SMC Networks TigerStack II SMC8848M,TigerStack II SMC8824M,8824M,8848M Installation Manual

TigerStack II

10/100/1000

Gigabit Ethernet Switch

◆ 24/48 auto-MDI/MDI-X 10/100/1000BASE-T ports

◆ 4 RJ-45 ports shared with 4 SFP transceiver slots

◆ 2 10GBASE extender module slots

◆ Non-blocking switching architecture

◆ Support for a redundant power unit

◆ Spanning Tree Protocol, RSTP, and MSTP

◆ Up to 32 LACP or static 8-port trunks

◆ Layer 2/3/4 CoS support through eight priority queues

◆ Layer 3/4 traffic priority with IP Precedence and IP DSCP

◆ Full support for VLANs with GVRP

◆ IGMP multicast filtering and snooping

◆ Manageable via console, Web, SNMP/RMON

◆ Security features: ACL, RADIUS, 802.1x

◆ Supports IPv4/IPv6, dual protocol stack

Installation Guide

SMC8824M

SMC8848M

38 Tesla

Irvine, CA 92618

Phone: (949) 679-8000

TigerStack II 10/100/1000

Installation Guide

From SMC’s Tiger line of feature-rich workgroup LAN solutions

February 2006

Pub. # 150200054300A

Information furnished by SMC Networks, Inc. (SMC) is believed to be accurate and reliable. However, no

responsibility is assumed by SMC for its use, nor for any infringements of patents or other rights of third

parties which may result from its use. No license is granted by implication or otherwise under any patent or

patent rights of SMC. SMC reserves the right to change specifications at any time without notice.

Copyright © 2006 by

SMC Networks, Inc.

38 Tesla

Irvine, CA 92618

All rights reserved. Printed in Taiwan

Trademarks:

SMC is a registered trademark; and EZ Switch, TigerStack and TigerSwitch are trademarks of SMC

Networks, Inc. Other product and company names are trademarks or registered trademarks of their

respective holders.

i

L

IMITED

W

ARRANTY

Limited Warranty Statement: SMC Networks, Inc. (“SMC”) warrants its products to be

free from defects in workmanship and materials, under normal use and service, for the

applicable warranty term. All SMC products carry a standard 90-day limited warranty from

the date of purchase from SMC or its Authorized Reseller. SMC may, at its own discretion,

repair or replace any product not operating as warranted with a similar or functionally

equivalent product, during the applicable warranty term. SMC will endeavor to repair or

replace any product returned under warranty within 30 days of receipt of the product.

The standard limited warranty can be upgraded to a Limited Lifetime* warranty by registering

new products within 30 days of purchase from SMC or its Authorized Reseller. Registration

can be accomplished via the enclosed product registration card or online via the SMC Web

site. Failure to register will not affect the standard limited warranty. The Limited Lifetime

warranty covers a product during the Life of that Product, which is defined as the period of

time during which the product is an “Active” SMC product. A product is considered to be

“Active” while it is listed on the current SMC price list. As new technologies emerge, older

technologies become obsolete and SMC will, at its discretion, replace an older product in its

product line with one that incorporates these newer technologies. At that point, the obsolete

product is discontinued and is no longer an “Active” SMC product. A list of discontinued

products with their respective dates of discontinuance can be found at:

http://www.smc.com/index.cfm?action=customer_service_warranty.

All products that are replaced become the property of SMC. Replacement products may be

either new or reconditioned. Any replaced or repaired product carries either a 30-day limited

warranty or the remainder of the initial warranty, whichever is longer. SMC is not responsible

for any custom software or firmware, configuration information, or memory data of

Customer contained in, stored on, or integrated with any products returned to SMC pursuant

to any warranty. Products returned to SMC should have any customer-installed accessory or

add-on components, such as expansion modules, removed prior to returning the product for

replacement. SMC is not responsible for these items if they are returned with the product.

Customers must contact SMC for a Return Material Authorization number prior to returning

any product to SMC. Proof of purchase may be required. Any product returned to SMC

without a valid Return Material Authorization (RMA) number clearly marked on the outside

of the package will be returned to customer at customer’s expense. For warranty claims within

North America, please call our toll-free customer support number at (800) 762-4968.

Customers are responsible for all shipping charges from their facility to SMC. SMC is

responsible for return shipping charges from SMC to customer.

ii

WARRANTIES EXCLUSIVE: IF AN SMC PRODUCT DOES NOT OPERATE AS

WARRANTED ABOVE, CUSTOMER’S SOLE REMEDY SHALL BE REPAIR OR

REPLACEMENT OF THE PRODUCT IN QUESTION, AT SMC’S OPTION. THE

FOREGOING WARRANTIES AND REMEDIES ARE EXCLUSIVE AND ARE IN

LIEU OF ALL OTHER WARRANTIES OR CONDITIONS, EXPRESS OR IMPLIED,

EITHER IN FACT OR BY OPERATION OF LAW, STATUTORY OR OTHERWISE,

INCLUDING WARRANTIES OR CONDITIONS OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE. SMC NEITHER ASSUMES NOR

AUTHORIZES ANY OTHER PERSON TO ASSUME FOR IT ANY OTHER

LIABILITY IN CONNECTION WITH THE SALE, INSTALLATION,

MAINTENANCE OR USE OF ITS PRODUCTS. SMC SHALL NOT BE LIABLE

UNDER THIS WARRANTY IF ITS TESTING AND EXAMINATION DISCLOSE THE

ALLEGED DEFECT IN THE PRODUCT DOES NOT EXIST OR WAS CAUSED BY

CUSTOMER’S OR ANY THIRD PERSON’S MISUSE, NEGLECT, IMPROPER

INSTALLATION OR TESTING, UNAUTHORIZED ATTEMPTS TO REPAIR, OR

ANY OTHER CAUSE BEYOND THE RANGE OF THE INTENDED USE, OR BY

ACCIDENT, FIRE, LIGHTNING, OR OTHER HAZARD.

LIMITATION OF LIABILITY: IN NO EVENT, WHETHER BASED IN CONTRACT

OR TORT (INCLUDING NEGLIGENCE), SHALL SMC BE LIABLE FOR

INCIDENTAL, CONSEQUENTIAL, INDIRECT, SPECIAL, OR PUNITIVE

DAMAGES OF ANY KIND, OR FOR LOSS OF REVENUE, LOSS OF BUSINESS, OR

OTHER FINANCIAL LOSS ARISING OUT OF OR IN CONNECTION WITH THE

SALE, INSTALLATION, MAINTENANCE, USE, PERFORMANCE, FAILURE, OR

INTERRUPTION OF ITS PRODUCTS, EVEN IF SMC OR ITS AUTHORIZED

RESELLER HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

SOME STATES DO NOT ALLOW THE EXCLUSION OF IMPLIED WARRANTIES

OR THE LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES FOR

CONSUMER PRODUCTS, SO THE ABOVE LIMITATIONS AND EXCLUSIONS

MAY NOT APPLY TO YOU. THIS WARRANTY GIVES YOU SPECIFIC LEGAL

RIGHTS, WHICH MAY VARY FROM STATE TO STATE. NOTHING IN THIS

WARRANTY SHALL BE TAKEN TO AFFECT YOUR STATUTORY RIGHTS.

* SMC will provide warranty service for one year following discontinuance from the active

SMC price list. Under the limited lifetime warranty, internal and external power supplies, fans,

and cables are covered by a standard one-year warranty from date of purchase.

SMC Networks, Inc.

38 Tesla

Irvine, CA 92618

iii

COMPLIANCES

FCC - Class A

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

You are cautioned that changes or modifications not expressly approved by the party

responsible for compliance could void your authority to operate the equipment.

You may use unshielded twisted-pair (UTP) for RJ-45 connections - Category 3 or better for

10 Mbps connections, Category 5 or better for 100 Mbps connections, Category 5, 5e, or 6

for 1000 Mbps connections. For fiber optic connections, you may use 50/125 or 62.5/125

micron multimode fiber or 9/125 micron single-mode fiber.

Industry Canada - Class A

This digital apparatus does not exceed the Class A limits for radio noise emissions from

digital apparatus as set out in the interference-causing equipment standard entitled “Digital

Apparatus,” ICES-003 of the Department of Communications.

Cet appareil numérique respecte les limites de bruits radioélectriques applicables aux appareils

numériques de Classe A prescrites dans la norme sur le matériel brouilleur: “Appareils

Numériques,” NMB-003 édictée par le ministère des Communications.

Japan VCCI Class A

C

OMPLIANCES

iv

CE Mark Declaration of Conformance for EMI and

Safety (EEC)

SMC contact for these products in Europe is:

SMC Networks Europe,

Edificio Conata II,

Calle Fructuós Gelabert 6-8, 2

o

, 4a,

08970 - Sant Joan Despí, Barcelona, Spain.

This information technology equipment complies with the requirements of the Council

Directive 89/336/EEC on the Approximation of the laws of the Member States relating to

Electromagnetic Compatibility and 73/23/EEC for electrical equipment used within certain

voltage limits and the Amendment Directive 93/68/EEC. For the evaluation of the

compliance with these Directives, the following standards were applied:

War ning:

Do not plug a phone jack connector in the RJ-45 port. This may damage this device.

Attention: Les raccordeurs ne sont pas utilisés pour le système téléphonique!

RFI Emission:

• Limit class A according to EN 55022:1998

• Limit class A for harmonic current emission according to

EN 61000-3-2/1995

• Limitation of voltage fluctuation and flicker in low-voltage supply

system according to EN 61000-3-3/1995

Immunity:

• Product family standard according to EN 55024:1998

• Electrostatic Discharge according to EN 61000-4-2:1995

(Contact Discharge: ±4 kV, Air Discharge: ±8 kV)

• Radio-frequency electromagnetic field according to EN 61000-4-3:1996

(80 - 1000 MHz with 1 kHz AM 80% Modulation: 3 V/m)

• Electrical fast transient/burst according to EN 61000-4-4:1995 (AC/

DC power supply: ±1 kV, Data/Signal lines: ±0.5 kV)

• Surge immunity test according to EN 61000-4-5:1995

(AC/DC Line to Line: ±1 kV, AC/DC Line to Earth: ±2 kV)

• Immunity to conducted disturbances, Induced by radio-frequency

fields: EN 61000-4-6:1996 (0.15 - 80 MHz with

1 kHz AM 80% Modulation: 3 V/m)

• Power frequency magnetic field immunity test according to

EN 61000-4-8:1993 (1 A/m at frequency 50 Hz)

• Voltage dips, short interruptions and voltage variations immunity test

according to EN 61000-4-11:1994 (>95% Reduction @10 ms, 30%

Reduction @500 ms, >95% Reduction @5000 ms)

LVD:

• EN 60950-1:2001

C

OMPLIANCES

v

Australia AS/NZS 3548 (1995) - Class A

SMC contact for products in Australia is:

SMC Communications Pty. Ltd.

Suite 18, 12 Tryon Road,

Lindfield NSW2070,

Phone: 61-2-94160437

Fax: 61-2-94160474

Safety Compliance

Warning: Fiber Optic Port Safety

Avertissment: Ports pour fibres optiques - sécurité sur le plan optique

Warnhinweis: Faseroptikanschlüsse - Optische Sicherheit

Power Cord Safety

Please read the following safety information carefully before installing the switch:

War ning:

Installation and removal of the unit must be carried out by qualified personnel only.

• The unit must be connected to an earthed (grounded) outlet to comply with international

safety standards.

• Do not connect the unit to an A.C. outlet (power supply) without an earth (ground)

connection.

• The appliance coupler (the connector to the unit and not the wall plug) must have a

configuration for mating with an EN 60320/IEC 320 appliance inlet.

• The socket outlet must be near to the unit and easily accessible. You can only remove power

from the unit by disconnecting the power cord from the outlet.

When using a fiber optic port, never look at the transmit laser while

it is powered on. Also, never look directly at the fiber TX port and

fiber cable ends when they are powered on.

Ne regardez jamais le laser tant qu’il est sous tension. Ne regardez

jamais directement le port TX (Transmission) à fibres optiques et les

embouts de câbles à fibres optiques tant qu’ils sont sous tension.

Niemals ein Übertragungslaser betrachten, während dieses

eingeschaltet ist. Niemals direkt auf den Faser-TX-Anschluß und auf

die Faserkabelenden schauen, während diese eingeschaltet sind.

N11846

CLASS I

LASER DEVICE

DISPOSITIF LASER

DE CLASSE I

LASERGER

DER KLASSE I

ÄT

C

OMPLIANCES

vi

• This unit operates under SELV (Safety Extra Low Voltage) conditions according to

IEC 60950. The conditions are only maintained if the equipment to which it is connected

also operates under SELV conditions.

France and Peru only

This unit cannot be powered from IT

†

supplies. If your supplies are of IT type, this unit must

be powered by 230 V (2P+T) via an isolation transformer ratio 1:1, with the secondary

connection point labelled Neutral, connected directly to earth (ground).

†

Impédance à la terre

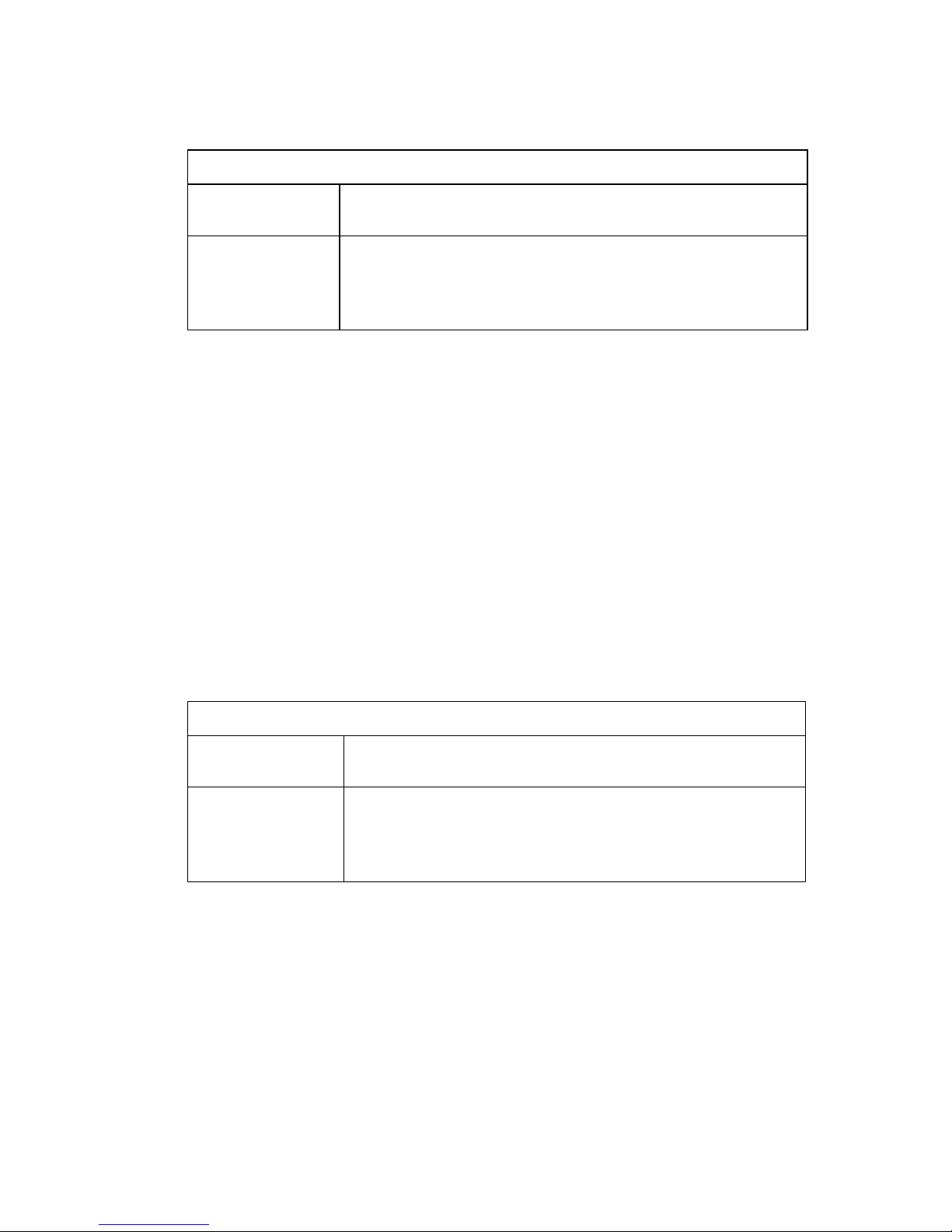

Important! Before making connections, make sure you have the correct cord set. Check it

(read the label on the cable) against the following:

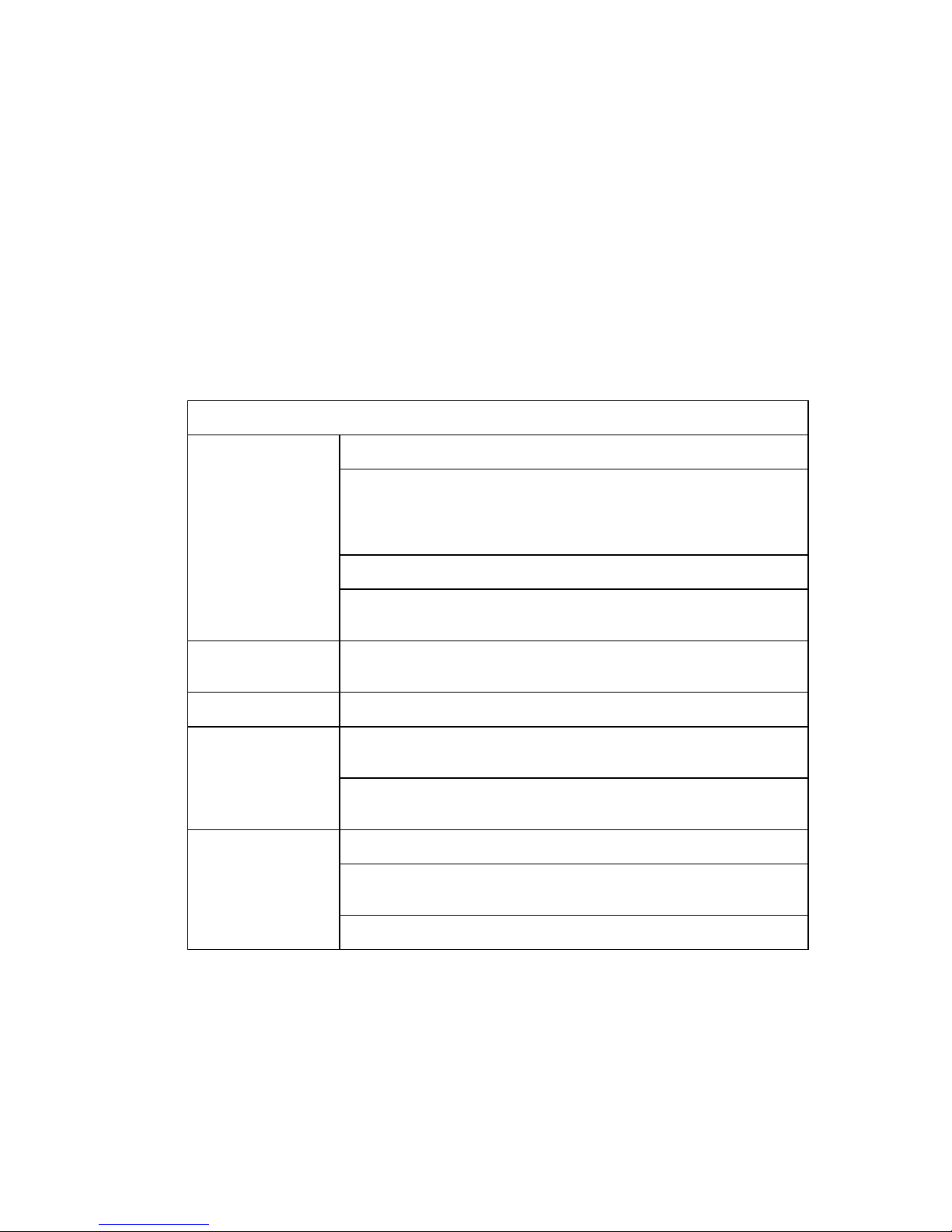

Power Cord Set

U.S.A. and Canada The cord set must be UL-approved and CSA certified.

The minimum specifications for the flexible cord are:

- No. 18 AWG - not longer than 2 meters, or 16 AWG.

- Type SV or SJ

- 3-conductor

The cord set must have a rated current capacity of at least 10 A

The attachment plug must be an earth-grounding type with NEMA

5-15P (15 A, 125 V) or NEMA 6-15P (15 A, 250 V) configuration.

Denmark The supply plug must comply with Section 107-2-D1, Standard

DK2-1a or DK2-5a.

Switzerland The supply plug must comply with SEV/ASE 1011.

U.K. The supply plug must comply with BS1363 (3-pin 13 A) and be

fitted with a 5 A fuse which complies with BS1362.

The mains cord must be <HAR> or <BASEC> marked and be of

type HO3VVF3GO.75 (minimum).

Europe The supply plug must comply with CEE7/7 (“SCHUKO”).

The mains cord must be <HAR> or <BASEC> marked and be of

type HO3VVF3GO.75 (minimum).

IEC-320 receptacle.

C

OMPLIANCES

vii

Veuillez lire à fond l'information de la sécurité suivante avant

d'installer le Switch:

AVERTISSEMENT: L’installation et la dépose de ce groupe doivent être confiés à un

personnel qualifié.

• Ne branchez pas votre appareil sur une prise secteur (alimentation électrique) lorsqu'il n'y a

pas de connexion de mise à la terre (mise à la masse).

• Vous devez raccorder ce groupe à une sortie mise à la terre (mise à la masse) afin de

respecter les normes internationales de sécurité.

• Le coupleur d’appareil (le connecteur du groupe et non pas la prise murale) doit respecter

une configuration qui permet un branchement sur une entrée d’appareil EN 60320/IEC

320.

• La prise secteur doit se trouver à proximité de l’appareil et son accès doit être facile. Vous

ne pouvez mettre l’appareil hors circuit qu’en débranchant son cordon électrique au niveau

de cette prise.

• L’appareil fonctionne à une tension extrêmement basse de sécurité qui est conforme à la

norme IEC 60950. Ces conditions ne sont maintenues que si l’équipement auquel il est

raccordé fonctionne dans les mêmes conditions.

France et Pérou uniquement:

Ce groupe ne peut pas être alimenté par un dispositif à impédance à la terre. Si vos

alimentations sont du type impédance à la terre, ce groupe doit être alimenté par une tension

de 230 V (2 P+T) par le biais d’un transformateur d’isolement à rapport 1:1, avec un point

secondaire de connexion portant l’appellation Neutre et avec raccordement direct à la terre

(masse).

Cordon électrique - Il doit être agréé dans le pays d’utilisation

Etats-Unis et

Canada:

Le cordon doit avoir reçu l’homologation des UL et un certificat de

la CSA.

Les spécifications minimales pour un cable flexible sont AWG No.

18, ouAWG No. 16 pour un cable de longueur inférieure

à

2 métres.

- type SV ou SJ

- 3 conducteurs

Le cordon doit être en mesure d’acheminer un courant nominal

d’au moins 10 A.

La prise femelle de branchement doit être du type à mise à la terre

(mise à la masse) et respecter la configuration NEMA 5-15P (15 A,

125 V) ou NEMA 6-15P (15 A, 250 V).

Danemark: La prise mâle d’alimentation doit respecter la section 107-2 D1 de

la norme DK2 1a ou DK2 5a.

C

OMPLIANCES

viii

Bitte unbedingt vor dem Einbauen des Switches die folgenden

Sicherheitsanweisungen durchlesen:

WARNUNG: Die Installation und der Ausbau des Geräts darf nur durch Fachpersonal

erfolgen.

• Das Gerät sollte nicht an eine ungeerdete Wechselstromsteckdose angeschlossen werden.

• Das Gerät muß an eine geerdete Steckdose angeschlossen werden, welche die

internationalen Sicherheitsnormen erfüllt.

• Der Gerätestecker (der Anschluß an das Gerät, nicht der Wandsteckdosenstecker) muß

einen gemäß EN 60320/IEC 320 konfigurierten Geräteeingang haben.

• Die Netzsteckdose muß in der Nähe des Geräts und leicht zugänglich sein. Die

Stromversorgung des Geräts kann nur durch Herausziehen des Gerätenetzkabels aus der

Netzsteckdose unterbrochen werden.

• Der Betrieb dieses Geräts erfolgt unter den SELV-Bedingungen

(Sicherheitskleinstspannung) gemäß IEC 60950. Diese Bedingungen sind nur gegeben,

wenn auch die an das Gerät angeschlossenen Geräte unter SELV-Bedingungen betrieben

werden.

Suisse: La prise mâle d’alimentation doit respecter la norme SEV/ASE

1011.

Europe La prise secteur doit être conforme aux normes CEE 7/7

(“SCHUKO”)

LE cordon secteur doit porter la mention <HAR> ou <BASEC>

et doit être de type HO3VVF3GO.75 (minimum).

Stromkabel. Dies muss von dem Land, in dem es benutzt wird geprüft werden:

Schweiz Dieser Stromstecker muß die SEV/ASE 1011Bestimmungen

einhalten.

Europe Das Netzkabel muß vom Typ HO3VVF3GO.75

(Mindestanforderung) sein und die Aufschrift <HAR> oder

<BASEC> tragen.

Der Netzstecker muß die Norm CEE 7/7 erfüllen (”SCHUKO”).

Cordon électrique - Il doit être agréé dans le pays d’utilisation

C

OMPLIANCES

ix

Warnings and Cautionary Messages

War nings (in German)

Environmental Statement

The manufacturer of this product endeavours to sustain an environmentally-friendly policy

throughout the entire production process. This is achieved though the following means:

• Adherence to national legislation and regulations on environmental production standards.

• Conservation of operational resources.

• Waste reduction and safe disposal of all harmful un-recyclable by-products.

• Recycling of all reusable waste content.

• Design of products to maximize recyclables at the end of the product’s life span.

• Continual monitoring of safety standards.

Warning: This product does not contain any serviceable user parts.

Warning: Installation and removal of the unit must be carried out by qualified personnel

only.

Warning: When connecting this device to a power outlet, connect the field ground lead

on the tri-pole power plug to a valid earth ground line to prevent electrical

hazards.

Warning: This switch uses lasers to transmit signals over fiber optic cable. The lasers are

compliant with the requirements of a Class 1 Laser Product and are inherently

eye safe in normal operation. However, you should never look directly at a

transmit port when it is powered on.

Caution: Wear an anti-static wrist strap or take other suitable measures to prevent

electrostatic discharge when handling this equipment.

Caution: Do not plug a phone jack connector in the RJ-45 port. This may damage this

device. Les raccordeurs ne sont pas utilisé pour le système téléphonique!

Caution: Use only twisted-pair cables with RJ-45 connectors that conform to FCC

standards.

Achtung: Dieses Produkt enthält keine Teile, die eine Wartung vom Benutzer benötigen.

Achtung: Installation und Deinstallation des Gerätes müssen von qualifiziertem

Servicepersonal durchgeführt werden.

Achtung: Wenn das Gerät an eine Steckdose angeschlossen wird, muß der Masseanschluß

am dreipoligen Netzstecker mit Schutzerde verbunden werden, um elektrische

Gefahren zu vermeiden.

Achtung: Dieses Gerät nutzt Laser zur Signalübertragung über Glasfasern. Die Laser

entsprechen den Anforderungen an eine Lasereinrichtung der Klasse 1 und sind

durch ihre Bauart im normalen Betrieb sicher für die Augen. Trotzdem sollte

niemals direkt in den einen Übertragungskanal geblickt werden, wenn er

eingeschaltet ist.

C

OMPLIANCES

x

End of Product Life Span

This product is manufactured in such a way as to allow for the recovery and disposal of all

included electrical components once the product has reached the end of its life.

Manufacturing Materials

There are no hazardous nor ozone-depleting materials in this product.

Documentation

All printed documentation for this product uses biodegradable paper that originates from

sustained and managed forests. The inks used in the printing process are non-toxic.

Purpose

This guide details the hardware features of the switches, including Its physical and

performance-related characteristics, and how to install each switch.

Audience

This guide is for system administrators with a working knowledge of network management.

You should be familiar with switching and networking concepts.

Zielgruppe Dieser Anleitung ist fuer Systemadministratoren mit Erfahrung im

Netzwerkmangement. Sie sollten mit Switch- und Netzwerkkonzepten vertraut sein.

Related Publications

The following publication gives specific information on how to operate and use the

management functions of the switches:

The SMC8824M, SMC8848M Management Guide

Also, as part of both switches firmware, there is an online web-based help that describes all

management related features.

xi

T

ABLE OF

C

ONTENTS

1 About the TigerStack II 10/100/1000 . . . . . . . . . . . . . 1-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Switch Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Network Management Options . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Description of Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

10/100/1000BASE-T Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

SFP Slots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

10 Gigabit Ethernet Module Slots . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Stacking Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Port and System Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Optional Redundant Power Supply . . . . . . . . . . . . . . . . . . . . . . . 1-8

Power Supply Sockets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Optional Media Extender Module . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Features and Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Expandability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

2 Network Planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Introduction to Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Application Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Collapsed Backbone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Network Aggregation Plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Remote Connections with Fiber Cable . . . . . . . . . . . . . . . . . . . . 2-4

Making VLAN Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Application Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

3 Installing the Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Selecting a Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Ethernet Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Equipment Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Package Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Optional Rack-Mounting Equipment . . . . . . . . . . . . . . . . . . . . . 3-3

T

ABLE OF CONTENTS

xii

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Rack Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Desktop or Shelf Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Installing an Optional Module into the Switch . . . . . . . . . . . . . . . . . . . . 3-7

Installing an Optional

SFP or XFP Transceiver into the Switch . . . . . . . . . . . . . . . . . . . . 3-8

Connecting Switches in a Stack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Stacking Topologies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Connecting to a Power Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Connecting to the Console Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Wiring Map for Serial Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

4 Making Network Connections . . . . . . . . . . . . . . . . . . . 4-1

Connecting Network Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Twisted-Pair Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Cabling Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Connecting to PCs, Servers, Hubs and Switches . . . . . . . . . . . . 4-2

Network Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Fiber Optic SFP Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

10 Gbps Fiber Optic Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Connectivity Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

1000BASE-T Cable Requirements . . . . . . . . . . . . . . . . . . . . . . . 4-8

10 Gbps Ethernet Collision Domain . . . . . . . . . . . . . . . . . . . . . . 4-8

1000 Mbps Gigabit Ethernet Collision Domain . . . . . . . . . . . . . 4-9

100 Mbps Fast Ethernet Collision Domain . . . . . . 4-10

10 Mbps Ethernet Collision Domain . . . . . . . . . . . . . . . . . . . . 4-10

Cable Labeling and Connection Records . . . . . . . . . . . . . . . . . . . . . . . 4-11

T

ABLE OF CONTENTS

xiii

APPENDICES:

A Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Diagnosing Switch Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Diagnosing Power Problems with the LEDs . . . . . . . . . . . . . . . A-2

Power and Cooling Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

In-Band Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Stack Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

B Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

Twisted-Pair Cable and Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . B-1

10BASE-T/100BASE-TX Pin Assignments . . . . . . . . . . . . . . . . B-2

Straight-Through Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Crossover Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

1000BASE-T Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Cable Testing for Existing Category 5 Cable . . . . . . . . . . . . . . . B-5

Adjusting Existing Category 5 Cabling to Run 1000BASE-T . . B-6

Fiber Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

C Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

Physical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Switch Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Management Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

Compliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

Extender Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

10G Extender Module (XFP) . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

D German Instructions . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Eine Site Auswählen (Selecting a Site - German) . . . . . . . . . . . . . . . . . .D-1

Montage (Rack Mounting Instructions - German) . . . . . . . . . . . . . . . . .D-2

Rack-Montage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-2

E Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . .E-1

T

ABLE OF CONTENTS

xiv

Glossary

Index

xv

T

ABLES

Table 1-1 Port Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Table 1-2 System Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Table 1-3 Module LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Table 3-1 Optional Transcievers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Table 3-2 Wiring Map for Serial Cable . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Table 4-1 Maximum 10GBASE-SR 10 Gigabit Ethernet Cable Length 4-8

Table 4-2 Maximum 10GBASE-LR 10 Gigabit Ethernet Cable Length 4-9

Table 4-3 Maximum 10GBASE-ER 10 Gigabit Ethernet Cable Length 4-9

Table 4-4 Maximum 1000BASE-T Gigabit Ethernet Cable Length . . . . 4-9

Table 4-5 Maximum 1000BASE-SX Fiber Optic Cable Length . . . . . . . 4-9

Table 4-6 Maximum 1000BASE-LX Fiber Optic Cable Length . . . . . . . 4-9

Table 4-7 Maximum 1000BASE-ZX Fiber Optic Cable Length . . . . . 4-10

Table 4-8 Maximum Fast Ethernet Cable Length . . . . . . . . . . . . . . . . . 4-10

Table 4-9 Maximum Ethernet Cable Length . . . . . . . . . . . . . . . . . . . . . 4-10

Table A-1 Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Table A-2 Power/RPS LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

Table B-1 10/100BASE-TX MDI and MDI-X Port Pinouts . . . . . . . . . B-2

Table B-2 1000BASE-T MDI and MDI-X Port Pinouts . . . . . . . . . . . . . B-5

Table E-1 TigerStack II 10/100/1000 Products and Accessories . . . . . .E-1

xvi

F

IGURES

Figure 1-1 Front Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Figure 1-2 Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Figure 1-3 Port LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Figure 1-4 System LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Figure 1-5 Power Supply Sockets . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Figure 1-6 Single-Port 10GBASE Module (XFP) . . . . . . . . . . . . . . . 1-8

Figure 2-1 Collapsed Backbone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Figure 2-2 Network Aggregation Plan . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Figure 2-3 Remote Connections with Fiber Cable . . . . . . . . . . . . . . 2-4

Figure 2-4 Making VLAN Connections . . . . . . . . . . . . . . . . . . . . . . . 2-5

Figure 3-1 RJ-45 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Figure 3-2 Attaching the Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Figure 3-3 Installing the Switch in a Rack . . . . . . . . . . . . . . . . . . . . . 3-5

Figure 3-4 Attaching the Adhesive Feet . . . . . . . . . . . . . . . . . . . . . . 3-6

Figure 3-5 Installing an Optional Module . . . . . . . . . . . . . . . . . . . . . 3-7

Figure 3-6 Inserting an SFP Transceiver into a Slot . . . . . . . . . . . . . 3-8

Figure 3-7 Making Stacking Connections . . . . . . . . . . . . . . . . . . . . 3-10

Figure 3-8 Power Socket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Figure 3-9 Serial Port (RJ-11) Pin-Out . . . . . . . . . . . . . . . . . . . . . . . 3-13

Figure 4-1 Making Twisted-Pair Connections . . . . . . . . . . . . . . . . . . 4-2

Figure 4-2 Wiring Closet Connections . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Figure 4-3 Making Connections to SFP Transceivers . . . . . . . . . . . . 4-5

Figure 4-4 Connecting to an XFP Transceiver . . . . . . . . . . . . . . . . . 4-7

Figure B-1 RJ-45 Connector Pin Numbers . . . . . . . . . . . . . . . . . . . . B-1

Figure B-2 Straight-through Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Figure B-3 Crossover Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

1-1

C

HAPTER

1

A

BOUT THE

T

IGERSTACK

II 10/100/1000

Overview

SMC’s TigerStack II 10/100/1000 SMC8824M and SMC8848M are

intelligent multilayer switches (Layer 2, 3) with 24/48 10/100/

1000BASE-T ports, four of which are combination ports

*

that are shared

with four SFP transceiver slots (see Figure 1-1, Ports 21-24/45-48). The

rear panel provides two slots for single-port 10 Gigabit Ethernet

hot-swappable expansion modules, and two stacking ports. Units can be

stacked up to eight high through the built-in stacking ports that provide a

4

8 Gbps stack backplane.

The switches include an SNMP-based management agent embedded on

the main board, which supports both in-band and out-of-band access for

managing the stack.

These switches can easily enhance your network with full support for

Spanning Tree Protocol, Multicast Switching, Virtual LANs, and IP

routing. It brings order to poorly performing networks by segregating

them into separate broadcast domains with IEEE 802.1Q compliant

VLANs, empowers multimedia applications with multicast switching and

CoS services, and eliminates conventional router bottlenecks.

* If an SFP transceiver is plugged in, the corresponding RJ-45 port is disabled for ports 21-24 on

SMC8824M or ports 45-48 on SMC8848M.

A

BOUT THE TIGERSTACK

II 10/100/1000

1-2

These switches can be used to augment or completely replace slow legacy

routers, off-loading local IP traffic to release valuable resources for non-IP

routing or WAN access. With wire-speed performance, these switches can

significantly improve the throughput between IP segments or VLANs.

Figure 1-1 Front Panels

Figure 1-2 Rear Panel

Switch Architecture

These Gigabit Ethernet switches employ a wire-speed, non-blocking

switching fabric. This permits simultaneous wire-speed transport of

multiple packets at low latency on all ports. The switches also feature

full-duplex capability on all ports, which effectively doubles the bandwidth

of each connection.

For communications between different VLANs, these switches use IP

routing. For communications within the same VLAN, they use

store-and-forward switching to ensure maximum data integrity. With

store-and-forward switching, the entire packet must be received into a

buffer and checked for validity before being forwarded. This prevents

errors from being propagated throughout the network.

1

2

3

4

5

6

7

8910

11

12

13

14

15

16

17

18 19 20

21 222324

37

38

39

40

41

42 43 44

45 464748

25

26

27

28

29

30 31 32

33 343536

Master

Select

StackID

45 46

47

48

Console

Pwr

RPS

Diag

StackMaster

TigerStackII

10/100/1000

8848M

Module

StackLink

SMC8848M

10/100/1000 Mbps RJ-45 Ports

System Indicators

Port Status LEDs

Console Port

Stack ID

SFP Slots

SMC8824M

Master

Select

StackID

Pwr

Stack

Master

RPS

Diag

21 22

23

24

Console

TigerStackII

10/100/1000

8824M

StackLink

Module

1

2

3

4

5

6

7

8910

11

12

13

14

15

16

17

18 19 20

21 222324

Stacking Ports

Power Socket

Redundant Power Socket

Module Slots

M1 M2

D

ESCRIPTION OF HARDWARE

1-3

These switches include built-in stacking ports that enable up to eight units

to be connected together through a 4

8 Gbps stack backplane. The switch

stack can be managed from a master unit using a single IP address.

These switches also include two slots on the rear panel for slide-in

single-port 10GBASE modules with XFP transceivers.

Network Management Options

These switches contain a comprehensive array of LEDs for “at-a-glance”

monitoring of network and port status. They also include a management

agent that allows you to configure or monitor the switch using its

embedded management software, or via SNMP applications. To manage

each switch, you can make a direct connection to the console port

(out-of-band), or you can manage the switches through a network

connection (in-band) using Telnet, the on-board web agent, or

SNMP-based network management software.

For a detailed description of both switches’ advanced features, refer to the

Management Guide.

Description of Hardware

10/100/1000BASE-T Ports

The switches contain 24/48 RJ-45 ports that operate at 10 Mbps or

100 Mbps, half or full duplex, or at 1000 Mbps, full duplex. Because all

ports on these switches support automatic MDI/MDI-X operation, you

can use straight-through cables for all network connections to PCs or

servers, or to other switches or hubs. (See “1000BASE-T Pin

Assignments” on page B-5.)

Each of these ports support auto-negotiation, so the optimum

transmission mode (half or full duplex), and data rate (10, 100, or

1000 Mbps) can be selected automatically. If a device connected to one of

these ports does not support auto-negotiation, the communication mode

of that port can be configured manually.

A

BOUT THE TIGERSTACK

II 10/100/1000

1-4

SFP Slots

The Small Form Factor Pluggable (SFP) transceiver slots are shared with

four of the RJ-45 ports (ports 21-24 for the SMC8824M and ports 45-48

for the SMC8848M). In its default configuration, if an SFP transceiver

(purchased separately) is installed in a slot and has a valid link on its port,

the associated RJ-45 port is disabled and cannot be used. The switch can

also be configured to force the use of an RJ-45 port or SFP slot, as

required.

10 Gigabit Ethernet Module Slots

These switches include two slots on the rear panel for hot-swappable

single-port 10GBASE modules with XFP transceivers. Refer to “Optional

Media Extender Module” on page 1-8 for more information on this

module and the supported 10G transceivers.

Stacking Ports

Each unit includes two stacking ports that provide a 48 Gbps high-speed

serial stack backplane connection. Up to eight SMC8824M or SMC8848M

switches can be connected together using optional stacking cables. Note

that the 24-port and 48-port switches can be mixed in the same stack. The

Stack Master button enables one switch in the stack to be selected as the

Master unit for managing the entire stack.

D

ESCRIPTION OF HARDWARE

1-5

Port and System Status LEDs

These switches include a display panel for key system and port indications

that simplify installation and network troubleshooting. The LEDs, which

are located on the front panel for easy viewing, are shown below and

described in the following tables.

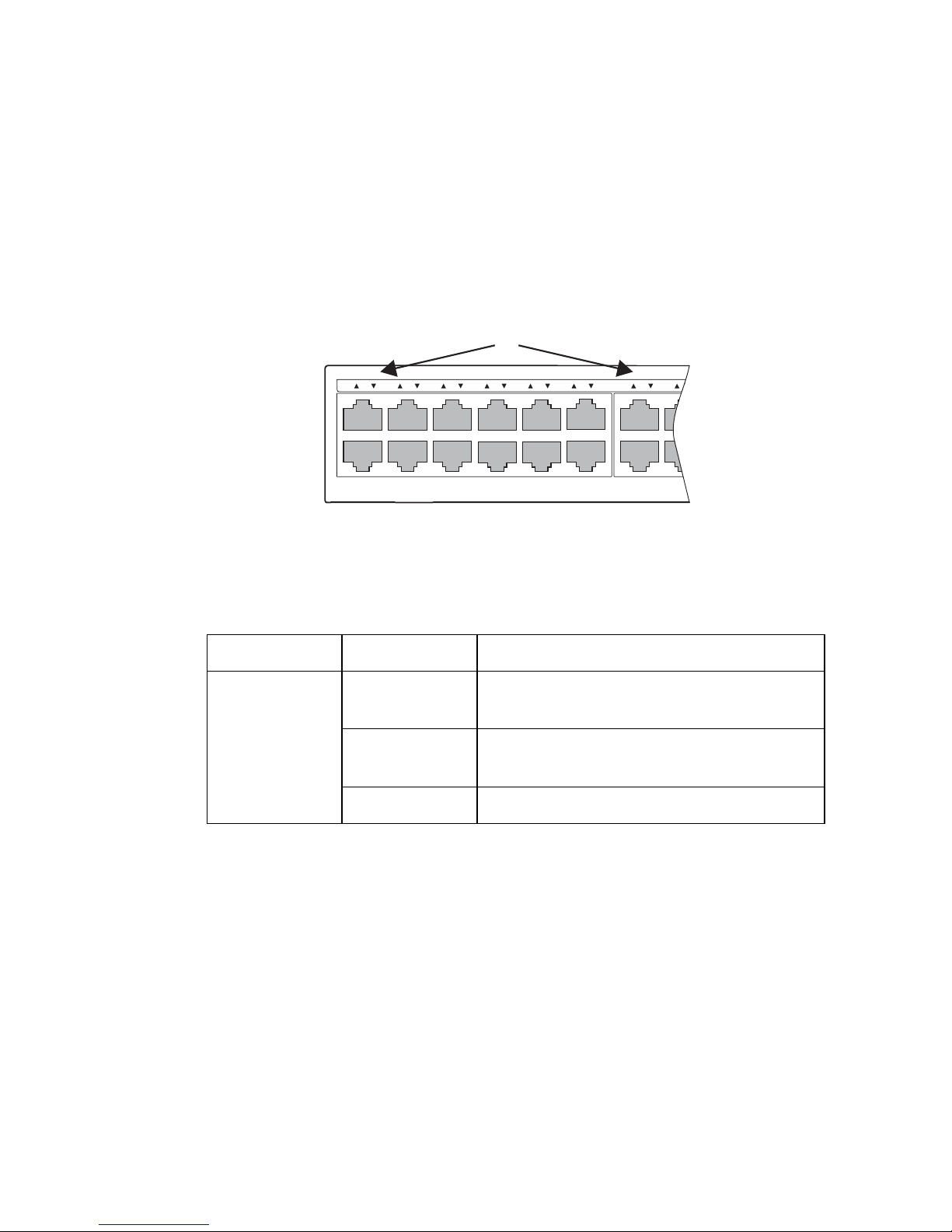

Figure 1-3 Port LEDs

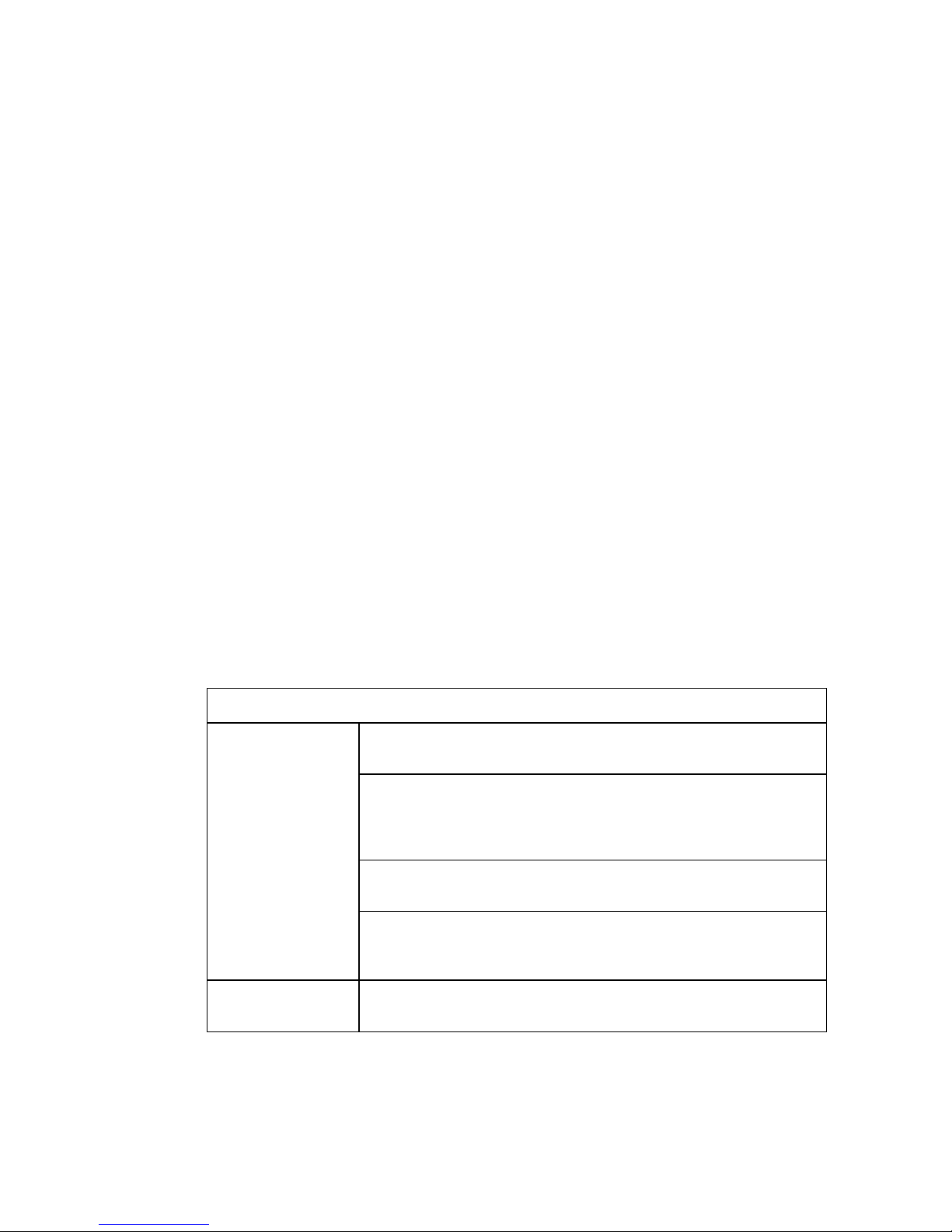

Table 1-1 Port Status LEDs

LED Condition Status

1-24/1-48

(Link/Activity/

Speed)

On/Flashing

Amber

Port has a valid link at 10 or 100 Mbps.

Flashing indicates activity.

On/Flashing

Green

Port has a valid link at 1000 Mbps. Flashing

indicates activity.

Off There is no link on the port.

Port Status LEDs

1

2

3

4

5

6

7

8910

11

12

13

14

15

A

BOUT THE TIGERSTACK

II 10/100/1000

1-6

Figure 1-4 System LEDs

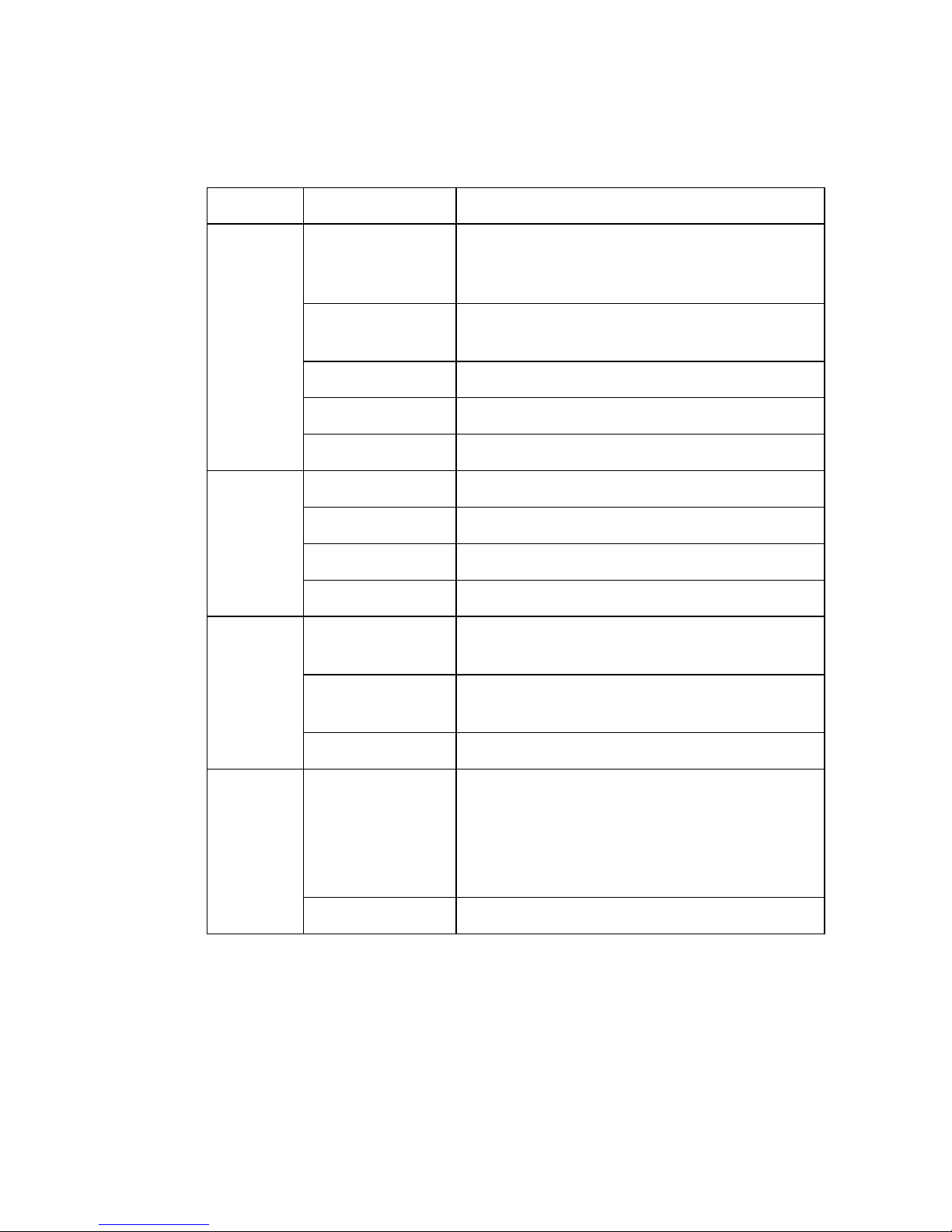

Table 1-2 System Status LEDs

LED Condition Status

Power Green Internal power is operating normally.

Amber Internal power supply fault.

Off Power off.

Diag Flashing Green System self-diagnostic test in progress.

Green System self-diagnostic test successfully

completed.

Amber System self-diagnostic test has detected a fault.

RPS Green Redundant power supply is receiving power.

Amber Fault in redundant power supply, including

thermal or fan failure.

Off Redundant power supply is off or not plugged

in.

System Status LEDs

Master

Select

Stack ID

45 46

47

48

Console

Pwr

RPS

Diag

Stack Master

TigerStack II

10/100/1000

8848M

Module

Stack Link

D

ESCRIPTION OF HARDWARE

1-7

Stack

Master

Green Switch is the Master unit of the stack. State

may include topology discovery, IP

assignment, or normal operations.

Flashing Green Switch is the Master unit of the stack, system

is initializing.

Amber Switch is operating as a Slave unit in the stack.

Flashing Amber System in Master arbitration/election state.

Off System in standalone mode.

Stack

Link

Green Uplink and downlink operating normally.

Flashing Green Uplink has failed.

Flashing Amber Downlink has failed.

Off No stacking link present.

Module Green An expansion module is installed and

operating normally.

Amber An expansion module is installed but has

failed.

Off There is no module installed.

Stack ID 1-8 Indicates the switch stack ID.

The Master unit is numbered 1. (Note that If

the master unit fails and a backup unit takes

over, the stack IDs do not change.)

Slave units are numbered 2-8.

Off In standalone mode.

Table 1-2 System Status LEDs (Continued)

LED Condition Status

A

BOUT THE TIGERSTACK

II 10/100/1000

1-8

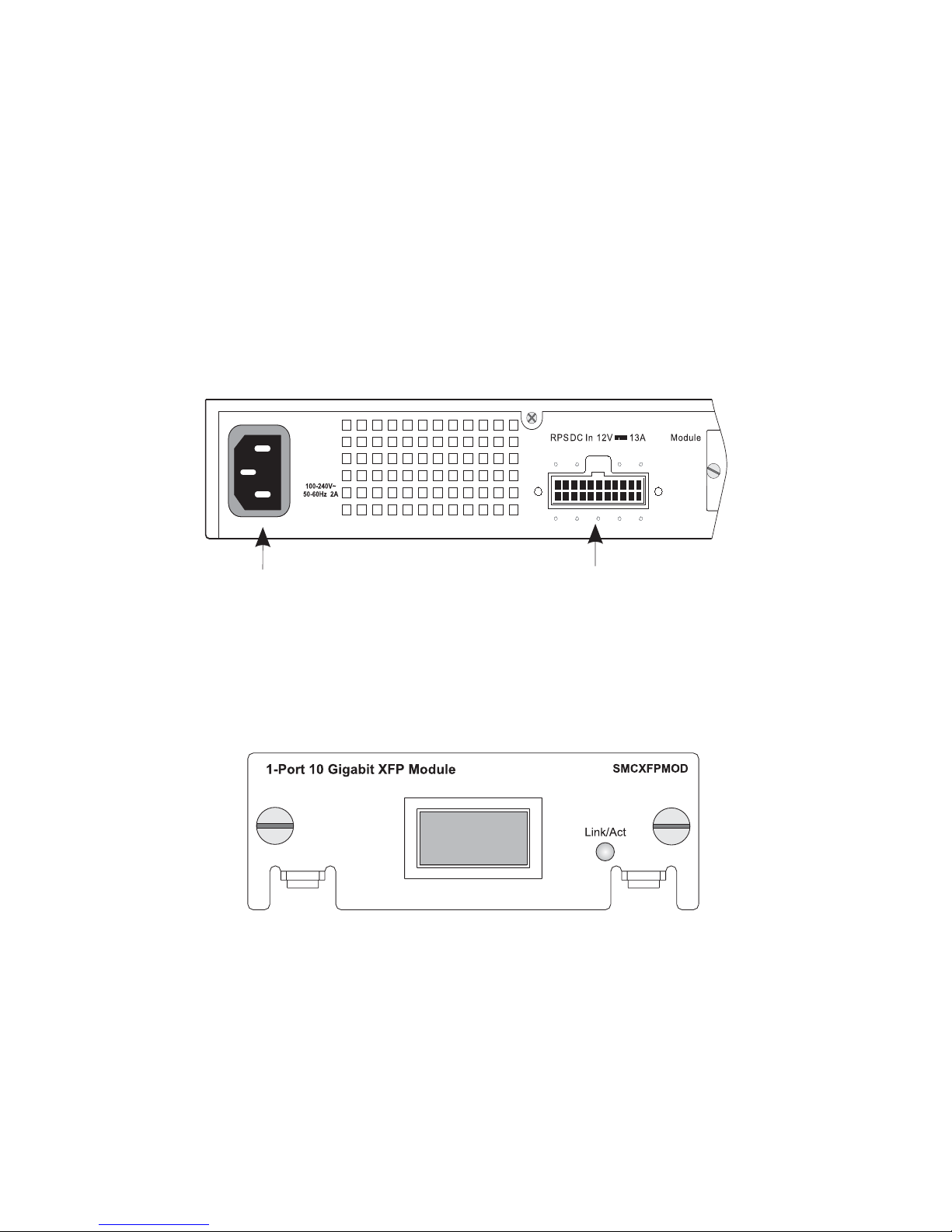

Optional Redundant Power Supply

SMC supports an optional Redundant Power Supply (RPS), that can supply

power to the switch in the event the internal power supply fails.

Power Supply Sockets

There are two power sockets on the rear panel of each switch. The

standard power socket is for the AC power cord. The socket labeled “RPS”

is for the optional Redundant Power Supply (RPS).

Figure 1-5 Power Supply Sockets

Optional Media Extender Module

10GBASE XFP Module

Figure 1-6 Single-Port 10GBASE Module (XFP)

The module’s XFP slot supports standard 10 Gigabit Ethernet (10G) XFP

transceivers. All 10GBASE transceivers operate at 10 Gbps full duplex.

with support for flow control.

Power Socket

Redundant Power Socket

F

EATURES AND BENEFITS

1-9

Extender Module LEDs

The optional 10GBASE slide-in module includes its own integrated LED

indicators on the module’s front panel. The following table describes the

LEDs.

Features and Benefits

Connectivity

• 24 or 48 10/100/1000 Mbps ports for easy Gigabit Ethernet

integration and for protection of your investment in legacy LAN

equipment.

• Auto-negotiation enables each RJ-45 port to automatically select the

optimum communication mode (half or full duplex) if this feature is

supported by the attached device; otherwise the port can be configured

manually.

• RJ-45

10/100/1000BASE-T ports support auto MDI/MDI-X pinout

selection.

• Unshielded (UTP) cable supported on all RJ-45 ports: Category 3 or

better for 10 Mbps connections, Category 5 or better for 100 Mbps

connections, and Category 5, 5e, 6 or better for 1000 Mbps

connections.

• IEEE 802.3-2002 Ethernet, Fast Ethernet, Gigabit Ethernet, and

IEEE 802.3ae 10 Gigabit Ethernet compliance ensures compatibility

with standards-based hubs, network cards and switches from any

vendor.

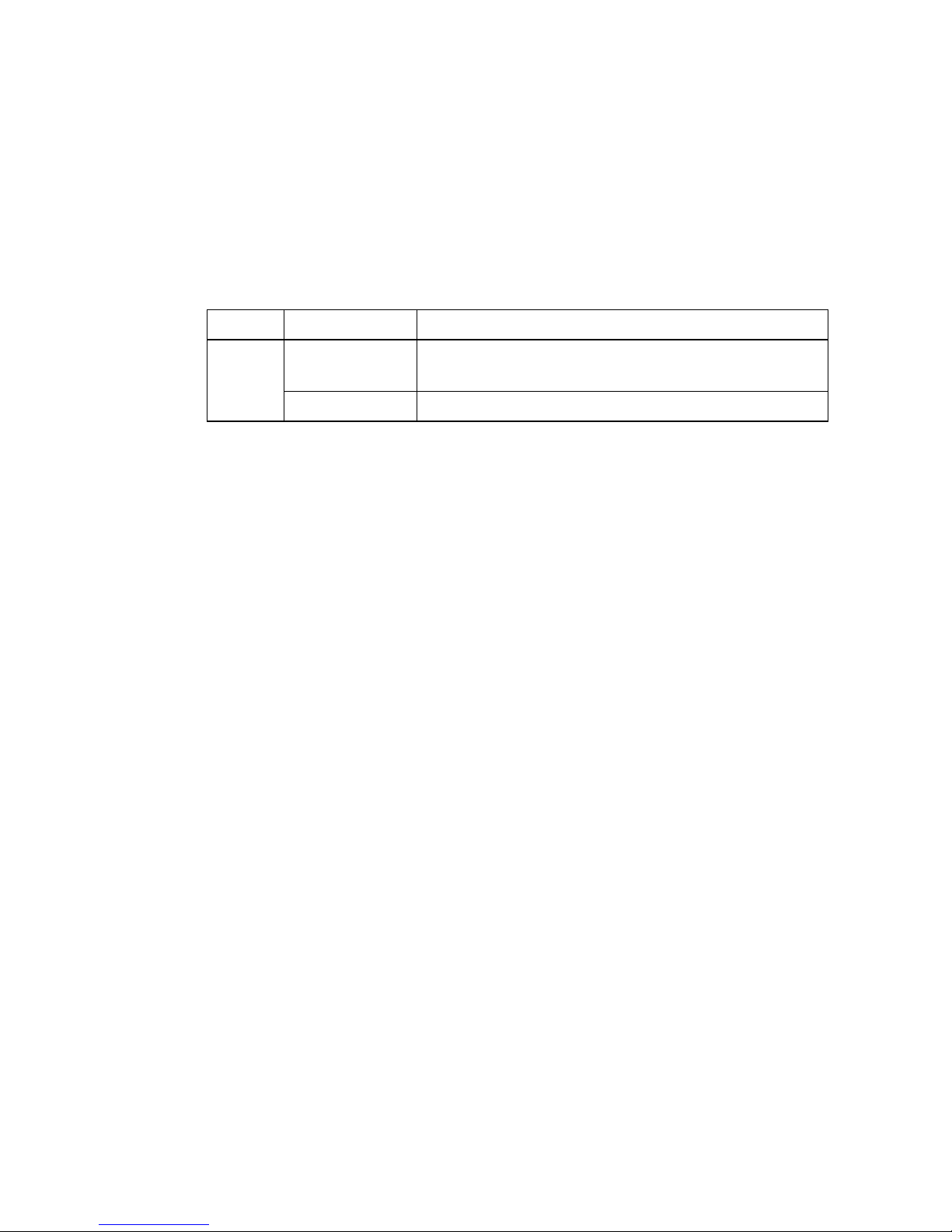

Table 1-3 Module LEDs

LED Condition Status

Link/

Activity

On/Flashing

Green

Port has a valid link at 10 Gbps. Flashing indicates

activity.

Off There is no link on the port.

Loading...

Loading...