SMC Networks PFMV3 Series Operation Manual

Flow Monitor

Operation Manual

PFMV3

Safety Instructions

Safety Instructions

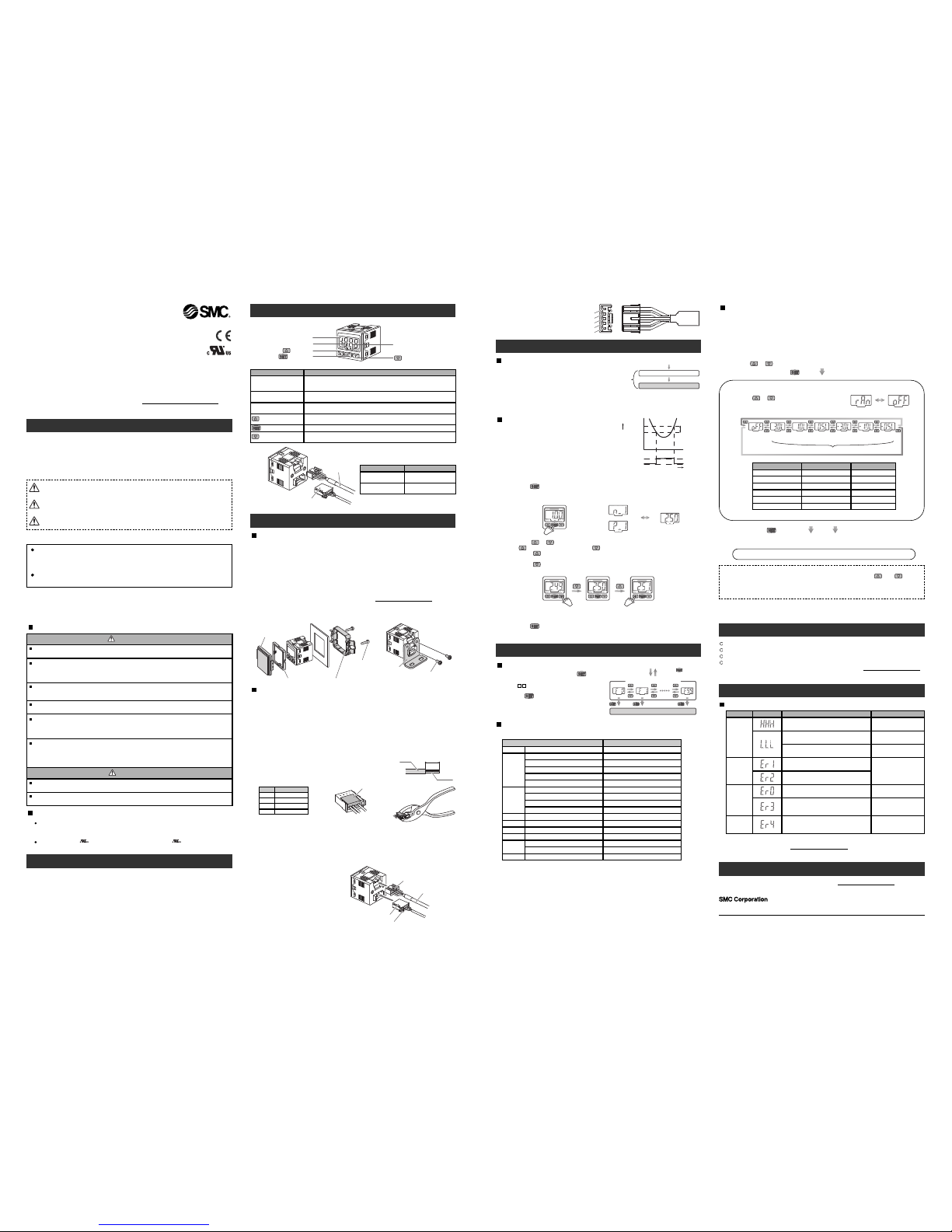

Summary of Product parts

Mounting and Installation

button (UP)

button (SET)

button (DOWN)

Indicator LED (OUT2)

I

ndicator LED (OUT1)

LCD Display

CAUTION indicates a hazard with a low level of risk which, if

n

ot avoided, could result in minor or moderate injury.

Caution:

Warning:

Danger:

WARNING indicates a hazard with a medium level of risk

w

hich, if not avoided, could result in death or serious injury.

D

ANGER indicates a hazard with a high level of risk which, if

not avoided, will result in death or serious injury.

L

CD Display

Displays the flow value, setting mode, and error indication.

F

our display modes can be selected: display always in red or green, or display

changing from green to red, or red to green, according to the output status (OUT1).

Indicator LED (OUT1)

Indicates the output status of OUT1.

LED is ON (Green) when OUT1 is ON.

Indicator LED (OUT2)

Indicates the output status of OUT2.

LED is ON (Red) when OUT2 is ON.

button (UP)

Selects the mode or increases the ON/OFF set value.

P

ress this button to change to the peak display mode.

button (SET)

Press this button to change to another mode and to set a value.

Item Description

Thank you for purchasing an SMC PFMV3 Series Flow Monitor.

Please read this manual carefully before operating the product and make sure you

understand its capabilities and limitations.

Please keep this manual handy for future reference.

To obtain more detailed information about operating this product,

p

lease refer to the SMC website (URL http://www.smcworld.com

)

or

contact SMC directly.

These safety instructions are intended to prevent hazardous situations and/or

equipment damage.

These instructions indicate the level of potential hazard with the labels of

"Caution", "Warning" or "Danger". They are all important notes for safety and must

b

e followed in addition to International standards (ISO/IEC) and other safety

regulations.

Operator

This operation manual is intended for those who have knowledge of machinery

u

sing pneumatic equipment, and have sufficient knowledge of assembly,

operation and maintenace of such equipment. Only those persons are allowed

to perform assembly, operation and maintenance.

R

ead and understand this operation manual carefully before assembling,

operating or providing maintenance to the product.

D

o not operate the product outside of the specifications.

Do not use for flammable or harmful fluids.

Fire, malfunction, or damage to the product can result.

Verify the specifications before use.

D

o not disassemble, modify (including changing the printed circuit board) or repair.

A

n injury or failure can result.

Do not operate in an atmosphere containing flammable or explosive gases.

Fire or an explosion can result.

This product is not designed to be explosion proof.

Do not use the product in a place where static electricity is a problem.

Otherwise it can cause failure or malfunction of the system.

If using the product in an interlocking circuit:

•Provide a double interlocking system, for example a mechanical system.

•Check the product regularly for proper operation.

Otherwise malfunction can result, causing an accident.

The following instructions must be followed during maintenance :

•Turn off the power supply

•Stop the air supply, exhaust the residual pressure and verify that the air is released before performing

maintenance work

Otherwise an injury can result.

After maintenance is complete, perform appropriate functional inspections and leak tests.

Stop operation if the equipment does not function properly or there is a leakage of fluid.

Do not touch the terminals and connectors while the power is on.

Otherwise electric shock, malfunction or damage to the product can result.

Warning

Caution

NOTE

The direct current power supply used should be UL approved as follows.

Circuit (of class 2) which is of maximum 30Vrms (42.4 V peak), with UL 1310

class 2 power supply unit or UL 1585 class 2 transformer.

The product is a approved product only if it has a mark on the body.

button (DOWN)

Selects the mode or decreases the ON/OFF set value.

P

ress this button to change to the bottom display mode.

Mounting screw (M3 x 5 L)

Bracket

Installation

P

anel mounting

•

Fix the panel mount adapter to the product with the mounting screws (nominal size:

3 x 8 L, 2 pcs.) supplied.

•The monitor can be mounted on a panel with a thickness of 0.5 to 6.0 mm.

Bracket mounting

•Mount the bracket using the mounting screws (M3 x 5 L) supplied.

•The required tightening torque is 0.5 to 0.7 Nm.

•

Install the product (with bracket) using the M4 screws (2 pcs.).

•Bracket thickness is approximately 1.6 mm.

R

efer to the product catalogue or SMC website (URL http://www.smcworld.com

)

for more

information about panel cut-out and mounting hole dimensions.

<

Operation>

∗: The Product outputs will continue operating during setting.

1

. Press the button in measurement mode to display the set values.

[

P_1] or [n_1] and the set value are displayed in turn.

∗

: [LLL] is displayed during measurement mode when the sensor is not connected.

3

. Press the button to complete the setting of OUT1.

[n_2] or [P_2] will be displayed. Set as above.

PFMV

V

Displayed in turn

Normal output

Reversed output

PFMV

V

PFMV

V

PFMV

V

Flow Setting

Measurement mode

T

he mode in which the flow is detected

and displayed, and the switch function is

o

perating. This is the basic operating

mode; other modes should be selected for

s

et-point and other Function Setting changes.

∗: The display will indicate [LLL] if a sensor is not connected.

Power is supplied

The product identification is displayed

Measurement mode

(the output remains off

for this period)

approx.3 seconds

Switch operation

W

hen the flow (or voltage) falls below the set

v

alue by the amount of hysteresis or more, the

s

witch will turn ON.

W

hen the flow (or voltage) exceeds the set value,

t

he switch will turn OFF.

I

f this condition, shown to the right, is acceptable,

t

hen keep these settings.

S

w

i

t

ch

O

N

S

w

i

t

ch

O

F

F

S

e

t

v

a

l

u

e

n

_

1

T

i

m

e

[

s]

V

o

l

t

a

g

e

[

V

]

F

l

o

w

[

L

/

m

i

n

]

H

y

s

t

e

r

e

s

i

s

H

_

1

Other Settings

Standard value offset function

Peak/Bottom value display

Indicated content check function

Key lock function

To set each of these functions, refer to the SMC website (URL http://www.smcworld.com

)

for more detailed information, or contact SMC.

Troubleshooting

Error indication

Input voltage

flow error

The flow (input voltage) has exceeded the upper

limit of the display range.

Reduce input voltage

(= flow).

Error name Error display Error type Troubleshooting method

Overcurrent

error

The switch output load current (OUT1) has

exceeded 80 mA.

The switch output load current (OUT2) has

exceeded 80 mA.

Turn off the power supply

and remove the cause of

the over current. Then

supply the power again.

System error

The product has lost the factory adjustment

settings. The internal circuit may be damaged.

Stop operation immediately

and contact SMC.

Standard

value offset

error

Perform the standard value

offset under no flow

conditions.

The standard value offset function has been

performed outside the effective range for

correction.

System error.

The product has failed to store the data, or the

internal circuit may be damaged.

Turn the power off and turn

it on again, then repeat the

Function Setting.

The flow (input voltage) is less than the lower

limit of the display range.

Increase input voltage

(= flow).

Note: Specifications are subject to change without prior notice and any obligation on the part of the manufacturer.

© 2011 SMC Corporation All Rights Reserved

Akihabara UDX 15F, 4-14-1, Sotokanda, Chiyoda-ku, Tokyo 101-0021, JAPAN

Phone: +81 3-5207-8249 Fax: +81 3-5298-5362

URL http://www.smcworld.com

Function selection mode

In measurement mode, press the button

for 2 seconds or longer, to display [F 0].

The [F ] indicates the mode for changing

each function setting.

Press the button for 2 seconds or longer

in function selection mode to return to

measurement mode.

Function Setting

Measurement mode

Function selection mode

Function Setting

Press the button

for 2 seconds or longer

Mounting screw

Panel mount adapter (can be rotated 90 degrees for mounting).

Front protective

cover (option)

A sensor may be disconnected or wired

incorrectly.

Check the connection and

wiring of the sensor.

Sensor connector

P

ower and output

lead wire and

connector

Front

B

ack

P

ower and output lead

w

ire and connector

C

able to supply power and

t

ransmit output signals.

Sensor connector

C

onnector for sensor

l

ead wire.

Item Description

Attaching the connector to the sensor wire

•Strip the sensor wire as shown.

•Do not cut the insulator.

•Insert the corresponding wire colour shown in the table into the

pin number printed on the sensor connector, to the bottom.

Wiring

Wiring of connector

•Connections should only be made with the power supply turned off.

•Use separate routes for the product wiring and any power or high voltage wiring.

Otherwise, malfunction may result due to noise.

•Ensure that the FG terminal is connected to ground when using a commercially

available switch-mode power supply. When a switch-mode power supply is connected

to the product, switching noise will be superimposed and the product specification can

no longer be met. This can be prevented by inserting a noise filter, such as a line noise

filter and ferrite core, between the switch-mode power supply and the product, or by

using a series power supply instead of a switch-mode power supply.

more than 20 mmCover

Insulator

A

1

2

Pin no.

Brown (DC+)

NC

Wire colour

3

4

Blue (DC−)

Black (IN (1 to 5 V))

•

Check that the above preparation has been performed

correctly, then part A shown should be pressed in by hand to make temporary connection.

•Part A should then be pressed in using a suitable tool, such as pliers.

•The sensor connector cannot be re-used once it has been fully crimped.

In cases of connection failure such as incorrect order of wires or incomplete insertion,

please use a new connector.

•If the sensor is not connected correctly “LLL” or “HHH” will be displayed.

Connecting / Disconnecting

•When mounting the connector, insert it

straight into the socket, holding the

lever and connector body, and push the

connector until the lever hooks into the

housing, and locks.

•When removing the connector, press

down the lever to release the hook from

the housing and pull the connector

straight out.

Power and output

lead wire

and connector

Connector for sensor

lead wire

Lever

Lever

1

DC(-) Blue

DC(+) Brown

OUT1 Black

O

UT2 White

Analogue output / External input Grey

2

3

4

5

P

ower and output connector

p

in numbers

[F95]

Selection of flow indication

T

he flow rate can be displayed. The flow rate units can be selected (for models with unit

selection function) after selecting the connected sensor.

L

/min. or CFM(ft

3

/

min.) x 10

-

2

a

re the selectable display units.

To use for flow rate indication, select the sensor and units before setting the functions

[

F1], [F2], [F4].

The set values for [F1], [F2] and [F4] will be reset when the flow indication setting is

c

hanged.

Default setting

The default settings are provided as follows. If these settings are acceptable, retain for use.

Item

[oU1] Output mode (OUT1)

[1ot ] Reversed output (OUT1)

[H_1] Setting of hysteresis (OUT1)

[CoL] Display colour

Default setting

[

HYS

] Hysteresis mode

[

1_n

] Reversed output

[

0.12

] (Voltage display)

[

SoG

] ON: Green OFF: Red

[oU2] Output mode (OUT2)

[2ot ] Reversed output (OUT2)

[

n_2

] Input of Set value (OUT2)

[H_2] Setting of hysteresis (OUT2)

[

HYS

] Hysteresis mode

[

2_n

] Normal output

[

2.50

] (Voltage display)

[

0.12

] (Voltage display)

[

rES

] Response time

[ inP

] External input

[

.002

] 2 msec.

[oFF] Unused

[

n_1

] Input of set value (OUT1)

[

2.50

] (Voltage display)

[

Eco

] Power saving mode

[P in] Security code

[oFF] Unused

[oFF] Unused

Auto-preset

-

[F 0]

[F 1]

[F 2]

[F 3]

[F 4]

[F 5]

[F 6]

[F95]

[F99]

[

r An

] Select connected sensor [oFF] Unused

[Un i] Unit selection function

[ in i ] Reset to the default settings

[

LPm

] L/min

[oFF] Unused

∗: If the error cannot be reset after the above measures are taken, then please contact SMC.

Specifications / Outline with Dimensions

Refer to the product catalogue or SMC website (URL http://www.smcworld.com) for more

information about the product specifications and outline dimensions.

Refer to the SMC website (URL http://www.smcworld.com

) for more information about

troubleshooting.

T

o use the product for flow rate indication, select the connected flow sensor using

function [F95] before setting any other functions.

S

tandard value offset function

The dis play can be off set to the stan dard value by pr essing the and but tons

s

imultaneously for 1 second or longer.

For the initial op eration, always perform the standard value offset function with no f low

a

pplied.

<

Operation>

Press the or button in function selection mode to display [F95].

P

ress the button.

S

elect connected sensor

[

rAn] and the set value are displayed in turn.

P

ress the or button to select.

Flow display

PFMV530 PFMV510 PFMV505 PFMV530F PFMV510F PFMV505F

V

oltage

display

Displayed in turn

Flow range Set value

PFMV505

C

onnected sensor model

PFMV510

PFMV505F

P

FMV530

PFMV510F

PFMV530F

3

.0 L

D

isplayed flow range

1.0 L

-3.0 L

0.5 L

-1.0 L

-0.5 L

0

to 3.0 [L/min]

R

ated flow range

0 to 1.0 [L/min]

-3.0 to 3.0 [L/min]

0

to 0.5 [L/min]

-0.5 to 0.5 [L/min]

∗: The set values of OUT1 and OUT2 will be reset when the flow range setting is changed.

S

election of flow indication completed. Return to Function selection mode.

Maintenance

How to reset the product after a power cut forcible de-energizing

The setting of the product will be retained as it was before a power cut or de-energizing.

The output condition is also basically recovered to that before a power cut or de-energizing,

but may change depending on the operating environment.

Therefore, check the safety of the whole installation before operating the product.

2. Press the or button to change the set value.

T

he button is to increase and the button is to decrease the set value.

•

Press the button once to increase by one digit, or press it continuously to keep

increasing the set value.

•

Press the button once to decrease by one digit, or press it continuously to keep

decreasing the set value.

-1.0 to 1.0 [L/min]

Press the button to set. Move on to unit selection function

(

for models with unit selection

function).

Loading...

Loading...