Page 1

Safety Instructions

Flow Sensor

Instruction Manual

PFMV5

Series

URL http://www.smcworld.com

Specifications are subject to change without prior notice and any obligation

on the part of the manufacturer.

The descriptions of products shown in this document may be used by the

other companies as their trademarks.

© 2005 SMC Corporation All Rights Reserved

To facilitate recycling, this

manual is printed using

biodegradable soy ink, which

can easily be de-inked.

This manual is printed in the

"non-water system", which does

not output toxic liquid waste.

Thank you for purchasing the SMC PFMV5 Series Flow Sensor.

Please read this manual carefully before operating the flow sensor

and make sure you understand the flow sensor, its capabilities and

limitations.

Please keep this manual handy for future reference.

OPERATOR

•This manual has been written for those who have knowledge of machinery

and apparatuses that use pneumatic equipment and have full knowledge of

assembly, operation and maintenance of such equipment.

•Please read this manual carefully and understand it before assembling,

operating or providing maintenance service to the flow sensor.

Phone

AUSTRIA / (43) 2262-62 280 ITALY / (39) 02-92711

BELGIUM / (32) 3-355 1464 NETHERLANDS / (31) 20-531 8888

CZECH REP. / (420) 5-414 24611 NORWAY / (47) 67 12 90 20

DENMARK / (45) 70 25 29 00 POLAND / (48) 22-548 50 85

FINLAND / (358) 207 513 513 PORTUGAL / (351) 2 610 89 22

FRANCE / (33) 1-64 76 1000 SPAIN / (34) 945-18 4100

GERMANY / (49) 6103 4020 SWEDEN / (46) 8-603 0700

GREECE / (30) 1- 342 6076 SWITZERLAND / (41) 52-396 3131

HUNGARY / (36) 1-371 1343 TURKEY / (90) 212 221 1512

IRELAND / (353) 1-403 9000 UNITED KINGDOM / (44) 1908-56 3888

Precaution on Handling

Use UL approved product for direct current power supply.

1.Clamping voltage current circuit complies with UL508

Circuit which power supply if insulation transducer satisfying

following conditions

Max. voltage (No load) : 30Vrms (42.4V peak) or less

Max. current : (1) 8A or less (Including short circuit)

(2) When limited by the circuit

protector (fuse etc.) with the ratings in the table

below.

Voltage without load (V peak)

0 to 20 [V]

Over 20 [V] up to 30 [V]

Max. current rating (A)

5.0

100/peak voltage

2.Circuit (of class 2) which is of 30Vrms (42.4V peak) or less with the

power supply unit of class 2 complying with L1310 or transducer of

class 2 complying with UL1585.

The Flow Sensor have in after referred to as flow sensor and this

manual contain essential information for the protection of users and

others from possible injury and property damage and to ensure

correct handling.

Please check that you fully understand the definition of the following

messages (signs) before going on to read the text, and always follow

the instructions.

Read this manual and follow its instructions. Signal words such

as WARNING, CAUTION and NOTE, will be followed by

important safety information that must be carefully reviewed.

IMPORTANT MESSAGES

Indicates a potentially hazardous situation

which could result in death or serious injury

if you do not follow instructions.

Gives you helpful information.

Indicates a potentially hazardous situation

which if not avoided, may result in minor

injury or moderate injury.

Do not disassemble, modify (including change of printed circuit

board) or repair.

An injury or failure can result.

Do not operate outside of the specification.

Fire, malfunction or flow sensor damage can result.

Please use it after confirming the specification.

NOTE

Follow the instructions given below when handling the flow sensor.

Otherwise, the flow sensor may be damaged or may fail, thereby

resulting in malfunction.

•Make sure to use a sensor by the specified voltage.

•Make sure to use specified measurement flow and operating pressure.

Perform proper functional checks and leak tests after

maintenance.

Stop operation when an abnormality is observed such that the flow sensor

does not work properly or there is a leakage of fluid. Safety is not be assured

due to unexpected malfunction. When leakage occurred from other parts

except piping, the flow sensor might break. Cut off power supply and stop

supplying pressure. Don’t apply pressure at leaking condition.

To avoid fire and explosion, Do not use the product for

flammable fluid.

This flow sensor is designed for air. Only dry air, N2are applicable.

Do not operate in an environment of inflammable, explosive or

corrosive gas.

Fire or an explosion can result.

This flow

sensor is not an explosion proof type.

Do not use this product near by a place where static electricity

is a problem.

Otherwise it can cause failure or malfunction of a system.

These instructions must be followed while in maintenance ;

Turn off the power supply, stop the supplied air, exhaust the

residual pressure and verify the release of air before

performing maintenance.

Otherwise it can cause injury.

Page 2

Specifications

•Prepare maintenance space.

•Do not drop or bump, or apply excess impact.

•Do not pull the lead wire forcefully, not lift the product by pulling the lead

wire. (Tensile force 49N or less).

•Mount a sensor by observing the proper tightening torque.

•Install or connect the flow sensor so that the flow direction specified on the

label matches with actual flow direction.

•Pipe the flow sensor after eliminating dust in piping by air blow to avoid

failure and malfunction.

•Use dry air which complies with the quality grade of ISO 8573-1 1.1.2 to

1.6.2 : 2001.

•If the entering of foreign material to the fluid is possible, install and pipe the

filter or the mist separator to the inle to avoid failure and malfunction.

•Avoid repeatedly bending or stretching the lead wire.

•Wire correctly.

•Do not wire while the power is supplied.

•Do not wire in conjunction with power lines or high voltage lines.

•Wire as short as possible to avoid the affect of noise and surge.

•Never use in the presence of explosive gases.

•Do not use in an area where magnetic field is generated to avoid

malfunction of sensor.

•Do not operate where the flow sensor is exposed to water.

•Do not use the sensor for poisonous substances, deleterious substances

and corrosive gas. This sensor is not a explosion proof. Do not use for

flammable gas.

•Do not apply heat cycle to the flow sensor.

•Do not used in an area where surges are generated.

•Sensors are not equipped with surge protection against lightening.

•Avoid using sensors in an environment where the likelihood of splashing or

spraying of water, chemicals, and oil to avoid failure and malfunction.

•Consider operating environment according to protection class.

•Do not use the flow sensor where exposed to vibration or impact. Vibration

may interfere correct measurement.

•Flow sensor has to be fixed when used.

•Operation under low temperature (5 or less) leads to cause damage or

operation failure due to frozen moist in the fluid or air.

•Do not short circuit the load.

• Maintenance and inspection should be performed periodically.

• Analog output may fluctuate by 2 to 3% for 5 minutes after supplying power

to the flow sensor.

• Do not poke inside a piping port with a stick.

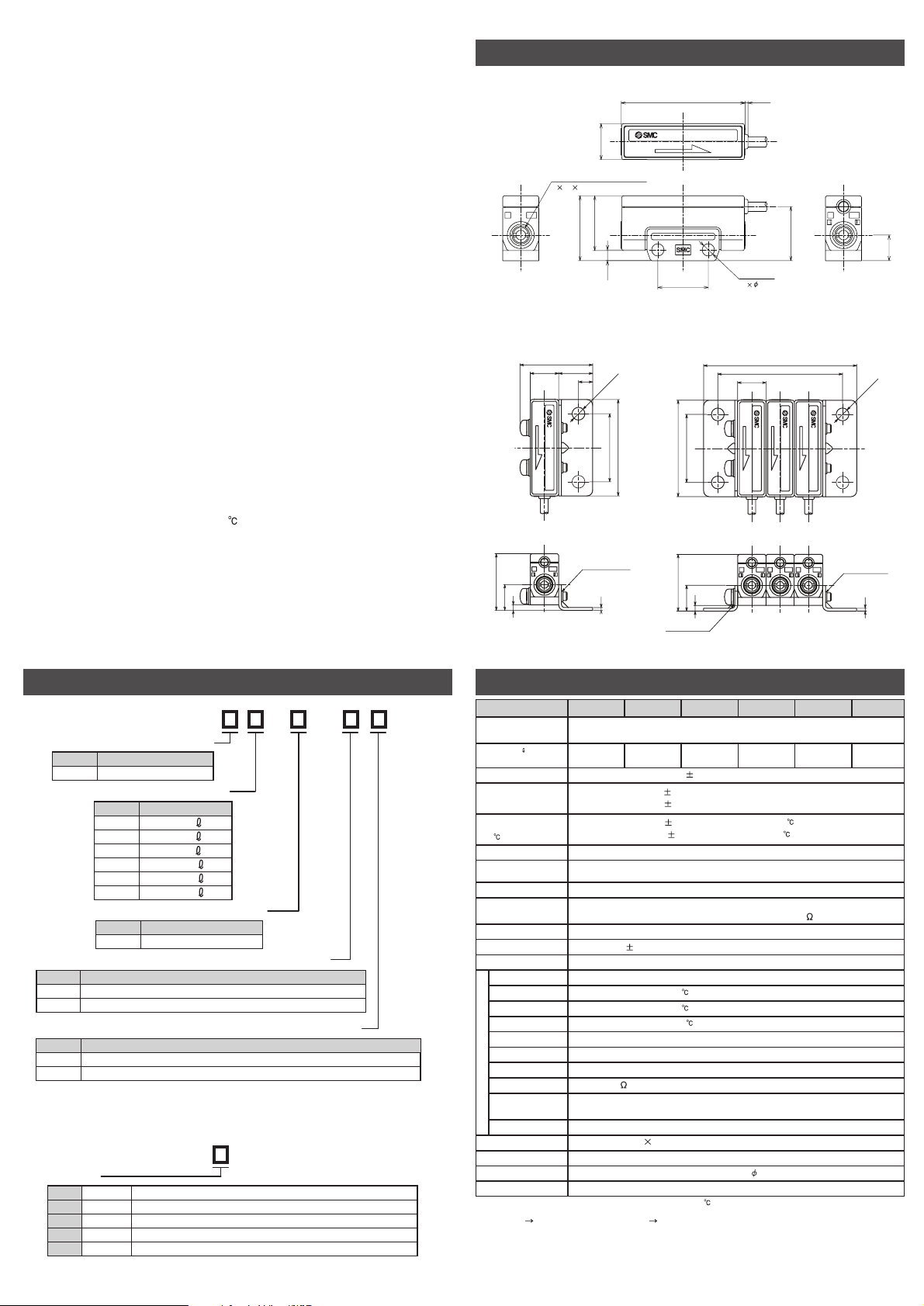

Dimensions and Names of Individual Parts (unit: mm)

With L-type bracket

Note 1) Converted value of volume flow at ANR (20 , 101.3kPa, 65%R.H.).

Note 2) Analog output shows 3V when flow is zero. Changes to 5V side when flow direction is

IN OUT. 1V side when OUT IN.

Note 3) %F.S. in the table takes 4V (1-5V) as a full scale.

Note 4) 0kPa means release to the atmosphere.

Note 5) Applicable pressure range.

Note 6) Pressure range satisfies product specification.

Model

Measured fluid

Dry air, N2

(Air quality class is ISO 8573-1 1.1.2 to 1.6.2 : 2001)

Flow rate /min

Note1)

(measurement range)

2%F.S. or less

Note3)

Repeatability

2%F.S. or less (0 to 300kPa)

5%F.S. or less (-70 to 0kPa)

Pressure

characteristic

(0kPa reference

Note4)

)

2% F.S. or less (15 to 35 )

5% F.S. or less (0 to 50 )

-100kPa to 400kPa

500kPaProof pressure

At voltage output : 1 to 5V

Output impedance : approx. 1k

5ms or less (Response 90%)Response time

12 to 24VDC 10%, ripple(p-p) 10% or less (Protected against inverse connection)

IP40Enclosure

0 to 50 (No freezing or condensation)Operating fluid temp.

0 to 50 (No freezing or condensation)Operating temp. range

35 to 85%R.H. (No condensation)Storage humidity range

1000V AC, 1min Between battery and the bodyWithstand voltage

50M or more(500V DC Mega) Between battery and the body

10 to 150Hz 1.5mm amplitude

98m/s

2

acceleration in X, Y, Z directions for 2 hours(Power is not supplied)

Vibration resistance

980m/s2X, Y, Z directions 3 times for each(Power is not supplied)

Impact resistance

M5 0.8 (tightening torque : 1 to 1.5N•m or less)Port size

PPS, Si, Au, SUS316, C3604(Electroless nickel plating)Fluid contact material

3 core vinyl cabtire cable 2.6, 0.15mm2, 2mLead wire

10g (without lead wire)Weight

-10 to 60 (No freezing or condensation)Storage temp. range

16mA or lessPower consumption

Source voltage

-70kPa to 300kPaPressure rate

Note5)

Analog output

(Non-linear output)

Insulation resistance

Resistance

Temperature

characteristics

(25 reference)

Operating pressure

range

Note6)

35 to 85%R.H. (No condensation)Operating humidity range

PFMV505 PFMV530FPFMV505FPFMV530

0 to 0.5

-3 to 3

Note2)

-0.5 to 0.5

Note2)

0 to 3

PFMV510 PFMV510F

0 to 1 -1 to 1

Note2)

Model Indication Method

PFM - -

Output specification

Type

V5 Remote type sensor

ContentsModel

1Analog (1 to 5V)

ContentsModel

Measurement flow range

05

ContentsModel

0.0 to 0.5 /min

10300.0 to 1.0 /min

0.0 to 3.0 /min

05F -0.5 to 0.5 /min

10F -1.0 to 1.0 /min

30F -3.0 to 3.0 /min

Operation manual

NilNWith Operation manual (in Japanese and English)

ContentsModel

Without Operation manual

Option(Included in the same package)

NilAWithout L-type bracket

Contents

Model

With 2 L-type brackets and 2 mount screws M3 x 15L included for 1station

ZS - 36 - A

L-type bracket

Stations

22 stns

1 stn1

44 stns

55 stns

3 stns

2 L-type brackets, 2 mount screws M3 x 25L included

2 L-type brackets, 2 mount screws M3 x 15L included

2 L-type brackets, 2 mount screws M3 x 45L included

2 L-type brackets, 2 mount screws M3 x 55L included

2 L-type brackets, 2 mount screws M3 x 35L included3

When optional part is needed by part alone, or to be mounted to the manifold,

please order by part number below.

Mount on one side

Mount on both sides

34.4

10

Piping

2 M5 0.8 Thread depth 3.8

1IN 2

15.2

18

3

FLOW SENSOR

14

(25.7)

10 12

5

FLOW SENSOR

2

20

9.1

2

L-type brack

OUT

(Tapped)

2 x 4.5

1

34

24

et

34

24

20

2

9.1

L-type brack

(Through hole)

et

0.8

(15)

Mounting

2 3.4

10 x n + 24 (n=1 to 5)

10 x n + 14

10

FLOW SENSOR

FLOW SENSOR

2

OUT

OUT2OUT

FLOW SENSOR

2

OUT

2 x 4.5

L-type brack

(Tapped)

1

7.1

et

Page 3

Mounting and Installation (unit: mm)

Manifold mount (using ZS-36-A )

Thread tightening torque is 0.32 0.02N•m.

Mounting screw

Mount on one sideMount on direct

Mount on both sides

Thread tightening torque is 0.32 0.02N•m.

Depending on fittings, they interfere each other and not possible for mounting

in series by using bracket.

Piping Circuit

Flow characteristic chart (Reference)

PFMV5(05/10/30)

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

0% 20% 40% 60% 80% 100%

Maximum

rated flow

Flow

PFMV5(05/10/30)F

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

-100% -50% 0% 50% 100%

Maximum

rated flow

Flow

Analog output voltage[V]

Analog output voltage[V]

Recommended fitting list

One-Touch fitting

• Male Connector (One-Touch Male Connector)/KQ2H04-M5

• Hexagon Socket head Male Connector/KQ2S04-M5

• Male Elbow/KQ2L04-M5

One-Touch mini fittings

• Male Connector/KJH04-M5

• Hexagon Socket head Male Connector/KJS04-M5

• Male Elbow/KJL04-M5

PFMV5 series recommended fitting list

Miniature fitting

• Barb fittings for nylon tubing/M-5AN-4/M-5AN-6

During installation of the flow sensor to the pipe, hold the body with specified

spanner

Tightening torque to mount the fitting is 1 to 1.5N

.

m

Refer to catalog for details of flow characteristic.

L-type bracket

(Tapped)

L-type bracket

(Through hole)

L-type bracket

(Tapped)

L-type bracket

(Tapped)

Mounting screw

(M3 x 15L)

L-type bracket

(Through hole)

Mounting screw

(M3 x 15L)

Analog output : 1 to 5V

Output impedance : Approx. 1kΩ

1kΩ

Main Circuit

Brown

DC(+)

Black OUT (Analog output)

Blue DC(-)

Load

Mounting screw

12 to 24VDC

Loading...

Loading...