SMC Networks V100 Series Operation Manual

Doc. No.V100-OMV0001

3 Port Solenoid Valve

PRODUCT NAME

V100 Series

MODEL/ Series

Contents

Safety Instructions ---------------------------------------------------------------------------- 2,3

Design / Selection ---------------------------------------------------------------------------- 4,5

Mounting ---------------------------------------------------------------------------------------- 5

Piping -------------------------------------------------------------------------------------------- 6

Wiring -------------------------------------------------------------------------------------------- 6

Lubrication -------------------------------------------------------------------------------------- 7

Air Supply --------------------------------------------------------------------------------------- 7

Operating Environment ---------------------------------------------------------------------- 7

Maintenance ------------------------------------------------------------------------------------ 8

UL approved product -------------------------------------------------------------------------- 8

Specific Product Precautions --------------------------------------------------------------- 9,10

Trouble shooting ------------------------------------------------------------------------------- 11,12

-1-

No.V100-OMV0001

Safety Instructions

These safety instructions ar e int ended to prevent hazardous sit uations and/or equipme nt damage.

These instructions indicate the level of potential hazard with the labels of “Caution,” “Warning” or “Dan ger.”

They are all important notes for safety and must be followed in addition to International Standards

(ISO/IEC)*1) , and other safety regulations.

*1) ISO 4414: Pneumatic fluid power -- General rules relating to systems.

ISO 4413: Hydraulic fluid pow er -- General rules relating to systems.

IEC 60204-1: Safety of machinery -- Electrical equipment of machines .(Part 1: General r equir eme nts)

ISO 10218: Manipulating industrial robots -Safety.

etc.

Caution

Caution indicates a hazard with a low level of risk which, if not avoided, could result

in minor or moderate injury.

Warning

Warning

indicates a hazard with a medium level of risk which, if not avoided, could

result in death or serious injury.

Danger

Danger

indicates a hazard with a high level of risk which, if not avoided, will result

in death or serious injury.

Warning

1.

The compatibil ity of the pr oduc t i s the r es pon si bil ity of t he pers on wh o desi gn s the equi pm en t or

decides its specification s.

Since the product specified here is used under various operating conditions, its compatibility with specific

equipment must be dec ided by the person who d esigns the e quipm ent or decide s its spec ifications based o n

necessary analysis and test results.

The expected performance and safety assurance of the equipment will be the responsibility of the person who

has determined its compatibility with the product.

This person should also continuously review all specifications of the product r eferring to its latest catalog

information, with a view to giving due consideration to any possibility of equipment failure when configuring the

equipment.

2. Only personnel with appropriat e t r aining should operate machine r y and equipment.

The product specified here may become unsafe if handled incorrectly.

The assembly, operation and maintenance of machines or equipment including our products must be

performed by an operator who is appropriately trained and experienced.

3. Do not service or at tempt to remove product and machinery/equi pm ent until safety is confirmed.

1.The inspection and maintenance of machinery/equipment should only be performed after measures to

prevent falling or runaway of the driven objects have been confirmed.

2.When the product is to be removed, confirm that the safety measures as mentioned above are implemented

and the power from any appropriate source is cut, and read and understand the specific product precautions

of all relevant products carefully.

3. Before machinery/equipment is restarted, take measures to prevent unexpected operation and malfunction.

4. Contact SMC beforehand and take special consideration of safety measures if the product is to

be used in any of the following condi t ions.

1. Conditions and environments outside of the given specifications, or use outdoors or in a place exposed to

direct sunlight.

2. Installation on equipment in conjunction with atomic energy, railways, air navigation, space, shipping,

vehicles, military, medical treatment, combustion and recreation, or equipment in contact with food and

beverages, emergency stop circuits, clutch and brake circuits in press applications, safety equipment or

other applications unsuitable for the standard specifications described in the product catalog.

3. An application which could have negative effects on people, property, or animals requiring special safety

analysis.

4.Use in an interlock circuit, which requires the provision of double interlock for possible failure by using a

mechanical protective function, and periodical checks to confirm proper operation.

- 2 -

No.V100-OMV0001

Safety Instructions

Caution

1. The product is provided for use in manufacturing industries.

The product herein descr ibed is basically provided f or peaceful use in manufacturing indus trie s.

If considering using the product in other industries, consult SMC

beforehand and exchange

specifications or a contract if necessary.

If anything is unclear, contact your nearest sales branch.

Limited warranty and Disclaimer/Compliance Requirements

The product used is subject to the following “Limited warranty and Disclaimer” and “Compliance

Requirements”.

Read and accept them before using the prod uc t .

Limited warranty and Disclaimer

1.The warranty period of the product is 1 year in service or 1.5 years after the product is

delivered,whichever is first.

∗

2)

Also, the product may have speci f i ed durability, running distance or replacement parts. Please

consult your nearest sales branch.

2. For any failure or da mage reported within the warra nty period which is clearly our r es ponsibility,

a replacement product or necessary part s will be provided.

This limited warr anty applies only to our product independently, and not to any other damage

incurred due to the failure of the product.

3. Prior to using SMC products, pl ease read and understa nd the warranty terms and di sclaimers

noted in the specified catalog for the particular products.

∗

2) Vacu um pads are excluded from this 1 year warranty.

A vacuum pad is a consumable part , so i t i s warranted for a year after it i s del i vered.

Also, even within the warranty period, the wear of a product due to the us e of t he vacuum

pad or failure due to the deterioration of rubber material are not covered by the limited

warranty.

Compliance Requireme nt s

1.

The use of SMC products with production equipment for the manufacture of weapons of mass

destruction(WMD) or any other weapon is strictl y prohibited.

2. The exports of SMC products or technology from one country to another are governed by the

relevant

security laws and regulation of the countries involved in the transaction. Prior to the

shipment of a SMC product to another country, assure that all local rules governing that export

are known and f

ollowed.

Caution

SMC products are not intended for use as instruments for legal metrology.

Measurement instruments that SMC manufactures or sells have not been qualified by type approval tests

relevant to the metrology (measurement) laws of each country.

Therefore, SMC products cannot be used for business or certification ordained by the metrology

(measurement) laws of each country.

- 3 -

No.V100-OMV0001

Design / Selection

1. Confirm the specifications

Products represented in this instruction manual are designed

only for use in compressed air systems ( including vacuum).

Do not operate at pressures or temperatures, etc., beyond

the range of specifications, as this can cause damage or

malfunction. (Refer to the specifications.) Please contact

SMC when using a fluid other than compressed air (including

vacuum). We do not guarantee against any damage if the

product is used outside of the specification range.

2. Actuator drive

When an actuator, such as a cylinder, is to be driven using a

valve, take appropriate measures (cover installation or

approach prohibition) to prevent potential danger caused by

actuator operation.

3. Effect of back pressure when using a manifold.

Use caution when valves are used on a manifold, because

an actuator may malfunction due to

back-pressure.

4. Holding pressure (including vacuum).

Since the valve are subject to air leakage, they cannot be

used for applications such as holding pressure (including

vacuum) in a pressure vessel.

5. Not suitable for use as an emergency shut-off

valve, etc.

The valves listed in this instruction manual are not designed

for safety applications such as an emergency shutoff valve. If

the valves are used for the mentioned applications, additional

safety measures should be adopted.

6. Release of residual pressure

For maintenance purposes install a system for releasing

residual pressure.

7. Operation in a vacuum condition

When a valve is used for switching a vacuum, take measures

to install a suction filter or similar to prevent external dust

or other foreign matter from entering inside the valve. In

addition, at the time of vacuum adsorption, be sure to supply

a constant supply of vacuum. Failure to do so may result in

foreign matter sticking to the adsorption pad or air leakage,

causing the workpiece to drop.

8. Regarding a vacuum switch valve

For maintenance purposes install a system for releasing

residual pressure.

9. Ventilation

Provide ventilation when using a valve in a confined area,

such as in a closed control panel. For example, install a

ventilation opening, etc. in order to prevent pressure from

increasing inside of the confined area and to release the heat

generated by the valve.

10. Extended periods of continuous energization.

If a valve will be continuously energized for an extended

period of time, the temperature of the valve will increase due

to the heat generated by the coil assembly. This will likely

adversely affect the performance of the valve and any nearby

peripheral equipment. Therefore, if the valve is to be

energized for periods of longer than 30 minutes at a time or if

during the hours of operation the energized period per day is

longer than the de-energized period, we advise using a valve

with specifications listed below.

• Pilot operated: A 0.4 W or lower valve, such as the SY

series, or a valve with a power-saving circuit

11. Do not disassemble the product of make any

modifications, including addit ional mach ining.

It may cause human injury and/or an accident.

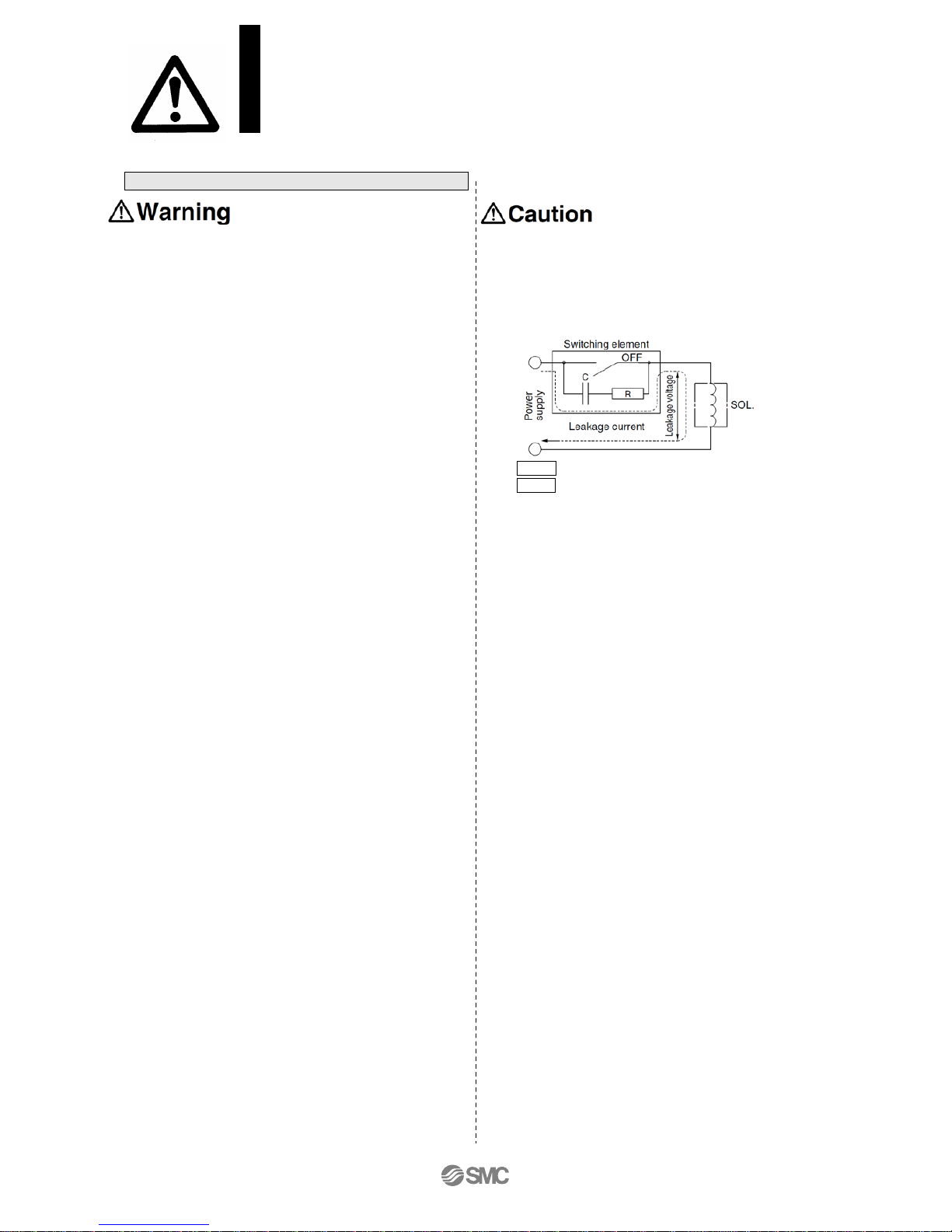

1. Leakage voltage

Take note that the leakage voltage will increase when a

resistor is used in parallel with a switching element or when a

C-R circuit (surge voltage suppressor) is used for protecting a

switching device because of the leakage voltage passing

through the C-R circuit. The suppressor residual leakage

voltage should be as follows.

DC coil

3% or less of the rated voltage

AC coil 8% or less of the rated voltage

2. Solenoid valve drive for AC with a solid state

output (SSR, TRIAC output, etc.)

1) Current leakage

When using a snubber circuit (C-R element) for surge

protection of the output, a very small amount of

electrical current will continue to flow even during the

OFF state. This results in the valve not returning. In a

situation where the tolerance is exceeded, as in the

above case, take measures to install a bleeder

resistor.

2) Minimum allowable load amount (Min. load current)

When the consumption current of a valve is less than

the output’s minimum allowable load volume or the

margin is small, the output may not switch normally.

Please contact SMC.

3) Solenoid valve with full wave rectifier circuit

When the solenoid valve built-in full wave rectif i er

circuit with AC specifications is used, a return failure of

the solenoid valve may occur depending on the kind of

triac output circuit. Carefully check this point when

selecting a SSR or sequencer. For details, contact the

SSR or sequencer manufacturer.

3. Surge voltage suppressor

1) The surge voltage suppressor built into the valve is

intended to protect the output contacts so that the surge

generated inside valve does not adversely affect the output

contacts. Therefore, if an overvoltage or overcurrent is

received from an external peripheral device, the surge

voltage protection element inside the valve is overloaded,

causing the element to break. In the worst case, the

breakage causes the electric circuit to enter short-circuit

status. If energizing continues while in this state, a large

current flows. This may cause secondary damage to the

output circuit, external peripheral device, or valve, and may

also cause a fire. So, take appropriate protective measures,

such as the installation of an overcurrent protection circuit

in the power supply or a drive circuit to maintain a sufficient

level of safety.

2) If a surge protection circuit contains nonstandard diodes,

such as Zener diodes or varistor, a residual voltage that is

in proportion to the protective circuit and the rated voltage

will remain. Therefore, take into consideration the surge

voltage protection of the controller. In the case of diodes,

the residual voltage is approximately 1V.

V100 Series

Precautions for 3 Port Solenoid Valve 1

Be sure to read before handling.

- 4 -

No.V100-OMV0001

Loading...

Loading...