Page 1

™

TigerAccess

Fast Ethernet Switch

◆ 24 10/100BASE-TX ports

◆ 2 10/100/1000BASE-T ports shared with SFP slots

◆ 2 module slots for Gigabit extender modules

◆ Non-blocking switching architecture

◆ Spanning Tree Protocol, RSTP and MSTP

◆ Up to 12 LACP or static 8-port trunks

◆ Layer 2/3/4 CoS support through eight priority queues

10/100

◆ Layer 3/4 traffic priority with IP Precedence and IP DSCP

◆ Full support for VLANs with GVRP and QinQ

◆ IGMP multicast filtering and snooping

◆ Support for jumbo frames up to 9 KB

◆ Manageable via console, Web, SNMP/RMON

◆ Security features: ACL, RADIUS, 802.1X

Installation Guide

SMC7824M/ESW

Page 2

Page 3

TigerAccess™ 10/100

Installation Guide

From SMC’s Tiger line of feature-rich workgroup LAN solutions

38 Tesla

Irvine, CA 92618

Phone: (949) 679-8000

January 2007

Pub. # 150200058900A

Page 4

Information furnished by SMC Networks, Inc. (SMC) is believed to be accurate and reliable. However, no

responsibility is assumed by SMC for its use, nor for any infringements of patents or other rights of third

parties which may result from its use. No license is granted by implication or otherwise under any patent or

patent rights of SMC. SMC reserves the right to change specifications at any time without notice.

Copyright © 2007 by

SMC Networks, Inc.

38 Tesla

Irvine, CA 92618

All rights reserved. Printed in Taiwan

Trademarks:

SMC is a registered trademark; and EZ Switch, TigerAccess, TigerStack and TigerSwitch are trademarks of

SMC Networks, Inc. Other product and company names are trademarks or registered trademarks of their

respective holders.

Page 5

L

IMITED

Limited Warranty Statement: SMC Networks, Inc. (“SMC”) warrants its products to be

free from defects in workmanship and materials, under normal use and service, for the

applicable warranty term. All SMC products carry a standard 90-day limited warranty from

the date of purchase from SMC or its Authorized Reseller. SMC may, at its own discretion,

repair or replace any product not operating as warranted with a similar or functionally

equivalent product, during the applicable warranty term. SMC will endeavor to repair or

replace any product returned under warranty within 30 days of receipt of the product.

The standard limited warranty can be upgraded to a Limited Lifetime* warranty by registering

new products within 30 days of purchase from SMC or its Authorized Reseller. Registration

can be accomplished via the enclosed product registration card or online via the SMC Web

site. Failure to register will not affect the standard limited warranty. The Limited Lifetime

warranty covers a product during the Life of that Product, which is defined as the period of

time during which the product is an “Active” SMC product. A product is considered to be

“Active” while it is listed on the current SMC price list. As new technologies emerge, older

technologies become obsolete and SMC will, at its discretion, replace an older product in its

product line with one that incorporates these newer technologies. At that point, the obsolete

product is discontinued and is no longer an “Active” SMC product. A list of discontinued

products with their respective dates of discontinuance can be found at:

http://www.smc.com/index.cfm?action=customer_service_warranty.

All products that are replaced become the property of SMC. Replacement products may be

either new or reconditioned. Any replaced or repaired product carries either a 30-day limited

warranty or the remainder of the initial warranty, whichever is longer. SMC is not responsible

for any custom software or firmware, configuration information, or memory data of

Customer contained in, stored on, or integrated with any products returned to SMC pursuant

to any warranty. Products returned to SMC should have any customer-installed accessory or

add-on components, such as expansion modules, removed prior to returning the product for

replacement. SMC is not responsible for these items if they are returned with the product.

Customers must contact SMC for a Return Material Authorization number prior to returning

any product to SMC. Proof of purchase may be required. Any product returned to SMC

without a valid Return Material Authorization (RMA) number clearly marked on the outside

of the package will be returned to customer at customer’s expense. For warranty claims within

North America, please call our toll-free customer support number at (800) 762-4968.

Customers are responsible for all shipping charges from their facility to SMC. SMC is

responsible for return shipping charges from SMC to customer.

W

ARRANTY

v

Page 6

WARRANTIES EXCLUSIVE: IF AN SMC PRODUCT DOES NOT OPERATE AS

WARRANTED ABOVE, CUSTOMER’S SOLE REMEDY SHALL BE REPAIR OR

REPLACEMENT OF THE PRODUCT IN QUESTION, AT SMC’S OPTION. THE

FOREGOING WARRANTIES AND REMEDIES ARE EXCLUSIVE AND ARE IN

LIEU OF ALL OTHER WARRANTIES OR CONDITIONS, EXPRESS OR IMPLIED,

EITHER IN FACT OR BY OPERATION OF LAW, STATUTORY OR OTHERWISE,

INCLUDING WARRANTIES OR CONDITIONS OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE. SMC NEITHER ASSUMES NOR

AUTHORIZES ANY OTHER PERSON TO ASSUME FOR IT ANY OTHER

LIABILITY IN CONNECTION WITH THE SALE, INSTALLATION,

MAINTENANCE OR USE OF ITS PRODUCTS. SMC SHALL NOT BE LIABLE

UNDER THIS WARRANTY IF ITS TESTING AND EXAMINATION DISCLOSE THE

ALLEGED DEFECT IN THE PRODUCT DOES NOT EXIST OR WAS CAUSED BY

CUSTOMER’S OR ANY THIRD PERSON’S MISUSE, NEGLECT, IMPROPER

INSTALLATION OR TESTING, UNAUTHORIZED ATTEMPTS TO REPAIR, OR

ANY OTHER CAUSE BEYOND THE RANGE OF THE INTENDED USE, OR BY

ACCIDENT, FIRE, LIGHTNING, OR OTHER HAZARD.

LIMITATION OF LIABILITY: IN NO EVENT, WHETHER BASED IN CONTRACT

OR TORT (INCLUDING NEGLIGENCE), SHALL SMC BE LIABLE FOR

INCIDENTAL, CONSEQUENTIAL, INDIRECT, SPECIAL, OR PUNITIVE

DAMAGES OF ANY KIND, OR FOR LOSS OF REVENUE, LOSS OF BUSINESS, OR

OTHER FINANCIAL LOSS ARISING OUT OF OR IN CONNECTION WITH THE

SALE, INSTALLATION, MAINTENANCE, USE, PERFORMANCE, FAILURE, OR

INTERRUPTION OF ITS PRODUCTS, EVEN IF SMC OR ITS AUTHORIZED

RESELLER HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

SOME STATES DO NOT ALLOW THE EXCLUSION OF IMPLIED WARRANTIES

OR THE LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES FOR

CONSUMER PRODUCTS, SO THE ABOVE LIMITATIONS AND EXCLUSIONS

MAY NOT APPLY TO YOU. THIS WARRANTY GIVES YOU SPECIFIC LEGAL

RIGHTS, WHICH MAY VARY FROM STATE TO STATE. NOTHING IN THIS

WARRANTY SHALL BE TAKEN TO AFFECT YOUR STATUTORY RIGHTS.

* SMC will provide warranty service for one year following discontinuance from the active

SMC price list. Under the limited lifetime warranty, internal and external power supplies, fans,

and cables are covered by a standard one-year warranty from date of purchase.

vi

SMC Networks, Inc.

38 Tesla

Irvine, CA 92618

Page 7

COMPLIANCES

FCC - Class A

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

You are cautioned that changes or modifications not expressly approved by the party

responsible for compliance could void your authority to operate the equipment.

You may use unshielded twisted-pair (UTP) for RJ-45 connections - Category 3 or better for

10 Mbps connections, Category 5 or better for 100 Mbps connections, Category 5, 5e, or 6

for 1000 Mbps connections. For fiber optic connections, you may use 50/125 or 62.5/125

micron multimode fiber or 9/125 micron single-mode fiber.

Industry Canada - Class A

This digital apparatus does not exceed the Class A limits for radio noise emissions from

digital apparatus as set out in the interference-causing equipment standard entitled “Digital

Apparatus,” ICES-003 of the Department of Communications.

Cet appareil numérique respecte les limites de bruits radioélectriques applicables aux appareils

numériques de Classe A prescrites dans la norme sur le matériel brouilleur: “Appareils

Numériques,” NMB-003 édictée par le ministère des Communications.

Japan VCCI Class A

vii

Page 8

C

OMPLIANCES

CE Mark Declaration of Conformance for EMI and

Safety (EEC)

SMC contact for these products in Europe is:

SMC Networks Europe,

Edificio Conata II,

Calle Fructuós Gelabert 6-8, 2

08970 - Sant Joan Despí, Barcelona, Spain.

This information technology equipment complies with the requirements of the Council

Directive 89/336/EEC on the Approximation of the laws of the Member States relating to

Electromagnetic Compatibility and 73/23/EEC for electrical equipment used within certain

voltage limits and the Amendment Directive 93/68/EEC. For the evaluation of the

compliance with these Directives, the following standards were applied:

RFI Emission:

Immunity:

LVD:

War ni ng:

Attention: Les raccordeurs ne sont pas utilisés pour le système téléphonique!

• Limit class A according to EN 55022:1998

• Limit class A for harmonic current emission according to

EN 61000-3-2/1995

• Limitation of voltage fluctuation and flicker in low-voltage supply

system according to EN 61000-3-3/1995

• Product family standard according to EN 55024:1998

• Electrostatic Discharge according to EN 61000-4-2:1995

(Contact Discharge: ±4 kV, Air Discharge: ±8 kV)

• Radio-frequency electromagnetic field according to EN 61000-4-3:1996

(80 - 1000 MHz with 1 kHz AM 80% Modulation: 3 V/m)

• Electrical fast transient/burst according to EN 61000-4-4:1995 (AC/

DC power supply: ±1 kV, Data/Signal lines: ±0.5 kV)

• Surge immunity test according to EN 61000-4-5:1995

(AC/DC Line to Line: ±1 kV, AC/DC Line to Earth: ±2 kV)

• Immunity to conducted disturbances, Induced by radio-frequency

fields: EN 61000-4-6:1996 (0.15 - 80 MHz with 1 kHz AM 80%

Modulation: 3 V/m)

• Power frequency magnetic field immunity test according to

EN 61000-4-8:1993

(1 A/m at frequency 50 Hz)

• Voltage dips, short interruptions and voltage variations immunity test

according to EN 61000-4-11:1994 (>95% Reduction @10 ms, 30%

Reduction @500 ms, >95% Reduction @5000 ms)

• EN 60950-1:2001

Do not plug a phone jack connector in the RJ-45 port. This may damage this device.

o

, 4a,

viii

Page 9

C

OMPLIANCES

Australia AS/NZS 3548 (1995) - Class A

N11846

SMC contact for products in Australia is:

SMC Communications Pty. Ltd.

Suite 18, 12 Tryon Road,

Lindfield NSW2070,

Phone: 61-2-94160437

Fax: 61-2-94160474

Safety Compliance

Warning: Fiber Optic Port Safety

CLASS I

LASER DEVICE

Avertissment: Ports pour fibres optiques - sécurité sur le plan optique

DISPOSITIF LASER

DE CLASSE I

Warnhinweis: Faseroptikanschlüsse - Optische Sicherheit

LASERGER

DER KLASSE I

When using a fiber optic port, never look at the transmit laser while

it is powered on. Also, never look directly at the fiber TX port and

fiber cable ends when they are powered on.

Ne regardez jamais le laser tant qu’il est sous tension. Ne regardez

jamais directement le port TX (Transmission) à fibres optiques et les

embouts de câbles à fibres optiques tant qu’ils sont sous tension.

Niemals ein Übertragungslaser betrachten, während dieses

ÄT

eingeschaltet ist. Niemals direkt auf den Faser-TX-Anschluß und auf

die Faserkabelenden schauen, während diese eingeschaltet sind.

ix

Page 10

C

OMPLIANCES

Power Cord Safety

Please read the following safety information carefully before installing the switch:

War ni ng:

• The unit must be connected to an earthed (grounded) outlet to comply with international

• Do not connect the unit to an A.C. outlet (power supply) without an earth (ground)

• The appliance coupler (the connector to the unit and not the wall plug) must have a

• The socket outlet must be near to the unit and easily accessible. You can only remove power

• This unit operates under SELV (Safety Extra Low Voltage) conditions according to

• When using an AC-power module, the customer must provide a 20 A listed circuit breaker

Installation and removal of the unit must be carried out by qualified personnel only.

safety standards.

connection.

configuration for mating with an EN 60320/IEC 320 appliance inlet.

from the unit by disconnecting the power cord from the outlet.

IEC 60950. The conditions are only maintained if the equipment to which it is connected

also operates under SELV conditions.

on the branch circuit. When using a DC-power conversion module, a listed circuit breaker

or other appropriate disconnect device must be provided as part of the building installation.

France and Peru only

This unit cannot be powered from IT

be powered by 230 V (2P+T) via an isolation transformer ratio 1:1, with the secondary

connection point labelled Neutral, connected directly to earth (ground).

†

Impédance à la terre

Important! Before making connections, make sure you have the correct cord set. Check it

(read the label on the cable) against the following:

Power Cord Set

U.S.A. and Canada The cord set must be UL-approved and CSA certified.

The minimum specifications for the flexible cord are:

- No. 18 AWG - not longer than 2 meters, or 16 AWG.

- Type SV or SJ

- 3-conductor

The cord set must have a rated current capacity of at least 10 A

The attachment plug must be an earth-grounding type with NEMA

5-15P (15 A, 125 V) or NEMA 6-15P (15 A, 250 V) configuration.

Denmark The supply plug must comply with Section 107-2-D1, Standard

Switzerland The supply plug must comply with SEV/ASE 1011.

U.K. The supply plug must comply with BS1363 (3-pin 13 A) and be

DK2-1a or DK2-5a.

fitted with a 5 A fuse which complies with BS1362.

The mains cord must be <HAR> or <BASEC> marked and be of

type HO3VVF3GO.75 (minimum).

†

supplies. If your supplies are of IT type, this unit must

x

Page 11

C

OMPLIANCES

Power Cord Set (Continued)

Europe The supply plug must comply with CEE7/7 (“SCHUKO”).

The mains cord must be <HAR> or <BASEC> marked and be of

type HO3VVF3GO.75 (minimum).

IEC-320 receptacle.

Veuillez lire à fond l'information de la sécurité suivante avant

d'installer le Switch:

AVERTISSEMENT: L’installation et la dépose de ce groupe doivent être confiés à un

personnel qualifié.

• Ne branchez pas votre appareil sur une prise secteur (alimentation électrique) lorsqu'il n'y a

pas de connexion de mise à la terre (mise à la masse).

• Vous devez raccorder ce groupe à une sortie mise à la terre (mise à la masse) afin de

respecter les normes internationales de sécurité.

• Le coupleur d’appareil (le connecteur du groupe et non pas la prise murale) doit respecter

une configuration qui permet un branchement sur une entrée d’appareil EN 60320/IEC

320.

• La prise secteur doit se trouver à proximité de l’appareil et son accès doit être facile. Vous

ne pouvez mettre l’appareil hors circuit qu’en débranchant son cordon électrique au niveau

de cette prise.

• L’appareil fonctionne à une tension extrêmement basse de sécurité qui est conforme à la

norme IEC 60950. Ces conditions ne sont maintenues que si l’équipement auquel il est

raccordé fonctionne dans les mêmes conditions.

France et Pérou uniquement:

Ce groupe ne peut pas être alimenté par un dispositif à impédance à la terre. Si vos

alimentations sont du type impédance à la terre, ce groupe doit être alimenté par une tension

de 230 V (2 P+T) par le biais d’un transformateur d’isolement à rapport 1:1, avec un point

secondaire de connexion portant l’appellation Neutre et avec raccordement direct à la terre

(masse).

Cordon électrique - Il doit être agréé dans le pays d’utilisation

Etats-Unis et

Canada:

Le cordon doit avoir reçu l’homologation des UL et un certificat de

la CSA.

Les spécifications minimales pour un cable flexible sont AWG No.

18, ou AWG No. 16 pour un cable de longueur inférieure à 2 mètres.

- type SV ou SJ

- 3 conducteurs

Le cordon doit être en mesure d’acheminer un courant nominal

d’au moins 10 A.

La prise femelle de branchement doit être du type à mise à la terre

(mise à la masse) et respecter la configuration NEMA 5-15P (15 A,

125 V) ou NEMA 6-15P (15 A, 250 V).

xi

Page 12

C

OMPLIANCES

Cordon électrique - Il doit être agréé dans le pays d’utilisation (Continued)

Danemark: La prise mâle d’alimentation doit respecter la section 107-2 D1 de

Suisse: La prise mâle d’alimentation doit respecter la norme SEV/ASE

Europe La prise secteur doit être conforme aux normes CEE 7/7

la norme DK2 1a ou DK2 5a.

1011.

(“SCHUKO”)

LE cordon secteur doit porter la mention <HAR> ou <BASEC>

et doit être de type HO3VVF3GO.75 (minimum).

Bitte unbedingt vor dem Einbauen des Switches die folgenden

Sicherheitsanweisungen durchlesen:

WARNUNG: Die Installation und der Ausbau des Geräts darf nur durch Fachpersonal

erfolgen.

• Das Gerät sollte nicht an eine ungeerdete Wechselstromsteckdose angeschlossen werden.

• Das Gerät muß an eine geerdete Steckdose angeschlossen werden, welche die

internationalen Sicherheitsnormen erfüllt.

• Der Gerätestecker (der Anschluß an das Gerät, nicht der Wandsteckdosenstecker) muß

einen gemäß EN 60320/IEC 320 konfigurierten Geräteeingang haben.

• Die Netzsteckdose muß in der Nähe des Geräts und leicht zugänglich sein. Die

Stromversorgung des Geräts kann nur durch Herausziehen des Gerätenetzkabels aus der

Netzsteckdose unterbrochen werden.

• Der Betrieb dieses Geräts erfolgt unter den SELV-Bedingungen

(Sicherheitskleinstspannung) gemäß IEC 60950. Diese Bedingungen sind nur gegeben,

wenn auch die an das Gerät angeschlossenen Geräte unter SELV-Bedingungen betrieben

werden.

Stromkabel. Dies muss von dem Land, in dem es benutzt wird geprüft werden:

Schweiz Dieser Stromstecker muß die SEV/ASE 1011Bestimmungen

Europe Das Netzkabel muß vom Typ HO3VVF3GO.75

einhalten.

(Mindestanforderung) sein und die Aufschrift <HAR> oder

<BASEC> tragen.

Der Netzstecker muß die Norm CEE 7/7 erfüllen (”SCHUKO”).

PSE Alarm

本製品に同梱いたしております電源コードセットは、

本製品専用です。本電源コードセットは、本製品以外の

製品並びに他の用途でご使用いただくことは出来ません。

製品本体に同梱された電源コードセットを利用し、他製品

の電源コードセットを使用しないで下さい。

xii

Page 13

C

OMPLIANCES

Warnings and Cautionary Messages

Warning: This product does not contain any serviceable user parts.

Warning: Installation and removal of the unit must be carried out by qualified personnel

Warning: When connecting this device to a power outlet, connect the field ground lead

Warning: This switch uses lasers to transmit signals over fiber optic cable. The lasers are

Caution: Wear an anti-static wrist strap or take other suitable measures to prevent

Caution: Do not plug a phone jack connector in the RJ-45 port. This may damage this

Caution: Use only twisted-pair cables with RJ-45 connectors that conform to FCC

only.

on the tri-pole power plug to a valid earth ground line to prevent electrical

hazards.

compliant with the requirements of a Class 1 Laser Product and are inherently

eye safe in normal operation. However, you should never look directly at a

transmit port when it is powered on.

electrostatic discharge when handling this equipment.

device. Les raccordeurs ne sont pas utilisé pour le système téléphonique!

standards.

Warnin gs (in German)

Achtung: Dieses Produkt enthält keine Teile, die eine Wartung vom Benutzer benötigen.

Achtung: Installation und Deinstallation des Gerätes müssen von qualifiziertem

Achtung: Wenn das Gerät an eine Steckdose angeschlossen wird, muß der Masseanschluß

Achtung: Dieses Gerät nutzt Laser zur Signalübertragung über Glasfasern. Die Laser

Servicepersonal durchgeführt werden.

am dreipoligen Netzstecker mit Schutzerde verbunden werden, um elektrische

Gefahren zu vermeiden.

entsprechen den Anforderungen an eine Lasereinrichtung der Klasse 1 und sind

durch ihre Bauart im normalen Betrieb sicher für die Augen. Trotzdem sollte

niemals direkt in den einen Übertragungskanal geblickt werden, wenn er

eingeschaltet ist.

xiii

Page 14

C

OMPLIANCES

Environmental Statement

The manufacturer of this product endeavours to sustain an environmentally-friendly policy

throughout the entire production process. This is achieved though the following means:

• Adherence to national legislation and regulations on environmental production standards.

• Conservation of operational resources.

• Waste reduction and safe disposal of all harmful un-recyclable by-products.

• Recycling of all reusable waste content.

• Design of products to maximize recyclables at the end of the product’s life span.

• Continual monitoring of safety standards.

End of Product Life Span

This product is manufactured in such a way as to allow for the recovery and disposal of all

included electrical components once the product has reached the end of its life.

Manufacturing Materials

There are no hazardous nor ozone-depleting materials in this product.

Documentation

All printed documentation for this product uses biodegradable paper that originates from

sustained and managed forests. The inks used in the printing process are non-toxic.

Purpose

This guide details the hardware features of the switches, including their physical and

performance-related characteristics, and how to install each switch.

Audience

This guide is for system administrators with a working knowledge of network management.

You should be familiar with switching and networking concepts.

Zielgruppe Dieser Anleitung ist fuer Systemadministratoren mit Erfahrung im

Netzwerkmangement. Sie sollten mit Switch- und Netzwerkkonzepten vertraut sein.

Related Publications

The following publication gives specific information on how to operate and use the

management functions of the switch: SMC7824M/ESW Management Guide

Also, as part of both switches’ firmware, there is an online web-based help that describes all

management related features.

xiv

Page 15

T

ABLE OF

C

ONTENTS

1 About the TigerAccess Switch . . . . . . . . . . . . . . . . . . . 1-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Switch Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Network Management Options . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Description of Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

100BASE-TX and 1000BASE-T Ports . . . . . . . . . . . . . . . . . . . . 1-3

100BASE-TX Management Port . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Console Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

SFP Slots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Alarm Interface Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Port and System Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Power Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Optional Media Extender Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1000BASE Combo Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Features and Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Expandability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

2 Network Planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Introduction to Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Application Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Collapsed Backbone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Network Aggregation Plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Remote Connections with Fiber Cable . . . . . . . . . . . . . . . . . . . . 2-4

Making VLAN Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Application Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

3 Installing the Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Selecting a Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Ethernet Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Equipment Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Package Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

xv

Page 16

T

ABLE OF CONTENTS

Optional Rack-Mounting Equipment . . . . . . . . . . . . . . . . . . . . . 3-3

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Rack Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Desktop or Shelf Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Installing an Optional Module into the Switch . . . . . . . . . . . . . . . . . . . . 3-7

Installing an Optional SFP Transceiver . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Grounding the Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Connecting to a Power Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Connecting DC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Connecting AC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Connecting to the Console Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Wiring Map for Serial Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Connecting to the Alarm Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Wiring Map for Alarm Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

4 Making Network Connections . . . . . . . . . . . . . . . . . . . 4-1

Connecting Network Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Twisted-Pair Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Cabling Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Connecting to PCs, Servers, Hubs and Switches . . . . . . . . . . . . 4-2

Network Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Fiber Optic SFP Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Connectivity Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

1000BASE-T Cable Requirements . . . . . . . . . . . . . . . . . . . . . . . 4-6

1000 Mbps Gigabit Ethernet Cable Lengths . . . . . . . . . . . . . . . . 4-6

100 Mbps Fast Ethernet Cable Lengths . . . . . . . . . . . . . . . . . . . 4-7

10 Mbps Ethernet Cable Lengths . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Cable Labeling and Connection Records . . . . . . . . . . . . . . . . . . . . . . . . 4-8

xvi

Page 17

T

ABLE OF CONTENTS

APPENDICES:

A Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Diagnosing Switch Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Power and Cooling Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

In-Band Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

B Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

Twisted-Pair Cable and Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . B-1

10BASE-T/100BASE-TX Pin Assignments . . . . . . . . . . . . . . . . B-2

Straight-Through Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Crossover Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

1000BASE-T Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

1000BASE-T Cable Requirements . . . . . . . . . . . . . . . . . . . . . . . B-6

Cable Testing for Existing Category 5 Cable . . . . . . . . . . . . . . . B-6

Adjusting Existing Category 5 Cabling to Run 1000BASE-T . . B-6

Fiber Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

C Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

Physical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Switch Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Management Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

Compliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

Extender Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

Gigabit Extender Module (RJ-45/SFP) . . . . . . . . . . . . . . . . . . . . C-5

D German Instructions . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Eine Site Auswählen (Selecting a Site) . . . . . . . . . . . . . . . . . . . . . . . . . .D-1

Montage (Rack Mounting Instructions) . . . . . . . . . . . . . . . . . . . . . . . . .D-2

Rack-Montage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-2

Das Erden des Gehäuses (Grounding the Chassis) . . . . . . . . . . . . . . . .D-3

Anschluss an eine Stromquelle (Connecting to a Power Source) . . . . .D-4

Anschluss an Gleichstrom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-4

Wechselstromanschluss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-7

xvii

Page 18

T

ABLE OF CONTENTS

E Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . .E-1

Glossary

Index

xviii

Page 19

T

ABLES

Table 1-1 Optional SFP Transceivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Table 1-2 Port and System Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Table 3-1 Serial Cable Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Table 3-2 Alarm Cable Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Table 4-1 Maximum 1000BASE-T Gigabit Ethernet Cable Length . . . . 4-6

Table 4-2 Maximum 1000BASE-SX Gigabit Ethernet Cable Length . . 4-6

Table 4-5 Maximum Fast Ethernet Cable Length . . . . . . . . . . . . . . . . . . 4-7

Table 4-6 Maximum Ethernet Cable Length . . . . . . . . . . . . . . . . . . . . . . 4-7

Table 4-3 Maximum 1000BASE-LX Gigabit Ethernet Cable Length . . 4-7

Table 4-4 Maximum 1000BASE-ZX Gigabit Ethernet Cable Length . . 4-7

Table A-1 Diagnosing Switch Indicators . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Table B-1 10/100BASE-TX MDI and MDI-X Port Pinouts . . . . . . . . . B-2

Table B-2 1000BASE-T MDI and MDI-X Port Pinouts . . . . . . . . . . . . . B-5

Table E-1 TigerAccess 10/100 Products and Accessories . . . . . . . . . . . . E-1

xix

Page 20

F

IGURES

Figure 1-1 Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Figure 1-2 Port and System LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

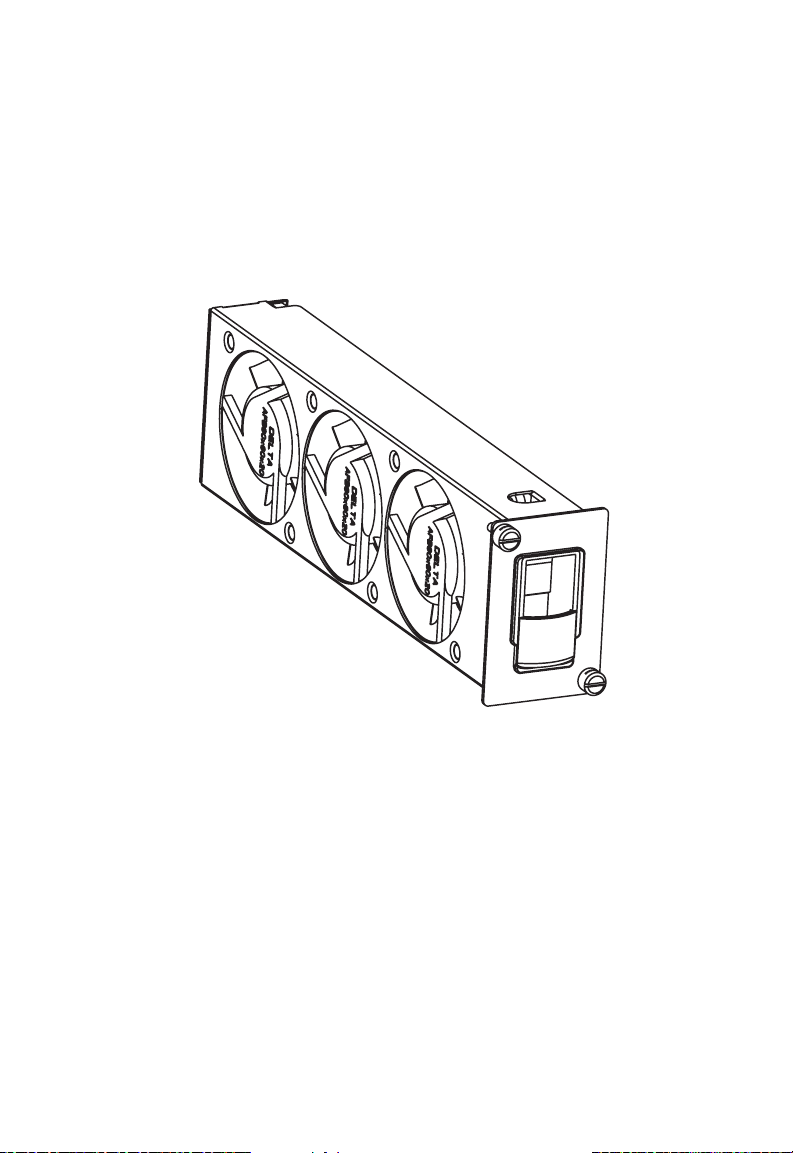

Figure 1-3 Fan Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Figure 1-4 Optional Power Modules . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

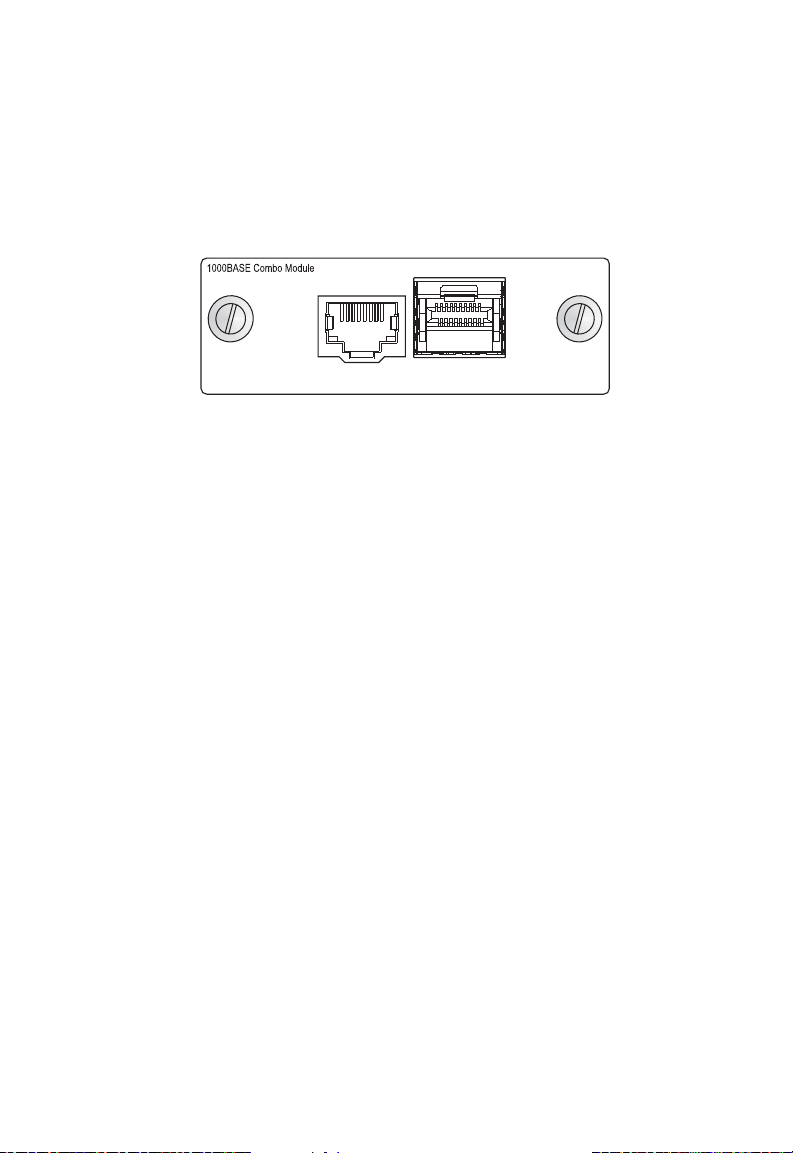

Figure 1-5 Single-Port 1000BASE-T/SFP Combo Module . . . . . . . 1-9

Figure 2-1 Collapsed Backbone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Figure 2-2 Network Aggregation Plan . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Figure 2-3 Remote Connections with Fiber Cable . . . . . . . . . . . . . . 2-4

Figure 2-4 Making VLAN Connections . . . . . . . . . . . . . . . . . . . . . . . 2-5

Figure 3-1 RJ-45 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Figure 3-2 Attaching the Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Figure 3-3 Installing the Switch in a Rack . . . . . . . . . . . . . . . . . . . . . 3-5

Figure 3-4 Attaching the Adhesive Feet . . . . . . . . . . . . . . . . . . . . . . 3-6

Figure 3-5 Installing an Optional Module . . . . . . . . . . . . . . . . . . . . . 3-7

Figure 3-6 Inserting an SFP Transceiver into a Slot . . . . . . . . . . . . . 3-8

Figure 3-7 DC Plug Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Figure 3-8 AC Power Receptacle . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Figure 3-9 Serial Port (RJ-45) Pin-Out . . . . . . . . . . . . . . . . . . . . . . . 3-14

Figure 3-10 Alarm Port (D-15) Pin-Out . . . . . . . . . . . . . . . . . . . . . . 3-15

Figure 3-11 External Alarm I/O Connections . . . . . . . . . . . . . . . . . 3-17

Figure 4-1 Making Twisted-Pair Connections . . . . . . . . . . . . . . . . . . 4-2

Figure 4-2 Network Wiring Connections . . . . . . . . . . . . . . . . . . . . . 4-3

Figure 4-3 Making Connections to SFP Transceivers . . . . . . . . . . . . 4-5

Figure B-1 RJ-45 Connector Pin Numbers . . . . . . . . . . . . . . . . . . . . B-1

Figure B-2 Straight-through Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Figure B-3 Crossover Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Figure D-1 Gleichstromanschlüsse . . . . . . . . . . . . . . . . . . . . . . . . . . .D-6

Figure D-2 Wechselstromanschluss . . . . . . . . . . . . . . . . . . . . . . . . . .D-8

xx

Page 21

C

HAPTER

A

BOUT THE

T

IGER

A

CCESSSWITCH

Overview

The TigerAccess 10/100 is an intelligent Layer 2 switch with 24

10/100BASE-TX ports for subscriber access to the data network, two

*

Gigabit Ethernet combination ports

are implemented as 10/100/1000BASE-T ports shared with SFP

transceiver slots (see Figure 1-1, Ports 27-28). The switch also includes one

10/100BASE-TX port for dedicated management access (which can be

operated outside the data channel), and two slots for optional Gigabit

Ethernet combination modules (one 10/100/1000BASE-T port shared

with an SFP slot).

The switch includes an SNMP-based management agent embedded on the

main board, which supports both in-band and out-of-band access.

for uplink traffic. The uplink ports

1

This switch can enhance your network with full support for Spanning Tree

Protocol, Multicast Switching, and Virtual LANs. It brings order to poorly

performing networks by segregating them into separate broadcast domains

with IEEE 802.1Q compliant VLANs, empowers multimedia applications

with multicast switching and CoS services.

* If an SFP transceiver is plugged in, the corresponding RJ-45 port is disabled for ports

27-28 built into the front panel, or ports 25-26 on the optional media expansion

modules.

1-1

Page 22

A

BOUT THE TIGERACCESSSWITCH

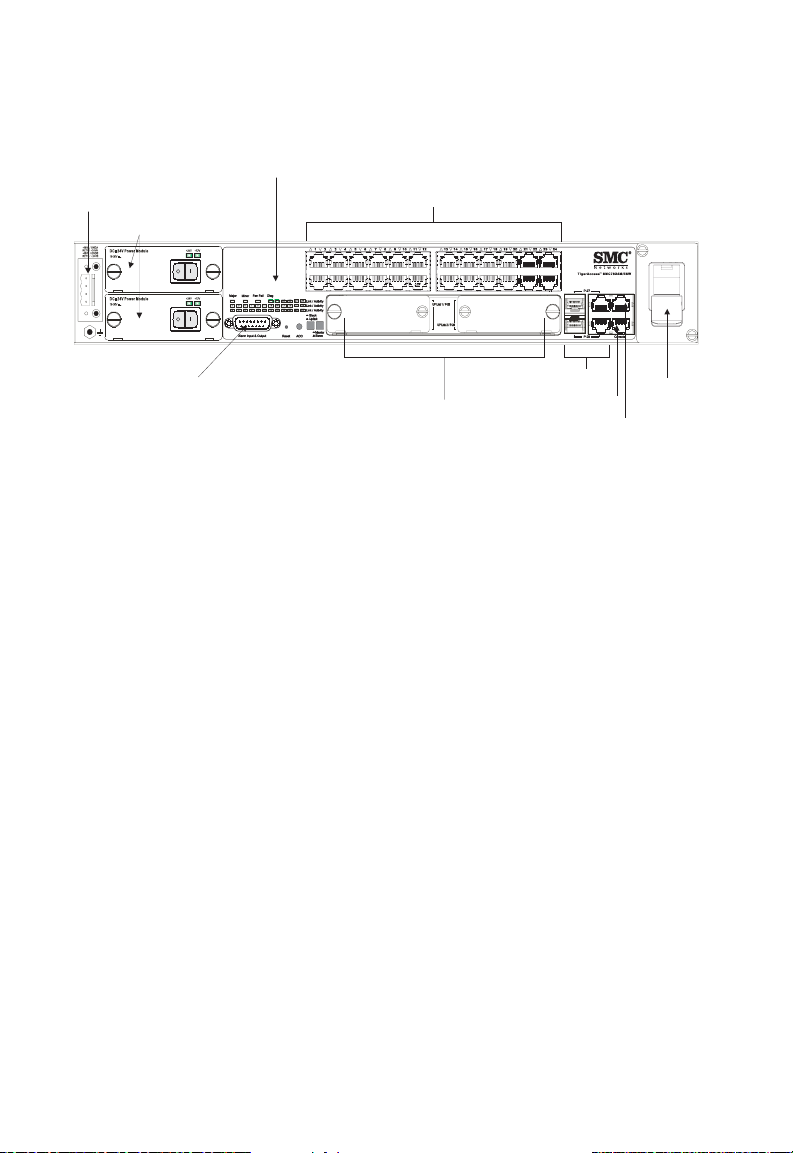

System and Port indicators

Ground and Power Connection Points

Power Trays

8.7A

8.7A

MgmtMgmt

100BASE-TX Subscriber Ports

MgmtMgmt

Alarm Connector

GPON/GEPON Module Slot

(located behind the Gigabit combo

module slots and mounting tray)

Gigabit Combo Module Slots

(for 1000BASE-T/SFP Ports)

Gigabit Combo Ports

Console Port

Management Port

Figure 1-1 Front Panel

Switch Architecture

This switch employs a wire-speed, non-blocking switching fabric. This

permits simultaneous wire-speed transport of multiple packets at low

latency on all ports. The switch also features full-duplex capability on all

ports, which effectively doubles the bandwidth of each connection.

For communications within the same VLAN, the switch uses

store-and-forward switching to ensure maximum data integrity. With

store-and-forward switching, the entire packet must be received into a

buffer and checked for validity before being forwarded. This prevents

errors from being propagated throughout the network.

Network Management Options

This switch contains a comprehensive array of LEDs for “at-a-glance”

monitoring of network and port status. It also includes a management

agent that allows you to configure or monitor the switch using its

embedded management software, or via SNMP applications. To manage

the switch, you can make a direct connection to the console port

(out-of-band), or you can manage the switches through a network

Fan Tray

1-2

Page 23

D

ESCRIPTION OF HARDWARE

connection (in-band) using Telnet, the on-board web agent, or

SNMP-based network management software.

The management port (RJ-45) provides a dedicated management channel

that operates outside of the data transport network. This makes it possible

to re-configure or troubleshoot the switch over either a local or remote

connection to the management port when access via the data channel is

not possible or deemed insecure.

For a detailed description of the switch’s advanced features, refer to the

SMC7824M/ESW Management Guide.

Description of Hardware

100BASE-TX and 1000BASE-T Ports

The switch contains 24 100BASE-TX RJ-45 ports that operate at

10/100 Mbps, half or full duplex, and two 1000BASE-T RJ-45 ports that

operate at 10 Mbps or 100 Mbps, half or full duplex, or at 1000 Mbps, full

duplex. Because all of the RJ-45 ports support automatic MDI/MDI-X

operation, you can use straight-through cables for all network connections

to PCs or servers, or to other switches or hubs. (See “1000BASE-T Pin

Assignments” on page B-5.)

Each of these ports support auto-negotiation, so the optimum

transmission mode (half or full duplex), and data rate (10, 100 or

1000 Mbps) can be selected automatically. If a device connected to one of

these ports does not support auto-negotiation, the communication mode

of that port can be configured manually.

Each port also supports auto-negotiation of flow control, so the switch

can automatically prevent port buffers from becoming saturated.

100BASE-TX Management Port

The 10/100BASE-TX port labeled “Mgmt” provides a dedicated

management interface which is segregated from the data traffic crossing

the other ports.

1-3

Page 24

A

BOUT THE TIGERACCESSSWITCH

This port supports auto-negotiation, so the optimum transmission mode

(half or full duplex) and data rate (10 or 100 Mbps) can be selected

automatically, if this feature is also supported by the attached device.

However, note that the interface connection parameters of this port

cannot be configured.

Console Port

The console port on the switch’s front panel is an RJ-45 connection using

a male DB-9 connector that enables a connection to a terminal for

performing switch monitoring and configuration functions. The terminal

may be a PC or workstation running terminal emulation software, or a

terminal configured as a Data Terminal Equipment (DTE) connection. A

null-modem wired serial cable is supplied with the switch for connecting to

this interface.

SFP Slots

The Small Form Factor Pluggable (SFP) transceiver slots are shared with

RJ-45 ports (ports 25~26 on the front panel or ports 27~28 on the

optional modules). In its default configuration, if an SFP transceiver

(purchased separately) is installed in a slot and has a valid link on its port,

the associated RJ-45 port is disabled and cannot be used. The switch can

also be configured to force the use of an RJ-45 port or SFP slot, as

required.

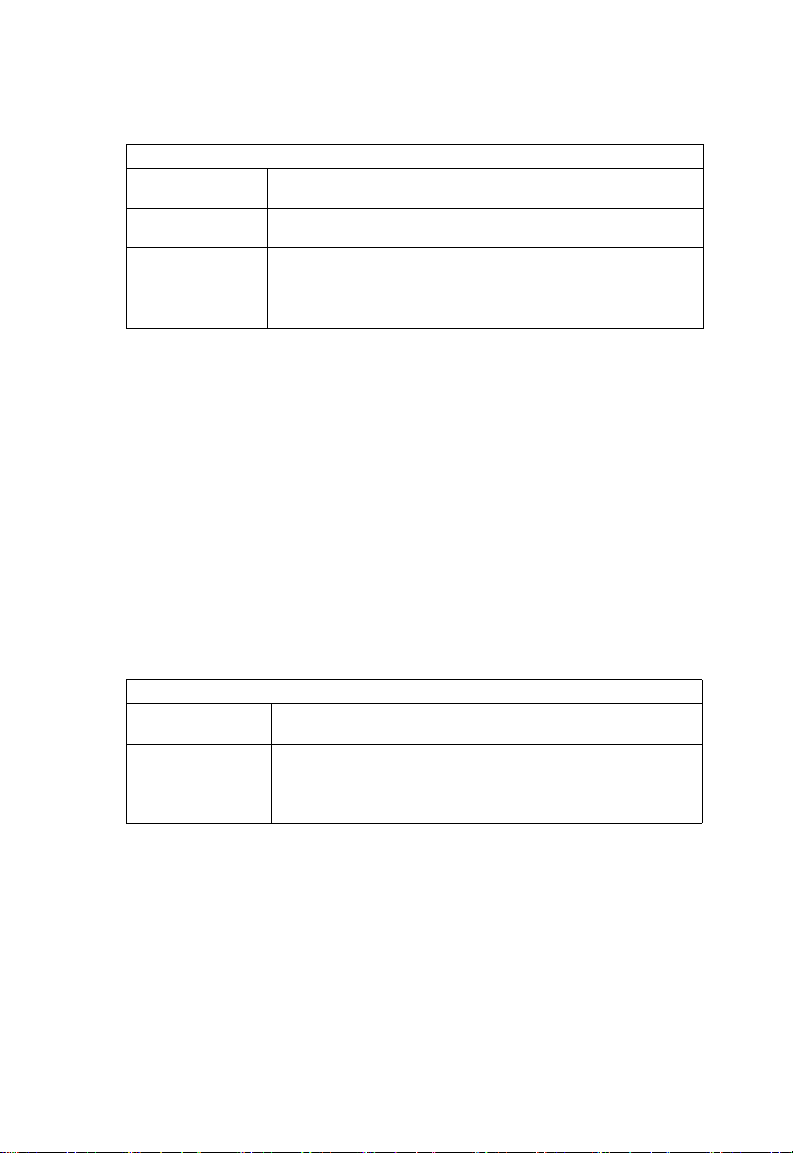

Table 1-1 Optional SFP Transceivers

1000BASE-SX (SMCBGSLCX1)

1000BASE-LX (SMCBGLLCX1)

1000BASE-ZX (SMCBGZLCX1)

Note that 1000BASE-SX transceivers use multimode duplex fiber cable,

1000BASE-LX and 1000BASE-ZX transceivers use single-mode duplex

fiber cable.

1-4

Page 25

D

MgmtMgmt

ESCRIPTION OF HARDWARE

Alarm Interface Port

The DB-15 alarm port on the switch’s front panel can be used to provide

alarm, service port, and BITS clock reference interfaces. The switch

supports two sets of alarm relay contacts (major and minor), and 4 external

customer site alarm inputs. It also provides an alarm cutoff button (labeled

ACO). Refer to “Connecting to the Alarm Port” on page 3-15 for a

description of the pin assignments used to connect to the alarm port.

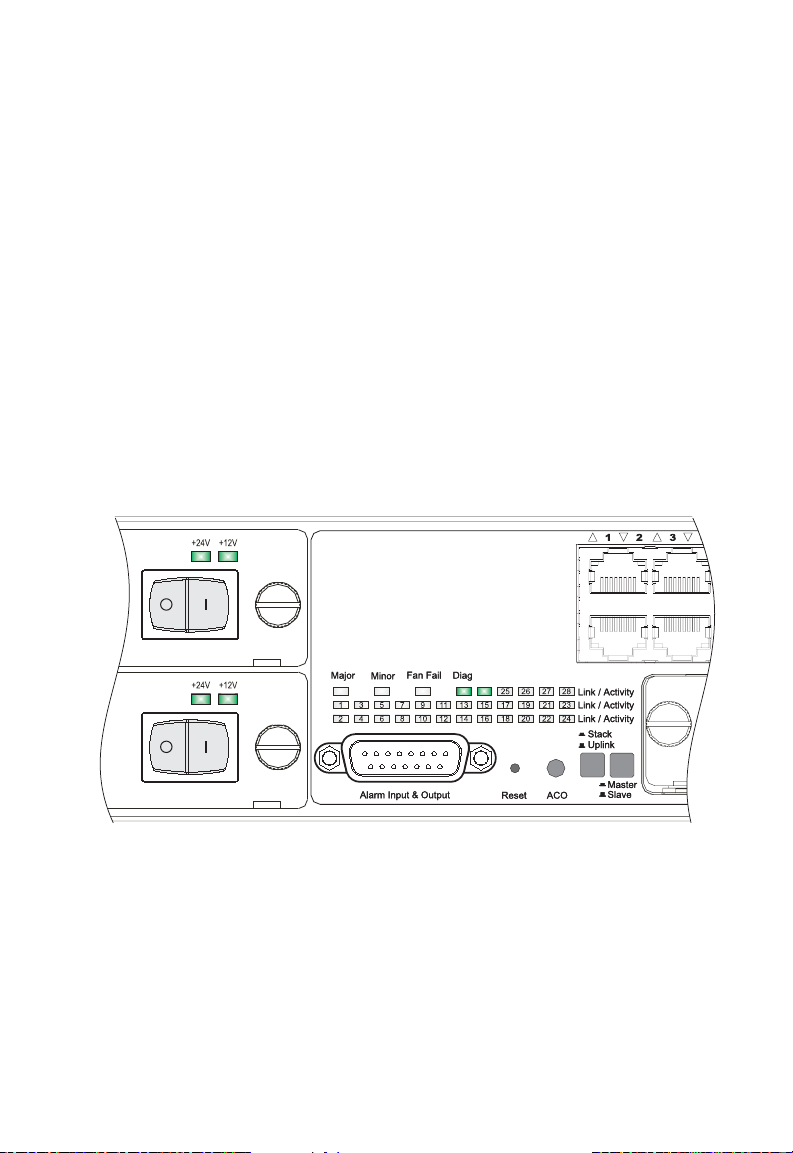

Port and System Status LEDs

This switch includes a display panel for key system and port indications

that simplifies installation and network troubleshooting. The LEDs, which

are located on the front panel and the power module trays for easy

viewing, are shown below and described in the following tables.

Figure 1-2 Port and System LEDs

1-5

Page 26

A

BOUT THE TIGERACCESSSWITCH

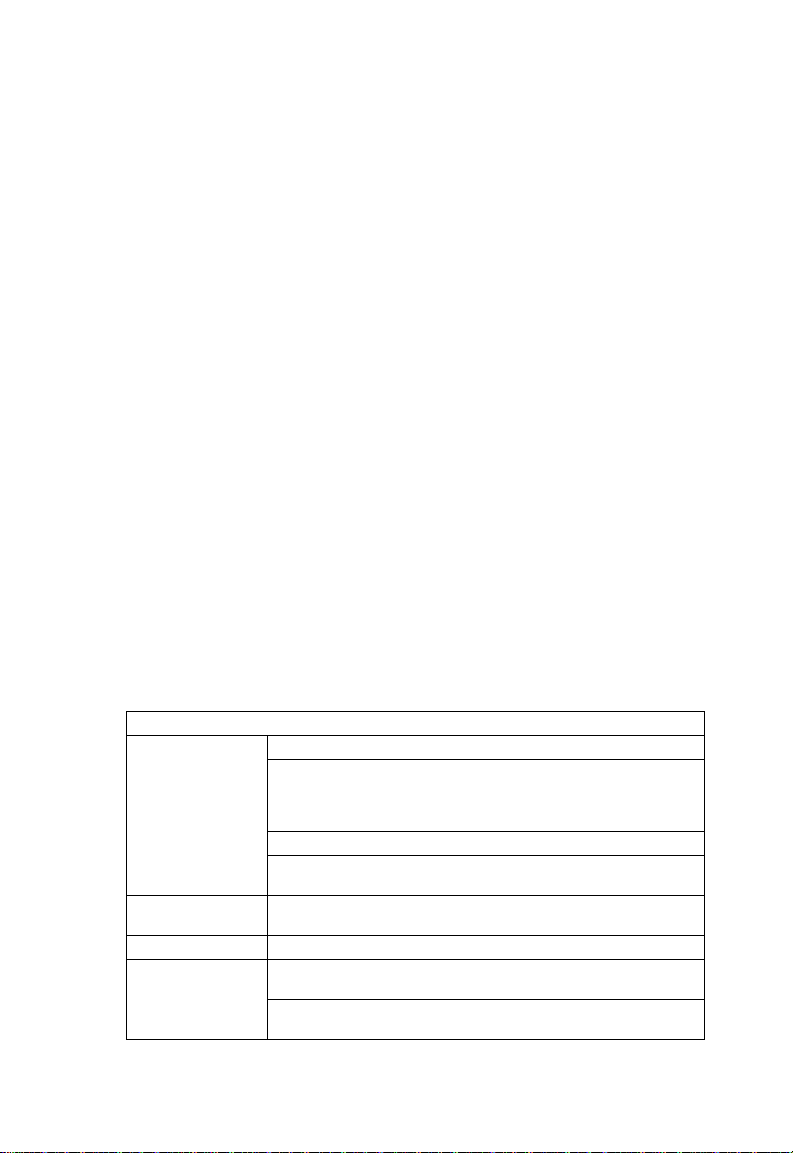

Table 1-2 Port and System Status LEDs

LED Condition Status

Major Red Indicates presence within the system of one

Minor Amber Indicates presence within the system of one

Fan Fail Red Indicates failure of one or more fans.

Diag Flashing Green System self-diagnostic test in progress.

Green System self-diagnostic test successfully

Off System self-diagnostic test has detected a

Link/Activity Green Port has a valid link.

Flashing Green Flashing indicates activity on the port.

Off The link is down.

Power

*

Module

-48V/+12V

or AC/+12V

* The -48V/AC LEDs on the left indicate the status of external power. The

+12V LED on the right indicates the status of the internal power conversion

process.

Green DC or AC power is functioning normally.

Off External power not connected or has failed.

or more major traffic-affecting system

alarm(s) that are not masked by the alarm

filter.

or more minor traffic-affecting system

alarm(s) that are not masked by the alarm

filter.

completed.

fault.

1-6

Page 27

D

ESCRIPTION OF HARDWARE

Fan Tray

A removable fan tray on the right side of the front panel contains three

fans that provide cooling for the chassis. The following figure shows the

fan tray removed from the switch

Figure 1-3 Fan Tray

1-7

Page 28

A

BOUT THE TIGERACCESSSWITCH

Power Modules

This switch provides two power module options: -48 VDC and universal

AC. For specifications on the power conversion modules and external

input power requirements, see “Power Supply” on page C-2.

4A

Figure 1-4 Optional Power Modules

1-8

Page 29

O

PTIONAL MEDIA EXTENDER MODULE

Optional Media Extender Module

1000BASE Combo Module

Figure 1-5 Single-Port 1000BASE-T/SFP Combo Module

The 1000BASE-T RJ-45 port and SFP slot on this module share the same

internal interface. If an SFP transceiver (purchased separately) is installed

in a slot and has a valid link, the associated RJ-45 port is disabled and

cannot be used. The switch can also be configured to force the use of an

RJ-45 port or SFP slot, as required.

When connecting to the 1000BASE-T RJ-45 port, Category 5, 5e, or 6

twisted-pair cable can be used to connect to another device up to 100 m

(328 ft) away. The 1000BASE-T port operates at 10, 100, and 1000 Mbps.

At 1000 Mbps it operates at full duplex and supports auto-negotiation of

flow control. At 10/100 Mbps it supports auto-negotiation of speed,

duplex mode (i.e., half or full duplex), and flow control. Note that you

should first test the cable installation for IEEE 802.3ab compliance. See

“1000BASE-T Cable Requirements” on page 4-6.

This module also provides an SFP slot that supports 1000BASE-SX,

1000BASE-LX and 1000BASE-ZX transceivers. For a full listing of the

supported transceivers, see “Ordering Information” on page E-1.

1-9

Page 30

A

BOUT THE TIGERACCESSSWITCH

Features and Benefits

Connectivity

• 24 100BASE-TX ports for 10 or 100 Mbps Ethernet connections to

subscribers.

• 2 1000BASE-T ports provide 4 Gbps of aggregate bandwidth for

network uplink.

• Auto-negotiation enables each RJ-45 data port and uplink port to

automatically select the optimum communication mode (half or full

duplex) if this feature is supported by the attached device; otherwise

the port can be configured manually.

• RJ-45 10/100/1000BASE-T ports support auto MDI/MDI-X pinout

selection.

• Unshielded (UTP) cable supported on all RJ-45 ports: Category 3 or

better for 10 Mbps connections, Category 5 or better for 100 Mbps

connections, and Category 5, 5e, 6 or better for 1000 Mbps

connections.

• IEEE 802.3-2005 Ethernet, Fast Ethernet, Gigabit Ethernet

compliance ensures compatibility with standards-based hubs, network

cards and switches from any vendor.

Expandability

• Supports 1000BASE-SX, 1000BASE-LX and 1000BASE-ZX

transceivers.

Performance

• Transparent bridging.

• Aggregate duplex bandwidth of up to 12.8 Gbps.

1-10

Page 31

F

EATURES AND BENEFITS

• Switching table with a total of 16K MAC address entries and 1K static

addresses.

• Provides store-and-forward switching for intra-VLAN traffic.

• Supports wire-speed switching.

• Supports flow control, using back pressure for half duplex and IEEE

802.3x for full duplex.

Management

• “At-a-glance” LEDs for easy troubleshooting

• Network management agent:

- Manages switch in-band or out-of-band

- Supports console, Telnet, SSH, SNMP v1/v2c/v3, RMON

(4 groups) and web-based interface

- Dedicated management port for in-band access

1-11

Page 32

A

BOUT THE TIGERACCESSSWITCH

1-12

Page 33

C

HAPTER

N

ETWORK

P

LANNING

Introduction to Switching

A network switch allows simultaneous transmission of multiple packets via

non-crossbar switching. This means that it can partition a network more

efficiently than bridges or routers. These switches have, therefore, been

recognized as one of the most important building blocks for today’s

networking technology.

When performance bottlenecks are caused by congestion at the network

access point (such as the network card for a high-volume file server), the

device experiencing congestion (server, power user or hub) can be attached

directly to a switched port. And, by using full-duplex mode, the bandwidth

of the dedicated segment can be doubled to maximize throughput.

When networks are based on repeater (hub) technology, the distance

between end stations is limited by a maximum hop count. However, a

switch turns the hop count back to zero. So subdividing the network into

smaller and more manageable segments, and linking them to the larger

network by means of a switch, removes this limitation.

2

A switch can be easily configured in any Ethernet, Fast Ethernet, or

Gigabit Ethernet network to significantly boost bandwidth while using

conventional cabling and network cards.

Application Examples

This switch is not only designed to segment your network, but also to

provide a wide range of options in setting up network connections. Some

typical applications are described below.

2-1

Page 34

N

p

ETWORK PLANNING

Collapsed Backbone

This switch is an excellent choice for mixed Ethernet, Fast Ethernet, and

Gigabit Ethernet installations where significant growth is expected in the

near future. In a basic stand-alone configuration, it can provide direct

full-duplex connections for up to 28 workstations or servers. You can

easily build on this basic configuration, adding direct full-duplex

connections to workstations or servers. When the time comes for further

expansion, just connect to another hub or switch using one of the Gigabit

Ethernet ports built into the front panel, or a Gigabit Ethernet port on a

plug-in SFP transceiver.

In the figure below, the switch is operating as a collapsed backbone for a

small LAN. It is providing dedicated 100 Mbps full-duplex connections to

workstations, and 1 Gbps full-duplex connections to servers

8.7A

8.7A

MgmtMgmt

MgmtMgmt

2-2

...

Servers

1 Gbps

Full Du

lex

...

Workstations

100 Mbps

Full Duplex

Figure 2-1 Collapsed Backbone

...

Page 35

A

PPLICATION EXAMPLES

Network Aggregation Plan

With 28 parallel bridging ports (i.e., distinct collision domains), this switch

can collapse a complex network down into a single efficient bridged node,

increasing overall bandwidth and throughput.

In the figure below, the 10/100/1000BASE-T ports are providing 1 Gbps

connectivity through cascaded switches. In addition, the switches are also

connecting several servers at 1 Gbps.

10/100/1000 Switch

Fast Ethernet Switch Stack

.

.

.

.

.

.

...

8.7A

8.7A

MgmtMgmt

MgmtMgmt

Fast Ethernet Switch Stack

1

ES3526F

1

ES3526F

.

.

.

.

.

.

10/100 Mbps Segments

...

Figure 2-2 Network Aggregation Plan

Server Farm

1

ES3526F

1

ES3526F

2-3

Page 36

N

ETWORK PLANNING

Remote Connections with Fiber Cable

Fiber optic technology allows for longer cabling than any other media type.

A 1000BASE-SX (MMF) link can connect to a site up to 550 meters away,

a 1000BASE-LX (SMF) link up to 10 km, and a 1000BASE-ZX link up to

70 km. This allows a switch to serve as a collapsed backbone, providing

direct connectivity for a widespread LAN.

A 1000BASE-SX SFP transceiver can be used for a high-speed connection

between floors in the same building. For long-haul connections, a

1000BASE-ZX SFP transceiver can be used to reach another site up to 70

kilometers away.

The figure below illustrates three switches interconnecting multiple

segments with fiber cable.

Headquarters

Warehouse

8.7A

8.7A

Research & Development

8.7A

8.7A

Server Farm

Remote Switch

8.7A

MgmtMgmt

8.7A

...

8.7A

MgmtMgmt

8.7A

1000BASE-SX MMF

(500 meters)

Remote Switch

MgmtMgmt

8.7A

8.7A

10/100/1000 Mbps Segments

1000BASE-LX SMF

(10 kilometers)

MgmtMgmt

MgmtMgmt

...

MgmtMgmt

1000BASE-ZX SMF

(70 kilometers)

MgmtMgmt

MgmtMgmt

...

MgmtMgmt

MgmtMgmt

2-4

...

Figure 2-3 Remote Connections with Fiber Cable

Page 37

A

PPLICATION EXAMPLES

Making VLAN Connections

These switches support VLANs which can be used to organize any group

of network nodes into separate broadcast domains. VLANs confine

broadcast traffic to the originating group, and can eliminate broadcast

storms in large networks. This provides a more secure and cleaner network

environment.

VLANs can be based on untagged port groups, or traffic can be explicitly

tagged to identify the VLAN group to which it belongs. Untagged VLANs

can be used for small networks attached to a single switch. However,

tagged VLANs should be used for larger networks, and all the VLANs

assigned to the inter-switch links.

These switches also support multiple spanning trees which allow VLAN

groups to maintain a more stable path between all VLAN members. This

can reduce the overall amount of protocol traffic crossing the network, and

provide a shorter reconfiguration time if any link in the spanning tree fails.

Finance

VLAN 4

8.7A

8.7A

Untagged Ports

Marketing

VLAN

unaware

switch

VLAN 1

R&D

VLAN 2

MgmtMgmt

VLAN

aware

switch

Testing

MgmtMgmt

Tagged Port

Finance

VLAN 3

R&D

Testing

VLAN 2

VLAN 1

Tagged

Ports

VLAN 3

Figure 2-4 Making VLAN Connections

Note: When connecting to a switch that does not support IEEE 802.1Q

VLAN tags, use untagged ports.

2-5

Page 38

N

ETWORK PLANNING

Application Notes

1. Full-duplex operation only applies to point-to-point access (such as

when a switch is attached to a workstation, server or another switch).

When the switch is connected to a hub, both devices must operate in

half-duplex mode.

2. To interconnect distinct VLANs or IP subnets, you can attach the

switch to a standard Layer 3 router. For network applications that

require routing between dissimilar network types, attach the switch to a

multi-protocol router.

3. As a general rule, the length of fiber optic cable for a single switched

link should not exceed:

• 1000BASE-SX: 550 m (1805 ft) for multimode fiber, duplex fiber

• 1000BASE-LX: 10 km (6.2 miles) for single-mode fiber, duplex

fiber

• 1000BASE-ZX: 70 km (43 miles) for single-mode fiber, duplex

fiber

2-6

However, power budget constraints must also be considered when

calculating the maximum cable length for your specific environment.

Page 39

C

HAPTER

I

NSTALLING THE

S

WITCH

Selecting a Site

TigerAccess 10/100 units can be mounted in a standard 19-inch

equipment rack or on a flat surface. Be sure to follow the guidelines below

when choosing a location.

•The site should:

- restrict access to authorized service personnel in accordance with IEC

60950-1. A restricted access location is one where access is secure and

limited to service personnel who have a special key, or other means of

security.

- be at the center of all the devices you want to link and near a power

outlet.

- be able to maintain its temperature within 0 to 50 °C (32 to 122 °F) and

its humidity within 5% to 95%, non-condensing

- provide adequate space (approximately five centimeters or two inches)

on all sides for proper air flow

- be accessible for installing, cabling and maintaining the devices

- allow the status LEDs to be clearly visible

3

• Make sure twisted-pair cable is always routed away from power lines,

fluorescent lighting fixtures and other sources of electrical interference,

such as radios and transmitters.

• Make sure that the unit is connected to a separate grounded power outlet

within 2 m (6.6 feet) of each device and is powered from an independent

circuit breaker. As with any equipment, using a filter or surge suppressor

3-1

Page 40

I

NSTALLING THE SWITCH

is recommended. This switch provides two power module options:

-48 VDC and universal AC. Verify that the external power requirements

for the selected option can be met as listed under “Power Supply” on

page C-2.

Ethernet Cabling

To ensure proper operation when installing switches into a network, make

sure that the current cables are suitable for 10BASE-T, 100BASE-TX or

1000BASE-T operation. Check the following criteria against the current

installation of your network:

• Cable type: Unshielded twisted pair (UTP) or shielded twisted pair (STP)

cables with RJ-45 connectors; Category 3 or better for 10BASE-T,

Category 5 or better for 100BASE-TX, and Category 5, 5e or 6 for

1000BASE-T.

• Protection from radio frequency interference emissions

• Electrical surge suppression

• Separation of electrical wires (switch related or other) and

electromagnetic fields from data based network wiring

• Safe connections with no damaged cables, connectors or shields

RJ-45 Connector

Figure 3-1 RJ-45 Connections

3-2

Page 41

E

QUIPMENT CHECKLIST

Equipment Checklist

After unpacking the TigerAccess 10/100 unit, check the contents to be

sure you have received all the components. Then, before beginning the

installation, be sure you have all other necessary installation equipment.

Package Contents

• TigerAccess 10/100 (SMC7824M/ESW)

• Four adhesive foot pads

• Bracket Mounting Kit containing two brackets and eight screws for

attaching the brackets to the switch

• Power cord—either US, Continental Europe or UK

• Console cable (RJ-45 to RS-232)

• This Installation Guide

• Installation and Management Guide CD

• SMC Warranty Registration Card—be sure to complete and return to

SMC

Optional Rack-Mounting Equipment

If you plan to rack-mount the switches, be sure to have the following

equipment available:

• Four mounting screws for each device you plan to install in a rack—these

are not included

• A screwdriver (Phillips or flathead, depending on the type of screws used)

3-3

Page 42

I

NSTALLING THE SWITCH

Mounting

A TigerAccess 10/100 unit can be mounted in a standard 19-inch

equipment rack or on a desktop or shelf. Mounting instructions for each

type of site follow.

Rack Mounting

Before rack mounting the switch, pay particular attention to the following

factors:

• Temperature: Since the temperature within a rack assembly may be

higher than the ambient room temperature, check that the

rack-environment temperature is within the specified operating

temperature range. (See page C-2.)

• Mechanical Loading: Do not place any equipment on top of a

rack-mounted unit.

• Circuit Overloading: Be sure that the supply circuit to the rack assembly

is not overloaded.

• Grounding: Rack-mounted equipment should be properly grounded.

To rack-mount devices:

1. Attach the brackets to the device using the screws provided in the

Bracket Mounting Kit.

M

M

g

g

m

m

t

t

Figure 3-2 Attaching the Brackets

3-4

Page 43

M

OUNTING

2. Mount the device in the rack, using four rack-mounting screws (not

provided).

M

M

g

g

m

m

t

t

Figure 3-3 Installing the Switch in a Rack

3. If installing a single switch only, turn to Grounding the Chassis at the

end of this chapter.

4. If installing multiple switches, mount them in the rack, one below the

other, in any order.

3-5

Page 44

I

NSTALLING THE SWITCH

Desktop or Shelf Mounting

1. Attach the four adhesive feet to the bottom of the first switch.

t

t

m

m

g

g

M

M

t

t

m

m

g

g

M

M

A

7

.

8

A

7

.

8

Figure 3-4 Attaching the Adhesive Feet

2. Set the device on a flat surface near an external power source, making

sure there are at least two inches of space on all sides for proper air

flow.

3. If installing a single switch only, go to Grounding the Chassis at the

end of this chapter.

4. If installing multiple switches, attach four adhesive feet to each one.

Place each device squarely on top of the one below, in any order.

3-6

Page 45

I

M

gm

t

M

gm

t

NSTALLING AN OPTIONAL MODULE INTO THE SWITCH

Installing an Optional Module into the Switch

Figure 3-5 Installing an Optional Module

Note: The slide-in modules are hot-swappable, you do not need to power

off the switch before installing or removing a module.

To install an optional module into the switch, do the following:

1. Remove the blank metal plate (or a previously installed module) from

the appropriate slot by removing the two screws with a flat-head

screwdriver.

2. Before opening the package that contains the module, touch the bag to

the switch casing to discharge any potential static electricity. Also, it is

recommended to use an ESD wrist strap during installation.

3. Remove the module from the anti-static shielded bag.

4. Holding the module level, guide it into the carrier rails on each side

and gently push it all the way into the slot, ensuring that it firmly

engages with the connector.

3-7

Page 46

I

NSTALLING THE SWITCH

5. If you are sure the module is properly mated with the connector,

tighten the retainer screws to secure the module in the slot.

6. To confirm that the module is correctly installed and ready to use,

connect an active device to the module, and verify that the

corresponding port indicator on the switch’s front panel turns green to

show that there is a valid link.

Installing an Optional SFP Transceiver

M

M

g

g

m

m

t

t

Figure 3-6 Inserting an SFP Transceiver into a Slot

This switch supports 1000BASE-SX/LX/ZX SFP-compatible

transceivers. To install an SFP transceiver, do the following:

1. Consider network and cabling requirements to select an appropriate

SFP transceiver type.

2. Insert the transceiver with the optical connector facing outward and

the slot connector facing down. Note that SFP transceivers are keyed

so they can only be installed in one orientation.

3. Slide the SFP transceiver into the slot until it clicks into place.

3-8

Page 47

G

ROUNDING THE CHASSIS

Notes: 1. SFP transceivers are hot-swappable. The switch does not need

to be powered off before installing or removing a transceiver.

However, always first disconnect the network cable before

removing a transceiver.

2. SFP transceivers are not provided in the switch package.

Grounding the Chassis

Before powering on the switch, ground the switch to earth as described

below.

1. Ensure that the rack on which the switch is to be mounted is properly

grounded and in compliance with ETSI ETS 300 253.

2. Ensure that there is a good electrical connection to the grounding

point on the rack (no paint or isolating surface treatment).

3. Disconnect all power cables to the switch.

4. The switch chassis is connected internaly to 0 V. This circuit is

connected to the single-hole grounding terminal on the back of the

switch. The surface area around this terminal is not painted in order to

provide for a good connection. Attach a 6 AWG stranded copper wire

to the grounding terminal on the switch.

5. Then attach the grounding wire to the ground point on the rack.

Caution: The earth connection must not be removed unless all supply

connections have been disconnected.

3-9

Page 48

I

NSTALLING THE SWITCH

Connecting to a Power Source

This switch supports both AC and DC power conversion modules.

Connecting DC Power

When a -48 VDC power conversion module is installed in the switch, an

external DC power supply must be connected to the DC power

connection on the left side of the front panel.

Warning: Before wiring the DC plug or connecting power to the switch,

ensure that power to the feed lines is turned off at the supply

circuit breaker or disconnected from the power bus.

Notes: 1. To provide adequate circuit protection between the DC

power supply and the switch, all intermediate wiring and

circuitry should be rated to carry a load at least two times the

maximum rating for this switch (see “Power Supply” on

page C-2).

2. The wiring between the DC power supply and the switch

must be stranded copper wire within the range of 10 to 24

AWG.

3. Wiring for the power input terminals on the switch are

described below. Wiring of the DC power supply terminals

depends on the equipment in use on the local site, but

should be wired in such a way as to meet the input

requirements shown in Figure 3-7 “DC Plug Connections”

on page 3-12. The wiring should also be color coded

according to local standards to ensure that the input power

and ground lines can be easily distinguished.

3-10

4. When using two power conversion modules with the switch,

either AC or DC modules can be used – both AC, both DC,

or one AC and one DC.

Page 49

C

ONNECTING TO A POWER SOURCE

To connect the switch to a power source:

1. First verify that the external DC power supply can provide -36 to

-72 VDC, 4 A minimum for the -48 VDC power conversion module.

2. Prepare two wires for each power source to be used (A or B). Use 10

to 24 AWG stranded copper wire. Make sure these wires are not

plugged into the power source.

3. Use a wire stripper to carefully strip about a half an inch of the outer

insulation off the end of each wire, exposing the copper core.

4. Twist the copper wire strands together to form a tight braid. If

possible, solder the exposed braid of wire together for better

conductivity.

5. Connect the external power feed and power ground/return lines to

the DC plug (provided with the switch) as shown below. The power

leads are labeled on the front of the chassis, above the DC power

connection block. The -48 VDC power feed uses the “-48VDC” input

and RETA/B (Return) lines for power source A and B respectively,

while +24 VDC power feed uses the indicated “24VDC” input and

*

GNDA/B (Ground) lines for power source A and B respectively

. Use

a small flat-tip screwdriver to loosen the screws on the power plug and

open the wire clamps.

6. Insert the wire leads into the openings shown in the figure below. Each

lead inserted in the power plug must match the lead attached to the

power source. Use the label above the DC power connection block to

identify the appropriate power input and return or ground lines.

Warning: If the power leads are plugged into the wrong holes, the power

supply will not work properly and may damage the switch.

*

The 24 VDC power conversion module is not currently supported for this switch.

3-11

Page 50

I

NSTALLING THE SWITCH

-48VDC/Ground (Source A)

Return/24VDC A)(Source

-48VDC/Ground B)(Source

Return/24VDC B)(Source

Figure 3-7 DC Plug Connections

7. Push each wire about half an inch into the opening on the plug, and

tighten down the clamp screw securely. You should not be able to pull

on the wire and dislodge it.

8. Insert the power plug in the power receptacle on the left side of the

front panel.

9. At the power source, turn on the power for the feed lines or power

bus.

10. After the power source is tuned on, set the power button on the front

of the power conversion module to the ON position (marked “–”).

11. Check the indicators on the power conversion module as the switch is

powered on to verify that the -48V LED indicating external power

status is on, and that the +12V LED indicating internal power

conversion is on. If not, recheck the power supply and power cable

connections at the supply source and at power conversion module.

12. If you have installed both a primary and redundant power conversion

module, verify that the LEDs on both modules are lit as indicated in

the preceding step.

3-12

Page 51

C

ONNECTING TO A POWER SOURCE

Connecting AC Power

When a universal AC power module is installed in the switch, external AC

power must be supplied to the module.

To connect the switch to a power source:

1. First verify that the external AC power supply can provide 100 to

240 VAC, 50-60 Hz, 2 A minimum.

2. Plug the power cable into a grounded, 3-pin, AC power source.

Note: For international use, you may need to change the AC line

cord. You must use a line cord set that has been approved for

the receptacle type in your country.

3. Insert the plug on the other end of the power cable directly into the

receptacle on the AC power module.

Figure 3-8 AC Power Receptacle

4. Check the indicators on the power module as the switch is powered on

to verify that the AC LED indicating external power status is on, and

that the +12V LED indicating internal power conversion is on. If not,

recheck the power supply and power cable connections at the supply

source and at power module.

3-13

Page 52

I

NSTALLING THE SWITCH

5. If you have installed both a primary and redundant power conversion

modules, verify that the LEDs on both modules are lit as indicated in

the preceding step.

Connecting to the Console Port

The RJ-45 serial port on the switch’s front panel is used to connect to the

switch for out-of-band console configuration. The on-board configuration

program can be accessed from a terminal or a PC running a terminal

emulation program. The pin assignments used to connect to the serial port

are provided in the following table.

Figure 3-9 Serial Port (RJ-45) Pin-Out

Wiring Map for Serial Cable

Table 3-1 Serial Cable Wiring

Switch’s 8-Pin

Serial Port

6 RXD (receive data) <---------------------------- 3 TXD (transmit data)

3 TXD (transmit data) -----------------------------> 2 RXD (receive data)

5 SGND (signal ground) ------------------------------ 5 SGND (signal ground)

No other pins are used.

Null Modem PC’s 9-Pin

3-14

8

1

8

1

DTE Port

Page 53

C

ONNECTING TO THE ALARM PORT

The serial port’s configuration requirements are as follows:

• Default Baud rate—9,600 bps

• Character Size—8 Characters

•Parity—None

•Stop bit—One

• Data bits—8

• Flow control—none

Connecting to the Alarm Port

The DB-15 alarm port on the switch’s front panel is used to provide alarm,

service port, and BITS clock reference interfaces. The switch supports two

sets of alarm relay contacts (major and minor), and 4 external customer

site alarm inputs. It also provides an alarm cutoff button (labeled ACO).

The pin assignments used to connect to the alarm port are provided in the

following table.

1

15

Figure 3-10 Alarm Port (D-15) Pin-Out

3-15

Page 54

I

NSTALLING THE SWITCH

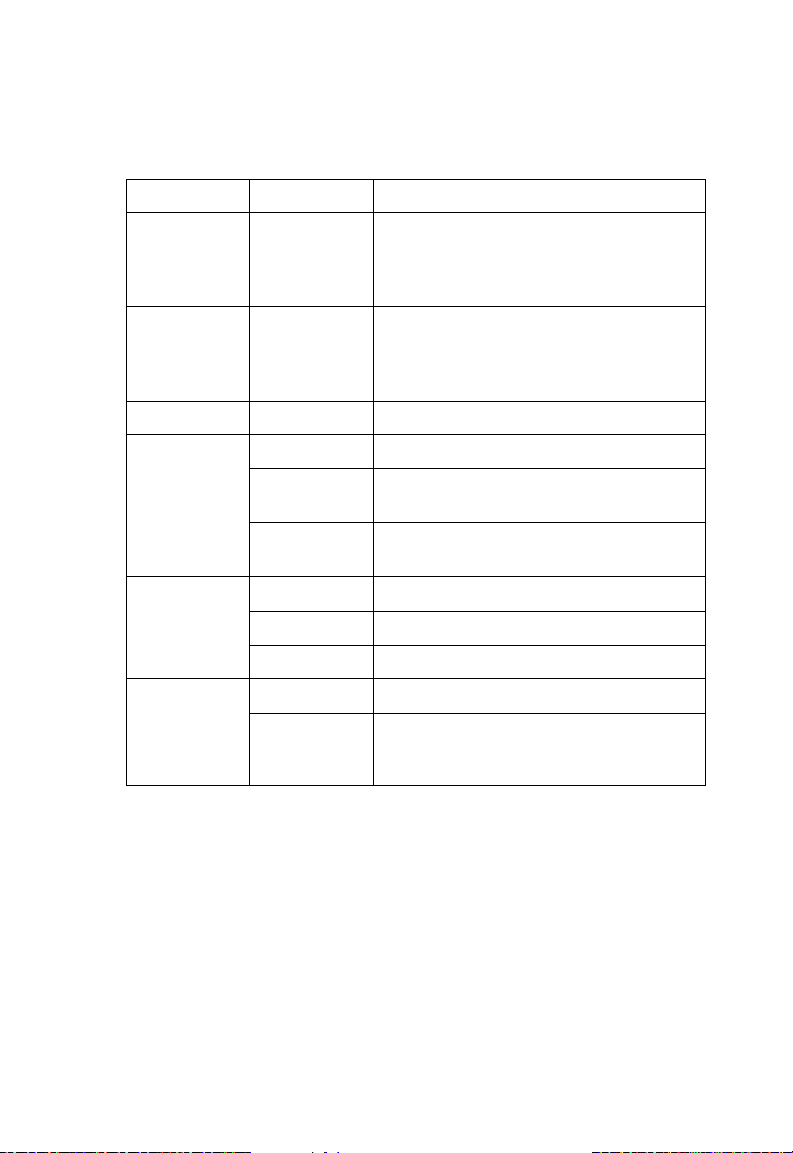

Wiring Map for Alarm Cable

The signals include relay contacts for major and minor system alarms, and

external alarm inputs.

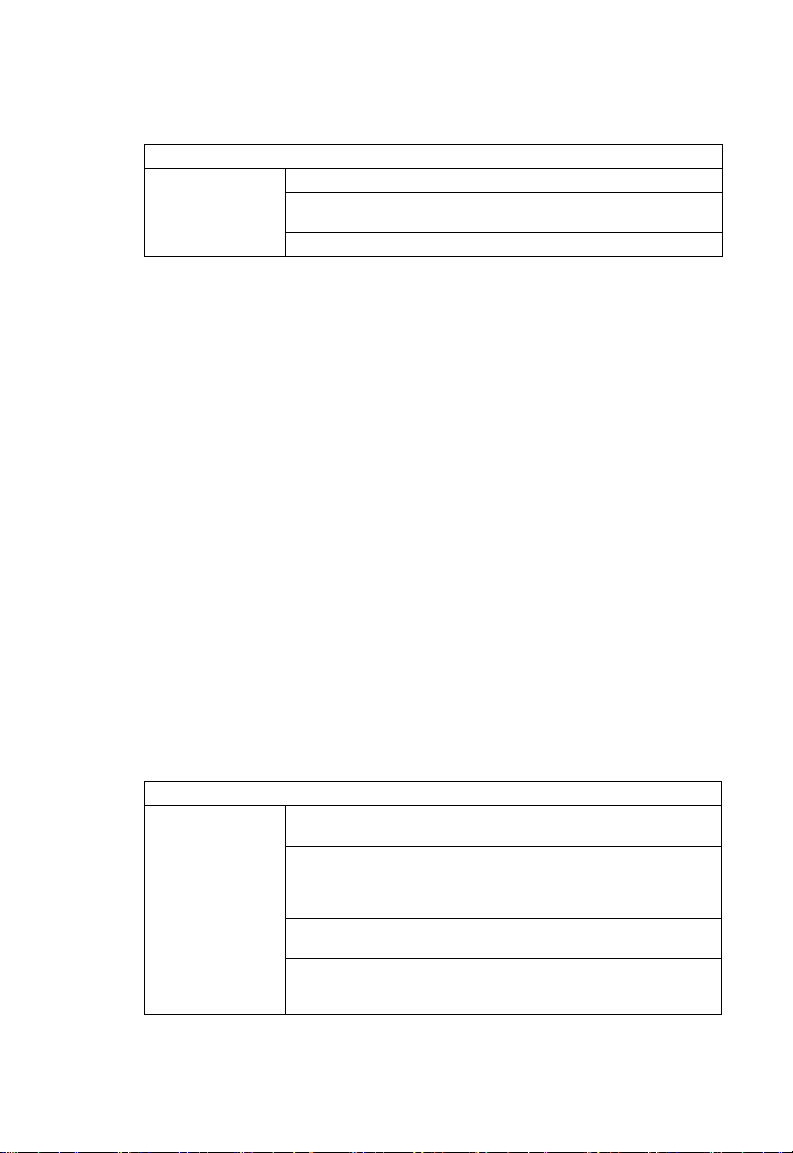

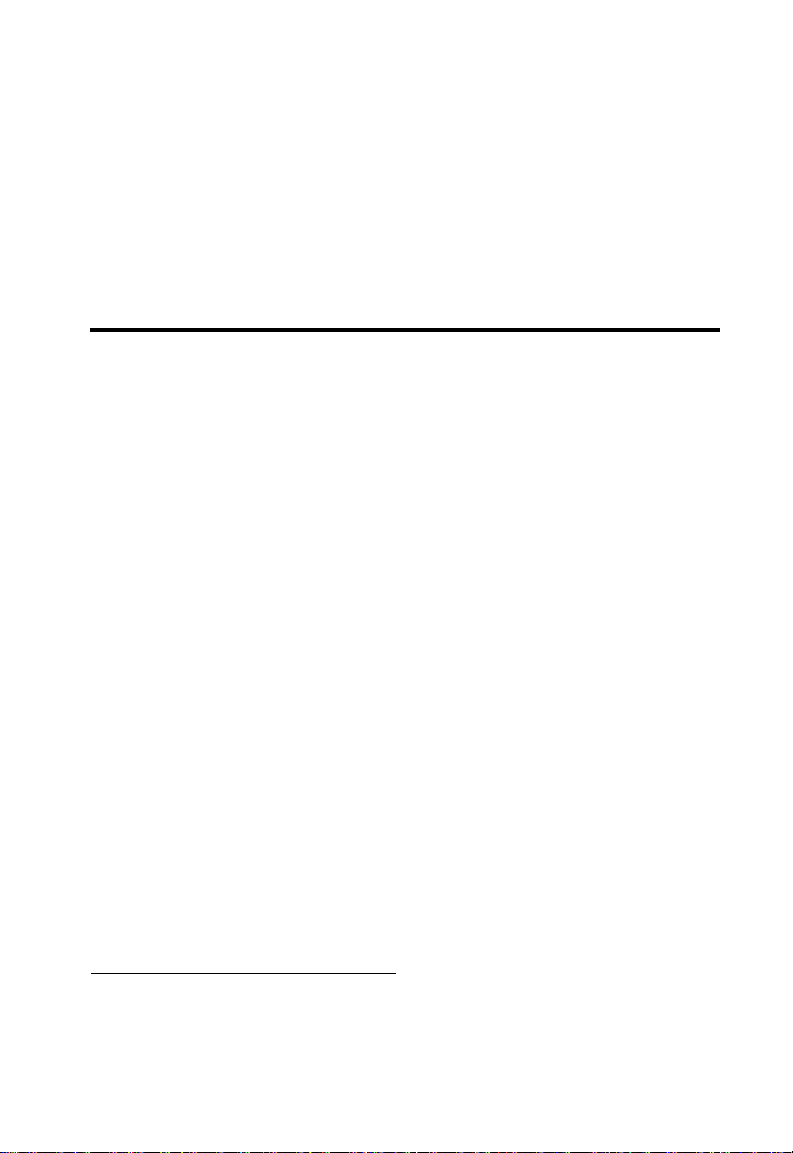

Table 3-2 Alarm Cable Wiring

Switch’s Alarm Port Function

1 (MJR_ALARM_CNTR) Common contact for major alarm relay.

2 (MNR_ALARM_CNTR) Common contact for minor alarm relay.

*

3 (ALARM_IN3_EXT_P

External alarm input 3 (external relay dry

)

contact closure to pin 13).

4 (ALARM_IN4_EXT_P) External alarm input 4 (external relay dry

5 (No Contact)

6 (MJR_ALARM_NO) Normally open during major alarm state.

7 (MNR_ALARM_NO) Normally open during minor alarm state.

8 (ALARM_IN4_EXT_RTN

9 (ALARM_IN1_EXT_P) External alarm input 1 (external relay dry

10 (ALARM_IN2_EXT_P) External alarm input 2 (external relay dry

11 (MJR_ALARM_NC) Normally closed during major alarm state.

12 (MNR_ALARM_NC) Normally closed during minor alarm state.

13 (ALARM_IN3_EXT_RTN) External alarm input 3 (external relay dry

14 (ALARM_IN1_EXT_RTN) External alarm input 1 (external relay dry

15 (ALARM_IN2_EXT_RTN) External alarm input 2 (external relay dry

* P indicates positive input.

† RTN indicates return to Ground.

contact closure to pin 8).

†

External alarm input 4 (external relay dry

)

contact closure from pin 3).

contact closure to pin14).

contact closure to pin 15).

contact closure from pin 3).

contact closure from pin 9).

contact closure from pin 10).

3-16

Page 55

C

ONNECTING TO THE ALARM PORT

The following figure shows the pinout information for the DB-15

ALARM connector on the front panel.

Alarm Connector

1

NC

11

COM

6

NO

Major Alarm

2

NC

12

COM

7

External Alarm Input 1

9

External Alarm Input 2

10

External Alarm Input 3

3

External Alarm Input 4

4

NO

Minor Alarm

To backplane via internal signal

converter circuits.

External input uses dry relay contact

to pins 14, 15, 13 and 8 for grounding.

For active alarm, the relay is closed.

ALARM_IN1_EXT_P

ALARM_IN1_EXT_RTN

Alarm input is isolated by photo-coupler.

Figure 3-11 External Alarm I/O Connections

3-17

Page 56

I

NSTALLING THE SWITCH

3-18

Page 57

C

HAPTER

M

AKING

C

Connecting Network Devices

The TigerAccess 10/100 switch is designed to interconnect multiple

segments (or collision domains). It can be connected to network cards in

PCs and servers, as well as to hubs, switches or routers. It may also be

connected to devices using optional SFP transceivers.

Twisted-Pair Devices

Each device requires an unshielded twisted-pair (UTP) cable with RJ-45

connectors at both ends. Use Category 5, 5e or 6 cable for 1000BASE-T

connections, Category 5 or better for 100BASE-TX connections, and

Category 3 or better for 10BASE-T connections.

N

ETWORK

ONNECTIONS

4

Cabling Guidelines