Page 1

Doc. No. CE

※-

OMP0016-A

OPERATION MANUAL

READ THIS OPERATION MANUAL CAREFULLY BEFORE USE IT.

NEVER INSTALL THE PRODUCT UNTIL FINISH READING THIS MANUAL.

KEEP THIS MANUAL ALL THE TIME FOR YOUR REFERENCE.

PRODUCT NAME

:

HYRODLESS MONOSASHI-KUN

MODEL :

ML2B Series

Page 2

2

Contents

Chapter 1: Read Before Use ·····························································4~9

Chapter 2: General Description/Features

2-1. General Description ··································································· 10

2-2. Features ·················································································· 10

Chapter 3: System Configuration

3-1. System Configuration ································································ 11

3-2. Example of System Configuration ········································ 11~12

3-3. Pneumatic Circuit ······························································· 13~14

Chapter 4: Operating Principle

4-1. Operating Principle of Brake ······················································· 15

Chapter 5: Selecting Procedure

5-1. Precaution················································································ 16

5-2. Selecting Procedure ·································································· 17

5-3. Selection Information ·························································· 18~19

5-4. Example of Selection ·························································· 20~21

Chapter 6: Specifications

6-1. Cylinder Specifications ······························································· 22

6-2. Sensor Specifications ································································ 22

Chapter 7: How to Order

7-1. Cylinder ··················································································· 23

7-2. Controller / 3 Points Preset Counter············································· 23

7-3. Extension Cable········································································ 24

7-4. Specifications of Made to Order ML2B ·································· 24~25

Chapter 8: External Dimension Drawing

8-1. Hyrodless Monosashi-kun (with Brake, scale) ······························· 26

8-2. Hyrodless Monosashi-kun (with Scale)········································· 27

8-3. Hyrodless Monosashi-kun (with Brake) ········································ 28

8-4. Hyrodless Monosashi-kun (with Shock Absorber) ·························· 29

8-5. Hyrodless Monosashi-kun (with Stroke Adjustment Unit, X416) ······· 30

8-6. Hyrodless Monosashi-kun (with Stroke Adjustment Unit, X417) ······· 31

Chapter 9: Construction / Parts List ······················································· 32

Chapter 10: Cushion Capacity

10-1. Cushion Selection ··································································· 33

10-2. Absorbing Capacity of Air Cushion, Stroke Adjustment Unit··········· 34

10-3. Adjusting Method····································································· 35

Page 3

3

Chapter 11: Stopping Operation

11-1. Over run ················································································· 36

11-2. Dispersion of Stopping Position ················································· 36

Chapter 12: Manual Operating Procedure ·············································· 37

Chapter 13: Installation / Wiring

13-1. Installation of Cylinder ······················································· 38~39

13-2. Electrical Wiring ······································································ 40

13-3. Connection of Extension Cable ················································· 41

Specifications are subject to change without prior notice

Page 4

4

Chapter 1: Read before Use

These safety instructions are intended to prevent a hazardous situation and/or equipment damage.

These instructions indicate the level of potential hazard by label of “Caution”, ”Warning”, or ”Danger”.

To ensure safety, follow the instructions below as well as ISO/IEC, JIS

*1)

and other safety laws

*2)

.

Caution

Operator error could result in injury or equipment damage.

Warning

Operator error could result in serious injury or loss of life.

Danger

In extreme conditions, there is a possible result of serious injury or

loss of life.

*1) ISO 4414: Pneumatic fluid power - General rules relating to systems

ISO 10218-1: 2006: Robots for industrial environments - Safety requirements - Part 1: Robot

IEC 60204-1: Safety of machinery - Electrical equipment of machines - Part 1:General

requirements

JIS B 8370: General Rules for Pneumatic s ystems

JIS B 9960-1: Safety of machinery - Electrical equipment of machines - Part 1: General

requirements

JIS B 8433-1:2007: Robots for industrial environments - Safety requirements - Part 1: Robot

*2) Labor Safety and Sanitation Law etc.

Warning

1. The compatibility of pneumatic equipment is the responsibility of the person who designs the

pneumatic system or decides its specifications.

Since the products specified here are used in various operating conditions, their compatibility for

the specific pneumatic system must be based on specifications or after analysis and/or tests to

meet your specific requirements. Ensuring the initial performance and safety are the responsibility

of the person who decides the compatibility of the pneumatic system. Pneumatic systems should be

constructed after full review of the details of the products other than specifications and possibilities

of failures by checking the latest product information.

2. Only trained personnel should operate poneumaticallly operated machinery and equipment.

Assembly, handling, or repair of pneumatic systems should be performed by trained and

experienced operators.

3. Do not service machinery/equipment or attempt to remove component until safety is confirmed.

a. Inspection and maintenance of machinery/equipment should only be performed after confirmation

of safe locked-out control positions.

b. When equipment is to be removed, confirm the safety process as mentioned above. Cut the

supply pressure for this equipment and exhaust all residual compressed air in the system.

c. Before machinery/equipment is re-started, take measure to prevent shooting-out of cylinder piston

rod etc.

4. Contact SMC and take necessary safety measures if the products are to be used in any of the

following conditions:

a. Conditions and environments beyond the given specifications, or if products are used outdoors.

b. Installation on equipment in conjunction with atomic energy, railway, air navigation, vehicles,

medical equipment, food and beverages, recreation equipment, emergency stop circuits, press

applications, or safety equipment.

c. An application which has the possibility of having negative effects on people, property, or animals,

requiring special safety analysis.

d. When used in an interlock circuit, dual interlock such as mechanical protection is necessary in

case of accident. Periodical inspection is also necessary to confirm proper operation.

! ! !

!

Page 5

5

Operating and Storage Environments

Warning

1. Envionments to avoid

Avoid using or storing the products in the

following environments which may cause

failures.

If the products need to be used or stored in

those environments, take necessary measures.

a. Place where ambient temperature exceeds

the range of 5℃ to 60℃.

b. Place where ambient humidity exceeds the

range of 35% to 85% RH.

c. Place where condensation occurs due to

sudden temperature change.

d. Place where atmosphere containing corrosive

gas, flammable gas or organic solvent.

e. Place where atmosphere containing

con-ductive powder such as dust and iron

chips, oil mist, salt, or organic solvent, or

splashing cutting chips, dust and cutting oil

(water , liquid) over the products.

f. Place where the products are exposed to

direct sunlight or radiated heat.

g. Place where strong electromagnetic noise is

generated (place where strong electric field,

strong magnetic field or surge is generated).

h. Place where static electricity is discharged or

condition that the products have electrostatic

discharge.

i. Place where strong high frequency is

gene-rated.

j. Place where damages of thunder are

expected.

k. Place where vibration or impact is directly

given to the products.

l. Condition that the products are deformed by

force or weight applied.

2. Do not close any objects which are affected

by magnets.

Since magnets are built in cylinders, do not close

magnetic disks, magnetic cards or magnetic

tapes. The data may be destroyed.

Precaution on Design

Warning

1. There is a possibility of dangerous sudden

action by cylinders if sliding parts of

machi-nery are twisted due to external forces,

etc.

In such cases, human injury may occur; e. g., by

catching hands or feet in the machinery, or

damage to the machinery itself may occur.

2. Provide a cover to minimize the risk of

human injury.

When a driven object or moving parts of a

cylinder may cause the risk of human injury,

design a structure to avoid contact with human

body.

3. Securely tighten all stationary parts and

connected parts of cylinders so that they will

not become loose.

Tighten cylinders securely especially when they

are used in high frequency or in locations where

direct vibration or impact shock, etc. will be

applied to the body of the cylinder.

4. Deceleration circuits or shock absorbers are

needed in some cases.

If a driven object travels at a high speed or is

heavy, impact will not be sufficiently absorbed

only with the cylinder cushion. In such cases,

use a circuit to decelerate the cylinder speed

before the cushion becomes effective or use

external shock absorbers to reduce impact. At

this time, take the rigidity of machinery into

account.

5. Consider possible drop of pressure in circuit

due to power outage.

For cylinders used in clamping mechanism, a

work may become loose due to less clamping

force by pressure drop in circuit at the time of

power outage. Install safety devices to prevent

human injury and machinery damage. Measures

should be taken to prevent drop of hanging or

lifing equipment.

6. Consider possible loss of power sources.

Measures should be taken to protect against

human injury and machinery damage in the

event that there is a loss of air pressure,

electricity or hydraulic power.

7. Design circuit to prevent shooting out of a

driven object.

A driven object is quickly shot out when pressure

is supplied from one side of the piston after air in

the cylinder is exhausted in such cases that

cylinder is actuated by exhaust center type of

directional control valve or started after residual

air is exhausted from the circuit. At this time,

human injury may occur; e.g., by catching hands

or feet in the machinery, or damage to the

machinery itself may occur. Therefore, the

machine should be designed and constructed to

prevent shooting out.

!

!

Page 6

6

8. Consider emergency stops.

Design the machinery so that human injury

and/or damage to machinery and equipment will

not be caused when machinery is stopped by a

safety device under abnormal conditions, a

power outage or a manual emergency stop.

9. Consider actions when operation is restarted

after an emergency stop or abnormal stop.

Design the machinery so that human injury or

equipment damage will not occur upon restart of

operation. When the cylinder is required to return

to the initial position, provide the equipment with

a safe override.

10.Construct the machinery so that moving

objects and the moving parts of the cylinder

with brake do not come into direct contact with

the human body.

11.Use a balanced circuit in which lurching of the

cylinder is prevented. When operation is locked

in specified intermediate positions of the stroke,

and air pressure is applied to only one side of

the cylinder, the piston will lurch when the lock

is released. This might cause injury or damage

to machinery.

Selection

Warning

1. Confirm the specifications.

The product in this manual is designed to be

used only in industrial compressed air system.

The product should not be used with pressures

or temperatures outside the range of the

specifications, as this may cause damage or

malfunction, etc.

2. Intermediate stop

When cylinder piston is stopped intermediately

by 3-position closed center type of directional

control valve, intermediate stop positions may

not be as precise and exact as hydraulic

operation due to compressibility of air. Valves

and cylinders are not guaranteed for zero air

leakage, and stop position may not be held in a

long period of time. Consult SMC for long term

holding of stop positions.

3. When a cylinder is in a no-load and locked state,

the holding force (maximum static load) is the

lock’s ability to hold a static load that does not

involve vibrations or shocks. To ensure braking

force, the maximum load must be set as

described below.

①For constant static loads, such as for drop

prevention:

35% or less of holding force (Maximum

static load)

Note) For applications such as drop prevention,

consider situations in which the air source

is shut off, and make selections based on

the holding force of the spring locked state.

Do not use the pneumatic lock for drop

prevention purposes.

②When kinetic energy acts upon the cylinder,

such as when effecting an intermediate stop,

there are constraints in terms of the allowable

kinetic energy that can be applied to the

cylinder in a locked state. Refer to the

allowable kinetic energy of the respective

series. Furthermore, during locking, the

mechanism must sustain the thrust of the

cylinder itself, in addition to absorbing the

kinetic energy. Therefore, even within a given

allowable kinetic energy level, there is an

upper limit to the amount of the load that can

be sustained.

- Maximum load for horizontal mounting: 70%

or less of the holding force (Maximum

static load) for spring lock

- Maximum load for vertical mounting: 35% or

less of the holding force (Maximum static

load) for spring lock

③ In a locked state, do not apply impact, strong

vibrations or rotational forces. Any impact,

strong vibrations or rotational forces from

external sources could damage or shorten

the life of the lock unit.

④ Although the cylinder can be locked in both

directions.

Caution

1. Mount speed controller and adjust cylinder

operation speed gradually from low speed to

a desired speed.

Air Supply

Warning

1. Do not use the product out of the specified

ranges for pressure and temperature to

pre-vent equipment damage and

mal-function.

!

!

!

Page 7

7

①Operating pressure:

Actuating part: 0.1 – 1.0MPa

Braking part

: 0.3 – 0.5MPa

②Fluid & ambient temperature: 5 to 60C

2. Use clean air.

Do not use the product with compressed air

includes chemicals, synthetic materials

(including organic solvents), salinity, corrosive

gases, etc., as this may cause damage or

malfunction.

Caution

1. Install air filter.

Install air filter before and in vicinity of valve. The

filter should be able to collect particles of 5

microns or smaller. A large quantity of drain may

cause malfunction of pneumatic components.

2. Install after cooler, air dryer, auto drain, etc.

Compressed air that includes excessive

condensate may cause malfunction of valve and

other pneumatic equipment. To prevent this,

install after cooler, air dryer, auto drain, etc.

Pneumatic circuit

Warning

1. Be certain to use a pneumatic circuit which will

apply balanced pressure to both sides of the

piston when in a locked stop. (Refer to Chapter 6

for recommended pneumatic circuit.)

In order to prevent the cylinder lurching after a

locked stop, use a circuit which applies balanced

pressure to both sides of the piston when restarting

or when manually releasing the lock, thereby

canceling the force generated by the load in the

direction of piston movement.

2. Use a solenoid valve for unlocking which has a

larger effective area, as a rule 50% or more of

the effective area of the cylinder drive solenoid

valve.

(Refer to Chapter 6 for recommended

pneumatic components.)

The larger the effective area is, the shorter

the locking time will be, and stopping

accuracy will be improved.

3. Place the solenoid for unlocking close to the

cylinder, and no farther than the cylinder drive

solenoid valve.

The shorter the distance from the cylinder, the

shorter the overrun amount will be, and stopping

accuracy will be improved.

4. Allow at least 0.5 seconds from a locked stop

(intermediate stop of the cylinder) until release of

the lock.

When the locked stop time is too short, the

piston rod may lurch at a speed greater than the

control speed of the speed controller.

5. When restarting, control the switching signal for

the unlocking solenoid valve so that it acts before

or at the same time as the cylinder drive solenoid

valve.

If the signal is delayed, the piston rod may lurch at

a speed greater than the control speed of the

speed controller.

Installation

Warning

1. Connect the slider end and the load with the lock

released.

2. Ensure that the equipment operates properly

before the use.

3. Operation manual

Do not install the products unless the safety

instruction have been read and understood.

Keep this operation manual on file for future

reference.

Caution

1. Maintenance space

When installing the products, allow space for

maintenance.

2. Do not give strong impact and/or excessive

moment when work is mounted.

External force other than allowable moment may

cause rattle at guide part and/or increase in

sliding resistance.

5. Be careful to avoid scratches or dents, etc. on

the sliding sections of the slider.

!

! ! !

Page 8

8

Wiring

Warning

1. Preparation for wiring

Shut off the power before wiring (including

insertion and removal of connectors). Mount a

protective cover on the terminal block after

wiring.

2. Check the power

Make sure the power has sufficient capacity and

voltages are within the specified range before

wiring.

3. Grounding

Ground terminal block F.G. (Frame Ground).

Do not ground it with devices generating strong

electromagnetic noise.

4. Check wiring

Incorrect wiring may cause damage or

malfunction of the products. Make sure the

wiring is correct before operation.

Caution

1. Separation of signal wires from power wire

Avoid common or parallel wiring of signal and

power wires to prevent malfunction due to noise.

2. Wiring arrangement and fixation

Avoid bending cables sharply at connector part

or electrical entry in wiring arrangement.

Inproper arrangement may cause disconnection

which in turn causes malfunction. Fix cables

close enough not to give excessive force to the

connector.

Piping

Caution

1. Before piping

Remove cutting chips, cutting oil, dust, etc. in

piping by flushing or cleaning before piping.

Care should be taken especially that any cutting

chips, cutting oil, dust, etc. do not exist after a

filter.

2. At piping

①Foreign matter should not enter. Entering of

foreign matter will cause malfunction.

②Cutting chips and sealing materials at piping

threads should not enter valves when piping

and fittings are screwed in. Leave 1.5 to 2

threads when seal tape is used.

Lubrication

Caution

1. Lubrication of cylinder

①This cylinder is pre-lubricated and can be used

without lubrication.

②In case of lubrication, use a equivalent of the

turbine oil type 1 ISO VG32. Once lubrication

is performed, it should be continued since the

initial lubricant flows out causing malfunction.

Adjustment

Caution

1. The locks are manually disengaged when the

cylinder is shipped from the factory. Be sure to

change them to the locked state before using

the cylinder.

2. Adjust the cylinder’s air balance. In the state in

which a load is attached to the cylinder,

disengage the lock and adjust the air pressure

on the rod side and the head side of the

cylinder to obtain a load balance. By

maintaining a proper air balance, the piston rod

can be prevented from lurching when the lock is

disengaged.

3. Adjust the mounting position of detection

devices such as autoswitches.

Sensor unit

Caution

1. Do not remove the sensor unit.

The position and sensitivity of the sensor is

adjusted properly before shipment.

Removing or replacing the sensor may cause

malfunction.

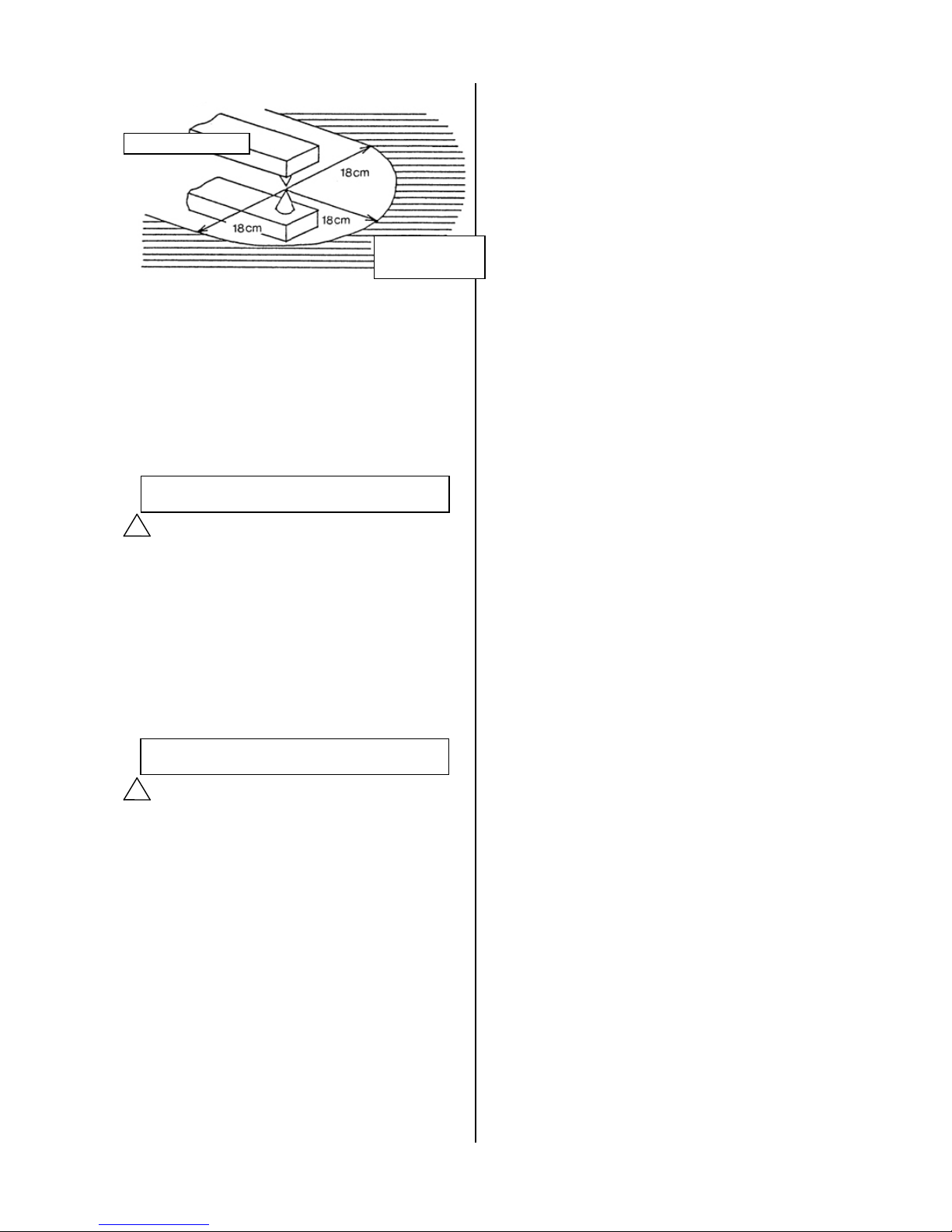

2. Operate the system with an external magnetic

field of 14.5mT or less.

Strong magnetic field in the vicinity may cause

malfunction, since ML2 sensor is magnetic

type.

This is equivalent to a magnetic field of

approximately 18cm in radius from a welding

area using a welding current of almost 15,000

amperes. To use the system in a magnetic field

that exceeds this value, use a magnetic material

to shield the sensor unit

! ! ! ! !

!

Page 9

9

3. Do not pull sensor cable strongly.

Such action may cause failure.

4. Water shall be kept away from the sensor unit to

avoid failure.

5. Power supply line

Do not mount any switch or relay to power

supply line (12 VDC).

Measurement

Caution

SMC products are not intended for use as

instruments for legal metrology.

Measurement instruments that SMC manufactures

or sells have not been qualified by type approval

tests relevant to the metrology (measurement) laws

of each country. Therefore, SMC products cannot

be used for business or certification ordained by the

metrology (measurement) laws of each country.

Maintenance and Check

Warning

1. Performing regular check

Check regularly that the products do not operate

with failures unsolved. Check should be done

by trained and experienced operators.

2. Dismantling of product and supply/exhaust

of compressed air.

Before dismantling, ensure that drop preventing

and runaway preventing treatments are properly

provided, shut the power source of air supplied,

and exhausts compressed air in the system.

When starting operation again, operate the

product with care after ensuring that a treatment

for preventing extrusion is properly provided.

3. Prohibition of disassembly and modification

To prevent accidents such as failures and

electric shocks, do not remove the cover to

perform disassembly or modification. If the

cover has to be removed, shut off the power

before removal.

4. Disposal

Request a special agent for handling industrial

waste to dispose the products.

!

Operating

range

Welding machine

!

Page 10

10

Chapter 2: General Description / Features

2-1 General Description

Positioning with high reproducibility has been realized by Hyrodless Monosashi-kun, which brake and

stroke sensor are installed in mechanical joint type rodless cylinder (MY1B Series). (Stopping

accuracy is ±0.5mm when specified controller. CEU2, is used.)

2-2 Features

Brake Structure

・Adoption of integrated pneumatic and spring

Slider stops instant due to quick response of brake. Also the current position is hold by spring lock

when the air pressure is lowered or the compressed air is stopped.

・Lock is possible for both directions

Lock is possible for reciprocation of cylinder stroke.

・Easy maintenance

Brake can be replaced and disassembled, and can be opened manually for its unit structure.

・Brake structure which does not give a load on cylinder

Slider can be stopped without losing its performance since brake does not give a load on cylinder

for its structure, which spring acts on brake shoe directly to put between upper and lower brake

plates.

Scale

・Minimum measuring unit : 0.1mm

This is measured by scale plate and detection head built-in body.

Page 11

11

Chapter 3: System Configuration

3-1 System Configuration

HYRODLESS MONOSASHI-KUN (ML2 Series) can be used for measurement or to prevent falling

besides positioning application.

Model

type

Function

Connected

equipment

Application

Brake

Scale

Keeping

Intermediate

stop

Measurement

Positioning

①

ML2B※

○

○

CEU1

○ ○ ○

②

ML2B※

○

○

CEU2

○

③

ML2B※S

○

CEU1

○

④

ML2B※B

○

Sequence, etc.

○ ○

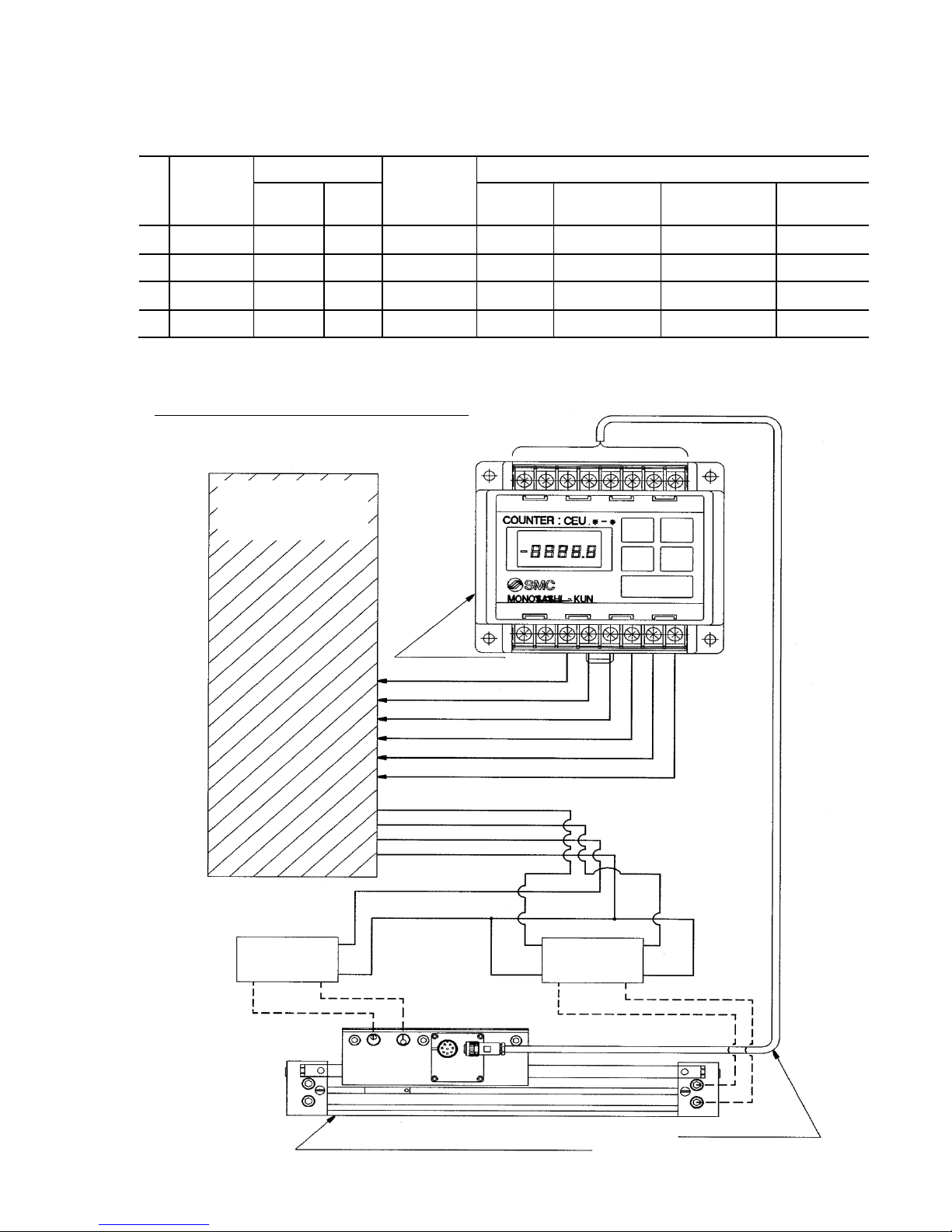

3-2 Example of system Configuration

■For Keeping

Hyrodless Monosashi-kun + Counter

3 points preset counter : CEU1 Series

Brake valve

Solenoid

valve

Hyrodless Monosashi-kun (ML2※)

Extension cable

(CE1-R□□)

Counter

(CEU1)

External equipment

(Sequence

controller, etc.)

Page 12

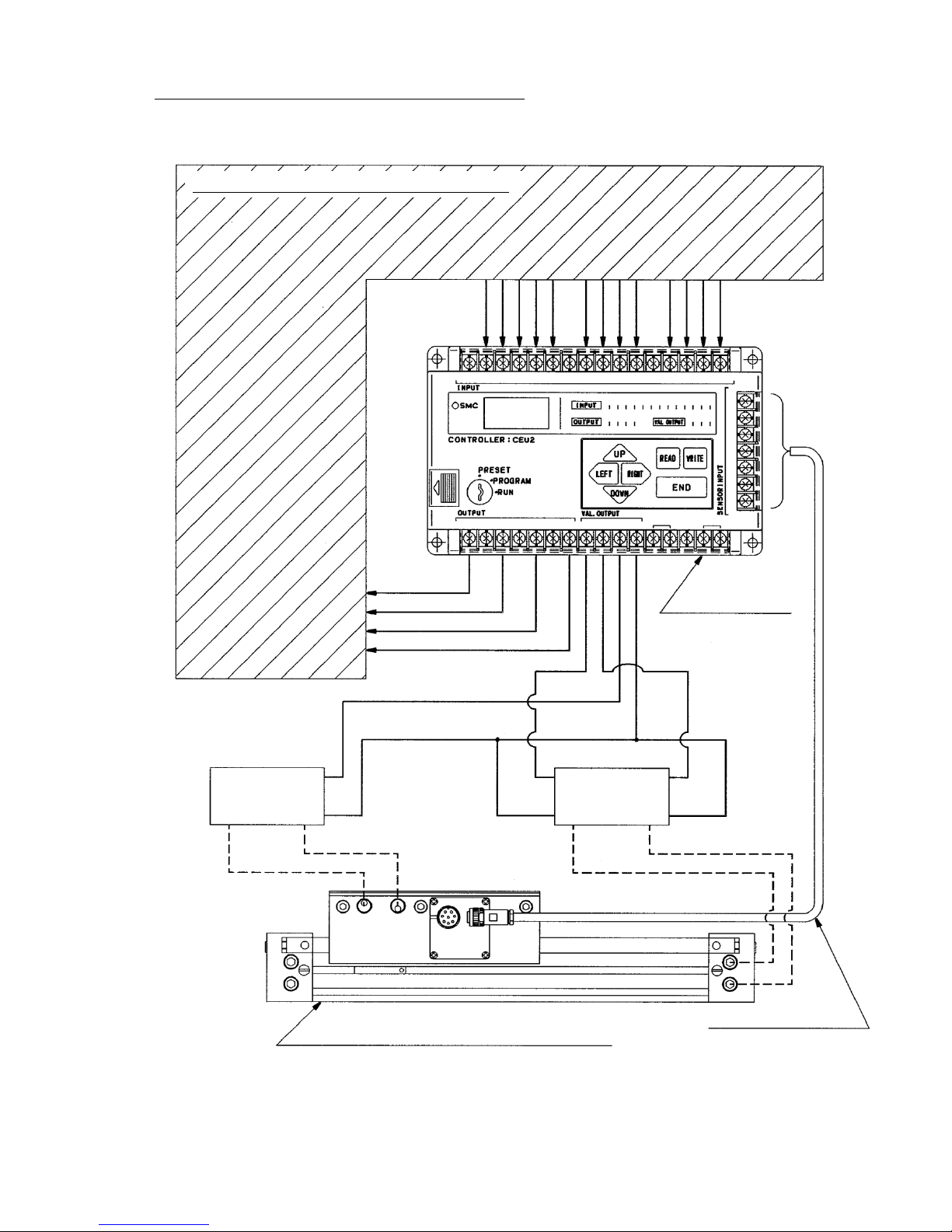

12

■For precise positioning (Stopping accuracy ±0.5mm)

Hyrodless Monosashi-kun + Controller

Controller : CEU2 Series

Brake valve

Solenoid

valve

Hyrodless Monosashi-kun (ML2※)

Extension cable

(CE1-R□□)

Controller

(CEU2)

External equipment (Sequence controller, etc.)

Page 13

13

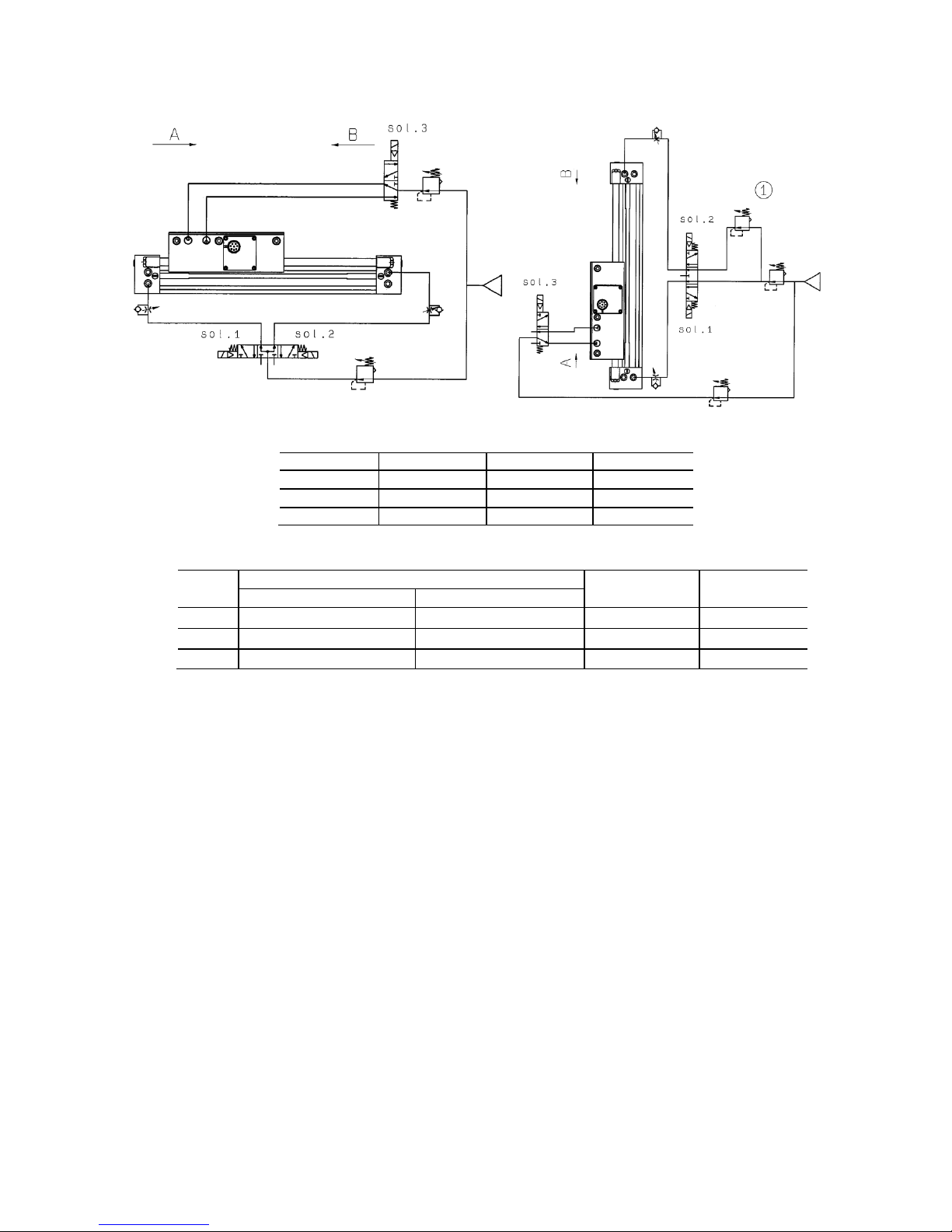

3-3 Pneumatic Circuit

Sol.1

Sol.2

Sol.3

A

ON

OFF

ON B OFF

ON

ON

Stop

OFF

OFF

OFF

Pneumatic Equipment

Bore

Size

Directional Valve

Brake Valve

Regulator

Horizontal Mounting

Vertical Mounting

25

VFS25□0

VFS24□0R

VFS21□0

AR425

32

VFS25□0

VFS24□0R

VFS21□0

AR425

40

VFS25□0

VFS24□0R

VFS21□0

AR425

・Air Balance

・ With the above circuit, maintaining the slider at center by balancing both sides (left & right) supply

pressure to achieve air balance state.

・ At the situation of vertical mounting, maintain the slider at the center and reduce the upper

portion’s supply pressure accordingly to counter for the weight due to gravity. If air balance is not

achieved, motion after center positioning will be either accelerating abnormally or false movement.

Hence, the accuracy of positioning will be affected.

・Tubing

・ Use larger diameter’s tube and reduce the tubing length between solenoid valve and cylinder, so

as to increase position determination’s precision.

・ Connect brake valve near to slider. If tubing between brake valve and slider is long, its motion

response time will be slower. Moreover, it may rush vigorously when brake is released.

・ During installation, connected tubing should be flushed thoroughly, and prevent dust and chips

from entering into cylinder.

・Supply Pressure

・ Set brake release port’s supply pressure as 0.3~0.5MPa. With supply pressure of below 0.3MPa,

brake’s release will not be activated. While with pressure of above 0.5MPa, brake’s life span will

be shortened.

・ Direct pressure supply from pressure line will cause pressure variation problem and thus, affect

cylinder performance. Hence, it is advisable to connect regulator before driving and brake

solenoid valve. Besides that, if there is a lot of cylinder activated and moving at the same time,

use regulator with larger flow characteristic and install air tank.

・ Connect head cover tubing wisely with consideration of surrounding conditions.

Horizontal Mounting

<Air Circuit Diagram>

Vertical Mounting

Page 14

14

The most suitable tubing can be selected according to the situation when tubing head cover.

Tube face No.

1 2 3 4 5 6 Type of head cover

Head Cover-WL

Head Cover-WR

Tubing face

Front

Side

Bottom

Front

Side

Bottom

Operating

direction

Left A C E G I K

Right B D F H J L

Note: 1)Tubing should be group according to the grouping in the table

above, 6 on each sides.

2)SMC’s one-touch speed controller can be mounted directly on

tubing No.1,2,4 and 5.

Installating dimension of bottom face

φ25,φ32

φ40

O-ring

C9

C11.2

φA

φ6

φ8

Driving Direction

Left

Right

<Back>

<Side>

<Front>

<Side>

<Back>

Brake Operating Port

Brake Release Port

Head Cover-WL

Head Cover-WR

Rz12.5

Head cover

O-ring

φA

Fixing plate

Speed

controller

Page 15

15

Chapter 4: Operating Principle

4-1 Operating principle of brake

Brake operation

Spring force caused by brake spring and the air pressure supplied from brake operating port work

on brake shoe 1 fixed with brake holder, bend brake plate fixed on head cover on both sides, and

stop slider by putting brake plate between brake shoe 1 and brake shoe 2 fixed on the slider side.

Brake release

The air pressure supplied from brake releasing port work on diaphragm, decline brake spring, and

cancel brake.

Brake operating port

Brake releasing port

Slider

Brake shoe 2

Diaphragm

Brake holder

Brake spring

Brake shoe 1

Brake plate

Page 16

16

NO

NO

No particular problems for

operation.

YES

1. Is there any influence by

magneteic field?

YES

2. Is cylinder exposed to

coolant, oil, water and

power, etc?

YES

Start

NO

Is the total of moment of

each direction to cylinder

and load factor of movable

load within "1"?

(in the case of without

guide)

Is kinetic energy within

allowable kinetic energy?

(in the case of with guide)

Select cylinder size so that

load factor will become

less than "1"?

Select cylinder size so that

kinetic energy will become

within allowable kinetic

energy.

Is it possible to use at less

than 14.5mT?

NO

Do not use it since it will

cause miscount and

insufficient control.

YES

NO

Do not use it since it will

cause brekage of sensor

or degradation of

YES

Can the cable of

Hyrodless Monosashi-kun

be wired separate from

the other power cable?

Do not use it since it is

easily affected by noise

due to pulse output, which

will cause maloperation.

NO

YES

Can the cylinder be

protected with a cover,

etc?

Chapter 5: Selecting Procedure

5-1 Precaution

Be sure to check with the procedure below before using Hyrodless Monosashi-kun. For positioning

with CEU2, check with the procedure of “Operation Manual of Brake Positioning System (Rodless

type)”.

Page 17

17

W : Load (N) Mounting Direction :

Va : Average Speed (mm/s) Guide :

P : Operating Pressure (Mpa) Impact Absorption :

Autoswitch :

With Guide

NG

NG

OK OK

NG

OK OK

Operating Condition

Predetermined Cylinder Bore Size

With / Without Guide

Calculate Load,

W≦Wmax

Calculate Kinetic Energy

E≦Emax

Without Guide

Selection of Autoswitch

Determination of Model

Calculate Momentum

Σan≦1

Selection of Shock Absorption Unit

Air Cushion

Stroke Adjustment Unit

5-2 Selecting Procedure

Follow the procedure below to select the most suitable ML2 series.

As allowable moment, maximum movable load, and allowable kinetic energy vary with the conditions,

such as mounting position, piston speed, and with / without guide, ①maximum movable load, ②static

moment, ③dynamic moment (during impact with stopper and locking), and ④allowable kinetic energy

should be considered so that the total amount of load factor will not exceed 1 (∑an≦1) when

calculating allowable load. (In the case of ∑an>1, select a cylinder with larger bore size.)

When positioning is necessary, maximum speed should be not more than 500mm/s.

Page 18

18

5-3 Selection Information

W

(N)

: Load

We

(N)

: Impact loading (during locking or knocking of stopper)

V

(m/s)

: Impact speed (during locking or knocking of stopper)

Va

(m/s)

: Average speed

L

(m)

: Distance from C.G. of load

M

(Nm)

: Maximum moment

E

(J)

: Kinetic energy of load

g

(m/s)

: Gravity acceleration (9.8m/s2)

<Piston speed>

V=1.4xVa

<Maximum load>

We=1.4xVaxWx10

<Maximum allowable moment>

M=

WexL

=5xVaxWxL

3

<Load factor>

an=

F

Fmax

F ^ : Calculated load

Fmax : Maximum allowable load under the condition of allowable speed

(value obtained from graph)

<Allowable kinetic energy>

Ek=

W

V2

2g

・Allowable moment and maximum load

Model

Allowable moment N.m

Maximum load N

M1

M2

M3

W1

W2

W3

W4

ML2B25

10.0

1.2

3.0

200.0

58.0

65.0

100.0

ML2B32

20.0

2.4

6.0

300.0

80.0

96.0

150.0

ML2B40

40.0

4.8

12.0

500.0

106.0

140.0

250.0

・Allowable kinetic energy

ML2B25

ML2B32

ML2B40

Allowable kinetic energy J

0.43

0.68

1.21

Moment (N.m)

L

1

F

1

L

2

F

2

L

3

F

3

M1=F1x L

1

M2=F2x L

2

M3=F3x L

3

Load (N)

W1

W2

W3

W4

Page 19

19

Max. Allowable Momentum

Select cylinder accordingly with refer to the graph

below. Its momentum should not over the specified

range. However, selected cylinder may have larger

loading value than specified max. load. Counter

check with loading condition.

Max. Load

Select cylinder accordingly with refer to the graph

below. Its load should not over than specified

range. However, selected cylinder may have larger

momentum value than specified max. momentum.

Counter check with momentum condition.

Moment N・m

Piston speed m/s

Moment N・m

Piston speed m/s

Piston speed m/s

Moment N・m

Load N

Piston speed m/s

Allowable kinetic energy

Load N

Piston speed m/s

Piston speed m/s

Load N

Load N

Load N

Piston speed m/s

Piston speed m/s

horizontal Mounting

Vertical Mounting

Page 20

20

5-4 Example of selection

Ⅰ. Without Guide

① Operating Conditions

Loading

Static Load

Dynamic Load

①

Side load due to W

W3

-

②

Moment due to W

M2

-

③

Moment due to we when stopping

-

M

3

V

④

〃

-

M

1

V

② Static Load <normal load>

① W3max=60Nm (Checked from graph with Va)

Load factor a1=

W3

=

15

=0.25

W3max

60

② M2max=2N・ m (Checked from graph with Va)

M2=Wx L1=15x0.05=0.725N・m

Load factor a2=

M2

=

0.75

=0.375

M2max

2

③ Dynamic load <load applied during stopping)

Impact Loading, We=1.4x10xVaxW=1.4x10x0.25x15=52.2N

③ M3max=3.5N・m (Checked with V=1.4xVa)

M3=WexL2x

1

=52.5x0.05x

1

=0.88N・m

3

3

Load factor a3=

M3

=

0.88

=0.25

M3max

3.5

④ M1max=12N・m (Checked with V=1.4xVa)

M1=WexL1x

1

=52.5x0.05x

1

=0.88N・m

3

3

Load factor a4=

M1

=

0.88

=0.073

M1max

12

④ Examination of load factor

an ① 0.25

②

0.375

③

0.25

④

0.073

∑an

0.948

Decision

OK from ∑an≦1

Model : ML2B32 Load : 15N

Speed , Va : 0.25m/s Pressure : 0.5MPa

L1 : 0.05m L2 : 0.05m

W

L

1

W

L

1

ML2B32 is selected.

Page 21

21

Model : ML2B25 Load : 30N

Speed , Va : 350mm/s Mounting position : wall

Ⅱ. With Guide

① Operating conditions

② Allowable kinetic energy

E max=0.43 (J)

V=Vax1.4=350x1.4=490mm/s

Ev=

W

xV2=

30

x0.492=0.36 (J)

2g

2x9.8

Load factor a5=

E = 0.36

=0.84

Emax

0.43

③ Examination of load factor

a5 = 0.84 ≦ 1 OK

With above allowable value, there is no problem on the selection.

∴ If values are in the range of graph in page 19, there is no

problem on the operating conditions.

W

ML2B25 is selected.

∴ The weight of table is considered as 0 in this case.

However, during actual operation, the weight of table

should be taken into consideration.

Page 22

22

Chapter 6: Specifications

6-1 Cylinder Specifications

Bore size

φ25

φ32

φ40

Fluid

Air

Operating method

Cylinder

Double acting type

Brake

Integrated pneumatic and spring

Operating pressure

range

Cylinder

0.1~0.8MPa

Brake

0.3~0.5MPa

Proof pressure

Cylinder

1.2MPa

Brake

0.75 MPa

Piston speed

100~1500mm/s (during positioning, 100~500mm/s)

Ambient and fluid temperature

5~50℃(No freezing)

Cushion

Both sides air cushion

Brake type

Integrated pneumatic and spring

Lubrication

Not required

Stroke tolerance mm

0~+1.8

Hardware

JIS B 0209

Port size

Front and side port

Rc1/8

Rc1/4

Bottom port

φ5

φ6

φ8

6-2 Sensor specifications

Cable

(Standard product with connector :

R04-R8M made by TAJIMI MUSEN DENKI CO.)

Max. transmission distance

20m (when using 6 core twist spare shield wire)

Position detection method

Magnetic scale rod, Detection head

(Incremental type)

Magnetic field resistance

14.5mT

Power supply

DC12V±10% (Power supply ripple : Less than 1%)

Current consumption

40mA

Resolution

0.1mm / pulse

Accuracy

±0.2mm (20℃) Note1)

Output method

Open collector (DC35V, 80mA)

Output signal

Phase A/B phase difference output

Max. response speed

500mm/s

Withstand voltage

AC500V, For one minute (Between case and 12E)

Insulation resistance

DC500V, 50MΩ (Between case and 12E)

Shock resistance

33.3Hz6.8G X,Y directions : For 2 hours, Z : 4 hours

In accordance with JIS D1061

Impact resistance

30G X,Y,Z directions : 3 times

Extension cable

(Option)

5m,10m,15m,20m

(Connector : R03-P8F made by TAJIMI MUSEN DENKI CO.)

Note1) Include digital error of the counter (CEU1,CEU5).

The accuracy as a whole unit after assembling to the device may vary depending on the mount

condition and environment. Please execute calibration of the device on customer ’s own

responsibility.

Page 23

23

Bore size

25 25mm

32 32mm

40 40mm

Control method

None

With brake and scale

S With scale only

B With brake only

No. of autoswitch

None 2

s 1

n n

No. of adjustment unit

None 2

S 1

L

Shock absorber + Adjust bolt

Stroke adjustment unit

Output method

None NPN open collector output

P PNP open collector output

Standard stroke

Standard stroke (mm)

25

32

40

1~2000

(It is possible to produce it at intervals of 1mm. )

Output method

None

NPN open collector

P

PNP open collector

Counter operating power supply

None

AC80~120V

D

DC24V±5%

Chapter 7: How to Order

7-1 Cylinder (Hyrodless Monosashi-kun)

ML2 B 25 ― 500 L - Z73

Option

Stroke adjustment unit Stroke adjustment unit

φ25

MY-A25L

φ25

MY-S25A

MY-S25B

φ32

MY-A32L

φ32

MY-S25A

MY-S25B

φ40

MY-A40L

φ40

MY-S32A

MY-S32B

7-2 Controller

CEU2

3 points preset counter

CEU1 -

Mounting

B Standard

Type of autoswitch

(See catalog)

Page 24

24

Stroke adjustment unit

None without adjustment unit

L Shock absorber + adjust bolt

Bracket

None One side only

W Both sides bracket

Z

The one for X417

is

No. of stroke adjustment unit

None 2

S 1

Length of cable

05 5m

10 10m

15 15m

20 20m

Additional symbol

None Extension cable

C Extensin cable + Connector

7-3 Extension cable

CE1-R

Connection of connector

Contact

A B C, D

E F G

Color of wire

White

Yellow

Brown, Blue

Red

Black

(Shield)

7-4 Specifications of Made to order ML2B

[Holder mounting bracket : ① ②]

Holder mounting bracket ① : -X416

Holder mounting bracket ② : -X417

Stroke fine adjustment range

Holder mounting bracket

X416

X417

Length of spacer

L (mm)

ML2B25

11.5

23

ML2B32

12

24

ML2B40

16

32

Stroke fine

adjustment range

(mm)

ML2B25

per one side

-11.5~-23

-23~-34.5

Both sides

-23~-46

-46~-69

ML2B32

per one side

-12~-24

-24~-36

Both sides

-24~-48

-48~-72

ML2B40

per one side

-16~-32

-32~-48

Both sides

-32~-64

-64~-96

How to order

1) When ordering stroke adjustment unit integrated into cylinder body.

ML2B25― 300 L - X416 Z

Note)This stroke shows

the stroke before

mounting stroke

adjustment unit.

Symbol of holder mounting bracket

X416

X417

Page 25

25

2) When ordering stroke adjustment unit only.

Add “X416” and “X417” at the end of part No. of unit.

Ex. MY-A25L-X416

3) When ordering holder mounting bracket only.

Add “N” at the end of part No. of unit.

Ex. MY-A25L-X416N

Page 26

26

Chapter 8: External Dimension Drawing

8-1 Hyrodless Monosashi-kun (with brake, scale)

Page 27

27

8-2 With scale

Page 28

28

8-3 With brake

Page 29

29

8-4 With shock absorber

Page 30

30

8-5 With stroke adjustment unit, X416

Page 31

31

8-6 With stroke adjustment unit, X417

Page 32

32

Chapter 9: Construction / Parts list

Page 33

33

Chapter 10: Cushion Capacity

10-1 Selection of cushion

<Air cushion>

Standard Hyrodless Monosashi-kun is equipped with an air cushion.

Air cushion is installed not to operate piston at low speed when piston approaches to stroke end, but

to avoid shock when piston with large kinetic energy stops at stroke end. The range of load and speed

absorbed by air cushion is within the limit line of air cushion in graph.

<Stroke adjustment unit with shock absorber>

This is used on the occasion when operating with load and speed of over the limit line of air cushion or

when cushion is needed out of the air cushion stroke range due to stroke adjustment.

<L-Unit>

This is used on the occasion when cushion is needed out of the air cushion stroke range although

load and speed are within the limit line of air cushion or when operating with the range of load and

speed of over the air cushion limit line and below the unit limit line.

<Note>

① Absorbing capacity of unit is for the occasion when all stroke of equipped shock absorber is used.

When effective stroke becomes shorter due to stroke adjustment, absorbing capacity becomes

extremely small. Therefore, fix adjustment bolt to project 0.5mm above shock absorber.

② When shock absorber is used in the range of air cushion stroke, air cushion needle shall be

almost full opened (about one and a half turn from the position of full close.)

Air cushion stroke

Unit : mm

Bore size (mm)

Cushion stroke

φ25

15

φ32

19

φ40

24

Shock absorber

Adjustment bolt

Page 34

34

10-2 Absorbing capacity of air cushion and stroke adjustment unit

Stroke adjustment unit with shock absorber

Calculation of absorbing energy

Type of collision

Horizontal collision

Vertical collision

(descent)

Vertical collision

(ascent)

Kinetic energy E1

1

m・v2

2

Thrust energy E2

F・s

F・s + m・g・s

F・s - m・g・s

Absorption energy E

E1 + E2

V: Speed of load (m/s) m: Weight of load (kg) F: Thrust of cylinder (N)

g: Gravitational acceleration (9.8m/s) s: Stroke of shock absorber (m)

Note) Speed of load is the speed of the moment when load collides with shock absorber.

Torque for bolt unit : N.m

Bore size (mm) Torque

25 3

32 5

40 10

Stroke adjustment unit lock plate

Torque for bolt unit : N.m

Bore size (mm) Torque

25 1.2

32 3.3

40 3.3

Stroke adjustment unit

Page 35

35

10-2 Adjusting Method

<Travel and fix of unit body>

Unit body can be traveled by loosening 4 pieces of bolt. Unit body can be fixed by tightening unit

body evenly with 4 pieces of bolt at the specific position. The position, however, may got out of the

position depending on the energy size for collision. Mounting brackets for adjusting holder are

provided for –X416 and –X417. For the length of your request other than that, please consult with

us separately. (See bolt torque for fixing stroke adjusting unit.)

<Stroke adjustment of adjusting bolt>

Loosen lock nut for adjusting bolt and fix with lock nut after adjusting stroke with wrench from lock plate

side.

<Stroke adjustment of shock absorber>

After adjusting stroke by loosening two pieces of lock plate fixing bolt to turn shock absorber, fix shock

absorber by tightening lock plate fixing bolt evenly. On this occasion, care shall be taken so that bolts are

not tightened too much. (Please refer to torque for stroke adjustment unit lock plate bolt.)

Note) Although there are some cases where a little bend will be caused on lock plate due to tightening of

lock plate bolt, it does not affect on shock absorber and locking function.

Page 36

36

Chapter 11: Stopping Operation

11-1 Overrun (ML2 + Sequence controller)

The graph below shows the relation between piston speed and overrun.

(The length of overrun is changed by piston speed, load, tubing condition and control method. Be sure to

adjust the stop signal position, etc. by trial operation with the actual machine.)

11-2 Dispersion of stopping position

When cylinder is stopped intermediately, the stopping position is not fixed.

Dispersion of stopping position is changed by piston speed, load, tubing condition and control method,

etc. Please refer to the table below.

ML2 + Sequence controller

Piston speed

just

before stop

mm/s

100

300

500

800

1000

Stopping accuracy

mm

±0.5

±1.0

±2.0

±3.0

±4.0

ML2 + CEU2

Piston speed just

before stop

mm/s

500mm/s

Stopping accuracy

mm

±0.5

Start

Stop signal

Stop position

Idle

running

distance

Stop distance

(run)

(overrun)

Braking

distance

When cylinder is stopped intermediately, “idle running distance”

(from detection of stop signal to

beginning of brake operation)

and “braking distance “(from beginning

of brake operation to slider stop) are

occurred as shown in the figure left.

0.5

1.0

Piston speed just before stop m/s

No load

Load factor 50%

100

50

The length of

overrun

mm

Operating pressure 0.5MPa

Brake releasing pressure 0.3MPa

Mounting position Horizontal

Conditions

Operating pressure 0.5MPa

Brake releasing pressure 0.3MPa

Load factor 25%

Page 37

37

Chapter 12: Manual Operating Procedure

[Brake release]

①Supply brake releasing pressure of 0.3~0.5MPa from brake releasing port on slider side.

②Thread bolt into manual port on slider side.

③Exhaust brake releasing air.

[Brake operation]

①Supply brake releasing pressure of 0.3~0.5MPa from brake releasing port on slider side.

②Remove bolt threaded into manual port.

③Exhaust brake releasing air.

Bolt for manual release

ML2B25

M5×0.8

L=8

ML2B32

M6×1

L=10

ML2B40

M8×1.25

L=12

Page 38

38

Chapter 13: Installation & Wiring

13-1 Installation of Cylinder

1. It should be installed at high flatness surface. For uneven surface. Shim adjustment should be done

to achieve smooth operation of slider with a minimum operating pressure of 0.1MPa.

2. Installed with utilizing both sides head cover. Do not fix cylinder’s position through slider, as shown

in diagram (a). With overloading the bearing, operation error occurs.

Besides that, for the case of single sided fixing method (as refer in diagram (b), consultancy should

be made, due to bending of tube may occur and thus, lead to the occurs of operation error.

(a) Fixing through Slide (b) Single side’s Fixing

There are 2 ways, as shown in diagram below, to fix cylinder’s position.

Utilizing the installation method, with the consideration of mounting surface and situation.

(Side support, option, should be used for support purposes only.)

(c) Fastening through Upper Surface (d) Fastening through Lower Surface

3. With loading within allowable range of Hyrodless Monosashi-kun, supporting structure (LM Guide)

is still necessary to be installed as a support for the applied loading. Besides that, for the case of

long stroke, floating structure design should be brought in to overcome misalignment problem.

4. Cylinder has to be covered when it is used at environment that has chips, dust, oil mist and etc.

5. Be aware of not to harm (dented marks and etc.) the outer surface of cylinder tube, which will lead

to the damage of bearing and scraper. Consequently, disoperation will occur. Besies that, be aware

of not to apply too much of impact and momentum upon slider as slider is only supported by plastic

made bearing.

6. Do not apply load onto brake and scale plate, its bending will lead to operation error. Once, brake

and scale plate have been adjusted during installation state. Re-adjustment is not required and

should be advoided.

Page 39

39

Note:Grease used are lithium based grease with concentration class 1 or 2.

・Hyrodless Monosashi-kun uses magnetic sensor to detect position. Therefore, if strong magnetic field

appears nearby, operation error will occur.

Surrounding magnetic field should be below than 14.5mT.

Note: 14.5mT magnetic field will be just as the same as the resulted magnet field from 15,000A welding

current’s welding machine (within 18cm). To prevent from the effect of magnetic field, sensor should

be covered by magnetic material.

・Prevent sensor unit from contacting with water, oil and etc.

・Do not install Hyrodless Monosashi-kun near to motor, welding machine, and others facility which will

produce noise, which will cause counter malfunction.

Besides that, separate the power line from others.

The longest transmission distance for Hyrodless Monosashi-kun is 20m. Wiring above than the figure,

should be taken noted at.

Page 40

40

13-2 Electrical Wiring

Output method

Output signal of Hyrodless Monosashi-kun is phase difference output of A phase / B phase (open

collector output) as shown in the figure below.

1 pulse signal is sent to both output terminals A and B at every 0.1mm travel of Hyrodless

Monosahi-kun.

Also maximum response time of sensor for Hyrodless Monosashi-kun is maximum 1500 mm/sec

(15Kcps) in cylinder speed.

Input / Output

Input / Output of Hyrodless Monosashi-kun is performed by connector came from sensor.

Signal

Symbol of contact

Signal

A

A phase

B

B phase

C,D

COM (0V)

E

12V (Power supply)

F

0V (Power supply)

G

GND (Shield)

Reversed cylinder travelling direction

13432

Counter value

012

0.7

Cylinder

stroke mm

A phase output

pulse

B phase output

pulse

0.0

0.1

0.2

0.3

0.4

0.5

0.6

A phase

(white)

B phase

(yellow)

COM (0V)

(brown, blue)

Output circuit of Hyrodless Monosashi-kun

Page 41

41

13-3 Connection of Extension Cable

Use specified (SMC) extension cable. Cable length is 5m – 20m with interval of 5m. For the distance of

more than 20m, use specified transmission box (Model No.: CE1-H0374).

*Example of cable connection

*Note

①Clamp and fix the connector and sensor connection to reduce tension acting on them.

②Separate cable with power line or other lines which make noise.

③When cable is necessary to have U-shaped bend, set the bending radius to be above 25mm.

Bending performance: According to the drawing shown below, life span about 4 million cycle can

be achieved.

Extension cable

(CE1-R※※)

R25

Reciprocating with

bending speed 100times/min.

200mm

More than 20m

Receiving

Transmitter

Box

Receiver

Box

Sending

Less than 5m

100m

Less than 20m

Twisted pair shield wire

CE1-H0374

Page 42

42

Loading...

Loading...