SMC Networks LEY series,LECSC,LEYG series LECSA,LECSB,LECSS Operation Manual

LEY Series

(Rod type)

Doc. no. LEY-OM00407

LEYG Series

(Guide Rod type)

LECSA

(

Positioning)

LECSS

(

Ⅲ)

(SSCNETⅢ/H)

AC Servo Motor

LECS Series

LECSB

(

)

LECSC

(

)

PRODUCT NAME

Electric Actuator / Rod Type

《 AC Servo Motor 》

MODEL / Series

LEY Series

Applicable models: LEY□ , LEYG□

Pulse input /

CC-Link

Driver

Pulse input

SSCNET

Contents

Safety Instructions ....................................................................2

1. Procedure before ope ra t ion ............................................4

2. Rod type / LEY Series .........................................................13

3. Guide rod type / LEYG Series ........................................17

1.1 Preparation ................................................................... 4

1.2 Startup .......................................................................... 6

1.3 Gain tuning ................................................................... 7

1.3.1 Procedure .................................................................. 7

1.3.2 The recommended the parameter for each driver . 8

2.1 Specification .............................................................. 13

2.2 How to Order .............................................................. 15

2.3 Construction .............................................................. 16

3.1 Specification .............................................................. 17

3.2 How to Order .............................................................. 18

3.3 Construction .............................................................. 19

4. Product Outline ......................................................................20

4.1 System construction ................................................. 20

4.2 Function/Configuration ............................................. 23

5. Wiring of cables / Common precautions .................24

6. Electric actuator s / Comm on pre caut ions ..............25

6.1 Design and selection ................................................. 25

6.2 Mounting .................................................................... 26

6.3 Handling ..................................................................... 27

6.4 Operating environment ............................................. 28

6.5 Maintenance ............................................................... 29

6.6 Precautions for actuator with lock ........................... 29

7. Electric actuator s / Rod Type Common precautions ........30

7.1 Design ........................................................................ 30

7.2 Selection..................................................................... 30

7.3 Handling ..................................................................... 30

7.4 Mounting .................................................................... 32

7.5 Precaution on maintenance ...................................... 35

8. Troubleshooting ....................................................................36

8.1 Alarms and Warning ................................................ 36

-1-

indicates a hazard with a low level of risk which, if not avoided, could result in minor

indicates a hazard with a high level of risk which, if not avoided, will result in death or

Warning

Do not service or attempt to remove product and machinery /equipment until safety is

4. Contact SMC beforehand and take special consideration of safety measures if the product is to

LEY Series / Electric Rod type

Safety Instructions

These safety instructions are intended to prevent hazardous situations and /or equipment damage.

These instructions indicat e the lev el of potentia l hazard w ith the labels o f “Caut ion,” “Warning” or “Dange r.”

They are all important notes for safety and must be followed in addition to International Standards (ISO

/IEC), Japan Industrial St andards (JIS)*1) and other saf ety regulations*2).

*1) ISO 4414: Pneumatic fluid power -- General rules relating to systems

ISO 4413: Hydraulic fluid power -- General rules relating to systems

IEC 60204-1: Safety of machinery -- Electrical equipment of machines (Part 1: General requirements)

ISO 10218-1992: Manipulating industrial robots -- Safety

JIS B 8370: General rules for pneumatic equipment.

JIS B 8361: General rules for hydraulic equipment.

JIS B 9960-1: Safety of machinery – Electrical equipment for machines. (Part 1: General requirements)

JIS B 8433-1993: Manipulating industrial robots - Safety. etc.

*2) Labor Safety and Sanitation Law, etc.

Caution

Warning

Danger

Caution

or moderate injury.

Warning indicates a hazard with a medium level of risk which, if not avoided, could res ult in

death or serious injury.

Danger

serious injury.

1. The compatibility of the product is the responsibility of the person who designs the equipment

or decides its specifications.

Since the product spec ified here is used under var ious operating conditions, its compatibility with specific

equipment must be decided by the person who designs the equipment or decides its specifications based on

necessary analysis and test results.

The expected perform ance and safety assurance of the equipment will be the r esponsibility of the perso n

who has determined its compatibility with the product.

This person should also c ontinuously review all specificatio ns of the product referring to its latest catalog

information, with a v iew to giving d ue considerat ion to any possi bility of equi pment failure when configurin g

the equipment.

2. Only personne l with appropriate training should operate mac hi nery and equipm ent.

The product specified here may become unsafe if handled incorrectly.

The assembly, operation and maintenance of machines or equipment including our products must be

performed by an operator who is appropriately trained and experienced.

3.

confirmed.

The inspection and maintenance of machinery /equipment should only be performed after measures to

prevent falling or runaway of the driven objects have been confirmed.

When the product is to be removed, confirm that the safety measures as mentioned above are implemented

and the power from any appropriate source is cut, and read and understand the specific product precautions

of all relevant products carefully.

Before machinery /equipment is restarted, take measures to prevent unexpected operation and malfunction.

be used in any of t he f oll owing conditions.

1) Conditions and environments outside of the given specifications, or use outdoors or in a place exposed to

direct sunlight.

2) Installation on equipment in conjunction with atomic energy, railways, air navigation, space, shipping,

vehicles, military, medical treatment, combustion and recreation, or equipment in contact with food and

beverages, emergency stop circuits, clutch and brake circuits in press applications, safety equipment or

other applications unsuitable for the standard specifications described in the product catalog.

3) An application which co uld have negat ive effects on people, propert y, or animals requiring special safety

analysis.

4) Use in an inter lock circ uit, which requ ires the prov ision of do uble interloc k for pos sible failure by using a

mechanical protective function, and periodical checks to confirm proper operation.

-2-

Caution

the product in other industries, consult SMC beforehand and exchange specifications

If anything is unclear, contact your nearest sales branch.

Also, the product may have specified durability, running distance or replacement parts. Please

For any failure or damage reported within the warranty period which is clearly our responsibility, a

This limited warranty applies only to our product independently, and not to any other damage

erms and disclaimers

due to the deterioration of rubber material are not covered by the limited warranty.

by the Ministry of Economy, Trade and

LEY Series / Electric Rod type

Safety Instructions

The product is pr ovided for use in manufacturing industries.

The product herein described is basically provided f or peaceful use in manufacturing industries.

If considering using

or a contract if necessary.

Limited warranty and Disclaimer /Compliance Requirements

The product used is subject to the following “Limited warranty and Disclaimer” and “Compliance

Requirements”.

Read and accept them before using the product.

Limited warran ty and Disclaimer

The warranty period of the pr od uct is 1 year in service or 1.5 years after the product i s delivered.*3)

consult your nearest sal es branch.

replacement product or necessary parts will be provide d.

incurred due to the failure of the product.

Prior to using SMC products, please read and understand the warranty t

noted in the specified cat a log for the p a r t icular products.

*3) Vacuum pads are excluded from this 1 year warranty.

A vacuum pad is a consumable part, so it is warranted for a year after it is delivered.

Also, even within the warranty period, the wear of a product due to the use of the vacuum pad or failure

Compliance Requirem e nts

When the product is exported, strictly follow the laws required

Industry (Foreign Exchan ge and Foreign Trade Control Law).

-3-

No.

Part name

Qty

(1)

Electric Actuator /LEY Series

1

(2)

Driver / LECS Series

1(in case with driver)

(3)

Motor cable

(4)

Encoder cable

(5)

Lock cable

(6)

I/O Connector

1(in case with I/O connector )

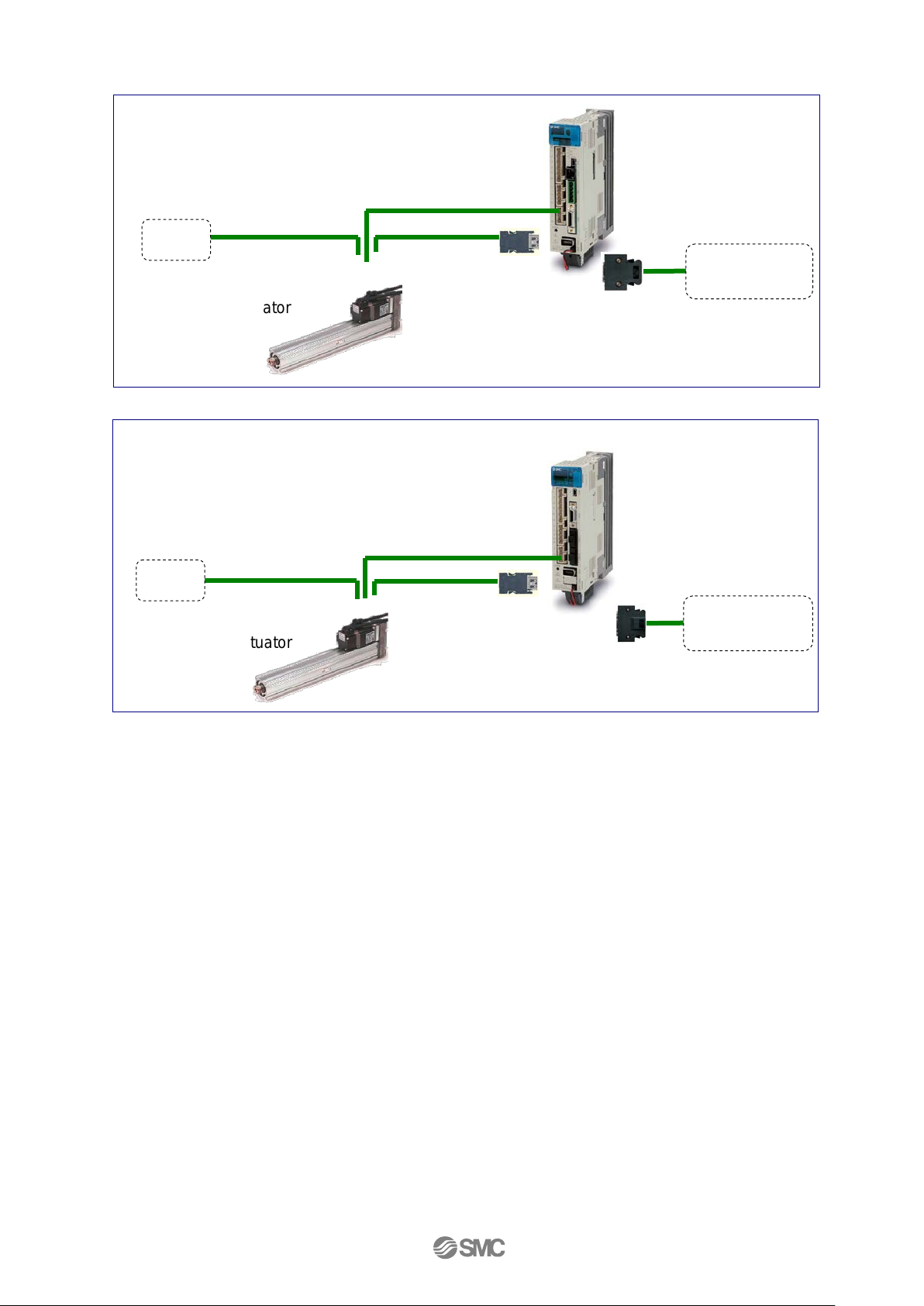

LECSA(Pulse input / Positioning)

(2) Driver

(3) Motor cable

(4) Encoder cable

(1) Electric Actuator

(5) Lock cable

(2) Driver

(3) Motor cable

(4) Encoder cable

(1) Electric Actuator

(5) Lock cable

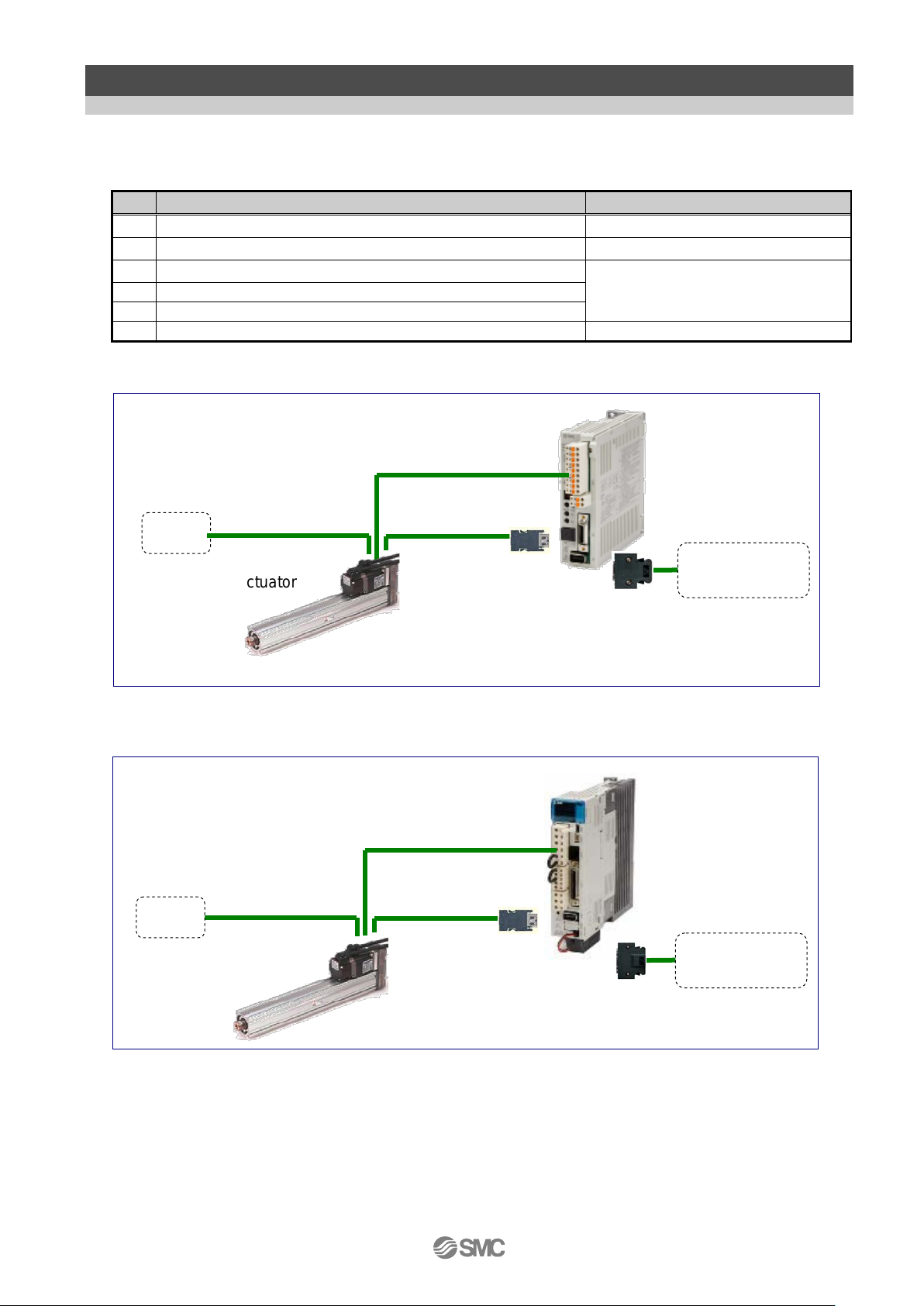

LECSB(Pulse input)

(6) I/O Connector

(6) I/O Connector

1. Procedure before opera t ion

1.1 Preparation

(1) Items to be prepared

Please check on the label, and the quantity of accessories, to confirm that it is the product that was

ordered.

Table 1. Componets

Pre-installed (1)

(in case with cable)

DC24V

PC, PLC, etc

DC24V

PC, PLC, etc

-4-

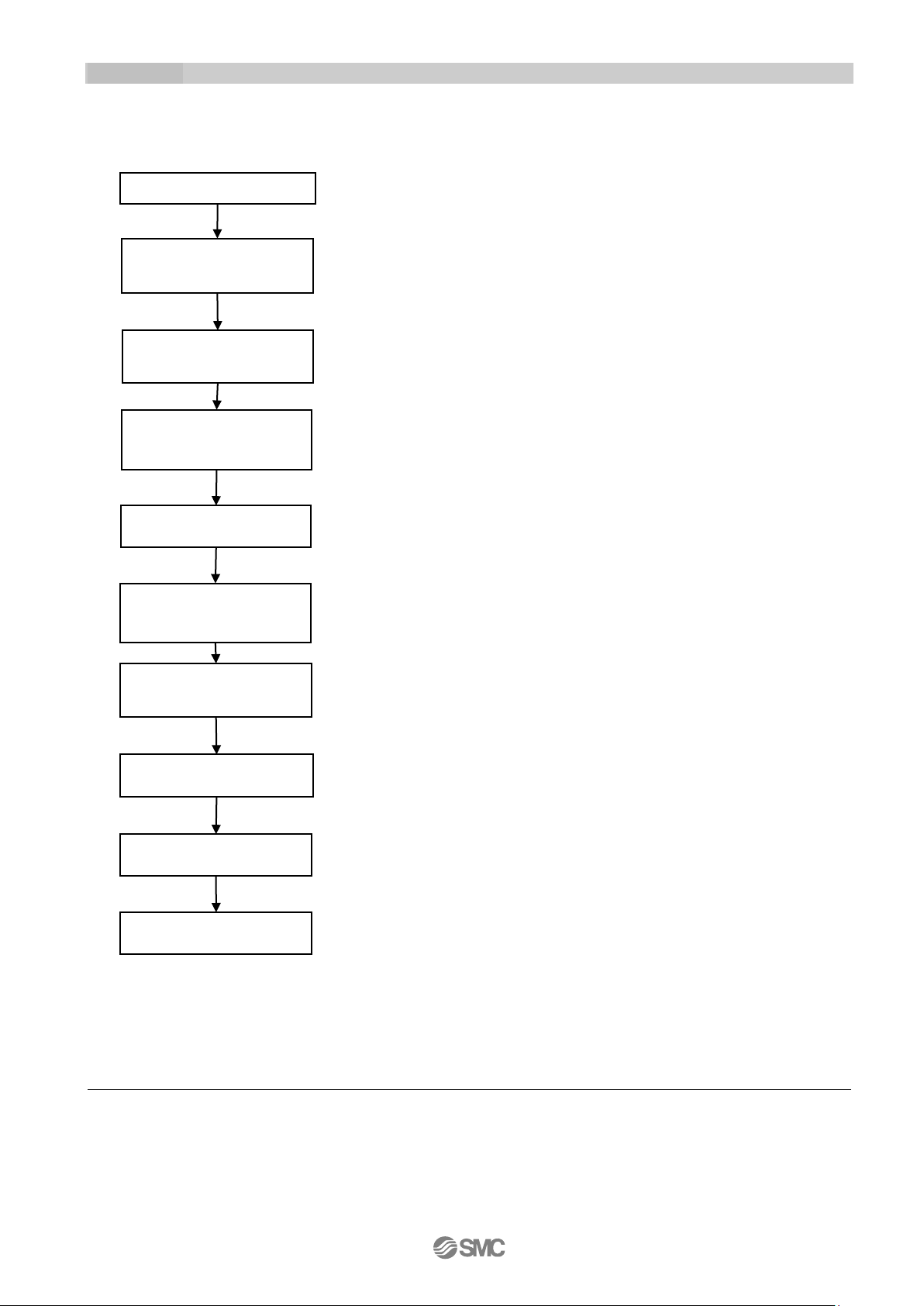

LECSC(CC-Link)

(2) Driver

(3) Motor cable

(4) Encoder cable

(1) Electric actuator

(5) Lock cable

(2) Driver

(3) Motor cable

(4) Encoder cable

(1) Electric actuator

(5) Lock cable

LECSS(SSCNET III) /LECSS-T ( SSCNET III / H )

(6) I/O connector

(

I/O connector

DC24V

Host controller,

etc

DC24V

Host controller,

etc

6)

Refer to the “ Electric actuator / Common precautions 6.2 Mounting No.11” for details and for cable

connection methods.

-5-

Wiring check

circuit power supply

I/O signal wiring and

during power-on

Confirm that the cables to the driver and actuator are

Check the surrounding environment (cable routing and

Follow the procedure shown in the "Driver Operation

Check the wiring of the input and output signals and

according to the procedure shown in the "Driver

control mode and each control value.

Follow the procedure shown in the "Driver Operation

Use the test operation mode (JOG operation) at the

slowest speed and check whether the servo motor

rotates.

Operation with a vibration might be done according to the

In that case, adjust gain. (Refer to section 1.3)

Check if the cables to the driver and actuator are

Stops command to stop the operation.

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

1)CC-Link cable (LECSC), SSCNETIII cable (LECSS)

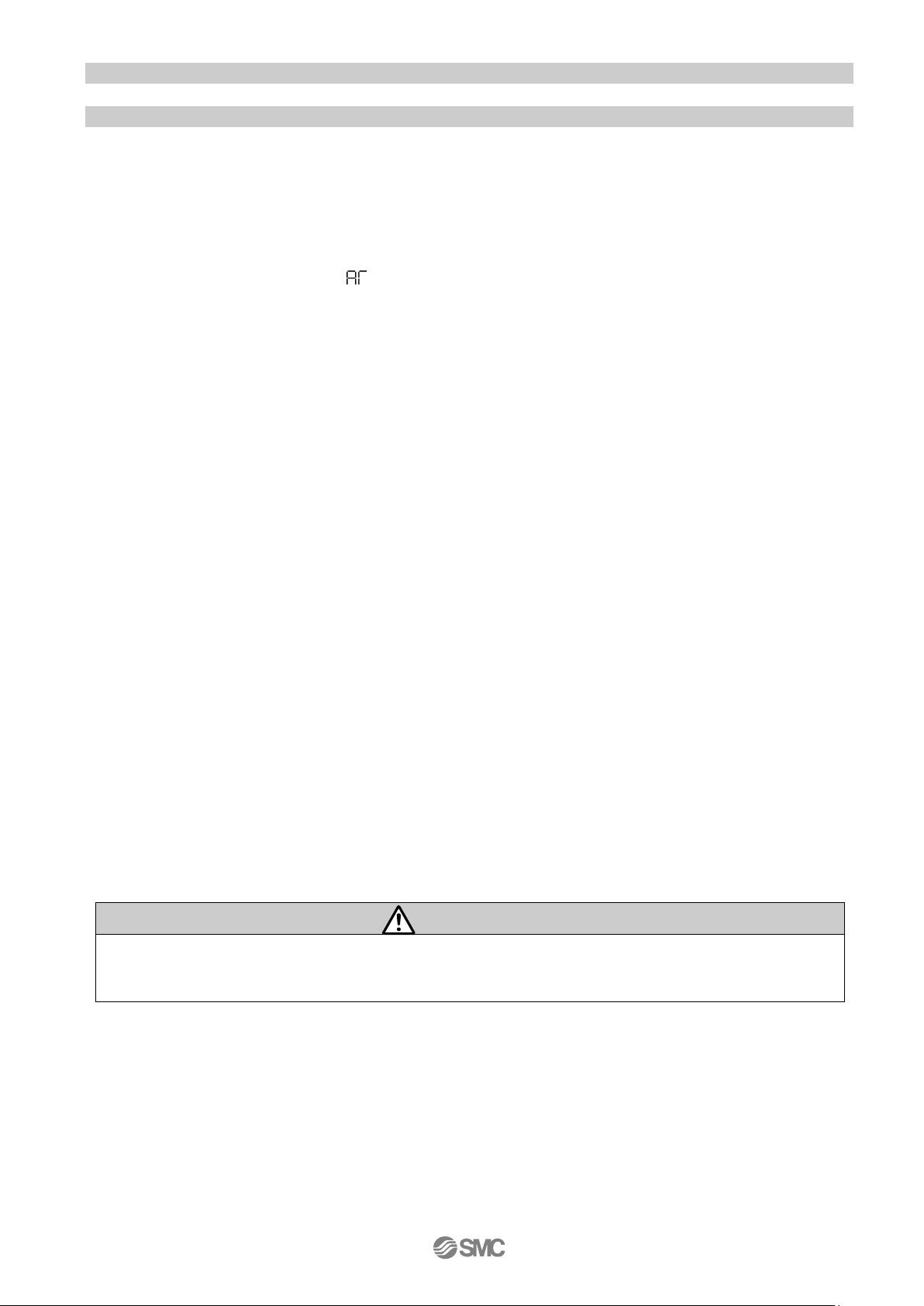

1.2 Startup

When switching the power on for the first time, follow the startup procedure below.

Refer to the “Driver operation manual” for wiring method and deta iled pr ocedure.

connected correctly.

Surrounding

environment check

Power-on of the contrd

cables check

Parameter setting

Power-on of the main

circuit power supply

Test oper ation

(JOG operation)

impurity such as wire offcuts or metallic dust) of the driver

and the servo motor.

Manual" to supply power to t he pr oduct.

cables1)

Operation Manual".

Set the parameters as necessary, such as selecting the

Manual" to supply power to t he pr oduct.

2)

Gain tuning

Actual operation

Stop

2)When using test operation mode (JOG operation), the LECSC and LECSS need the

MR-Configurator, the LECSS-T needs the MR-Configurator2.

condition.

connected correctly.

-6-

Warning

Refer to "The recommend ed t he parameter for each dri ver" for the parameter.

1.3 Gain tuning

1.3.1 Procedure

Here are the steps for basic gain tuning.

Refer to the “Driver operation manual” for details and for tuning methods other than shown below.

●For LECSA (Pulse input / Positio ni ng)

A. One-touch tuning

During motor driving, push “AUTO” button on the front of the driv er for three seconds.

When display panel becomes “ ”, push “AUTO” button again.

⇒The gain (including filter, etc) is adjuste d automatically.

When the error occurs, refer to the “Driver operation manual”.

B. Auto tuning (Mode1) 1)

Do this operation, if you ar e not satisfied with the result of “One-touch tuning”.

Set parameter N o. PA08 “001”. Afterwards, do 1 and 2 alternately.

1. Reduce value of parameter No.PA09 to be less than present value.

2. Operate and ascer tain the situation.

⇒The gain is adjusted automatically.

●For LECSB (Pulse input), LECSC (CC-Link), LECSS(SSCNETIII)

A. Adaptive filter II

Set parameter N o. PB01 “0001” and drive t he m otor.

⇒The filter is adjuste d aut omatically.

B. Auto tuning (Mode1)

Do this operation, if you ar e not satisfied with the result of “Adaptive f ilter II”.

Set parameter N o. PA08 “0001”. Afterwards, do 1 and 2 a lter nat ely.

1. Reduce value of parameter No.PA09 to be less than present value.

2. Operate and ascer tain the situation.

⇒The gain is adjusted automatically.

●For LECSS-T(SSCNET III/H)

A. Auto tuning (Mode1)

Set parameter N o. PA08 “0001”. Afterwards, do 1 and 2 a lter nat ely.

1. Reduce value of parameter No.PA09 to be less than present value.

2. Operate and ascer tain the situation.

⇒The gain is adjusted automatically.

B. Robust filter

Do this operation, if you ar e not sat isfied with the result of “Auto tuning”.

Set parameter N o. PE41 “0001” and drive t he m otor.

⇒The filter is adjuste d aut omatically.

A mechanical resonance may occ ur depending on the configurat ion or t he mounting orientati on of the

transferred object. Plea se change the appropriate parameter in the initial setting.

1) The auto tuning mode 1 may not be perfor m ed pr operly if the following conditions are not satisfied.

・Time to reac h 2,000rpm is the acceleration/deceleration time constant of 5[s] or less.

・Speed is 150rpm or higher.

・Load to motor inertia is 100 times or less.

・The acceleration/dece leration is 10% or more of the rated torque.

-7-

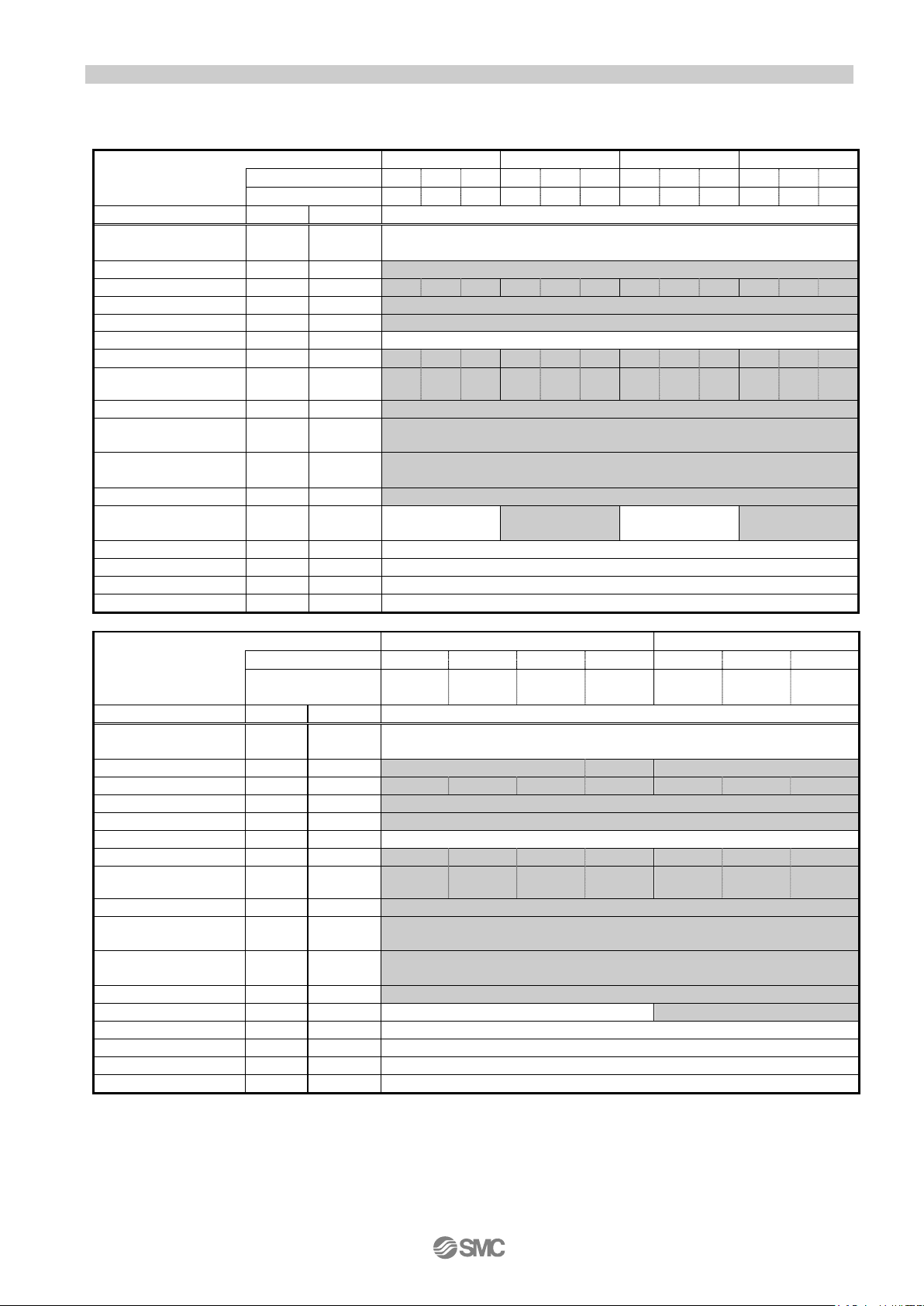

LEY25/LEYG25

LEY25D/LEYG25D

LEY32/LEYG32

LEY32D/LEYG32D

Lead symbol

A B C A B C A B C A B C Lead

12 6 3

12 6 3

20

10 5 16 8 4

Parameter

Para. No

Initial value

Recommended value

Number of command input pulses per

revolution *3

Electronic gear numerator *3

PA06

1

100 (Positioning mode: 10)

Electronic gear denominator *3

PA07

1

12 6 3

12 6 3

20

10 5 16 8 4

Feel length multiplication (STM) (Multiplier)

PE02

0000

0000 (Less than stroke 1000) / 0001 (Stroke 1000 or more)

Home position return type

PE03

0010

□□□3 (Stopper type)

Home position return direction

PE03

0010

□□1□(Motor side)

Home position return Speed (rpm)

PE04

500

150

300

600

150

300

600

90

180

360

112

225

450

Home position return/JOG operation

acceleration/deceleration time constants (msec)

Home position return position data (μm)

PE08 0 -2000(Less than stroke 1000) / -200 (Stroke 1000 or more)

Stopper type home position return

stopper time (msec)

Stopper type home position return torque limit

value (%)

Regenerative option

PA02

000

000 (Non)/ 002 (LEC-MR-RB032)

0

(+:Counter motors side)

1

(+:Counter motors side )

0

(+:Counter motors side)

1

(+:Counter motors side )

Adaptive tuning mode

PB01

000

000

Load to motor inertia moment ratio

PB06

7

7

Machine resonance suppression filter 1

PB13

4500

4500

Notch shape selection 1

PB14

000

000

LEY63

LEY63D

Lead symbol

A B C L A B C

5(2.86)

Parameter

Para. No

Initial value

Recommended value

Number of command input pulses per

revolution *3

Electronic gear numerator *3

PA06 1 100 (10)

35 (7)

100 (10)

Electronic gear denominator *3

PA07 1 20

10 5 1(2)

20

10

5

Feel length multiplication (STM) (Multiplier)

PE02

0000

0000 (Less than stroke 1000) / 0001 (Stroke 1000 or more)

Home position return type

PE03

0010

□□□3 (Stopper type)

Home position return direction

PE03

0010

□□1□(Motor side)

Home position return Speed (rpm)

PE04

500

90

180

360

629

90

180

360

Home position return/JOG operation

acceleration/decel eration time constants (msec)

Home position return position data (μm)

PE08 0 -4000(Less than stroke 1000) / -400 (Stroke 1000 or more)

Stopper type home position return

stopper time (msec)

Stopper type home position return torque limit

value (%)

Regenerative option

PA02

000

000 (Non)/ 002 (LEC-MR-RB032)/ 003 (LEC-MR-RB12)

Rotation di rection sel ection

PA14 0 0 (+:Counter motors side)

1 (+:Counter motors side )

Adaptive t uning mode

PB01

000

000

Load to motor inertia moment ratio

PB06

7

7

Machine resonance suppression filter 1

PB13

4500

4500

Notch shape selection 1

PB14

000

000

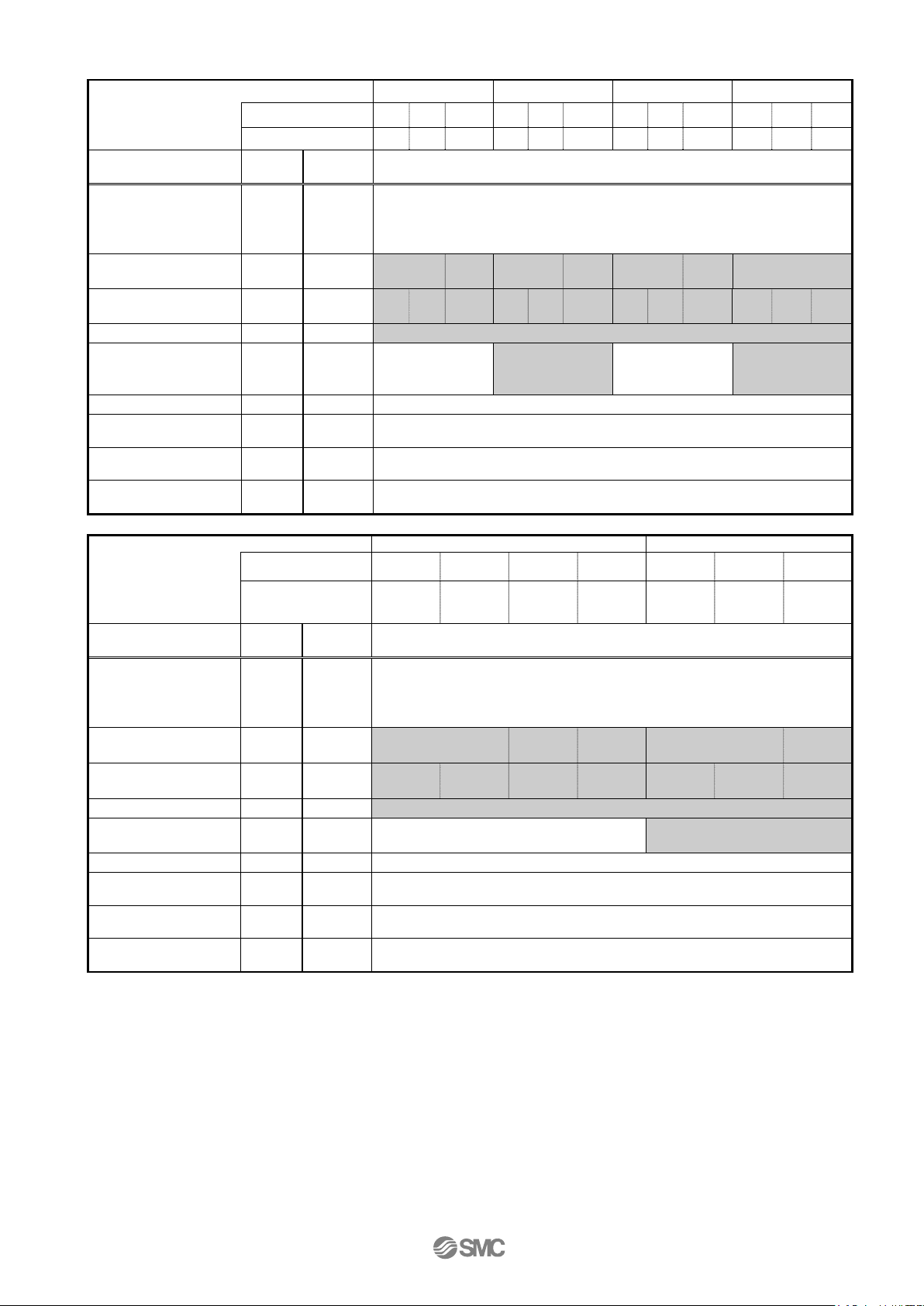

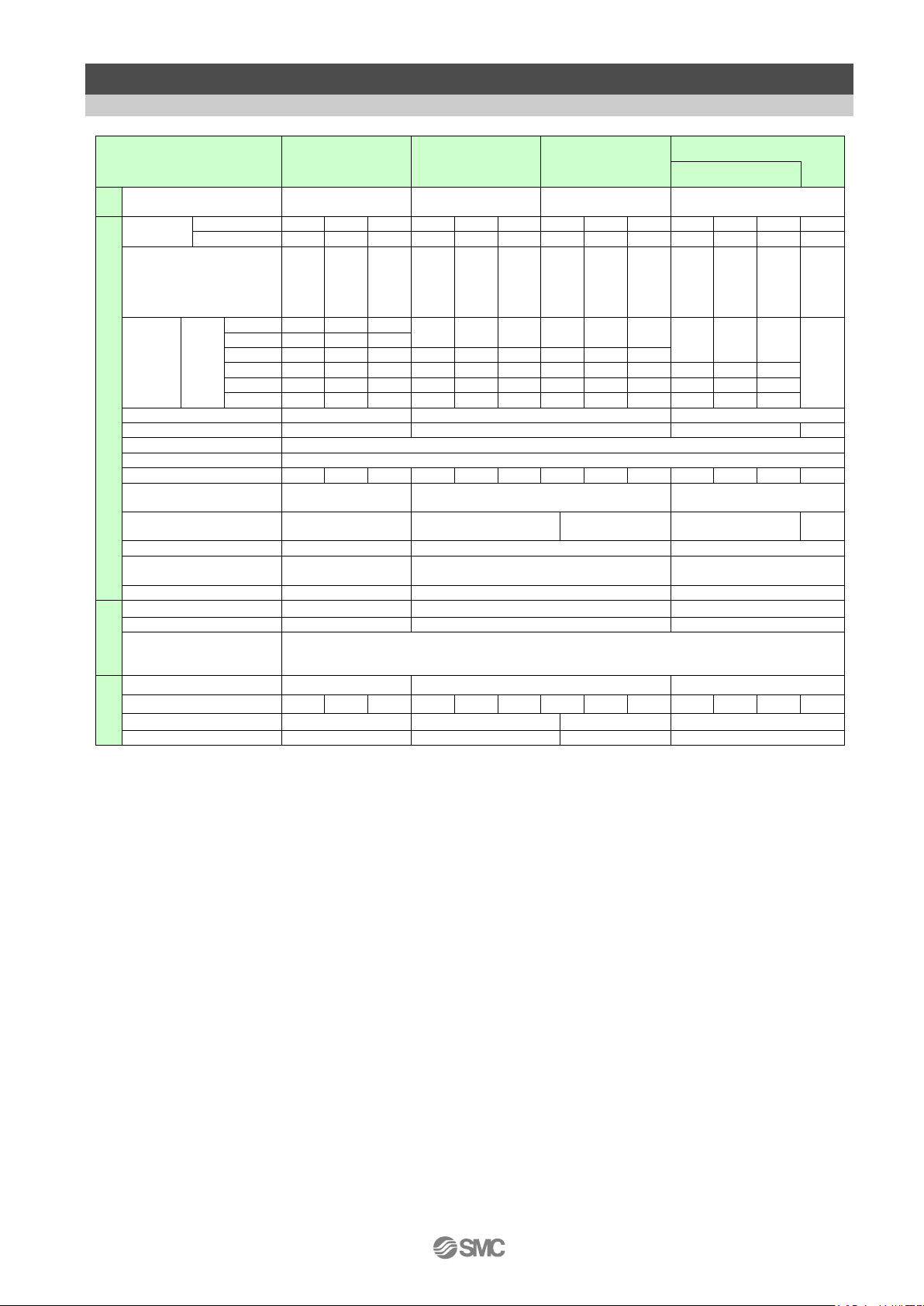

1.3.2 The recomme nde d the parameter for each driver

The recommended the parameter for each driver. Please change the parameter values by use of the

customer.Please refer to the manual of the driver for more details.

[LECSA]

Series

PA05 100 100

Rotation di rection sel ection

Series

PE07 100 600 300 150 600 300 150

PE10 100 200

PE11 15 30

PA14 0

Lead 20 10 5

PA05 100 100

(Pulley raito 4/7)

1000

500 250 800 400 200

20 10 5

PE07 100 1000 500 250 143 1000 500 250

PE10 100 200

PE11 15 30

*1 Parameter is the recommended value. Please change the parameter to make appropriate value for your

operating method.

*2 A mechanical resonance may occur depending on the configuration or the mounting orientation of the

transferred object. Please change the parameter in the initial setting.

*3 When the positioning mode is not set: The travel distance of the actuator per 1 pulse should be 10 [μm/pulse].

When the positioning mode is set: The minimum unit of the travel distance of the actuator should be 1 [μm].

-8-

Initial

value

Number of

revolution

*3

Electronic gear

numerator *3

Electronic gear

denominator *3

15

0

15

0

250 12

5

Regenerative option

PA02

0000

0000 (Non)/ 0002 (LEC-MR-RB032)

0

motors side)

1

motors side )

0

motors side)

1

motors side )

Adaptive tuning mode

PB01

0000

0000

Load to motor inertia

moment ratio

Machine resonance

suppression filter 1

Notch shape selection

1

LEY63

LEY63D

5(2.86)

raito 4/7)

Initial

value

Number of

revolution

*3

Electronic gear

numerator *3

Electronic gear

denominator *3

Regenerative option

PA02

0000

0000 (Non)/ 0002 (LEC-MR-RB032)/ 0003 (LEC-MR-RB12)

Rotation direction

selection

0

(

+:Counter motors side)

1

(+:Counter motors side )

Adaptive tuning mode

PB01

0000

0000

Load to motor inertia

moment ratio

Machine resonance

suppression filter 1

Notch shape selection

1

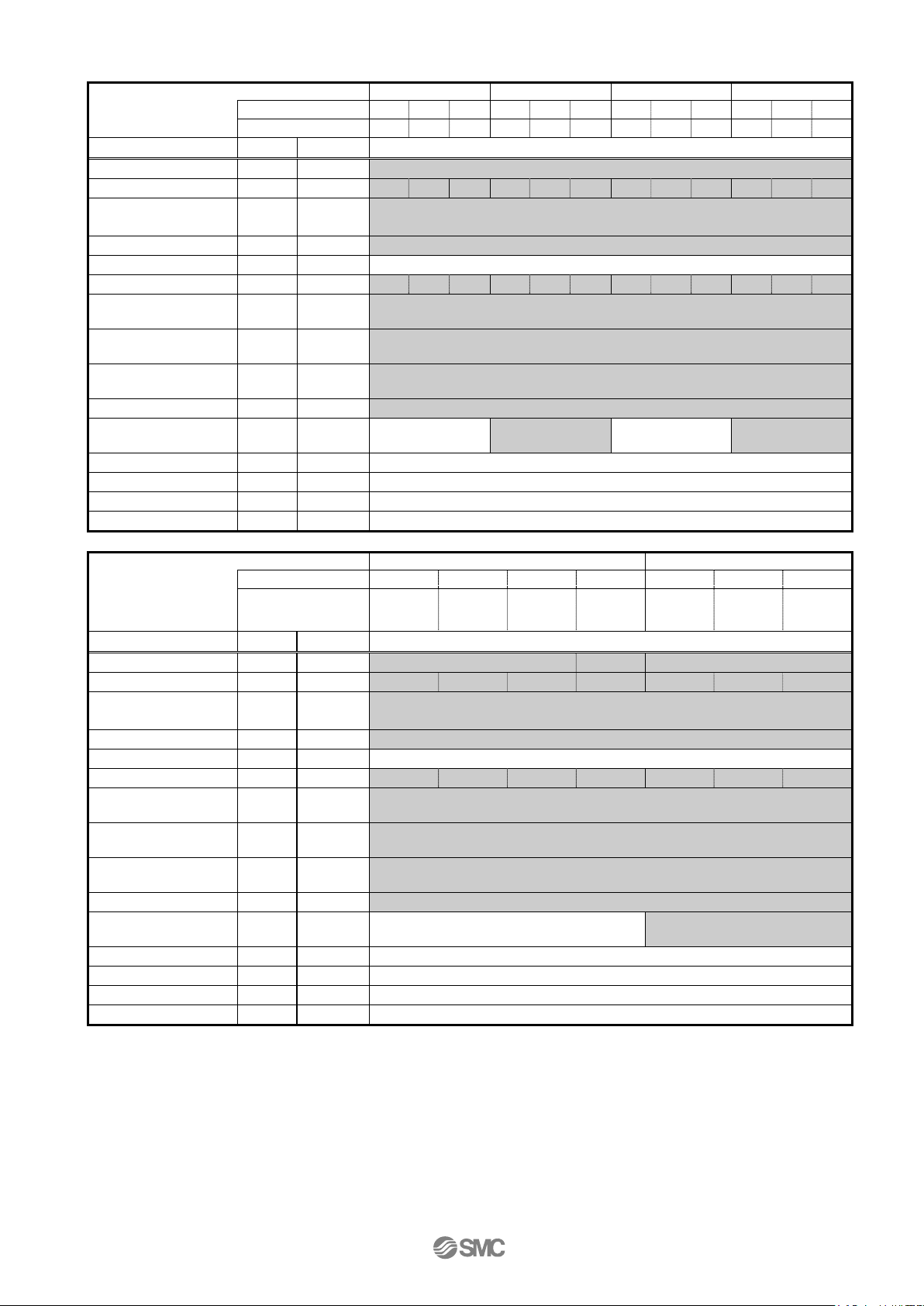

[LECSB]

Series

Lead symbol A B C A B C A B C A B C

Lead

LEY25/LEYG25 LEY25D/LEYG25D LEY32/LEYG32 LEY32D/LEYG32D

12 6 3 12 6 3 20 10 5 16 8 4

Parameter

command input

pulses per

Rotation direction

selection

Series

Para. No

PA05 0 0

PA06 1 32768

PA07 1

(

PA14

PB06 7 7

PB13 4500 4500

PB14 0000 0000

Lead symbol A B C L A B C

0

Lead 20 10 5

+:Counter

75

65536

75

Recommended value

32768

(+:Counter

75

65536

75

(Pulley

32768

(

+:Counter

65536

125 200 100 50

20 10 5

(+:Counter

32768

Parameter

command input

pulses per

Para. No

PA05 0

PA06 1 32768 65536 114688 32768 65536

PA07 1

PA14 0

PB06 7 7

PB13 4500 4500

PB14 0000 0000

250 125 125 125 250 125 125

Recommended value

0

*1 Parameter is the reco mmende d v alue. P lease c h ange the p ara meter to ma ke appr opri ate v alue for y our

operating method.

*2 A mechanical resonance may occur depend ing on the configuration or the mo unt ing orientation of the

transferred object. Plea se change the parameter i n the initial setting.

*3 The travel distance of the actuator per 1 pul s e should be 10 [μm/pulse].

-9-

[LECSC]

LEY25/LEYG25

LEY25D/ EYG25D

LEY32/LEYG32

LEY32D/ EYG32D

Lead symbol

A B C A B C A B C A B

C

Lead

12 6 3

12 6 3

20

10 5 16 8 4

Parameter

Para. No

Initial value

Recommended value

Electronic gear numerator *3

PA06

1

32768

Electronic gear enominator *3

PA07

1

1500

750

375

1500

750

375

2500

1250

625

2000

1000

500

Feel length multiplication

(STM) (Multiplier)

Home position return type

PC02

0000

□□□3 (Stopper type)

Home position return direction

PC03

0001

□□□1 (Motor side)

Home position return Speed (rpm)

PC04

500

150

300

600

150

300

600

90

180

360

112

225

450

Home position return p osition

data (μm)

Stopper type home posi tion

return stop per time (ms ec)

Stopper type home posi tion

return tor qu e limit value (%)

Regenerative option

PA02

0000

0000 (Non)/ 0002 (LEC-MR-RB032)

0

(+:Counter motors side)

1

(+:Counter motors side )

0

(+:Counter motors side)

1

(+:Counter motors side )

Adaptive t uning mode

PB01

0000

0000

Load to motor inertia moment ratio

PB06

7

7

Machine resonance suppression filter 1

PB13

4500

4500

Notch shape selecti on 1

PB14

0000

0000

LEY63

LEY63D

Lead symbol

A B C L A B C

5(2.86)

raito 4/7)

Parameter

Para. No

Initial value

Recommended value

Electronic gear numerator *3

PA06

1

32768

57344

32768

Electronic gear enominator *3

PA07

1

2500

1250

625

625

2500

1250

625

(STM) (Multiplier)

Home position return type

PC02

0000

□□□3 (Stopper type)

Home position return direction

PC03

0001

□□□1 (Motor side)

Home position return speed (rpm)

PC04

500

90

180

360

629

90

180

360

Home position return p osition

data (μm)

Stopper type home posi tion

return stop per time (ms ec)

Stopper type home posi tion

return tor qu e limit value (%)

Regenerative option

PA02

0000

0000 (Non)/ 0002 (LEC-MR-RB032)/ 0003 (LEC-MR-RB12)

0

(

+:Counter motors side)

1

(+:Counter motors side )

Adaptive t uning mode

PB01

0000

0000

Load to motor inertia moment ratio

PB06

7

7

Machine resonance suppression filter 1

PB13

4500

4500

Notch shape selecti on 1

PB14

0000

0000

Series

PA05 0000 0000 (Less than stroke 1000) / 0001 (Stroke 1000 or more)

PC07 0 -2000(Less than stroke 1000) / -200 (Stroke 1000 or more)

PC09 100 200

PC10 15 30

Rotation di rection sel ection

Series

Feel length multiplication

PA14 0

Lead

PA05 0000 0000 (Less than stroke 1000) / 0001 (Stroke 1000 or more)

PC07 0 -4000(Less than stroke 1000) / -400 (Stroke 1000 or more)

PC09 100 200

PC10 15 30

20 10 5

(Pulley

20 10 5

Rotation di rection sel ection

*1 Parameter is the reco mmende d v alue. P lease c h ange the par am eter t o ma ke appr opri ate v alue for y our

operating method.

*2 A mechanical resonance may occur depend ing on the configuration or the mo unt ing orientation of the

transferred object. Plea se change the parameter i n the initial setting.

*3 The minimum unit o f t he travel distance of the actuator should be 1 [μm].

PA14 0

-10-

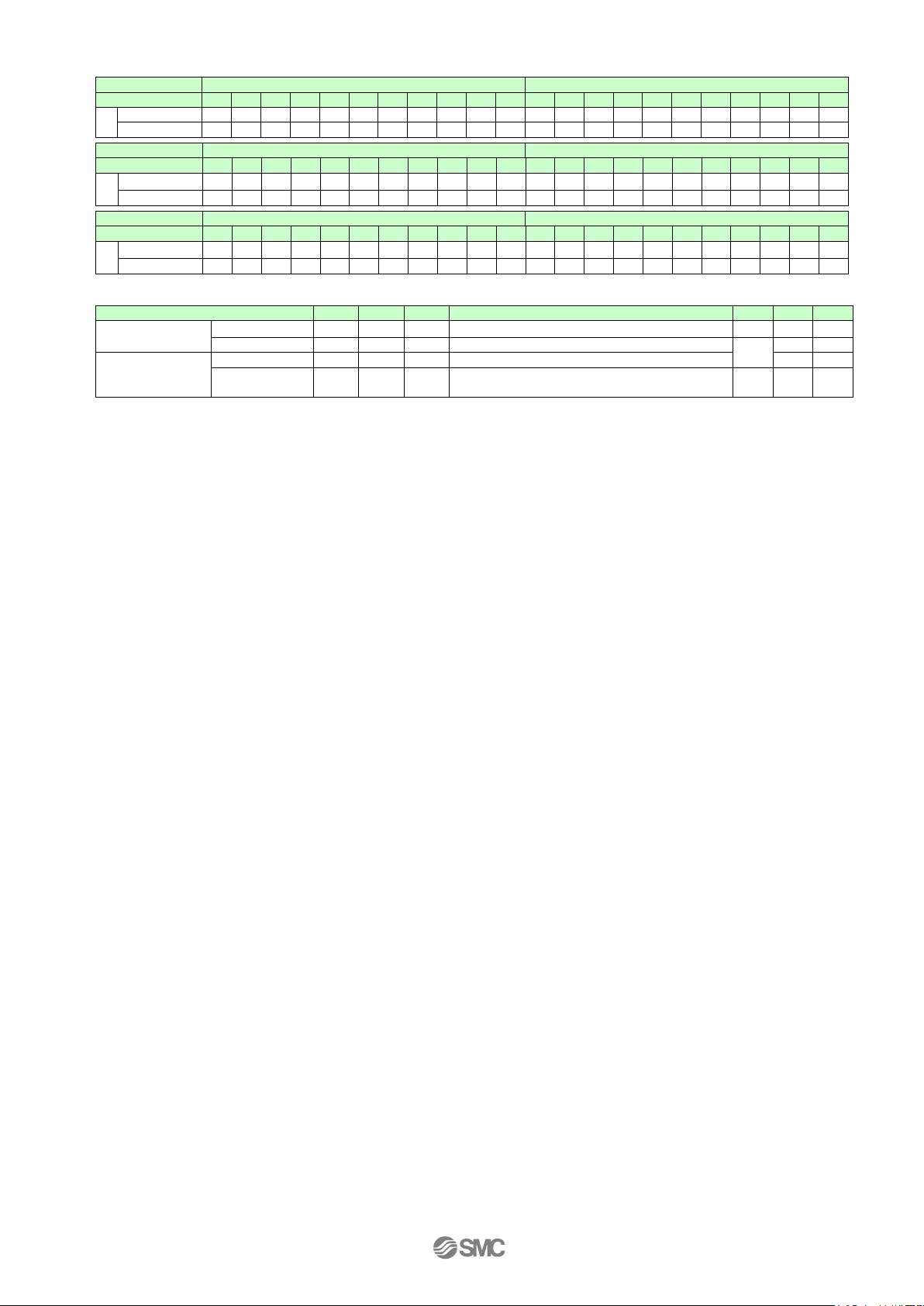

Lead symbol

A B C A B C A B C A B

C

Lead

12 6 3

12 6 3

20

10 5 16 8 4

Para.

No

Initial

value

Regenerative option

PA02

0000

0000 (Non)/ 0002 (LEC-MR-RB032)

0

motors side)

1

motors side )

0

motors side)

1

motors side )

Adaptive tuning mode

PB01

0000

0000

Machine resonance

suppression filter 1

Notch shape selection 1

PB14

0000

0000

LEY63

LEY63D

Lead symbol

A B C L A B C

5(2.86)

raito 4/7)

Para.

No

Initial

value

Regenerative option

PA02

0000

0000 (Non)/ 0002 (LEC-MR-RB032)/ 0003 (LEC-MR-RB12)

Rotation direction

selection

0

(

+:Counter motors side)

1

(+:Counter motors side )

Adaptive tuning mode

PB01

0000

0000

Load to motor inertia

moment ratio

Machine resonance

suppression filter 1

Notch shape selection 1

PB14

0000

0000

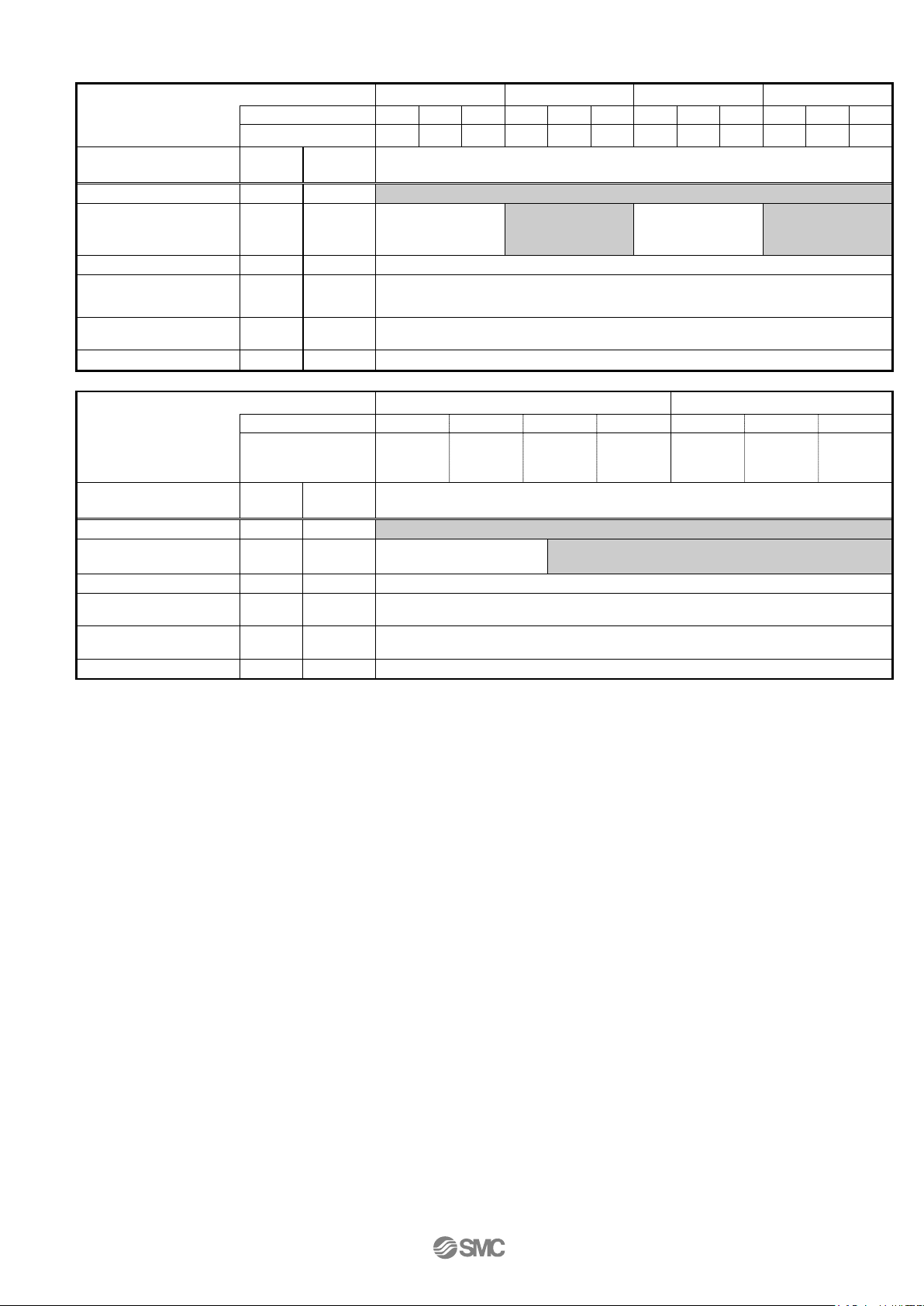

[LECSS]

Series

LEY25/LEYG25 LEY25D/LEYG25D LEY32/LEYG32 LEY32D/LEYG32D

Parameter

Rotation direction

selection

Load to motor inertia

moment ratio

Series

Parameter

Recommended value

(

PA14

PB06

PB13 4500 4500

PA14 0

PB06 7 7

0

7 7

Lead 20 10 5

+:Counter

(+:Counter

(Pulley

Recommended value

(

+:Counter

20 10 5

(+:Counter

PB13 4500 4500

*1 Parameter is the reco mme nded value. P leas e ch ange t he p ara met er to m ake appr opriat e value for y our

operating method.

*2 A mechanical resonance may occur depend ing o n t he c onfiguration or the mounting or ientation of the

transferred object. Plea se change the parameter i n the initial setting.

* For LECSS, please set the el ect r onic gear with PC, PLC etc. in y our application.

-11-

LEY25T6

/ LEYG25T6

LEY25DT6

/ LEYG25DT6

LEY32T7

/ LEYG32T7

LEY32DT7

/ LEYG32DT7

Lead symbol

A B C A B C A B C A B

C

Lead

12 6 3

12 6 3

20

10 5 16 8 4

Para.

No

Initial

value

Regenerative option

PA02

0000

0000 (Non)/ 0002 (LEC-MR-RB-032)

0

motors side)

1

motors side )

0

motors side)

1

motors side )

Function selection E-3

PE41

0000

0000

LEY63T8

LEY63DT8

Lead symbol

A B C L A B C

Lead

20

10 5 2.86

20

10

5

Para.

No

Initial

value

Regenerative option

PA02

0000

0000 (Non)/ 0002 (LEC-MR-RB-032)/ 0003 (LEC-MR-RB-12)

Rotation direction

selection

0

(

+:Counter motors side)

1

(+:Counter motors side )

Load to motor inertia

moment ratio

Function selection E-3

PE41

0000

0000

[LECSS-T]

Series

Parameter

Rotation direction

selection

Load to motor inertia

moment ratio

PA14

PB06

(

0

7 7

+:Counter

Recommended value

(+:Counter

(

+:Counter

(+:Counter

Series

Parameter

PA14 0

PB06 7 7

Recommended value

*1 Parameter is the reco mme nded value. P leas e ch ange t he p ara met er to m ake appr opriat e value for y our

operating method.

*2 A mechanical resonanc e may oc cur depending on the configuration or the mounting orientation of the

transferred object. Plea se change the parameter i n the initial setting.

* For LECSS2-T□, please set the electronic gear with PC, PLC etc. in your appl ication.

-12-

LEY63*

(Parallel type)

LEY63D*

(In-line type)

30, 50, 100, 150, 200,

250,300, 350, 400

30, 50, 100, 150, 200,

250,300, 350, 400, 500

30, 50, 100, 150, 200,

250,300, 350, 400, 500

100, 200, 300, 400, 500, 600,

700, 800

Work load

[kg]

Horizontal

Note 2)

18

50

50

30

60

60

30

60

60

40

70

80

200

Vertical

8

16

30 9 19

37

12

24

46

19

38

72

115

Thrust [N]

Note3)

12 to 24%)

(Set value LEY63T :12 to 40%)

Maximum

Speed

Note4)

[mm/s]

Range

to 300

900

450

225

305 to 400

600

300

150

405 to 500

- - -

800

400

200

640

320

160

505 to 600

- - - - - - - - -

800

400

200

605 to 700

- - - - - - - - -

600

300

150

705 to 800

- - - - - - - - -

500

250

125

Pushing speed [mm/s]

Note5)

35 or less

30 or less

30 or less

acceleration/de cel erati on [m m/s2]

5,000

5,000

5,000

3,000

Positioning re peatability [mm]

±0.02[Basic type] / ±0.01[High precision type]

Lost motion[mm]

0.1 or less[Basic type] / 0.05 or less[High precision type]

Lead[mm] (

Including pulley ratio

)

12 6 3

20

10 5 16 8 4

20

10 5 2.86

Impact resistance/vibration

Resistance [m/s2]

Ball screw

and Belt [4:7]

Guide type

Sliding bush (Piston rod part)

Sliding bush (Piston rod part)

Sliding bush (Piston rod part)

Operating temperature range

[℃]

Operating humidity range [%RH]

90 or less(No condensation)

90 or less (No condensation)

90 or less (No conden sation)

Motor output/size

100W/☐40

200W/☐60

400W/☐60

Type of Motor

AC servo motor (100/200VAC

)

AC servo motor (100/200VAC)

AC servo mot or ( 20 0V A C)

[Type of Motor: S2,S3,S4]: Incremental 17bit encoder (Resolution: 131072 p/rev)

[Type of Moto: T6,T7,T8]: Absolute 22bit encoder (Resolution: 4194304 p/rev)

Type

Note7)

No excitation operating type

No excitation operating type

No excitation operating type

Power consumption [W] at 20

℃ Note8)

6.3

7.9

7.9

7.9

Rated voltage [V]

24VDC

0

-10%

24VDC

0

-10%

DC24

0

-10%

DC24

0

-10%

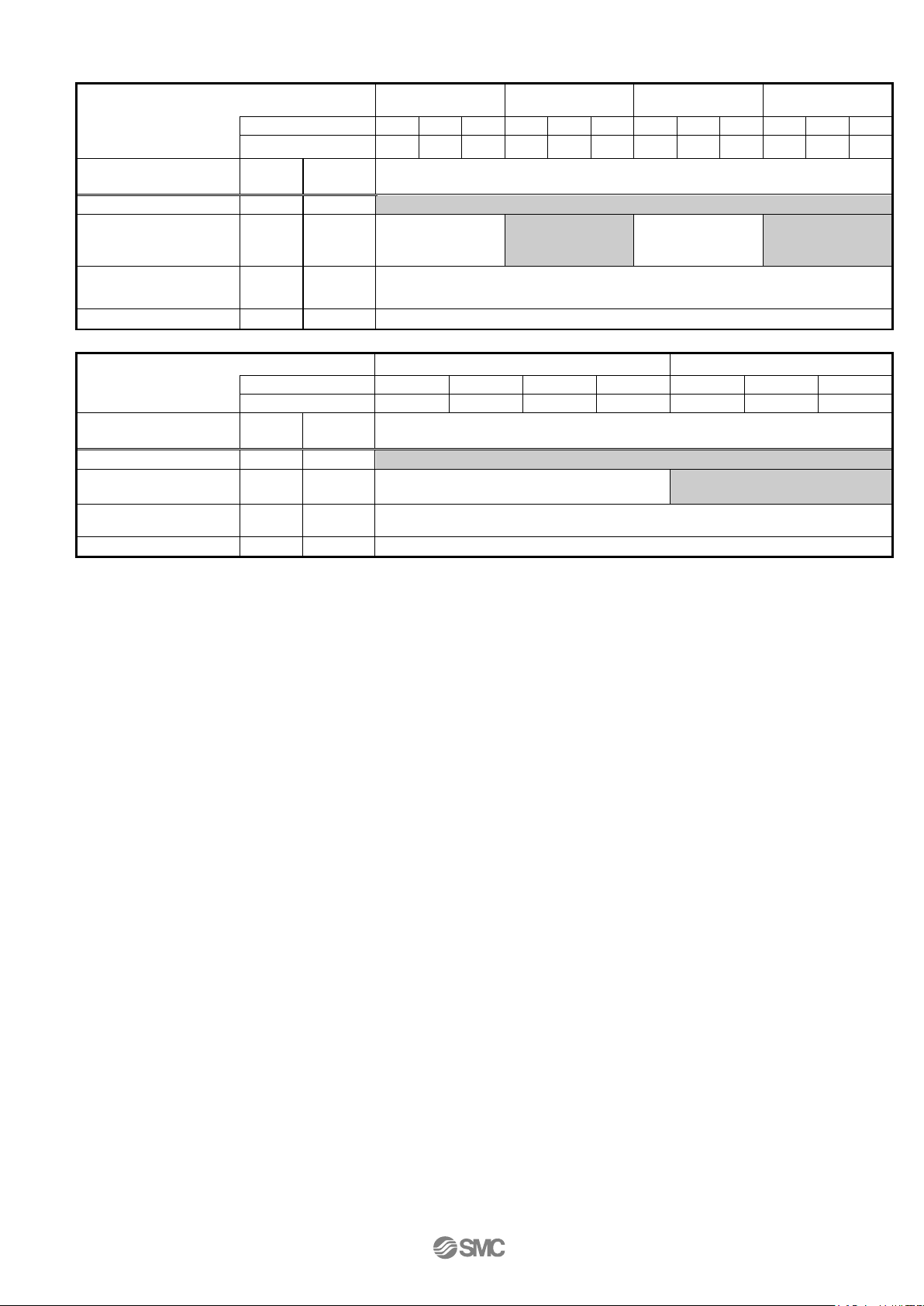

2. Rod type / LEY Series

2.1 Specification

Model

Stroke [mm]

Note1)

(Set value LEY25/32:15 to 30%)

(Set value LEY63

(Set value LEY25T32T

of

stroke

:

15 to 50%)

:

Actuator specification

Note6)

Drive method

LEY25* / LEY25D*

(Parallel / In-line)

65

131

~

127

255

~

~

242

485

LEY32*

(Parallel type)

79

157

~

154

308

~

~

294

588

LEY32D*

(In-line type)

98

192

~

197

~

385

368

~

736

1200 600 300 1000 500 250

156

~

521

1000 500 250

50 / 20 50 / 20 50 / 20

Ball screw and Belt [1:1] / Ball screw

Ball screw and Belt [1.25:1]

Ball screw Ball screw

5 to 40 5 to 40 5 to 40

~

304

1012

~

573

1910

1003

~

3343

70

Encoder

[Type of Moto: S6,S7,S8]: Absolute 18bit encoder (Resolution: 262144 p/rev)

Holding force [N] 131 255 607 607 607 588 197 385 736 313 607 1146 2006

Lock specification

Note 1) The middle stroke other than the above are produced upon receipt of order.

Note 2) The maximum value of the horizontal workload. (An external guide is necessary[Coefficient of friction: 0.1 or less]).

The actual workload will depend on the type of external guide.

Note 3) Thrust setting range when "thrust control" in torque control mode, etc. Set it referring to the thrust conversion graph shown in the

catalog as a guide.

Note 4) The allowable speed changes by the stroke.

Note 5) Allowable impact speed when "impact work" in torque control mode, etc.

Note 6) Impact resistance:

Vibration resistance:

No malfunction occurred when the actuator was tested with a drop tester in both an axial direction and perpendicular direction

to the lead screw. (The test was performed with the actuator in the initial state.)

No malfunction occurred in a test ranging between 45 to 2000 Hz, when the actuator was tested in both an axial direction

and a perpend icular direction to the lead screw. (The test was per f ormed with th e a ctuator in the i ni tial state.)

Note 7) Only when the motor option, "with lock", is selected.

Note 8) For an actuator with lock, add the power consumption for the lock.

-13-

Model

LEY25* (Parallel type)

LEY25D* (In-line mounting type)

Stroke [mm]

30

50

100

150

200

250

300

350

400

30

50

100

150

200

250

300

350

400

Type of Motor

Incremental Enco der

1.31

1.38

1.55

1.81

1.99

2.16

2.34

2.51

2.69

1.34

1.41

1.58

1.84

2.02

2.19

2.37

2.54

2.72

Absolute Enco de r

1.37

1.44

1.61

1.87

2.05

2.22

2.40

2.57

2.75

1.40

1.47

1.64

1.90

2.08

2.25

2.43

2.60

2.78

Model

LEY32* (Parallel type)

LEY32D* (In-line mounting type)

Stroke [mm]

30

50

100

150

200

250

300

350

400

450

500

30

50

100

150

200

250

300

350

400

450

500

Incremental Enco der

2.42

2.53

2.82

3.29

3.57

3.85

4.14

4.42

4.70

4.98

5.26

2.44

2.55

2.84

3.31

3.59

3.87

4.16

4.44

4.72

5.00

5.28

Absolute Enco de r

2.36

2.47

2.76

3.23

3.51

3.79

4.08

4.36

4.64

4.92

5.20

2.38

2.49

2.78

3.25

3.53

3.81

4.10

4.38

4.66

4.94

5.22

Model

LEY63* (Parallel type)

LEY63D* (In-line mounting type)

Stroke [mm]

100

200

300

400

500

600

700

800 100

200

300

400

500

600

700

800

Incremental Enco der

5.4

6.6

8.3

9.4

10.5

12.2

13.4

14.5 5.6

6.7

8.4

9.6

10.7

12.4

13.5

14.7

Absolute Enco de r

5.5

6.7

8.4

9.5

10.6

12.3

13.5

14.6 5.7

6.8

8.5

9.7

10.8

12.5

13.6

14.8

Size

25

32

63

Size

25

32

63

Incremental Encod er

0.20

0.40

0.4

Foot style (Body mounting bolt is included、2sets)

0.08

0.14

0.26

Absolute Encoder

0.30

0.66

0.6

Rod side flange style (Body mounting bolt is included)

0.20

0.51

Rod end male thread

Part of male thread

0.03

0.03

0.12

Motor side fl a nge style (Body mounting bolt isincluded)

-

-

Double clevis style (Clevis pin, Type C retaining ring for axis,

Body mounting bolt is include d)

[kg]

[kg]

[Product Weight]

Type of Motor

Type of Motor

[Additional weight for lock]

Lock

0.17

Nut 0.02 0.02 0.04

0.16 0.22 0.58

-14-

Loading...

Loading...