SMC Networks TigerStack 3312TA,TigerStack 3326TA,TigerStack 3314T,TigerStack 3328T,TigerStack 3306BC ,TigerStack 3306FC,TigerStack 3328TELCO User Manual

Page 1

User Guide

Unmatched Bandwidth

Scalability for

Ethernet

Workgroups

TigerStack

SwitchReady

™

Multi-Segment Stackable Ethernet Hubs

Page 2

USER GUIDE

FOR

SMC’S

TIGERSTACK

FAMILY OF ETHERNET HUBS

March 1997

Pub. # 900.166 Rev. A

Standard Microsystems Corporation

80 Arkay Drive

Hauppauge, New York 11788

Page 3

Information furnished by Standard Microsystems Corporation

(SMC) is believed to be accurate and reliable. However, no

responsibility is assumed by SMC for its use, nor for any

infringements of patents or other rights of third parties which

may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of SMC. SMC

reserves the right to change specifications at any time without

notice.

Copyright © 1997 by

Standard Microsystems Corporation

Hauppauge, New York.

All rights reserved. Printed in U.S.A.

Trademarks:

SMC and Standard Microsystems are registered trademarks; and TigerStack, TigerHub and

EliteView are trademarks of Standard Microsystems Corporation. Other product and company names are trademarks or registered trademarks of their respective holders.

Page 4

Limited Warranty

HARDWARE: Standard Microsystems Corporation (“SMC”) warrants its hub

products to be free from defects in workmanship and materials, under normal

use and service, for the following length of time from the date of purchase

from SMC or its Authorized Reseller:

TigerStack Hubs (excluding Power Supply and Fan) . . .. . . .. . .Limited Lifetime

TigerStack Power Supply and Fan . . . . . . . . . . . . . . . . . . . . . . . . . .Five Years

If the product does not operate as warranted during the applicable warranty

period, SMC shall, at its option and expense, repair the defective product or

part, deliver to Customer an equivalent product or part to replace the defective

item, or refund to customer the purchase price paid for the defective product.

All products that are replaced will become the property of SMC. Replacement

products may be new or reconditioned. Any replaced or repaired product or

part has a ninety (90) day warranty or the remainder of the initial warranty

period, whichever is longer.

SMC shall not be responsible for any custom software or firmware, configuration information, or memory data of Customer contained in, stored on, or integrated with any products returned to SMC pursuant to any warranty.

LIMITED LIFETIME: TigerStack hubs have a standard three-year warranty. If

you wish to extend your three-year warranty on this unit to a lifetime warranty,

please complete and return the enclosed product registration card within 90

days of purchase from SMC or its Authorized Reseller. Failure to complete and

return this card does not affect the standard, three-year warranty. After registration, any defective TigerStack hub will be repaired or replaced at SMC’s option.

SOFTWARE: SMC warrants that the software programs licensed from it will perform in substantial conformance to the program specifications for a period of

ninety (90) days from the date of purchase from SMC or its Authorized Reseller.

SMC warrants the magnetic media containing software against failure during the

warranty period. No updates are provided. SMC’s sole obligation hereunder

shall be (at SMC’s discretion) to refund the purchase price paid by Customer for

any defective software products or to replace any defective media with software which substantially conforms to SMC’s applicable published specifications.

Customer assumes responsibility for the selection of the appropriate applications program and associated reference materials. SMC makes no warranty that

its software products will work in combination with any hardware or applications software products provided by third parties, that the operation of the

software products will be uninterrupted or error free, or that all defects in the

software products will be corrected. For any third party products listed in the

SMC software product documentation or specifications as being compatible,

SMC will make reasonable efforts to prove compatibility, except where the

non-compatibility is caused by a “bug” or defect in the third party’s product.

Page 5

STANDARD WARRANTY SERVICE: Standard warranty service for hardware

products may be obtained by delivering the defective product, accompanied by

a copy of the dated proof of purchase, to SMC’s Service Center or to an

Authorized SMC Service Center during the applicable warranty period. Standard

warranty service for software products may be obtained by telephoning SMC’s

Service Center or an Authorized SMC Service Center, within the warranty

period. Products returned to SMC’s Service Center must be pre-authorized by

SMC with a Return Material Authorization (RMA) number marked on the outside of the package, and sent prepaid, insured, and packaged appropriately for

safe shipment. The repaired or replaced item will be shipped to Customer, at

SMC’s expense, not later than thirty (30) days after receipt by SMC.

WARRANTIES EXCLUSIVE: IF AN SMC PRODUCT DOES NOT OPERATE AS

WARRANTED ABOVE, CUSTOMER’S SOLE REMEDY SHALL BE REPAIR,

REPLACEMENT OR REFUND OF THE PURCHASE PRICE PAID, AT SMC’S

OPTION. THE FOREGOING WARRANTIES AND REMEDIES ARE EXCLUSIVE

AND ARE IN LIEU OF ALL OTHER WARRANTIES OR CONDITIONS, EXPRESS

OR IMPLIED, EITHER IN FACT OR BY OPERATION OF LAW, STATUTORY OR

OTHERWISE, INCLUDING WARRANTIES OR CONDITIONS OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. SMC NEITHER

ASSUMES NOR AUTHORIZES ANY OTHER PERSON TO ASSUME FOR IT ANY

OTHER LIABILITY IN CONNECTION WITH THE SALE, INSTALLATION, MAINTENANCE OR USE OF ITS PRODUCTS.

SMC SHALL NOT BE LIABLE UNDER THIS WARRANTY IF ITS TESTING AND

EXAMINATION DISCLOSE THE ALLEGED DEFECT IN THE PRODUCT DOES

NOT EXIST OR WAS CAUSED BY CUSTOMER’S OR ANY THIRD PERSON’S

MISUSE, NEGLECT, IMPROPER INSTALLATION OR TESTING, UNAUTHORIZED

ATTEMPTS TO REPAIR, OR ANY OTHER CAUSE BEYOND THE RANGE OF

THE INTENDED USE, OR BY ACCIDENT, FIRE, LIGHTNING, OR OTHER

HAZARD.

LIMITATION OF LIABILITY: IN NO EVENT, WHETHER BASED IN CONTRACT

OR TORT (INCLUDING NEGLIGENCE) SHALL SMC BE LIABLE FOR INCIDENTAL, CONSEQUENTIAL, INDIRECT, SPECIAL, OR PUNITIVE DAMAGES OF

ANY KIND, OR FOR LOSS OF REVENUE, LOSS OF BUSINESS, OR OTHER

FINANCIAL LOSS ARISING OUT OF OR IN CONNECTION WITH THE SALE,

INSTALLATION, MAINTENANCE, USE, PERFORMANCE, FAILURE, OR INTERRUPTION OF ITS PRODUCTS, EVEN IF SMC OR ITS AUTHORIZED RESELLER

HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. NOTHING

HEREIN SHALL HAVE THE EFFECT OF LIMITING OR EXCLUDING SMC’S

LIABILITY FOR DEATH OR PERSONAL INJURY CAUSED BY NEGLIGENCE.

Some states do not allow the exclusion of implied warranties or the limitation

of incidental or consequential damages for consumer products, so the above

limitations and exclusions may not apply to you. This warranty gives you specific legal rights which may vary from state to state. Nothing in this warranty

shall be taken to affect your statutory rights.

Standard Microsystems Corporation

80 Arkay Drive

Hauppauge, NY 11788

516-273-3100

Page 6

Compliances............................................................ v

1 About the Hubs................................................ 1

Benefits.................................................................................. 2

Features.................................................................................. 5

2 Installing.......................................................... 7

Locating the Hub................................................................... 8

Equipment Checklist............................................................. 8

Slide-in Modules.................................................................... 9

Rack Mounting ...................................................................... 10

Desktop or Shelf Mounting .................................................. 12

Stacking.................................................................................. 13

Connecting Power................................................................. 15

3 Connecting...................................................... 17

Making Network Connections.............................................. 18

Connecting to Twisted-Pair Cabling..................................... 21

Connecting to Thin Coax Cabling........................................ 26

Connecting to Thick Coax Cabling ...................................... 27

Connecting to Fiber Cabling................................................. 28

4 Segmenting...................................................... 29

The Segmentation Concept................................................... 30

Segmenting the Hub ............................................................. 34

5 Troubleshooting.............................................. 37

Status/Diagnostic LEDs ......................................................... 38

Testing the Installation.......................................................... 41

i

TABLE OF CONTENTS

Page 7

A Specifications.................................................. 43

TigerStack 3312TA................................................................. 44

TigerStack 3326TA................................................................. 44

TigerStack 3314T................................................................... 45

TigerStack 3328T................................................................... 45

TigerStack 3338TELCO.......................................................... 46

TigerStack 3306BC ................................................................ 46

TigerStack 3306FC................................................................. 47

All TigerStack Hubs............................................................... 47

Stacking Cable....................................................................... 48

B Cables............................................................... 49

Types/Connectors ................................................................. 50

Cable Specifications .............................................................. 51

Extended Distance ................................................................ 53

10BASE-T Pin Assignments................................................... 54

AUI Pin Assignments............................................................. 63

Index........................................................................ 65

ii

TABLE OF CONTENTS

Page 8

List of Figures

TigerStack 3312TA................................................................. 4

TigerStack 3326TA................................................................. 4

Removing the Screws............................................................ 10

Attaching the Brackets.......................................................... 11

Installing the Hub in a Rack................................................. 11

Attaching the Adhesive Feet................................................. 12

Stacking the Hubs ................................................................. 14

Power Connector on Rear of Hub ....................................... 15

Attaching a Transceiver to the AUI Port.............................. 19

Crossover Buttons ................................................................. 21

10BASE-T Connections ......................................................... 23

Wiring Closet Connections via RJ-45 Connectors................ 24

Wiring Closet Connections via Telco Connectors............... 25

Thin Coax Connection via BNC Port ................................... 26

Thick Coax Connection via AUI Port................................... 27

Duplex Fiber Connections via Dual ST Port........................ 28

3326TA Segments A, B, C, and D......................................... 30

3328T Segments A, B, C, and D........................................... 30

3328TELCO Segments A, B, C, and D.................................. 30

3306BC Segments A and B................................................... 30

3306FC Segments A and B.................................................... 30

Segmenting the Stack............................................................ 31

3326TA Segment Switches A, B, C, and D........................... 32

3328T Segment Buttons A, B, C, and D............................... 32

3328TELCO Segment Buttons A, B, C, and D ..................... 32

3306BC Segment Buttons A and B....................................... 32

3306FC Segment Buttons A and B ....................................... 33

Linking 10BASE-T Segments Through a Switch .................. 33

Segmenting the Hubs............................................................ 35

3312TA Front Panel LEDs ..................................................... 38

iii

TABLE OF CONTENTS

Page 9

3326TA Front Panel LEDs ..................................................... 38

3328T Front Panel LEDs........................................................ 39

3328TELCO Front Panel LEDs.............................................. 39

3306BC Front Panel LEDs..................................................... 39

3306FC Front Panel LEDs ..................................................... 39

RJ-45 Connector Pin Numbers.............................................. 54

25-Pair Telco Connector Pin Numbers................................. 55

List of Tables

Crossover/Straight-Through Wiring Requirements.............. 22

RJ-45 Fixed Crossover and Uplink Ports.............................. 22

Segment Button/Switch Functions ....................................... 35

Front Panel LEDs................................................................... 40

Cable Types and Connectors................................................ 50

Twisted-Pair Link Segment Specifications............................ 51

AUI Cable Specifications....................................................... 51

Thick Coax Cable Specifications .......................................... 51

Thin Coax Cable Specifications............................................ 52

Duplex Fiber Cable Specifications ....................................... 52

Extended Distance Specifications......................................... 53

RJ-45 Pin Assignments .......................................................... 54

50-Pin Telco Pin Assignments .............................................. 56

Straight-Through RJ-45 Pin Assignments.............................. 57

Straight-Through 50-Pin Telco Pin Assignments.................. 58

Crossover RJ-45 Pin Assignments......................................... 60

Crossover 50-Pin Telco Pin Assignments............................. 61

AUI Pin Assignments............................................................. 63

iv

CONTENTS

Page 10

FCC A

This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause

interference to radio communications. It has been tested and found to comply

with the limits for a Class A computing device pursuant to Subpart B of Part 15

of FCC Rules, which are designed to provide reasonable protection against such

interference when operated in a commercial environment. Operation of this

equipment in a residential area is likely to cause interference, in which case the

user, at his own expense, will be required to take whatever measures may be

required to correct the interference.

Canada Department of Communications - Class A

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital apparatus as set out in the interference-causing equipment

standard entitled "Digital Apparatus", ICES-003 of the Department of

Communications.

Cet appareil numérique respecte les limites de bruits radioélectriques applicables aux appareils numériques de Classe A prescrites dans la norme sur le

matériel brouilleur : "Appareils Numériques", NMB-003 édictée par le ministère

des Communications.

European Community

This information technology product was found to comply with EC General

Directives 89/336/EEC and 73/23/EEC. An EC Declaration of Conformity was

issued for this product by:

Standard Microsystems (Europe) Limited

2nd Floor, Building B, Berkshire Court, Western Road

Bracknell, Berkshire RG12 1RE, United Kingdom

Japan VCCI Class 1

Australia AS/NZS 3548 (1995)

SMC contact for products in Australia is:

SMC Australia Pty. Ltd., ACN 069 351 613

LVL 66 MLC Center

Martin Place

Sydney NSW 2000

Phone: 61-2-9238-2206

Fax: 61-2-9238-2220

v

COMPLIANCES

Page 11

DO NOT PLUG A PHONE JACK CONNECTOR INTO ANY OF THE

RJ-45 PORTS. THIS MAY DAMAGE THE DEVICE.

KUN FOR DATA. MÅ IKKE KOPLES TIL TELEFONNETTVERKET.

SÓLO PARA TRANSFERIR DATOS. NO ENCHUFAR EN LA LÍNEA

TELEFÓNICA.

LES RACCORDEURS NE SONT PAS UTILISÉ POUR LE SYSTÈME

TÉLÉFONIQUE.

VAIN TIEDONSIIRTOON. ÄLÄ KYTKE PUHELINLINJAAN.

SOLO PER DATI. NON COLLEGARE ALLE LINEE TELEFONICHE.

NUR FÜR DATENKOMMUNIKATION. NICHT AN TELEFONLEITUNG

ANSCHLIESSEN.

vi

☎

Page 12

1

Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Stackable . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Segmentable . . . . . . . . . . . . . . . . . . . . . . . . 2

Scalable . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SNMP Manageable . . . . . . . . . . . . . . . . . . . 3

Easy to Install . . . . . . . . . . . . . . . . . . . . . . . 3

Available in a Wide Range of Models . . . . . . 3

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

All Models . . . . . . . . . . . . . . . . . . . . . . . . . 5

Models 3312TA and 3326TA . . . . . . . . . . . . . 6

CHAPTER 1

ABOUT THE HUBS

Page 13

Benefits

SMC’s TigerStack™hubs provide a powerful combination of

scalable bandwidth, network management, and configuration

options for building high-performance Ethernet networks.

These multi-segment, stackable, workgroup hubs feature unsurpassed flexibility, allowing users to grow or modify their networks as their needs change.

Several models are available, with a variety of port densities

and a wide range of cabling options, to meet the needs of your

particular installation.

Stackable

A single TigerStack hub supporting a small workgroup can be

expanded to a stack of eight units with up to 224 ports. Since

the entire stack is still counted as one logical repeater (one of

the four repeater hops permitted between any pair of PCs),

TigerStack hubs make it easier to configure the network.

For additional flexibility, all models can be mixed in the same

stack, in any order or combination.

Segmentable

Each hub contains two or four repeater groups. These groups

can be isolated from the stack to form independent 10 Mbps

networks or collision domains. A fully configured stack of

eight hubs can be segmented into up to 32 collision domains.

Reducing the number of nodes on a LAN minimizes contention

for the network and boosts the available bandwidth.

Scalable

Repeater groups, once isolated, can be interconnected via LAN

switches. This TigerStack/switch combination allows bandwidth to be scaled to workgroups that need it.

2

ABOUT THE HUBS

Page 14

SNMP Manageable

The optional Network Management Module (NMM) adds monitoring, control, and fault isolation functions to the LAN. For

economy, only a single NMM is needed to manage an entire

stack, whether it‘s one segment or as many as 32. For flexibility, the NMM is field-installable and can be placed in any

hub, not just the top- or bottom-most units. With the NMM, the

stack can be managed in-band and out-of-band (both locally

and remotely) using SMC’s EliteView™or any other SNMP-based

manager.

Easy to Install

TigerStack hubs can be easily installed in a 19-inch equipment

rack or on a desktop or shelf.

Available in a Wide Range of Models

TigerStack hubs are available with 10BASE-T ports for twistedpair cabling, AUI ports for backbone or mixed media connectivity, BNC ports for thin coax cabling, and dual ST ports for

fiber cabling. Their ports are segmentable into as many as four

groups, depending upon the model.

The TigerStack family includes the following models:

• TigerStack 3312TA — a two-segment hub with twelve

10BASE-T ports and two expansion slots for optional AUI,

BNC, dual ST and 10BASE-T ports

• TigerStack 3326TA — a four-segment hub with 26

10BASE-T ports and two expansion slots for optional AUI,

BNC, dual ST and 10BASE-T ports

• TigerStack 3314T — a two-segment hub with 14 10BASE-T

ports

• TigerStack 3328T — a four-segment hub with 28 10BASE-T

ports

• TigerStack 3306BC — a two-segment hub with six BNC

ports, one AUI port, and one 10BASE-T port

3

ABOUT THE HUBS

Page 15

• TigerStack 3306FC — a two-segment hub with six dual ST

ports, one AUI port, and one BNC port

• TigerStack 3328TELCO — a four-segment hub with 28

10BASE-T ports: 24 ports on two Telco connectors and four

ports on RJ-45 connectors

Since all the TigerStack hubs have the same footprint, only two

— the TigerStack 3312TA and 3326TA — are shown below.

ABOUT THE HUBS

4

TigerStack 3312TA

TigerStack 3326TA

Page 16

Features

All Models

• Push-buttons or switches to segment each hub into independent networks

• Front panel LEDs for “status-at-a-glance” troubleshooting:

• Power — one per hub

• NMM — one per hub

• Collision — one per segment

• Segment —one per segment

• Port Status (Link/Partition/Source) — one per port

• Automatic port/segment partitioning and reconnection for

physical level network management and fault tolerance

• Internal transmit/receive crossover on all twisted-pair ports

for connection to adapters with straight-through wiring

• Crossover enable/disable function on one twisted-pair port

in each segment to uplink to a LAN switch or cascade to

another hub with straight-through wiring

• Automatic polarity detection and correction on 10BASE-T

receive pairs to correct miswiring and make connections

simple and quick

• Link integrity checking on all twisted-pair connections

• Smart squelch digital noise filter on all 10BASE-T ports

• Extended distance support for both 10BASE-T and thin coax

cable

• Jabber lock-up protection to prevent overly long

transmissions

• Rack-, table-, or wall-mount chassis design for installation

flexibility

• Internal, auto-ranging power supply

• Reliable point-to-point connections

5

ABOUT THE HUBS

Page 17

Models 3312TA and 3326TA

The following additional features are provided by Models

3312TA and 3326TA:

• Optional Redundant Power Unit to minimize downtime in

the event of an internal power supply failure

• Two expansion slots for optional slide-in 10BASE-T, BNC,

fiber and AUI modules

• Larger segments — depending on the model, 14-, 21-, or 28port segments may be formed by combining repeater

groups

ABOUT THE HUBS

6

Page 18

CHAPTER 2

INSTALLING

7

Locating the Hub . . . . . . . . . . . . . . . . . . . . . . 8

Equipment Checklist . . . . . . . . . . . . . . . . . . . . 8

Package Contents . . . . . . . . . . . . . . . . . . . . 8

Optional Equipment . . . . . . . . . . . . . . . . . . 9

Required Rack-Mounting Tools . . . . . . . . . . 9

Slide-in Modules . . . . . . . . . . . . . . . . . . . . . . . 9

Rack Mounting . . . . . . . . . . . . . . . . . . . . . . . . 10

Desktop or Shelf Mounting . . . . . . . . . . . . . . . 12

Stacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Connecting Power . . . . . . . . . . . . . . . . . . . . . . 15

Page 19

Locating the Hub

The hub can be installed in a standard 19-inch equipment rack,

or on a desktop or shelf. Be sure to follow the guidelines

below when choosing a location:

• Select a suitable location for the hub:

• It should be accessible for installing, cabling, and maintaining the hub.

• The temperature and humidity should be within the

ranges listed in Appendix A.

• The status LEDs should be clearly visible.

• There should be adequate space (approximately two

inches) on all sides for proper air flow.

• Make sure twisted-pair cable is always routed away from

power lines, fluorescent lighting fixtures, and other sources

of electrical interference such as radios, transmitters, etc.

• Make sure that a separate grounded power outlet is within 8

feet (2.44 m) of the hub and is powered from an independent circuit breaker. As with any equipment, using a filter

or surge suppressor is recommended.

Equipment Checklist

Package Contents

Check that the following equipment is included in your

package:

• The TigerStack hub

• Bracket Mounting Kit, containing two brackets and four

screws for attaching the brackets to the hub

• Four adhesive feet

• This User Guide

• One SMC Warranty Registration Card — be sure to complete

and return this card within 90 days to extend the three-year

warranty to a lifetime warranty

• The appropriate power cord for your country — either US,

Continental or UK

8

INSTALLING

Page 20

Optional Equipment

The following equipment is not provided:

• Stacking cable, order number SMC3300-CABLE — one is

required for each hub you want to stack

• Rack-mounting screws — four are required for each hub

you want to mount in a rack

Required Rack-Mounting Tools

Be sure to have the following tools available when rack mounting your hub:

• Screws for mounting the hub in a rack (not included)

• A screwdriver (Phillips-head or flathead, depending on type

of screws used)

Slide-in Modules

(Models 3312TA and 3326TA Only)

SMC’s TigerStack 3312TA and 3326TA hubs are equipped with

two expansion slots (port 7, port 14) for slide-in modules. AUI,

10BASE2, 10BASE-T and 10BASE-F modules are available.

Port 7 is accessible from the front panel and port 14 is located

on the rear of the hubs.

If you have purchased a slide-in module for port 7 and/or 14,

install the module(s) now. Follow the installation instructions

provided in the slide-in module package.

9

INSTALLING

Page 21

Rack Mounting

Before rack mounting the hub, pay particular attention to the

following factors:

• Temperature: Since the temperature within a rack assem-

bly may be higher than the ambient room temperature,

check that the rack-environment temperature is within the

operating temperature range specified in Appendix A.

• Mechanical Loading: Do not place any equipment on top

of a rack-mounted unit.

• Circuit Overloading: Be sure that the supply circuit to the

rack assembly is not overloaded.

• Grounding: Rack-mounted equipment should be properly

grounded. Particular attention should be given to supply

connections other than direct connections to the mains.

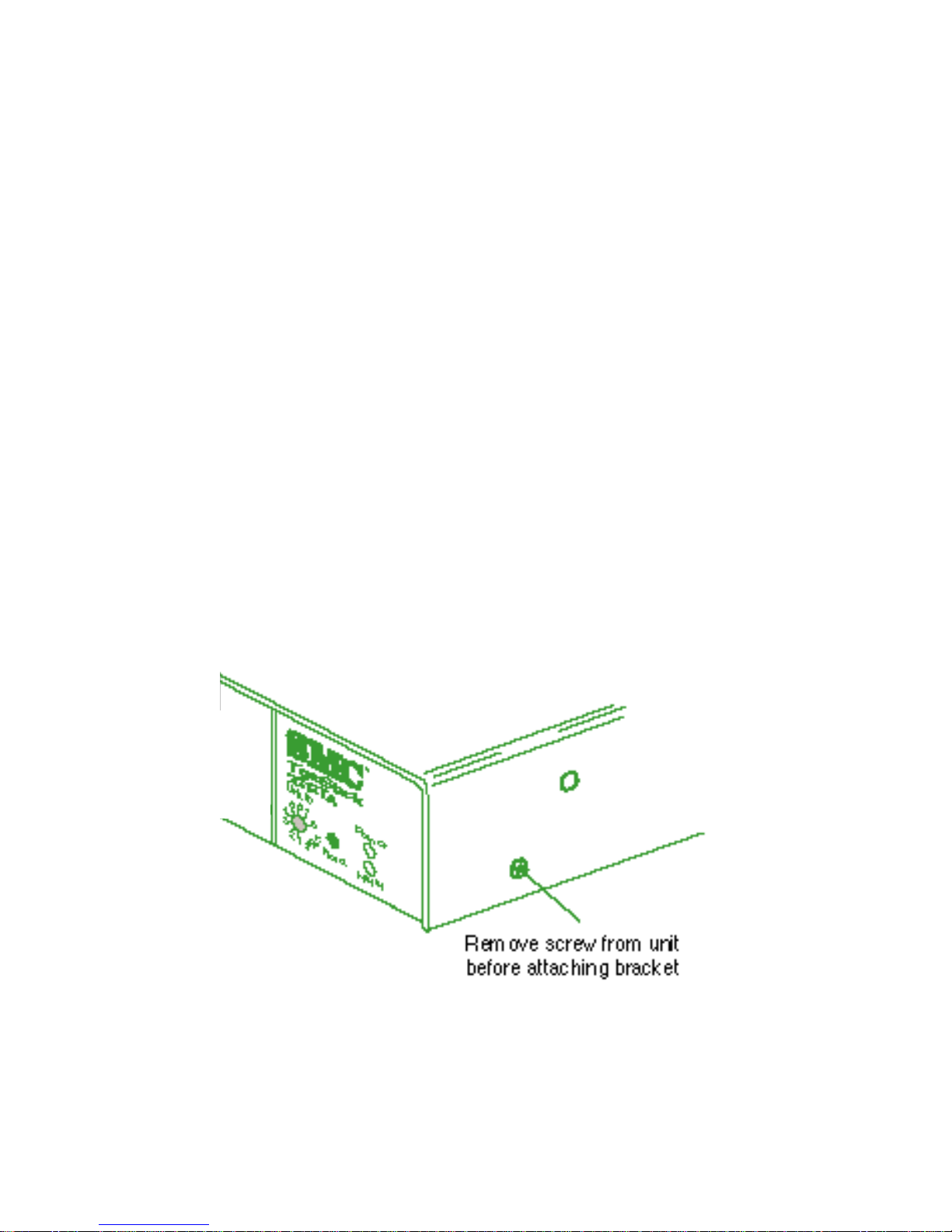

To rack mount the hub:

1. Remove the two screws from the sides of the unit.

Removing the Screws

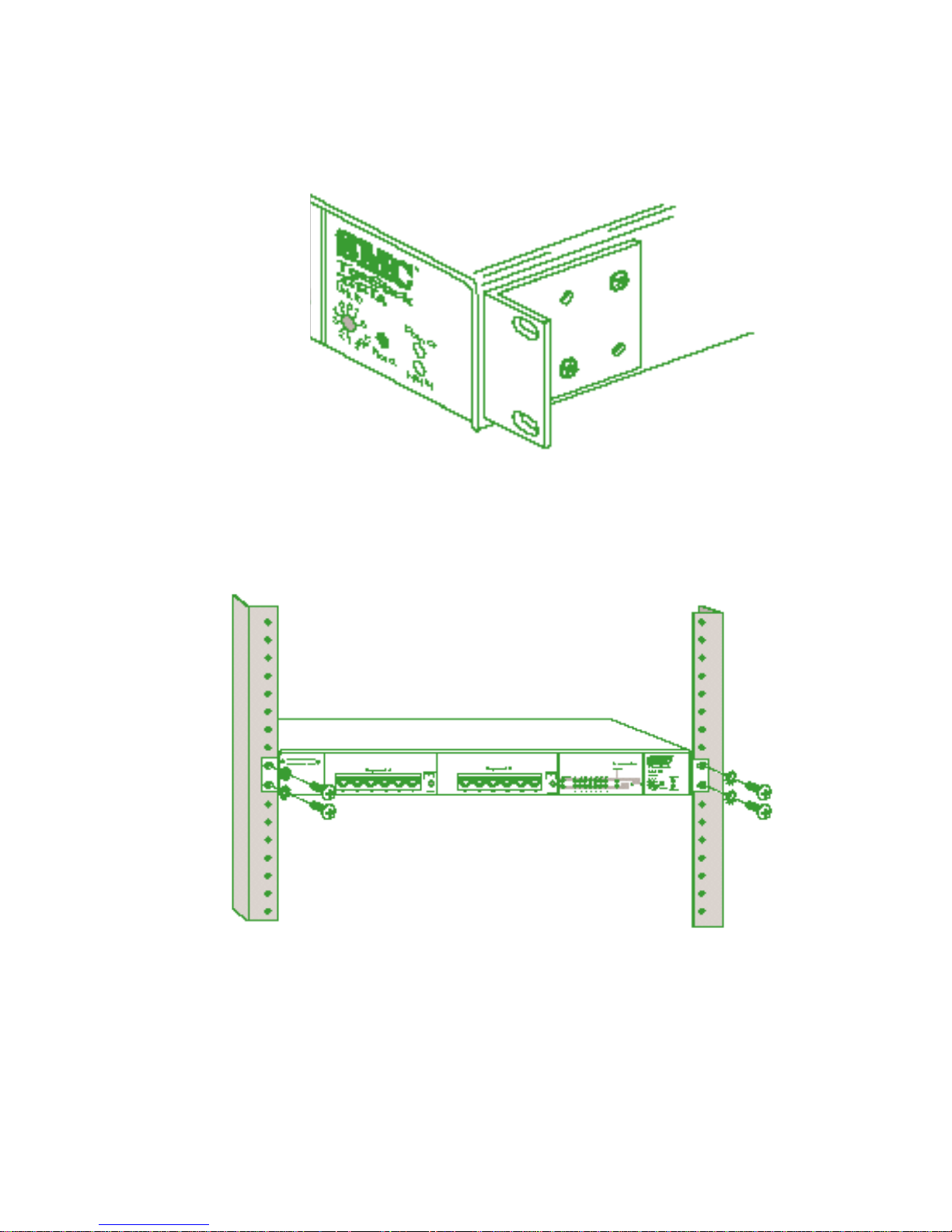

2. Attach the brackets using the screws provided in the Bracket

Mounting Kit.

10

INSTALLING

Page 22

Attaching the Brackets

3. Install the hub in the rack, using four rack-mounting screws

(not provided).

Installing the Hub in a Rack

4. If stacking hubs, install the remaining hubs in the rack, one

atop the other. Then go to “Stacking” later in this chapter.

5. If installing a single hub, go to “Connecting Power” at the

end of this chapter.

11

INSTALLING

Page 23

Desktop or Shelf Mounting

1. Attach the four adhesive feet to the bottom of the hub.

Attaching the Adhesive Feet

2. Set the hub on a flat surface near an AC power source,

making sure there are at least two inches of space on all

sides for proper air flow.

3. If stacking hubs, install four adhesive feet on each unit and

place each hub squarely on top of the hub below. Then go

to “Stacking” on the next page of this chapter.

4. If installing a single hub, go to “Connecting Power” later in

this chapter.

INSTALLING

12

Page 24

Stacking

The hubs can be stacked as many as eight high, and all models

can be mixed in the same stack, in any order or combination.

Note: Although hubs can be stacked after being connected to

a power source, it is not recommended as a safe networking practice.

Before stacking the hubs, pay attention to the following guidelines:

• Be sure to have one stacking cable for each hub you want

to stack. This cable (order number SMC3300-CABLE) is not

provided with the hub, and must be ordered separately.

• If an NMM is installed in one of the hubs, be sure to set

the Unit ID switch on each hub in the stack to a unique

number. See your NMM User Guide for instructions about

setting the Unit ID switch.

To stack the hubs:

1. Locate the SCSI connectors labeled “A” and “B” on the rear

of each hub (refer to the the illustration on the next page).

2. Attach one end of the stacking cable to the SCSI connector

labeled “B” on the right hand side of the lower hub. Attach

the other end of the cable to the left connector labeled “A”

on the upper hub.

3. Repeat Step 2 until all the hubs (maximum eight) have been

stacked.

4. Go to “Connecting Power” at the end of this chapter.

13

INSTALLING

Page 25

Stacking the Hubs

INSTALLING

14

Page 26

Connecting Power

Note: It is recommended that the hubs be stacked before

power is applied.

To connect each hub to a power source:

1. Insert the power cable plug directly into the receptacle

located at the back of the hub.

Power Connector on Rear of Hub

2. Plug the other end of the cable into the appropriate

receptacle.

Note: For international use, you may need to change the AC

line cord. You must use a line cord set for the receptacle type in your country. The cord should be HARCertified, and the mark HAR should appear on the outer

sheath or jacket, or on the insulation of one of the inner

conductors. The female receptacle of the cord set must

meet CEE-22 requirements. If you have any questions

concerning the proper power cord to use, please contact your local SMC Supplier.

3. Check the front panel LEDs. At power on, the:

• Power LED — lights and remains on.

• NMM LED:

• If the NMM is installed, this LED blinks green for a

few seconds during power-on diagnostics, then turns

solid green. If diagnostics fail, the LED blinks yellow.

• If the NMM is not installed, the LED remains off.

15

INSTALLING

Page 27

• Segment LEDs — flash yellow, then change to the color

indicating the position of the Segment switch.

• Port Status LEDs:

• 10BASE-T and Dual ST LEDs flash yellow and then

go off. Once testing is complete, these LEDs indicate

port activity.

• AUI and BNC LEDs turn green after the power-on

sequence and remain on until a data packet has been

passed successfully. If the BNC port is not terminated, the BNC LED will light yellow and the port

will partition due to excessive collisions.

• Collision LEDs — turn yellow for a fraction of a sec-

ond, then go off. Once testing is complete these LEDs

indicate network activity.

Refer to Chapter 5, “Troubleshooting,” for more information

about the LEDs.

4. For TigerStack 3312TA and 3326TA Only – If you have

purchased one or more Redundant Power Units, connect

them to these devices and to an AC power source now, following the instructions included with the package.

INSTALLING

16

Page 28

Making Network Connections . . . . . . . . . . . . . 18

Directly . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Via Transceiver . . . . . . . . . . . . . . . . . . . . . . 18

The SMC 5 - 4 - 3 Rule . . . . . . . . . . . . . . . . 20

Connecting to Twisted-Pair Cabling . . . . . . . . . 21

Crossover Function . . . . . . . . . . . . . . . . . . . 21

Connecting Devices . . . . . . . . . . . . . . . . . . 22

Wiring Closet Connections . . . . . . . . . . . . . . 24

Connecting to Thin Coax Cabling . . . . . . . . . . 26

Connecting to Thick Coax Cabling . . . . . . . . . . 27

Connecting to Fiber Cabling . . . . . . . . . . . . . . 28

CHAPTER 3

CONNECTING

17

Page 29

Making Network Connections

Hubs are designed to link multiple workstations and other hubs

to an Ethernet network.

Directly

Hubs can be joined directly to other network devices via their

front-panel ports as long as both devices have one port with an

identical connector.

For example, the TigerStack 3312TA with its twelve 10BASE-T

ports and a slide-in BNC module can be:

• cascaded to a LAN switch or another 10BASE-T hub via one

of its two uplink (twisted-pair, switch-selectable crossover)

ports

• connected to a 10BASE-T adapter via one of its fixed

crossover ports

• cascaded to SMC’s TigerHub™FL6, since they each have a

BNC port

• attached directly to a thin coax backbone via its BNC port

Via Transceiver

If both devices have an AUI (Attachment Unit Interface) port

(designated by the IEEE as the standard interface for 10 Mbps

Ethernet networks), they may be joined with two identical

transceivers* and a length of the appropriate type of cable.

For example, the TigerStack 3306BC hub (with its six BNC

ports, one AUI port, and one 10BASE-T port) can be:

• cascaded to another TigerStack 3306BC hub with two fiber

transceivers that are joined with a fiber link segment, to span

the distance between two buildings

* Transceivers are typically 2-port devices with one AUI connector and

one connector for a specific medium (RJ-45 for twisted pair, BNC for thin

coax, or ST for fiber).

18

CONNECTING

Page 30

Caution:When attaching a BNC transceiver to an AUI port, be

sure to disable the transceiver’s SQE switch.

Even if only one of the devices has an AUI port, it can be

joined to any port on an another device with the appropriate

transceiver and cable.

For example, the TigerStack 3306FC (with its six fiber ports,

one AUI port, and one BNC port) can be:

• connected to any 10BASE-T adapter with a 10BASE-T transceiver and a length of twisted-pair cable

To attach a transceiver to the AUI port:

1. Slide the hold-down clip on the AUI female D-Connector to

the open position.

2. Attach the transceiver to the AUI female D-Connector.

3. Slide the clip back to the closed position.

Attaching a Transceiver to the AUI Port

19

CONNECTING

Page 31

The SMC 5 - 4 - 3 Rule

When making connections, check to be sure that you do not

exceed the IEEE guidelines for Ethernet networks. The easiest

way is with the SMC 5 - 4 - 3 Rule given below.

Note: This rule is completely consistent with the IEEE 802.3

specification.

20

CONNECTING

Between any two PCs or other stations on the network, there

may be:

• up to 5 cable segments in series,

• up to 4 repeaters (hubs or multi-port concentrators),

• up to 3 populated cable segments, that is, segments

attached to two or more PCs (coax networks only).*

* The remaining two segments are unpopulated; these are

known as inter-repeater links or IRLs. Remember, this distinction between populated and unpopulated segments is

significant for coax networks only.

Page 32

Connecting to Twisted-Pair Cabling

A twisted-pair cable segment is used for point-to-point connections. With it, you can cascade a pair of hubs, link a hub to a

LAN switch, or connect a hub to an adapter.

Crossover Function

Every twisted-pair connection must have a wiring crossover to

transmit and receive data. This crossover can be implemented

in the wiring or the device itself.

For convenience, the crossover is already built into the

10BASE-T ports that are labeled with an “X” — these are called

fixed crossover ports. Adapters can be connected to these

ports with straight-through cable.

Additionally, one twisted-pair port in each segment on the

10BASE-T TigerStack hubs, and the lone twisted-pair port on

the thin coax model, features a crossover enable/disable button

— these are called uplink or switch-selectable crossover ports.

When the wiring crossover is disabled, other 10BASE-T hubs

and LAN switches can be connected to these ports with

straight-through cable.

The locations of the crossover buttons on the TigerStack

3326TA are shown below. Buttons for the other models appear

in a similar position.

Crossover Buttons

21

CONNECTING

Page 33

When a port labeled with an “X” is connected to a device that

does not support the crossover function, straight-through

cabling can be used. However, when connecting two identical

ports (that is, ports that either both support or do not support

the crossover function), the crossover must be implemented in

the wiring. This is summarized in the following table:

A list of the fixed and switch-selectable crossover (uplink) ports

for each TigerStack model can be found in the following table:

Connecting Devices

Adapters, other hubs, and LAN switches are connected to

10BASE-T ports of a TigerStack hub with a twisted-pair cable

segment. If the hub is located in a wiring closet, the connection to an adapter is made via a patch cable, modular wall outlet, punch-down block, and patch panel.

22

CONNECTING

Crossover/Straight-Through Wiring Requirements

If one port is... And the other port is... Then use...

Crossover (X) Crossover (X) Crossover cable

Crossover (X) Straight-through Straight-through cable

Straight-through Straight-through Crossover cable

RJ-45 Fixed Crossover and Uplink Ports

Port Numbers

Model Fixed Crossover Uplink

3312TA 1-5, 8-12 6, 13

3326TA 1-5, 8-12, 15-20, 22-27 6, 13, 21, 28

3314T 1-6, 8-13 7, 14

3328T 1-6, 8-13, 15-20, 22-27 7, 14, 21, 28

3328TELCO N/A 7, 14, 21, 28

3306BC N/A 8

Page 34

Caution: Regulations regarding the connection of equipment to

telephone networks vary from country to country.

Check with your local telephone network supplier

before using existing telephone wiring.

Note: Refer to the table on the preceding page to determine

whether you need straight-through or crossover cable.

To connect a device to a 10BASE-T port on a TigerStack hub:

1. Attach one end of a twisted-pair cable segment to the

device’s RJ-45 connector.

10BASE-T Connections

2. If the device is another hub or a LAN switch, attach the

other end of the cable segment to an open 10BASE-T port

on the hub.

3. If the device is an adapter and the TigerStack hub is in a

wiring closet, attach the other end of the cable segment to

a 10BASE-T modular wall outlet that is connected to the

wiring closet (see “Wiring Closet Connections“ on the

next page). Otherwise, attach the other end to an open

10BASE-T port on the hub.

23

CONNECTING

Page 35

Wiring Closet Connections

If the TigerStack hub has RJ-45 connectors:

1. Attach one end of a 50-pin Telco cable to the punch-down

block in the wiring closet, and the other end to the patch

panel on the rack.

2. Attach one end of the patch cable to the patch panel, and

the other end to an open 10BASE-T port on the hub.

3. Label the cables to simplify future troubleshooting.

Wiring Closet Connections via RJ-45 Connectors

24

CONNECTING

Page 36

If the TigerStack hub has Telco connectors:

1. Attach one end of a 50-pin Telco cable to the punch-down

block in the wiring closet

2. Attach the other end to the 50-pin connector on the

TigerStack 3328Telco hub.

Wiring Closet Connections via Telco Connectors

25

CONNECTING

Page 37

Connecting to Thin Coax Cabling

Up to 30 devices (hubs, workstations, servers, etc.) may

be connected to a thin coax cable segment with BNC

T-Connectors.

Each cable segment must be terminated at both ends by a 50

ohm BNC terminator. One of the terminators must be grounded.

Note: TigerStack hub BNC ports support extended distance

capability up to 305 m (1,000 ft.) with cable meeting certain specifications (see Appendix B, “Cables”). However ,

if other devices are attached to the same cable segment,

then the maximum length of the cable segment is limited

to the length supported by those products.

To connect a TigerStack BNC port to a thin coax cable

segment:

1. Attach the male end of a BNC T-Connector to the BNC port.

2. Connect one end of a length of thin coax cable to one side

of the BNC T-Connector.

3. Connect either another length of thin coax cable or a

50-ohm BNC terminator to the other side of the BNC

T-Connector.

Thin Coax Connection via BNC Port

26

CONNECTING

Page 38

Connecting to Thick Coax Cabling

Up to 100 devices (hubs, workstations, servers, etc.) may be

attached to a thick coax cable segment using AUI drop cables

and tap-type transceivers.

Each cable segment must be terminated at both ends by a 50

ohm N-Series terminator. One terminator must be grounded.

To connect a TigerStack AUI port to a thick coax cable

segment:

1. Attach a tap-type transceiver to the thick coax cable segment. Refer to the documentation provided with the transceiver for installation instructions.

2. Connect one end of the AUI drop cable to the tap-type

transceiver, and the other end to the AUI port on the hub.

Slide the hold-down clip on the female D-Connector to the

open position, attach the male D-Connector, and then slide

the clip back to the closed position.

Thick Coax Connection via AUI Port

27

CONNECTING

Page 39

Connecting to Fiber Cabling

A fiber cable segment is used for point-to-point connections.

When using two simplex cables:

1. Connect one end of the first cable to the hub’s Tx connector

and the other end to the Rx connector on the other device.

2. Connect one end of the second cable to the hub’s Rx connector and the other end to the Tx connector on the other

device.

When using one duplex cable:

1. Differentiate the two fiber strands by banding one strand at

both ends, as shown below.

2. Connect one end of the banded strand to the hub’s Tx connector and the other end to the Rx connector on the other

device.

3. Connect one end of the remaining strand to the hub’s Rx

connector and the other end to the Tx connector on the

other device.

Duplex Fiber Connections via Dual ST Port

28

CONNECTING

Page 40

The Segmentation Concept . . . . . . . . . . . . . . . 30

Isolating Segments . . . . . . . . . . . . . . . . . . . 31

Interconnecting Isolated Segments . . . . . . . . 33

Segmenting the Hub . . . . . . . . . . . . . . . . . . . . 34

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . 36

CHAPTER 4

SEGMENTING

29

Page 41

The Segmentation Concept

Each TigerStack hub is composed of two or four repeater

groups, with each group containing four or seven ports, depending upon the model. Thus, a stack eight high can have as

many as 32 repeater groups. Initially, these groups are united

into a single 10 Mbps segment via the inter-repeater bus which

runs through the stacking cable.

SEGMENTING

30

3306FC Segments A and B

3306BC Segments A and B

3328TELCO Segments A, B, C, and D

3328T Segments A, B, C, and D

(the 3314T has Two Segments: A and B)

3326TA Segments A, B, C, and D

(the 3312TA has Two Segments: A and B)

Page 42

Isolating Segments

Suppose you have a number of small, high-traffic workgroups

that do not need to share data but do need additional bandwidth. Each workgroup can be attached to a different repeater

group. Then the repeater groups can be isolated from the bus

to form independent 10 Mbps networks (also known as collision domains or segments).

Microsegmentation is accomplished via front panel buttons or

switches, depending on the model. A LED for each segment

indicates the status of that segment.

Note: With the NMM installed, repeater groups can also be iso-

lated through EliteView, SMC’s SNMP-based management software.

A stack can have as many as 32 separate 10 Mbps segments.

These segments can be isolated from, and rejoined to, the bus

quickly and easily via their front panel buttons or switches, or

under SNMP software control.

31

SEGMENTING

TigerStack

Segments 1-32

Segmenting the Stack

Page 43

32

3326TA Segment Switches A, B, C, and D

(the 3312TA has Two Switches: A and B)

3328TELCO Segment Buttons A, B, C, and D

3306BC Segment Buttons A and B

SEGMENTING

3328T Segment Buttons A, B, C, and D

(the 3314T has Two Buttons: A and B)

Page 44

Interconnecting Isolated Segments

Suppose you have a number of small, high-traffic workgroups

that do need to share data and also need additional bandwidth.

Once isolated from the bus, these workgroups can be interconnected through a switch.

Linking 10BASE-T Segments Through a Switch

33

SEGMENTING

3306FC Segment Buttons A and B

Switch

Servers

Workstations

TigerStack

Multiple

10 Mbps

Uplinks

Page 45

Segmenting the Hub

The hub can be segmented either via hardware with the front

panel switches (TA models) or buttons (all other models), or

via software with EliteView or any other SNMP-based manager.

Note: Unless the hardware lockout feature has been enabled

via software, the latest action (either hardware or software) overrides the previous setting.

Each segment button has two positions: Enable ON and Enable

OFF. Each segment switch has three positions: Hub, Stack and

Isolate. The figure on the following page illustrates how these

buttons and switches can be used to segment the hubs. These

functions are defined in the table on the next page.

Model 3328T (bottom) contains four segment buttons. The

buttons for segments A and C are in the Enable OFF position,

so these segments are not isolated; they are connected to the

inter-repeater bus. The buttons for segments B and D are in

the Enable ON position, so these segments are removed or

isolated from the inter-repeater bus and from each other.

Model 3312TA (middle) contains two segment switches. The

switches for both segments are in the Hub position so these

segments are joined together to form a single 14-port segment.

Model 3326TA (top) contains four segment switches. The

switch for segment D is in the Stack position, so segment D is

connected to the stack through the inter-repeater bus. The

switch for segment C is in the Isolate position, so segment C is

removed from the inter-repeater bus. The switches for

segments A and B are in the Hub position, so these segments

are joined to form a 14-port segment.

SEGMENTING

34

Page 46

35

SEGMENTING

Segmenting the Hubs

Segment Button/Switch Functions

Button Switch Function

Off Stack Connects segment to the stack

On Isolate Isolates segment from the stack

-- Hub Joins hub segments to form larger collision

domain

Page 47

Procedure

Models 3314T, 3328T, 3328TELCO, 3306BC, 3306FC

1. To isolate a segment, move the button labeled Segmentation

Enable to the On position (out).

2. Either press the Reset button (using a small, pointed instrument) or power the hub off, then on again.

Models 3312TA and 3326TA

1. Move the 3-position switch to one of the following positions:

Stack – Select Stack to connect the segment to the stack via

the inter-repeater bus. The Select LED will be off.

Hub – Select Hub to isolate the segment from the hub and

to combine it with the other segments in the hub that have

been set similarly, forming a larger segment. The Select

LED will be green.

Isolate – Select Isolate to completely isolate the segment.

The Select LED will be yellow.

2. Either press the Reset button (using a small, pointed instrument) or power the hub off, then on again.

SEGMENTING

36

Page 48

Status/Diagnostic LEDs . . . . . . . . . . . . . . . . . . 38

Testing the Installation . . . . . . . . . . . . . . . . . . 41

CHAPTER 5

TROUBLESHOOTING

37

Page 49

Status/Diagnostic LEDs

The following front-panel LEDs aid in testing the hub and diagnosing network problems:

• One green Power LED

• One bi-color NMM Status LED

• One yellow Collision LED for each segment

• One yellow Segment LED for each segment

(Bi-color for Models 3312TA and 3326TA)

• One bi-color Port Status LED for each port

38

TROUBLESHOOTING

3312TA Front Panel LEDs

3326TA Front Panel LEDs

Page 50

39

TROUBLESHOOTING

3328TELCO Front Panel LEDs

3306BC Front Panel LEDs

3306FC Front Panel LEDs

3328T Front Panel LEDs

Page 51

The function of these LEDs is summarized in the table below:

Note: With some network adapters, the Port Status LED will light only

after the board has been initialized with the appropriate driver software (e.g., after IPX has been loaded in a NetWare environment).

TROUBLESHOOTING

40

Front Panel LEDs

LED Condition Status

Power Off No AC power

Green AC power on

NMM Off NMM not installed

Blinking Green Power-on diagnostics being

performed on NMM

Green NMM has passed power-on

diagnostics

Blinking Yellow NMM failed power-on diagnostics

Collision Off No collisions detected

(one per segment) Blinking Yellow A collision has been detected on

the network (i.e., the hub is

receiving data from two or more

nodes at the same time)

Segment Off Repeater group is connected to the

(one per segment) stack

Yellow Repeater group is segmented

(i.e., isolated from rest of stack)

Green Repeater group is combined with

other groups within the hub

(Models 3312TA and 3326TA)

Port Status Off Port not connected or wiring is

(one per port) faulty

Green:

RJ-45 / ST Link between hub and attached

device is good

BNC / AUI Loopback function is working

Blinking Green Packet data is originating from

(Source) this port

Yellow Port is partitioned

(Partition)

Page 52

Testing the Installation

1. Power up or reset the hub and check the LEDs (refer to

“Connecting Power” in Chapter 2).

2. If the Power LED is not lit and there is no activity on the

entire unit:

• Check the connections between the hub, the power

cord, and the wall outlet.

• Check the connections to the punch-down block and

patch panel (if the hub is installed in a rack).

If the Power LED still does not light, contact SMC Tech

Support.

3. If the NMM LED blinks yellow, the power-on diagnostics

have failed. Contact SMC Tech Support.

4. If the Port Status LEDs are not responding:

• Check the connections between each network device

and the hub port, including wiring.

• Check that the devices are powered on and functioning

properly.

5. If the BNC Port Status LED is yellow, be sure the cable

attached to this port is properly terminated.

Note: If the BNC port is not used, it does not need to be

terminated.

41

TROUBLESHOOTING

Page 53

42

Page 54

TigerStack 3312TA . . . . . . . . . . . . . . . . . . . . . . 44

TigerStack 3326TA . . . . . . . . . . . . . . . . . . . . . . 44

TigerStack 3314T . . . . . . . . . . . . . . . . . . . . . . . 45

TigerStack 3328T . . . . . . . . . . . . . . . . . . . . . . . 45

TigerStack 3328TELCO . . . . . . . . . . . . . . . . . . 46

TigerStack 3306BC . . . . . . . . . . . . . . . . . . . . . 46

TigerStack 3306FC . . . . . . . . . . . . . . . . . . . . . . 47

All TigerStack Hubs . . . . . . . . . . . . . . . . . . . . . 47

Stacking Cable . . . . . . . . . . . . . . . . . . . . . . . . 48

APPENDIX A

SPECIFICATIONS

43

Page 55

TigerStack 3312TA

Order Numbers

SMC3312TA (with US power cord)

SMC3312TA EUR (with Continental power cord)

SMC3312TA UK (with UK power cord)

Ports

12 10BASE-T

2 expansion slots for optional AUI, 10BASE2, 10BASE-T and

10BASE-F modules

Segments/Unit

2

Weight

7.2 lbs. (3.27 kg)

AC Input Power

Maximum: 18.5 watts (23.0 watts with NMM)

Typical: 14.8 watts (19.0 watts with NMM)

DC Input Connector

14-pin, for optional RPU

DC Input Power (from optional RPU)

Maximum: +5 V @ 1.8 A, +12 V @ 700 mA (without NMM)

+5 V @ 2.7 A, +12 V @ 800 mA (with NMM)

TigerStack 3326TA

Order Numbers

SMC3326TA (with US power cord)

SMC3326TA EUR (with Continental power cord)

SMC3326TA UK (with UK power cord)

Ports

26 10BASE-T

2 expansion slots for optional AUI, 10BASE2, 10BASE-T and

10BASE-F modules

Segments/Unit

4

44

SPECIFICATIONS

Page 56

Weight

7.6 lbs. (3.45 kg)

AC Input Power

Maximum: 26.7 watts (32.0 watts with NMM)

Typical: 21.0 watts (25.5 watts with NMM

DC Input Connector

14-pin, for optional RPU

DC Input Power (from optional RPU)

Maximum: +5 V @ 3 A, +12 V @ 700 mA (without NMM)

+5 V @ 3.9 A, +12 V @ 800 mA (with NMM)

TigerStack 3314T

Order Numbers

SMC3314T (with US power cord)

SMC3314T EUR (with Continental power cord)

SMC3314T UK (with UK power cord)

Ports

14 10BASE-T

Segments/Unit

2

Weight

4.15 lbs. (1.88 kg)

AC Input Power

Maximum: 11.0 watts (15.7 watts with NMM)

Typical: 9.8 watts (14.0 watts with NMM)

TigerStack 3328T

Order Numbers

SMC3328T (with US power cord)

SMC3328T EUR (with Continental power cord)

SMC3328T UK (with UK power cord)

Ports

28 10BASE-T

Segments/Unit

4

45

SPECIFICATIONS

Page 57

Weight

4.7 lbs. (2.13 kg)

AC Input Power

Maximum: 22.7 watts (26.0 watts with NMM)

Typical: 17.0 watts (21.5 watts with NMM)

TigerStack 3328TELCO

Order Numbers

SMC3328TELCO (with US power cord)

SMC3328TELCO EUR (with Continental power cord)

SMC3328TELCO UK (with UK power cord)

Ports

28 10BASE-T

Segments/Unit

4

Weight

4.7 lbs. (2.13 kg)

AC Input Power

Maximum: 22.7 watts (26.0 watts with NMM)

Typical: 17.0 watts (21.5 watts with NMM)

TigerStack 3306BC

Order Numbers

SMC3306BC (with US power cord)

SMC3306BC EUR (with Continental power cord)

SMC3306BC UK (with UK power cord)

Ports

6 BNC

1 10BASE-T

1 AUI

Segments/Unit

2

Weight

4.35 lbs. (1.97 kg)

SPECIFICATIONS

46

Page 58

AC Input Power

Maximum: 36.5 watts (40.0 watts with NMM)

Typical: 28 watts (34.0 watts with NMM

TigerStack 3306FC

Order Numbers

SMC3306FC (with US power cord)

SMC3306FC EUR (with Continental power cord)

SMC3306FC UK (with UK power cord)

Ports

6 ST

1 BNC

1 AUI

Segments/Unit

2

Weight

4.15 lbs. (1.88 kg)

AC Input Power

Maximum: 27.3 watts (33.88 watts with NMM)

Typical: 21.84 watts (27.1 watts with NMM)

All TigerStack Hubs

Network Interface

10BASE-T

RJ-45, 100 Ohm UTP cable (EIA/TIA categories 3, 4, 5)

10BASE2

BNC, 50 Ohm coax (RG-58A/U or RG-58C/U)

10BASE-F

Dual ST, 62.5/125 micron core duplex fiber

AUI

D-Type 15-pin female, multi 78 Ohm STP with overall shield

Size

1.75 in. H x 16.875 in. W x 9.00 in. D

(4.4 cm x 43.2 cm x 22.9 cm)

Temperature

Operating: 0˚ to 45˚ C (32˚ to 113˚ F)

Storage: 0˚ to 85˚ C (32˚ to 185˚ F)

47

SPECIFICATIONS

Page 59

Relative Humidity, non-condensing

Operating: 0% to 90%

Storage: 0% to 95%

Power Supply

Internal, auto-ranging transformer

100 to 240 VAC, 50 to 60 Hz

Compliances

Safety

UL 1950

EN60950 (TÜV)

CSA 22.2 No. 950

Emissions

FCC Class A

Canada Department of Communications, Class A

EN55022 (CISPR 22) Class A

VCCI Class 1

Immunity

EN50082-1

Standards

IEEE 802.3

ISO/IEC 8802-3

Warranty

Unit

Limited Lifetime

Power Supply and Fan

5 years

Stacking Cable

Order Number

SMC3300-CABLE

Connector

50-pin conductor

Cable

SCSI

SPECIFICATIONS

48

Page 60

Types/Connectors . . . . . . . . . . . . . . . . . . . . . . 50

Cable Specifications . . . . . . . . . . . . . . . . . . . . . 51

Extended Distance . . . . . . . . . . . . . . . . . . . . . 53

10BASE-T Pin Assignments . . . . . . . . . . . . . . . 54

RJ-45 Connectors . . . . . . . . . . . . . . . . . . . . . 54

Telco Connectors . . . . . . . . . . . . . . . . . . . . 55

Automatic Polarity Detection and Correction . 57

Straight-Through Wiring . . . . . . . . . . . . . . . 57

Crossover Wiring . . . . . . . . . . . . . . . . . . . . 60

AUI Pin Assignments . . . . . . . . . . . . . . . . . . . . 63

APPENDIX B

CABLES

49

Page 61

Types/Connectors

CABLES

50

Cable Type Connectors

10BASE-T 100 ohm UTP, male 8-pin RJ-45

(Twisted-Pair) 22 - 26 AWG, or 50-pin Telco

0.4 - 0.6 mm,

2 pairs

AUI External male 15-pin, D-type, AUI

Transceiver Drop

Thick Coax 50 ohm Coax N-Series

Thin Coax RG-58A/U or Bayonet style BNC

RG-58C/U

50 ohm Coax

Dual Fiber 50/125, 62.5/125, Bayonet style Dual ST

80/125 or 100/140

Micron Core

Cable Types and Connectors

Page 62

Cable Specifications

51

CABLES

Type 100 ohm UTP

(e.g., IBM Type 3 or AT&T DIW)

Number of Pairs 2

Max. Link Segment Length 328 ft. (100 m)

Min. Link Segment Length 2.0 ft. (0.6 m)

Max. Number of Attachments 2

per Link Segment

Type 78 ohm STP

Max. Drop Cable Length 165 ft. (50 m)

Min. Drop Cable Length 0.0 ft. (0.0 m)

Max. Number of Attachments 2

per Drop Cable

Type 50 ohm Coax

Max. Segment Length 1,640 ft. (500 m)

Min. Distance Between 8.2 ft. (2.5 m)

Transceivers

Max. Number of Attachments 100

per Cable Segment

Twisted-Pair Link Segment Specifications

Thick Coax Cable Specifications

AUI Cable Specifications

Page 63

* See “Extended Distance.”

52

Type 50/125, 62.5/125, 80/125

100/140 micron core

Number of Pairs 2

Max. Link Segment Length 0.62 mi. (1.0 km)

Min. Link Segment Length no minimum

Max. Number of Attachments 2

per Link Segment

CABLES

Type RG-58A/U or RG-58C/U Coax

Max. Segment Length 1,000 ft.* (305 m)

Min. Distance Between 1.5 ft. (0.5 m)

Devices

Max. Number of Attachments 30

per Cable Segment

Thin Coax Cable Specifications

Duplex Fiber Cable Specifications

Page 64

Extended Distance

The IEEE 802.3 10BASE2 specification defines the maximum

length of a thin coax segment as 607 feet (185 m). However,

TigerStack BNC ports support thin coax segments of up to

1,000 feet (305 m) in length with 50 ohm RG-58 cabling meeting the following specifications:

Note: If other Ethernet products are attached to the same

cable segment, then the maximum length of that cable

segment is limited by the length these products support.

53

CABLES

Number of Nodes Nominal Attenuation at 10 MHz

per 1,000 feet (305 m) per 100 feet (30 m)

Maximum 10 13 dB or less 1.3 dB or less

Maximum 30 12 dB or less 1.2 dB or less

Extended Distance Specifications

Page 65

10BASE-T Pin Assignments

Caution: Regulations regarding the connection of equipment to

telephone networks vary from country to country.

Check with your local telephone network supplier

before using existing telephone wiring.

An Ethernet twisted-pair link segment requires two pairs of

wires. Each wire pair is identified by two different colors. For

example, one wire might be red and the other, red with white

stripes.

Caution: Each wire pair must be attached to the RJ-45 connec-

tors in a specific orientation (see “Crossover Function”

in Chapter 3 for an explanation).

RJ-45 Connectors

Each twisted-pair link segment must have an RJ-45

male connector attached to

both ends. According to the

10BASE-T specification,

pins 1 and 2 are used for

transmitting data, and pins 3

and 6 for receiving data.

* The “+” and “-” signs are used to represent the polarity of the two

wires that make up each wire pair.

Note how the

pins are numbered. Be sure

to hold the connectors in the

same orientation

when attaching

the wires to the

pins.

54

CABLES

Pin Number Assignment*

1 Tx+

2 Tx3 Rx+

6 Rx-

RJ-45 Pin Assignments

RJ-45 Connector Pin Numbers

Page 66

Telco Connectors

Twisted-pair wiring is available in bundles of twenty-five wire

pairs. A bundle requires 50-pin Telco male connectors at each

end.

Note how the pins are numbered on the 50-pin female connector shown below. Be sure to hold the 50-pin male connector

in the same orientation when attaching it to the hub.

The TigerStack 3328TELCO is equipped with two Telco connectors: the first for ports 1 to 6 and 8 to 13, and the second for

ports 15 to 20 and 22 to 27. The table on the following page

provides the pin assignments for both connectors.

55

CABLES

25-Pair Telco Connector Pin Numbers

Page 67

* The “+” and “-” signs are used to represent the polarity of the two

wires that make up each wire pair.

CABLES

56

50-Pin Telco Pin Assignments

Pin

Number

Ports

Assign-

ment*

Pin

Numbers

Ports

Assign-

ment*

1 1, 15 Rx- 26 1, 15 Rx+

2 1, 15 Tx- 27 1, 15 Tx+

3 2, 16 Rx- 28 2, 16 Rx+

4 2, 16 Tx- 29 2, 16 Tx+

5 3, 17 Rx- 30 3, 17 Rx+

6 3, 17 Tx- 31 3, 17 Tx+

7 4, 18 Rx- 32 4, 18 Rx+

8 4, 18 Tx- 33 4, 18 Tx+

9 5, 19 Rx- 34 5, 19 Rx+

10 5, 19 Tx- 35 5, 19 Tx+

11 6, 20 Rx- 36 6, 20 Rx+

12 6, 20 Tx- 37 6, 20 Tx+

13 8, 22 Rx- 38 8, 22 Rx+

14 8, 22 Tx- 39 8, 22 Tx+

15 9, 23 Rx- 40 9, 23 Rx+

16 9, 23 Tx- 41 9, 23 Tx+

17 10, 24 Rx- 42 10, 24 Rx+

18 10, 24 Tx- 43 10, 24 Tx+

19 11, 25 Rx- 44 11, 25 Rx+

20 11, 25 Tx- 45 11, 25 Tx+

21 12, 26 Rx- 46 12, 26 Rx+

22 12, 26 Tx- 47 12, 26 Tx+

23 13, 27 Rx- 48 13, 27 Rx+

24 13, 27 Tx- 49 13, 27 Tx+

25 nc nc 50 nc nc

Page 68

Automatic Polarity Detection and Correction

If a receive data pair has the “+” and “-” signals inadvertently

switched, the hubs correct the signal inversion automatically,

allowing the data path to operate correctly.

Straight-Through Wiring

If the twisted-pair link segment is to join two ports and only

one of the ports has an internal crossover, the two pairs of

wires must be straight-through.

Pin assignments for Telco connectors are given on the next

page.

57

CABLES

End 1 End 2

1 (Tx+) 1 (Tx+)

2 (Tx-) 2 (Tx-)

3 (Rx+) 3 (Rx+)

6 (Rx-) 6 (Rx-)

Straight-Through RJ-45 Pin Assignments

Page 69

CABLES

58

Straight-Through 50-Pin Telco Pin Assignments

Hub Port Device Equiv. RJ-45 Pin

1 (Rx-) 1 (Rx-) 2

2 (Tx-) 1 (Tx-) 6

3 (Rx-) 2 (Rx-) 2

4 (Tx-) 2 (Tx-) 6

5 (Rx-) 3 (Rx-) 2

6 (Tx-) 3 (Tx-) 6

7 (Rx-) 4 (Rx-) 2

8 (Tx-) 4 (Tx-) 6

9 (Rx-) 5 (Rx-) 2

10 (Tx-) 5 (Tx-) 6

11 (Rx-) 6 (Rx-) 2

12 (Tx-) 6 (Tx-) 6

13 (Rx-) 8 (Rx-) 2

14 (Tx-) 8 (Tx-) 6

15 (Rx-) 9 (Rx-) 2

16 (Tx-) 9 (Tx-) 6

17 (Rx-) 10 (Rx-) 2

18 (Tx-) 10 (Tx-) 6

19 (Rx-) 11 (Rx-) 2

20 (Tx-) 11 (Tx-) 6

21 (Rx-) 12 (Rx-) 2

22 (Tx-) 12 (Tx-) 6

23 (Rx-) 13 (Rx-) 2

24 (Tx-) 13 (Tx-) 6

25 (nc) nc (nc) nc

Page 70

59

CABLES

Straight-Through 50-Pin Telco Pin Assignments - Continued

Hub Port Device Equiv. RJ-45 Pin

26 (Rx+) 1 (Rx+) 1

27 (Tx+) 1 (Tx+) 3

28 (Rx+) 2 (Rx+) 1

29 (Tx+) 2 (Tx+) 3

30 (Rx+) 3 (Rx+) 1

31 (Tx+) 3 (Tx+) 3

32 (Rx+) 4 (Rx+) 1

33 (Tx+) 4 (Tx+) 3

34 (Rx+) 5 (Rx+) 1

35 (Tx+) 5 (Tx+) 3

36 (Rx+) 6 (Rx+) 1

37 (Tx+) 6 (Tx+) 3

38 (Rx+) 8 (Rx+) 1

39 (Tx+) 8 (Tx+) 3

40 (Rx+) 9 (Rx+) 1

41 (Tx+) 9 (Tx+) 3

42 (Rx+) 10 (Rx+) 1

43 (Tx+) 10 (Tx+) 3

44 (Rx+) 11 (Rx+) 1

45 (Tx+) 11 (Tx+) 3

46 (Rx+) 12 (Rx+) 1

47 (Tx+) 12 (Tx+) 3

48 (Rx+) 13 (Rx+) 1

49 (Tx+) 13 (Tx+) 3

50 (nc) nc (nc) nc

Page 71

Crossover Wiring

If the twisted-pair link segment is to join two ports and either

both ports are labeled with an “X” or neither port is labeled

with an “X,” a crossover must be implemented in the wiring.

Pin assignments for Telco connectors are given on the next

page.

CABLES

60

End 1 End 2

1 (Tx+) 3 (Rx+)

2 (Tx-) 6 (Rx-)

3 (Rx+) 1 (Tx+)

6 (Rx-) 2 (Tx-)

Crossover RJ-45 Pin Assignments

Page 72

61

CABLES

Crossover 50-Pin Telco Pin Assignments

Hub Port Device Equiv. RJ-45 Pin

1 (Rx-) 1 (Tx-) 6

2 (Tx-) 1 (Rx-) 2

3 (Rx-) 2 (Tx-) 6

4 (Tx-) 2 (Rx-) 2

5 (Rx-) 3 (Tx-) 6

6 (Tx-) 3 (Rx-) 2

7 (Rx-) 4 (Tx-) 6

8 (Tx-) 4 (Rx-) 2

9 (Rx-) 5 (Tx-) 6

10 (Tx-) 5 (Rx-) 2

11 (Rx-) 6 (Tx-) 6

12 (Tx-) 6 (Rx-) 2

13 (Rx-) 8 (Tx-) 6

14 (Tx-) 8 (Rx-) 2

15 (Rx-) 9 (Tx-) 6

16 (Tx-) 9 (Rx-) 2

17 (Rx-) 10 (Tx-) 6

18 (Tx-) 10 (Rx-) 2

19 (Rx-) 11 (Tx-) 6

20 (Tx-) 11 (Rx-) 2

21 (Rx-) 12 (Tx-) 6

22 (Tx-) 12 (Rx-) 2

23 (Rx-) 13 (Tx-) 6

24 (Tx-) 13 (Rx-) 2

25 (nc) nc (nc) nc

Page 73

62

CABLES

Crossover 50-Pin Telco Pin Assignments - Continued

Hub Port Device Equiv. RJ-45 Pin

26 (Rx+) 1 (Tx+) 3

27 (Tx+) 1 (Rx+) 1

28 (Rx+) 2 (Tx+) 3

29 (Tx+) 2 (Rx+) 1

30 (Rx+) 3 (Tx+) 3

31 (Tx+) 3 (Rx+) 1

32 (Rx+) 4 (Tx+) 3

33 (Tx+) 4 (Rx+) 1

34 (Rx+) 5 (Tx+) 3

35 (Tx+) 5 (Rx+) 1

36 (Rx+) 6 (Tx+) 3

37 (Tx+) 6 (Rx+) 1

38 (Rx+) 8 (Tx+) 3

39 (Tx+) 8 (Rx+) 1

40 (Rx+) 9 (Tx+) 3

41 (Tx+) 9 (Rx+) 1

42 (Rx+) 10 (Tx+) 3

43 (Tx+) 10 (Rx+) 1

44 (Rx+) 11 (Tx+) 3

45 (Tx+) 11 (Rx+) 1

46 (Rx+) 12 (Tx+) 3

47 (Tx+) 12 (Rx+) 1

48 (Rx+) 13 (Tx+) 3

49 (Tx+) 13 (Rx+) 1

50 (nc) nc nc nc

Page 74

AUI Pin Assignments

Note: Voltage Plus (VP) and Voltage Common (Vc) use a

single twisted-pair in the AUI cable.

63

CABLES

Pin Circuit Signal Name

3 DO-A Data Out Circuit A

10 DO-B Data Out Circuit B

11 DO-S Data Out Circuit Shield

5 DI-A Data In Circuit A

12 DI-B Data In Circuit B

4 DI-S Data In Circuit Shield

8 CO-S Control Out Circuit Shield

2 CI-A Control In Circuit A

9 CI-B Control In Circuit B

1 CI-S Control In Circuit Shield

6 Vc Voltage Common

13 VP Voltage Plus

14 VS Voltage Shield

Shell PG Protective Ground

(Conductive Shell)

AUI Pin Assignments

Page 75

64

Page 76

65

A

AC line cord 15

Adhesive feet 8, 12

Attaching

adhesive feet 12

BNC transceiver 19

brackets 11

power cord 15

transceiver to AUI port 19

AUI

attaching transceiver to 19

drop cable 27

pin assignments 63

port 18, 19, 27, 50

Automatic

polarity detection and

correction 5, 57

port/segment partitioning

and reconnection 5

B

Bandwidth

boosting 2, 31

scaling 2, 33

BNC

connector 26, 50

transceiver, SQE switch 19

Boosting bandwidth 2, 31

Bracket Mounting Kit 8

Brackets, attaching 11

Buttons

crossover 21

segment 5, 31-36

C

Cable

connectors 50

crossover 21, 22, 60

specifications 51, 52

straight-through 21, 22, 57

types 50

INDEX

Cable segment

IRL (Inter-Repeater Link) 20

populated 20

unpopulated 20

Cascading hubs 18

Changing AC line cord 15

Checklist, equipment 8

Collision

domain, definition of 2

LEDs 5, 16, 38-40

Compliances v, 48

Connecting to

adapters 18

fiber cable 28

LAN switch 33

network 18

other hubs 18

power source 13, 15

telephone networks 23, 54

thick coax cable 27

thin coax cable 26

twisted-pair cable 21, 23

wiring closet 22-25

Connectivity

SMC 5 - 4 - 3 Rule 20

Connectors

AUI 18, 19, 27, 50

BNC 26, 50

RJ-45 23, 50

SCSI 13, 14

ST 28, 50

Telco 24, 25, 50, 55

Crossover

buttons 21

function 21

pin assignments

RJ-45 60

Telco 61, 62

wiring 60

wiring requirements 22

Page 77

66

D

Desktop mounting 12

Diagnostics, power-on 15

Distance, extended 5, 26, 53

Drop cable, AUI 27

Duplex cable, fiber 28

E

Equipment checklist 8

Extended distance 5, 26, 53

F

Fiber

cable connections 28

cable specifications 52

connector 28, 50

Fixed crossover ports 5, 21, 22

Front Panel LEDs 38, 39

H

Hubs

cascading 18

installing 8-12

locating 8, 10

managing 3

stacking 2, 13-15

I

Installing hubs 8-12

Interconnecting

repeater groups 2, 33

segments 2, 33

International line cords 15

IRL (Inter-Repeater Link) 20

Isolating segments

via hardware 31, 34-36

via software 31, 34

J

Jabber lockup protection 5

INDEX

L

LAN switch 33

LEDs

Collision 5, 16, 38-40

NMM 5, 15, 38-41

Port Status 5, 16, 38-41

Power 5, 15, 38-41

power-up sequence 15

Segment 5, 16, 38-40

Line cord 15

Link integrity checking 5

Locating hubs 8, 10

Logical repeater, definition of 2

M

Making network connections 18

directly 18

via transceiver 18

Making Telco connections 24, 25

Managing hubs 3

Microsegmentation 31

Mounting hubs

in a rack 10

on a desktop 12

on a shelf 12

N

Network Management Module 3

field-installable 3

placement in stack 3

NMM LED 5, 15, 38-41

O

Optional equipment 9

Overriding segmentation

settings 34

P

Package contents 8

Partitioning, automatic

port/segment 5

Page 78

Pin assignments

10BASE-T 54, 56-62

crossover 60-62

straight-through 57-59

AUI 63

Pin numbers

RJ-45 54

Telco 55

Point-to-point

connections 21, 28

Polarity

automatic detection and

correction of 5, 57

of wires 54

Populated cable segment 20

Port

AUI 18, 19, 27, 50

fixed crossover 5, 21, 22

RJ-45 23, 50

ST 28, 50

status LEDs 5, 16, 38-41

switch-selectable

crossover 5, 21, 22

uplink 5, 21, 22

Power

connecting to 13, 15

connector 15

cord, attaching 15

LED 5, 15, 38-41

supply 5

Power-on diagnostics 15, 41

Power-up LED sequence 15

R

Rack mounting

hubs 10

screws 9

site guidelines 10

tools, required 9

Reconnection, automatic

port/segment 5

Rejoining repeater groups 31

Removing screws 10

Repeater

hops 2

logical, definition of 2

Repeater groups

definition of 30

interconnecting 2, 33

isolating 2, 31

rejoining 31

segmenting 2, 31

uniting 30

RJ-45 connector 23, 50

pin assignments 54

pin numbers 54

Routing twisted-pair cable 8

S

Scaling bandwidth 2, 33

SCSI connectors 13, 14

Segment

buttons 5, 31-36

definition of 31

LEDs 5, 16, 38-40

settings, overriding 34

switches 5, 31, 32, 34-36

Segmentation hardware

lockout 34

Segmenting

hubs 2, 31, 34-36

via hardware 31, 34-36

via software 31, 34

repeater groups 2, 31

Segments

interconnecting 2, 33

isolating 31

rejoining 31

Setting unit ID switch 13

Shelf mounting 12

Simplex cable, fiber 28

Site guidelines 8, 10

67

INDEX

Page 79

Smart squelch digital noise

filter 5

SMC 5 - 4 - 3 Rule 20

Specifications

cable 51, 52

extended distance 53

hubs 44-48

network interface 47

stacking cable 48

SQE switch 19

ST connectors 28, 50

Stacking

cable 9, 13, 48

hubs 2, 13, 14, 15

Standards 48

Status/Diagnostic

LEDs 5, 15, 16, 38-40

Straight-through

pin assignments

RJ-45 57

Telco 58, 59

wiring 22, 57

wiring requirements 22

Subdividing a workgroup 2

Switch-selectable crossover

ports 5, 21, 22

Switches

segment 5, 31-36

T

Tap-type transceiver 27

Telco

connections 24, 25

connector 24, 25, 50

pin assignments 56

pin numbers 55

Telephone networks 23, 54

Terminating

thick coax cable 27

thin coax cable 26, 41

Terminator 26, 27

Testing the installation 15, 16, 41

Thick coax

cable specifications 51

connections 27

terminating 27

Thin coax

cable specifications 52

connections 26

terminating 26, 41