Page 1

SF6 6100 Pump Back Analyser

Instruction Manual

SMC

5840 S. Memorial Drive

Suite 208

Tulsa, Oklahoma

74145

Tel. 918-622-5725

Fax. 918-664-2073

sales@noramsmc.com

Page 2

Warnings

Electrical Shock Hazard

Do NOT remove internal metal panel

There are no user-serviceable parts in this unit

Do not attempt to repair the analyser yourself

Refer all servicing to qualified personnel

The unit should not be exposed to extreme temperatures

< -5°C or > +50°C (< +23°F or > +122°F)

Normal operating temperature is +5°C to +35°C (+41°F

or +95°F)

Do not operate the unit with the carry case lid closed

Avoid direct sunlight exposure

Do not use liquid cleaners, aerosols or solvents to clean

the case

Use a damp cloth for cleaning with the power cable

disconnected

Do not use this equipment near water

Only use fingers to touch and operate the display panel

Make sure any ventilation slots and the fan on the side

panel are free of obstruction

This unit is NOT designed for use in life support

No responsibility can be held for injury or loss of life

Always use a tube connected to the gas outlet (4) which

situations or any use that is not specified by the

manufacturer.

caused by inappropriate use of this equipment.

is vented to atmosphere when working with gases that

may by toxic or injurious.

Page 3

Warnings

HF & SO2 are toxic and can be fatal if inhaled

HF & SO2 cause severe skin burns

HF causes severe damage to the eyes

H2S & CO are toxic and can be fatal if inhaled

Read the MSDS sheets carefully before working with

these toxic gases

HF and SO2 are extremely corrosive to the respiratory

tract

Read the MSDS sheets carefully before working with

these corrosive gases

H2S and CO are extremely flammable in high

concentrations

Long term exposure to CO causes organ damage

SO2, HF and H2S are harmful irritants to the eyes, skin

and respiratory tract even in small doses

Very toxic to aquatic life

Contents

1 Introduction ........................................................................................................................................... 4

2 Technical Specification ...................................................................................................................... 5

3 Analyser Description .......................................................................................................................... 7

4 Getting Started ...................................................................................................................................... 8

4.1 Battery Charging .......................................................................................................................... 8

4.2 Advisory Screens ......................................................................................................................... 9

5 Performing a Test ............................................................................................................................. 10

5.1 Main Screen Display ................................................................................................................ 10

5.2 Setting the Test Parameters ................................................................................................. 10

5.3 Preparing the Analyser ........................................................................................................... 11

5.4 Sampling ....................................................................................................................................... 13

5.5 Results and Finishing .............................................................................................................. 14

5.6 Notes about Dewpoint Measurements ............................................................................. 15

6 Operational Description ................................................................................................................. 17

6.1 Main Screen................................................................................................................................. 17

6.2 Live Graph Display ................................................................................................................... 18

6.3 Line Purge Option ..................................................................................................................... 18

Page 4

6.4 Pump Back Option .................................................................................................................... 20

6.5 Start Delay ................................................................................................................................... 21

6.6 Working with Pre-Loaded Test Parameters .................................................................. 22

6.7 Working with SF6 and N2 mixtures .................................................................................... 23

6.8 Working with SF6 and Air mixtures................................................................................... 24

6.9 Working with SF6 and CF4 mixtures .................................................................................. 25

7 Rapidox Menu System .................................................................................................................... 27

7.1 Calibrate ....................................................................................................................................... 27

7.2 Data-Logging .............................................................................................................................. 31

7.3 Auto Abort ................................................................................................................................... 34

7.4 Sampling Modes ........................................................................................................................ 35

7.5 Timed Mode ................................................................................................................................ 36

7.6 Continuous Mode ...................................................................................................................... 38

7.7 Set Units ....................................................................................................................................... 39

7.8 Date & Time ................................................................................................................................ 39

7.9 Passwords ................................................................................................................................... 40

8 Options Menu System ..................................................................................................................... 43

8.1 Data Transfer ............................................................................................................................. 43

8.2 System Control .......................................................................................................................... 47

8.3 Gas Cylinder Testing ................................................................................................................ 48

8.4 Auto N2 System Clean .............................................................................................................. 49

8.5 Language ...................................................................................................................................... 49

8.6 Screen Colour ............................................................................................................................. 50

8.7 Screen Brightness ..................................................................................................................... 51

8.8 Diagnostics .................................................................................................................................. 51

8.9 Restore .......................................................................................................................................... 52

8.10 About ......................................................................................................................................... 52

9 Troubleshooting ................................................................................................................................ 53

10 Warranty .............................................................................................................................................. 56

10.1 Conditions of Warranty: .................................................................................................... 56

1 Introduction

The Rapidox SF6 6100 Pump Back is a battery-powered “zero emission” SF6 multigas

analyser capable of measuring multiple gases simultaneously in a rugged and portable case.

Depending on the configuration the analyser can measure up to eight parameters including

sulphur hexafluoride (0-100% SF6), sulfur dioxide (0-100ppm* SO2), dew-point (60/20°Cdp H2O), carbon tetrafluomethane (20-80% CF4), hydrogen fluoride (0-10ppm HF),

air (0-100%), carbon monoxide (0-100ppm) and hydrogen sulphide (0-100ppm). In

addition, the SF6 compartment gas pressure is displayed on-screen as well as some other

selectable parameters.

* 0-500ppm is available on request

Page 5

The sample gas can be used if the inlet pressure is between 0.3 bar and 10.0 bar.

The analyser has a full pump back facility allowing any gas stored inside the analyser to be

re-pressurised and returned to the SF6 compartment. The sample hose and storage bag can

be vacuum purged before testing to ensure no mixing of contaminated gas occurs. During

the testing cycle no SF6 can escape into the atmosphere.

The sampled gas is stored inside a special flexible bag held within the analyser. This bag

inflates and deflates during the testing cycle and can be used to store any SF6 that is not to

be pumped back afterwards. The bag is constructed from a material that is highly resistant

to moisture or air penetration. Various safety features are in place to prevent the bag from

over-filling during use.

The analyser has a built-in PC and all functions are accessed via a 7” touch screen panel.

The analyser is fully automatic and will run in various sampling modes where sample gas is

drawn into the analyser via a special FEP-lined sample hose and DILO couplings. The gases

pass through the various sensors and data is processed and displayed on the screen. The

analyser is fitted with a printer, alarms, data-logging functions and USB output.

The portability of the analyser is achieved by means of two lithium battery packs (one for

the main operation and one for the pump back) which can be charged on any worldwide

mains power. The unit will run for up to eight hours on the battery before recharging is

required. The unit will also run directly on mains power while the battery is recharging.

Up to twenty pump back cycles can be performed on a single charge.

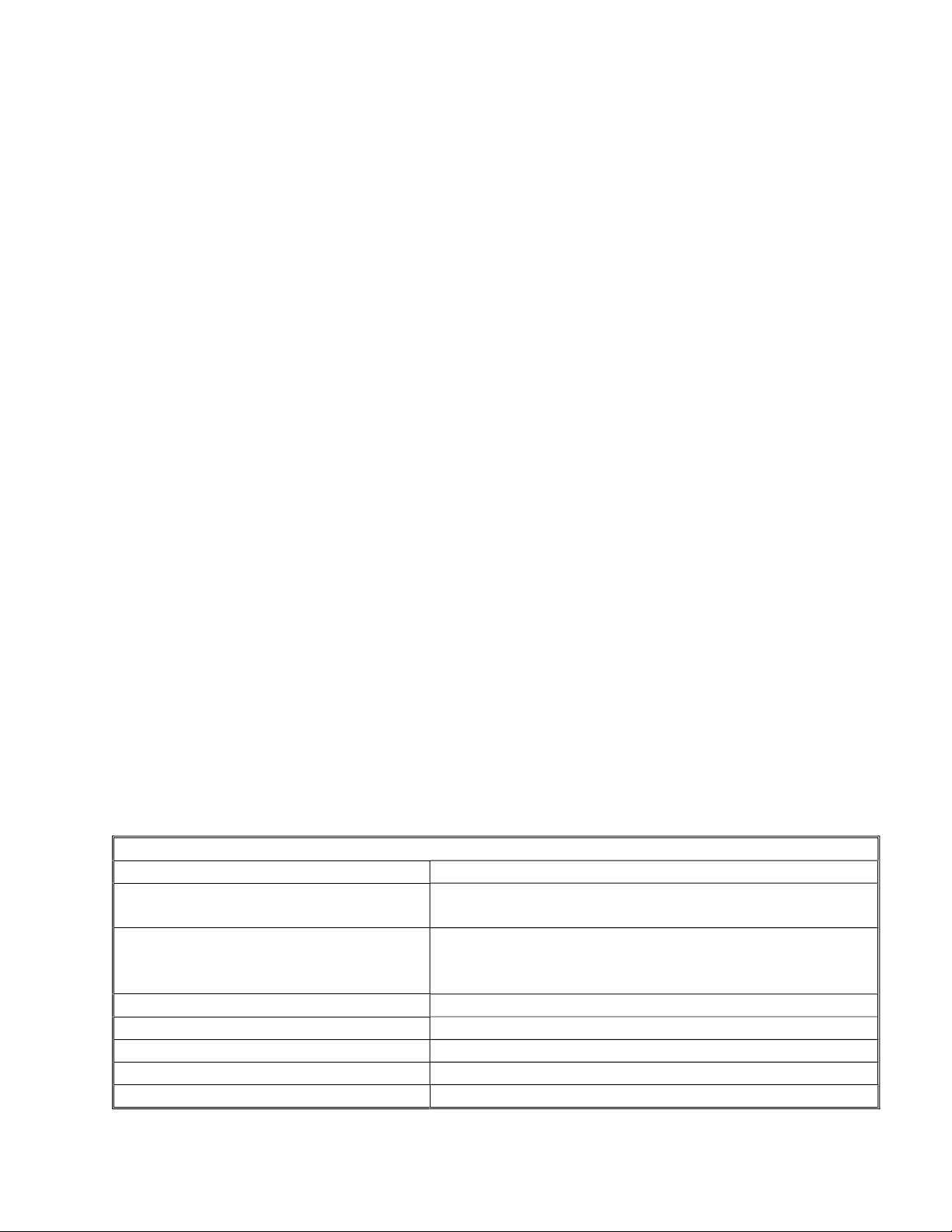

2 Technical Specification

Rapidox SF6 6100 Pump Back Analyser

Mains Voltage for charging 90-260Vac 50/60 Hz

Main Lithium Battery Operation

Pump back Lithium

Battery Operation

Analyser dimension 570mm (w) X 470mm (d) X 280mm (h)

Weight 21 kg without accessories

Gas Storage Bag 5 Litres capacity at sea level

Sample Time 8 minutes

Display 7” full colour PC touch screen

Up to 8 hours on a single charge

5-7 hours to fully charge from flat

Up to 20 pump back cycles on a single charge

(depending on the final gas pressure)

5-7 hours to fully charge from flat

Page 6

Warm up time 15 minutes at 20°C

Temperature -10°C to 40oC

Normal operating conditions

Minimum Gas Inlet Pressure 0.3 bar

Maximum Gas Inlet Pressure 10 bar

Maximum Pump Back Pressure 10.5 bar

Data Output Via USB memory stick or thermal printer

Sampling Timed or Continuous modes

SF6 Sensor (infra red)

SO2 Sensor (electrochemical)

H2O Sensor (polymer)

CF4 Sensor (balance)

HF Sensor (electrochemical)

Air (electrochemical O2 sensor) or N2

(balance)

CO & H2S Sensor (electrochemical)

Calibration

Data-logging

Fuse 1 (main PC) T3.15A H250V 20mm anti surge

Fuse 2 (compressor) T16A H250V 20mm anti surge

Humidity 10 to 90% RH

Pressure 800 to 1100 mbar absolute.

0-100% scale

+/- 0.5% full scale accuracy

0-100ppm (or 0-500ppm) scale

+/- 2% full scale accuracy

-60 to +20°Cdp

+/- 2°Cdp of reading accuracy

Optional display corrected to 20°C available

>20 <80% scale

calculated as a balance gas

0-10ppm scale

+/-2% full scale accuracy

0-100% scale

+/-2% full scale accuracy

0-1000ppm scale

+/- 2% full scale accuracy

Calibration by the user using zero and span gases.

Not H2O sensor*

Continuous on-board data-logging downloadable via

USB

Page 7

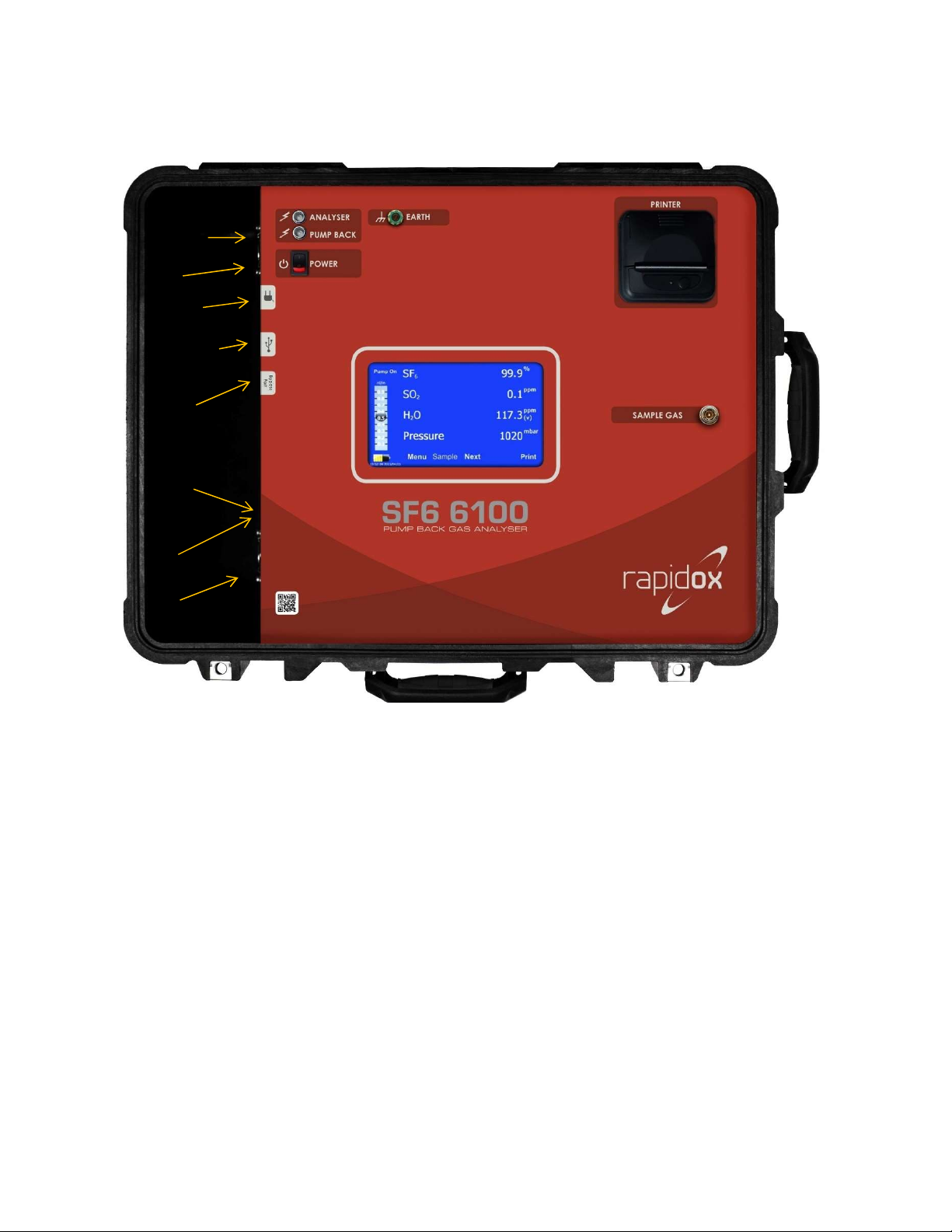

3 Analyser Description

1

2

4

3

6

7

8

9

10

5

11

12

13

1

4

1

5

Figure1: Layout of the SF6 6100 Pump Back Analyser

1. Main display and touch screen menu system

2. Thermal printer

3. Sample gas inlet (via closed coupled fitting)

4. Earth fixing point

5. Gas flow indicator on the display

6. Power on/off switch

7. LED battery charging lights

8. USB memory stick port

9. Fuse holders (see Table 1)

10. Mains inlet

11. 18V charging point (using special vehicle charging adapter)

12. Service Connection Point

13. Ventilation Slot

14. Cooling Fan

15. Bypass Port

Page 8

4 Getting Started

The two labelled fuses will be removed for transportation safety reasons. There are two

fuses located in fuse holders labelled with the values listed in Table 1. This completely

isolates the lithium batteries. These fuses are different and must not be mixed up. The

fuses should be inserted into the correct holders (9) and fixed into position before first use.

Remove the fuses temporarily if you are transporting the analyser by air. If you require the

analyser to be earthed during operation, please connect your earth lead to the earth fixing

point (4).

Open the Peli-case fully and switch on the Rapidox using the switch (6). The analyser

screen will boot up and the display will show readings from the sensors after

approximately sixty seconds.

Note that if the analyser was previously being used in “Continuous” mode, then the

warning picture shown in Figure 2 number 5 will be displayed on the screen during boot

up. This is to remind you that the gas is free flowing out of the bypass port, and a separate

gas recovery system should be attached.

4.1 Battery Charging

The analyser can run on battery OR mains power. When on mains power and the battery is

charging the LEDs (7) will show a red colour. This will eventually turn orange and finally

green when the unit is fully charged. There is an on-screen battery life meter which shows

the remaining battery life and indicates if the unit is charging or not. It takes between five

and seven hours to fully charge a flat battery depending on operational circumstances.

To charge the battery, attach the IEC mains lead to the mains socket on the side of the

analyser (10). Alternatively, an optional vehicle charger can be used with the 18V charging

point (11). Note that you must leave the lid open when on charge as the cooling fan will

operate to vent the battery compartment.

Lithium batteries need to be charged carefully and the analyser is fitted with various safety

features to make sure the batteries do not over heat during a charge. The temperature of

the batteries is measured and should it exceed safe limits the charger circuit will disable

itself. The LED will flash slowly to indicate it is too hot to charge. This may occur if the unit

is used in very hot countries. Please place the unit in a cool location such as an air

conditioned office to charge correctly.

When the unit is running on battery power the LCD indicators (7) remain switched off until

the mains lead is re-connected.

Page 9

compartment)

detached

separate gas recovery system

deactivated

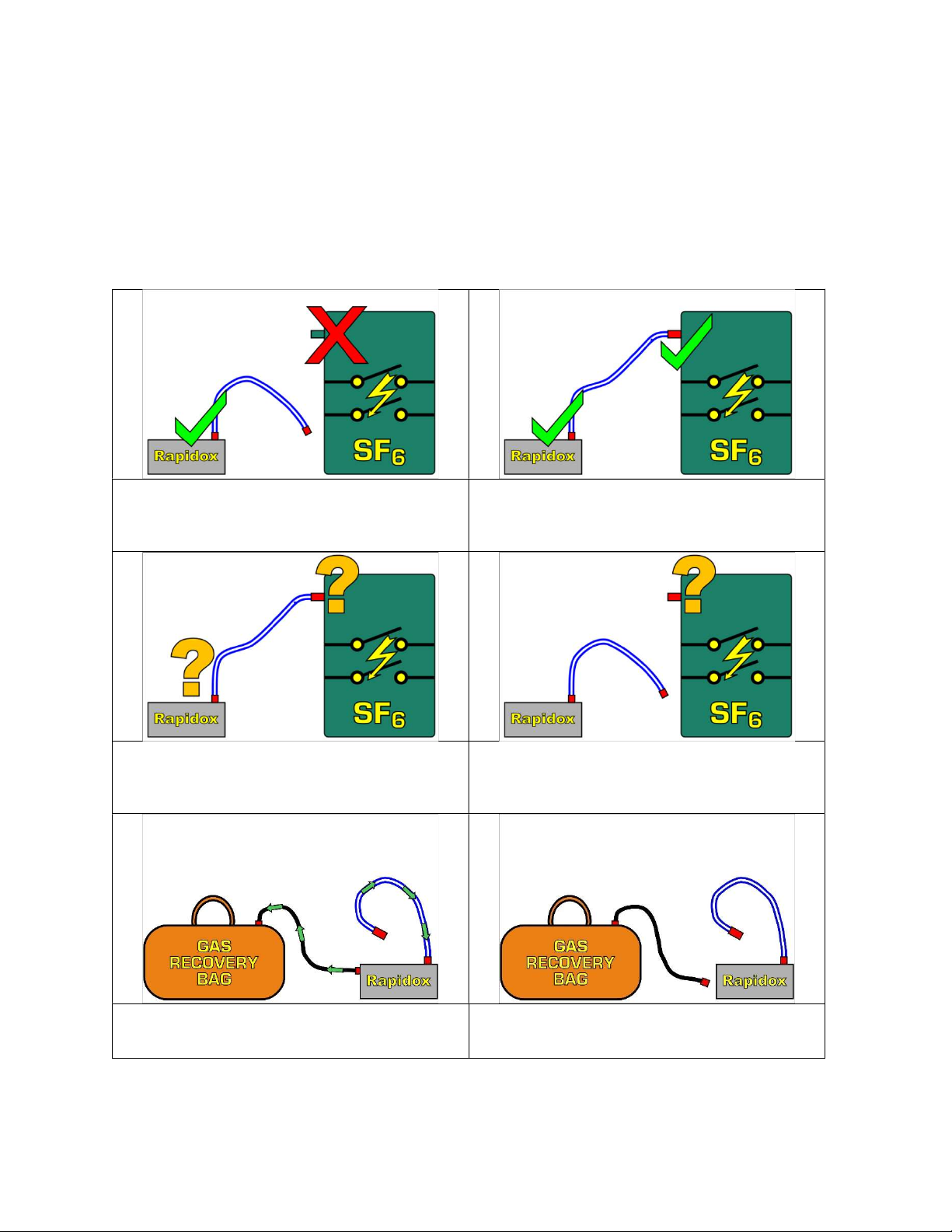

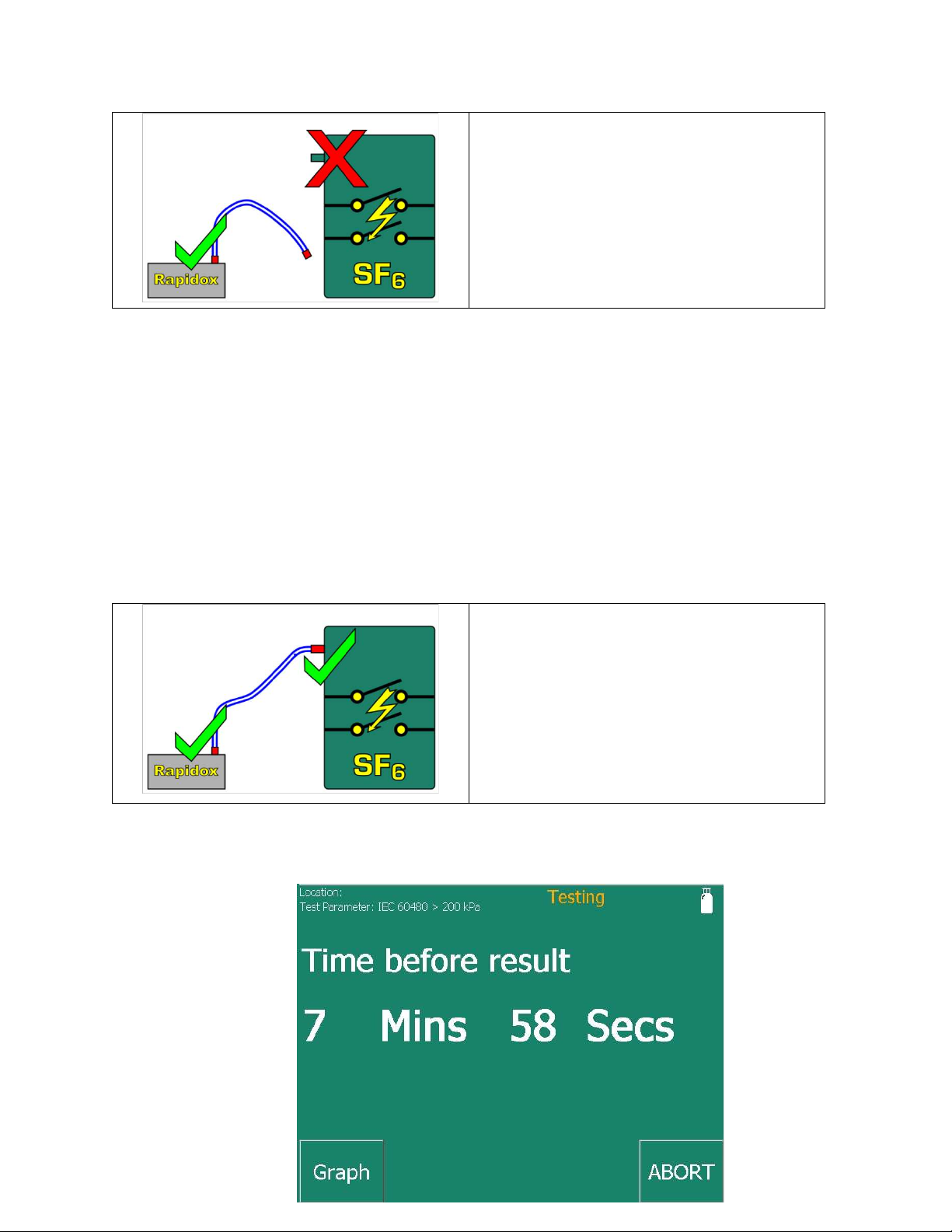

4.2 Advisory Screens

During sampling, line purge and pump back the analyser checks to see if the sample line

hose is correctly fitted to ensure that the cycle works correctly and doesn’t allow any

contamination of the compartment gas with air, or any SF6 is allowed to escape into the

atmosphere. Various simple instructions are displayed on-screen to make it easy to follow

the correct sequence. These are as follows:

1) Shows how to correctly set up the analyser

for a line purge (line must be connected to

the Rapidox but NOT to the gas

3) Questions if the sample line doesn’t appear

to be connected to anything that has gas

pressure i.e. the sample line has become

2) Shows that the Rapidox sample line should

be connected to the pressurised gas

compartment ready to take a sample

4) Questions if the operator has disconnected

the sample hose from the gas compartment

before attempting a line purge

5) Analyser is running in continuous mode so

the bypass outlet should be connected to a

6) Asks for the external gas recovery system to

be disconnected once continuous mode is

Page 10

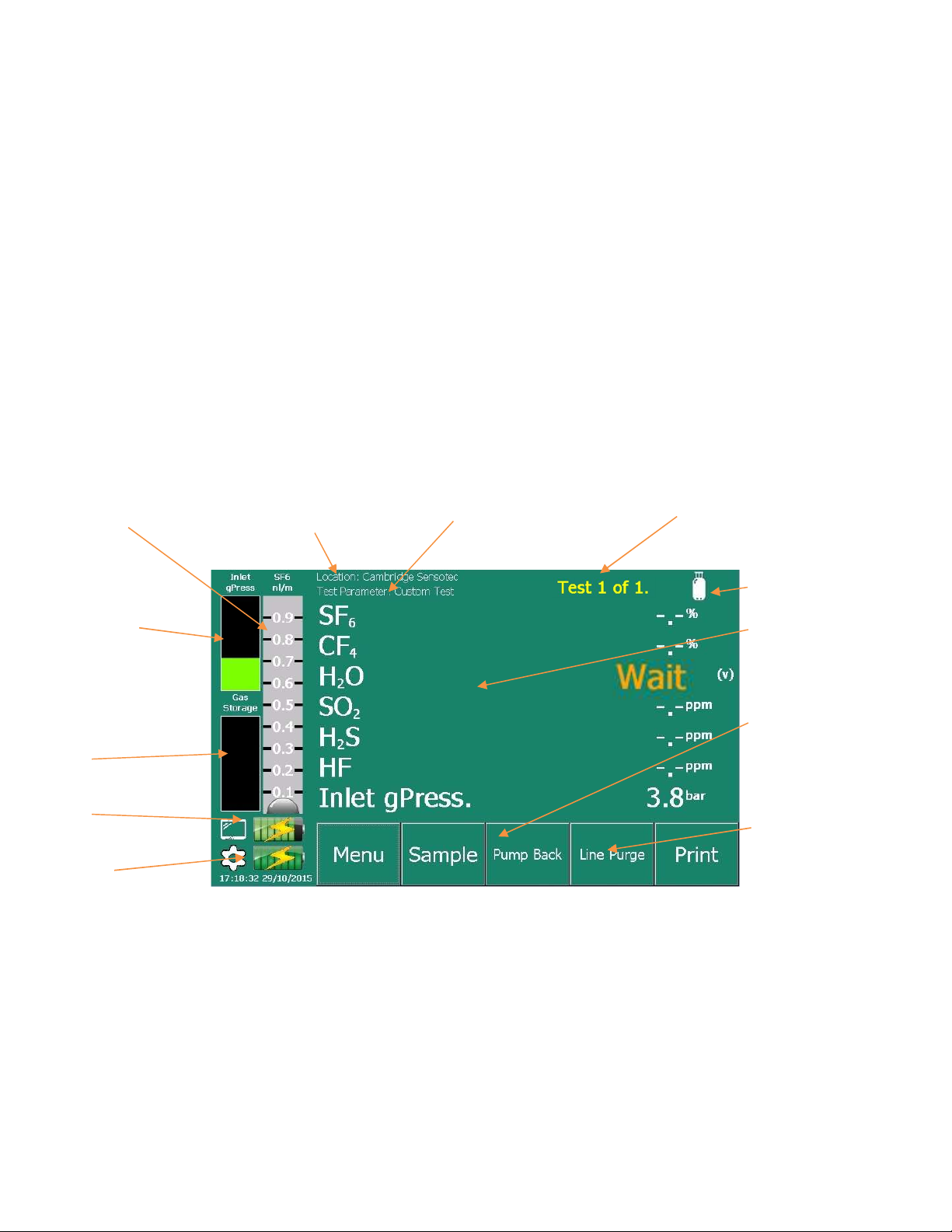

5 Performing a Test

Tap on the

gas

of

Analyser Status

Gas inlet pr

essure

meter

Icon for using “Gas

See section

8.3

With the analyser switched on and ready, use this guide to prepare the machine for testing

and complete an analysis. All screens and menus are soft keys so to change or access

anything you gently press the screen with your fingertips. Pressing over the name of a gas

will open a live graph screen (see 6.2) showing the progress of the sample over time.

5.1 Main Screen Display

Flow Gauge

Indicator

Figure 2: Examples of different on-screen help messages you may encounter during operation. The screen

message includes text prompts explaining what action to perform.

User Editable

Test Location

User Editable IEC / CIGRE

Test Parameter

Message

Bottle” mode

Gas Storage Bag

Capacity

Battery Status

Analyser

Battery Status

Pump Back

5.2 Setting the Test Parameters

Timed tests are fixed at 8 minutes long to complete the testing correctly without filling the

bag to capacity. To set this option press MENU – SAMPLING and enter these parameters as

shown in Figure 4. Full details of this menu option are in section 7.4.

interest to produce

a live time graph

(6.2)

See section 6.4 for a

full description of

how to perform a

Pump-Back cycle

See Section 6.3 for a

full description of

how to Line Purge

Figure 3: Main screen just after boot up. The H2O sensor is still warming up which takes approximately 60

seconds. Note that not all sensors may be present in your equipment

Page 11

Figure 4: Use this option to change the sampling method to “Timed” or “continuous” and set the sampling

duration and other options.

An initial set up is recommended as follows (see 7.4 for full details):

1) Measurement Mode: Set this to TIMED.

2) Sample Duration: This is fixed to 8 minutes and the option is greyed out

3) Start Delay: Set this to 0 unless you must walk away from the equipment before a

test starts. Please see section 6.5 for details on this function.

4) Line Purge: Set this to MANUAL.

5) Pump Back: Set this to AUTO if you are measuring gas from an in-service

switchgear or circuit breaker.

6) Print Results: Set this to AUTO so the printer will produce a report at the end of

the test.

7) Number of Tests: Set this to 1.

8) Location: If you want to name the location EDIT it now and it will be saved with

the results.

9) Test Parameter: Please refer to section 6.6 for details on this feature.

10) SF6 / CF4 mix in use: Only change this to YES if you are working with CF4 blends

otherwise leave it as NO. Selecting the wrong option will make the results

inaccurate. Please see section 6.9 for details on this function*

11) Make sure you press SET to save your choices.

*note that this feature will only be visible if it was specified at the time of order.

5.3 Preparing the Analyser

Page 12

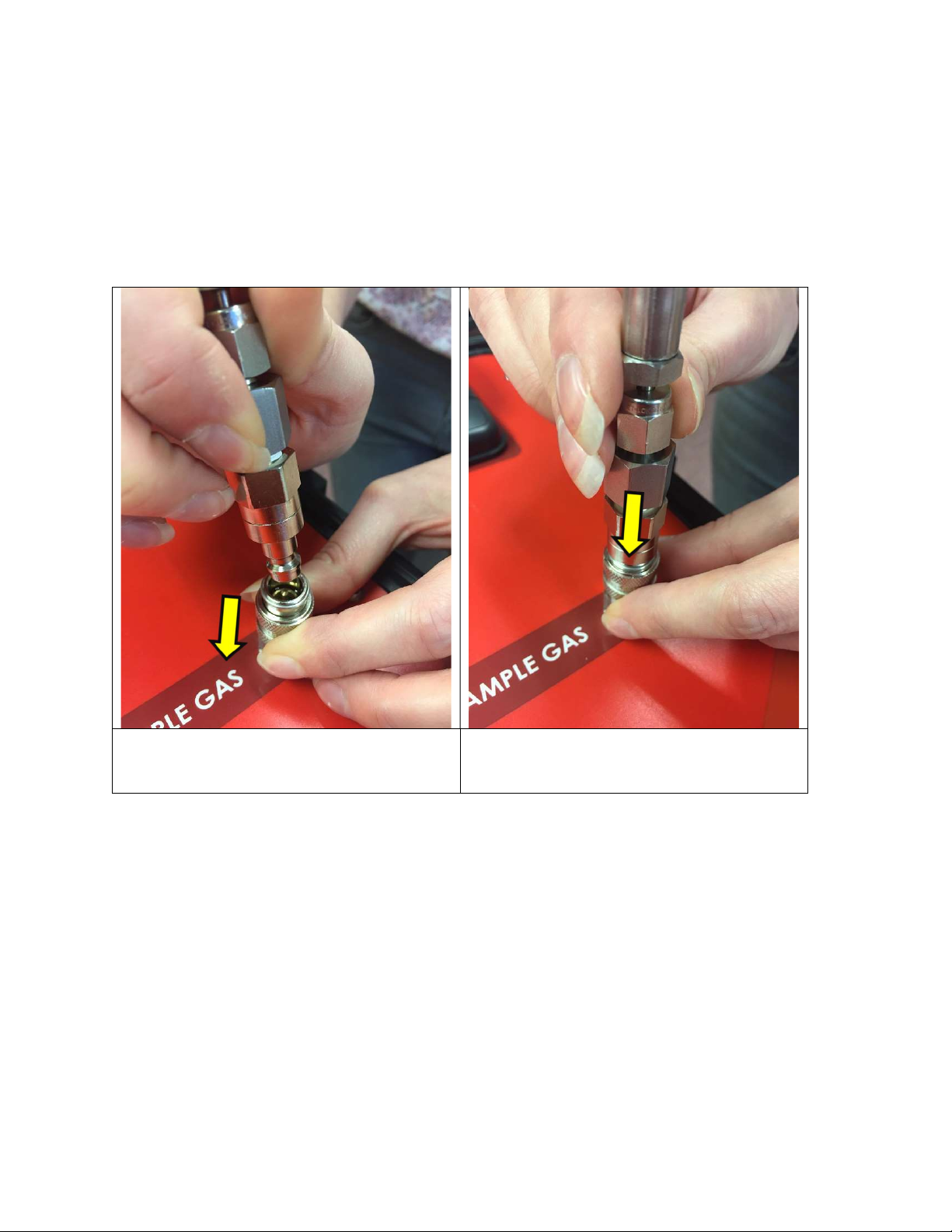

Make sure that the sample line hose is clean and dry. A brand new 2m long sample hose is

supplied pre-pressurised with dry SF

at 5bar pressure. Take the male end of the hose and

6

insert it into the Sample Gas Inlet as shown in Figure 5. Do NOT attach the other end to

anything yet. Use both hands to pull the knurled collar of the inlet coupling downwards as

you push the male fitting into place.

Release the collar to lock in position. To release the coupling simply pull down on the

knurled collar and the hose will self-eject.

Pull the knurled collar down with your finger tips

before trying to attach the male hose fitting. Line up

the hose fitting before attempting to connect

Figure 5: Correct procedure for attaching the sampling hose to the analyser.

Push male coupling into the female firmly whilst

holding the collar down. Release the collar only

when fully engaged

As this is the first test it is recommended to perform a vacuum purge of the sample hose by

pressing the button labelled “Line Purge”. This will vacuum out any unwanted air from the

system and takes approximately 45 seconds to complete. You will see on-screen message

(see Figure 6) to remind you NOT to connect to the gas compartment. Once completed the

following message will show:

Page 13

Connect the Rapidox sample hose to

the analyser but NOT the gas

compartment

Figure 6: Screen message displayed when attempting a line purge.

5.4 Sampling

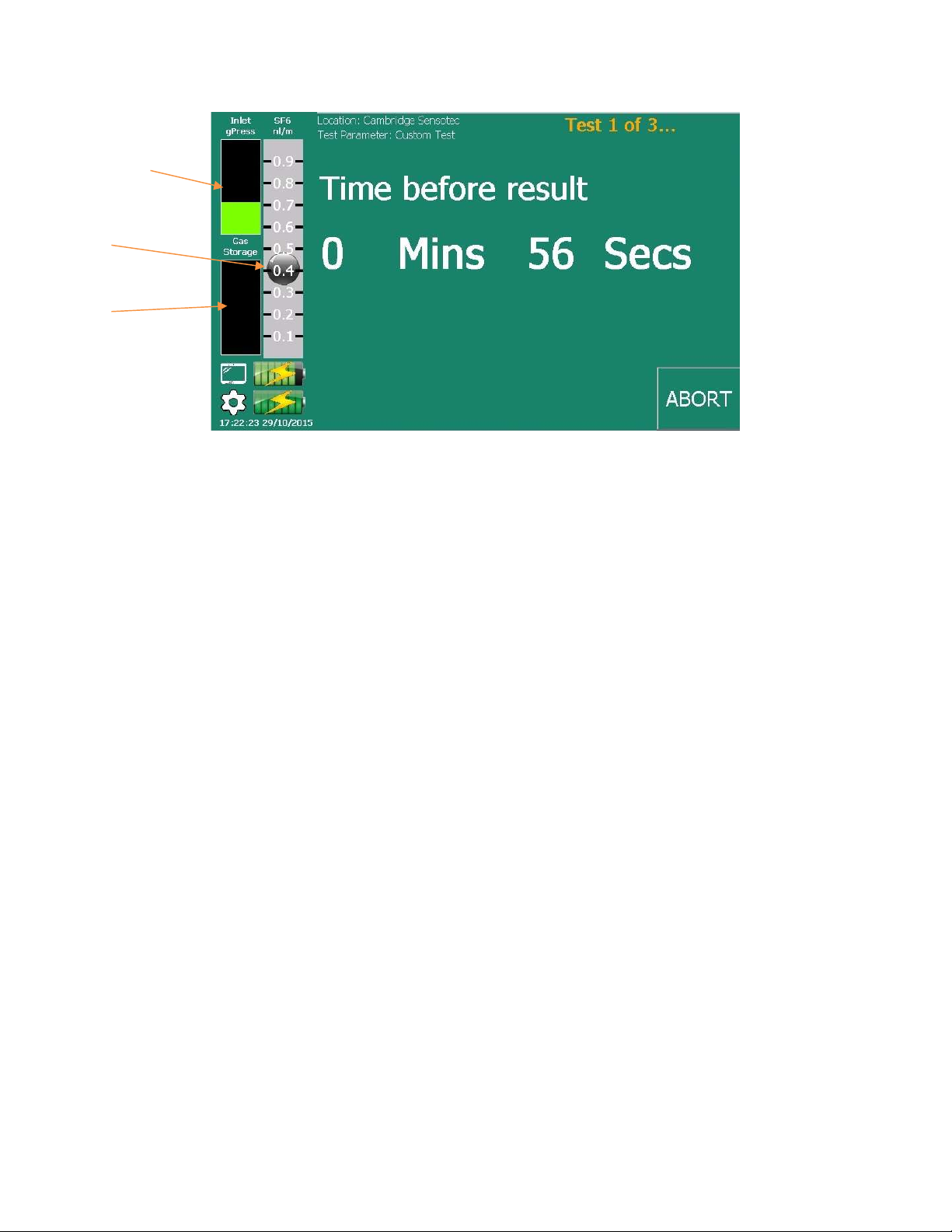

Once the line purge is completed press SAMPLE to begin the test. You will be instructed

(see Figure 7) to connect the female coupling on the end of the hose to the gas

compartment using a DILO male coupling adapter (supplied).

Gas

compartment

pressure is OK

Connect the Rapidox sample hose to

the gas compartment to pressurise

the analyser with sample gas

Figure 7: Screen message displayed when performing a sample analysis.

Page 14

Sample gas is

flowing

Storage bag is

empty

Figure 8: Screen message displayed when performing a Timed analysis. The test will take eight minutes to

Once the hose is correctly connected you will see the Gas Inlet Pressure Meter (see Figure

8) rise and the pressure display will indicate the gas compartment pressure. Note that

there must be a minimum pressure of 0.5bar to proceed. If the pressure is acceptable the

gauge will appear green. Press OK to continue.

A timer will appear on the screen and count down eight minutes. During this period the

SF6 gas will flow into the analyser at a rate of 0.5L.min-1. The black ball on the electronic

flow gauge will rise and settle in the mid-point (see Figure 8). Press “Graph” to see a live

display of the readings and “Abort” to cancel the test.

If at any time during the test, large amounts of toxic gases are detected and “Auto Abort” is

enabled then the test will stop mid-way with an advisory warning.

When the test is completed the results of the analysis will display on the screen and the

printer will produce a short summary report. If pump back is set to “Auto” the unit will

immediately begin pumping the gas back to the compartment.

complete.

5.5 Results and Finishing

With the test completed and all the gas pumped back the analyser storage bag will be

empty and the machine is ready for the next test. If multiple tests were selected, then the

cycle will repeat itself until everything is completed. Finally, the screen will indicate to the

user that it is safe to disconnect the hose from the gas compartment and then from the

Rapidox before moving on to the next location.

Note that if a sequence of repeated tests is performed it is not usually necessary to do a line

purge each time, as the hose is full of dry SF6 from the previous test.

Page 15

Note that if you are testing very small volume circuit breakers at low pressures then it is

NOT recommended to do repeated testing as continual sampling and pumping back can

eventually make a noticeable change in the gas quality; particularly the overall moisture

content.

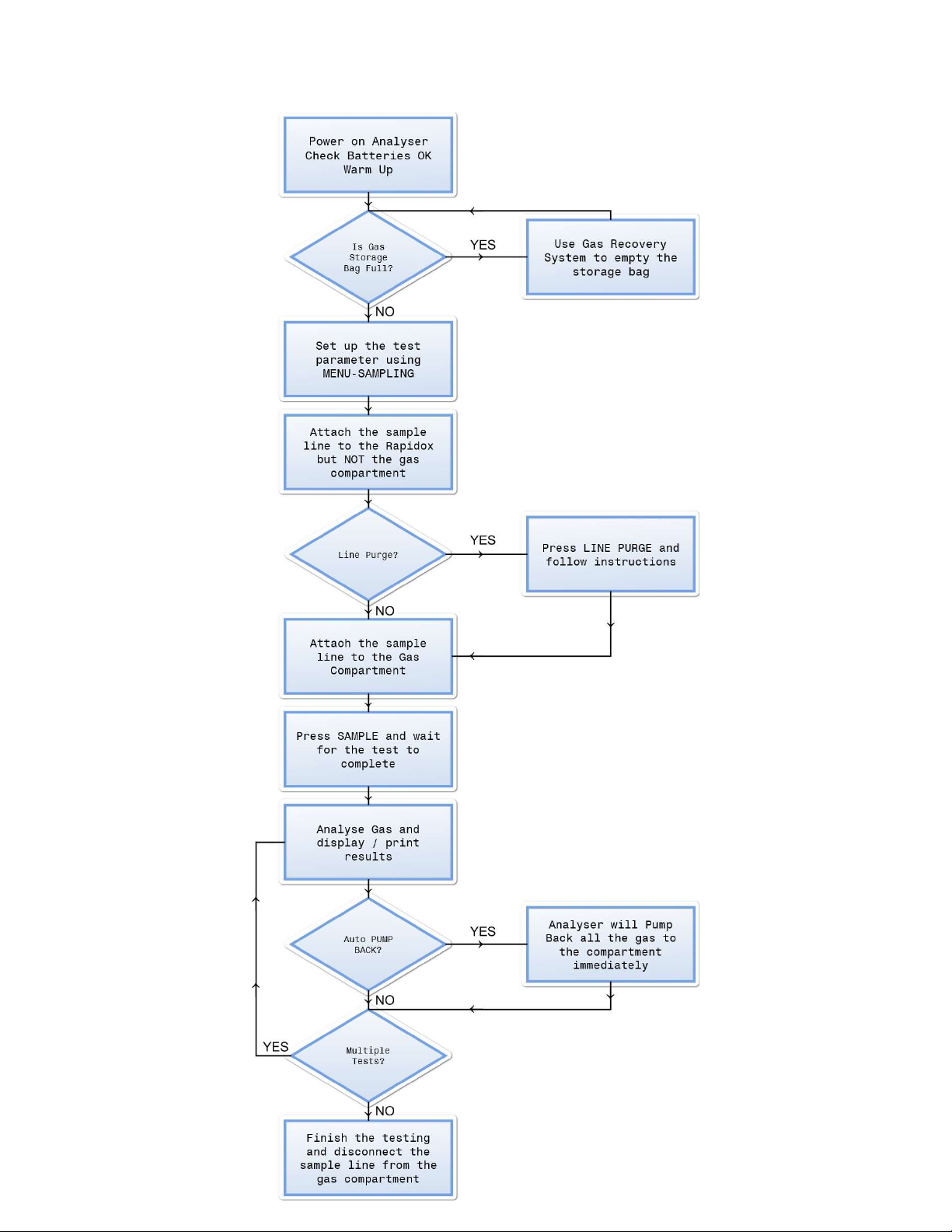

The following flow chart in Figure 9 shows the complete operational sequence for

performing a gas sample test with the Rapidox Pump Back Analyser.

5.6 Notes about Dewpoint Measurements

The dewpoint sensor fitted to this equipment is a special high speed polymeric type

designed for use in SF6. For optimal readings dewpoint is measured at compartment

pressure and the readings are then pressure corrected to atmospheric pressure

1013mbara.

The sensor itself is electronically “cleaned” regularly by the analyser to prevent

contamination building up and causing a drift of readings. At the start of each timed test

the sensor is cleaned. This takes approximately two minutes to complete and an additional

four minutes is then required to allow the readings to settle. In exceptional circumstances

the sensor will perform an advanced clean which takes up to six minutes to complete.

During this time no readings are visible on the plot or recorded in the data logger. The

logger will record the words “Clean” or “Adv. Clean” instead.

If the analyser is operated in continuous mode, then the cleaning will happen automatically

every thirty minutes. The initial clean cycle will begin five minutes after the analyser is

powered on. During any clean cycle the continuous mode will display “Please Wait” on the

main screen which will disappear once the cleaning is complete.

The dewpoint reading displayed on the screen shows the units as °Cdp but this is calculated

as frost point when readings are below 0°C. Although there is no actual frost generated on

a capacitive sensor surface, the readings are calculated as frost point so direct comparisons

can be made with a chilled mirror analyser. This is important because the difference

between “over ice” and “over water” calculations become significant in very dry

measurements. All CIGRE and IEC test standards are in terms of frost point “over ice”

regardless of the measurement method.

As well as recording the absolute dewpoint at room temperature it is possible to display an

equivalent dewpoint corrected for temperature at 20°C This options features in the Units

menu and the unit can be accessed by tapping on the main screen over the displayed unit.

Tap the screen with your finger to change from “°Cdp@RT” to “°Cdp@20°C”.

Page 16

Figure 9: Operational Flow Chart

Page 17

6 Operational Description

6.1 Main Screen

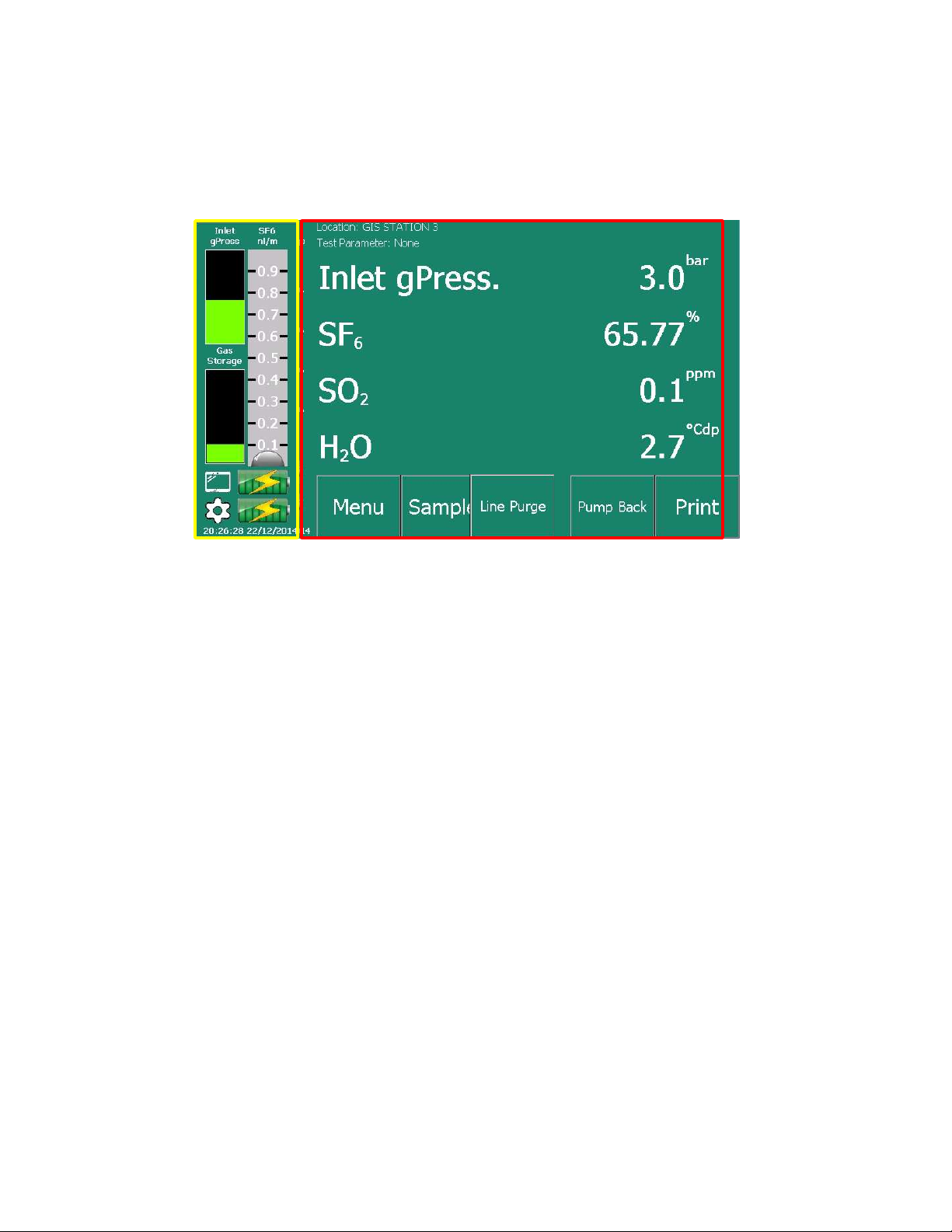

Figure 10: Main operation screen (RED) configured with just three sensors, showing sensor readings with

side panel (YELLOW) indicating the gas flow, bag, battery and pressure status

During sampling the target gas flow is factory set to 0.5L.min-1 and this is displayed on the

side panel using the electronic gauge (Figure 10 – YELLOW) . The inlet gas pressure and

the gas analysis readings are also displayed on the side panel. At the top of the main screen

(Figure 10 – RED) is information about the name of the test location and the type of

standard test being performed. These can be edited and selected in the menu system

(section 7.4). Press “Sample” to begin a test. Press “Menu” to enter the analyser menu

screen and “Print” to produce a printout of the data as seen on the display.

Press “Line Purge” to vacuum purge the sample hose. This removes any air already inside

the hose before a test is performed. You will be prompted to attach the hose before

proceeding. A full description of this feature is in section 6.3.

Pressing “Pump Back” will allow you to return the gas inside the analyser to the gas

compartment. On pressing this button you will be prompted what to do before pump back

commences. See section 6.4 for a more detailed description of the pump back feature.

A status message will display in the top right hand corner to indicate what the machine is

doing. For example, the display might show “Testing Sample 1 of 3……” if multiple cycles

have been selected.

During a test, a button labelled “Abort” appears instead of “Print”. This can be pressed at

any time to stop the cycle.

Page 18

The gas storage gauge will give you an indication of how full the internal storage bag is.

The bag will hold up to five litres of gas at standard temperature and pressure. This is

more than sufficient capacity to complete a single eight-minute timed test in normal

atmospheric conditions including at high altitude. In exceptional atmospheric conditions

or during calibration the bag may become full prematurely and testing will stop. The gauge

will change red to indicate “Bag Full” and no further testing will be allowed until a pump

back cycle has been performed. To empty the bag, press the “Pump Back” button and you

will be prompted to make the correct connections before pump back commences. Note

that if there is any residual gas inside the bag and you attempt to perform a timed test, the

unit will show a message indicating that a pump back is required before proceeding.

If you want to see a live chart of any of the channels finger tap over the live reading display

of the gas / measurement of interest and the display will change:

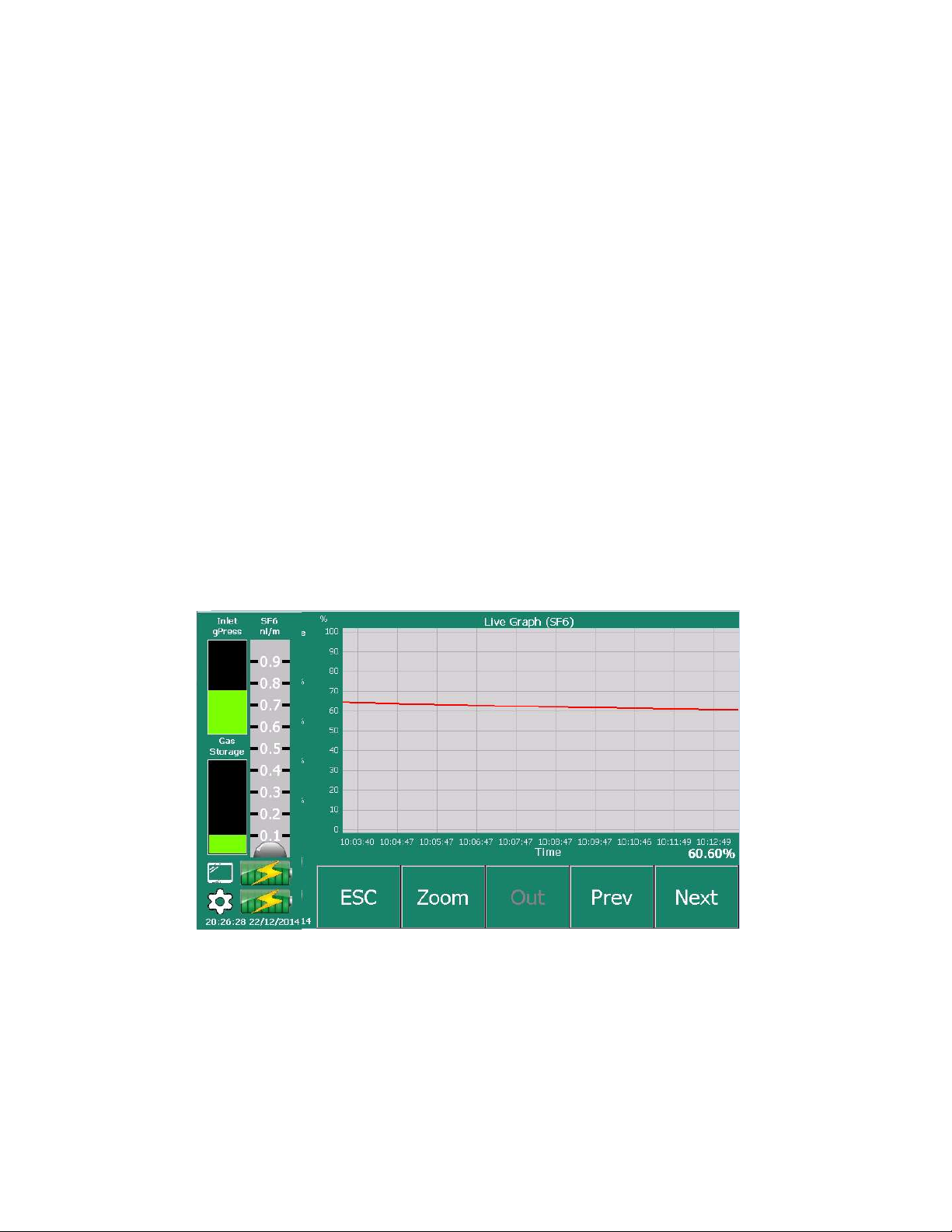

6.2 Live Graph Display

To view a live graph recording of the gas values or compartment pressure, press on the

appropriate label on the main display and the graph function will open. The main panel

shows a live display graph of the reading from the sensor. Use the “Esc” button to return to

the main display screen and the “Prev” & “Next” buttons to change the sensor you are

viewing. Each gas type is assigned a colour and this is shown in Figure 35 below.

Figure 11: Pressing on any gas name on the main screen will display a live graph of that measurement.

6.3 Line Purge Option

Pressing this button will activate the line purge feature. This uses a vacuum to remove all

the air from the special sample hose that is supplied with the analyser. It is recommended

to do a line purge of your hose at the start of a day’s testing to ensure no air gets mixed in

Page 19

with the SF6. If you are doing a series of tests it is not necessary to line purge every time as

the hose will be full of SF6 from the previous test.

The small volume of residual gas in the sample hose that is removed during the line purge

operation is vented to the “Bypass Port” (Figure 1-15). As there is a possibility that this

may contain SF6, the gas may be collected using an optional gas recovery bag. Connect the

recovery bag using a 4mm OD tube to the bypass port ( Figure1-15). There are screen

shots to remind you to do this should it be deemed necessary (see Figure 6).

Only use the sample hose that is supplied with this equipment to do your testing. This hose

has closed couplings that are gas and vacuum tight. The inside of the hose is lined with FEP

to make sure moisture and other gases don’t stick to the lining.

Connect the sample hose to the Gas Inlet socket (Figure 5) but DO NOT connect the other

end to the gas compartment. You will get a prompt and a diagram on screen to assist you

(Figure 6). Once you confirm that the hose is correctly in position the pump will run for

approximately 45 seconds to extract all the gas from the line. Afterwards you will receive a

prompt stating the line purge is complete. The sample line is now ready to be connected to

the gas compartment for testing.

Figure 12: Line Purge takes 45 seconds to complete and finishes with the above message

If you have the line attached to the gas compartment so there is pressurised gas present

then the pump will stop after a few seconds and question if the hose is still connected (see

Figure 2 - 4). This is a safety feature.

Note that occasionally the H2O sensor will display “U/Range” after a line purge because the

vacuum causes the moisture to drop below the minimum reading. This is not a problem

and the sensor will recover itself as soon as the analyser is pressurised with new SF6.

Page 20

6.4 Pump Back Option

If you have completed a test, or have gas in the storage bag, or have a bag that is full then

you can pump the gas back in to the gas compartment or gas recovery unit with this option.

You will receive a screen message and a diagram asking you to check and confirm the

sample hose is connected to the gas compartment (Figure 2 – 2). After confirmation, the

internal compressor will activate to pump all the SF6 back into the gas compartment.

Depending on how full the bag is and the pressure of the gas in the compartment this can

take up to five minutes to complete but is typically much faster than this. Once all the SF6

has been removed from the analyser the compressor will switch off and a message will

display confirming you can now remove the sample line again.

Page 21

6.5 Start Delay

In certain test environments, you are required to walk away from the equipment while the

test is being performed. The Rapidox allows the user to enter a start delay time in the

Sampling Menu. When enabled, the unit will count down the delay time before starting a

test. The feature works in both Timed and Continuous modes. To enable or edit this

function press “Menu” followed by “Sampling” to display the following screen. Press on the

button labelled “Start Delay” and enter a delay time in minutes. Set zero for no delay. The

minimum time delay is 0.1 mins (6 seconds) and the maximum time delay is 10 minutes.

Press “Set” to store the new value.

Figure 13: Use this feature to set a Start Delay time before a test begins

Figure 14: Enter a time up to ten minutes to use a delayed start

Page 22

Figure 15: The delayed start is shown on the screen before a sample commences

6.6 Working with Pre-Loaded Test Parameters

The Rapidox has several commonly used SF6 test parameters pre-loaded for quick and easy

selection. The list includes CIGRE and IEC international test standards as well as the option

to create and name your own custom test. Note that the dewpoint values used in these

standards are “Over Ice” i.e. frost point. To set up this function press “Menu” and then

“Sampling”. The pre-loaded tests are accessed by pressing the “Edit” button alongside the

label “Test Parameter”:

Figure 16: Pre-loaded test parameter screen. Press the “None” button to remove any tests that have been

selected.

Page 23

On this screen the user can remove any tests by pressing “None”. This will clear all

previous selections. To select the relevant test simply press on the labelled button of

choice and the pass/fail alarm settings will be loaded as displayed. Or if the user wants to

create a new bespoke test click on the button labelled “Custom” to access the editing

screen.

Figure 17: Custom test parameter edit screen

By clicking on the button below “Name” the user can re-name the test e.g. “Taiwan GIS

recycle”. Next the three gas parameters can be edited in turn. For each gas a pass/fail set

point can be entered as well as > and <. Or alternatively the test can be disabled for the gas

in question. Once the custom test parameters are set up press “Set” to store them. Pressing

“Back” returns you to the Sampling screen where you will see that the test name has

changed to your custom name. This new test can be selected and used in the same way as

the standard tests until it is edited and modified again.

With the test of choice selected the user can return to the main screen and begin sampling

gas. If the readings are outside the test parameter, the screen will display “FAIL” in red

alongside the gas symbol. Or if the sample is within the test parameter the word “PASS” in

green will be displayed. This information is logged and printed as a permanent record.

6.7 Working with SF6 and N2 mixtures

In certain countries SF6 is mixed with dry nitrogen in gas compartments. In this case it is

possible to reconfigure the analyser, so the balance gas analysis is displayed as the nitrogen

content. This option is not factory enabled and requires a re-boot to operate if selected.

To enable the N2 Balance option press ”Menu” and “Options” followed by “System Control”.

Enter the admin password (default it 8888) to continue.

Page 24

Figure 18: Use the System Control Menu to switch on / off the Balance Gas option

Select YES and press SET. The analyser will respond by asking to re-boot to enable this

function. Once restarted the main screen will now display N2 as the balance gas.

Figure 19: Main screen with N2 mode enabled.

6.8 Working with SF6 and Air mixtures

With the N2 balance mode enabled as described above in section 6.7, it is possible to change

the display to indicate “Air” instead of “N2”. This option is enabled in the “Set Units” menu

as described in section 7.7 below. In this case the Set Units menu is modified as shown in

Figure 20 below.

Page 25

Figure 20: With the balance gas option enabled it is possible to change the display units from “N2” to “Air” if

required.

Figure 21: With Air selected as the unit for the balance gas, the display now looks like this.

The balance mode can be enabled or disabled ay time by the use by accessing the System

Control Menu. A reboot is required to complete the task.

6.9 Working with SF6 and CF4 mixtures

*This feature is specified on ordering and may not be available on your instrument*

Page 26

In certain cold countries SF6 is blended with carbon tetrafluoromethane (CF4) normally in a

50:50 mix. This is used as an anti-freeze to prevent the SF6 from becoming liquid at

extreme cold temperatures.

This Rapidox will correctly measure the SF6 and CF4 content of your gas mixture in the

range specified using a combination of sensor readings and mathematics. To enable the

CF4 reading option press “Menu” followed by “Options” and “System Control”. Enter the

admin password to enter this menu (default is 8888) Here is an option “SF6 / CF4 mix in

use”. Please select Yes if you are using CF4 mixtures or No if you are using SF6 only. It is

important the CORRECT option is selected to ensure accurate readings are maintained!

Please see section 7.4 for full details. Note that the analyser must be re-booted if this

option is required.

Figure 22: To select CF4 mix operation use the menu option “Sampling” to select “YES”

Figure 23: When working with CF4/SF6 blended mixtures select this option and re-boot the analyser

Page 27

7 Rapidox Menu System

Pressing “Menu” enters the main Rapidox Menu system as seen below. Press “Back” to

return to the main analyser screen. If padlocks are displayed then these options are

password protected. See 7.9 for more information on passwords.

Figure 24: Rapidox Main Menu Screen. Note that on the pump back versions of this analyser the alarms are

disabled

7.1 Calibrate

Use this screen to calibrate the gas sensors should they require updating. Note that it is not

possible to field calibrate the H2O sensor because it has a special factory calibration over

many measurement points. Should the H2O sensor need re-calibrating please contact SMC

Sensotec for advice.

Page 28

to the Rapidox u

sing the sample hose

Rapidox using the sample hose

Rapidox to purge the cal gas from the system

Figure 25: Main calibration screen

During calibration, the cal gases are either diverted through the analyser and ejected via

the Bypass Port (Figure 1-15) so no gas enters the storage bag (set unit to CONTINUOUS

mode) or the cal gases enter the internal storage bag so no gas escapes intro the

atmosphere (set unit to TIMED mode). For the latter the calibration time is restricted to

around eight minutes until the storage bag is full. At this point the calibration will stop and

warn you to pump back. It is recommended that timed mode is selected when calibrating

with SF6 gases and continuous mode is selected when calibrating or zeroing with nitrogen

gases (eg toxic gases).

If calibrating with the bypass port, either connect a suitable gas recovery bag to this port or

ensure that a tube is connected to vent the gas to the outside air, subject to local laws and

regulations. After calibration the analyser sample hose must be line purged before further

sampling of SF6 is performed. This will ensure that no residual calibration gas gets mixed

with the sample gas and inadvertently pumped back into a gas compartment. Various

simple diagrams are displayed on-screen to make it easy to follow the correct sequence.

These are as follows:

1) Attach a pressurised nitrogen gas bottle

3) Attach a pressurised SF6 gas bottle to the

Figure 26: Various prompts are displayed on the screen to assist you in performing a calibration

2) Disconnect the nitrogen gas source

4) Attach a suitable gas recovery bag to the

Press on the option you have chosen to either zero or span calibrate the sensor of choice.

To zero the sensors first make sure that you have fresh air or nitrogen flowing through the

analyser. To calibrate the span of the sensor you will need a gas bottle of known

concentration gas (normally 100% SF6 and 100ppm SO2). The current calibration values

Page 29

are displayed on the calibrate screen as seen in Figure 25 above but these can be changed if

they do not match the value of your gas bottle.

You can load a previous calibration by pressing “Load” and you can save the calibration you

have just performed by pressing “Save”. All calibrations including the initial factory one are

stored on the hard drive of the analyser.

Figure 27: Historical calibrations can be re-loaded and new ones saved using the “Load” and “Save” buttons.

Figure 28: Use the “Zoom” button to magnify the graph when calibrating & “Out” to return to full

The current calibration gas concentration is shown in the top right hand corner of the main

screen. To change this value press “Conc” and enter a new value using the number pad.

This will be remembered for next time.

Page 30

Figure 29: The zero and span calibration gas concentrations can be modified by the user

Once you are happy that the reading is stable press “Cal” to save the new calibration. Use

the “Out” button to redraw the graph full scale. Use the “Back” button to return to the main

calibration screen. Repeat the process for any other sensors that you want to calibrate.

Note that if you calibrate with the wrong gas or try to calibrate ‘back to front’ the analyser

will give you a warning to check before proceeding.

Figure 30: To complete the calibration press “Cal”. Note that the analyser will warn you if the expected value

is out of range.

Page 31

7.2 Data-Logging

The test set data-logs all parameters and test results constantly whilst the machine is

operating. The data is stored indefinitely until the hard drive is full and then data will be

overwritten oldest first. There is sufficient space on the hard drive for a minimum of

twelve months of continuous data storage based on how the unit is used. You can use this

option to search, review and re-graph historical data.

Figure 31: Use this screen to select data-files stored in date blocks and view them in graph form.

Use the “Prev” and “Next” buttons to search though the history of data files. Press the “Esc”

to stop searching. Each session is recorded as a separate file on the hard drive. To return

to the current set press “Today”. To view the data as a graph press on the file icon of

interest and press “Go”.

A list of separate files representing sessions for the selected day are now displayed. Use

the “Up” and “Down” buttons to scroll the list and select the session of interest. Note that if

the test was timed then the end result can be displayed and reprinted, as well as graphed.

If the test was continuous then some viewing options will be disabled. If the test has a “*”

alongside it then this indicates the data are a complete test, as opposed to un-starred tests

which are either continuous measurements or a test where the user aborted before the

timer reached zero.

Page 32

Figure 32: The Data is loaded from the hard disc drive and displayed on the screen

To display the basic test result press “Show Results”. The result information will be

displayed as follows:

Figure 33: The Data is loaded from the hard disc drive and displayed on the screen. Here it can be printed

out.

To show a full graphical reporesentation of the sample test press “Graph Sample”. A full

colour graph of the test will be displayed as shown in Figure 34. Note that if the data is

from a large continuous test that it may take up to a minute to load and graph the results.

The graph Y axis is set to display the percent scale of the sensor so that all types of sensor

reading can be shown on a single graph. Press Next and Back to display individual gas

charts.

Page 33

Figure 34: Historical data-log graph with colour coded key

Figure 35: RGB Colours used for each gas type shown on a graph. Not all gas types are fitted to Rapidox

machines.

Pressing “Back” and “Next” will redraw the graph with a single gas or parameter to aid with

clarity. Using the “Options” button seen on Figure 32 the user can set a default choice for

what sensors are displayed on the historical graph:

Page 34

Figure 36: The user can customise the historical graphs using the “Options” button and selecting which

sensors to display and which to hide.

7.3 Auto Abort

The Auto Abort function allows users to set limits for toxic gases entering the analyser.

This helps to prevent damage to the equipment if excessive amounts of harmful gases such

as SO2, H2S, CO and HF enter the pipework. With the function set and enabled as soon as

any toxic gas level rises beyond the limit set, the test will abort, and the gas will be returned

to the compartment if auto-pumpback is enabled. To enter this function press “Menu”

followed by “Auto Abort” to see the following screen:

Figure 37: Auto Abort function. Depending on what toxic gas sensors are fitted a list of gases will be present

here.

Page 35

Note that you cannot set over-gas limits for SF6 CF4 and H2O. Only the toxic gas sensors

fitted to your machine will be listed here. Toggle the Enable/Disable button to switch on

the over-gas protection. Press on the gas value to edit the over-gas set point. Toggle the

pumpback switch to “Auto” or “Manual”. Once all the settings have been configured press

“Set” to store permanently.

If a gas reading exceeds an over-gas limit, then the analyser will report this as shown

below:

Figure 38: Message indicating that the SO2 over-gas limit has been exceeded. The test has been aborted and

the gas needs to be returned to the compartment.

7.4 Sampling Modes

You can choose the method of gas analysis as “Timed” or “Continuous” mode. For normal

testing Timed mode should be used in this mode the user selects a fixed time to sample gas

of eight minutes. The analyser then samples for this period and then displays the result on

the screen until the next sample is required. Multiple repeat tests are allowed, and the

testing can be aborted at any time. You can choose if the gas is automatically pumped back

after each test is completed and select if you would like an automatic print out of the

results at the end. During the test it is also possible to enter the live graph viewing mode.

In “Continuous” mode the analyser will sample gas permanently and pass the waste gas out

through the bypass port. A separate SF6 gas recovery system is required to prevent the gas

entering the atmosphere. This mode is used exclusively for calibration, validation and

service purposes.

Page 36

For both modes There is an option to identify the sample with a name (e.g. “GIS Station 3”)

that is displayed on the main screen. This name is also recorded on the data log file and on

the print out.

7.5 Timed Mode

Figure 39: Use this option to change the sampling method from “Timed” to “Continuous” and set the sampling

duration and other options.

The sample duration is fixed at eight minutes in this mode. For accurate dewpoint readings

the H2O sensor is cleaned every cycle which takes just under four minutes to complete, and

a further four minutes are required to get a stable reading.

If desired, a start delay can be incorporated to allow the user to walk away from the

equipment during testing. See 6.5 for a full description of this feature. It is recommended

that three repeat tests are performed to make sure that the sample line and equipment has

fully dried down and the dewpoint reading is accurate. If the dewpoint measurement is

still falling, then repeat the test again until a stable and consistent measurement is

obtained.

Note that the unit waits thirty seconds in between each test before starting the next one.

This allows all the sample gas to re-disperse inside the gas compartment prior to new

sampling.

Tap on the buttons labelled “Line Purge”, “Pump Back” and “Print Results” to toggle these

options on or off during a test. Setting “Line Purge” to “Auto” will cause the analyser to ask

you to do a vacuum purge of the sample line prior to each sample. This is important to do

on first use but may not be necessary each time so it is suggested this is left on “None” until

you are more familiar with your testing regime. Setting the “Pump Back” option to Auto

Page 37

will force the analyser to pump back the gas into the compartment after each set of tests is

completed. This is a normal procedure, so it is suggested to leave this set to “Auto”. Both

these options can also be manually commanded from the main display screen as well. Note

that if you choose multiple tests using the “Number of Tests” button then the “Auto” mode

will pump back after each to prevent the storage bag from over filling. Setting the printer

option to Auto will produce a print out of every test result if required. It is normal to have

this option set to “Auto”.

Figure 40: The Location name can be edited here using the alphabet keypad. Names are displayed on the

main screen and are printed and saved with the data.

Figure 41: During a “Timed” test the main screen displays a count down while the sample is being taken. The

results are displayed after the clock reaches zero. Press “Graph” to review the live data and “Abort” to abort

the sample mid-run.

Page 38

Figure 42: If during sampling the user wants to escape, pressing the “Abort” button will stop the sample and

the screen will show -.- to indicate that the sample was incomplete.

7.6 Continuous Mode

Figure 43: Continuous Mode set up page

This mode is used only when calibrating, validating or servicing the analyser. When this

mode is set, the test gas is diverted through the analyser and sent to the Bypass Port

(Figure 1-15). No gas enters the storage bag in this mode. Consequently, several of the

options are greyed out as they are not applicable in this mode.

The gas leaving the bypass port may be either collected for recycling using an optional gas

recovery bag or vented in accordance with local regulations, using a length of tube

Page 39

connected to the port. Note that each time the analyser is started, a reminder screen will

be displayed as shown in Figure 2 number 5).

In this mode the start delay option is still available. See 6.5 for a full description of this

feature. An additional option is available called “Free Flow”. This option is only used when

connecting external calibration equipment such as mass flow controllers dewpoint

generators. Selecting yes will disable all the flow control on the analyser which may

otherwise interfere with external flow control equipment. Leave this option set to “No”

unless you are working with such equipment.

Note that in continuous mode the dewpoint sensor will clean itself five minutes after

powering on and then every thirty minutes afterwards. During the two minute clean

period the display will indicate “Wait” while the sensor is off-line. Occasionally the

dewpoint sensor will perform a more advanced clean cycle which lasts slightly longer and

repeats itself up tot six times. If you observe this please leave the analyser running until

the cycle is complete and readings settle down again.

7.7 Set Units

Use this menu to change the units displayed by the analyser for the different measurement

parameters. The number of decimal places displayed can also be set here. Use the “Back”

button to return to the main menu. Note that you can also change the units directly from

the main display screen by tapping on them with your finger.

Figure 44: Setting the display units for the different sensors. T. Once selected the choice will be saved as the

default until changed again.

7.8 Date & Time

Page 40

There are various options for setting the analyser date and time and how it is displayed.

This information appears in the bottom left-hand corner of the display and is used for datalogging and record keeping.

Figure 45: Use this screen to set the date and time and how it should be displayed on the main screen.

7.9 Passwords

Default password USER = 2222

Default password ADMIN = 8888

Various levels of password protection can be set allowing access to selected menus and

options. This gives the user full flexibility to set the analyser up in a way that restricts

access only to sensitive screens and settings if desired. A four digit numerical

administrator password is required to enter the password screen. The default admin

password is 8888 but this can be changed later:

Page 41

Figure 46: To enter the password menu the user must enter the Admin password. The factory default is 8888.

Once you have entered the password menu as the Administrator then you can set the

restrictions and change the passwords as you so desire. There is an Admin password (used

to enter only the password screens) and a user password (used to access menus and

options on the analyser). The default factory user password is 2222. Once a menu is set to

“User” a padlock symbol will appear on the button and to continue the user password will

need to be entered to gain access.

Figure 47: The password administration screen allows sensitive menus to be locked with a user password.

Page 42

Figure 48: Once a password is enabled the user password will have to be entered to gain access to the menu

button that is locked.

Press “Set” to store the new settings. Please contact SMC for advice about how to recover a

lost Administrator password.

Page 43

8 Options Menu System

The Options Menu displays various settings that the user may use to set the analyser up

initially. Also included here are some diagnostics and other system tools. The “Data

Transfer” button remains grey until you insert a memory stick into the socket (8) as shown

in Figure 49. If padlocks are displayed then these options are password protected. See 7.9

for more information on passwords.

Figure 49: List of options Menu. The “Data Transfer” option remains grey until a suitable USB memory stick is

attached.

8.1 Data Transfer

Use this function to transfer results and sample data onto a memory stick and view with

Excel or similar programs. The memory stick should have sufficient space available to

transfer the files selected. A warning is given if there is insufficient space.

Select a start data and end date of interest and the size of the files to be transferred will

display. Press “Copy Results” to transfer just the basic results of each test (as printed) or

“Copy Data” to transfer the complete data log file.

Page 44

Figure 50: Use this screen to select the range of data to transfer onto your memory stick

Figure 51: Press “Copy” to begin the transfer. Do not remove the memory stick until told to do so.

Page 45

Figure 52: It is now safe to remove the USB memory stick.

The individual results file is in csv format that can be opened directly into Excel. Each test

is listed in order of date and time and each sensor result is placed on an individual row:

Page 46

Figure 53: Basic test results downloaded from the Rapidox are easily imported into an Excel spread sheet.

The complete data log files are also in csv format and can be opened directly into Excel.

This time the tests can be re-graphed as shown in Figure 54 using the functions available in

Excel.

Page 47

Figure 54: Data from the Rapidox is easily imported into an Excel spread sheet.

8.2 System Control

This options menu is used to set how the line purge and pump back operates and to

manually allow a purge of the complete system. As a complete system purge can involve

releasing small amounts of SF6 into the atmosphere if precautions have been ignored it is

generally a password controlled menu option.

Figure 55: For analysers with CF4 option enabled this is what is displayed

Page 48

Figure 56: For analysers NOT fitted with CF4 option this is what is displayed.

Pressing “System Purge Now” will perform a complete vacuum purge of the analyser

including all pipework, sample hose and gas storage bag. This is normally only required if

the analyser has just been calibrated and the user needs to purge the system of calibration

gas, or contaminated gas has been allowed to enter the machine. Once purged the analyser

is ready to take gas samples again.

Pressing “Pump back now” manually operates a pump back cycle. This option is also

available from the main display window. Once pressed the analyser will prompt you to

connect the sample line to the gas compartment and begin pumping back. Depending on

the pressure in the gas compartment and the volume of gas in the bag the pump back cycle

can take up to five minutes to complete.

“SF6 / CF4 mix in use” enables or disables the CF4 measurement mode. This function

requires a system reboot and is described in detail in section 6.9 above.

“Display Balance Gas” changes the main display so that the missing balance is shown as

either nitrogen or air. This function requires a system reboot and is described in detail in

sections 6.7 & 6.8 above.

The option to set a line purge before every test should be set to “no” unless instructed

otherwise by SMC.

8.3 Gas Cylinder Testing

The “Gas Cylinder Testing” option is used when you want to use the analyser with a gas

bottle of SF6 rather than a switch gear or circuit breaker. With this option set to “Yes” the

Page 49

analyser will accept gas directly from a gas bottle fitted with a regulator. A small gas

cylinder icon is displayed on the main screen to indicate this mode is in operation.

When sampling directly from gas bottles, it is normal for the regulator pressure to drop

momentarily when the test begins and in “normal” mode this can cause the Rapidox to stop

the test. In this cylinder mode, pressure drop monitoring is suspended making it easier to

sample directly from a bottle.

Note that in normal circumstances you cannot pump back directly into a gas cylinder

unless the internal cylinder pressure is below 10 bars. Auto pump back should normally be

disabled in this case.

8.4 Auto N2 System Clean

On occasions where the gas analyse has become contaminated with toxic gases such as SO2,

H2S, CO or HF, or the sample was excessively wet, this N2 System Clean mode allows the

entire analyser to be purged with bottled nitrogen to clean and dry it. Using this mode the

user is instructed to attach a cylinder of nitrogen and the unit will then run automatically

until all readings on the toxic gas sensors have reached zero once again. Nitrogen is fed into

the storage bag until it is full and then the gas is purged out of the instrument via the

bypass port using the pump. The auto clean mode will repeat itself up to a maximum of

XXX times if necessary.

8.5 Language

The default language is set to English but the user can change the screen language to

Spanish, French, German, Chinese (Simple or Traditional), Korean, Turkish or Portuguese.

Note that the analyser will request a system reboot if a different language is selected.

Page 50

Figure 57: Use this option to change the language setting of the analyser. Requires a system re-boot. Not all

options are shown on this screen

Figure 58: The analyser will ask you to confirm you really want to change the language before performing a

re-boot.

8.6 Screen Colour

There are several choices of screen colour and two choices of text colour (black or white).

Use the menu below to change the colours to your preference.

Figure 59: Use this option to change the colour scheme of the display

Page 51

8.7 Screen Brightness

The brightness of the screen can be increased or decreased using this menu option. The

screen brightness does have a significant impact on the battery life of the instrument.

There is also a screen saver option that can be enabled or disabled to help increase battery

life. The screen will darken when the saver is active. The user can select a delay time in

minutes before the screen saver switches on. The minimum time that can be set is one

minute.

Use this screen to change the brightness level. The value will be stored until changed again.

Figure 60: Use this option to adjust the screen brightness and screen saving feature.

8.8 Diagnostics

The diagnostics page provides information that is useful to SMC when diagnosing

problems with sensors or calibrations. The screen also displays readings from internal

pressure sensors and the battery. Please note that the screen is provided for information

purposes only.

Page 52

Figure 61: Diagnostics Page

8.9 Restore

This screen can be accessed and used to perform a factory restore of the analyser. In

normal circumstances this would only be required is the user is experiencing difficulties

with a calibration. Note that all data is lost during a factory restore and the sensors will

require a fresh calibration afterwards as only a basic calibration is loaded. The analyser

will ask you to confirm that you really do want to restore the machine and will reboot once

this has been completed.

Figure 62: Use this option to perform a system restore.

8.10 About

This screen is for information purposes only and shows the configuration of the analyser

including sensors and their ranges.

Page 53

Figure 63: This screen shows important system information about the analyser and sensors connected.

9 Troubleshooting

Q: When I switch on the unit the SF6 sensor display says “Wait”.

A: The infra-red SF6 sensor needs a bit of extra time to warm up before it can give

readings. The Rapidox waits for an internal signal coming from the sensor to say it

is ready before displaying readings. This should take around sixty seconds to

complete. If the “Wait” message does not clear please contact us for advice.

Q: When I start the machine I get a “Hardware Error Fault” message.

A: Very occasionally when the battery has been allowed to run very flat the start up

voltage isn’t quite enough to get the sensors re-started and this message can display.

To fix the problem try switching the unit off and removing the fuses for ten seconds

and refitting. Restart the analyser and in nearly all cases it will reboot correctly.

Q: One or more of the sensor readings is flashing.

A: The reading flashes if the value has gone above 101% of full scale and is to warn you

that the reading / calibration is just out of calibration spec. Please contact us for

advice

Q: I see other messages such as “O/Range” or “U/Range” instead of the gas reading.

A: This message displays if the reading goes above 102% or below 0%. This is usually

caused by a bad calibration Try recalibrating the sensor in question once more,

making sure that a sensible flow and pressure are being used. If all else fails try

restoring the analyser back to factory setting (see 8.9 for details). Contact SMC if the

message refuses to clear.

Page 54

Q: The H2O sensor reading shows “U/Range” right after I perform a line purge.

A: This is quite normal and caused by the fact the dewpoint sensor is sitting in a

vacuum. Because of the pressure compensation maths the reading can be pushed

below its minimum for a moment but this will fully recover once pressurised

compartment gas is applied.

Q: After a few minutes of testing the unit stops with question marks displayed.

A: Are you testing gas from a bottle? If you are, please check to see if you are using

“Gas Cylinder Mode”. The pressure in certain gas cylinders can drop a little during

testing and normal mode is very sensitive to this for safety reasons. Gas Cylinder

mode should be used in this case and the warnings should stop.

Q: One or both of the red charging lights is flashing on the top of the unit

A: If this happens then it means that the battery is too hot to charge. It is a safety

feature to make sure the lithium batteries don’t get damaged. If you are in a hot

location >30C then move the unit to somewhere cooler to charge – e.g. an air

conditioned office.

Q: One or more of the sensor readings says “Fault”

A: Please contact SMC for further advice.

Q: The Rapidox won't power up at all.

A: If the battery is flat then please connect the mains IEC cable and leave the unit to

charge for five to six hours. Note that you can use the analyser whilst it is charging.

The red LED should change to orange (almost fully charged) to green (fully

charged).

Q: The Rapidox still won't power up at all.

A: Please check that the two fuses located on the side are fitted and not blown. This

fuses are different and must not be installed the wrong way around. See Error!

Reference source not found. for correct fuse values.

Q: I get a “Sensor out of Range” warning when I try to calibrate

A: Check that the calibration gas value on the bottle matches the value you have

programmed into the Rapidox. If they are different then the Rapidox will get a

signal it is not expecting and try to warn you with this message. Check that you are

not trying to calibrate the sensor ‘backwards’ by applying span gas when you are

setting the zero point.

Q: I messed up the calibration procedure and the analyser is not working properly.

A: Return the box to the factory defaults using the instructions given in section 8.9 and

try again.

Q: I’m working in a location that has CF4 but can’t get the CF4 to display.

A: This option must be enabled by the user and the machine re-booted. Please make

sure that the gas does indeed have a blend of SF6 & CF4 before enabling. If you use

Page 55

this mode without CF4 present, then the results will be inaccurate.

Q: The SF6 reading seems very inaccurate

A: Please check the settings MENU – SAMPLING and check to see if the CF4 option is set

to yes or no. If it is set to yes and there is no CF4 in the gas then the SF6 reading will

be inaccurate. If everything seems normal, then please contact SMC for advice.

Q: The cooling fan seems to operate even though it is cold?

A: The cooling fan is set to operate each time a sample is taken to make sure no SF6 gas

leaks into the peli-case. Any build-up of SF6 inside the peli-case from external

sources can cause errors on the measurements. The fan also runs for five minutes

each time the unit is powered on.

Q: My storage bag says it is full before the 8 minutes are up!

A: The storage bag is five litres in capacity so at normal atmospheric temperature and

pressure there is at least ten minutes of storage space in the bag. So, in normal

circumstances you should never see a “Bag Full” message. However, since the flow

rate is based on gas density in exceptional circumstances it may be possible to fill

the bag too quickly: eg if the gas changes from SF6 to N2 very quickly during the

test. Also, in extreme weather conditions the volume of gas in the bag may be too

big even if the gas flow was correct. And the gas bag full may appear if calibration

takes longer than eight minutes. If the problem persists there may be an issue with

the calculated flow rate so please contact SMC for advice.

Q: Why does the sampling need to take eight minutes?

A: The Rapidox uses a special polymer dewpoint sensor to give high speed and reliable

dewpoint measurements. Normally these take hours to stabilise, but this sensor is

exceptionally fast. However, all dewpoint sensors are susceptible to drift so this

unit re-calibrates itself at the start of every test. This takes four to six minutes to

complete and we then need another two minutes to get a settle reading from it. So it

really has to be eight minutes to get a decent dewpoint measurement.

Q: Why do the dewpoint graph traces have such strange patterns?

A: The dewpoint sensor takes 4-6 minutes to clean and is off-line during this time. So

part of the trace of the H2O sensor is zero. After this both pressure correcting maths

and a regression algorithm kick in and these both take about thirty seconds of

readings before they become stable as they are both rolling averages. The result is

that only the last minute or so is a true reflection of the correct dewpoint.

Q: What is this 20°Cdp corrected function? Surely dewpoint is absolute?

A: Temperature corrected dewpoint seems to be a nonsense because it is an absolute

measurement unaffected by the temperature. However, most SF6 measurements of

dewpoint are performed using readings that are corrected somehow to 20°C. In

fact, what is happening is that the H2O is being measured in terms of relative

humidity (%RH), which is indeed temperature dependent. The Rapidox dewpoint

sensor measures humidity and temperature and then works out the equivalent

Page 56

dewpoint both at actual temperature (RT) and at the corrected point (@20°Cdp). In

hot countries this produces a drier reading and in colder countries this produces a

wetter reading. And of course if the ambient temperature is 20°C then the readings

are both identical.

Q: Why does it take several tests before the dewpoint falls to an acceptable level?

A: This question is the one we get asked about the most. Fundamentally water is a

very difficult gas to measure because it absorbs onto every surface and takes ages to

completely dry. And all the materials in contact with the gas including the bottle

regulators need to be high quality stainless steel or FEP. If you are in a hot and

humid country trying to run some tests then you have to accept that the hoses and

couplings will be covered in water and this will take a while to dry off completely. If

the first one or two tests are too wet but the readings are falling then please repeat

the testing a few times to observe a trend of dryness.

10 Warranty

The Rapidox analyser and the sensors have been carefully tested and inspected before

shipment and are guaranteed to be free from defective materials and workmanship for a

period of twelve months from date of purchase and delivery. However, if the analysis gas

contains corrosive gases or large quantities of particulates, sensor life may be shortened.

In the case of the latter, it is normally possible to insert a filter prior to the sensor head to

remove the particulate material. Damage caused to the sensors by contamination, chemical

attack or water ingress will not be covered by this warranty.

10.1 Conditions of Warranty:

1) This warranty is in addition to and does not affect any statutory rights of consumer

purchasers. This warranty is valid worldwide on a “back to base basis”.

2) This warranty covers breakdowns due to design or manufacturing faults; it does not

apply to damage, however caused, wear and tear, neglect, unauthorised adjustment or

repair, or any items of limited natural life.

3) In the event of failure, please take the following action:

a] Refer to the “Troubleshooting” section of your instruction manual to identify and

possibly correct the problem.

b] If the fault cannot be resolved, please contact the SMC service and repair centre at

the address given on the cover of the manual.

4) The warranty period applicable shall be 12 months from the date of delivery provided

that:

Page 57

a] Notice in writing of the defects complained of shall be given to SMC (The Seller)

upon their appearance, and

b] such defects shall be found to have arisen from the Seller's faulty design,

workmanship or materials, and

c] The defective goods shall be returned to the Seller's premises at the Purchaser's

expense if so requested by the Seller.

d] Any repaired or replaced goods shall be redelivered by the Seller free of charge to

the original point of delivery but otherwise in accordance with and subject to these

Conditions of Sale.

e] Alternatively the Seller shall be entitled at its absolute discretion to refund the price of

the defective goods in the event that such price shall already have been paid by the

Purchaser to the Seller, or, if such price has not been so paid, to relieve the Purchaser of all

obligation to pay the same by the issue of a credit note in favour of the Purchaser in the

amount of such price.

Loading...

Loading...