

The change of vacuum pressure is explained in sequence as follows.

1) When the vacuum port (V) is closed, the suction flow will be “0” and the vacuum pressure will reach its

maximum (Pmax).

2) When the vacuum port (V) is opened gradually, air will flow. (If there is bleeding air, the suction flow will

increase, but the vacuum pressure will decrease.): [State of P1 – Q1]

3) If the vacuum port (V) is opened fully, the suction flow will reach its maximum (Qmax), but the vacuum

pressure will become almost ”0” (atmospheric pressure).

As described above, the vacuum pressure changes when the suction flow changes.

Converting this to the adsorption state of the workpiece, the vacuum pressure reaches its maximum when the

pad and the piping on the vacuum port (V) have no leakage. Vacuum pressure decreases when there is a lot

of leakage when adsorbing a workpiece. When the amount of leakage and the maximum suction flow are

equal, the vacuum pressure becomes almost “0”, and it fails to adsorb the workpiece.

Vacuum pressure will not increase if the product is used for adsorption of permeable workpieces or in an

adsorption state with leakage. In such a case, sufficient verification and prior tests are required.

Suction flow

Vacuum pressure

Page 28

Document No.ZL-OM01001

- 27 -

Troubleshooting

■Problems when using ejector/ vacuum pump system and troubleshooting

Trouble

Cause

Countermeasures

Initial

adsorption

failure

(It fails to

adsorb

during the

trial run.)

The adsorption area is too small;

the adsorption force is not strong

enough compared with the weight

of the work piece and the force

applied during transfer.

Increase the lifting force.

→ Increase the pad diameter

→ Increase the number of pads.

Vacuum pressure is too small, due

to leakage at the adsorption part or

generation of a space between the

pad and the work piece due to

deformation of the work piece.

Reduce the vacuum leakage (by increasing the

vacuum pressure).

→ Change the pad configuration. Increase the

adsorption area.

→ Change the pad material (e.g. to a material that

fits the uneven surface).

→ If the workpiece is thin, change to a suitable pad.

Vacuum pressure is too small, due

to leakage of vacuum pressure

because of permeability of the work

piece.

Check the vacuum pressure and the suction flow.

→ Change to an ejector with larger suction flow.

Vacuum pressure is too small due

to leakage from the vacuum piping.

→ Repair vacuum leaking part.

Suction flow is too small.

(Ejector performance is not high

enough.)

→ Change to an ejector with larger suction flow.

Suction flow is too small because

the piping diameter is too small and

the length is too long, causing

restriction of suction flow from the

ejector.

→ Increase the piping diameter and decrease

length on the vacuum side.

Vacuum pressure and/or suction

flow are too small, because supply

pressure to the ejector is

insufficient.

→ Measure the supply pressure when the vacuum

is generated, and increase the supply pressure to

the standard supply pressure. Especially when more

than one product is operated at the same time in a

manifold, the supply air can be insufficient, causing

decrease of the supply pressure.

Vacuum pressure and/or suction

flow are too small, due to clogging

of the nozzle and the diffuser.

→ Remove foreign matter and substances sticking

to it. (Needs to be repaired.)

Perform flushing and mount an air filter on the

supply side to prevent it happening again.

Supply valve malfunction.<0}

Measure the supply voltage to the solenoid valve.

→ Revise the electrical circuit, wiring and

connectors.

→ Use within the rated voltage range.

Page 29

Document No.ZL-OM01001

- 28 -

Trouble

Cause

Countermeasures

Adsorption

response

is not

quick enough.

Internal capacity of the circuit on

the vacuum side is too large for

the ejector performance.

→ Reduce the internal capacity of the vacuum

circuit.

→ Change to an ejector with larger suction flow.

The set vacuum pressure for the

suction verification is too high,

making the time before

it reaches the set value longer.

Optimize the lifting force and change the setting to

have the suction verification of vacuum pressure as

low as possible.

Fluctuation of

vacuum

pressure

Supply pressure fluctuates.

Install a tank in the compressed air line on the

supply side, and reduce the air consumption of other

equipment.

The generated vacuum pressure

fluctuates, making the exhaust

noise intermittent at a certain

supply pressure range.

This is a phenomenon peculiar to ejectors which is

caused when the supply pressure is a little lower

than the standard supply pressure. → Increase or

decrease the supply pressure a small amount.

Vacuum

failure over

time (absorbs

properly

initially.)

Vacuum pressure is reduced,

due to clogging of the suction

filter (caused by dust in the

environment on the vacuum

side, sucking of foreign matter

from surface of work piece,

adsorption of humidity, etc.)

Replace the filter element with a new one.

Increase the number of suction filters (such as

ZFA, ZFB and ZFC)

Vacuum pressure is reduced,

because of the clogging of the

silencer (due to foreign matter

such as drainage and carbon

particles in the supply air).

Clean the supply air.

Control the drainage.

Add an air filter and a mist separator.

Replace the silencer with a new one.

Vacuum pressure and/or suction

flow is reduced due to clogging

of the nozzle and the diffuser.

→ Remove foreign matter and substances sticking

to it. (Needs to be repaired.)

Mount an air filter on the supply side to prevent it

from happening again.

Vacuum pressure and/or suction

flow is reduced due to clogging

of the nozzle and the diffuser.

→ Remove foreign matter and substances sticking

to it. (Needs to be repaired.)

Mount an air filter on the supply side to prevent it

happening again.

Page 30

Document No.ZL-OM01001

- 29 -

Trouble

Cause

Countermeasures

Vacuum

failure

over time

(absorbs

properly

initially.)

Adsorbing part has some problem,

such as deterioration of the vacuum

pad, or leakage due to frictional

wear.

→ Replace the vacuum pad with a new one.

→ Revise the adsorption conditions (such as

compatibility of the vacuum pressure with the

pad/work piece)

The filter case gasket has come off

when the filter element

was replaced.

Vacuum pressure leaks if the gasket has come off or

out of the groove when maintenance of the filter was

performed .

→ Check if it is mounted properly.

Defective operation caused by

energization of solenoid valve for

an extended period of time.

(Energized for 10 minutes or more

or operated with the duty ratio of

50% or more.)

→ Shorten the energization time of the solenoid

valve.

→ Provide forced ventilation in the operating

environment in order to prevent temperature

increase around the solenoid valve.

Work

piece is

not

released

smoothly.

Vacuum break flow is not large

enough.

→ Open the vacuum break flow adjusting needle.

→ For the ejector with individual ports for release

pressure (PD) and supply pressure (PV), increase

the pressure at the release pressure port.

The vacuum pad surface is worn

out, making it sticky.

→ Replace the vacuum pad with a new one.

→ Revise the material and configuration of the

vacuum pad.

→ Use a special pad which has a blasted adsorption

surface. (Made-to-order)

Vacuum pressure is too high.

→ Decrease the supply pressure to lower the

vacuum pressure.

→ Decrease the pressure in the piping on the

vacuum side with a vacuum regulator.

Work piece sticks to the pad due to

static electricity.

→ Use a conductive pad.

Vacuum break signal timing

is inappropriate .

If the pad is lifted before the work piece is

completely released from the pad, the work piece is

lifted together with the pad due to the viscosity of the

pad.

→ Revise the timing of the vacuum break and the

lifting of the pad.

Page 31

Document No.ZL-OM01001

- 30 -

If the countermeasures above are not effective, there may be some problem with the product. In that case, stop

using the product immediately without disassembling or repairing it.

If any of the examples below are applicable, there may be a problem with the product.

1) It was used with a voltage other than the rated voltage. 2) Lubricant was contained in the supply air. 3) Liquid

such as water was directly splashed onto the product body. 4) A strong impact was applied to the product. 5)

Drainage and dust got mixed into the supply air. 6) Other actions corresponding to the precautions mentioned in

this operation manual have occurred.

When removing the product from the application, be sure to confirm that the safety measures are taken, and

shut off the compressed air supply and the power supply before removing the product.

Page 32

Document No.ZL-OM01001

- 31 -

Revision history

4-14-1, Sotokanda, Chiyoda-ku, Tokyo 101-0021 JAPAN

Tel: + 81 3 5207 8249 Fax: +81 3 5298 5362

URL http://www.smcworld.com

Note: Specifications are subject to change without prior notice and any obligation on the part of the manufacturer.

© 2019 SMC Corporation All Rights Reserved

Loading...

Loading...