SMC Networks VF1000 Series, VF3000 Series, VF5000 Series Installation And Maintenance Manual

No. VF1000(V200)-TFM121**

Installation and Maintenance Manual

5 port solenoid valve

Series VF1000/3000/5000

1 Safety Instructions

This manual contains essential information for the protection of users and

others from possible injury and/or equipment damage.

• Read this manual before using the product, to ensure correct handling,

and read the manuals of related apparatus before use.

• Keep this manual in a safe place for future reference.

• These instructions indicate the level of potential hazard by label of

“Caution”, “Warning” or “Danger”, followed by important safety

information which must be carefully followed.

• To ensure safety of personnel and equipment the safety instructions in

this manual and the product catalogue must be observed, along with

other relevant safety practices.

Caution

Indicates a hazard with a low level of risk, which if not

avoided, could result in minor or moderate injury.

Warning

Indicates a hazard with a medium level of risk, which

if not avoided, could result in death or serious injury.

Danger

Indicates a hazard with a high level of risk, which if

not avoided, will result in death or serious injury.

Warning

• The compatibility of pneumatic equipment is the responsibility of the

person who designs the pneumatic system or decides its specifications.

Since the products specified here can be used in various operating

conditions, their compatibility with the specific pneumatic system must

be based on specifications or after analysis and/or tests to meet specific

requirements.

• Only trained personnel should operate pneumatically operated

machinery and equipment.

Compressed air can be dangerous if an operator is unfamiliar with it.

Assembly, handling or repair of pneumatic systems should be performed

by trained and experienced personnel.

• Do not service machinery/equipment or attempt to remove

components until safety is confirmed.

1) Inspection and maintenance of machinery/equipment should only be

performed after confirmation of safe locked-out control positions.

2) When equipment is to be removed, confirm the safety process as

mentioned above. Switch off air and electrical supplies and exhaust all

residual compressed air in the system.

3) Before machinery/equipment is re-started, ensure all safety measures

to prevent sudden movement of cylinders etc. (Supply air into the

system gradually to create back pressure, i.e. incorporate a soft-start

valve).

• Do not use this product outside of the specifications. Contact SMC

if it is to be used in any of the following conditions:

1) Conditions and environments beyond the given specifications, or if

the product is to be used outdoors.

2) Installations in conjunction with atomic energy, railway, air navigation,

vehicles, medical equipment, food and beverage, recreation equipment,

emergency stop circuits, press applications, or safety equipment.

3) An application which has the possibility of having negative effects on

people, property, or animals, requiring special safety analysis.

Caution

• Ensure that the air supply system is filtered to 5 microns.

2 Specifications

Refer to the operation manual for this product.

2.1 Specifications

Valve specifications

Fluid

Air

2 position single/3 position

0.15 to 0.7 MPa

Standard

2 position double

0.1 to 0.7 MPa

2 position single/3 position 0.15 to 1.0 MPa

Operating

pressure

range

High

pressure

2 position double 0.1 to 1.0 MPa 0.2

Ambient and fluid temperature -10 ~ 50 °C (No freezing)

Series VF1000 VF3000 VF5000

2 position single /

2 position double

10 Hz 10 Hz 5 Hz

Maximum operating

frequency

3 position - 3 Hz 3 Hz

Manual override

Non-locking push type, Push turn

locking slotted type, Push turn locking

lever type

Pilot exhaust method

Individual exhaust.

Common exhaust for main valve and

pilot valve (except VF1000 series)

Lubrication

Not required

Mounting position

Unrestricted

Impact / Vibration resistance

300/50 m/s²

(1)

Protection structure

Dust proof (G,H,L,M : IP40)

(D,Y,T : IP65*)

Table 1

Note)

Impact resistance: No malfunction occurred when it was tested with a

drop tester in the axial direction and at right angles to the main valve &

armature; in both energised & de-energised states and for every time in

each condition (Values at the initial period.)

Vibration resistance: No malfunction occurred in a one-sweep test

between 45 and 2000 Hz. Tests are performed at both energised and deenergised states in the axial direction and at right angles to the main valve

& armature. (Valves at the initial period.)

*Based on IEC60529. Compliance to IP65 is limited to the common

exhaust option.

Solenoid Specifications

Grommet (G),(H),

L plug connector (L),

M plug connector (M)

DIN terminal (D),

DIN (EN175301-803)

terminal (Y),

Conduit terminal (T)

Electrical entry

G,H,L,M D,Y,T

DC 24,12 V Coil rated

voltage

AC (50/60 Hz) 100,110,200,220,240

Allowable voltage fluctuation ±10% rated voltage

1,2,3

Standard

1.5 W

(With indicator light: 1.55 W)

1.5 W

(With indicator light: 1.75 W)

DC

Power saving

type

0.55 W

(With indicator light only)

0.75 W

(With indicator light only)

100V

110V [115 V]

200V

220V [230 V]

Power

Consumption

AC

240V

1.55 VA

(With indicator light: 1.7 VA)

Surge voltage suppressor

Diode

(Non-polar type is varistor)

Indicator light LED

LED

(Neon bulb when AC)

Table 2

1) In common between 110 VAC and 115 VAC, and between 220 VAC and

230 VAC.

2) For 115 VAC and 230 VAC, the allowable voltage is -15% ~ +5% of

rated voltage.

3) S, Z and T type (with power saving circuit), should be used with the

following allowable voltage fluctuation range due to a voltage drop caused

by the internal circuit.

24 VDC: -7% to +10%

12 VDC: -4% to +10%

2 Specifications (continued) 3 Installation (Continued

alves, tighten as follows:

C fitting, etc.

Note r the

) W

2) T

the proper tightening torques shown below.

・m)

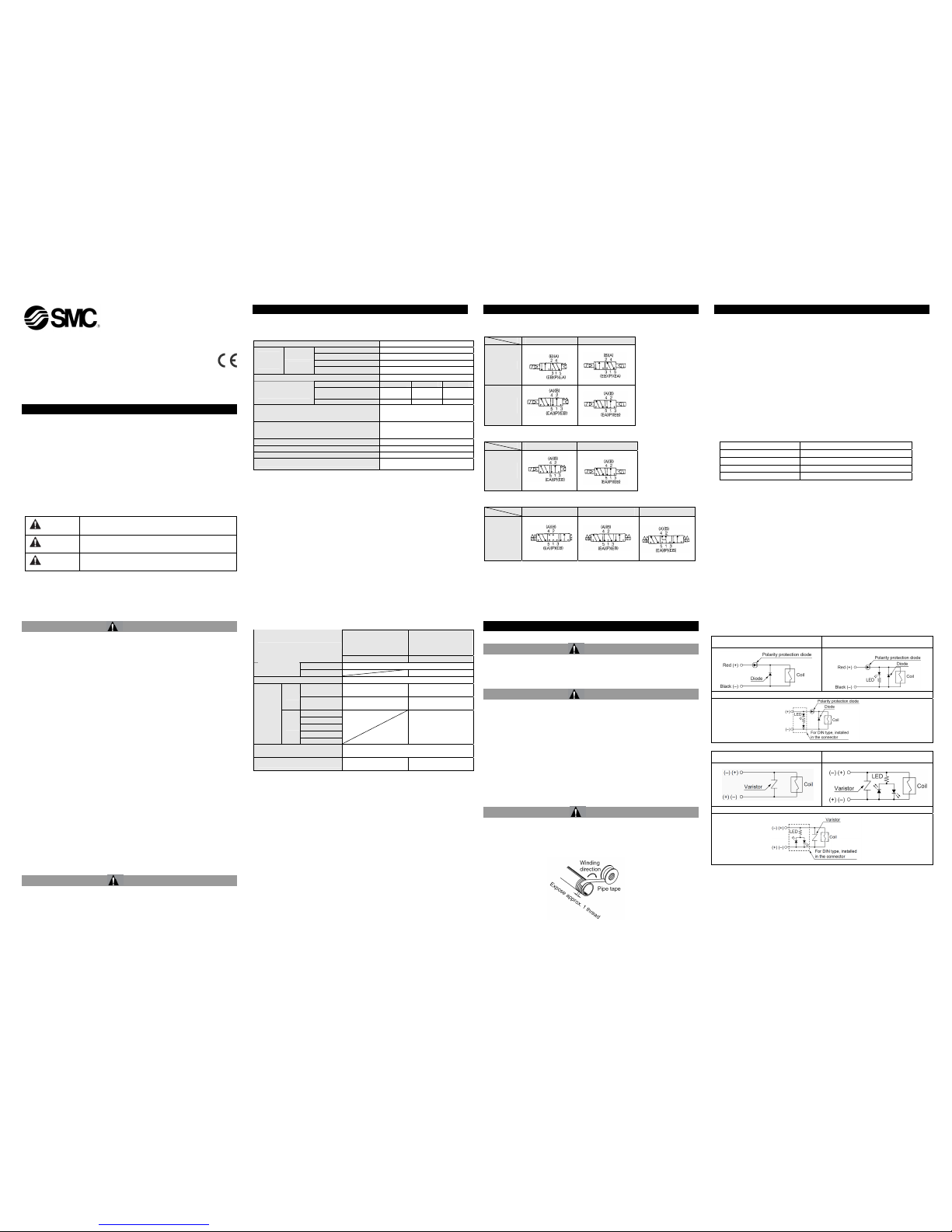

2.2 Symbol

Body ported

Single Double

VF1000

VF3000

VF5000

Base mounted

Single Double

VF3000

VF5000

Body ported / Base mounted

Closed centre Exhaust centre Pressure centre

VF3000

VF5000

Figure 1

3 Installation

3.1 Installation

Warning

• Do not install the product unless the safety instructions have been read

and understood.

3.2 Environment

Warning

• Do not use in an environment where corrosive gases, chemicals, salt

water or steam are present.

• Do not use in an explosive atmosphere.

• Do not expose to direct sunlight. Use a suitable protective cover.

• Do not install in a location subject to vibration or impact. Check the

product specifications.

• Do not mount in a location exposed to radiant heat.

• If it is used in an atmosphere where there is possible contact with water

droplets, oil, weld spatter, etc., exercise preventative measures.

• When the solenoid valve is mounted in a control panel or its energised

for a long time, make sure that the ambient temperature is within the

specification of the valve.

3.3 Piping

Caution

• Before piping make sure to clean up chips, cutting oil, dust etc.

• When installing piping or fittings, ensure sealant material does not enter

inside the port. When using seal tape, leave 1 thread exposed on the

end of the pipe/fitting.

• Tighten fittings according to appropriate tightening torque.

Figure 2

)

3.4 Con nection of fittings

When screwing fittings into v

(1) Follow the procedures belo

w when installing an SM

1) M5

After tightening the fitting by hand, use a wrench to tighten the fitting an

additional approximately 1/6 turn. However, if miniature fittings are

used, tighten an additional 1/4 turn with a tightening tool after

tightening by hand.

) If tightened excessively, the thread of the product may break o

gasket may defor

m. If tightened insufficiently, the thread of the

product may become loose. In either case, air leakage can occur.

hen fittings other than SMC fittings are used, follow the instructions of

(2

the respective fitting manufacturer.

hreads

Fasten with

Connection thread Tightening torque (N

1/8 7 to 9

1/4 12 to 14

3/8 22 to 24

1/2 28 to 30

Table 3

.5 Con nection of piping to products

uction manual to avoid mistakes

.6 Precauti ons on Design <DC>

□

With light/surge voltage suppressor (□Z)

3

When piping to a product, refer to its instr

regarding the supply port, etc.

3

・ Polar type

oltage suppressor ( S) With surge v

Grommet/L,M plug connecter

With light/surge voltage suppressor (□Z) DIN terminal/Conduit terminal

・Non-polar type

suppressor (□R)

With light/surge voltage suppressor (□U)

With surge voltage

Grommet/L,M plug connecter

With light/surge voltage suppressor (□U) DIN terminal/Conduit terminal

Table 4

• Please connect in accordance with olarity indication. (The non-polar type

•

•

the +,- p

can be used with the connections made either way.)

Please use caution regarding the allowable voltage fluctuation because there is

approximately a 1 V drop for a valve with polarity protection (For details, refer to

the solenoid specifications for the valve.)

When wiring is done at the factory, positive (+) is red and negative (-) is black.

No. VF1000(V200)-TFM121**

3 Installation (Continued)

Power saving circuit <DC type only>

Figure 3

Please use caution regarding th ble voltage fluctuation because

rectifier circuit.

terminal

e allowa

there is approximately a 0.5 V drop for a transistor. (For details, refer to the

solenoid specifications to the each valve.)

<AC>

is no “S” option, It is already built-in to the

There

Light/surge voltage suppressor (□Z) DIN terminal/Conduit

Figure 4

3.7 Residual voltage in the surg tion circuit. e protec

Caution

• Confirm the specifications

cir contains non-ordinary diodes, a

When the surge protection cuit

residual voltage that is in proportion to the protective elements and the

rated voltage will remain. Therefore, give consideration to surge voltage

protection of the controller. The following table lists the approximate

valves for the different types surge suppressor available.

In addition to this, the type of surge suppressor affects the response time

of the valve. Please see catalogue specifications for further details.

Residual voltage

DC

Surge voltage

24 12

AC

suppressor

S,Z Approx. 1 V Ap 1V prox.

R,U Approx. 32 V 47 V Approx. -

Table 5

3.8 Leakage voltage

Caution

ce (surge su is used for the protection of

Figure 5

AC coil: 8% or less of rated voltag

ous energisation

• Voltage leakage.

When a C-R devi

switching device, note tha

ppressor)

t voltage leakage will be increased by passing

voltage leakage through C-R device. Therefore, select circuit or device

which can limit residual voltage leakage to following value. And for

recovery failure due to voltage leakage, bleeder resistance should be

placed. For further information of bleeder resistance, contact SMC.

e

DC coil: 3% or less of rated voltage

3.9 Extended periods of continu

Caution

• Continuous energisation of the xtendevalve for e d periods of time may

•

have an adverse effect on the solenoid valve performance and the

peripheral equipment due to temperature rises caused by the heat

generation of the coil. Consult with SMC if valves will be continuously

energised for extended periods of time, or if the energised period per

day will be longer than the de-energised period. Use either DC

specification or power saving type.

When solenoid valves are mounted in a control panel, take measures

against radiation in order to ke

ep the valve temperature within the

specified range. Use special caution when three or more stations

sequentially aligned on the manifold are continuously energised since

this will cause a drastic temperature rise.

3 Installation (Continued)

3.10 Manual override operation

Warning

Without an electric signal for the solenoid valve the manual override is

used for switching the main valve.

When the manual override is operated, connected equipment will be

actuated. Confirm safety before operating.

■ Non-locking push type

■Push-turn locking slotted type [D type]

■Push-turn lever locking type [E type]

Figure 6

Caution

When locking the manual override on the push-turn locking types (D or E

type), be sure to push it down before turning. Turning without first

pushing it down can cause damage to the manual override and other

trouble such as air leakage, etc. [Torque : Less than 0.1N・m]

11 How to Use Plug Connector

3.

Caution

1. Attaching and detaching conn

connector unit between your

•

Figure 7

2. Crimping connection of lead socket.

rt the ends of the core

Figure 8

ectors

nd

• To attach a connector, hold the lever a

fingers and insert straight onto the pins of the solenoid valve so that the

lever’s pawl is pushed into the groove and locks.

To detach a connector, remove the pawl from the groove by pushing the

lever downward with your thumb, and pull the connector straight out.

wire and

Strip 3.2 to 3.7 mm at the end of lead wires, inse

wires evenly into the sockets, and then crimp with a crimping tool. When

this in done, take care that the coverings of the lead wires do not enter

the core wire crimping area.

3 Installation (Continued)

wires with sockets

es of the connector (+,- indication),

•

nnector, pull out the lead wire while

3. Attaching and detaching lead

• Attaching

ockets into the square hol

Insert the s

and continue to push the sockets all the way in until they lock by

hooking into the seats in the connector. (When they are pushed in, their

hooks open and they are locked automatically.) Then, confirm that they

are locked by pulling lightly on the lead wires.

Detaching

a socket from a co

To detach

pressing the socket’s hook with a stick with a thin tip (approx. 1 mm).

If the socket needs to used again, first spread the hook outward.

Figure 9

4 Settings and Programming

(based on IEC60529) are protected against

4.1 How to Use DIN terminal

Products with IP65 enclosures

dust and water, however, these products cannot be used in water.

Caution

Connection

set screw and pull the connector out of the solenoid valve

3.

4.

abtyre cords carefully because if

C

ck and housing, the cord entry direction

m

2

, 2-core or 3-core, equivalent to JIS C 3306.

Ltd.

1. Loosen the

terminal block.

2. After removing the set screw, insert a flat head screwdriver, etc. into the

notch on the bottom of the terminal block and pry it open, separating the

terminal block and the housing.

Loosen the terminal screws on the terminal block, insert the core of the

lead wire to the terminal, and attach securely with the terminal screws.

In case of a DC surge voltage suppressor attached type (polar: S and Z

types), connect wires corresponding to the polarity (+ or -) that is printed

on the terminal block.

Tighten the ground nut and fix the wire.

In the case of connecting wires, select c

those out of the specified range (Ø4.5 to Ø7) are used, it will not be able

to satisfy IP65 (enclosure). Tighten the ground nut and set screw within

the specified range of torque.

hanging the entry direction

lo

After separating the terminal b

can be changed by attaching the housing in the opposite direction.

* Be careful not to damage elements, etc. with the cord’s lead wires.

Caution

nd pull out the connector vertically without tilting to one side.

Plug in a

Compatible cable

Ø7

Cord O.D.: Ø4.5 to

(Reference) 0.5 to 1.5 m

Applicable crimped terminals

cified in JIS C 2805.

O-terminal: R1.25-4M that is spe

Y-terminal: 1.25-3L, which is released by JST Mfg. Co.,

Bar terminal: Size 1.5 or shorter.

Figure 10

4 Settings and Programming (Continued)

4.2 Circuit Diagram with Light/Surge Voltage Suppressor

Caution

Push down on the manual

override button with a small

screwdriver until it stops.

Release the screwdriver and

the manual override will

return.

Locked position

While pressing, turn in

the direction of the arrow

(90° clockwise). If it is

not turned, it can be

operated the same way

as the non-locking type.

Figure 11

4.3 DIN (EN175301-803) terminal

Y type DIN type terminal corresponds to the DIN connector with terminal

pitch 10 mm, which complies with EN175301-803B. Since the terminal

pitch is different from the D type DIN connector, these two types are not

interchangeable.

While pressing, turn it

the direction of the

arrow. If it is not

turned, it can be

operated the same

way as the nonlocking type.

Locked position

Figure 12

4.4 How to Use Conduit Terminal

Caution

Connection

1. Loosen the set screw and remove the terminal block

cover from the terminal block.

2. Loosen the terminal screws of the terminal block,

insert the core of the lead wire to the terminal, and

attach securely with the terminal screws.

In case of a DC surge voltage suppressor attached

type (S and Z type with limited polarity), care must

be taken that the positive and negative wires are

connected according to the figure on the right.

3. Tighten the ground nut and fix the cable.

In the case of connecting wires, select cabtyre cords carefully because if

those out of the specified range (Ø4.5 to Ø7) are used, it will not be able to

satisfy IP65 (enclosure). Tighten the ground nut and set screw within the

specified range of torque.

Compatible cable

Cord O.D. : Ø4.5 to Ø7

(Reference) 0.5 to 1.5 mm

2

, 2-core or 3-core, equivalent to JIS C 3306.

Applicable crimped terminals

O-terminal : Equivalent to R1.25-3 that is specified in JIS C 2805.

Y-terminal : Equivalent to 1.25-3, which is released by JST Mfg. Co., Ltd.

* Use O terminal when a ground terminal is used.

Figure 14

Figure 13

Loading...

Loading...