SMC Networks PPA100 Series,PPA101 Series,PPA102 Series Instruction Manual

PPA-SMW22EN

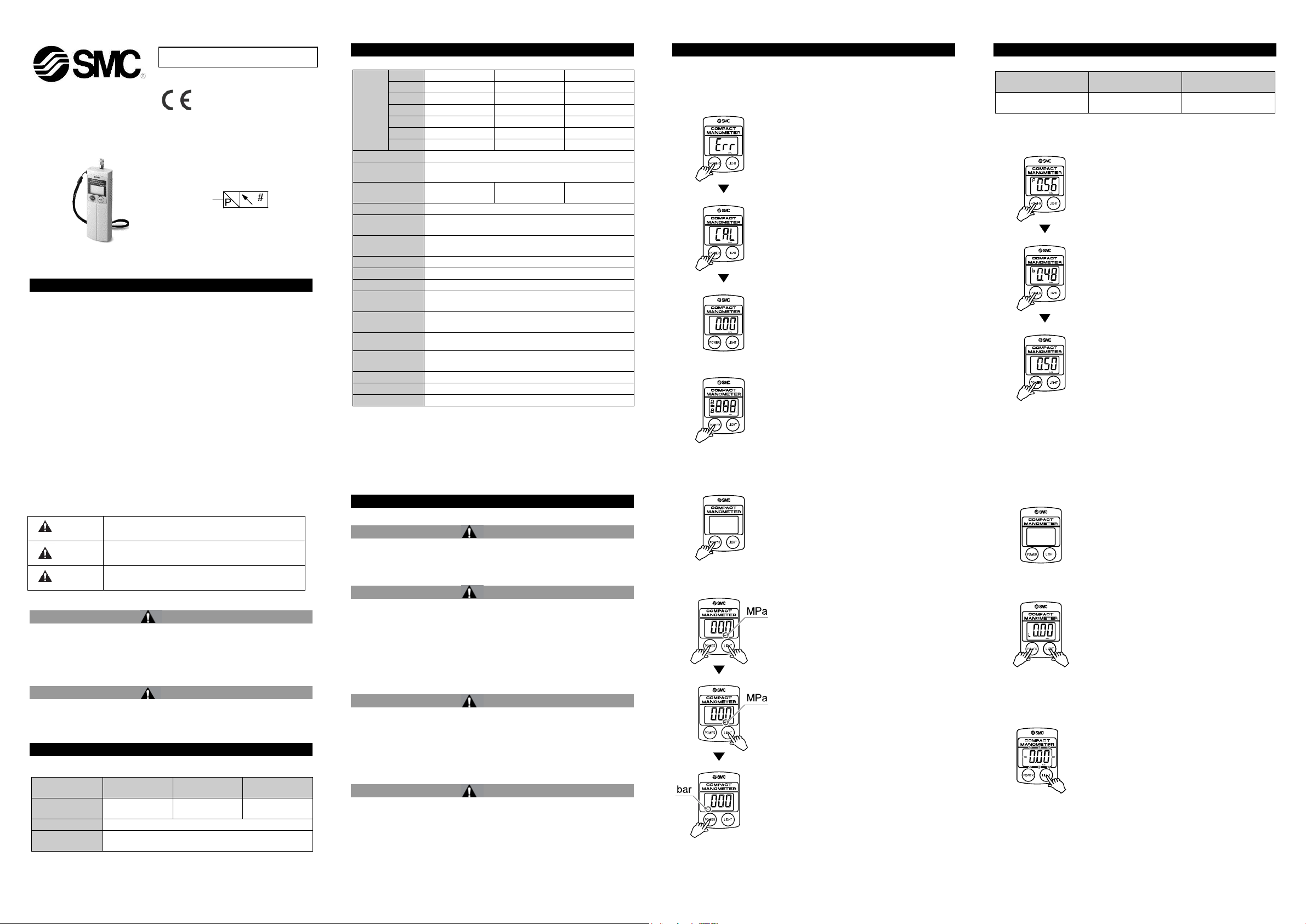

Model

PPA100 for

high pressure

PPA101 for

vacuum

PPA102 for

low pressure

Rated pressure

range

–0.1 to 1 MPa

–101 to 10 kPa

–10 to 100 kPa

Display method

3 digit LCD back light

Pressure display

discrimination

1/100

Min.

display

units

1

kPa — 1

1

MPa

0.01 — —

mmHg — 5

—

kgf/cm2

0.1

0.01

0.01

inHg — 0.2

—

psi 1 0.1

0.1

bar

0.1

0.01

0.01

Error display

Over pressure, Memory data error, Change battery sign

Function

Peak/bottom display, Backlight, Auto power OFF

Zero clear, Units display switching

Withstanding

pressure

1.5 MPa

200 kPa

200 kPa

Applicable fluid

Air, Non-corrosive gases, Nonflammable gas

Power supply

voltage

3 VDC, Type AA dry cell x 2 pcs.

Battery life

12 months continuous operation

(Without backlighting, temperature conditions: at 25°C)

Response speed

250 ms

Display accuracy

±2% F.S. (Temperature conditions: at 25°C)

2

Repeatability

±1% F.S. (Temperature conditions: at 25°C)

Temperature

characteristics

±3% F.S. (0 to 50°C with 25°C standard)

Connection port

size

M5 x 0.8

Operating

temperature range

0 to 50°C (With no condensation)

Operating

humidity range

35 to 85% RH (With no condensation)

Enclosure

IP40

Weight

Approx. 100 g (Unit 50 g, batteries 50 g)

Standard

CE marked (EMC directive/RoHS directive)

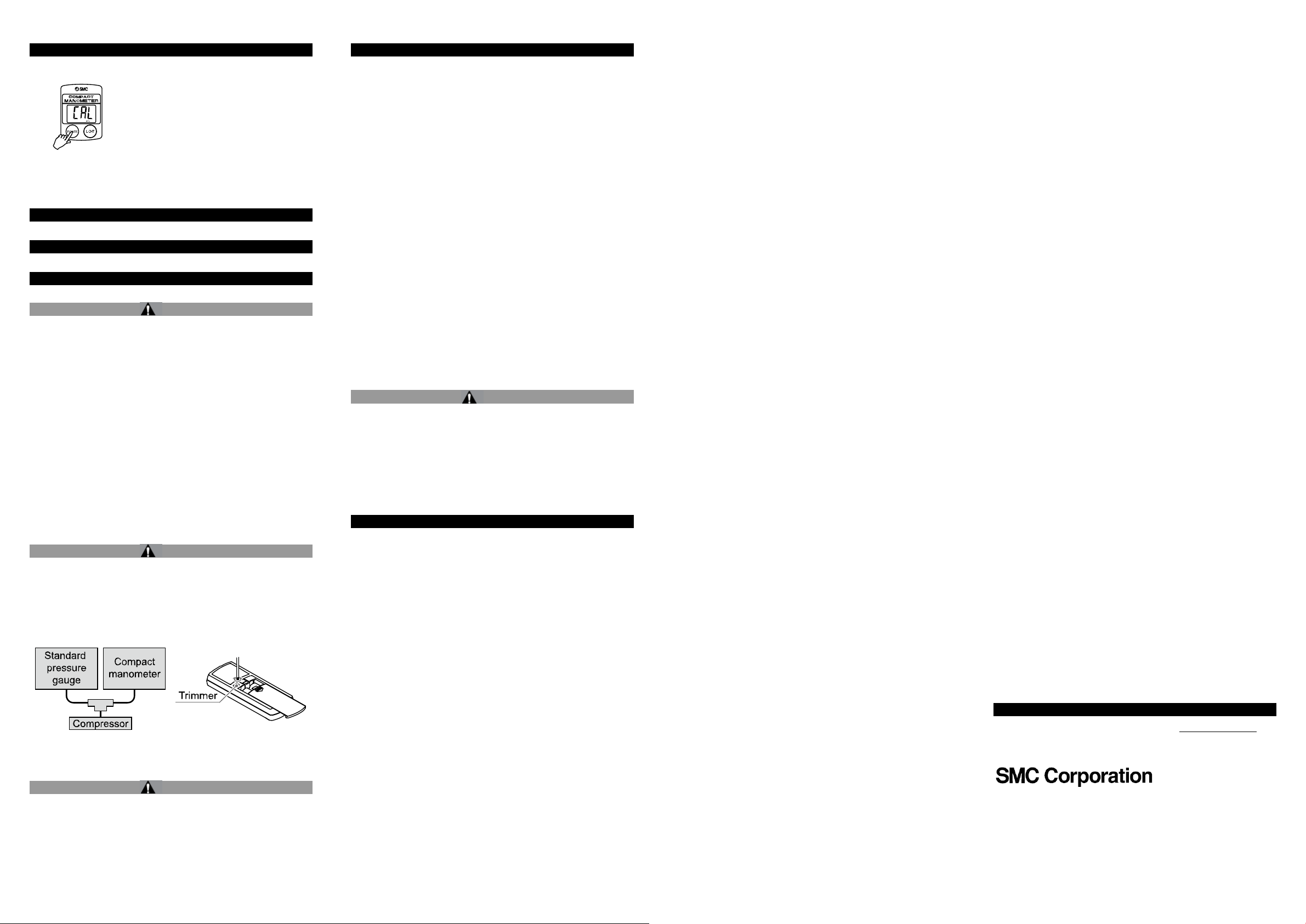

1. Confirmation of display.

When power is applied, if there is nothing on

the LCD display, proceed to step 2.

If "Err" is displayed on the LCD, switch the

power off and on again. Then the display

should be clear.

Proceed to step 2.

2. Press and hold the POWER button for

6 seconds or more.

Press and hold for 6 seconds or more. The

unit will go into zero clear. When this

happens "CAL" will appear on the LCD.

3. Release the POWER button.

When zero clear is finished, the unit can be

operated.

Press the POWER button.

•The power comes ON when it is pressed.

•When pressed and held for 6 seconds or

more, the unit goes into zero clear.

Press and hold the POWER button for 3

seconds or more.

•When pressed and held for 3 seconds or

more, the power turns OFF.

•When there is no button operation for more

than 5 minutes, the power turns OFF. (auto

power OFF function)

1. Press and hold the POWER and LIGHT

buttons for 3 seconds or more.

When pressed continuously for 3 seconds or

more, the units on the LCD will flash.

2. Press the LIGHT button.

The units will change.

(See the table below.)

3. Press the POWER button.

The units are set, and the unit display

switching is completed.

High pressure

(PPA100)

Vacuum

(PPA101)

Low pressure

(PPA102)

MPa → bar → psi → kgf

kPa → bar → psi → inHg

→ mmHg

kPa → bar → psi → kgf

Press the POWER button.

•Peak display

Displays the maximum pressure value and

"P" appears on the LCD. The display will

change if pressure increases beyond the

pressure value that is being held.

Press the POWER button.

•Bottom display

Displays the minimum pressure value and

"b" appears on the LCD. The display will

change if pressure falls below the pressure

value that is being held.

(These modes are useful for confirming

pressure fluctuations.)

Press the POWER button.

When the power is turned ON and there is

no button operation for more than 5 minutes,

the power will turn OFF.

: For cancelling this function, refer to the operation

of the lock mode (below).

Press and hold the POWER and LIGHT

buttons for 6 seconds or more.

The auto power OFF function is cancelled by

activating the lock mode (auto power OFF

cancel).

When continuously pressed for 6 seconds or

more, "L" is displayed on the LCD.

When the power is turned OFF, the lock

mode is released.

Press the LIGHT button.

The display lights up while the button is

being pressed. In the lock mode, it lights up

when pressed and turns off when pressed

again.

However, the maximum lighting time is

approximately one minute.

Caution

Caution indicates a hazard with a low level of risk which, if

not avoided, could result in minor or moderate injury.

Warning

Warning indicates a hazard with a medium level of risk

which, if not avoided, could result in death or serious injury.

Danger

Danger indicates a hazard with a high level of risk which, if

not avoided, will result in death or serious injury.

ORIGINAL INSTRUCTIONS

Refer to Declaration of

Directives

Conformity for relevant

Instruction Manual

Compact Manometer

Series PPA100/PPA101/PPA102

The intended use of this product is pressure measurement.

1 Safety Instructions

These safety instructions are intended to prevent hazardous situations

and/or equipment damage. These instructions indicate the level of

potential hazard with the labels of “Caution,” “Warning” or “Danger.”

They are all important notes for safety and must be followed in addition

to International Standards (ISO/IEC)

*1)

ISO 4414: Pneumatic fluid power - General rules relating to systems.

ISO 4413: Hydraulic fluid power - General rules relating to systems.

IEC 60204-1: Safety of machinery - Electrical equipment of machines.

(Part 1: General requirements)

ISO 10218-1: Manipulating industrial robots -Safety. etc.

Refer to product catalogue, Operation Manual and Handling

Precautions for SMC Products for additional information.

Keep this manual in a safe place for future reference.

*1)

, and other safety regulations.

2 Specifications - continued

: 2 pcs. of type AA dry batteries (manganese R6 or alkaline LR6) are not

included.

1: For the unit switching function (Types without the unit switching function is

fixed in SI unit (kPa or MPa)).

2: In regards to the compatibility condition of the EMC directives, the pressure

display value variation is ±15% F.S. or less.

4 Settings

Operation and Functions

• Initial Setting

Be certain to perform initial setting when using for the first time and after

changing batteries, as the unit will indicate memory data error.

• Power ON

4 Settings - continued

: The "inHg" unit cannot be displayed.

• Peak/Bottom Display

Do this when pressure is being displayed.

: Since this is combined with power OFF operation, the button should be

released at the point when "P" or "b" is displayed.

Warning

Always ensure compliance with relevant safety laws and

standards.

All work must be carried out in a safe manner by a qualified person in

compliance with applicable national regulations.

Caution

The product is provided for use in manufacturing industries.

This product may cause interference if used in residential premises.

2 Specifications

3 Installation

3.1 Installation

Warning

Do not install the product unless the safety instructions have been read

and understood.

3.2 Environment

Warning

Do not use in an environment where corrosive gases, chemicals, salt

water or steam are present.

Do not use in an explosive atmosphere.

Do not expose to direct sunlight. Use a suitable protective cover.

Do not install in a location subject to vibration or impact. Check the

product specifications.

Do not mount in a location exposed to radiant heat.

3.3 Piping

Caution

Before piping make sure to clean up chips, cutting oil, dust etc.

When installing piping or fittings, ensure sealant material does not

enter inside the port. When using seal tape, leave 1 thread exposed

on the end of the pipe/fitting.

Tighten fittings to the specified tightening torque.

3.4 Lubrication

Caution

SMC products have been lubricated for life at manufacture, and do

not require lubrication in service.

If a lubricant is used in the system, refer to catalogue for details.

• Power OFF

• Unit Display Switching

: This operation cannot be done for the type which does not have the unit

switching function.

• Auto Power OFF Function

• Lock Mode (Auto power OFF cancel)

• Turning on the Backlight

Page 1 of 2

PPA-SMW22EN

Press the POWER button for 6 seconds

or more.

The zero point displayed at atmospheric

pressure can be automatically adjusted. This

means it is possible to eliminate a display

discrepancy at atmospheric pressure.

•Turn the power OFF.

•Release the supply pressure to the

atmosphere.

•When continuously pressed for 6 seconds

or more, zero clear is performed and "CAL"

is displayed on the LCD.

URL :

http// www.smcworld.com (Global) http// www.smceu.com (Europe)

4 Settings - continued

•Zero Clear

5 How to Order

Refer to catalogue for ‘How to Order’.

6 Outline Dimensions (mm)

Refer to catalogue for outline dimensions.

7 Maintenance

7.1 General Maintenance

Caution

Not following proper maintenance procedures could cause the

product to malfunction and lead to equipment damage.

If handled improperly, compressed air can be dangerous.

Maintenance of pneumatic systems should be performed only by

qualified personnel.

Before performing maintenance, turn off the power supply and be

sure to cut off the supply pressure. Confirm that the air is released to

atmosphere.

After installation and maintenance, apply operating pressure and

power to the equipment and perform appropriate functional and

leakage tests to make sure the equipment is installed correctly.

If any electrical connections are disturbed during maintenance,

ensure they are reconnected correctly and safety checks are carried

out as required to ensure continued compliance with applicable

national regulations.

8 Limitations of Use

8.1 Limited warranty and Disclaimer/Compliance Requirements

The product used is subject to the following “Limited warranty

and Disclaimer” and “Compliance Requirements”. Read and

accept them before using the product.

Limited warranty and Disclaimer

1) The warranty period of the product is 1 year in service or 1.5 years

after the product is delivered, whichever is first

may have specified durability, running distance or replacement parts.

Please consult your nearest sales branch.

2) For any failure or damage reported within the warranty period

which is clearly our responsibility, a replacement product or

necessary parts will be provided.

This limited warranty applies only to our product independently, and

not to any other damage incurred due to the failure of the product.

3) Prior to using SMC products, please read and understand the

warranty terms and disclaimers noted in the specified catalogue for

the particular products.

(1)

Vacuum pads are excluded from this 1 year warranty.

A vacuum pad is a consumable part, so it is warranted for a year after

it is delivered. Also, even within the warranty period, the wear of a

product due to the use of the vacuum pad or failure due to the

deterioration of rubber material are not covered by the limited

warranty.

Compliance Requirements

1) The use of SMC products with production equipment for the

manufacture of weapons of mass destruction (WMD) or any other

weapon is strictly prohibited.

2) The exports of SMC products or technology from one country to

another are governed by the relevant security laws and regulations of

the countries involved in the transaction. Prior to the shipment of a

SMC product to another country, assure that all local rules governing

that export are known and followed.

Caution

SMC products are not intended for use as instruments for legal

metrology.

Measurement instruments that SMC manufactures or sells have not

been qualified by type approval tests relevant to the metrology

(measurement) laws of each country.

(1)

. Also, the product

Do not make any modification to the product.

Do not disassemble the product, unless required by installation or

maintenance instructions.

7.2 Span calibration method

Caution

Do not touch the span calibration trimmer except when performing

span calibration.

1. Perform zero clear at atmospheric pressure.

2. Apply the maximum rated pressure, and calibrate the span while

comparing with a standard pressure gauge.

3. If the display value of the compact manometer is “0” after returning to

atmospheric pressure, then calibration is complete.

If the display value is not “0”, calibrate again by repeating steps 1 and 2.

7.3 Replacing the batteries

When battery voltage becomes low the entire LCD will flash.

When the LCD flashes replace the batteries. Use 2 x AA dry batteries.

Caution

To replace the batteries, turn the power OFF and replace them

within approximately 30 seconds.

When not completed within 30 seconds, “Err” will be displayed.

In that case, perform zero clear once again.

In the event that the display runs out of control, remove the batteries for

one minute or longer, and then perform zero clear again for inserting

the batteries and turning on the power.

Therefore, SMC products cannot be used for business or certification

ordained by the metrology (measurement) laws of each country.

9 Disposal

This product is classed as Waste Electrical or Electronic Equipment

according to the WEEE Directive 2012/19/EU and should not be

disposed of as municipal waste, in order to reduce the impact on human

health and the environment.

Remove and dispose of old batteries and the remaining electrical or

electronic equipment according to local environmental regulations.

10 Contacts

Refer to Declaration of Conformity and www.smcworld.com for

contacts.

'SMC Corporation, Akihabara UDX15F, 4-14-1, Sotokanda, Chiyoda-ku, Tokyo

101 0021

Specifications are subject to change without prior notice from the manufacturer.

© 2018 SMC Corporation All Rights Reserved.

Template DKP50047-F-085H

Page 2 of 2

Loading...

Loading...