SMC Networks LFE series Installation And Maintenance Manual

LFE**-TFP41

Installation and Maintenance Manual

Electromagnetic Digital Flow Switch

LFE* Series

Thank you for purchasing the LFE*Series Electromagnetic type Digital

Flow Switch.

Please read this manual carefully before operating the product and make

sure you understand its capabilities and limitations.

Please keep this manual in a safe place for future reference.

To obtain more detailed information about operating this product, please

refer to the SMC website ( URL http://www.smcworld.com

) or contact SMC

directly.

1 Safety Instructions

These safety instruction are intended to prevent a hazardous situation

and/or equipment damage.

These instructions indicate the level of potential hazard with the labels of

“Caution”,”Warning” or ”Danger”. They are all important notes for safety

and must be followed in addition to International standards(ISO/IEC),Japan

Industrial Standards(JIS) and other safety regulations.

Caution

Indicates a hazard with a low level of risk, which if not

avoided, could result in minor or moderate injury.

Warning

Indicates a hazard with a medium level of risk, which if

not avoided, could result in death or serious injury.

Danger

Indicates a hazard with a high level of risk, which if not

avoided, will result in death or serious injury.

Operator

・This operation manual has been written for those who have knowledge

of machinery and apparatus that use pneumatic equipment and have full

knowledge of assembly, operation and maintenance of such equipment.

・Please read this operation manual carefully and understand it before

assembling, operating or providing maintenance to the product.

Warning

1. The compatibility of the product is the responsibility of the person

who designs the equipment or decides its specifications.

Since the product specified here is used under various operating

conditions, its compatibility with specific equipment must be decided by

the person who designs the equipment or decides its specifications

based on necessary analysis and test results.

The expected performance and safety assurance of the equipment will

be the responsibility of the person who has determined its compatibility

with the product.

This person should also continuously review all specifications of the

product referring to its latest catalog information, with a view to giving

due consideration to any possibility of equipment failure when configuring

the equipment.

2. Only personnel with appropriate training should operate machinery

and equipment.

The product specified here may become unsafe if handled incorrectly.

The assembly, operation and maintenance of machines or equipment

including our products must be performed by an operator who is

appropriately trained and experienced.

3. Do not service or attempt to remove product and

machinery/equipment until safety is confirmed.

1. The inspection and maintenance of machinery/equipment should only

be performed after measures to prevent falling or runaway of the

driven objects have been confirmed.

2. When the product is to be removed, confirm that the safety measures

as mentioned above are implemented and the power from any

appropriate source is cut, and read and understand the specific

product precautions of all relevant products carefully.

3. Before machinery/equipment is restarted, take measures to prevent

unexpected operation and malfunction.

1 Safety Instructions (continued)

■ Do not disassemble, modify (including changing the printed

circuit board) or repair.

An injury or failure can result.

■ Do not operate the product outside of the specifications.

Do not use for flammable or harmful fluids.

Fire, malfunction, or damage to the product can result.

Verify the specifications before use.

■ Do not operate in an atmosphere containing flammable or

explosive gases.

Fire or an explosion can result.

This product is not designed to be explosion proof.

■ Do not use with flammable or highly permeable fluids.

Fire, explosion, damage or corrosion can result.

■ Do not use the product in a place where static electricity is a

problem.

Otherwise it can cause failure or malfunction of the system.

■ If using the product in an interlocking circuit:

•Provide a double interlocking system, for example a mechanical system.

•Check the product regularly for proper operation.

Otherwise malfunction can result, causing an accident.

■ The following instructions must be followed during maintenance:

•Turn off the power supply.

•Ensure the flow is shut off before performing maintenance.

Otherwise an injury can result.

Caution

■Do not touch the terminals and connectors while the power is on.

Otherwise electric shock, malfunction or damage to the product can

result.

■Do not touch the piping or its connected parts when the fluid is at

high temperature.

It may cause burns.

Ensure the piping cools sufficiently before touching.

■After maintenance is complete, perform appropriate functional

inspections and leak tests.

Stop operation if the equipment does not function properly or there is a

leakage of fluid.

When leaks occur from parts other than the piping, the product may be

faulty.

Cut off power supply and stop supplying fluid.

Do not apply fluid at leaking condition.

Safety cannot be assured in the case of unexpected malfunction.

2 Specifications

Refer to the product catalogue or SMC website ( URL

http://www.smcworld.com

) to obtain more detailed information about the

product specifications.

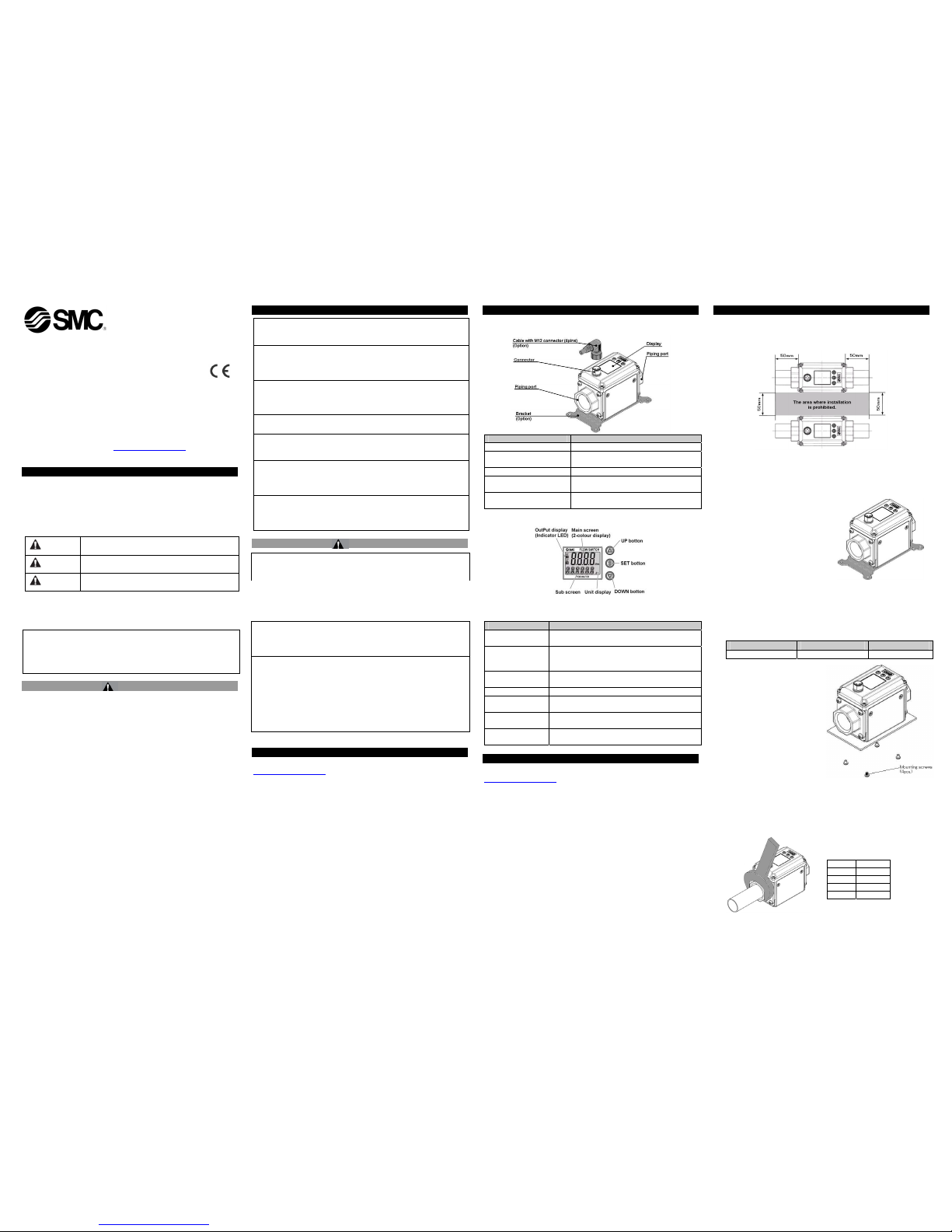

3 Summary of Product parts

3.1 Body

Item Description

Connector Connector for electrical connections.

Cable with M12 connector

Cable to supply power and transmit output

signals.

Piping port Port to connect the fluid.

Bracket

Mounting bracket used to install the

product.

Display

(With display only)

Displays the flow, settings and error codes.

(see below.)

3.2 Display (With display only)

Item Description

Main screen

(2-colour display)

Displays the flow, the status of setting mode and

error codes.

Sub screen

Displays the accumulated flow, set value,

peak/bottom value and line names. In

measurement mode, the set status is displayed.

Output display

(Indicator LED)

Displays the output status of OUT1 and OUT2.

When ON: Orange light is ON.

Unit display Displays the unit selected.

UP button

Selects the mode and the sub screen display, and

increases the ON/OFF set value.

SET button

Press this button to select mode and to confirm a

set value.

DOWN button

Selects the mode and the sub screen display, and

decreases the ON/OFF set value.

4 Mounting and Installation

Refer to the product catalogue or SMC website ( URL

http://www.smcworld.com

) for more detailed information.

4.1 Mounting

• Never mount the product in a location where it will be used as a support.

• Mount the product so that the fluid flows in the direction indicated by the

arrow on the side of the body.

• Check the flow characteristics data for pressure loss and the straight inlet

pipe length effect on accuracy, to determine inlet piping requirements.

• Do not sharply reduce the piping size.

• The piping port and metal part of the body are grounded to DC (-)/ blue.

Note that a power supply with positive ground cannot be used.

4 Mounting and Installation (continued)

• When several sensors are mounted in parallel, do not mount them in the

area where installation is prohibited as shown below.

If the product is mounted in the area where installation is prohibited, the

accuracy will decrease.

4.2 Installation

• Use the product within the specified operating pressure and temperature

range.

• Proof pressure is 2 MPa. Proof pressure could vary according to the fluid

temperature. Check the characteristics data for applying pressure.

Bracket mounting

Mount the product (with bracket)

using the mounting screws (M4 x 4

pcs).

Bracket thickness is approx. 1.6mm.

Refer to the outline dimension

drawing for the bracket thickness

and mounting hole dimensions.

Direct mounting

Mount the product with the screws stated below.

Thread type Nominal thread size Tightening torque

Self tapping screws 3 0.32 ±0.03 Nm

Refer to the dimension drawing

for mounting hole dimensions.

When a self tapping screw is

used, it should not be re-used

several times.

4.3 Piping

When connecting piping to the product, a spanner should be used on

the metal piping attachment only.

Using a spanner on other parts may damage the product.

In particular, do not let the spanner come into contact with the M12

connector.

The connector can be easily damaged.

Width across flats of attachment

Port Width

3/8 24 mm

1/2 28 mm

3/4 35 mm

1 41 mm

LFE**-TFP41

4 Mounting and Installation (continued)

Tighten to the specified torque for piping.

The tightening torque for connection threads is shown in the table below.

Nominal thread size Tightening torque

Rc(NPT)3/8 22 to 24 Nm

Rc(NPT)1/2 28 to 30 Nm

Rc(NPT)3/4 28 to 30 Nm

Rc(NPT)1 36 to 38 Nm

If the tightening torque is exceeded, the product can be damaged. If the

correct tightening torque is not applied, the fittings may become loose.

Avoid any sealing tape getting inside the port.

Ensure there is no leakage from loose piping.

4.4 Wiring

Wiring of connector

Connections should only be made with the power supply turned off.

Use separate routes for the Flow switch wiring and any power or high

voltage wiring. Otherwise, malfunction may result due to noise.

Ensure that the FG terminal is connected to ground when using a

commercially available switch-mode power supply. When a switch-mode

power supply is connected to the product, switching noise will be

superimposed and the product specification can no longer be met.

This can be prevented by inserting a noise filter, such as a line noise

filter and ferrite core, between the switch-mode power supply and the

product, or by using a series power supply instead of a switch-mode

power supply.

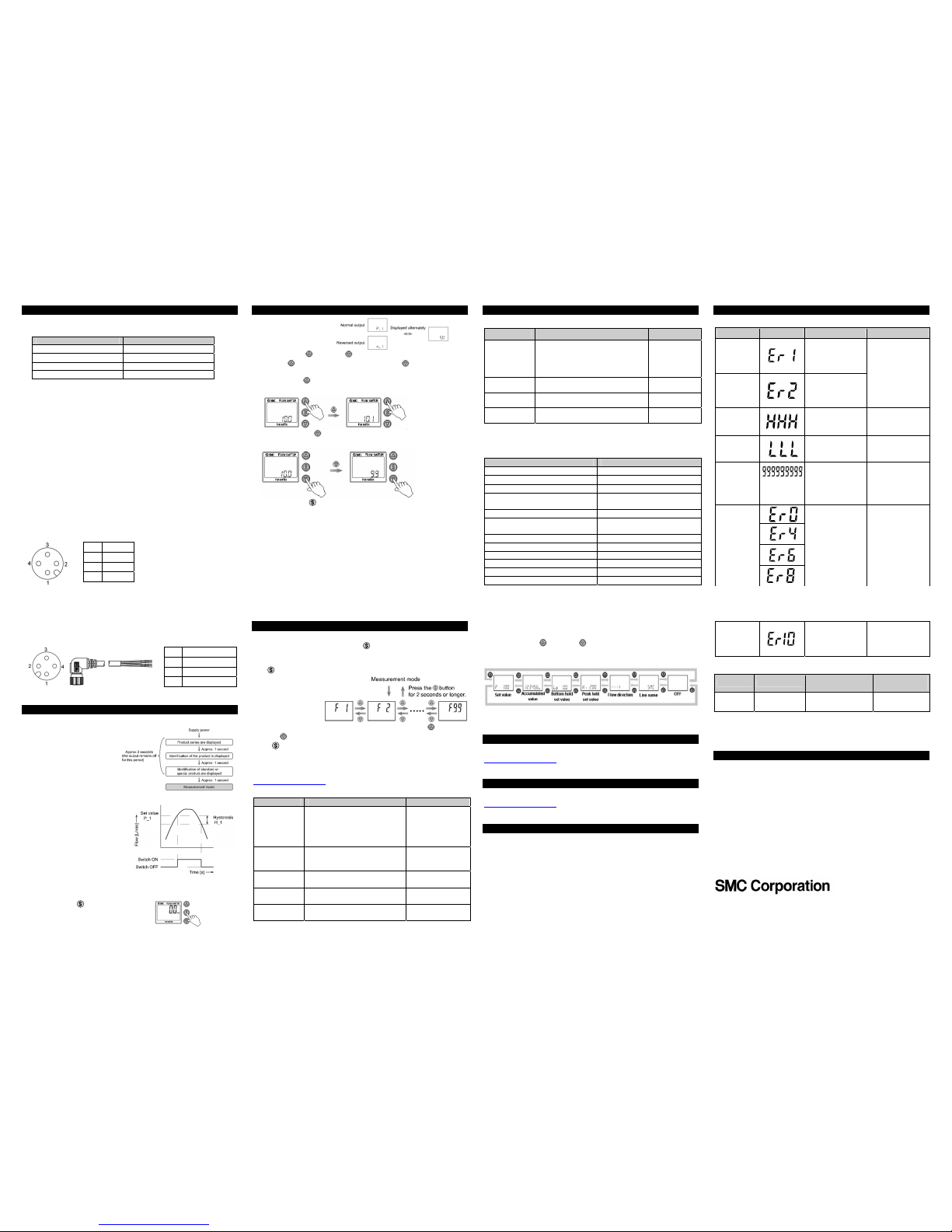

・Pin number of the connector ( on the product )

1 DC(+)

2 OUT2

3 DC(-)

4 OUT1

・Pin number of the connector ( on the cable )

1 DC(+): Brown

2 OUT2: White

3 DC(-): Blue

4 OUT1: Black

∗: When using the lead wire with M12 right angle connector.

5 Flow Setting

5.1 Measurement mode

The mode in which the flow is

detected and displayed, and

the switch function is

operating.

This is the basic operating

mode; other modes should be

selected for set-point and

other function setting changes.

Set ON and OFF points of the

switch output.

(With display only)

Switch operation

When the flow exceeds the set

value, the switch will be turned ON.

When the flow falls below the set

value by the amount of hysteresis

or more, the switch will be turned

OFF.

If the operation shown is

acceptable, keep this setting.

<Operation>

1. Press the SET

button in

measurement mode to display the set

values.

5 Flow Setting (continued)

2. [P_1] or [n_1] and the

set value are displayed

alternately.

3. Press the UP

or DOWN

button to change the set value.

The UP

button is to increase and the DOWN button is to

decrease the set value.

• Press the UP

button once to increase by one digit, press and hold

to continuously increase.

• Press the DOWN

button once to decrease by one digit, press and

hold to continuously decrease.

4. Press the SET button to finish the setting.

The switch turns on within a set flow range (from P1L to P1H) during

window comparator mode.

Set P1L (switch lower limit) and P1H (switch upper limit) using the

setting procedure above.

When reversed output is selected, the main screen displays [n1L] and

[n1H].

For models with 2 outputs, [P_2] or [n_2] will be displayed. Set as

above.

∗: If a button operation is not performed for 30 seconds during the setting

changes, the set value will start flashing.

6 Function Setting

6.1 Function selection mode (With display only)

In measurement mode, press the SET button for 2 seconds or longer,

to display [F 1].

[F] indicates the mode for changing each functional setting. Press the

SET button for 2 seconds or longer to return to measurement mode.

∗

: The sub screen will

display the content

of the function and

the setting

alternately.

The function number is increased and decreased by the UP

and

DOWN

buttons. Display the required function number and press the

SET button.

6.2 Default settings

The default settings are as follows. If these settings are acceptable, retain

for use.To change a setting, refer to the SMC website (URL

http://www.smcworld.com

) for more detailed information or contact SMC.

●[F 1] Setting of OUT1

Item Content Default setting

Output mode

Selects the switch output type

from: Instantaneous flow (either

hysteresis or window comparator

mode), accumulated flow or

accumulated pulse output.

Hysteresis mode

Reversed

output

Selects which type of switch

output is used, normal or

reversed.

Normal output

Set value

Sets the ON or OFF point of the

switch output.

50% of rated flow

Hysteresis

Setting of hysteresis can prevent

chattering.

5% of rated flow

Display colour

The display colour can be

selected.

Output ON: Green

Output OFF: Red

6 Function Setting (continued)

●[F 2] Setting of OUT2

Item Content Default setting

Output mode

Selects the switch output type from:

Instantaneous flow (either hysteresis

or window comparator mode),

accumulated flow or accumulated

pulse output.

Hysteresis

mode

Reversed

output

Selects which type of switch output

is used, normal or reversed.

Normal output

Set value

Sets the ON or OFF point of the

switch output.

50% of rated

flow

Hysteresis

Setting of hysteresis can prevent

chattering.

5% of rated

flow

∗: The display colour is linked to the setting of OUT1, and cannot be set for

OUT2.

●Other parameter settings

Item Default setting

[F 3] Response time 1 second

[F10] Sub screen Display of flow direction

[F20] External input Accumulated flow external reset

[F22] Analogue output

Free range analogue output for

instantaneous flow: OFF

[F30] Accumulated flow OFF [not held]

[F32] Flow direction mode,

Reversed flow detection

Normal flow

OFF

[F80] Power saving mode No setting [display is turned on]

[F81] Security code OFF

[F82] Input of line name No name [∗∗∗∗∗∗]

[F90] Setting of all functions OFF

[F98] Output check OFF

[F99] Reset to the default settings OFF

6.3 Sub screen display

In measurement mode, the sub screen display can be temporarily changed

by pressing the UP

or DOWN

buttons.

∗: After 30 seconds, it will automatically return to the display selected in

[F10].

The set values and accumulated output of OUT2 cannot be displayed.

(example shown is for 20 L/min type)

7 Other Settings

Refer to the product catalogue or SMC website ( URL

http://www.smcworld.com

) to obtain more detailed information about other

settings.

8 Outline Dimensions

Refer to the product catalogue or SMC website ( URL

http://www.smcworld.com

) to obtain more detailed information about outline

dimensions.

9 Maintenance

■ How to reset the product after a power cut or when the power has

been unexpectedly removed

The settings of the product are retained from before the power cut or deenergizing.

The output condition also recovers to that before the power cut or deenergizing, but may change depending on the operating environment.

Therefore, check the safety of the whole installation before operating the

product.

10 Troubleshooting

10.1 Error indication (With display only)

Error Name Display Content Remedy

OUT1

over current

error

The switch output

load current has

exceeded 80 mA

(OUT1).

OUT2

over current

error

The switch output

load current has

exceeded 80 mA

(OUT2).

Turn the power off

and remove the

cause of the over

current. Then turn

the power on again.

Excessive

instantaneous

flow

The flow rate has

exceeded the flow

rate range

Reset applied flow to

a level within the

flow range.

Reverse flow

error

The flow rate is in

the reverse direction

to the settings.

Apply the flow in the

correct direction.

Excessive

accumulated

flow

(Displays 「999」

and 「999999」

alternately)

The accumulated

flow range has been

exceeded.

Clear the

accumulated flow.

(applicable only if

the accumulated

flow is used)

System error

Internal data error

has occurred.

Turn the power off

and turn it on again.

Sensor error

The power supply

voltage has

exceeded the range

of 24 V ±10%.

Check the power

supply voltage, and

turn the power off

and on again.

10.2 Cross-reference for troubleshooting

Problem Probable cause

Recommended error

handling

Recommended

action

Output

error

Insufficient fluid

supply

Confirm whether the

fluid path is full

Fill the fluid path

If the error cannot be reset after the above measures are taken, please

contact SMC.

11 Contacts

AUSTRIA (43) 2262 62280-0 LATVIA (371) 781 77 00

BELGIUM (32) 3 355 1464 LITHUANIA (370) 5 264 8126

BULGARIA (359) 2 974 4492 NETHERLANDS (31) 20 531 8888

CZECH REP. (420) 541 424 611 NORWAY (47) 67 12 90 20

DENMARK (45) 7025 2900 POLAND (48) 22 211 9600

ESTONIA (372) 651 0370 PORTUGAL (351) 21 471 1880

FINLAND (358) 207 513513 ROMANIA (40) 21 320 5111

FRANCE (33) 1 6476 1000 SLOVAKIA (421) 2 444 56725

GERMANY (49) 6103 4020 SLOVENIA (386) 73 885 412

GREECE (30) 210 271 7265 SPAIN (34) 945 184 100

HUNGARY (36) 23 511 390 SWEDEN (46) 8 603 1200

IRELAND (353) 1 403 9000 SWITZERLAND (41) 52 396 3131

ITALY (39) 02 92711 UNITED KINGDOM (44) 1908 563888

URL : http// www.smcworld.com (Global) http// www.smceu.com (Europe)

Specifications are subject to change without prior notice from the manufacturer.

© 2012 SMC Corporation All Rights Reserved.

Loading...

Loading...