Page 1

Page 2

MENTOR 12 USER’S MANUAL SECTION 1: PRODUCT INTRODUCTION – Page 2

MENTOR 12 USER’S MANUAL

REFERENCE: JAAVMV02

VERSION 1 – NOVEMBER 2006 – COPYRIGHT EUROSMC, S.A.

ALL RIGHTS RESERVED.

DISCLAIMER The information contained in this document is intended only to describe the

product MENTOR 12 and its operation. This document has no contractual

contents and implies no warranty about the product’s specifications.

EuroSMC, S.A. claims the right to change the characteristics of the product and

the contents of this document with no previous announcement.

The user of the product is the only responsible of any consequences from the use

of the product for the purposes described or not in this document.

EuroSMC, S.A. explicitly exonerate themselves from the responsibility of any

errors accidentally made in this document.

Copying, reproducing or in any other way publishing this document in whole or in

part is prohibited without written authorization from EuroSMC, S.A.

The only official version of this document is the version written in Spanish

language

Page 3

Page 4

MENTOR 12 USER’S MANUAL SECTION 1: PRODUCT INTRODUCTION – Page 4

INDEX

Safety considerations....................................................................................8

Package’s contents.......................................................................................9

Handling the Mentor 12...............................................................................10

Transport case........................................................................................10

Working position.....................................................................................11

Product description .....................................................................................11

Start-up process..........................................................................................12

Start-up process..........................................................................................13

Initial check .................................................................................................15

Quick Start ..................................................................................................17

Power output control and regulation.......................................................17

Monitoring the binary input.....................................................................18

Binary output control...............................................................................18

Battery simulator setup and control........................................................19

Measuring external quantities.................................................................20

SECTION 2: BASIC CONTROL 21

Introduction .................................................................................................21

Description of source controls.....................................................................23

Selection of an output value........................................................................24

Selection of one single source (INDEPENDENT mode) ........................25

Page 5

MENTOR 12 USER’S MANUAL SECTION 1: PRODUCT INTRODUCTION – Page 5

Simultaneous selection in several sources (SELECTED mode)............25

Selection when there are more than 3 available sources. ZOOM key. ..26

Application and Use of the function and help keys .....................................26

“Select all” key........................................................................................27

“Reset Values” key.................................................................................27

“Rotate” key............................................................................................28

“Save” and “Rest.” keys..........................................................................28

“Config. Status 2” and “Status 2” keys........................................................30

Measurement Window ................................................................................32

Configure times...........................................................................................33

TIMER START conditions ......................................................................34

TIMER STOP conditions ........................................................................36

TIMER Activation....................................................................................36

TIME DELAY..........................................................................................37

Configure measurements............................................................................38

System alarms ............................................................................................41

Battery Simulator.........................................................................................43

Logger.........................................................................................................44

SECTION 3: ADVANCED CONTROL 45

Introduction .................................................................................................45

FAULT Function..........................................................................................49

Page 6

MENTOR 12 USER’S MANUAL SECTION 1: PRODUCT INTRODUCTION – Page 6

Configuration..........................................................................................53

Execution................................................................................................54

RAMP Function...........................................................................................57

Configuration..........................................................................................58

Execution................................................................................................63

PULSE RAMP function ...............................................................................65

Configuration..........................................................................................66

Execution................................................................................................71

BINARY SEARCH Function........................................................................73

Configuration..........................................................................................75

Execution................................................................................................79

STATE SEQUENCER function...................................................................81

Configuration..........................................................................................82

Execution................................................................................................84

SECTION 4: CONFIGURATION 87

Introduction .................................................................................................87

Common Configuration Operations.............................................................88

Analog Outputs ...........................................................................................89

Power Outputs. Definitions.....................................................................90

Usage Procedure....................................................................................91

Power Output Configuration...................................................................92

Configuration of the Low Level Outputs .................................................92

Page 7

MENTOR 12 USER’S MANUAL SECTION 1: PRODUCT INTRODUCTION – Page 7

Binary Outputs ............................................................................................94

Definitions...............................................................................................94

Usage Procedure....................................................................................95

Binary Inputs...............................................................................................96

Definitions...............................................................................................96

Usage Procedure....................................................................................97

Miscellaneous .............................................................................................99

Definitions and Use ..............................................................................100

Maintenance..............................................................................................103

Definitions and Use ..............................................................................103

Page 8

MENTOR 12 USER’S MANUAL SECTION 1: PRODUCT INTRODUCTION – Page 8

Safety considerations

Do not operate this product before carefully reading and understanding this manual, especially the safety

warnings and recommendations. The use of this equipment is reserved to trained personnel only.

DANGER: Never try to use a Mentor 12 that looks damaged, dirty or incomplete. Connecting the unit to a power supply with any

or all of its case’s faces removed is extremely dangerous.

DANGER: If you notice lack of response from the control panel, switch the unit off immediately and refer to technical service.

Otherwise, the power outputs could be left inadvertently activated.

DANGER: Harmful voltage can build up at the u nit’s output connectors. Keep this in mind when handling the test leads and other

devices connected to them. Never introduce a non-isolated conductive tool or instrument into the unit’s connectors while the unit is

powered on or connected to the power supply.

CAUTION: Turn the unit ON before cabling anything to the connection’s board. Most input and output connectors in this board are

dynamic and feature self-protecting mechanisms that work only in if the Mentor 12 is powered on. Internal dama ge may result from

connecting the unit to wrong points when it is powered OFF.

CAUTION: Ensure that your power supply’s characteristics match the product’s supply requirements (voltage 100-260 Vac and

frequency 45-65 Hz) before connection. Use only the supplied power cord to an AC outlet that includes a good EARTH connection.

CAUTION: The equipment should only be serviced after adequate anti-static measures and procedures have been carried out.

WARNING: Keep the ventilation holes clear from any obstruction to avoid over-heating.

WARNING: Use only your finger or a soft pointer to operate th e touch panel. Avoid excessive pressures on the touch panel. A

subtle touch should immediately activate the desired action. Do not use abrasive or alcohol-based substances to clean the touch

panel. Use only a soft, lint-free tissue or a special cleaning product for touch panels.

Page 9

MENTOR 12 USER’S MANUAL SECTION 1: PRODUCT INTRODUCTION – Page 9

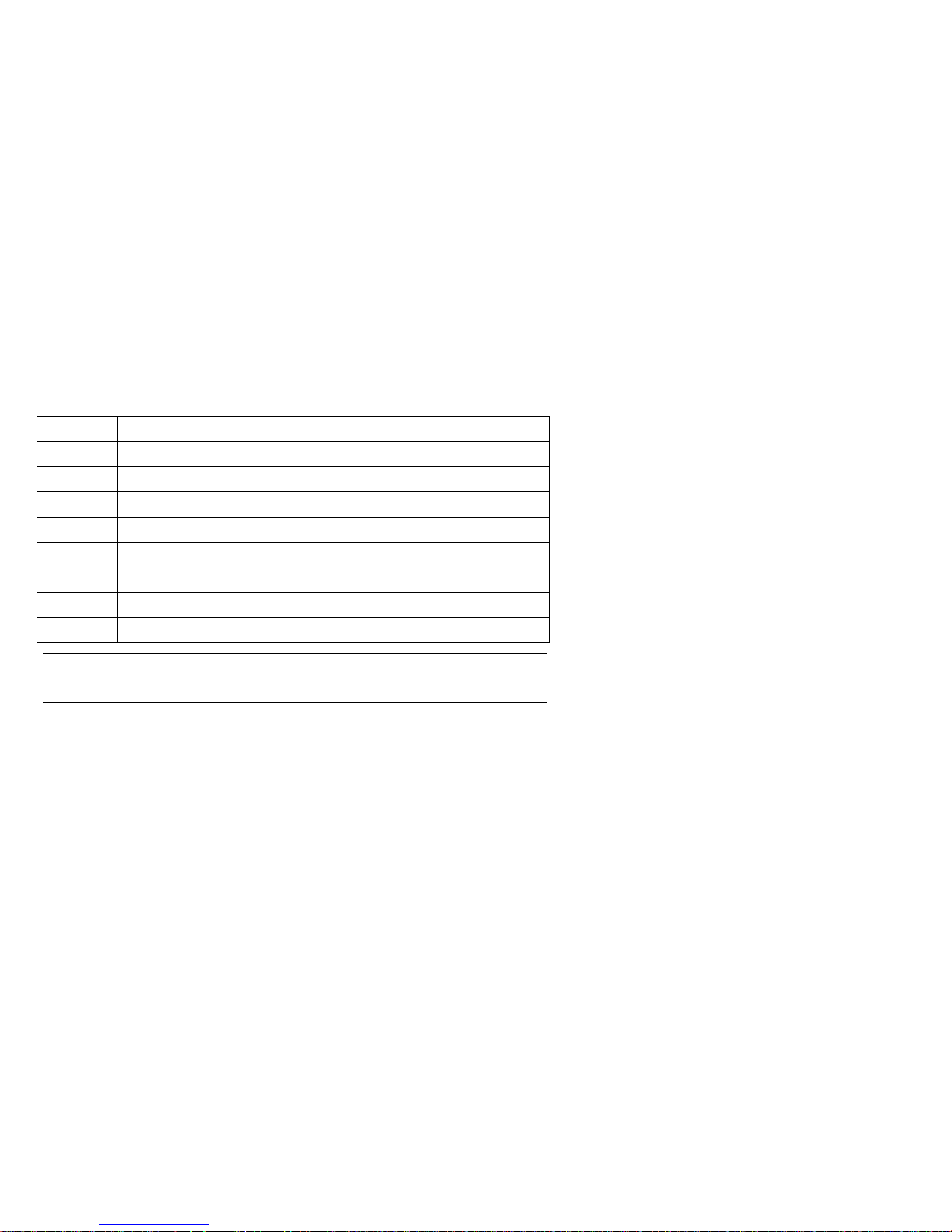

Package’s contents

Quantity Description

1 Mentor 12 unit, with variable power output channel configuration

1 Power Cord

1 Set of test leads in a nylon bag

1 Twisted-pair ETHERNET LAN cable

1 External mouse / keyboard PS/2 cord

1 User’s documentation

1 Certificate of calibration

1 Transportation hard case with wheels

NOTE: Contents may differ from the product’s standard packaging when

ordered with custom-specific options. If this is the case, refer to the

packing list included in the product’s shipping documentation.

Page 10

MENTOR 12 USER’S MANUAL SECTION 1: PRODUCT INTRODUCTION – Page 10

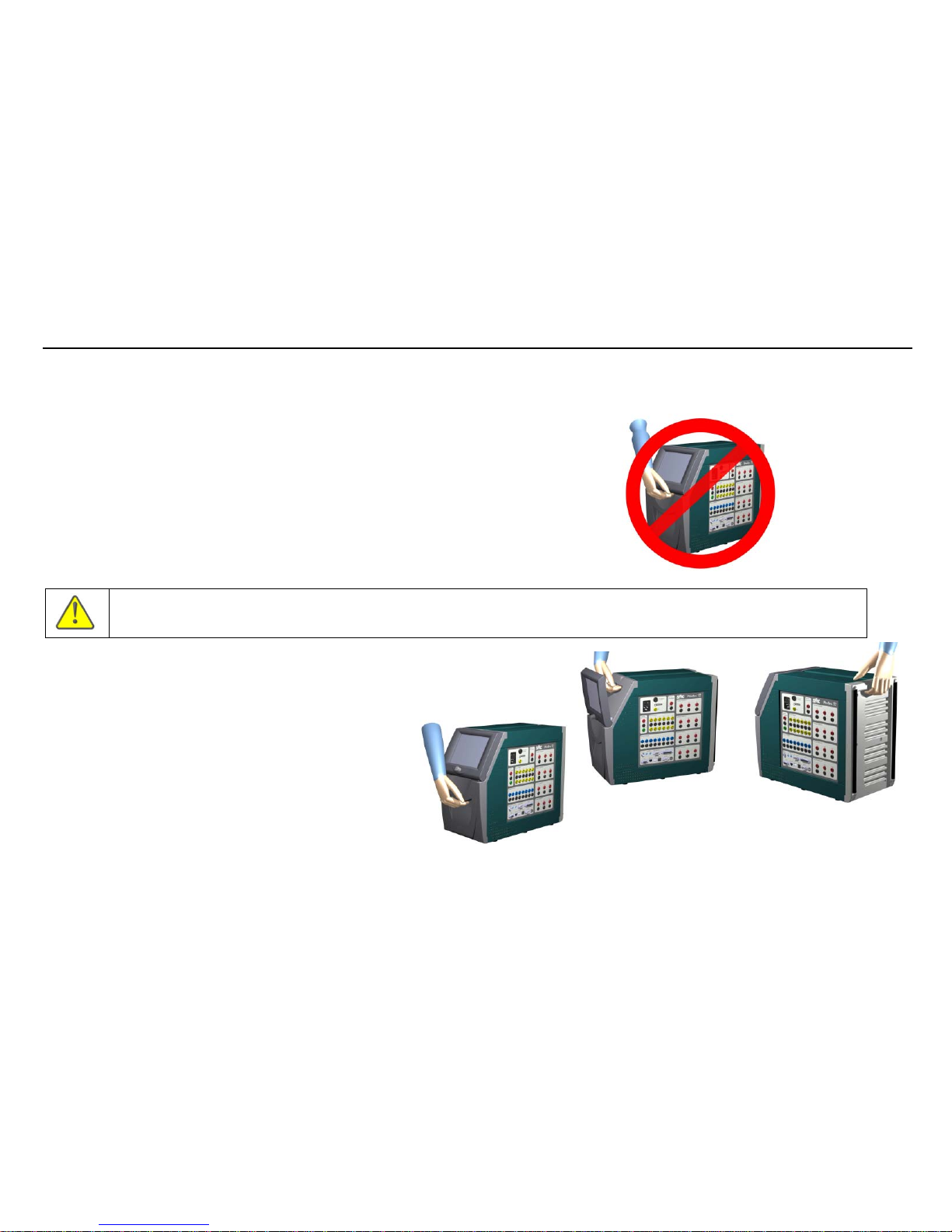

Handling the Mentor 12

The Mentor 12 has been designed with ergonomics in mind to provide a safe,

convenient and reliable operation.

Transport case

Use always the supplied transport case for long displacements. This will save you

useless efforts and will avoid accidental damages to the unit. The transport case

features wheels and an extensible handle for your convenience.

Rest the case flat on the ground before opening it.

CAUTION: Do not grab the unit by the touch panel. Slide one hand into the slot underneath the touch panel and grab the back of

the unit with the other hand to lift the unit off the case onto the working surface. Another slot can be found behind the touch panel.

The test leads are packaged in a nylon bag inside the transport case. Re-package them

always when you finish working.

Stick FRAGILE labels on the transport case for long distance shipment.

Avoid strong impact and vibration to the unit even when kept in

the transport case.

Use always the transport case and include all the accessories

when sending the unit for servicing or calibration.

Page 11

MENTOR 12 USER’S MANUAL SECTION 1: PRODUCT INTRODUCTION – Page 11

Working position

The Mentor 12 can stand up in two positions to better adapt to your work environment.

Both ways take up very little from your working surface. The standard position is

designed for a tabletop. Normally, you will not need to make any adjustment in the

touch panel orientation when using this position. Ventilation to the unit and access to

the connections are optimal in this position.

If you prefer to lay the Mentor 12 on the floor, stand it over the back side, where the

ventilation holes are found. Ensure that the surface is flat, hard and clean. Do not

operate the unit on soft carpets, cushioned or similar types of surface that can block the

normal ventilation air flow. Sand or excessive dust can get into the unit and cause

serious ventilation problems in the long term. You will need to adjust the touch panel’s

orientation when using the Mentor 12 in this position.

Product description

The Mentor 12 has been designed to make relay testing as easy, safe and efficient as

possible. The built-in computer eliminates the need of buying, carrying, connecting and

maintaining an external PC. This approach provides also stronger security against

operation mistakes and viruses. Yet, the Mentor 12 takes advantage of the best things

that are now common in the personal computing world: Plug & Play, graphical interface,

USB compatibility and access to the Internet, to say a few.

Page 12

MENTOR 12 USER’S MANUAL SECTION 1: PRODUCT INTRODUCTION – Page 12

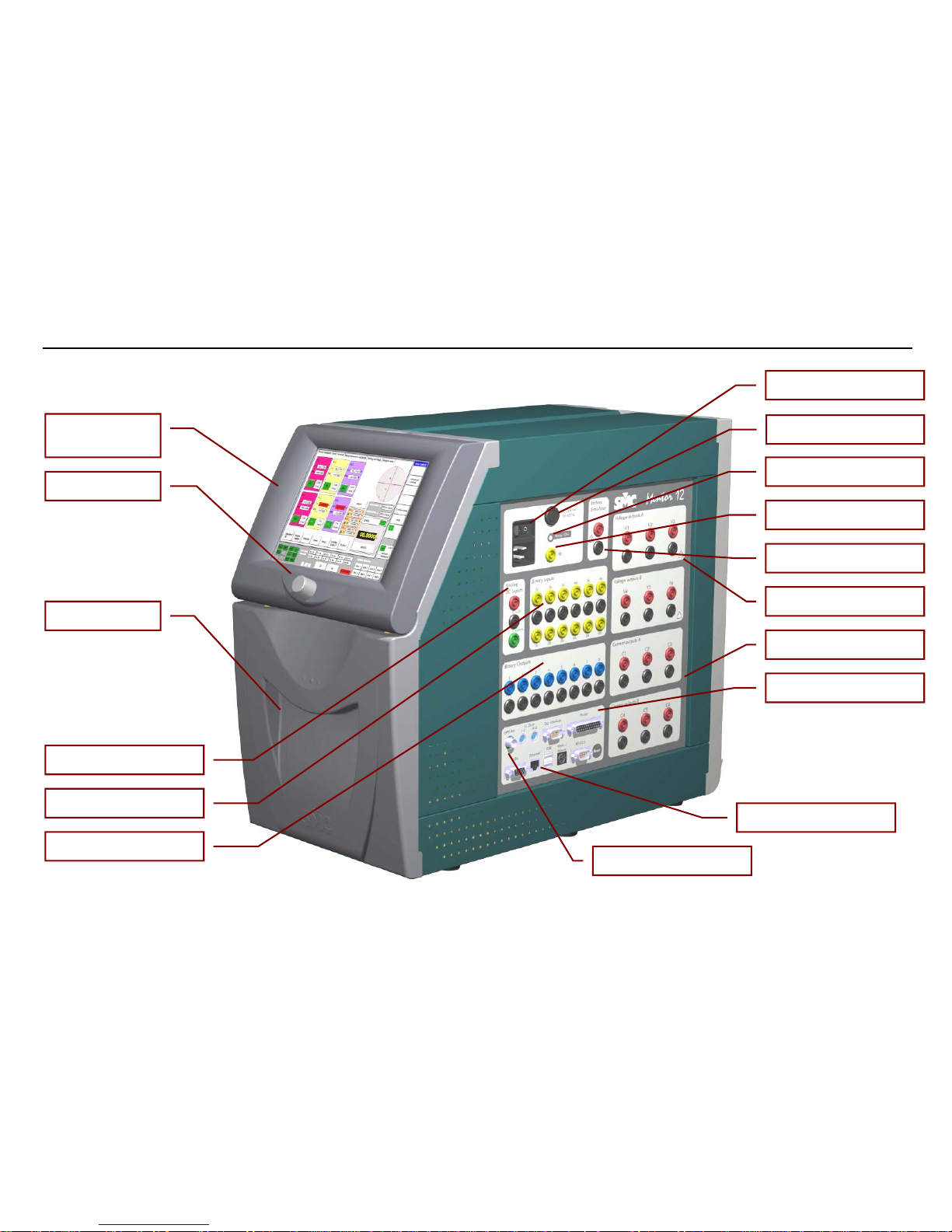

Touch Screen TFT

panel (swivel)

Adjustment knob

Handle

Main FUSE

BATTERY simulator

Power VOLTAGE outputs

Power CURRENT outputs

COMMUNICATIONS set

GPS antenna plug

Analogue MEASUREMENT

BINARY INPUT

BINARY OUTPUT

ETHERNET RJ-45 plug

GROUND connector

Power STATUS LED

Main ON/OFF switch

Page 13

MENTOR 12 USER’S MANUAL SECTION 1: PRODUCT INTRODUCTION – Page 13

Start-up process

Before connecting any other device to the connections panel, plug the Mentor 12 in to a

suitable AC supply using the supplied AC cord and switch the unit ON. Various start-up

screenshots will be displayed, with the TFT panel going occasionally black for a short

while: this is normal. The start up process takes less than 2 minutes and includes:

• General hardware check

• Embedded PC start up test & initialization

• Specific hardware check

• Mentor Application start up

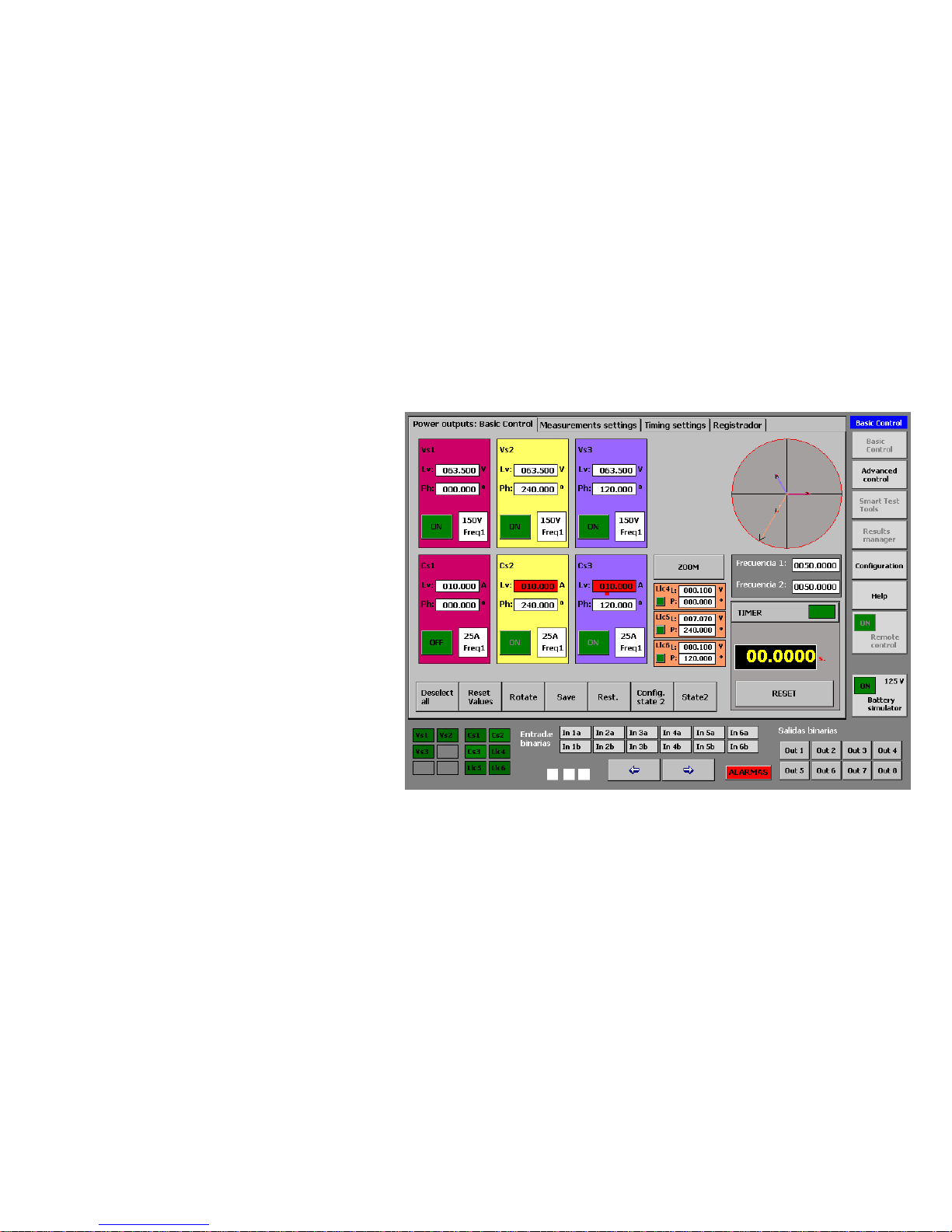

Upon completion of the start up process, the Basic Control screen will give you a

general glance of the standard Mentor 12’s characteristics:

CAUTION: Ensure that your power supply’s characteristics match the product’s supply requirements (voltage 100-260 Vac and

frequency 45-65 Hz) before connection. Use only the supplied power cord to an AC outlet that includes a good EARTH connection.

Page 14

MENTOR 12 USER’S MANUAL SECTION 1: PRODUCT INTRODUCTION – Page 14

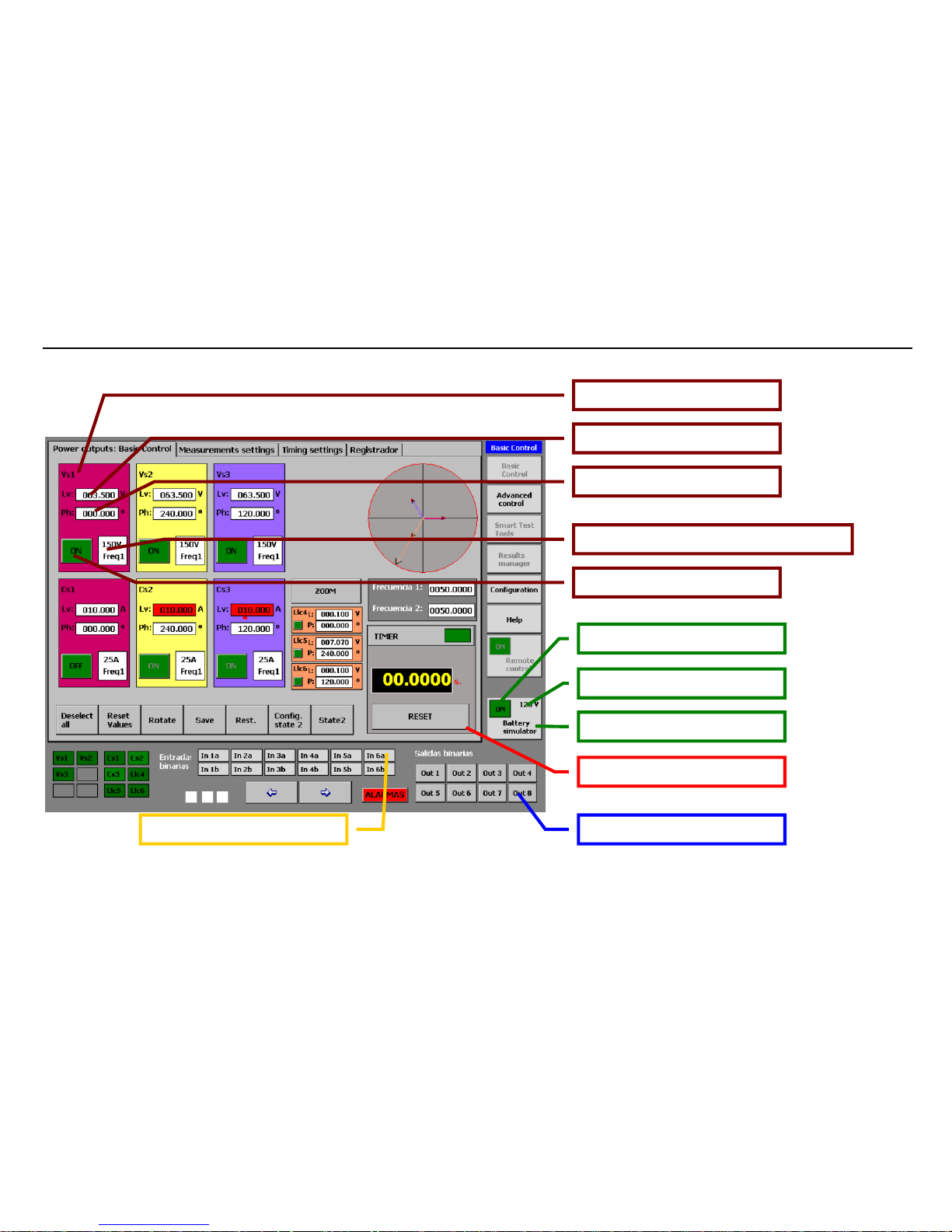

Output source selection area

Output source phase angle

Out

p

ut source level display

Output source level range & frequency bus

Output source ON/OFF

Battery Simulator setup area

Measurements window

Binar

y

Output ON/OFF buttons

Batter

y

Simulator DC setting

Batter

y

Simulator ON/OFF

Binary Input Monitorin

g

Page 15

MENTOR 12 USER’S MANUAL SECTION 1: PRODUCT INTRODUCTION – Page 15

You can now proceed to set up the control and power requirement s for you r test, and to

carry out the appropriate connections to the tested object (relay, IED, transducer, etc.).

You will find detailed directions how to configure the Mentor 12’s power and control

logic in the Configuration section in this manual.

When you finish your work, proceed to disconnect the test leads from the Mentor 12

first, then from the test objects. In this way you will prevent any voltage from

accidentally touching the surrounding objects or yourself.

You can then turn the unit off directly. No software shutdown procedure is required.

Initial check

We recommend you to carry out a general check on your particular unit, in order to

confirm that it has been configured properly according to your specifications. This will

take you less than 5 minutes:

NOTE: The procedures below assume that the Mentor 12 is in its initial

power-on state, i.e., no changes have been made to the default

factory settings.

• OUTPUT AMPLIFIERS CONFIGURATION: The initial factory-defined layout

shows three voltage sources at the upper half and three current sources at

the lower half of the Basic Control screen. Their default presets are: 63.5 V

for the voltage sources, 1 A for the current sources and 0º-240º-120º for the

angles.

Power sources are represented by colored (red, yellow, blue) rectangles

labelled Vs# for voltage and Cs# for current.

DANGER: Harmful voltage can build up at the u nit’s output connectors. Keep this in mind when handling the test leads and other

devices connected to them. Never introduce a non-isolated conductive tool or instrument into the unit’s connectors while the unit is

powered on or connected to the power supply.

Page 16

MENTOR 12 USER’S MANUAL SECTION 1: PRODUCT INTRODUCTION – Page 16

However, this basic layout does not represent the maximum output

capabilities of your Mentor 12. By means of the Configuration menu, you can

add the following to the standard power layout:

a) any combination of up to SIX current-mode or voltage-mode LOW

LEVEL SOURCES, regardless to the number of power channels that

you have ordered, or

b) any combination of up to SIX sources taken from the standard lowlevel outputs and from any number of additional voltage or current

AMPLIFIERS that you may have purchased with you Mentor 12.

Please refer to the Configuration section in this manual to find out how to

locate, set up and include all your available output resources into the effective

power layout of your particular unit.

• FREQUENCY: Each power source is attached to any of two frequency buses,

Freq1 being the default assignment. Actual frequency bus #1 and #2 settings

are displayed and adjusted at a small window next to the sources section,

underneath the phasorial power system representation. Be sure that the

frequency bus(es) you are using match the electrical characteristics of the

system that you are testing.

Any change made to a frequency bus is automatically taken by all the sources

attached to it.

• ALARMS: The ALARMS indicator should be alwa ys dim (grey) after power-

on. Otherwise, touch the indicator to bring the alarm details up and refer to

the corresponding section in this manual for information on alarm

interpretation, possible causes and solutions.

• BATTERY SIMULATOR: The pre-adjusted DC voltage is shown in the

corresponding rectangle on the lower right. Touch and hold on the Battery

Simulator label to select a different voltage level if required.

Page 17

MENTOR 12 USER’S MANUAL SECTION 1: PRODUCT INTRODUCTION – Page 17

Quick Start

You can quickly become familiar with your Mentor 12 by conducting a simple routine

through some basic manual operation functions:

• TFT panel operation

• Power output and regulation

• Binary input and output ports

• Battery simulator

• Analogue external measurement

To accomplish this, you will need at least the following materials:

• Multimeter

• One pair of test leads

Power output control and regulation

Choose one of the available current channels and try the following:

1. Adjust all the current channels to zero and be sure that the output is OFF.

2. Set up your meter and connect its current measurement input to the output

connector of a current channel.

3. Select the channel in the touch screen and turn the regulation knob gently

clockwise while you observe the meter’s display. Compare this display with

the regulated value of that channel in the Mentor 12.

Page 18

M TEN R SECTION 1: PRODUCT INTRODUCTION – Page 18 O 12 USER’S MANUAL

4. At a certain point, check the output control by touching the channel’s OFF

button in the Mentor 12 and then back ON. While you do this, check that the

meter’s output goes to zero and back to the adjusted quantity

correspondingly.

5. Turn the channel’s output OFF by touching its OFF button in the touch panel.

Now, set up your meter for voltage measurement and repeat the above procedure for

the voltage channels.

Monitoring the binary input

The Mentor 12 is permanently monitoring the presence / absence of contact or voltage

signal at its binary inputs. You can experience this easily:

1. Take one test lead and connect one end to the black connector between the

“1a” and “1b” yellow connectors in the Binary Inputs pad of the connections

board.

2. Connect the free end of the test lead to “1a”. The corresponding indicator

labelled “1a in” in the lower section of the Basic Control screen should lit in

yellow.

3. Move the same end of the test lead to “1b ”. The “1b in” indicator should lit in

yellow now.

Binary output control

Set up your meter for continuity testing, so it will beep when you short its test leads.

Now, perform the following steps:

1. Connect the meter’s leads between the black and blue connectors of binary

output 1 in the Binary Outputs pad of the connections board.

Page 19

MENTOR 12 USER’S MANUAL SECTION 1: PRODUCT INTRODUCTION – Page 19

2. Touch the Out 1 button of the Binary Output pad in the lower right corner of

the touch panel. The meter should beep until you touch the button again to

deactivate the output.

IMPORTANT: Instead of using the meter, you may want to connect the binary

output to a binary input as described in the previous procedure. In

this case, you will get a visual feedback in the touch panel rather

than a sound signal from the meter.

Battery simulator setup and control

The procedure here is similar to checking the voltage power outputs described at the

beginning of this chapter. However, rather than regulation, you can select the battery

simulator’s DC output voltage from a set of predefined values in the range of 0-250 Vdc.

Set up your meter for DC measurement, connect its leads to the Battery Simulator pad

in the connections board, and do the following:

1. Touch the ON button in the Battery Simulator pad at the bottom right corner of

the touch panel and check that the voltage displayed there is now being

measured by the meter.

2. Switch to a different DC value by touching the Battery Simulator pad (not the

ON/OFF button) for a few seconds and selecting from the emerging window.

When you do this, the battery simulator’s output is automatically stopped, so

you should see zero in your meter’s display now.

3. Repeat steps 1 and 2 if you want to check other available DC output values in

the battery simulator.

Page 20

MENTOR 12 USER’S MANUAL SECTION 1: PRODUCT INTRODUCTION – Page 20

Measuring external quantities

Unless you also have an external source of electrical quantities, you can use the lowlevel signal generation and regulation resources in your Mentor 12 to accomplish this

practice:

1. Ensure that all the power sources (voltage and current) are set to zero level

and the output control is switched OFF.

2. Plug one of the supplied multi-lead adapters into one of the connectors

labelled LL Outs 1-3 or 1-6 at the lower left section of the connections board.

3. Choose one red / black pair of bananas at the free end of the adapter and

plug them into the red / black connectors at the Analog DC Inputs pad.

4. Set the measurements window in the Basic Control screen to External

Measurement mode by touching the measurem ent readings as many times

as necessary.

5. Configure the connected low level output as a source using the Configuration

menus.

6. Select the added low level source in the Basic Control screen and turn the

adjustment knob while you watch the readings changing at the Measurements

window. Values at this window and at the source’s pad should match if you

have set a 1:1 ratio for the low-level source configuration.

Page 21

SECTION 2: BASIC CONTROL

Introduction

The section called Basic Control refers to the control of the

equipment in an entirely manual mode. It has different

controls for total control over all its functions. It is also the

default home screen for Mentor 12, once the system has

been booted. This section includes a detailed explanation of

the operating mode of the different Mentor 12 controls, which

is common for all its screens. This operating mode will not

be described in the sections corresponding to these

functions, as it will be taken for granted that the procedure is

already known, so it is very important to carefully read this

section.

Page 22

MENTOR 12 USER’S MANUAL SECTION 2: BASIC CONTROL – Page 22

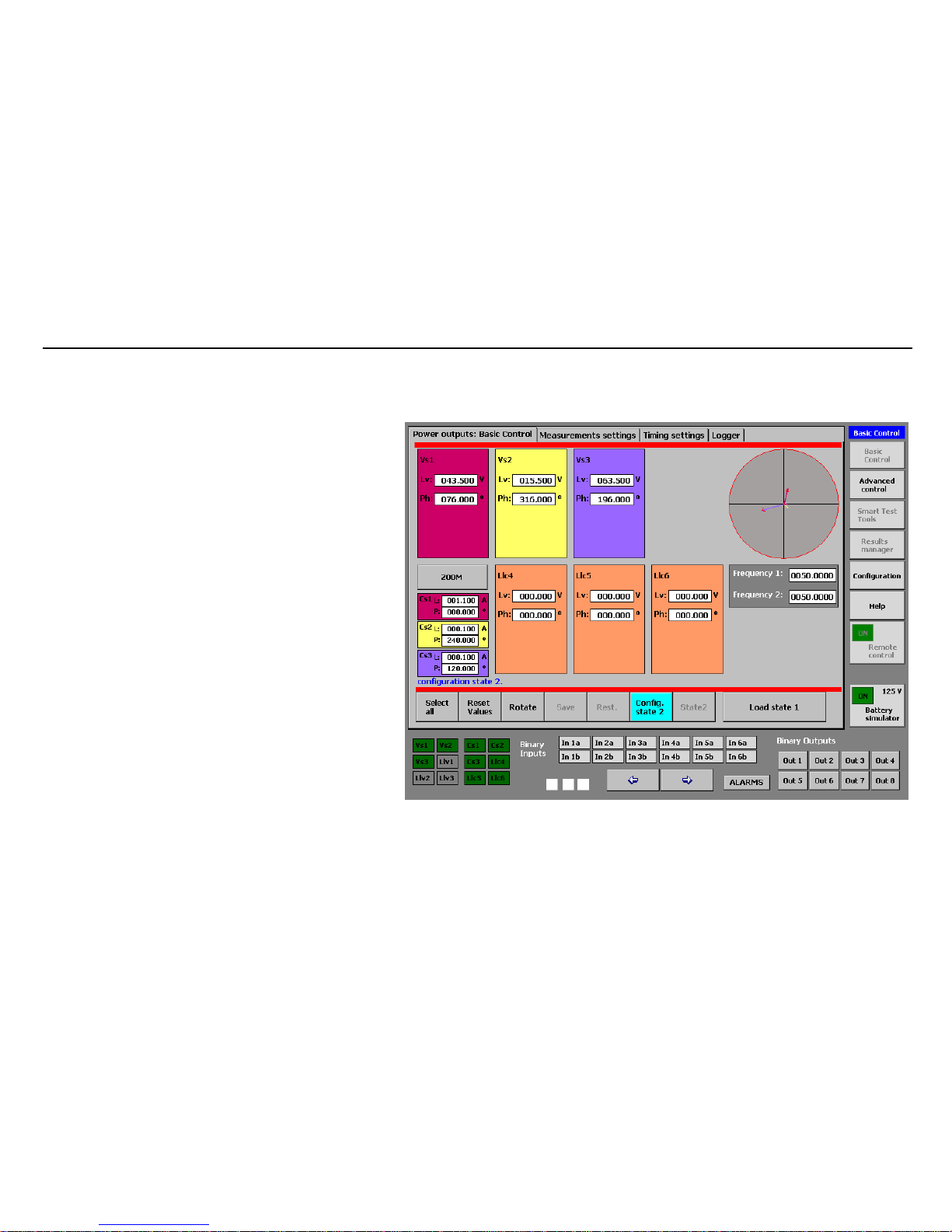

As shown in the picture, in the upper left-hand section of the screen, we can find the

controls of all the outlet sources configured (see Configuration section), the frequency

control, the chronometer or timer, several quick access command keys and the vectorial

view of the magnitudes selected.

• Different selection tabs are located on the top of the screen, providing access

exclusively to the selection and configuration of different functions that are

directly related to the Basic Control.

• The status of all the Mentor 12 inputs and outputs, both digital and analogical,

is shown on the bottom of the screen. There are also two arrows on the

bottom of the screen, which, combined with the rotary knob, enable the

desired output values to be selected, with the selected resolution. There is

also a button called “alarms” which lights up in RED whenever an operation

alarm occurs in any of the equipment outputs. A screen appears, when you

press this button, which describes the type of alarm that has occurred and the

module it corresponds to.

• The line of buttons on the right of the screen provides direct access to the

different Control Modes of Mentor 12. Apart from the access to these

modules, the Battery Simulator control can also be accessed, in order to

either select the output value or activate or deactivate the output. These

buttons and functions are always available for use from any control screen of

the equipment.

Page 23

MENTOR 12 USER’S MANUAL SECTION 2: BASIC CONTROL – Page 23

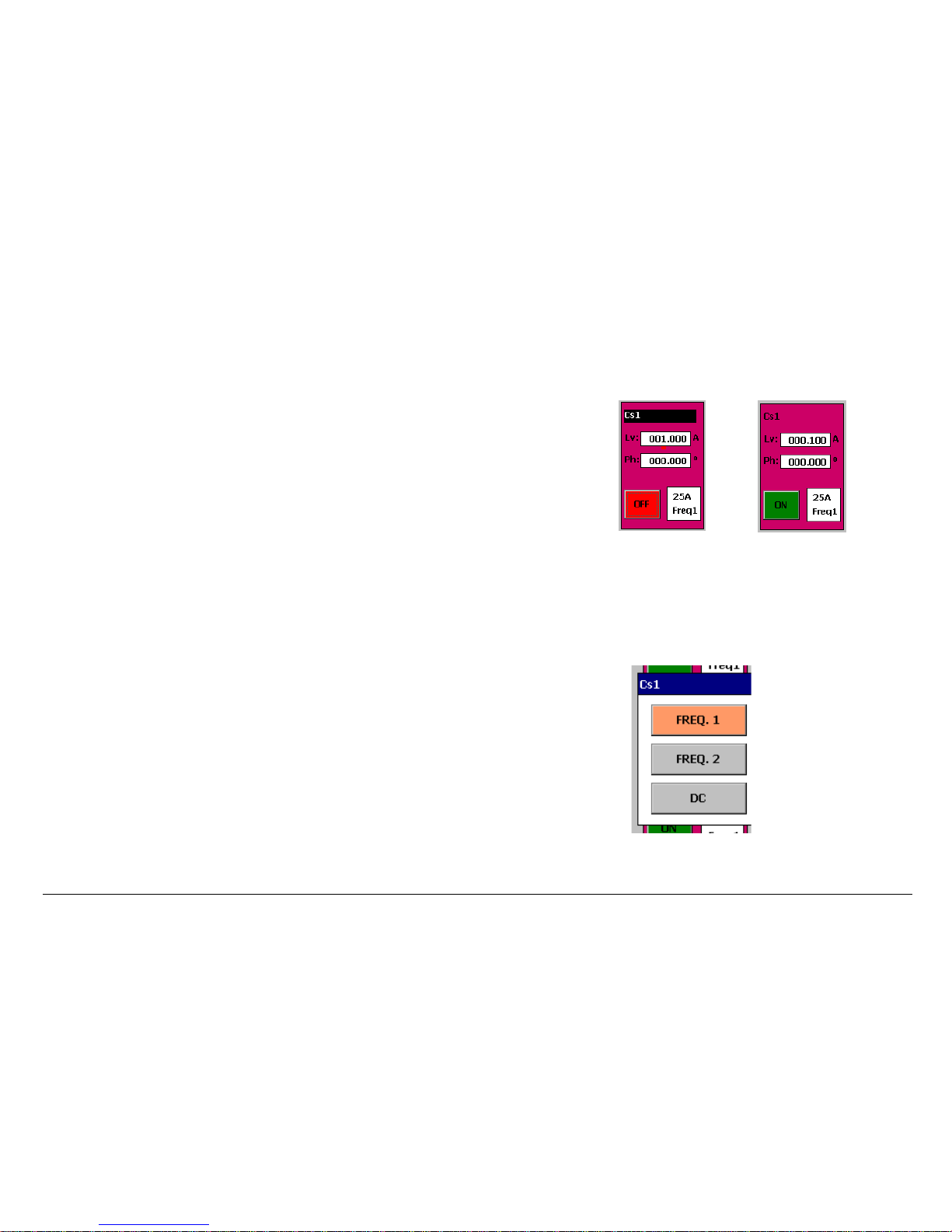

Description of source controls

Source with

output

ACTIVATED

and SELECTED

Default source with

deactivated,

independent output

(NOT SELECTED)

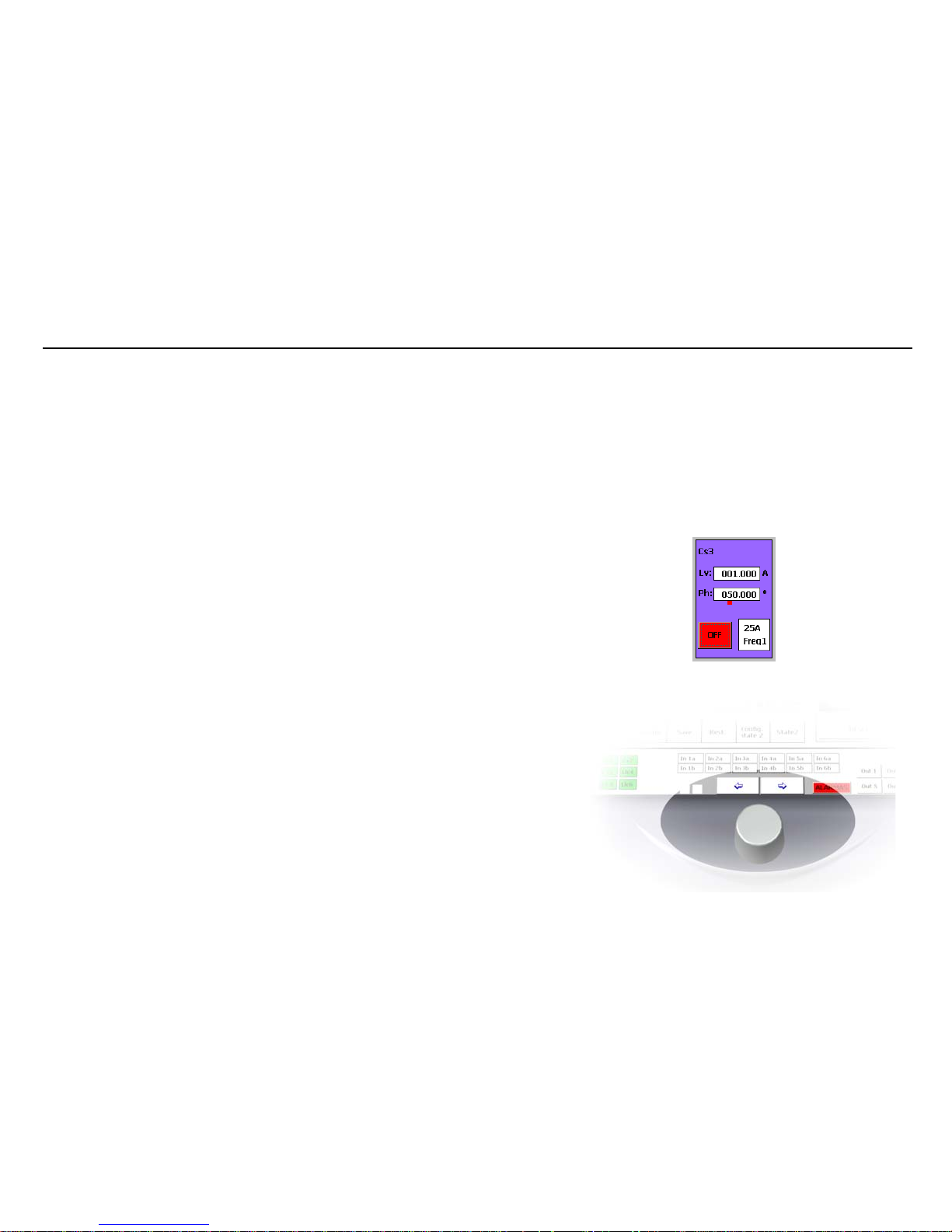

The controls of a power output source are described below.

The figure shows what the control of a power output source looks like, before it has

been manipulated in any way, which is, in default conditions (see Configuration). We

can see the following controls and tags:

• Cs1:

This indicates the type of Cs (Current Source) source and its number

(1).

There can be up to 6 current sources, depending on the equipment

configuration (Cs1 … Cs6).

When pressed, the background color changes to BLACK meaning that the

source has been SELECTED.

The following tags can be found, indicating the different types and numbers of

sources available, which are, apart from the current sources described:

• Vs…n: This indicates that it is a Voltage Source. There can be up to 6 at the

same time depending on the configuration.

Source in Frequency BUS

selection mode

• Ll…n: This indicates that the output source used is a Low Level Output.

There can be up to 6 outputs at the same time, depending on the

configuration of the power sources (See Configuration Section for greater

detail). They tally with the output of the Connectors marked LL OUT from 1 –

3 and from 4 – 6.

• Lv xxx.xxx A:

The Lv tag indicates that the value selection made in the

associated setting window is for SIGNAL LEVEL. The next tag (in this case A

for amperes) indicates the unit of the level selected. This can be A (amperes),

or V (Voltage) and this corresponds with the type of output source. The level

is selected with the resolution and number of available digits indicated

therein.

Page 24

MENTOR 12 US SECTION 2: BASIC CONTROL – Page 24 ER’S MANUAL

• Ph xxx.xxx º:

The Ph tag indicates that the value selection made in the

associated setting window is for PHASE ANGLE in degrees, which

corresponds to the level value selected previously, that is, to the source. The

angle is selected with the resolution and number of available digits indicated

in the relative window. The value selection and direction of rotation are

determined by the selections made in CONFIGURATION.

• ON/OFF: This is used to ACTIVATE or DEACTIVATE the source output.

The INACTIVE status (Output disconnected) corresponds with the GREEN

color and the ON legend on the key. This legend indica tes the action that

the key will carry out when pressed, NOT ITS STATUS, which is

indicated by its color.

The ACTIVE status (Output connected) corresponds with the RED COLOR

and the OFF legend on the key

• 25 A/ Freq 1:

This button is both indicator and selector.

As indicator, the top line (in this case 25 A) indicates the maximum permitted

level selection (25) with its relative unit (A). The bottom line (in this case Freq.

1) indicates which of the two frequency buses (Freq 1 or Freq 2) it is assigned

to, or if it is assigned as a direct output, in which case DC

appears.

As selector, it permits selecting the frequency bus or direct mode. To do so,

it suffices to press the button and a menu drops down with the three

possibilities. After the desired one has been pressed, the menu closes and it

is selected.

Selection of an output value

A description is given below of the action to be taken to obtain a certain output value

from one or several Mentor sources at the same time. This description is given step by

step, and it can be applied at any time to any value selection on any control screen as

the process is common to all the equipment control programming:

Page 25

MENTOR 12 USER’S MANUAL OL – Page 25

Selection of one single source (INDEPENDENT mode)

To select any value, be it level or phase angle, it suffices to press on the setting window

you wish to vary. A red-colored cursor will appear under some of the digits of this

window. If the cursor appears on the weight digit that you wish to adjust (e.g. The digit

that adjusts the angle by 10 degree intervals, as in the figure), you must only increase

with the endless rotary knob until the desired value is reached. In the case of the figure,

it will vary every 10 degrees.

If you wish to change its adjustment resolution, it suffices to press the arrow buttons

situated on the bottom of the screen, directly above the rotary knob. If you press the

right-hand arrow, the red-colored cursor will move to the right, increasing the resolution

by one decade. If you press the left-hand arrow, the red-colored cursor will move to the

left, decreasing the resolution by one decade.

In our example in the figure, if we press the right-hand key, our resolution increases to

achieve degree be degree adjustment. If we press the left-hand key, our resolution

decreases to achieve adjustment in 100 degree intervals.

Simultaneous selection in several sources (SELECTED

mode)

Mention has been made above of the SELECTED mode and how to activate it in each

source. This mode is used to make adjustments, changes in frequency reference and

actions on the output status all at the same time, thus permitting three-phase

adjustments or even of more sources, just by applying the single rotary knob, or any

ON/OFF output control button. However, there are logically some limitations to carry

out this practical function, depending on the parameters or actions that the change

affects. These are described below:

SECTION 2: BASIC CONTR

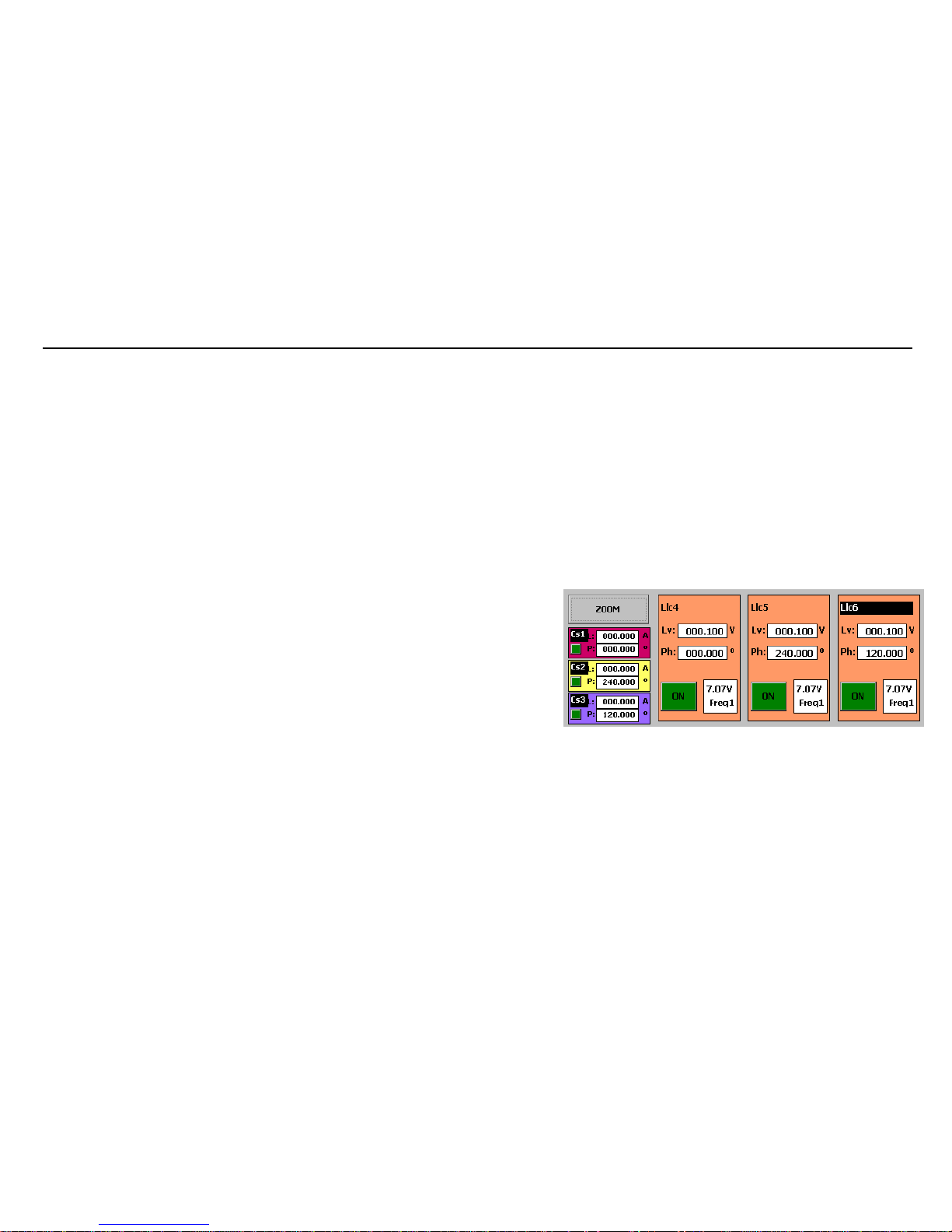

Sources C1, C2, C3 and Llc6 in SELECTED mode, Sources Llc4 and Llc5 in

INDEPENDENT mode

• When LEVEL or phase ANGLE values are adjusted, any change made in a

source on SELECTED mode, occurs in the same way in ALL the sources

OF THE SAME TYPE (V or I) that are in that mode. That is, a change in

Page 26

MENTOR 12 US SECTION 2: BASIC CONTROL – Page 26 ER’S MANUAL

level or angle in a Voltage source will only affect the voltage sources and not

the current ones. The changes that are sent to the sources are INCREASES,

both in phase angle and in level, so these increases sent will be added or

subtracted, depending on the direction of the adjustment, to or from the

values established at the start of the process.

• When you apply any ON/OFF key of a source in SELECTED mode, this

change will take effect in ALL the sources of this mode, regardless of the

output source type.

• When you apply any key that permits changing the frequency reference

(BUS) of a source in SELECTED mode, this change will take effect on ALL

the sources in this mode, regardless of the type of output source.

Selected expanded sources Llc4, Llc5 and Llc6 with the ZOOM key

Selection when there are more than 3 available sources.

ZOOM key.

As you can see on the previous screen, when there are more than 3 sources of one

type selected (see Configuration section), 3 of them appear in reduced form under a

key marked ZOOM. The sources that appear under this key ONLY PRESENT

INFORMATION about levels, phase angles and output status. None of the parameters

mentioned can be changed. However, the mode can be selected as INDEPENDENT

or SELECTED, by pressing them.

To be able to make changes in these sources you must go from reduced mode to

expanded mode. This is done by pressing the ZOOM key. This action expands the

sources under it and reduces the ones that were expanded, as you can see f rom the

picture below.

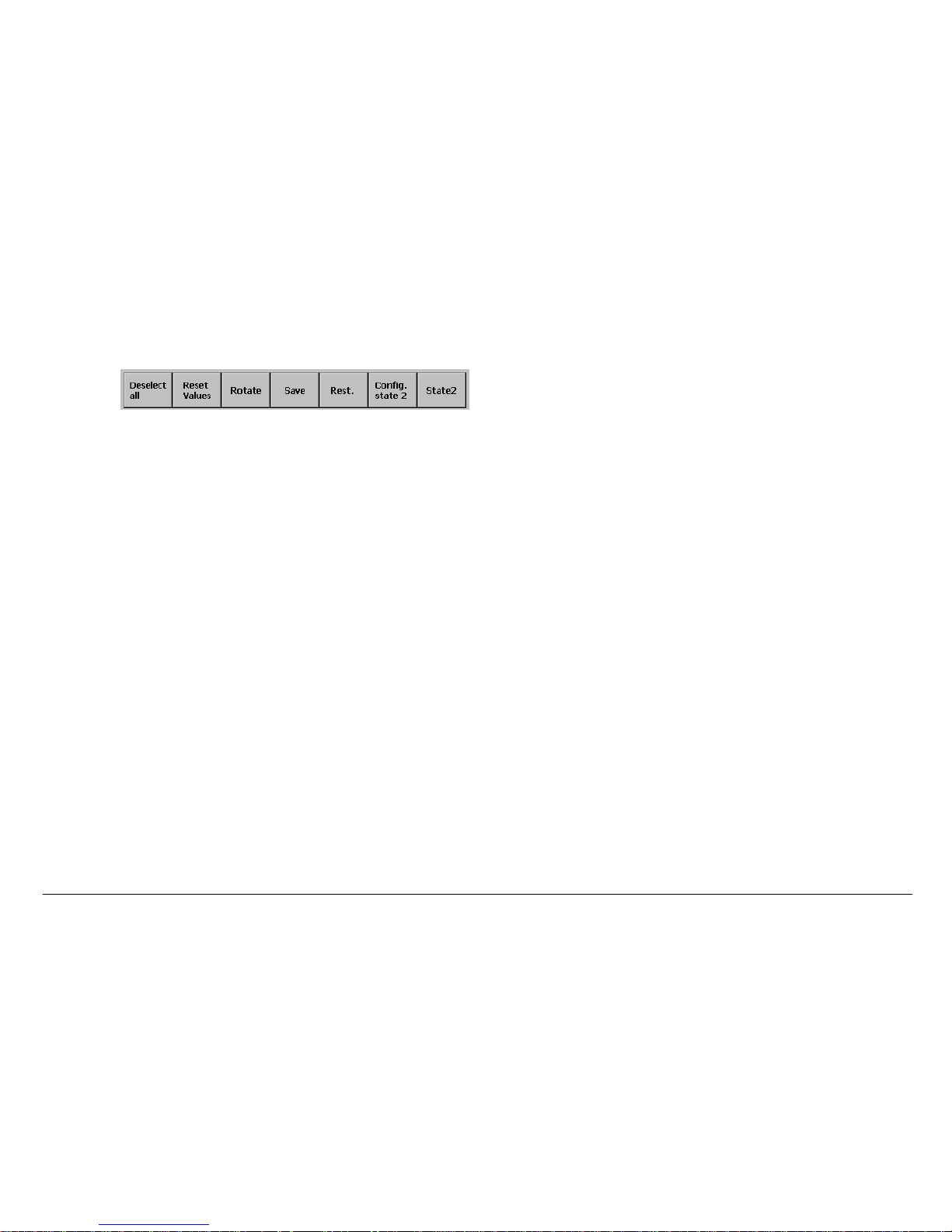

Application and Use of the function and help keys

Under the individual controls for each source, there is a row with different keys, whose

aim is to help carry out normal functions in the protections test, both quickly and easily,

so just by clicking once you can access the desired changes. The different keys are

described individually below:

Page 27

MENTOR 12 USER’S MANUAL SECTION 2: BASIC CONTROL – Page 27

“Select all” key

This is used to directly and simultaneously place the sources in SELECTED mode. It is

a function sequential selection key, that is, each pulse corresponds to a function. When

it reaches the last one it goes back to the first, and so on and so forth. Every time it is

pressed, the situation described by the tag is generated and this changes to indicate the

action that will occur when pressed again. It has the following possibilities:

• Select all: This is the default configuration. When you press the key ALL the

existing sources are placed in SELECTED mode.

• Select voltage: When you press this key, the selection of the current sources

is deactivated, and only the voltage sources remain in SELECTED mode.

• Select current: When you press this key, the selection of the voltage modes

is deactivated, and only the current sources remain in SELECTED mode.

• Deselect all: When you press this key the SELECTED mode is deactivated

in all the sources that might be in this mode.

“Reset Values” key

This is used to return to the default values established in the Configuration (see

Configuration section) in all the sources in SELECTED mode. It is important to point out

here that this key will have NO effect on sources that are in INDEPENDENT mode.

Page 28

MENTOR 12 USER’S MANUAL SECTION 2: BASIC CONTROL – Page 28

“Rotate” key

This key is designed to help the operator. It is quite normal during relay testing in threephase mode or phase to phase mode for it to be necessary to “rotate” the whole system

in terms of phase angles, in order to simplify calculations with phase angles or even

avoid connection changes to the relay itself. By doing this, the reference phase

connected to the relay will always have an angle of zero degrees, while maintaining the

appropriate phase rotation.

For example, if we assume a phase rotation ABC and a positive direction of rotation of

the angles selected on the screen in clockwise direction (see Configuration section), the

selected angles corresponding to each phase are:

• Phase A (0º) which corresponds to output source Cs1, Phase B (120º) which

corresponds to output source Cs2 and Phase C (240º) which corresponds to

output source Cs3, in our example.

If the “Rotate” key is pressed, the situation would change to the following:

• Phase C (240º) which corresponds to output source Cs1, Phase A (0º) which

corresponds to output source Cs2 and Phase B (120º) which corresponds to

output source Cs2, in our example.

If the “Rotate” key is pressed again, the situation would then change to:

• Phase B (120º) which corresponds to output source Cs1, Phase C (240º)

which corresponds to output source Cs2 and Phase A (0º) which corresponds

to output source Cs2, in our example.

If you press the “Rotate” key once again the situation returns to the original one. In

short, with this key we manage to change our reference phase, as the relay being

tested sees it, without physically having to change the output source that corresponds to

it or the connection to the relay.

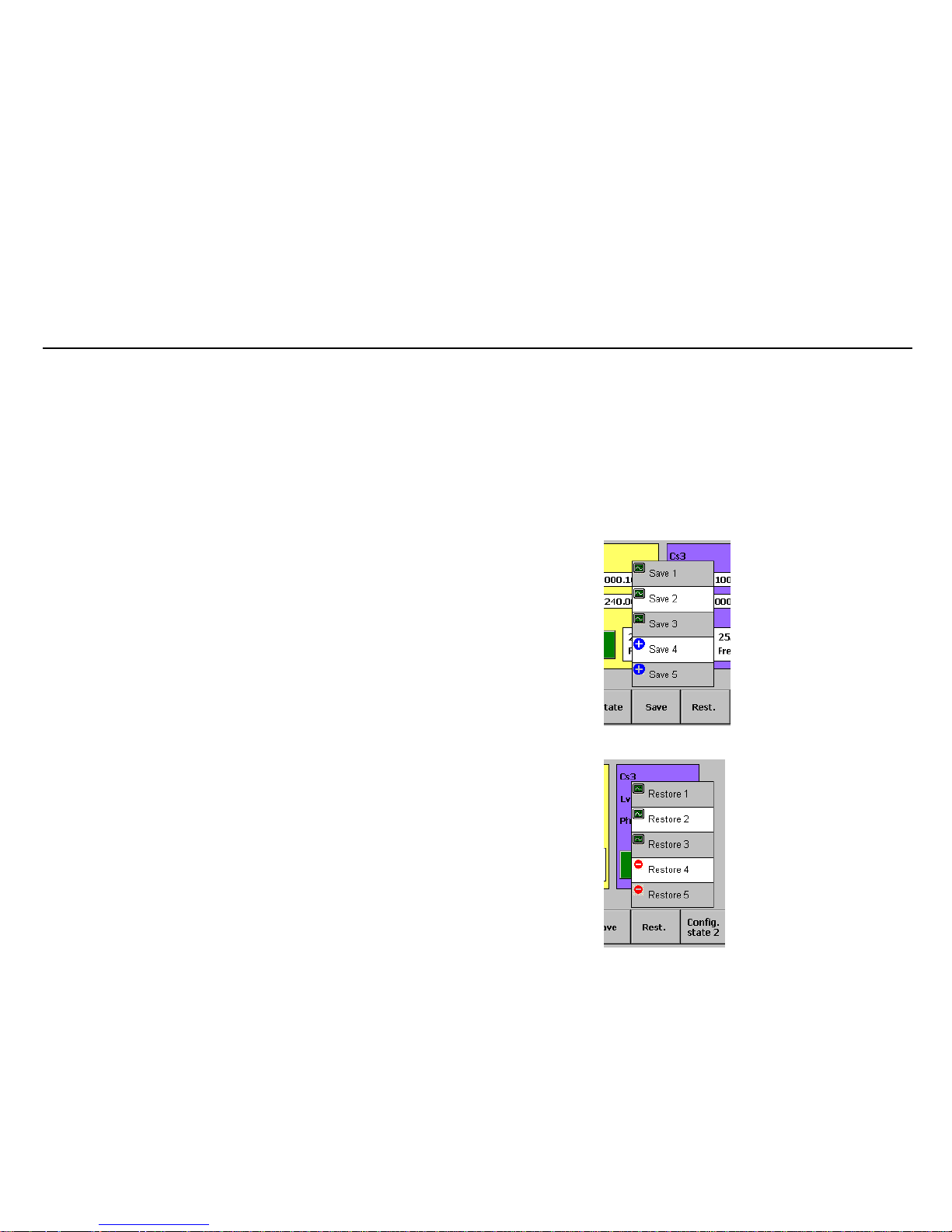

“Save” and “Rest.” keys

These keys are designed to help the operator. They are described together as they

complement each other. During relay testing in manual mode, it is quite normal to have

Page 29

MENTOR 12 USER’S MANUAL SECTION 2: BASIC CONTROL – Page 29

to repeatedly return to identical adjustment situations each time. This key combination

exists to prevent having to adjust them in each case, making it possible, on the one

hand, to save up to five adjustment situations or “panels”, and on the other hand,

permitting quick and easy recovery and application of saved panels. They are used as

follows:

• Save key:

When you press this key a drop-down menu appears with 5

buttons marked as “Save 1….5”. If you press on the one where you wish to

save the panel, this is saved in the selected position. Tags with “+” sign

indicate that the position is empty. Those marked with the other tag indicate

that they contain data. In the picture below, tags 1, 2 and 3 contain data and

positions 4 and 5 are empty.

• Rest. Key:

When you press this key a drop-down menu appears with 5

buttons marked as “Restore 1….5”.- Each number corresponds to the panel

saved with the “Save” key. When you press on the one you wish to make

active at that time, the panel is reproduced in the settings of the active panel.

Tags with “-“ sign indicate that the position is empty. Those marked with the

other tag indicate that they contain data. In the picture, tags 1, 2 and 3

contain data and positions 4 and 5 are empty.

IMPORTANT: All the panels saved during a work session are maintained until the

equipment is disconnected. When the system is booted again, none

of the work panels remains.

Page 30

MENTOR 12 USER’S MANUAL SECTION 2: BASIC CONTROL – Page 30

“Config. Status 2” and “Status 2” keys

During relay testing, be it manual or not, the possibility of

carrying out dynamic changes in both the analogical and

logic values of the different outputs selected is of great help

(and is sometimes essential), in order to assess the

response of the relay being tested to this change, either by

trip time measurement or by the subsequent study of the

performance of the outputs of this relay, using the “Logger”

function.

For this function to be practical it is necessary to be able to

configure this status, even while the conditions of the

“normal” or “1” status are activated. This is what the Config.

Status 2 key is used for. Once the operator has edited the

desired parameters on this screen, the condition of 2nd

value is activated with the Status 2 key.

Page 31

MENTOR 12 USER’S MANUAL SECTION 2: BASIC CONTROL – Page 31

The operation sequence is as follows:

7. Press Config. Status 2 once. The background

color of the key changes to blue. A screen

appears where you can configure the power

outputs and the logic outputs that you wish to skip.

8. Press Config. Status 2 again to return to the

normal control screen. The background color of

the keys changes back to grey.

9. Press the Status 2 key for the outputs to

instantaneously change to status 2 selected

previously; the timer starts (if configured to do so)

and they remain like that until stopped. To return

to Normal status, you must press “Status 2” key

again. In this case the screen only shows the

configured values. They cannot be varied. If you

wish to vary the values of “Status 2”, you must

repeat the process described.

Page 32

MENTOR 12 USER’S MANUAL SECTION 2: BASIC CONTROL – Page 32

Measurement Window

There is a section on the Basic Control panel that contains a window, which shows the

values measured of different magnitudes in real time. The following magnitudes are

available:

• Trip time in seconds (timer function): This measures the time elapsed

between two events and presents the measurement on the window. Their

selection and configuration (start and stop) are described further on in this

manual. The units may be “seconds” or “cycles” (See configuration section).

• Duration of the output in seconds (time delay function). It maintains both

the power outputs and the digital outputs during the time indicated on the

window. The selection of the time value and the selection of the simultaneous

actions with the end of count are described further on in this manual. The

units may be “seconds” or cycles” (See configuration section).

• Value of the magnitude measured through the analog ue measurement

input (configurable units)

• Value of the number of pulses or frequency measured through the logic

inputs that can work as counters, (configurable units)

As you can see in the figure, the measurement window is divided into two sections:

• The upper section where the name of the measurement function selected and

a green or red colored indicator appear. The function is not active when the

indicator is green and active when the indicator is red. If you press the

indicator the status of the measuring device changes in cycles.

• The bottom section where th e measurement appears. The measurement unit

used also appears after the digits. If you press the measurement window, the

parameter, to be measured in cycles, changes, out of those mentioned

above. The Reset button only appears with the time and pulse counter

parameters. If you press this button the window resets to zero and is ready for

a new measurement cycle.

Page 33

MENTOR 12 USER’S MANUAL SECTION 2: BASIC CONTROL – Page 33

Configure times

This tab marked as “Timing Settings” is situated at the top of the Basic Control screen. If

you press it you access a screen that enables you to configure the start and stop

conditions of the Timer, on the one hand, and on the other, the conditions and

times when it works as an Output Time Delay.

The following controls are available for the Start and Stop conditions in Timer

mode:

Page 34

MENTOR 12 USER’S MANUAL SECTION 2: BASIC CONTROL – Page 34

TIMER START conditions

• If you wish to start the timer by the action of the

Power Outputs, press the relative button and it will

be activated, its indicator lighting up in red. The

button on the right indicates the type of operation

of the selected outputs, ON or OFF, that is, the

timer will start when the outputs are connected

or by changing from Status 1 to Status 2,

in the

case of ON indication, or the timer will start when

the outputs are disconnected or by changing

from Status 2 to Status 1

in the case of OFF

indication. To select either one just press the

button mentioned and select either of the two

situations on the menu that immediately appears.

Page 35

MENTOR 12 USER’S MANUAL SECTION 2: BASIC CONTROL – Page 35

• If you wish to start the timer by the action of a Binary Input combination, press

the relative button to activate it and the indicator will light up in red. With the

button situated on the right you will access a menu which permits selecting

these inputs, simply by pressing the terminals of the input you wish to use.

Each one of the inputs has a cyclic operation button associated with it, which

selects its active mode between UP (input activation) DOWN (input

deactivation) or CHG (Change in input status). It can also be selected if the

action logic between the inputs is OR (the timer start will be activated when

ANY of the inputs selected changes to the logic status selected) or AND (the

timer start will be activated when ALL the inputs selected change to the logic

status selected)

• If you wish to start the chronometer by the action of a Binary Output,

press the relative button to activate it and its indicator will light up in red.

With the button situated on the right you will access a menu which

permits selecting these outputs, simply by pressing the terminals of the

output you wish to use. In this case neither status nor logic can be

configured. The selected outputs always act as OR and activate the start

when the status is CHANGED.

Page 36

MENTOR 12 USER’S MANUAL SECTION 2: BASIC CONTROL – Page 36

TIMER STOP conditions

The timer can only be stopped by the action of the Binary Inputs. If you press the

relative button it will be activated and the indicator will light up in red. With the button

situated on the right you will access a menu which permits selecting these inputs,

simply by pressing the terminals of the input you wish to use. Each one of the inputs

has a cyclic operation button associated with it, which selects its active mode between

UP (input activation) DOWN (input deactivation) or CHG (Change in input status). It can

also be selected if the action logic between the inputs is OR (the timer stop will be

activated when ANY of the inputs selected changes to the logic status selected) or AND

(the timer stop will be activated when ALL the inputs selected change to the logic status

selected)

TIMER Activation

• If you wish the timer to RESET and to start automatically

each time the start conditions selected occur, use the button

marked “Autoreset”. If you press the relative button it will be

activated and its indicator will light up in red. If you press it

again, it will be deactivated, and its indicator will change to

grey. If the “Autoreset” is deactivated the timer will start and

stop in agreement with the selected conditions and the time

unit will remain until the “Reset” button is pressed. If “Reset”

is not pressed and a new operation is carried out, the timer

will not start.

• Below the previous button there is a section called “when the

timer stops…” which permits selecting the desired action on

the outputs when the timer stops. “All outputs OFF” can be selected which

changes all the selected outputs, be they Voltage or Current, to OFF status,

or “Current outputs” which only changes the current outputs selected to OFF

status, leaving the voltage outputs active.

• The “Delay” button is on the right of these buttons. It is activated and

deactivated in cycles. When activated, a window is displayed to enter data

using the rotary knob, in this case in milliseconds, which defines the time that

Page 37

MENTOR 12 USER’S MANUAL SECTION 2: BASIC CONTROL – Page 37

elapses between the moment the timer stops (trip signal of the relay being

tested) and the effective disappearance of the voltages and/or currents in the

output (switch opening). In short, it enables us to simulate the so-called

“switch time”. When this button is deactivated or activated with time selection

“0” ms the selected outputs are immediately deactivated when the timer

stops.

TIME DELAY

In the section marked TIME DELAY there is a table that contains the

controls to select the waiting time, see the function start condition

and establish the actions when the time interval ends:

• The Time Delay START conditions are established with

the same controls as the ones with which the timer start

condition is established, as explained above. In any case,

the screen informs of the selected condition, following the

“start condition” tag.

• In the time setting window, the desired time is entered in milliseconds, using

the rotary knob. It is marked as “Time Delay: Initial value of the count”.

• There are two possible actions when the count down ends. One is to remove

all selected outputs and the other, assuming that we are in 2

nd

value status, is

to return to status 1 (initial)

• The Time Dela y can be activated at the same time as the Timer in all the

tests. If the timer count ends before the event selected to stop the timer

occurs, this will not stop.

Page 38

MENTOR 12 USER’S MANUAL SECTION 2: BASIC CONTROL – Page 38

Configure measurements

This tab, marked as “Measurement configuration” is situated

on the top of the Basic Control screen. When pressed, you

access a screen where you will be able to configure the units

that the values measures will be read in, through the

analogical input on the one hand, and through the binary

inputs, on the other hand. This function, specifically

designed for tests on measurement transducers with

analogical output in VDC or mA DC or on Counters with

analogical or digital output by pulses, makes the conversion

from the magnitude measured by the relative equipment

input (V, mA, Pulses) to the units that are assumed to be the

nominal ones of the element to be tested (V, A, KVA, Kw,

Kvar, Kw, time…. etc) entering the ratio between both.

Proceed as follows:

• There are two buttons in the section

corresponding to “Measurement of analogical

inputs”.

These are marked “Voltage” and

“Current” respectively, and are used to select the

type of output of the converter being tested. When

one of them is selected, the equipment terminal

connection diagram indicates the correct

connection of the converter to same.

• There is also another button marked “Convert”.

When this button is pressed, the measurement

conversion window appears and the button then indicates the status that will

exist when pressed again, namely “Do not convert”.

• Press on the space marked “Convert units to:” and the keyboard will appear

on the screen. Write the name of the units you wish to convert to (e.g. KVA).

• Enter the ratio values between these units and the real output of the

converter. One value for zero

is entered and a nother for the scale end.

Page 39

MENTOR 12 USER’S MANUAL SECTION 2: BASIC CONTROL – Page 39

This is because there are converters which, to

avoid errors in zero, are converted to a definite

value (for examples outputs from 4 to 20 mA). In

this case, we enter the value of 4 mA in the first

window and its correspondence in the next, which

would be the value 0 KVA. In the next group of

windows we would enter the scale end, in the first

window 20 mA and in the next its correspondence,

for example, 2000 KVA. The values are entered

with the numerical keyboard that appears on

screen when the relative window is pressed.

• Once the values and the u nits have been entered,

the reading of the value measured on the

measurement window of the Basic Control screen

(Analogue Input) is presented in converted units. If

you press the “Do not convert” button, the units

and ratios entry windows disappear from the

screen and the values shown by the measurement

window on the Basic Control screen are the direct

values in V DC or mA DC, depending on what has

been selected.

Page 40

MENTOR 12 USER’S MANUAL SECTION 2: BASIC CONTROL – Page 40

There are two buttons in the section corresponding to

“Measurement of binary input”.

These are marked

“Pulses” and “Frequency” respectively, and are used to

select the type of output of the converter/ energy measuring

device being tested. The number of the Digital Input selected

for the measurement is indicated on these buttons.

• To make this selection, press the button marked

“Select” which takes you to a menu where you can

select the input you wish to use just by pressing

the relative terminal as seen from the following

screen.

• For the unit conversion process, proceed in the

same way as for the analogical inputs, described

above.

Page 41

MENTOR 12 USER’S MANUAL SECTION 2: BASIC CONTROL – Page 41

System alarms

The Mentor has different alarms that warn the operator when

different systems are not working correctly as soon as they

are activated. They are mainly applied to the equipment

power outputs and are always visible on any of the screens

and/or applications except in the Configuration ones.

When any kind of alarm occurs in an output source, its level

indication window lights up in RED, also deactivating the

On/Off output control.

Furthermore, the button marked as “Alarms” situated on the

bottom of the screen, also lights up in RED.

When we press this button a screen appears that indicates

the type of alarm that has occurred and the module where it

has occurred. For this purpose, all the output sources are

divided into one section that corresponds to its Power

Supply Source and another section that corresponds to its

Amplifier.

The following types of alarms can be indicated by the

sy t

•

s em:

OVL.- This means overload of the source affected.

This alarm indicates that the source is being

overloaded, with respect to its maximum power

capacity. In the case of current sources this

generally indicates that their output is open or that the load connected is

excessive for the power and the values selected. In voltage

sources it

indicates that the load is excessive for their power or that there is a short-

Page 42

MENTOR 12 US SECTION 2: BASIC CONTROL – Page 42 ER’S MANUAL

• one or several fuses that a

source contains as final protection has or have blown and must be replaced

to be able to continue using it. When this occurs the module affected must be

taken out, following the instructions given in the Basic Maintenance section of

this manual, and the fuse affected replaced.

circuit. The appearance of this type of alarm implies an instantaneous

disconnection of the sources affected by it.

THERM.- This means that the source affected has surpassed the admissible

thermal limits for correct operation. When this a• larm appears it implies the

immediate disconnection of the source affected and the deactivation of the

relative On/Off key. After a cooling time (this may be several minutes), when

the temperature returns to safe values, this alarm resets on its own, enabling

the source to operate again.

Vout.- This means that the source is not giving the values that it should give

in its outputs. It may appear in the Source or in the Amplifier. The appearance

of this alarm implies an immediate disconnection of the source affected. This

alarm generally• indicates a FAULT in the source affected, so it does not reset

on its own. When this type of alarm occurs, it is advisable to reset the

equipment, by switching it off and then on again. If the alarm appears again

after switching it back on, this definitely indicates that the source is out of

service due to a fault.

FUSE.- The appearance of this alarm indicates that

Page 43

MENTOR 12 USER’S MANUAL SECTION 2: BASIC CONTROL – Page 43

Battery Simulator

The Mentor 12 has a built-in battery simulator. It is designed to produce three different

fixed voltage values in direct current, which must be used to supply the relays being

tested and which require an auxiliary power supply. The values that can be selected are

48 V, 125 V and 250 V. 60 W power exists in each one of these ranges, with continuous

working cycle.

The physical output is situated on the top of the Side Terminal panel, where there are

two terminals, a red Terminal that corresponds to the positive pole and a black Terminal

that corresponds to the negative output pole. It also has an optic indicator that lights up

when the output is activated, indicating the presence of more than 42 V and the relative

precaution when handling this output.

The Simulator control is located on the bottom right of the screen and is visible not only

in the Basic Control section but on all the accessible function screens. It has two main

functions:

• ON/OFF OUTPUT CONTROL: By briefly pressing the button indicated the

status alternates between ON and OFF. When the button is on green, this

indicates that the output is OFF and when it is on red, this indicates that it is

ON. There is a legend on the right of the button that indicates the value of the

output range selected, which will be the value injected into the load when the

output is activated.

• OUTPUT VALUE SELECTION: By pressing the button for LONGER a pop-up

window appears below the ON/OFF button, with 3 buttons that indicate 48 V,

125 V and 250 V respectively. The one that is active at that time appears in

blue. To select another value just press the relative button. The window will

close and the new output value selected will appear on the value indication of

the battery simulator control.

Page 44

MENTOR 12 USER’S MANUAL SECTION 2: BASIC CONTROL – Page 44

There is a screen in the Mentor where all events that occur to the unit are logged such

as when the sources are switched on, there is a change in status of the binary outputs

or a change in status of the binary inputs.

IMPORTANT: The output of the Battery Simulator, unlike the other power outputs,

is always ACTIVE, even in function changes (Basic C, Advanced C,

Configuration, etc.) until it is manually deactivated or the equipment

is switched off.

All these events are automatically recorded and can be viewed on the “Logger” screen.

• The logger does not show the latest event

recorded when you open it. If you want to see the

latest event, you need to hit the List of Events

button.

• You may want to clear up the logger’s screen

before you update it with the latest event. To do

so, hit the Clear List of Events button first.

• The ACTIVATE button must be pressed for the

recording function to capture the events that occur

between the start and stop of the chronometer.

This button will change to a light blue color while it

is activated. To see the list of captured events,

press the Events List button.

Logger

Page 45

SECTION 3: ADVANCED CONTROL

Introduction

If you press the button marked “Advanced Control” on the

right-hand column of the main screen you access a set of

advanced test functions that enable the user to quickly and

simply carry out a series of tests types that are very typical

for protection relays. These tests permit determining the

state of the relay and obtaining readings and results of

different relay parameters under different test conditions that

can be configured entirely by the user.

There are two screens in all the functions that comprise the

Advanced Control. One of them, which appears when you

select the Function is called “Graphic” or test configuration,

where the graphic appears that explains what the function

will do as well as the controls necessary to configure it

correctly. The other screen is the “Execution” screen, which,

when selected, shows a graphic of what the equipment is

doing. This screen moves in real time enabling the operator

to see how the test he has configured is carried out. One or

several vertical yellow-colored lines appear on the graphic of

the execution screen, when this ends, indicating the time

when the TRIP condition selected occurred. Depending on

where these TRIPs occur, (expected or not expected) the

function will stop or not, but in any case all the TRIPS will be

shown, be they valid or not to stop the test.

How to select values, times, etc. will not be described in this

chapter, as this has been described in depth in section 1

(Basic Control). One of the great advantages of the Mentor 12 is precisely this. The use

of all the controls is shared by all the functions so they are extremely easy to use, once

you know the setting and control process.

Not only the levels and angles of the analog power outputs can be configured in all the

Advanced Control Functions, but also the state of the different digital binary outputs.

The latter can be configured by pressing the rectangle that contains the 8 digital outputs

Page 46

MENTOR 12 USER’S MANUAL SECTION 3: ADVANCED CONTROL – Page 46

and that indicates their state (red they are active and white

deactivated). A window appears when this rectangle is

pressed displaying the binary outputs as they appear on the

equipment terminal panel. If you press the blue terminal of

each one of them, you select the relative output as active, as

shown in the picture below. Bear in mind that the state of the

output (active or deactivated) depends on how the output is

configured in CONFIGURATION (NO or NC)

The TRIP signal that stops the execution of the function can

also be configured in any of them, by combining the twelve

available binary inputs in OR or AND logic. This condition

can be selected by pressing the white-colored button marked

“TRIP” on the configuration screen.

Page 47

MENTOR 12 USER’S MANUAL SECTION 3: ADVANCED CONTROL – Page 47

Another of the characteristics that all the advanced functions

share is the existence of the “Logger”, which, when activated,

shows all the events that occur in the digital inputs

throughout the execution of the function, associated with their

time tag, name of the digital input and event occurred. It is

thus possible to carry out an in-depth study of the

performance of the relay tested throughout the function. This

is very important for analysing its results.

Page 48

MENTOR 12 USER’S MANUAL SECTION 3: ADVANCED CONTROL – Page 48

Each one of the available options is described below, listing,

in the first place, its possible application and then the use of

the available controls, which are accessed from the buttons

situated on the left of the Advanced Control screen. It is

important to highlight that the different test options always

start up with the last configuration.

Page 49

MENTOR 12 USER’S MANUAL SECTION 3: ADVANCED CONTROL – Page 49

FAULT Function

The FAULT function permits the user to configure a complete simple fault and execute

it, that is, the states called:

Page 50

MENTOR 12 USER’S MANUAL SECTION 3: ADVANCED CONTROL – Page 50

PRE-FAULT in terms of its electrical parameters (values and

angles) and in the state of the binary outputs (to simulate the

state of any device outside the relay such as the high

voltage switch). Furthermore, the duration of this state can

also be configured in the relative box indicated on the

function graphic. After the preset time has elapsed all the

outputs will change to the next state. This Pre-fault state

usually defines the load conditions of a line in its normal

service state, before a fault occurs. The load parameters

before the fault are often essential to assess the

performance of the protection tested, above all that its

duration is sufficient to “load” the protection tested. A

minimum default value of 1 second is suggested.

You can access the screen to configure these values by

pressing the GREEN colored button, marked “Pre-fault”. A

screen appears where you must enter the desired levels and

angles for the power outputs (See Output Value Selection in

Section 1 Basic Control) and also the logic states for the

digital outputs.

Page 51

MENTOR 12 USER’S MANUAL SECTION 3: ADVANCED CONTROL – Page 51

FAULT in terms of its electrical parameters (values and

angles) and in the state of the binary outputs (to simulate the

state of any device outside the relay, such as the high

voltage switch). The maximum duration of this state can also

be configured. Unlike the pre-fault state, where the only

conditioning factor to change to the next state (Fault) is for

the time established for this condition to elapse, in this case

the change to the next state generally occurs due to the

binary input condition defined on the TRIP button being

satisfied, and if this does not occur, because the maximum

time defined for the state has elapsed. If the expected trip

occurs, the function returns the time that it took for the trip to

take place from the moment when the Fault state began,

presenting this as a test result.

You can access the screen to configure these values by

pressing the RED colored button, marked “fault”. A screen

appears where you must enter the desired levels and angles

for the power outputs (See Output Value Selection in Section

1 Basic Control) and also the logic states for the digital

outputs.

Page 52

MENTOR 12 USER’S MANUAL SECTION 3: ADVANCED CONTROL – Page 52

POST-FAULT, in terms of its electrical parameters (values

and angles) and in the state of the binary outputs (to

simulate the state of any device outside the relay such as

the high voltage switch). Furthermore, the maximum duration

of this state can also be configured in the relative box

indicated on the function graphic. After the preset time

elapses all the outputs disconnect and change to

deactivated state.

The Post-fault state starts when the switch time, if any, ends,

when the trip occurs in the Fault state, or when the time

defined for the Fault state has elapsed, without any trip.

The Post-Fault state is important during the test, as it

enables us to simulate the real position of the protection and

define its performance depending on whether it is situated in

BARS (BUS) where the healthy voltages are maintained, or

on the LINE side, where these voltages disappear when the

switch is applied.

You can access the screen to configure these values by

pressing the BLUE colored button, marked “POST-fault”. A

screen appears where you must enter the desired levels and

angles for the power outputs (See Output Value Selection in

Section 1 Basic Control) and also the logic states for the

digital outputs.

Page 53

MENTOR 12 USER’S MANUAL SECTION 3: ADVANCED CONTROL – Page 53

There is also another button on the configuration screen,

called TRIP, which enables you to establish the TRIP

condition depending on the digital inputs chosen for this.

This is done in the same way as explained in Basic Control

(See Basic Control, selection of timer start and stop

conditions).

Configuration

In short, the following fields must be filled in, in order to

correctly configure a fault:

• Green button marked Pre-Fault provides access to

its configuration screen.

• Red button marked Fault provides access to its

configuration screen.

• Blue button marked Post-Fault provides access to

its configuration screen.

• White button marked TRIP provides access to the

configuration screen of the trip signal.

• Blue window on the pre-fault area of the graphic:

you must enter the duration of the pre-fault in

milliseconds, clicking on this and using the digit

adjustment selection arrows and the rotary knob.

• Blue window on the Fault area of the graphic: you must enter the maximum

duration of the fault in milliseconds, clicking on this and using the digit

adjustment selection arrows and the rotary knob.

Page 54

MENTOR 12 US SECTION 3: ADVANCED CONTROL – Page 54 ER’S MANUAL

• Blue window on the post-fault area of the graphic: you must enter the duration

of the post-fault in milliseconds, clicking on this and using the digit adjustment

selection arrows and the rotary knob.

• Blue window in the area of the graphic marked

Trip: you must enter the switch time to be

simulated in milliseconds. That is, it defines the

time lag between the trip signal of the relay

tested and the effective disappearance of the

voltages and/or currents in the output (Switch

opening).

Fault Execution: there have been no trips

Execution

After correctly configuring the fault as described above,

the system is ready to execute it. Proceed as follows:

• Press the key marked “Execute” on the upper

right-hand corner of the configuration screen.

The window will change to the execution screen and the

test will be carried out. It may take a few seconds for the

test to start, due to the process time.

Page 55

MENTOR 12 USER’S MANUAL SECTION 3: ADVANCED CONTROL – Page 55

The execution display will show the three states of the test by means of horizontal bars

in different colors (blue for pre-fault, red for fault and white for post-fault) presenting all

the events where the selected trip condition has been satisfied by means of yellowcolored vertical lines.

Fault Execution. The trip has occurred during the Fault state

Page 56

MENTOR 12 USER’S MANUAL SECTION 3: ADVANCED CONTROL – Page 56

However, only the first valid trip that occurs, which is the first

after initiating the Fault state, will stop the test and change

(after the switch time, if any) to the post-fault state.

Two times appear on the actual graphic. One is the time that

has elapsed from the start of the function until the valid trip

and the other is the time that has elapsed from the start of the

Fault state to the valid trip indicated of the relay being tested.

This latter time is considered as the final result of the

function.

The test results are shown on the window situated under the

graphic. Here the times of ALL the trips that have occurred

are indicated, measured from the start of the relative state

where it occurred, as well as the total execution time of the

function indicated by the “END” tag. That is, if there is a trip in

pre-fault, the time indicated on the screen will be from the

moment when it began with the pre-fault, if there is a trip in

the fault, from the moment the fault state began and, if there

is a trip in the post-fault, from the moment when the post-fault

state started.

Furthermore, to record and identify the test results better, a

key appears in the lower left-hand corner which says

“Logger”. If you press this key, you can see absolutely all the

digital events that have occurred during the function

execution, with their relative identification and time tag. (See

LOGGER).

Page 57

MENTOR 12 USER’S MANUAL SECTION 3: ADVANCED CONTROL – Page 57

RAMP Function

The Ramp function, which is selected when you press the relative button, marked

“Ramp” located on the functions selection column, on the left of the advanced control

Page 58

MENTOR 12 USER’S MANUAL SECTION 3: ADVANCED CONTROL – Page 58

screen, permits carrying out upward or downward ramps of any output parameter

available on the Mentor.

The ramps are generally used to systematically determine the trip level of a protection

relay with respect to the parameter that is varied.

This is really the equivalent to moving the value of the parameter by mechanical means,

such as turning a variac, which is a normal task in classical relay testing.

One of the real advantages of being able to carry out a programmed ramp, is that both

the increases in value and the duration of the injection are always exactly the same, so

the test is always performed in exactly the same conditions, obtaining equal conditions

in each test in order to test the repetitive measurement capacity of the relay.

The ramps are not normally used with the Current parameter, especially if they are ver y

fine (very small increases) as these are long-lasting and continuously apply the current

to the relay, so it is relatively easy to overload it or even destroy its input unit. To vary

this parameter it is better to use the Pulse Ramp, described below.

However, the linear ramp is the best way of handling parameters such as the Phase

Angle, Voltage and Frequency, especially the latter, as the real performance of these

parameters can be reproduced with great precision.

2 simultaneous ramps can be configured using different parameters, each one applied

to different types of output sources, for example, one ramp moving the Voltage and the

other moving the Current (Impedance ramp).

Simultaneous ramps, even of different parameters applied to the same selected output

source, for example one ramp moving the voltage and the other moving the frequ ency

at the same time on the same output source, in this case voltage ( V/Hz variation ramp).

Configuration

All the ramp parameters can be configured on the configuration screen. As we have

already mentioned, two simultaneous ramps can be configured but below we will

indicate how just one is configured. Whenever one single ramp is required, it must be

configured as Signal 1. The ramp corresponding to Signal 2 can only be configured as a

second ramp. Proceed as indicated below for this:

Page 59

MENTOR 12 USER’S MANUAL SECTION 3: ADVANCED CONTROL – Page 59

• Press on the button situated in the upper left-han d

corner, marked “Signal1”

• A window will appear; press on the name of the

parameter you wish to use for the ramp. This may