Page 1

IN20267

PRODUCT NAME

Ethernet MPC – Ethernet/IP

MODEL / Series / Product Number

Multi Position Cylinder

MPCXX-XXX-XXX-XX-DUT01607

MPC

TM

- 1 -

Page 2

IN20267

- 2 -

Page 3

IN20267

Table of Contents 1.

Table of Contents .................................................................................................................................... - 3 - 1.

Safety Instructions ................................................................................................................................. - 5 - 2.

About this Manual ............................................................................................................................... - 10 - 3.

MPC ....................................................................................................................................................... - 10 - 3.1.

Purpose ............................................................................................................................................... - 10 - 3.2.

Terminology .......................................................................................................................................... - 11 - 4.

Product Summary ............................................................................................................................... - 12 - 5.

How to Order ......................................................................................................................................... - 13 - 6.

Accessories ........................................................................................................................................ - 13 - 6.1.

Seal cap ............................................................................................................................................... - 14 - 6.2.

Summary of Product Elements ...................................................................................................... - 15 - 7.

Quick Start .............................................................................................................................................. - 16 - 8.

Pneumatics ........................................................................................................................................ - 16 - 8.1.

Supply Pressure .............................................................................................................................. - 16 - 8.2.

Power ................................................................................................................................................... - 17 - 8.3.

Network Cable ................................................................................................................................. - 17 - 8.4.

Ethernet/IP (From PLC Perspective) ..................................................................................... - 18 - 8.5.

IP Address .......................................................................................................................................... - 18 - 8.6.

MPC Default Parameters .................................................................................................................. - 19 - 9.

Ethernet/IP Network Parameters ................................................................................................ - 19 - 10.

Network Specifications ................................................................................................................ - 19 - 10.1.

DLR (Device Level Ring) .............................................................................................................. - 19 - 10.2.

Hold on Connection Loss ............................................................................................................. - 19 - 10.3.

Hold Till Connection ...................................................................................................................... - 19 - 10.4.

Quick Connect .................................................................................................................................. - 19 - 10.5.

Daisy Chaining Power and Ethernet ............................................................................................ - 20 - 11.

Connecting MPCs for Daisy Chaining ..................................................................................... - 20 - 11.1.

LED Indication ...................................................................................................................................... - 21 - 12.

Studio 5000 Setup ............................................................................................................................... - 23 - 13.

EDS file – Rockwell Studio 5000............................................................................................... - 23 - 13.1.

Adding a device to Ethernet - Rockwell Studio 5000 ...................................................... - 24 - 13.2.

Setpoint ................................................................................................................................................... - 27 - 14.

Example: Convert the Position to Counts ............................................................................. - 27 - 14.1.

Example: Pseudo Code for 100mm MPC mm ...................................................................... - 27 - 14.2.

Ladder Logic Example .................................................................................................................. - 27 - 14.3.

LabVIEW Example .......................................................................................................................... - 28 - 14.4.

Web Pages .............................................................................................................................................. - 29 - 15.

System Page ...................................................................................................................................... - 29 - 15.1.

Diagnostics Page ............................................................................................................................. - 30 - 15.2.

IO Data Page ...................................................................................................................................... - 31 - 15.3.

Version Page ..................................................................................................................................... - 32 - 15.4.

Ethernet MPC Status Page ........................................................................................................... - 33 - 15.5.

Login Page ......................................................................................................................................... - 34 - 15.6.

Contact Page ..................................................................................................................................... - 35 - 15.7.

MPC Configuration Page .............................................................................................................. - 36 - 15.8.

Network Page ................................................................................................................................... - 38 - 15.9.

Explicit Messaging ............................................................................................................................... - 41 - 16.

Installation and Handling ................................................................................................................. - 42 - 17.

Air supply ........................................................................................................................................... - 42 - 17.1.

- 3 -

Page 4

IN20267

Operating environment................................................................................................................ - 42 - 17.2.

Do not use the product in a food zone: .................................................................................. - 42 - 17.3.

OK to use the product in: ............................................................................................................. - 42 - 17.4.

Non-food zone - An environment in which foods do not contact the cylinder: .... - 42 - 17.5.

Do not use in an area where surges are generated: ......................................................... - 42 - 17.6.

Installation ........................................................................................................................................ - 43 - 17.7.

Wiring (Including connecting/disconnecting of the connectors) .............................. - 44 - 17.8.

Adjustment and Operation ......................................................................................................... - 46 - 17.9.

Washing ................................................................................................................................................... - 47 - 18.

Maintenance .......................................................................................................................................... - 48 - 19.

Recovering the IP Address of SMC Ethernet MPC .................................................................. - 49 - 20.

- 4 -

Page 5

Caution :

CAUTION indicates a hazard with a low level of risk which, if not

avoided, could result in minor or moderate injury.

Warning:

WARNING indicates a hazard with a medium level of risk which,

if not avoided, could result in death or serious injury.

Danger :

DANGER indicates a hazard with a high level of risk which, if not

avoided, will result in death or serious injury.

Warning

1. The compatibility of the product is the responsibility of the person who designs the

equipment or decides its specifications.

Since the product specified here is used under various operating conditions, its compatibility with specific

equipment must be decided by the person who designs the equipment or decides its specifications

based on necessary analysis and test results. The expected performance and safety assurance of the

equipment will be the responsibility of the person who has determined its compatibility with the product.

This person should also continuously review all specifications of the product referring to its latest catalog

information, with a view to giving due consideration to any possibility of equipment failure when

configuring the equipment.

2. Only personnel with appropriate training should operate machinery and equipment.

The product specified here may become unsafe if handled incorrectly. The assembly, operation and

maintenance of machines or equipment including our products must be performed by an operator who is

appropriately trained and experienced.

3. Do not service or attempt to remove product and machinery/equipment until safety is

confirmed.

1. The inspection and maintenance of machinery/equipment should only be performed after measures to

prevent falling or runaway of the driven objects have been confirmed.

2. When the product is to be removed, confirm that the safety measures as mentioned above are

implemented and the power from any appropriate source is cut, and read and understand the specific

product precautions of all relevant products carefully.

3. Before machinery/equipment is restarted, take measures to prevent unexpected operation and

malfunction.

4. Contact SMC beforehand and take special consideration of safety measures if the

product is to be used in any of the following conditions.

1. Conditions and environments outside of the given specifications, or use outdoors or in a place exposed to

direct sunlight.

2. Installation on equipment in conjunction with atomic energy, railways, air navigation, space, shipping,

vehicles, military, medical treatment, combustion and recreation, or equipment in contact with food and

beverages, emergency stop circuits, clutch and brake circuits in press applications, safety equipment or other

applications unsuitable for the standard specifications described in the product catalog.

3. An application which could have negative effects on people, property, or animals requiring special

safety analysis.

4. Use in an interlock circuit, which requires the provision of double interlock for possible failure by using

a mechanical protective function, and periodical checks to confirm proper operation.

Safety Instructions 2.

These safety instructions are intended to prevent hazardous situations and/or equipment damage.

These instructions indicate the level of potential hazard with the labels of "Caution", "Warning" or

"Danger". They are all important notes for safety and must be followed in addition to International

standards (ISO/IEC), and other safety regulations.

ISO 4414: Pneumatic fluid power -- General rules relating to systems.

ISO 4413: Hydraulic fluid power -- General rules relating to systems.

IEC 60204-1: Safety of machinery -- Electrical equipment of machines. (Part 1: General requirements)

ISO 10218-1992: Manipulating industrial robots -- Safety.

Etc.

IN20267

- 5 -

Page 6

IN20267

Caution

The product is provided for use in manufacturing industries.

The product herein described is basically provided for peaceful use in manufacturing

industries.

If considering using the product in other industries consult SMC beforehand and

exchange specifications or a contract if necessary.

If anything is unclear, contact your nearest sales branch.

1. The warranty period of the product is 1 year in service or 1.5 years after the product is

delivered.

*1)

Also, the product may have specified durability, running distance or replacement parts.

Please consult your nearest sales branch.

2. For any failure or damage reported within the warranty period which is clearly our

responsibility, a replacement product or necessary parts will be provided.

This limited warranty applies only to our product independently, and not to any other damage

incurred due to the failure of the product.

3. Prior to using SMC products, please read and understand the warranty terms and

disclaimers noted in the specified catalog for the particular products.

*1) Vacuum pads are excluded from this 1 year warranty.

A vacuum pad is a consumable part, so it is warranted for a year after it is delivered.

Also, even within the warranty period, the wear of a product due to the use of the vacuum pad or failure due

to the deterioration of rubber material are not covered by the limited warranty.

When the product is exported, strictly follow the laws required by the Ministry of Economy, Trade

and Industry (Foreign Exchange and Foreign Trade Control Law).

This operation manual has been written for those who have knowledge of machinery and

apparatus that use pneumatic equipment and have full knowledge of assembly, operation

and maintenance of such equipment.

Please read this operation manual carefully and understand it before assembling,

operating or providing maintenance to the product.

Limited warranty and Disclaimer/Compliance Requirements

The product used is subject to the following "Limited warranty and Disclaimer" and "Compliance

Requirements".

Read and accept them before using the product.

Limited warranty and Disclaimer

Compliance Requirements

Operator

- 6 -

Page 7

Warning

■Do not disassemble, modify (including changing the printed circuit board) or repair.

An injury or failure can result.

■Do not operate the product outside of the specifications.

Do not use for flammable or harmful fluids.

Fire, malfunction, or damage to the product can result.

Verify the specifications before use.

■Do not operate in an atmosphere containing flammable or explosive gases.

Fire or an explosion can result.

This product is not designed to be explosion proof.

■If using the product in an interlocking circuit:

Provide a double interlocking system, for example a mechanical system.

Check the product regularly for proper operation.

Otherwise malfunction can result, causing an accident.

■The following instructions must be followed during maintenance:

Turn off the power supply.

Stop the air supply, exhaust the residual pressure and verify that the air is released

before performing maintenance.

Otherwise an injury can result.

Caution

■After maintenance is complete, perform appropriate functional inspections.

Stop operation if the equipment does not function properly.

Safety cannot be assured in the case of unexpected malfunction.

■Provide grounding to assure the safety and noise resistance of the Serial System.

Individual grounding should be provided close to the product with a short cable.

■Precautions

IN20267

- 7 -

Page 8

■NOTE

○Follow the instructions given below when designing, selecting and handling the product.

The instructions on design and selection (installation, wiring, environment, adjustment, operation,

maintenance, etc.) described below must also be followed.

Product specifications

When conformity to UL is necessary the SI unit must be used with a UL1310 Class2 power supply.

The SI unit is a approved product only if they have a mark on the body.

Use the specified voltage.

Otherwise failure or malfunction can result.

Reserve a space for maintenance.

Allow sufficient space for maintenance when designing the system.

Do not remove any nameplates or labels.

This can lead to incorrect maintenance, or misreading of the operation manual, which could cause

damage or malfunction to the product.

It may also result in non-conformity to safety standards.

Product handling

Installation

Do not drop, hit or apply excessive shock to the Ethernet ITV system.

Otherwise damage to the product can result, causing malfunction.

Tighten to the specified tightening torque.

If the tightening torque is exceeded the mounting screws may be broken.

IP65 protection cannot be guaranteed if the screws are not tightened to the specified torque.

Never mount a product in a location that will be used as a foothold.

The product may be damaged if excessive force is applied by stepping or climbing onto it.

Wiring

Avoid repeatedly bending or stretching the cables, or placing heavy load on them.

Repetitive bending stress or tensile stress can cause breakage of the cable.

Wire correctly.

Incorrect wiring can break the product.

Do not perform wiring while the power is on.

Otherwise damage to the fieldbus system and/or I/O device can result, causing malfunction.

Do not route wires and cables together with power or high voltage cables.

Otherwise the fieldbus system and/or I/O device can malfunction due to interference of noise and surge

voltage from power and high voltage cables to the signal line.

Route the wires (piping) of the fieldbus system and/or I/O device separately from power or high voltage

cables.

Confirm proper insulation of wiring.

Poor insulation (interference from another circuit, poor insulation between terminals, etc.) can lead to

excess voltage or current being applied to the product, causing damage.

Take appropriate measures against noise, such as using a noise filter, when the fieldbus system is

incorporated into equipment.

Otherwise noise can cause malfunction.

IN20267

- 8 -

Page 9

IN20267

Environment

Select the proper type of protection according to the operating environment.

IP65 protection is achieved when the following conditions are met.

(1) The units are connected properly with fieldbus cable with M12 connector and power cable with M12

connector.

(2) Suitable mounting of each unit (if using the optional manifold mount).

(3) All unused connectors are closed with a properly installed seal cap.

If using in an environment that is exposed to water splashes, please take measures such as using a

cover.

Do not use in a place where the product could be splashed by oil or chemicals.

If the product is to be used in an environment containing oils or chemicals such as coolant or cleaning

solvent, even for a short time, it may be adversely affected (damage, malfunction etc.).

Do not use the product in an environment where corrosive gases or fluids could be splashed.

Otherwise damage to the product and malfunction can result.

Do not use in an area where surges are generated.

If there is equipment which generates a large amount of surge (solenoid type lifter, high frequency

induction furnace, motor, etc.) close to the fieldbus system, this may cause deterioration or breakage of

the internal circuit of the fieldbus system. Avoid sources of surge generation and crossed lines.

When a surge-generating load such as a relay or solenoid is driven directly, use a fieldbus system with a

built-in surge absorbing element.

Direct drive of a load generating surge voltage can damage the fieldbus system.

The product is NOT immune to lightning strikes. Take measures against lightning strikes in the system.

Prevent foreign matter such as remnant of wires from entering the fieldbus system to avoid failure and

malfunction.

Mount the product in a place that is not exposed to vibration or impact.

Failure or malfunction can result.

Do not expose the product to direct sunlight.

If using in a location directly exposed to sunlight, shade the product from the sunlight. Failure or

malfunction can result.

Keep within the specified operating temperature range.

Malfunction can result.

Do not operate close to a heat source, or in a location exposed to radiant heat.

Malfunction can result.

Adjustment and Operation

Perform settings suitable for the operating conditions.

Incorrect setting can cause operation failure.

Please refer to the PLC manufacturer's manual etc. for details of programming and addresses.

For the PLC protocol and programming refer to the relevant manufacturer's documentation.

Maintenance

Turn off the power supply, stop the supplied air, exhaust the residual pressure and verify the release of

air before performing maintenance.

There is a risk of unexpected malfunction.

Perform regular maintenance and inspections.

There is a risk of unexpected malfunction.

After maintenance is complete, perform appropriate functional inspections.

Stop operation if the equipment does not function properly.

Otherwise safety is not assured due to an unexpected malfunction or incorrect operation.

Do not use solvents such as benzene, thinner etc. to clean the unit.

They could damage the surface of the body and erase the markings on the body. Use a soft cloth to

remove stains. For heavy stains, use a cloth soaked with diluted neutral detergent and fully squeezed,

then wipe up the stains again with a dry cloth.

- 9 -

Page 10

About this Manual 3.

MPC

3.1.

The MPC is SMC's low cost Ethernet positioning cylinder. The MPC series offers a cylinder, solenoid

valve, linear positioner, and controller in one package. With its integral position control, the MPC

needs only power and Ethernet input signal. The target position is kept by opening and closing

solenoid valves controlling pressure on the cylinder. The MPC has an output signal to give position

feedback to a customer's controller. Standard ball bushings protect against side load.

Purpose 3.2.

The purpose of this manual is to provide the user with necessary information to install, configure,

and use the MPCXX-XXX-XXX-XX-DUT01607. The MPC may be operated under the control of a

network connected PLC. This manual provides information for MPC setup and configuration,

examples of the web interface, and a brief overview of the PLC. This document is not an operator’s

manual for the Rockwell PLC or any other PLC. Please see the PLC manufacturer’s documentation

for detailed instructions on the setup and use of your PLC.

IN20267

- 10 -

Page 11

IN20267

Terms

Meaning

100

100BASE-TX

Standard LAN transmission line with communication speed of 100 Mbps.

A

Auto negotiation

The function that automatically optimizes the common communication parameters

such as speed, duplex mode, and flow control between Ethernet devices.

C

Counts

The MPC controls and reports position internally in Counts. The counts are used by

hardware devices to control and measure the position regulated by the MPC.

Current consumption

The current (power) necessary to operate each unit or device.

D

Downstream

Devices receiving power or communications signals which originate from or are

passed through a given device are downstream of that device.

DLR

An abbreviation for Device Level Ring: Performs a fast switching of the communication

route when any problem occurs with the Ring network to maintain communication.

E

Enclosure (IPxy)

Abbreviation of International (Ingress) Protection. A standard related to protection from

external objects (hands, steel balls, steel wire, dust, water, etc.) applied to the product.

F

Fieldbus

The protocol that uses digital communication to exchange signals between field

equipment (instruments and actuators).

Full duplex

Communication system that can send and receive data at the same time bidirectionally (similar to standard telephone).

H

Half duplex

Communication system that sends and receives data in one direction at a time (similar

to two-way radio).

I

IP address

A 32 bit digit sequence which is assigned to identify devices which are connected to

the network. This address must be unique for each device to ensure proper operation

of the network.

M

MAC address

A unique number inherent to all devices which are connected to Ethernet.

Ethernet/IP

By combining Ethernet, CANopen and hard real-time capabilities, Ethernet/IP

integrates features and abilities from three different worlds. In contrast to a number of

competing products, Ethernet/IP has remained extremely close to the Ethernet

standard, retaining original Ethernet features and so reducing the cost of deployment

in industrial environments. The protocol's second major advantage is the integration of

CANopen technology, a robust and proven protocol widely used throughout the field of

automation whose extensive standardization greatly simplifies network configuration.

P

PC

Personal Computer.

PLC

Abbreviation for Programmable Logic Controller. A digital computer/controller used for

automation of electromechanical processes.

R

Reboot

Unless otherwise noted, the term “reboot” in this document means that the MPC must

be power cycled.

S

Setpoint

The specified position which the MPC has been directed to maintain. Setpoint may be

specified via a setpoint sent from a PLC. Setpoint may refer to a human readable

value – including measurement units – used to specify the position to be maintained

by the MPC. Physical setpoint is a unit-less value (physical counts) used internally

to control and monitors the MPC’s physical position. Unless noted, setpoint refers to

the human readable value including measurement units. Setpoint and position status

values are sent between the MPC and a PLC in counts (physical setpoint).

Serial Interface (SI)

A communication interface between two digital systems that transmits data as a series

of voltage pulses down a wire. Each pulse represents a single bit of data.

SI unit

Abbreviation for Serial Interface unit. A unit connected to a PLC to communicate input

and output data. The MPC connection to another MPC or to a PLC or PC is a Serial

Interface (SI).

T

Topology

Connection configuration of the network.

U

Upstream

A device which provides power or communications signals to a given device is

upstream of that device.

Terminology 4.

Table 4-1 - Definitions and Terminology

- 11 -

Page 12

Product Summary 5.

The MPCXX-XXX-XXX-XX-DUT01607 (MPC) is a multi-position cylinder which is controlled by an

Ethernet interface. MPCs move to a position value specified by the user. In the past, an electric

actuator was the only option for applications demanding a multiple number of stroke positions.

SMC's MPC series now provides an alternative and economical solution.

The Ethernet interface allows a user to configure, control, and monitor the MPC over a

communication link using commands sent from a PLC or internal webserver. The user can change

the position setpoint as required. The user can also monitor the operation of the MPC, verifying the

actual position.

Offered as a pneumatic and lower cost alternative, the MPC (Multi Position Cylinder) uses an

Ethernet input signal to automatically adjust the actuator stroke. Once the MPC reaches the desired

position, it is pneumatically locked until the input signal is changed.

To accomplish this, the MPC utilizes an integrated cylinder, solenoid valve, linear sensor, and

controller all in one unit. You need only to supply air, power, and the appropriate input signal. This

easy adjustment makes the MPC perfect for on the fly changes to your process.

IN20267

- 12 -

Page 13

How to Order6.

MPC unit

connection

Description

Compatible cable

Part number

Length

Specifications

Fieldbus

interface

Cables

EX9-AC010ENPSRJ

1m

One end: molded M12 straight connector. Other end:

RJ45 connector (Ethernet).

EX9-AC020ENPSRJ

2m

EX9-AC030ENPSRJ

3m

EX9-AC050ENPSRJ

5m

EX9-AC100ENPSRJ

10m

PCA-1446566

5m

One end: molded M12 right angle connector. Other end:

flying leads.

EX9-AC005ENM12M12

0.5m

Both ends: molded M12 straight connectors.

EX9-AC050EN-

M12M12

5m

Field wireable

Connector

PCA-1446553

--

Connector: M12 straight plug connector. Use with PCA1446566 to make a cable of desired length.

Power

supply

Cables

EX500-AP010-SE

1m

One end: molded M12 straight connector. Other end:

flying leads.

EX500-AP050-S

5m

EX500-AP010-A

1m

One end: molded M12 right angle connector. Other end:

flying leads.

EX500-AP050-A

5m

Cable with

Speedcon

connector

PCA-1401804

1.5m

One end: molded M12 straight connector. Other end:

flying leads.

PCA-1401805

3m

PCA-1401806

5m

(Refer to product drawing for latest information)

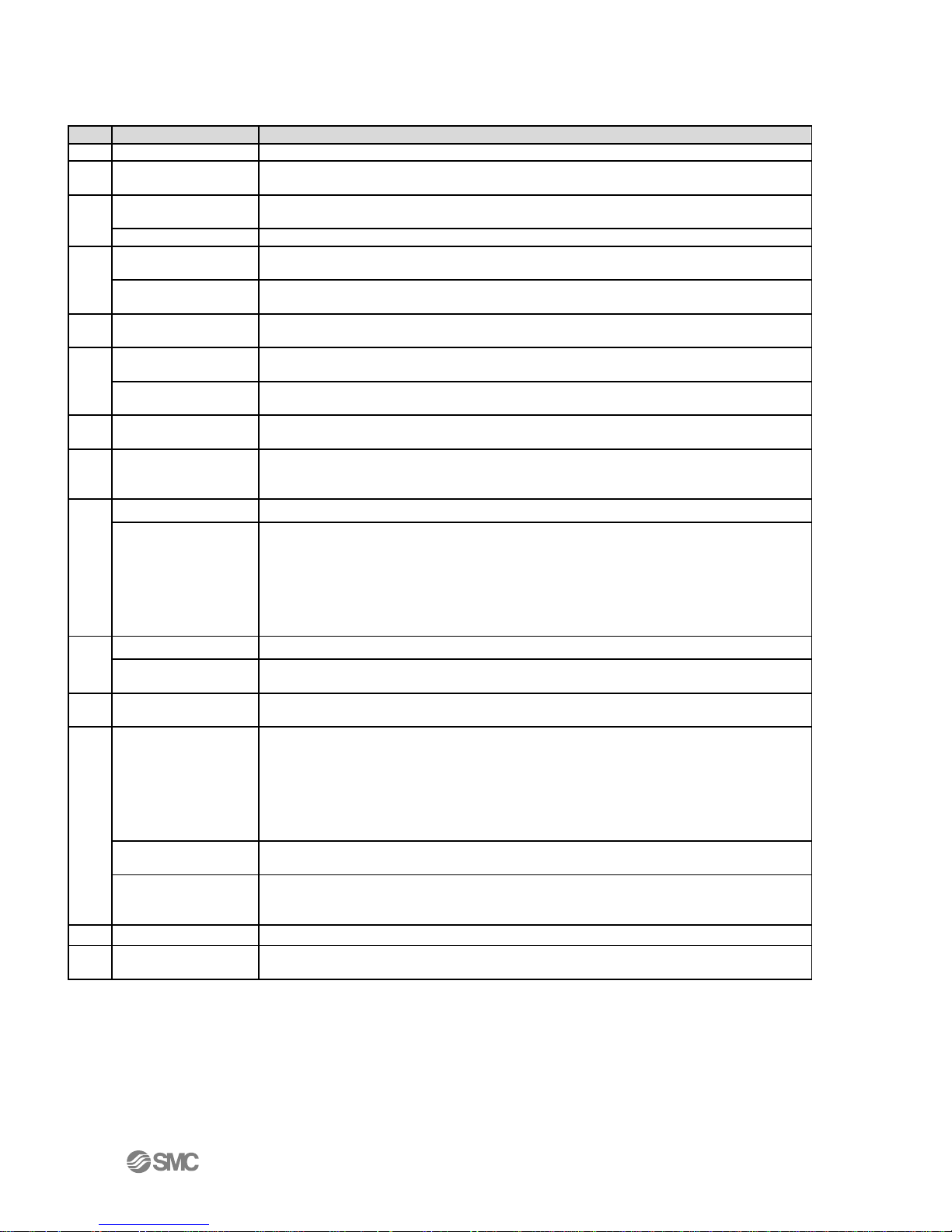

Specify the part number for your MPC. The part number describes the MPC as follows:

Figure 6-1 – MPC Part Numbers

Accessories 6.1.

Connector cables (recommended – not included with MPC)

IN20267

Note: More options are available. Contact SMC for information on these options.

- 13 -

Table 6-2 - Recommended Cables

Page 14

IN20267

Description

Part No.

Specification

Seal cap

EX9-AWTS

For M12 connector socket: 10pcs.

Seal cap

UIUSP-C08-DUQ00833

For M12 Female Connector 1 pcs.

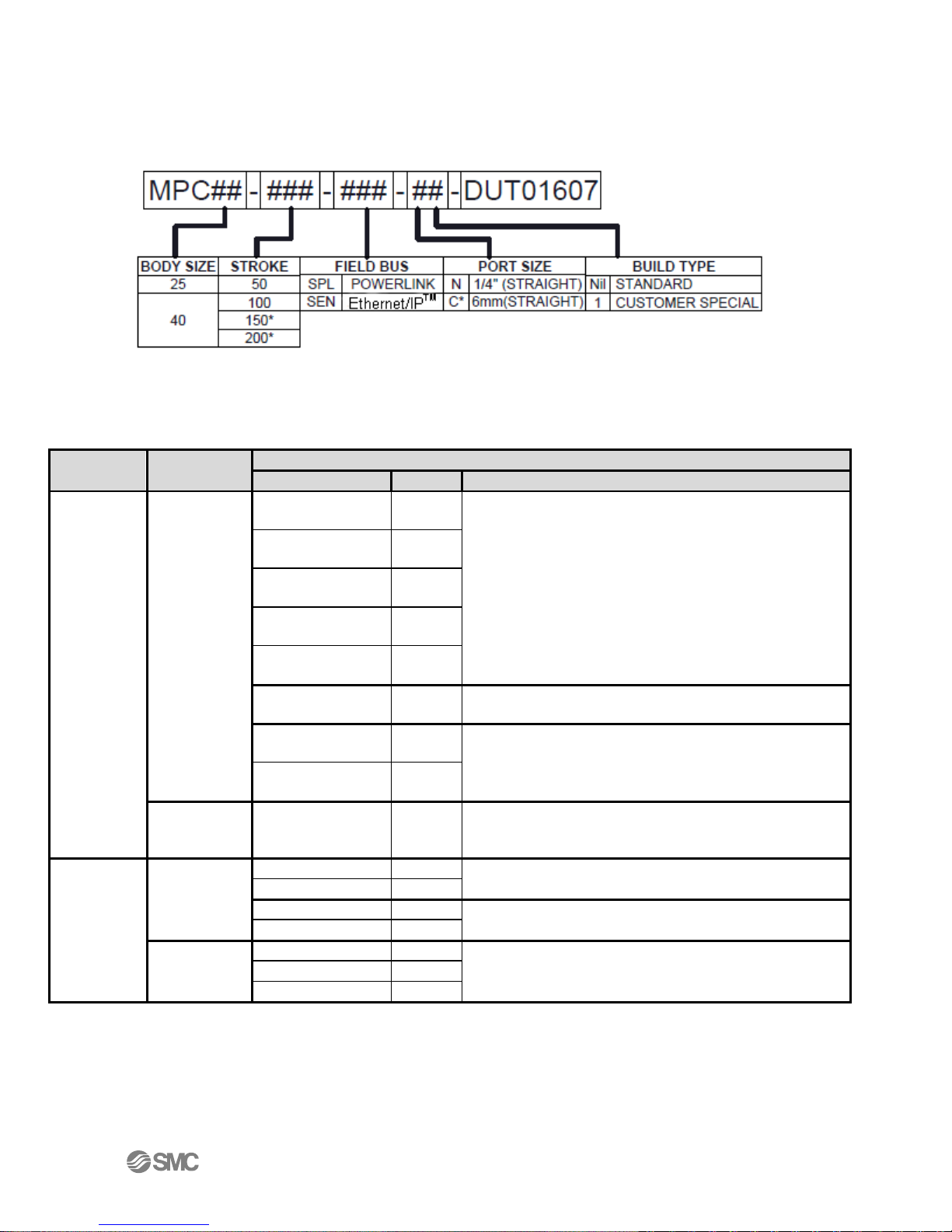

Seal cap 6.2.

Seal caps are used to protect the M12 size connector openings. It is recommended that seal caps be

used on all unused M12 connector openings. Use of seal caps is required for all unused connections

for IP65 rating. (One Ethernet and one Power seal cap are attached to the MPC when shipped from

factory as shown in figure 6-1.)

Figure 6-3 – Seal Cap

Table 6-4 - Seal Cap Part Numbers

- 14 -

Page 15

IN20267

N

o

.

Element

Description

1

Air Supply

CDA supply for cylinder

2

Vent

Cover / Valve Vent

3

Exhaust

Cylinder Exhaust Port

4

LED Display

Status LEDs

5

Fieldbus interface

connector (BUS IN)

Ethernet connection (Female M12, 4-pin socket, D-coded)

6

Fieldbus interface

connector (BUS OUT)

Ethernet connection (Female M12, 4-pin socket, D-coded for daisy chain

operation)

7

Power supply in

Cylinder operating voltage (Male M12 4-pin plug, A-coded connector)

8

Power supply out

Power Daisy chain (Female M12 4-pin socket, A-coded connector)

9

Seal Cap (Accessory)

1pc. seal cap for unused fieldbus interface connector (BUS OUT); 1pc seal

cap for unused power supply out connector

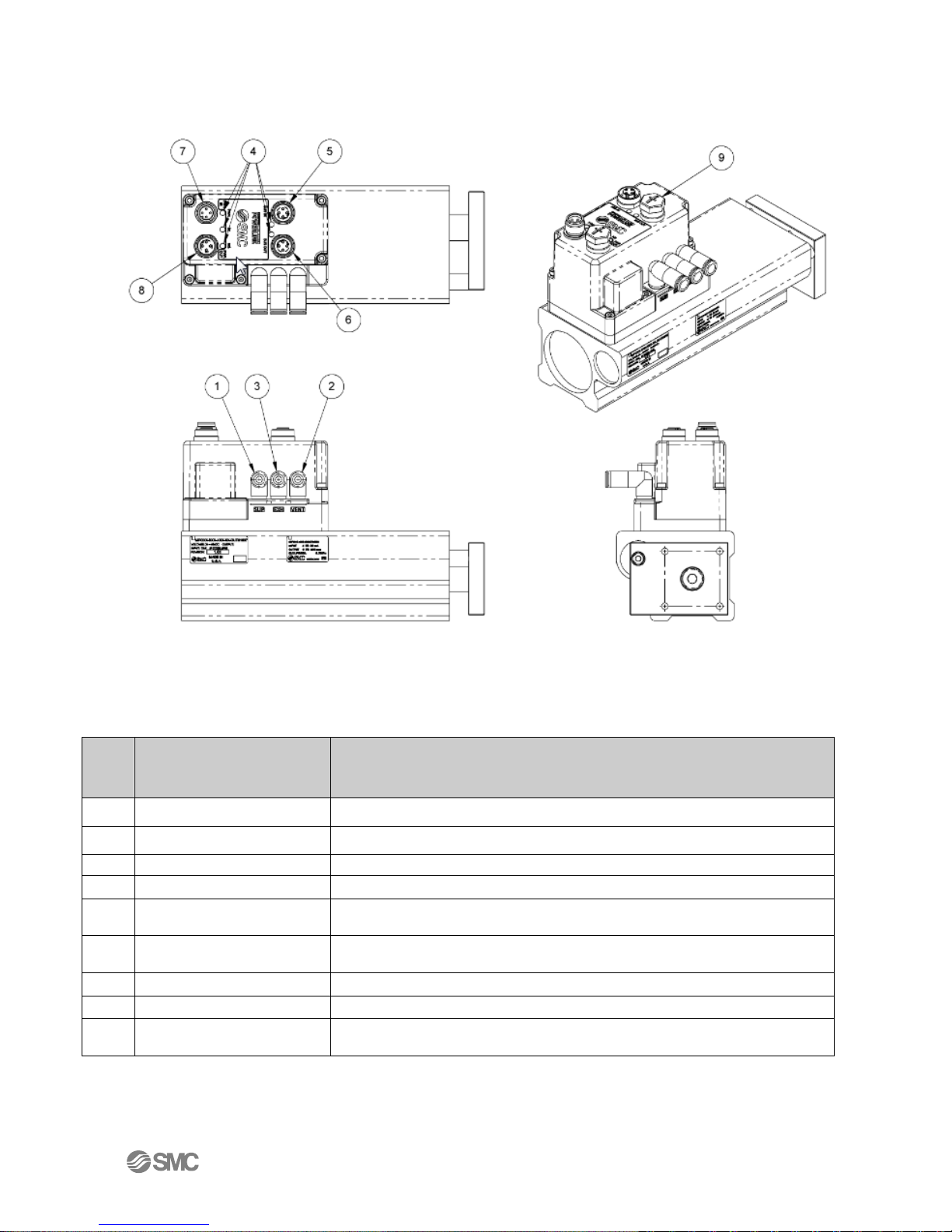

Summary of Product Elements 7.

Figure 7-1 - MPC Product Elements Drawing

Table 7-2 – MPC Products Elements Table

- 15 -

Page 16

IN20267

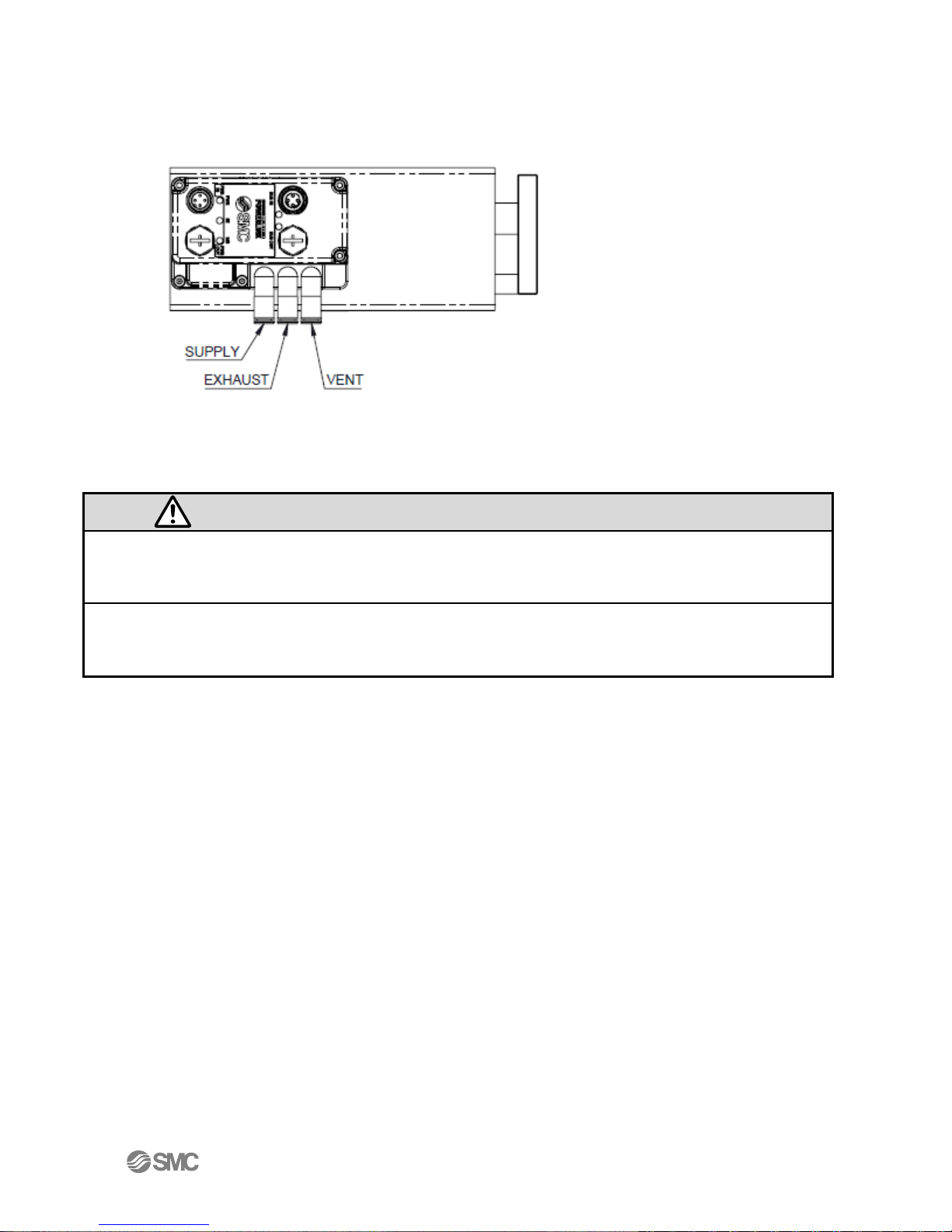

Caution

DO NOT enable air pressure until ALL pneumatic lines in the circuit have been properly

connected and the connections have been verified to be correct. Failure to follow this

requirement can result in severe injury or equipment damage.

Be SURE you understand the location and function of the ports BEFORE connecting the MPC

to an airline and an application device. VERIFY that these lines are properly connected

BEFORE enabling pneumatic pressure and BEFORE powering the MPC.

Quick Start 8.

Pneumatics 8.1.

Figure 8-1 – MPC Pneumatics Plumbing

Supply Pressure 8.2.

CDA Supply Pressure is 0.1 to 0.7MPa. 8.2.1.

- 16 -

Page 17

IN20267

No.

Designation

Description

1

TD+

Transmit Data +

2

RD+

Receive Data +

3

TD-

Transmit Data -

4

RD-

Receive Data -

Power 8.3.

Figure 8-2 – MPC Power Cable Pin Connections

Table 8-3 – MPC Power Pinout

Power in is 24 - 48 VDC +- 10% @ ~ 7Watts max 8.3.1.

For more about power refer to Daisy Chaining Power 8.3.2.

Network Cable 8.4.

Network Bus In and Bus Out: M12 4-pin socket D-coded connectors 8.4.1.

The Ethernet MPC Uses a standard M12 industrial Ethernet cable. For cable selection see

Accessories. You may use either port (“BUS IN” or “BUS OUT”) for the Ethernet connection to the

MPC.

- 17 -

Table 8-4 - MPC Ethernet Cable Pin Signals

Page 18

IN20267

TYPE

Instance

Size

Description

Output

100

1 INT or 2 SINT

Position set-point

Input

150

2 INT or 4 SINT

2 bytes measured position, 2 bytes diagnostics

Ethernet/IP (From PLC Perspective) 8.5.

The EDS File can be downloaded from www.smcusa.com

Refer to Studio 5000 Setup for more details on PLC setup

Table 8-5 - IO Data Key

Output Position: 12 bit value that is the position setpoint. 8.5.1.

The 4 most significant bits should be 0.

Input Position: 12 bit value of the current position. 8.5.2.

The 4 most significant bits are 0.

Input Diagnostics: 16 bit value (bits are numbered from the right) 8.5.3.

Bit zero = power OK: 0= OK, 1 = Out of range

IP Address 8.6.

The IP address is set to (192.168.1.20) at the factory. The IP address can be changed using the built

in MPC web server. The webserver can be accessed by a PC connected to the network and set to the

same subnet. DHCP/Bootp can be selected from the webserver if desired. Refer to Web pages for

more details.

- 18 -

Page 19

IN20267

Description

Value

IP Address

192.168.1.20

Subnet

255.255.0.0

Gateway

0.0.0.0

DNS Server

0.0.0.0

Hold on connection loss

Enabled

Hold till connection established

Enabled

Webpage Login ID

“user”

Webpage Login Password

“user”

MPC Default Parameters 9.

The default values of configuration parameters are given below. The user can change these

parameters, if needed, as part of the MPC setup process. Refer to Web pages for more details.

Refer to Studio 5000 Setup for more details on PLC setup.

Table 9-1 – Default Parameters

Ethernet/IP Network Parameters 10.

Network Specifications 10.1.

Two M12 Ethernet Ports 10.1.1.

Built in Ethernet switch 10.1.2.

Minimum cycle time (RPI) 4ms 10.1.3.

DLR (Device Level Ring) 10.2.

Ethernet MPC is capable of being configured into a DLR network 10.2.1.

Hold on Connection Loss 10.3.

MPC will hold last position communicated by the PLC. The Ethernet MPC will 10.3.1.

continue to maintain this position as long as power and air are still supplied.

Hold Till Connection 10.4.

MPC will hold its last position until a connection to PLC is established. The PLC 10.4.1.

should be ready to communicate the correct position upon connection to the

Ethernet MPC. The webserver or explicit messages can all be used to generate this

initial connection. This location is maintained by closed valves. Some drifting of

position could occur over time as air leaks from the cylinder.

Quick Connect 10.5.

The Ethernet MPC has Quick Connect functionality. 10.5.1.

- 19 -

Page 20

IN20267

Daisy Chaining Power and Ethernet 11.

The daisy chaining feature is an optional way to power MPC units. This eliminates the need to run a

power cable to each MPC from the power supply directly or running a separate power trunk line.

Daisy chaining can eliminates the need for long power cables.

Connecting MPCs for Daisy Chaining 11.1.

The cable connections are critical for proper operation of daisy chaining. The following is an

example of proper cable connections.

When daisy chaining, the first MPC can supply power to the next 19 MPCs without the need for

another power supply if using 48 volts. This drops to only 4 if using 24 volts. The MPC has under

voltage detection to let you know if you do not have enough voltage supplied to the MPC for proper

operation. The MPC does not limit the number of MPCs which can be connected to an Ethernet

network. The network size limits come from the PLC and how many devices it can talk to at one

time.

Figure 11-1 - MPC Group Power Connections

The diagram illustrates the Ethernet communication and power cable connections required to

support 21 MPCs when daisy chaining is in use. The MPCs in the dashed box form a single Power

daisy chain group. Note that power daisy chaining supports a maximum of 20 MPCs in one power

group. This does not mean that you cannot have more than 20 MPCs connected to a single supply.

More MPCs can be supported as long as the supply can source enough power to support multiple

chains of MPCs. Each MPC uses about 7 watts of power when moving.

The following rules must be followed for proper operation

Good quality power and Ethernet cables must be used when daisy chaining 11.1.1.

No more than 4 amps per connector pair should be placed across MPC power In to 11.1.2.

Power Out. This is a total of 8 amps if using both connector pairs as is suggested

when using daisy chaining to reduce line and connector voltage loss.

- 20 -

Page 21

IN20267

Balloon Number

Name

Description

1

PWR

Power OK indicator

2

NS

Network Status

3

MS

Module Status

4

Link/ACT

Bus In Ethernet Link and Activity Status

5

Link/ACT

Bus Out Ethernet Link and Activity Status

LED Indication 12.

Figure 12-1 MPC LED Locations

Table 12-2 MPC LED Indentifcation

- 21 -

Page 22

LED

LED Status

Description

PWR

Green ON

Voltage for the MPC is supplied.

OFF

Voltage for the MPC is not supplied or is outside the

tolerance range (24 VDC -10%)

NS

OFF

The MPC operating voltage is not supplied or the

MPC is in DHCP mode without a valid IP address.

Green ON

Communication established.

Green flashing

Idle link.

Red flashing

Communication time out.

Red ON

IP address duplicated.

MS

OFF

The MPC operating voltage is not supplied.

Green ON

Operating normally – communication in progress.

Green flashing

Operating normally – idle link.

Red flashing

Recoverable error – Possible low voltage.

Red ON

Unrecoverable error.

-

IN20267

Table 12-3 MPC LED Status Key

- 22 -

Page 23

Studio 5000 Setup 13.

EDS file – Rockwell Studio 5000

13.1.

The EDS file can be downloaded from the www.smcusa.com website. Install the EDS file by

selecting Tools then EDS Hardware Installation Tool.

IN20267

Figure 13-1 EDS Tool

Continue importing the EDS file by following the prompts then select the EDS file obtained from the

www.smcusa.com website.

- 23 -

Page 24

IN20267

Adding a device to Ethernet - Rockwell Studio 5000 13.2.

Add the Ethernet MPC by right clicking on Ethernet then clicking on New Module 13.2.1.

Figure 13-2 - New Module

Select Module Type - Uncheck the Module Type Vendor Filters then scroll down to 13.2.2.

SMC Corporation vendor and check the box. Select MPC from the list of items then

click on create. You can also use search to find the MPC.

- 24 -

Figure 13-3 – Module Select

Page 25

IN20267

New Module - Fill in the Name you want to give the MPC and the IP address. MPC 13.2.3.

will automatically be added to the name. Description is optional. Now select

Change…

Figure 13-4 – New ModuleSettings

Module Definition - Click on SINT and then select INT. Switching to INT makes 13.2.4.

using the Ethernet MPC easier. Click on OK and then OK again

Figure 13-5 – Module Connections

- 25 -

Page 26

IN20267

Ethernet - You now have an Ethernet MPC added to your Ethernet network 13.2.5.

Figure 13-6 – PLC Ethernet

MPC Tags will show up in the Controller Tags under the name you gave the MPC 13.2.6.

above

Figure 13-7 – PLC Input and Output Data for the Ethernet MPC

- 26 -

Page 27

Position

Body Type

mm

Counts / mm

inches

Counts / inch

%fs

Counts / %

50mm

81.90

2080.26

40.95

100mm

40.95

1040.13

40.95

150mm

27.30

693.42

40.95

200mm

20.48

520.07

40.95

Setpoint 14.

Users specifying the Setpoint (position) using a PLC need to be aware that the PLC and Ethernet

MPC use counts (see Terminology) to represent the position setpoint (from the PLC) and the

current position value (from the MPC). These values are displayed as 16-bit hexadecimal

quantities. (The 4 MSB should always be 0).

If the PLC allows a user to enter the position in units, for example, millimeters, it is the

responsibility of the PLC program to convert the position in millimeters to the appropriate count

value. It is also the responsibility of the PLC program to convert the position return value (current

position) from counts to millimeters as needed for use on the PLC.

The following formula is used to calculate the position in counts given the position in a

measurement unit and the scale factor: Position Value = Counts/Scale Factor or Counts =

Position Value * Scale Factor.

If a value larger than 4095 (0X0FFF) is sent from the PLC to the MPC, the MPC will go to the

maximum supported position (4095 counts).

IN20267

Table 14-1 - MPC Scale Factors

Example: Convert the Position to Counts 14.1.

Suppose you have specified a position of 50mm for a 100mm MPC. In order to convert that position

to counts, use the formula above as follows: Find the scale factor corresponding to the MPC body

type and the position measurement units in the table (above): In this case, the scale factor is 40.95.

As a result, counts = 50 * 40.95 = 2047.5. Since the pressure value in counts passed between the

PLC and the MPC must be an integer, round to 2048 or 0x800.

Example. : Pseudo Code for 100mm MPC mm 14.2.

// MPC slider and Feedback calculations

MPC_Setpoint = Slider_Setpoint * 40.95

Display_Feedback = MPC_Feedback / 40.95

Ladder Logic Example 14.3.

PLC Example Code: This is a quick PLC code snippet showing how to scale the position to which

you wish to move. The MUL instruction is used to convert from millimeters to counts. The tag

Set_Position_mm is used hold the engineering unit you wish to move to. The 40.95 is the scale

factor needed to convert from millimeters to counts that the 100 mm Ethernet MPC will

understand. MPC_1:O.Data[0] is tag for the output to the Ethernet MPC. The scale factor just has to

change if using a different stroke length MPC or if you prefer the imperial system to metric.

Figure 14-2 – PLC Code snippet (converting from millimeters to counts)

- 27 -

Page 28

IN20267

LabVIEW Example 14.4.

This is a LabVIEW png code snippet. It can be saved then dragged and dropped into a LabVIEW

block diagram.

- 28 -

Page 29

Web Pages 15.

Using a web browser (ex. Google Chrome, Fire Fox, Internet Explorer) on a PC, the user can view

various Ethernet MPC settings.

System Page 15.1.

Enter the IP address of the Ethernet MPC into your internet browser as shown below.

The “System Information” page will open. PC must be on the same subnet!

IN20267

- 29 -

Figure 15-1 – System Page

Page 30

IN20267

Diagnostics Page 15.2.

Click “Diagnostics” to view the communication and connection status of the Ethernet MPC.

This page provides an overview of the current communication status of the Ethernet MPC and is

helpful in analyzing network and communication issues.

Figure 15-2 – Network Diagnostics Page

If you are experiencing communication problems, SMC support personnel may need information

from this page to help resolve the problems.

- 30 -

Page 31

IN20267

IO Data Page 15.3.

Click “IO Data” to view the position setpoint sent to the Ethernet MPC and current Ethernet MPC

position and status information sent from the Ethernet MPC to the PLC.

Figure 15-3 – Network IO Data Page

The Data Status column indicates if data has been communicated on the bus after power up. “Bad”

indicates that data has not been written; “Good” indicates data has been written.

Row 0 is the most recent setpoint sent to the MPC.

Row 1 is the current MPC position value and status flags sent from the MPC.

- 31 -

Page 32

Version Page 15.4.

Click “Version” to see the versions of the firmware of the MPC.

IN20267

Figure 15-4 – Firmware Version Page

- 32 -

Page 33

IN20267

Ethernet MPC Status Page 15.5.

Click “Status” to see the current MPC Position and status of Ethernet MPC.

Note: The “MPC Status” page displays the current MPC position value based on the indicated

position units. The page automatically translates count values into the current position displayed.

Figure 15-5 - MPC Status Page

Note: Fault indicators MAY NOT reflect the actual current state of the MPC. There is a potential

delay between the occurrence of an event (alarm condition or status) and the screen refresh rate.

Also, if for any reason communication between the MPC and the web browser is disrupted, the

display will indicate the last state of the MPC BEFORE communication was lost. The LEDs on the

top of the MPC DO reflect the current state of the MPC.

- 33 -

Page 34

Login Page 15.6.

Click “Login” and enter “user” as both the Username and the Password.

Figure 15-6 – User Login Page

Login with user privileges allows the user to Configure and control the MPC.

This is a successful User login. Note that the Configuration web pages are now accessible.

IN20267

- 34 -

Figure 15-7 – Successful user login screen

Page 35

IN20267

Contact Page 15.7.

Click “Contact” to find the telephone numbers and email addresses for SMC Product Sales and

Technical Support.

Figure 15-8 – Contact Page

The “Product Information” contacts will connect you to the SMC sales team. Sales can help you

order accessories for your Ethernet MPC and other SMC products to support your application. Sales

can also help you obtain documentation for your Ethernet MPC.

The “Technical Support” contacts will connect you to the SMC technical support team. Tech

support can help you resolve technical questions or problems with the operation and use of your

Ethernet MPC. Tech support can also help you deal with questions related to the initial setup of

your Ethernet MPC.

- 35 -

Page 36

IN20267

MPC Configuration Page 15.8.

Below is a view of the “MPC Configuration” page. The top of the page (“MPC Status” frame)

displays the current MPC position value and MPC status indicators. The bottom of the page (“MPC

Position Override” frame) allows the user to override PLC control, change position, and change

position units. Note: The page automatically translates count values into the position displayed.

The “MPC Position Override” frame has the following user selectable controls:

Override PLC Control: This is a checkbox. If the checkbox is OFF (unchecked), the 15.8.1.

MPC is controlled externally (typically from a PLC). When the MPC is externally

controlled, the user cannot set the MPC position or change the position units from

the web page. When the Override PLC Control checkbox is checked, press “Submit”

or the keyboard Enter key for the change to take effect. Changing MPC control from

the master to the web page (checking the Override PLC Control checkbox) gives the

user control of the MPC from the webpage. There is no position change until the

- 36 -

Figure 15-9 – Position Override Page

Page 37

IN20267

Warning

BEFORE changing the position used by the MPC, verify that all equipment affected is in a safe

state. Be sure that ALL PERSONNEL are clear of ALL EQUIPMENT that may be affected by

the position change. Unexpected changes in equipment motion or behavior can result in

injury or death.

When Override PLC is enabled (checked), entering a valid value into the “Set Position” field

and pressing “Submit” or the keyboard Enter key will cause the MPC to change position. This

will result in an IMMEDIATE CHANGE in position. This change may cause an immediate

unexpected change in the behavior of equipment controlled by the MPC. This change

could cause injury or death.

When Override PLC is changed to the disabled state (cleared), control will return to the master

device. The current position will change to the setpoint value sent by the master device. This

will result in an IMMEDIATE CHANGE in regulated position. This change may cause an

immediate unexpected change in the behavior of equipment controlled by the MPC.

This change could cause injury or death.

user enters a position in the Set Position text box. Changing MPC control from the

web page to the master (clearing the Override PLC Control checkbox) gives the

master device control of the MPC. There may be an immediate position change to

the position setpoint sent from the master device. Note: Be sure that MPC

controlled equipment is in a SAFE STATE when you change Override PLC Control.

Note: Override PLC Control will remain in the same state when you exit this page.

You must uncheck the PLC override and click submit to give control back to the

PLC.

Position Units: This is a set of radio buttons indicating the current position unit. 15.8.2.

When Override PLC is set, the user can change the position unit. When Position

Units is changed, press “Submit” or the keyboard Enter key for the change to take

effect. The position value displayed in the “MPC Status” frame and in the “Set

Position” box will change to match the new Position Unit selection. No position

change will occur.

Set Position: This is a data entry box in the MPC “Position Override frame”. When 15.8.3.

Override PLC Control is set, the user can enter any legitimate setpoint value. When

the value of Set Position is changed, press “Submit” or the keyboard Enter key for

the change to take effect. If the setpoint value entered is legitimate, the MPC will

move to this new position. The position displayed in the “MPC Status” window will

change to the new value. If the value is out of range, the MPC position will not

change. The setpoint will change back to the previous value and the “Current

Position” value will not change. The title of “Set Position” will be displayed in RED,

and the error message “Set Position Out of Range” will also be displayed in RED

directly above the Submit button. Note: To change BOTH position units AND the

setpoint value, position units MUST be changed first.

- 37 -

Page 38

Network Page 15.9.

Click “Network” to view or change various network and operating parameters.

IN20267

Figure 15-10 Network Configuration

The following sections describe the items that can be changed on the “Network Configuration” page.

Multiple items can be changed at a time. When one or more items are modified, press “Submit” or

the keyboard Enter key for the change to take effect.

Note for some changes to take effect, an Ethernet MPC power cycle is required. A power cycle will

result in temporary loss of Ethernet MPC control. A power cycle will also result in temporary loss

of communication to all downstream devices connected to the Ethernet MPC.

Device Name is optional. It may be left blank since it is not used by the 15.9.1.

Ethernet/IPTM protocol. When Device Name is changed, press “Submit” or the

keyboard Enter key and then power cycle the Ethernet MPC to set the name.

IP Address is used to communicate with the Ethernet MPC. It MUST be unique on 15.9.2.

a network or subnet. Note: Use the SAME Subnet for ALL Ethernet MPCs for proper

communication. If you change the IP address, it is STRONGLY RECOMMENDED that

you record the new IP address before you press “Submit” or the keyboard Enter

key. A new IP Address will take effect in the Ethernet MPC immediately when you

- 38 -

Page 39

IN20267

Warning

Several setting changes in this section require an Ethernet MPC power cycle. Only power cycle

an Ethernet MPC when all devices and equipment controlled by the Ethernet MPC and all

devices receiving communication through the Ethernet MPC are in a verified safe state. Verify

press “Submit” or the keyboard Enter key. Control of the Ethernet MPC and

communication between the Ethernet MPC and the PC (or master device) will be

lost. To reconnect the PC to the Ethernet MPC web page. The Ethernet MPC IP

address used in the master device (typically a PLC) must match the new Ethernet

MPC IP address.

Netmask - The default value (255.255.0.0) is set to allow the MPC to monitor traffic 15.9.3.

in the 192.168.x.x range. The netmask can be used to expand or reduce the

network traffic that the MPC will monitor and or process.

Gateway Server - If the Ethernet MPC is not connected to a Gateway Server, the 15.9.4.

Gateway Server should be left as 0.0.0.0. If another address is specified, the

Ethernet MPC will attempt to use the indicated Gateway Server to manage network

communication.

DHCP - Use of DHCP (Dynamic Host Configuration Protocol) is not necessary since 15.9.5.

the initial IP address is statically set by the factory. The IP address can be changed

to match the specific application network requirements. When the Use DHCP

checkbox is OFF (unchecked), the Ethernet MPC is NOT in DHCP mode. The

Ethernet MPC will have a static IP address. When the Use DHCP checkbox is ON

(checked), the Ethernet MPC is in DHCP mode. The Ethernet MPC will not have an

IP Address until a DHCP server sets the Ethernet MPC IP address. An Ethernet MPC

without an IP address cannot be communicated with or controlled by either the

master or the Ethernet MPC webpage. When the Use DHCP checkbox is changed,

press “Submit” or the keyboard Enter key to set the DHCP state. Note: When

checking the Use DHCP checkbox (turning DHCP on), the web page may no longer

be connected to the Ethernet MPC. Also, the Ethernet MPC may require a power

cycle before the DHCP server will assign the Ethernet MPC an IP address. Note:

The DHCP checkbox setting is preserved across power cycles. In DHCP mode

(checkbox is checked), the Ethernet MPC IP address is NOT preserved across power

cycles.

DNS Server - If the Ethernet MPC is not connected to a DNS (Domain Name 15.9.6.

System) Server, the DNS Server should be left as 0.0.0.0. If another address is

specified, the Ethernet MPC will attempt to use the indicated DNS Server to manage

network communication.

Hold on Connection Loss - The “Enable Hold” checkbox is used to control Ethernet 15.9.7.

MPC behavior in the event Ethernet communication is lost. If Ethernet

communication is lost with “Enable Hold” ON (checked) and the Ethernet MPC is

powered, the Ethernet MPC will continue to hold position. If Ethernet

communication is lost with “Enable Hold” OFF (unchecked) and the Ethernet MPC

is powered, the Ethernet MPC will move to 0. If power is lost, the Ethernet MPC

will hold position with closed valves. To change the state of “Hold on Connection

Loss”, change the “Enable Hold” checkbox, press “Submit” or the keyboard Enter

key and then power cycle the Ethernet MPC.

- 39 -

Page 40

that all personnel are clear of all equipment which may be affected by power cycling an

Ethernet MPC.

When an Ethernet MPC is power cycled, communication to and control of the Ethernet MPC is

lost. When an Ethernet MPC is power cycled, communication to and control of ALL devices

downstream of the Ethernet MPC is lost.

IN20267

- 40 -

Page 41

IN20267

TYPE

Class

Instance

Attribute

Size

Description

Output

100

100 3 1 INT

Position set-point

Input

150

150 3 2 INT

2 bytes measured position, 2 bytes diagnostics

Explicit Messaging 16.

The Ethernet MPC can be controlled using explicit messaging instead of implicit messaging as some

PLCs do. This option is useful if using LabVIEW or another programming language that may not

have real time implicit libraries readily available.

Figure 16-1 Explicit Messaging

- 41 -

Page 42

Installation and Handling 17.

Air supply

17.1.

Use clean air.

Do not use compressed air that contains chemicals, synthetic oils including organic solvents, salts

or corrosive gases, etc., as this may cause damage or malfunction.

Air quality

Take measures to ensure air quality, such as installing an aftercooler, air dryer or water separator.

Compressed air containing large amounts of condensate may cause malfunction of pneumatic

equipment.

Lubrication

Do not lubricate the cylinders.

Lubrication of this cylinder may cause malfunction. Lubrication other than as specified may cause

operating failure. If grease is required for maintenance, order using the part number: GR-H-010 (

10g)

Do not wipe off the grease applied to the sliding part of the air cylinder.

If grease applied to the sliding part is forcibly removed, operation failure can result.

The sliding part may turn black if the cylinder is operated for a long distance. In such a case, wipe

off the grease on the sliding part and apply fresh grease for a long time operation. Use a cloth with

water to remove the grease. Alcohol or special solvent may cause damage to the seals.

Operating environment 17.2.

Do not use in an environment where corrosive gases, chemicals, or sea water are present. These

may cause failure or malfunction.

Do not use the product in an environment where the product may be splashed by oil or chemicals.

If the product is to be used in an environment containing oils or chemicals such as coolant or

cleaning solvent, even for a short time, it may be adversely affected (damage, malfunction, or

hardening of the lead wires).

Do not use the product in a food zone: 17.3.

Do not use the product in; Food zone: An environment in which foods directly get into contact with

the cylinder, and the food will be handled as a commodity.

OK to use the product in: 17.4.

Splash zone: An environment in which foods can directly contact the cylinder, but the food that has

contacted the cylinder will not be handled as a commodity.

Non-food zone - An environment in which foods do not contact the cylinder:

17.5.

In locations where the cylinder is exposed to water, dust etc., there is a possibility that these

contaminants can enter into the cylinder through the auxiliary ports. Connect tubing from the EXH

port and VENT port, and extend the tubing to a location where there is no contaminants.

Do not use in an area where surges are generated: 17.6.

If there are machines or equipment that generate large surges near the product (magnetic type

lifter, high frequency inductive furnace, motor, etc.), this can result in deterioration and damage to

internal components. Take protective measures to isolate the surge sources, and prevent the

lines from coming into close contact.

IN20267

- 42 -

Page 43

IN20267

Do not use a load which generates surge voltage.

When a surge-generating load such as a relay or solenoid is directly driven, use the product with a

surge absorbing element built-in.

The product is not immune to lightning strikes. Take measures against lightning strikes in the

system. Failure or malfunction may result.

Do not use in an area where a magnetic field is generated. Malfunction may result.

Do not let foreign matter, such as wire debris, get inside the product. Failure or malfunction may

result.

Do not use the product in an environment that is exposed to cyclic temperature patterns. Heat

cycles other than ordinary changes in temperature can adversely affect the internal components of

the product.

Do not expose the product to direct sunlight. If using in a location directly exposed to sunlight,

protect the product from the sunlight. Failure or malfunction may result.

Keep within the specified operating temperature range. The operating temperature range is 0 to

50oC. Operation under low temperature may lead to damage or operation failure due to frozen

moisture in the fluid or air. Protection against freezing is necessary. Avoid abrupt temperature

changes even within the specified temperature range.

Do not operate close to a heat source, or in a location exposed to radiant heat.

Installation 17.7.

Do not synchronize cylinders coupled to the same load.

As air is a compressible fluid, it is affected by fluctuations in the supply pressure, load, temperature

and lubrication conditions, and deviation in the performance of individual cylinders, and the change

of components over time. Therefore, it is possible to synchronize multiple cylinders for a short

period of time, but the synchronization could fail due to changes in various conditions. When the

synchronization fails, an excessive force will be applied to the piston rod, causing failure or

malfunction. If the synchronized use is unavoidable, provide a guide with high rigidity and high

precision to prevent failure of synchronization from the difference in force of the cylinders.

Do not place your hands or fingers in the clearance between the plate and the cylinder tube.

Injury may result if fingers are trapped between the plate and cylinder tube when the piston rod is

retracted. Never place hands or fingers in this area. The cylinder is able to generate great force; it

can lead to injury if hands or fingers are trapped.

Do not scratch or dent the sliding surfaces of the piston rod and the sensor rod.

Damage to the seals may lead to air leakage or operation failure.

Avoid applying rotating torque to the plate. When tightening a screw into the thread on the plate,

the piston rod should be fully retracted. Tighten it by giving consideration to preventing tightening

torque from being applied to the sensor rod.

Do not operate the cylinder in an application in which the piston rod stops before the positioning

stop. (e.g. Stoppage by clamping or external stopper) This may lead to premature failure of the

product.

- 43 -

Page 44

IN20267

Plate load should be mounted so that the center of the gravity of the load will be on the piston rod

shaft. Failure or malfunction may result.

Do not touch the sensor rod.

Do not drop, hit or apply shock to the product. Damage to the internal components may result,

causing malfunction.

Do not pull the lead wire forcefully, or lift the product by the lead wire. Hold the product body

when handling to prevent damage, failure or malfunction. The product will be damaged, leading to

failure and malfunction.

Never mount a product in a location that will be used as a foothold. The product may be damaged if

excessive force is applied by stepping or climbing onto it.

Do not use this cylinder as a stopper.

Minimum adjusting stroke necessary for a positioning stop is 5mm. Operate for 5mm or more

before a positioning stop.

Ex: 1. To operate from the stop position 20mm to 22mm; 20mm → 15mm → 22mm

Ex: 2. To operate to the stop position of 3mm; 0mm → 8mm → 3mm

Wiring (Including connecting/disconnecting of the connectors) 17.8.

Wire the cable to the connector of the body as shown below. Incorrect wiring can result in damage

to the product.

Make sure the product is grounded to ensure noise tolerance. Otherwise malfunction can result.

Do not pull hard on the lead wire.

Never lift the product equipped with tubing by holding the lead wires. Damage to the connector,

circuit board, cover or internal components may result, causing failure or malfunction.

Avoid repeatedly bending, stretching or applying a heavy object or force to the lead wire.

Repetitive bending stress or tensile stress can cause the sheath of the wire to peel off, or break the

wire. If the lead wire can move, fix it near the product. The recommended bend radius of the lead

wire is 6 times the outside diameter of the sheath, or 33 times the outside diameter of the

insulation material, whichever is larger. Replace a damaged lead wire with a new one.

Wire correctly. Incorrect wiring may cause malfunction or damage to the product. Do not perform

wiring while the power is on. Damage to the internal components may result, causing malfunction.

Do not route wires and cables together with power or high voltage cables. Route the wires of the

product separately from power or high voltage cables to prevent noise and surge from entering the

product.

Verify the insulation of wiring.

Poor insulation (interference with other circuits, poor insulation between terminals etc.) can apply

excessive voltage or current to the product causing damage.

Keep wiring as short as possible to prevent interference from electromagnetic noise and surge

voltage. Do not use a cable longer than 100m.

Wire the DC (-) line as close as possible to the power supply.

- 44 -

Page 45

IN20267

- 45 -

Page 46

IN20267

Adjustment and Operation 17.9.

When the product is supplied with pressure for the first time or when the operating pressure is

changed after the product is mounted to the application, operate the product for 1 or more

reciprocating operations before starting the operation. Failure to follow this procedure may cause

the product to malfunction.

There is a possibility of rod extrusion or overshooting when starting retraction depending on the

operating conditions such as vertical operation, plate load or operating pressure. Assure proper

operation before using the product.

Do not short circuit the load.

When the product load has a short circuit, over current may be generated, leading to damage of the

product.

- 46 -

Page 47

Washing 18.

When washing the product with steam, stay within the cylinder temperature range and wash

quickly. If the sliding part is washed, the grease may be washed away, reducing the product life.

Washing should be as infrequent as possible.

When washing the product using a brush, avoid applying excess force to the parts such as the lead

wire and plastic cover, as these components are easily damaged.

IN20267

- 47 -

Page 48

IN20267

Maintenance 19.

Do not disassemble or retrofit the product. Failure or malfunction may result.

Perform periodical checks.

There is a risk of unexpected failure of components due to the malfunction of equipment and

machinery.

Turn off the power supply, shut off the air supply, exhaust residual compressed air in the piping and

verify the release of air before performing maintenance. There is a risk of unexpected operation.

Do not use solvents such as benzene, thinner etc. to clean the product. This may damage the surface

of the body and erase the markings on the body. Use a soft cloth to remove stains. For heavy stains,

use a cloth soaked with diluted neutral detergent and fully squeezed, then wipe up the stains again

with a dry cloth.

- 48 -

Page 49

IN20267

Recovering the IP Address of SMC Ethernet MPC 20.

The Ethernet MPC has a factory preconfigured static IP address of (192.168.1.20). Use this

procedure when the current IP address of an Ethernet MPC is unknown. The IP address can be

modified using the eight switches located under the cover of the Ethernet MPC. Power should be off

to the unit or the power cable should be unplugged. In order to access the switches remove the 5

screws that hold the cover on using a 2.5mm Allen key. Carefully lift the cover off reveling the dip

switches at one end of the circuit board stack.

The switches represent the lower octet of the IP address, the value of X in this example:

192.168.1.X. A switch is a binary 1 when it is pushed up toward the upper circuit board or a binary

0 when pushed down. The switch which corresponds to the most-significant-bit (MSB) of the lower

octet is located on the right. The switches are read by the Ethernet MPC upon application of power.

When power is applied, the state of the switches will then be used to determine the lower octet of

the IP address.

The switches come from the factory set to a collective decimal value of 255 (all switches pushed up).

The IP address stored in flash (i.e. set from the webpage) is used when the switches are set to 255.

When the switches are set to 0 (all switches pushed down) the factory defaults of the device are

restored on power application.

The user can then modify the IP address to the desired value via the webpage. REMINDER: to use

the address set from the webpage the switches need to be returned to 255 or, if left at 0, the factory

defaults will return on the next power cycle. A switch value different from 0 or 255 will cause the

lower octet of the IP address to assume the corresponding value of the switches. Additional

information related to network setup can be found in the sections Web Page Access and Network

Page.

- 49 -

Figure 18-1 SMD Cover

Page 50

IN20267

Figure 18-2 Defualt Switch Position all up

- 50 -

Page 51

IN20267

Revision History

Revision

Description

Date

Author(s)

1.0

Initial release for Ethernet/IP MPC

010/11/2016

SMC US EPG

SMC Corporation of America

10100 SMC Boulevard

Noblesville, IN 46060

Phone: 1-800-SMC-SMC1 (1-800-762-7621)

URL: www.smcusa.com

- 51 -

Loading...

Loading...